#turbine flow

Explore tagged Tumblr posts

Text

Flow / Flux

2015.10.19

Wind turbine. Rice rustle. Car passes. Wind.

/ Flow | Flux project /

#chongming#china#shanghai#field recording#rural#farm#wind turbine#dusk#analog#tape#reel to reel#flow flux#SoundCloud

0 notes

Text

5 Signs Your Business Needs a Turbine Gas Meter Upgrade

Accurate gas measurement is essential for industries like oil and gas, utilities, and manufacturing, where even minor inefficiencies can lead to significant financial losses. If your business relies on outdated or underperforming turbine gas meters, it may be time to consider an upgrade.

Modern turbine gas meters from a trusted turbine gas meter manufacturer offer precision, durability, and advanced features that can transform your operations. Here are five signs your business needs a turbine gas meter upgrade.

Ready to transform your gas measurement systems? Consult a certified turbine gas meter manufacturer today.

One of the most obvious signs is rising operational costs. If your energy bills are increasing despite stable usage patterns, your current turbine gas meter may be delivering inaccurate readings. Older meters often lose calibration over time, leading to overbilling or missed inefficiencies. Upgrading to a modern turbine gas meter with advanced diagnostics can help identify energy waste and reduce costs.

Frequent maintenance issues are another red flag. If you’re constantly repairing or recalibrating your gas meters, it’s a clear indicator of aging or low quality equipment.

Partnering with a reputable turbine gas meter manufacturer ensures access to durable, corrosion resistant meters designed to withstand harsh industrial environments. These meters minimize downtime and maintenance expenses, saving you time and money in the long run.

Inconsistent or inaccurate readings are a major concern for businesses relying on precise gas measurements. If you’re noticing discrepancies in gas usage data, it’s time to upgrade to a high precision turbine gas meter.

Modern meters deliver accuracy within ±1%, ensuring reliable performance across varying flow rates and pressures. This level of precision is critical for accurate billing, inventory management, and process control.

Non compliance with industry standards is another sign your business needs an upgrade. Regulatory requirements for gas measurement are becoming increasingly stringent.

If your current meters fail to meet ISO, AGA, or regional standards, you risk fines, operational shutdowns, or reputational damage. A certified turbine gas meter manufacturer provides compliance-ready solutions to keep your business audit proof and running smoothly.

Finally, if your meters lack smart technology integration, you’re missing out on significant opportunities for optimization. In today’s data-driven world, manual gas measurement processes are no longer sufficient.

Modern turbine gas meters with IoT connectivity and real-time analytics enable you to optimize workflows, predict maintenance needs, and reduce energy consumption. These features unlock actionable insights for better decision-making and long-term savings.

Delaying a turbine gas meter upgrade can lead to escalating costs, compliance risks, and operational inefficiencies. For example, a European energy provider reduced maintenance costs by 25% and improved billing accuracy by 20% after upgrading to advanced meters from a leading turbine gas meter manufacturer.

If any of these signs resonate with your business, it’s time to consider a turbine gas meter upgrade. Modern meters from a trusted turbine gas meter manufacturer deliver precision, durability, and smart technology integration, ensuring long term ROI and operational excellence.

Discover how an upgrade can save costs request a free efficiency audit.

0 notes

Text

Best Turbine Flow Meters

Turbine flow meters provide accurate measurement of liquid or gas flow by utilizing a rotating turbine. Known for their reliability, they are ideal for high-velocity applications, offering precise and cost-effective flow monitoring across various industries

Visit: https://macnaught.ca/products/turbine-flow-meters

0 notes

Text

Why Gas Turbine Flow Meters are Essential for Natural Gas Meter Installation

In the realm of natural gas measurement and management, precision and reliability are paramount. One technology that stands out in this field is the gas turbine flow meter. But why are these meters essential for natural gas meter installations? This article will explore the critical role of gas turbine flow meters, their advantages, and why they are indispensable in natural gas applications.

