#valuestreammapping

Explore tagged Tumblr posts

Text

Building Operational Excellence: Lean Manufacturing Consulting by Seicho Consulting

In today’s competitive manufacturing world, doing more with less isn’t just an option — it’s a necessity. Lean Manufacturing empowers organizations to maximize productivity, minimize waste, and deliver consistent quality — all while improving worker satisfaction and reducing costs.

At Seicho Consulting, our Lean Manufacturing Consulting Services are designed to implement operational excellence at every level of your factory floor. From layout design to daily improvement systems, we help manufacturers transform operations through Lean principles.

🔧 Key Offerings:

Process Flow Optimization: Eliminate bottlenecks and improve production speed.

5S & Visual Workplace Setup: Create clean, organized, and efficient workspaces.

Value Stream Mapping (VSM): Understand where value is added—and where it’s lost.

Kaizen Programs: Cultivate a culture of continuous improvement through employee engagement.

Standard Work & Error Proofing (Poka-Yoke): Minimize variation and human error.

Lean Layout Redesign: Enhance space utilization and material flow.

📈 Benefits of Lean Implementation:

Higher productivity and throughput

Reduced inventory and faster delivery

Better product quality and fewer defects

Improved worker safety and morale

Significant cost savings

🏭 Who We Serve:

Automotive & Ancillary Units

FMCG & Packaging Plants

Chemical & Pharma Manufacturers

Textile & Engineering Setups

SMEs & Export-Oriented Units

With over 50+ successful Lean projects, our team understands the ground reality of factories and production units. We don’t just teach Lean tools — we help your people adopt Lean culture. Plus, our approach integrates smoothly with TPM, Six Sigma, TQM, and ERP systems, making your business more agile and scalable.

💡 Ready to make your factory future-ready with Lean? Reach out to Seicho Consulting — let’s build sustainable excellence together.

#LeanManufacturing#SeichoConsulting#OperationalExcellence#ManufacturingConsulting#5S#Kaizen#PokaYoke#LeanProduction#FactoryEfficiency#IndustrialConsulting#ValueStreamMapping#ProcessImprovement#ContinuousImprovement#TPM#SixSigma#EngineeringConsulting#TextileManufacturing#FMCGManufacturing#AutomotiveIndustry#LeanTransformation#SMEConsulting

0 notes

Text

Whatever you think, do it. He who conforms to the truth survives.

youtube

via @YouTube #valuestreammapping #valuestudy #truth

0 notes

Text

How can value stream mapping help in identifying waste and how TCard helps

Learn how Value Stream Mapping identifies waste and how TCards streamline workflows. Discover real-time monitoring, task tracking, and customised solutions to optimise processes and eliminate bottlenecks efficiently.

For more details read our blog :

#ValueStreamMapping#TCards#IdentifyWaste#WasteElimination#WorkflowManagement#TaskTracking#ProcessEfficiency#BottleneckAnalysis#ContinuousImprovement#LeanManagement

0 notes

Text

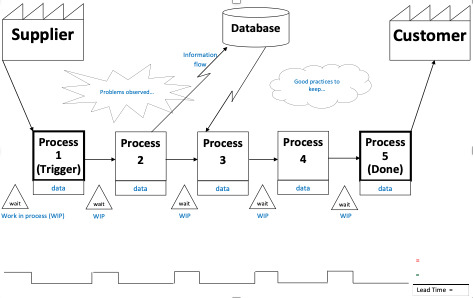

Businesses are continuously seeking ways to improve efficiency, reduce waste, and enhance value delivery. Two powerful methodologies that can significantly contribute to these goals are Project Management (PM) and Value Stream Mapping (VSM).

While project management provides a structured approach to planning, executing, and closing projects, Value Stream Mapping is a lean management technique that helps organizations visualize and optimize the flow of processes. By integrating these two disciplines, businesses can achieve improved project execution, reduced inefficiencies, and better alignment with customer needs. In this blog, we discuss the fundamentals of Project Management and Value Stream Mapping, how they complement each other, and how organizations can leverage them for success.