1. Understanding Gas Turbine Flow Meters

Gas turbine flow meters operate on the principle of velocity measurement. As natural gas flows through the meter, it passes over a turbine wheel, causing it to spin. The speed of the turbine wheel is directly proportional to the velocity of the gas. Sensors capture the rotational speed, converting it into a flow rate measurement. This method provides accurate and reliable data, which is crucial for managing natural gas flow.

2. Key Advantages of Gas Turbine Flow Meters

Gas turbine flow meters offer several benefits that make them ideal for natural gas applications:

High Accuracy and Precision: These meters provide precise measurements, which is critical for billing and regulatory compliance. Accurate data ensures that customers are billed correctly and that companies meet regulatory standards.

Wide Range of Flow Rates: Gas turbine flow meters can measure a wide range of flow rates, making them versatile for various applications, from residential to industrial.

Durability and Reliability: Designed to withstand harsh conditions, these meters are durable and require minimal maintenance, ensuring long-term reliability.

Low Pressure Drop: They have a low pressure drop, meaning they do not significantly affect the gas pressure in the pipeline, which is essential for maintaining efficient gas flow.

3. Applications in Natural Gas Meter Installations

The versatility and reliability of gas turbine flow meters make them suitable for a wide range of applications in natural gas meter installations:

Residential Metering: Ensuring accurate billing for residential customers is crucial. Gas turbine flow meters provide the precision needed for this task.

Commercial and Industrial Metering: In larger installations, such as commercial buildings and industrial plants, these meters handle higher flow rates and provide reliable data for operational efficiency.

Pipeline Management: For natural gas pipelines, accurate flow measurement is essential for monitoring and controlling the distribution network. Gas turbine flow meters offer the accuracy and durability required for this application.

4. Case Studies: Success in the Field

Several real-world examples illustrate the effectiveness of gas turbine flow meters in natural gas installations:

Utility Companies: Many utility companies use gas turbine flow meters for residential and commercial metering. These meters have proven to reduce billing discrepancies and improve customer satisfaction.

Industrial Plants: In industrial settings, where large volumes of gas are consumed, gas turbine flow meters have enhanced operational efficiency and ensured compliance with safety standards.

Pipeline Operators: Operators of natural gas pipelines rely on gas turbine flow meters to monitor flow rates accurately, ensuring the safe and efficient transport of gas.

5. Future Trends and Innovations

The future of gas turbine flow meters in natural gas installations looks promising, with several emerging trends and innovations:

Smart Metering: Integration with smart metering systems allows for real-time data collection and analysis, providing valuable insights for optimizing gas distribution and consumption.

Advanced Materials: Innovations in materials science are leading to more robust and corrosion-resistant turbine meters, extending their lifespan and reliability.

Enhanced Accuracy: Ongoing technological advancements are improving the accuracy and precision of gas turbine flow meters, making them even more reliable for critical applications.

Conclusion: The Indispensable Role of Gas Turbine Flow Meters

In conclusion, gas turbine flow meters are essential for natural gas meter installation due to their accuracy, reliability, and versatility. They provide precise measurements that are critical for billing, regulatory compliance, and efficient gas management. Their ability to handle a wide range of flow rates and withstand harsh conditions makes them suitable for various applications, from residential to industrial and pipeline management.

As technology continues to advance, gas turbine flow meters will become even more integral to natural gas installations, offering enhanced features and capabilities. For anyone involved in the natural gas industry, understanding and utilizing gas turbine flow meters is crucial for ensuring accuracy, efficiency, and reliability in gas measurement and management.

Are you ready to embrace the future of natural gas metering with gas turbine flow meters? Their proven track record and ongoing innovations make them the smart choice for any natural gas application. Make the switch today and experience the benefits of accurate and reliable gas measurement.

0 notes

Text

Houston's Trusted Air Filter Supplier

Discover superior air filtration solutions in Houston, TX, from Lake Charles Filtration. We provide reliable products for improved air quality, from turbine intake to high-flow particulate filters.

0 notes

Text

Premier Turbine Flow Meter Supplier and Manufacturer in Pune, Maharashtra, India, Odisha, Bangalore, Tamilnadu, Hyderabad, Raipur, Jamshedpur, Ahmedabad, Vijayawada, Kolkata, Haridwar, Lucknow - Reliable and Efficient Turbine Flow Meters for Accurate Measurement

0 notes

Text

"Scientists in Singapore have broken a long-standing limitation on the ability to generate electricity from flowing water, suggesting that another elemental force of nature could be leveraged for renewable electricity: rain.

With the simplest and smallest scale test setup, the team could power around 12 LED lightbulbs with simulated rain droplets flowing through a tube, but at scale, their method could generate meaningful amounts that could rival rooftop solar arrays.

Singapore experiences significant rainfall throughout the year, averaging 101 inches (2581 millimeters) of precipitation annually. The idea of generating electricity from such falling water is attractive, but the method has long been constrained by a principle called the Debye Length.

Nevertheless, the concept is possible because of a simple physical principle that charged entities on the surface of materials get nudged when they rub together—as true for water droplets as it is for a balloon rubbed against the hair on one’s head.

While this is true, the power values thus generated have been negligible, and electricity from flowing water has been limited to the driving of turbines in hydropower plants.

However, in a study published in the journal ACS Central Science, a team of physicists has found a way to break through the constraints of water’s Debye Length, and generate power from simulated rain.

“Water that falls through a vertical tube generates a substantial amount of electricity by using a specific pattern of water flow: plug flow,” says Siowling Soh, author of the study. “This plug flow pattern could allow rain energy to be harvested for generating clean and renewable electricity.”

The authors write in their study that in existing tests of the power production from water flows, pumps are always used to drive liquid through the small channels. But the pumps require so much energy to run that outputs are limited to miniscule amounts.

Instead, their setup to harness this plug flow pattern was scandalously simple. No moving parts or mechanisms of any kind were required. A simple plastic tube just 2 millimeters in diameter; a large plastic bottle; a small metallic needle. Water coming out of the bottle ran along the needle and bumped into the top section of the tube that had been cut in half, interrupting the water flow and allowing pockets of air to slide down the tube along with the water.

The air was the key to breaking through the limits set by the Debye Length, and key to the feasibility of electricity generation from water. Wires placed at the top of the tube and in the cup harvested the electricity.

The total generation rate of greater than 10% resulted in about 100 watts per square meter of tube. For context, a 100-watt solar panel can power an appliance as large as a blender or ceiling fan, charge a laptop, provide for several light bulbs, or even a Wi-Fi router.

Because the droplet speeds tested were much slower than rain, the researchers suggest that the real thing would provide even more than their tests, which were of course on a microscale."

-via Good News Network, April 30, 2025

#singapore#asia#rain#renewable energy#renewables#clean energy#electricity#science and technology#solarpunk#good news#hope

2K notes

·

View notes

Text

Why Choose Turbine Flow Meters for Digital Measurement

Discover the advantages of using turbine flow meters for digital measurement. Cost-effective, user-friendly, and reliable. The ideal solution for fluid monitoring.

#Turbine Flow Meter#Turbine Flow Meter Manufacturers#Turbine Flow Meter Manufacturers in Mumbai#Turbine Flow Meter Manufacturers in Thane#Turbine Flow Meter Manufacturers in India

0 notes

Text

Your Reliable Turbine Flow Meter Supplier: Burak Metering

For accurate flow measurement solutions, rely on Burak Metering as your turbine flow meter manufacturer. We provide premium meters and knowledgeable services.

#turbine flow meter#turbine flow meter manufacturer#turbine meter#turbine gas meter#turbine gas meter manufacturer

0 notes

Text

It's kinda weird how sometimes people get stuck in only thinking about long term/short term consequences seperately. Like yea maybe a wind turbine isn't pretty right now cause you're not used to it, and maybe they have to cut some trees to put down solar panels but that's now? You're going to need energy for hundreds of years? Do you think anyone is going to even remember if this one spot on a endless horizon didn't have wind turbines before? Do you think it's worse to cut down a dussin trees once than what ever other energy was used for decades before? Trees grow back. Birds get used to wind turbines. Oil doesn't grow back. You can't undo a nuclear catastrophe.