#ProjectManagement#ValueStreamMapping#LeanProjectManagement#ProcessOptimization#Efficiency#AgileProjectManagement#LeanThinking#BusinessSuccess#WorkflowImprovement#ContinuousImprovement#OperationalExcellence#PMO#RiskManagement#ProjectEfficiency#BusinessGrowth

0 notes

Text

Business Process Improvement

The importance of Business Process Improvement (BPI) cannot be overstated in today's highly competitive market, as technology is likely to have a significant impact on business processes. To achieve a successful BPI, it is imperative to focus more on the business requirements rather than the technology used to achieve the desired result.

Since BPI implementation is a project, it should adhere to all project management principles to ensure well-organized improvement processes without any conflicts.

#BPI#processautomation#existingbusinessprocesses#ERPproject#leansixsigma#kaizen#valuestreammapping#sixsigma#processimprovement#erp#erpsoftware#roadmaperp#softwareservices

0 notes

Text

Embracing Lean Manufacturing: A Blueprint for Success in Today's Economy:

In the ever-evolving landscape of the modern economy, businesses face the imperative to adapt and thrive amidst challenges. Lean manufacturing principles, rooted in efficiency, waste reduction, and continuous improvement, emerge as a guiding light for companies navigating the complexities of today’s economic terrain. This article explores the essence of lean manufacturing and how its principles…