A nuclear catastrophe is somehow something far off in the future and its just "barely a probability". Oil running out well thats in the faaar off future. You can just mine more coal! That's a consequence so far off I'll have died so it's not my problem! Environmental question? If it's even real thats for my great grandkids and not my problem! "The summers are so hot, when I was young we never had summers like this, but also don't be ridiculous there is no global warming".

#random thoughts#even water powerplants like it can ruin an entire ecosystem#it sounds environmental i guess cause yea water flows natually or what ever but those things are not exactly a little waterwheel#entire ecosystems can be destroyed#meanwhile you're angry that maybe the view from your window could have a wind turbine somewhere in the distance?#i don't know something's wrong with those priorities#not like im a particularly environmental person#and its a complex issue that im not educated enough on#i just wonder sometimes

1 note

·

View note

Note

In France, a YouTuber known for investigating scams and debunking pseudoscience (G Milgram) unveiled that a number of regional rural bodies, the Chambers of Agriculture, have been imposing the consultation of "geobiologist" for stuff like windmills turbines construction. It would be a bit funny to see that folk magic has developed and adapted through time, if this weren’t funded by tax money.

I was wondering if you knew of the movement ?

It combines some truly Middle age style magic practices like reciting the Gospel of Saint John on the magic mixture added to concrete, and more modern new age stuff, sacred geometry, all with a very heavy dose of pseudo scientific looking diagrams and words, plus a bit of homeopathy to sweeten the deal.

Oh yes! Geobiology! That's the one with telluric currents and the Benker Cube.

Iirc it's an early 20th century belief. Very much in the vein of Wilhelm Reich's bag. It's a blend of ley lines, dowsing, Feng shui, and sacred geometry. All about the flows of strange energies over extremely large distances. Neat stuff. Totally bonkers.

434 notes

·

View notes

Text

5 Surprising Benefits of Turbine Gas Meters You Need to Know

In industries where precision and reliability are critical, turbine gas meters have become a cornerstone of efficient gas flow measurement. These devices, which use a rotating turbine to measure the flow of gas, are widely used in sectors like oil and gas, utilities, and manufacturing.

But beyond their basic functionality, turbine gas meters offer a host of surprising benefits that can transform your operations. Here are five advantages you might not have considered.

Discover the perfect turbine gas meter for your needs. Contact us today for a free consultation!

Unmatched Accuracy in Flow Measurement

When it comes to measuring gas flow, accuracy is non negotiable. Turbine gas meters are renowned for their precision, even at low flow rates. This makes them ideal for applications where even a minor error can lead to significant financial losses or operational inefficiencies. For example, in the oil and gas industry, turbine gas meters have reduced measurement errors by up to 99%, saving companies millions annually.

Accurate measurements also ensure fair billing, regulatory compliance, and optimized processes, making these meters a must-have for any industry that relies on precise gas flow data.

Built to Last: Durability in Harsh Environments

Turbine gas meters are designed to withstand extreme conditions, including high pressure, corrosive gases, and fluctuating temperatures. Unlike other meters that may falter in harsh environments, turbine gas meters continue to perform reliably.

This durability translates to lower maintenance costs and fewer replacements, saving businesses both time and money. For instance, while diaphragm meters may require frequent repairs, turbine gas meters offer a longer lifespan with minimal upkeep, making them a cost-effective choice for demanding applications.

Energy Efficiency and Sustainability

In today’s world, sustainability is a top priority, and turbine gas meters are playing a key role in helping businesses reduce their environmental impact. These devices help minimize energy waste by detecting leaks and optimizing gas usage. For example, a utility company reduced its gas leaks by 30% after switching to turbine gas meters, saving both energy and costs.

By lowering gas loss, businesses can also reduce their carbon footprint and contribute to global sustainability goals, making turbine gas meters an eco-friendly choice.

Smart Technology Integration

Modern turbine gas meters are more than just mechanical devices—they’re smart. With IoT integration, these meters can provide real-time data, remote monitoring, and predictive maintenance alerts. This not only improves operational efficiency but also enables data-driven decision making.

For instance, a manufacturing plant used smart turbine gas meters to predict maintenance needs, reducing downtime by 20%. By leveraging smart technology, businesses can stay ahead of the curve and optimize their operations like never before.

Cost Effectiveness Over Time

While the initial cost of turbine gas meters may be higher than other options, their long term benefits far outweigh the investment. With lower maintenance costs, higher accuracy, and extended lifespan, these meters offer a strong return on investment (ROI).

A case study showed that a company recouped its initial investment within two years through reduced operational costs. This makes turbine gas meters a cost effective choice for businesses looking to maximize efficiency and minimize expenses over time.

Common Misconceptions About Turbine Gas Meters

Despite their many benefits, there are some misconceptions about turbine gas meters. For example, some believe they’re only suitable for large scale industries, but in reality, they’re versatile enough for small to medium applications as well. Others think they require frequent maintenance, but turbine gas meters are designed for durability and require minimal upkeep.

Finally, some assume they’re outdated compared to ultrasonic meters, but modern turbine gas meters incorporate advanced features like IoT connectivity, making them a cutting edge choice.

How to Choose the Right Turbine Gas Meter

Selecting the right turbine gas meter depends on several factors, including flow rate, gas type, environmental conditions, and budget. It’s important to choose a meter that can handle your required flow range and withstand your operating environment.

Additionally, evaluating the long term ROI, rather than just the upfront cost, can help you make a more informed decision. By considering these factors, you can find the perfect turbine gas meter for your needs.

Real World Applications

Turbine gas meters are making a difference across a variety of industries. In the oil and gas sector, they’re used to monitor pipeline flow with precision.

Utilities rely on them to ensure accurate billing for consumers, while manufacturers use them to optimize processes and reduce waste. No matter the industry, turbine gas meters are proving to be an invaluable tool for improving efficiency and accuracy.

Want to learn more about how turbine gas meters can save you money? Download our free guide now!

Conclusion

Turbine gas meters are more than just flow measurement devices they’re powerful tools that offer accuracy, durability, sustainability, smart technology, and cost effectiveness. Whether you’re in oil and gas, utilities, or manufacturing, these meters can transform your operations and help you achieve your goals.

Ready to experience the benefits of turbine gas meters for yourself? Explore our range of turbine gas meters today and take the first step toward smarter, more efficient flow measurement.

0 notes

Note

Joy I have to ask - what temperature do you think it is inside Wayne Manor?

Is it essentially outside temperature except where the fireplaces are? Does Alfred have a one man war against climate change? Is that why Bruce spends so much time in the basement?

Depending on which timeline you follow, Wayne Manor was built in the late 1800s. Having worked in giant historical homes, I'm telling you now it's a fucking pain in the ass to update the heating systems in those buildings. I know we've got comic book logic to contend with, and they've got massive generators in the basement to keep the cave running (sometimes it's turbines powered by the water flowing through the caves), but I also think it's plausible that to avoid damaging the historical facade of the building, you might walk around the house and see box fans shoved into the window frames during the summer because fuuuuck trying to install modern AC through 18th-century brickwork.

As for heat, well, for a frame of reference, the James J Hill house up here in MN—built roughly around the same time during the Gilded Age when the Waynes were pioneering industry in Gotham—was forced to rely on a boiler roughly the size of a steam engine to heat the house and used 250 tons of coal each year to keep it warm. That boiler provided hot water and ambient heat through steam radiators, but they also still had fireplaces in almost every room to try and compensate for the winter. The house was updated for modern heating and air conditioning within the last 40 years, but with a house that size and ceilings so tall, it's not particularly efficient. They still rely on box fans and space heaters to keep the space habitable during summer and winter.

New Jersey is not as far north as Minnesota, but the temperatures can still drop comparably low, especially when you factor in the seafront Gotham is on. So, while I do think they likely upgraded the heating systems at some point (they can't keep guzzling through coal like that), I also can't help but feel it's got to be cold as hell in that house unless they're being meticulous about lighting fires and airing every room out to prevent damp.