View On WordPress

0 notes

Link

👋 Welcome to our article on identifying symptoms of lean! Lean is a methodology that focuses on eliminating waste and maximizing value in any process. It's widely used in industries such as manufacturing, healthcare, and software development. However, implementing lean can be challenging, and it's important to know the symptoms of lean to ensure its success. 🔍 The first symptom of lean is a focus on continuous improvement. This means that lean organizations are always looking for ways to improve their processes, products, and services. They encourage their employees to identify problems and come up with solutions to eliminate waste and increase value. This creates a culture of innovation and collaboration, where everyone is working towards the same goal. 📈 The second symptom of lean is a focus on metrics and data. Lean organizations measure everything they do, from the time it takes to complete a task to the number of defects in a product. This data is used to identify areas for improvement and track progress towards goals. By focusing on metrics, lean organizations can make data-driven decisions and ensure that they are continuously improving.1. Understanding the Basics of Lean ManufacturingLean manufacturing is a systematic approach to reducing waste and increasing efficiency. It originated in Japan and has since been adopted worldwide. Lean manufacturing focuses on delivering value to customers while minimizing waste. It involves continuous improvement and eliminating non-value-added activities. Lean principles can be applied to any industry, not just manufacturing. One of the key principles of lean manufacturing is the concept of flow. This means that materials, information, and people should flow smoothly and efficiently through the production process. Other principles include pull, which means producing only what is needed when it is needed, and takt time, which is the rate at which products need to be produced to meet customer demand. Lean manufacturing also emphasizes the importance of visual management, which involves using visual cues to communicate information about the production process. Implementing lean manufacturing requires a cultural shift within an organization. It involves empowering employees to identify and solve problems and encouraging collaboration and teamwork. Lean manufacturing also requires a commitment to continuous improvement and a willingness to embrace change. Successful implementation of lean principles can result in increased efficiency, improved quality, and reduced costs. Overall, is essential for any organization looking to improve its operations and deliver value to customers. 👍🏽2. The Importance of Identifying Symptoms of LeanIdentifying symptoms of Lean is crucial for any organization to improve its processes and increase efficiency. Early detection of waste and inefficiencies can save time and money. It helps to identify areas that require improvement and focus on continuous improvement. It allows for better decision-making and problem-solving. Some common symptoms of Lean include: Overproduction Defects or errors Waiting times Excess inventory Unnecessary motion or movement Overprocessing Underutilized talent or resources By identifying these symptoms, organizations can take steps to eliminate waste and improve their processes. Implementing Lean tools and techniques Encouraging employee engagement and participation Streamlining processes and reducing cycle times Improving quality and reducing defects Reducing costs and increasing profitability Improving customer satisfaction and loyalty Ignoring symptoms of Lean can lead to decreased productivity, increased costs, and decreased customer satisfaction. 👍🏽3. Common Symptoms of Lean in Manufacturing ProcessesOne common symptom of lean in manufacturing processes is overproduction, which leads to excess inventory and waste. 🚫 Another symptom is waiting, where idle time and delays occur due to poor flow and lack of synchronization. ⏰ Defects are also a symptom of lean, where errors and mistakes in the process lead to rework and waste. 🚨 Transportation is a symptom of lean, where unnecessary movement of materials and products lead to increased lead times and costs. 🚚 Motion is another symptom, where unnecessary movement of people and equipment lead to inefficiencies and waste. 🏃♂️ Inventory is a symptom of lean, where excess materials and products lead to increased storage costs and waste. 📦 Overprocessing is a symptom of lean, where unnecessary steps and processes lead to increased costs and waste. 💸 Lastly, underutilized talent is a symptom of lean, where employees are not fully engaged and utilized in the process, leading to inefficiencies and waste. 💼4. How to Identify Symptoms of Lean in Your OrganizationIdentifying symptoms of Lean in your organization is crucial for improving efficiency and reducing waste. Here are some signs to look out for: Excessive inventory Long lead times Overproduction Defects and rework Unused talent Low morale Excessive inventory is a clear indication of overproduction and poor demand forecasting. Long lead times suggest inefficient processes and lack of flow. Overproduction leads to excess inventory and waste. Defects and rework indicate poor quality control and waste of resources. Unused talent is a symptom of not utilizing the full potential of employees and not empowering them to make improvements. Low morale can result from a lack of engagement and recognition, leading to decreased productivity. Addressing these symptoms requires a Lean mindset and continuous improvement. Implementing Lean principles and tools such as value stream mapping, 5S, and Kaizen can help identify and eliminate waste, improve processes, and engage employees. Don't wait until it's too late. Start identifying symptoms of Lean in your organization and take action to improve efficiency and reduce waste. 👀🚀🔍👨👩👧👦🌟5. Addressing Symptoms of Lean to Improve Efficiency and ProductivityImplementing lean principles can improve efficiency and productivity, but it's important to address symptoms of lean to maximize results. Identify bottlenecks and eliminate them. Standardize processes to reduce variation. Train employees on lean principles and problem-solving techniques. Use visual management to increase transparency and accountability. Implement continuous improvement initiatives to sustain progress. Addressing symptoms of lean requires a holistic approach that involves all levels of the organization. Encourage employee engagement and participation. Develop a culture of continuous improvement. Measure and track progress using key performance indicators. Use technology to automate processes and improve data collection. Communicate effectively to ensure everyone is aligned with the goals. By addressing symptoms of lean, organizations can achieve significant improvements in efficiency and productivity. Reduce lead times and cycle times. Improve quality and customer satisfaction. Increase capacity and throughput. Reduce costs and waste. Create a competitive advantage in the marketplace. Don't let symptoms of lean hold your organization back. Take action to address them and unlock the full potential of lean principles. 🚀💪🏼👨👩👧👦🏭📈6. Best Practices for Preventing Symptoms of Lean in Your BusinessPreventing symptoms of lean in your business is crucial for its success. Here are some best practices: Focus on customer needs: Understand your customers' needs and align your business processes accordingly. Empower employees: Encourage employees to take ownership and make decisions to improve processes. Continuous improvement: Implement a culture of continuous improvement to identify and eliminate waste. Standardize processes: Develop standard operating procedures to ensure consistency and efficiency. Eliminate non-value-added activities: Identify and eliminate activities that do not add value to the customer. Visual management: Use visual aids to communicate information and monitor progress. Implementing these best practices can help prevent symptoms of lean, such as overproduction, excess inventory, and wasted time and resources. 🚀 In conclusion, identifying symptoms of lean is crucial for early intervention. 🚨 Common signs include weight loss, fatigue, and decreased appetite. 🍽️ Other symptoms may include dizziness, headaches, and irregular periods. 🩸 If you or someone you know is experiencing these symptoms, seek medical attention immediately. 🏥 Remember, lean is a serious condition that can lead to long-term health complications. 🚑 It is important to address symptoms promptly to prevent further damage. 💪 Treatment may include a combination of therapy, medication, and lifestyle changes. 🙏 With proper care, individuals with lean can lead healthy, fulfilling lives. 🌟 Overall, understanding the symptoms of lean is the first step towards recovery. 🌈 By being aware of the warning signs and seeking help when needed, individuals can overcome this challenging condition. 💛 Don't hesitate to reach out for support and guidance. 🤝 You are not alone in this journey. https://symptomfinder.com/identifying-symptoms-of-lean/?_unique_id=64914d3374260