Because that's another thing. If you're not keeping your stone house warm, you risk damp and water damage, and I feel like Alfred would rather gnaw off his own arm than let Wayne Manor crumble to dust with black mold festering in the original French plaster.

So he's not so much fighting a one-man war against climate change as he's fighting a one-man war to keep the house dry. He's walking through rooms no one even uses, making sure the steam radiators are working and opening the windows a crack to let the condensation out.

Is he also turning off all the light switches as he goes? Yes. Is he always yelling, "Why is every screen in this house turned on if no one is using them?" also, yes.

Is Bruce also down in the cave huddled under an extra cape, overclocking the batcomputer to stay warm? Also a distinct possibility.

872 notes

·

View notes

Text

Breeding blankets for fusion reactors

So, barring a few ambitious projects involving helium-3, fusion reactor power plants will use hydrogen isotopes as fuel: a 50/50 mixture of deuterium (hydrogen-2) and tritium (hydrogen-3). Deuterium is very stable and relatively abundant, as far as these things go, and can be extracted from ordinary seawater. Tritium, however, has a half life of just over 12 years, so it doesn't occur in nature.

Fortunately, you can use your fusion reactor to synthesize its own tritium fuel, via the transmutation of lithium-6. You use the powerful neutron flux from the fusion plasma to “breed” tritium in lithium, extract it, then feed it back into the reactor. The figure of merit for this process is the tritium breeding ratio (TBR), which is simply the ratio of tritium bred to tritium used. The goal is to get a TBR substantially greater than 1.

This figure shows the physics of tritium breeding, where neutrons from the deuterium-tritium fusion plasma are absorbed by lithium, which then splits into helium and tritium. [source]

Generally speaking, most concepts for tritium breeding involve wrapping a lithium “breeding blanket” around the outside of the reactor, with as few gaps as you can manage. A deuterium-tritium reactor is constantly generating fast neutrons. You want to keep as much of that emission as possible inside the breeding blanket, for both tritium and power generation.

There are a few different ideas for breeding blanket designs, several of which are going to be tested on ITER, the massive reactor being built in France. One concept is a thick sheath of lithium ceramic that surrounds the vessel, either as solid slabs or pebbles. As tritium breeding occurs under the blanket, water or liquid helium is circulated through it, cooling the lithium and potentially extracting heat for electricity generation.

While such a blanket might be relatively “simple” (lol) to build, there are some pretty fundamental challenges. Neutrons will penetrate most materials with ease, and it might be tricky to extract tritium that's been bred deep inside of solid lithium. Ideally, you could do the extraction without pause, even as breeding is ongoing. For some designs, though, you have to cycle out breeder units for harvesting as they get a full load of tritium.

Another concept is “liquid breeding." This concept uses a molten mixture of metallic lithium and lead, or a lithium salt compound like FLiBe (fluorine-lithium-beryllium). The liquid would be pumped through a “breeding zone” around the vessel, where the neutron flux is thickest. The tritium will then be continuously extracted from the breeding fluid as it flows back out. As part of the process, you can run the hot liquid through a heat exchanger, heating water to power a steam turbine.

Liquid breeding does raise some prominent engineering challenges. Hot, molten breeding fluid will be very hard to handle – not just because of the heat, but also because you're trying to pump a massive quantity of viscous fluid into a very tight breeding zone. Moreover, molten lithium-lead might react explosively with air. If your breeding system springs a leak, you’ll have a serious mess on your hands!

It’s still unclear which of these breeding strategies will bear fruit. From conception to implementation, there are still a lot of unknowns! Both liquid and solid breeding will be conducted in France, and a number of private fusion companies have plans to breed tritium in their machines as well.