#Uncategorised#continuousimprovement.#Leanmanufacturing#processimprovement#valuestreammapping#wastereduction#aiomatic_0

0 notes

Text

Value Stream Mapping Is Like A Swiss Army Knife

There’s one idea that has stuck with me through the years since I first heard of it during a seminar in my “Philosophy of Science” university class. The professor asserted the idea that there hasn’t been an original idea since Christianity. He believed that every idea since then is not new but rather is only a variation of an existing older idea. In trying to find the source for this idea, I…

View On WordPress

0 notes

Photo

The term "set up time" refers to the amount of time it takes to transition a manufacturing process or production line from producing one product to another. This time includes all the tasks and activities that must be performed in order to prepare the line for the new product, such as cleaning and changing tools, adjusting machinery, and organizing raw materials and supplies. Set up time has its origins in the field of manufacturing, where reducing the time required to change over from one product to another has been a critical factor in improving efficiency and productivity. The idea behind reducing set up time is that the less time a production line is idle, the more products can be produced, and the more efficiently the production process can run. To improve set up time, organizations can use a variety of methods and techniques. One approach is to standardize set up procedures, so that the same steps are followed every time a change over is performed. This standardization helps to eliminate waste, reduce the risk of errors, and speed up the process. Read the full article and see how you can use it for your organization at operationsinsider.com Link in BIO 📚 Language of Lean Like❤️/Share✅/comment👇/follow👉@operationsinsider #operationsinsider #opex #waste #wasteattack #operationalexcellence #LeanManufacturing #Set-UpTime #ManufacturingEfficiency #ProcessImprovement #QuickChangeover #SMED #SingleMinuteExchangeOfDie #WasteReduction #Productivity #ContinuousImprovement #Kaizen #5S #StandardWork #VisualManagement #ValueStreamMapping #JustInTime #JIT #Flow #PullSystem #Kanban #WorkplaceOrganization #EliminateWaste #CycleTimeReduction #QualityImprovement #BusinessPerformance (hier: Warsaw,Poland) https://www.instagram.com/p/Co74mO_Itzp/?igshid=NGJjMDIxMWI=

#operationsinsider#opex#waste#wasteattack#operationalexcellence#leanmanufacturing#set#manufacturingefficiency#processimprovement#quickchangeover#smed#singleminuteexchangeofdie#wastereduction#productivity#continuousimprovement#kaizen#5s#standardwork#visualmanagement#valuestreammapping#justintime#jit#flow#pullsystem#kanban#workplaceorganization#eliminatewaste#cycletimereduction#qualityimprovement#businessperformance

1 note

·

View note

Text

#valuestreammapping#leanmanufacturing#5s training#kaizen#lean consutlant#lean manufacturing#5s system

0 notes

Link

Value stream mapping? What is it, and why is it so helpful?

Constant development and elimination of mistakes is the key to the success of any company. But is there a way to effectively find and delete these shortcomings?

VSM is a unique method of analysis and design of production chains, material flow, and information flow, invented to make business more economical in terms of time and resources.

0 notes

Text

Lean Strategy Implementation: Transform Your Business with Seicho Consulting

In a rapidly evolving world, operational excellence is no longer a luxury—it’s a necessity. Whether you’re a large manufacturer or a growing enterprise, the need to deliver faster, smarter, and leaner is universal. That’s where Lean Strategy Implementation by Seicho Consulting comes in.

At Seicho, we don’t just help you remove inefficiencies—we help you reshape your business to thrive.

💡 What is Lean Strategy?

Lean is more than a toolbox—it’s a strategic umbrella that shields your business from the constant “rain” of unproductive processes, operational waste, cost overruns, safety risks, and quality issues.

Implementing a Lean strategy transforms your organization into a high-efficiency, value-delivering machine, perfectly aligned with your long-term goals.

🚀 Why Choose Seicho for Lean Strategy Implementation?

At Seicho Consulting, we combine deep industry experience with data-driven strategies to bring Lean to life inside your organization. From the factory floor to the boardroom, we align execution with your Vision, Mission, and Strategic Goals.

🔍 Our Lean Implementation Approach

Every organization is unique—and so is our approach. We tailor each phase to match your needs:

✅ Comprehensive Lean Assessment

Baseline analysis of your current operations to identify value and waste across processes.

✅ Value Stream Mapping (VSM)

Visualizing the entire production or service process to eliminate non-value-adding steps.

✅ Strategic Data Collection & Mining

Using analytics to drive insight-led decision-making.

✅ Intelligent Lean Tool Selection

We don’t throw tools at problems—we prescribe what works best for your business.

✅ Execution for Long-Term Success

Implementation plans focused on skill development, system optimization, and strategic alignment.

🛠️ Lean Tools We Deploy

Our consultants handpick tools that fit your organization’s challenges, industry, and maturity level:

5S – Workplace organization and visual clarity

Kaizen – Continuous small improvements with big impact

Poka-Yoke – Error proofing to ensure first-time quality

Andon Systems – Real-time problem signaling and response

Heijunka – Production leveling for smooth flow

8D Problem Solving – Structured root-cause elimination

TPM & TQM – Asset care and total quality initiatives

Six Sigma – Reducing variation, improving precision

Hoshin Kanri – Strategic policy deployment across teams

Each tool is carefully deployed like a custom prescription—not one-size-fits-all, but strategic and tailored.

🏗️ Greenfield & Brownfield Project Expertise

No matter where you are in your operational lifecycle, Seicho helps optimize your infrastructure:

🟢 Greenfield Projects

Design efficient layouts from scratch

Ensure scalable, waste-free foundations

Embed Lean at the core of your systems

🟤 Brownfield Projects

Restructure existing operations

Identify bottlenecks and hidden inefficiencies

Retrofit Lean thinking into legacy systems

Layout is the backbone of Lean—and we ensure yours is built to support long-term success.

📈 The Impact of Lean Strategy Implementation

🔄 Reduced operational costs

📉 Elimination of waste and non-value activities

🚀 Improved throughput and productivity

📊 Data-backed decision-making

🤝 Cross-functional alignment and accountability

Whether you’re starting your Lean journey or scaling it organization-wide, Seicho Consulting helps you embed Lean into your DNA.

👣 Ready to Lead the Change?

Lean isn’t a trend—it’s a transformation journey. When implemented with strategic precision, it becomes a catalyst for growth, culture, and competitive advantage.

📞 Let’s build your Lean roadmap together. Contact Seicho Consulting today.

#LeanStrategy#LeanManufacturing#LeanConsulting#BusinessTransformation#OperationalExcellence#ContinuousImprovement#Kaizen#ValueStreamMapping#BusinessConsulting#SeichoConsulting#ProcessImprovement#LeanThinking#5S#SixSigma#EfficiencyMatters#LeadershipDevelopment#ProductivityHacks#BusinessGrowth#LeanTools#BusinessStrategy

0 notes

Text

What are Lean, Six Sigma, and Lean Six Sigma?

With regards to taking care of gigantic organizations, numerous things can get muddled during the time spent developing. What comes to utilize is how an organization or business works in a coordinated and precise way with the least exertion.

This not exclusively could twofold the benefits yet, in addition, give more joyful workers and clients. Also, for this reason, Lean Six Sigma has acquired a lot of fame. It helps associations in their general development.

What is Lean?

The term 'Lean' is taken from the Japanese assembling ventures however it has its underlying foundations in the Toyota Production System. Lean reasoning permits associations to turn out to be more practical. The essential objective of this procedure is to make the greatest incentive for clients by decreasing or dispensing with pointless advances engaged with an interaction.

It implies that any progression which doesn't increase the value of the cycle is killed methodically. The lean strategy helps in the evacuation of the following kinds of waste:

Abandons

Overproduction

Transportation

Pausing

Unutilized ability

Movement

What is Six Sigma?

Six Sigma is an information-driven administration approach that includes a bunch of procedures and instruments for business process improvement. Charge Smith, a designer in Motorola, created Six Sigma in 1986.

It has picked up colossal speed and acknowledgment all through the business. It tries to work on quality by estimating and dispensing with deserts deliberately until the deformity number goes to nothing.

Six Sigma system is utilized to further develop the business cycles, items, or administrations. Many associations have taken on this strategy of critical thinking and have saved a huge number of dollars.