486 notes

·

View notes

Text

baau post LOL

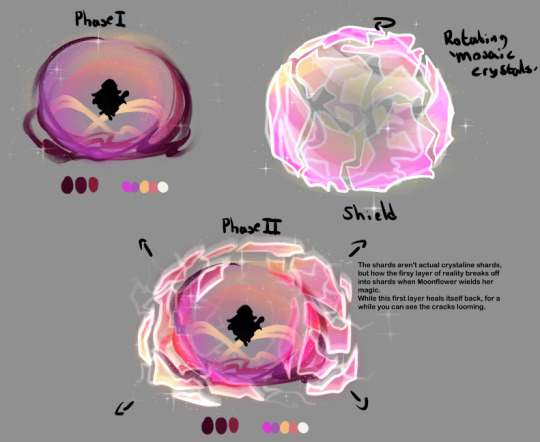

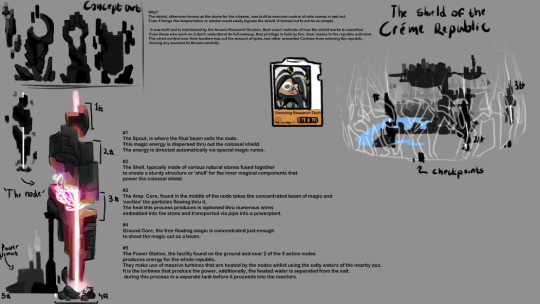

The Shell, typically made of various natural stones fused together to create a sturdy structure or 'shell' for the inner magical components that power the colossal shield.

The Amp. Core, found in the middle of the node takes the concentrated beam of magic and 'excites' the particles flowing thru it. The heat this process produces is siphoned thru numerous wires embedded into the stone and transported via pipe into a powerplant.

Ground Core, the free floating magic is concentrated just enough to shoot the magic out as a beam.

The Spout, is where the final beam exits the node. This magic energy is dispersed thru out the colossal shield. The energy is directed automatically via special magic runes.

The Power Station, the facility found on the ground and near 2 of the 5 active nodes produces energy for the whole republic. They make use of massive turbines that are heated by the nodes whilst using the salty waters of the nearby sea. It is the turbines that produce the power, additionally, the heated water is separated from the salt during this process in a separate tank before it proceeds into the reactors.

"Did some cookie in a silly costume and a gem take your power too?" "It ssspeaksss?!"

This is Moonflower Cookies "familiar", a strangely small and very ancient being that might pre-date Cookiekind itself. Once a mighty world serpent reduced to something as small as a long cat.

Moonflower Cookie herself has risen the ranks of the Creme Republic. She has no real family left, aside from the occasional visit to Midnight Lily. But, growing busy with the Republic those visits are less frequent.

She has built bonds with some Cookies who she stumbled upon on her short travels (Princess Cookie and her gang) but for the mage, it is fleeting. She spends her days working on the shield that protects the republic and doing her own research.

=== (wip)

'Runaways, hm?' Moonflower Cookie hummed, stirring the pot of soup. 'Yeah...' Princess Cookie mumbled, slumping over the table slightly. 'If you lot need to crash, or some food and rest. My doors are open.' She said, dumping some vegetables into the pot. 'Ah, thank you! We appreciate your kindness.' Knight Cookie chirped with a smile. 'You can crash anytime, you know?' Moonflower Cookie mentioned. 'How's your father, Princess Cookie?' She continued quizzically. Princess Cookie sighed, leaning back in her chair. 'He's holding up I guess.. At least he has mom.' She said, resting her face on her hand. 'Being lonely and stuck is a far worse fate..' Moonflower shrugged, stirring the pot.

Pitaya Cookie grunted out of annoyance. 'Ssstop tugging on my tail!' He hissed, turning his head. 'A clean cut... Who did this to you? Must be... humiliating.' The little four legged serpent chuckled. 'It wouldn't be that if you weren't tugging on it.' Pitaya snapped back, flicking his tail to try and shake the other off. Moonflower Cookie sighed. 'Seriously, Angus?' She sighed, rolling her eyes.

#cookie run kingdom#cookie run#crk#cookie run oc#cookie run au#crk au#au#moonflower cookie#baau#baau fanart#beast ancients au

204 notes

·

View notes