Contact us for Six Sigma Green Belt Cerfication in Mumbai.

It deals with a five-stage DMAIC structure. The stages specifically

Characterize

Measure

Dissect

Get to the next level

Control

What is Lean Six Sigma?

Having its underlying foundations during the 1980s, Lean Six Sigma was presented by Michael George and Robert Lawrence Jr. in their 2002 book: Lean six sigma: consolidating six sigma with lean speed.

Lean Six Sigma is the mix of the influential ideas 'Lean' and 'Six Sigma.' US fabricating organizations previously took on this technique.

This technique endeavors to guarantee quality underway and hierarchical cycles by taking out misuse of actual assets, time, exertion, and ability. The motivation behind this technique is to give clients the best quality, cost, and conveyance.

Incline mostly focuses on squander decreases while Six Sigma underscores a variety of decreases utilizing factual information. To accomplish six sigma objectives, factual information examination and theory tests are utilized though for Lean objectives instruments like kaizen and visual controls are utilized.

This technique has given business and assembling organizations a gigantic measure of benefits while ensuring their clients are blissful.

Contact us for Lean Six Sigma Green Belt Training

Why is Lean Six Sigma so Important?

Associations are confronting increasing expenses and high contests consistently because of a unique climate. Six Sigma permits you to develop your business by handling these issues.

Advantages of Using Lean Six Sigma:

Diminishes Cost

Builds Revenue

Expands Customer Satisfaction

Further develops Efficiency and Effectiveness

Creates Employees inside Your Organization

End

To summarize everything, a joined methodology of lean six sigma helps in further developing cycle proficiency, asset enhancement, consumer loyalty, cost-cutting, and benefits.

Lean focuses on squander decrease, while six sigma focuses on the decrease of cycle variety. By and by, both the methodologies mix to understand the maximum capacity of cycle enhancements.

Contact us for Lean Six Sigma Certification in Mumbai.

#leansixsigmacertificationinMumbai#sixsigmagreenbeltcertificationinMumbai#leansixsigmagreenbelt#greenbeltsixsigma#sixsigmaconsultantinMumbai#Valuestreammapping

0 notes

Text

How to implement Lean Practices in your workplace ?

Implementing lean practices in your workplace can significantly improve efficiency, productivity, and overall business performance. Integrating these lean practices into your workplace can achieve a more efficient, responsive, and customer-focused organisation. Remember to continuously review and refine your processes to maintain a culture of continuous improvement.

For more details read our blog : https://leantransitionsolutions.com/Lean-Technology/what-is-lean-methodology

#leanmethodology#continuousimprovement#Leanpractices#ValueStream#Kanban#Kaizen#leantools#valuestreammapping#leantechniques#Leanmanufacturing#5Ssoftware#kanbansoftware#tasktracking#CMMSSoftware

0 notes

Photo

Kant's aesthetics talk of "free play" (free lawfulness of the faculties of imagination and understanding when e.g. looking at conceptual art) In this work i was trying to link these faculties (also involved in cognition) together, into some sort of (meta) model that makes sense with how i experience life. Even though the 'painting' is done there is not a lot more sense then before i started it 🤨 But! the subject does not cease to make me wonder... This work is also inspired by the Alfred Barr's flowchart and ive done some writing on this subject at: www.standardlifeprocedure.com. #lifeline #contemporaryart #painting #alfredbarr #moma #flowchart #graph #graphpainting #valuestream #valuestreammapping #opex #painter #contemporaryartist #philosophy #drunkenphilosophy #metamodel #interface https://www.instagram.com/p/BmeA5wdBf11/?utm_source=ig_tumblr_share&igshid=ct87h8aosyjv

#lifeline#contemporaryart#painting#alfredbarr#moma#flowchart#graph#graphpainting#valuestream#valuestreammapping#opex#painter#contemporaryartist#philosophy#drunkenphilosophy#metamodel#interface

2 notes

·

View notes

Photo

Message to all Plant Managers! When was the last time you mapped the value and non-value inside your key processes? In most cases, this can be done inside one day, it does not have to be a complicated process and the findings can really explode your opportunities in 2020! Reasons to run a VSM session in your operations in late 2019: ★Engage a team of your people ★Tap into their knowledge and experience ★Gain valuable aha pointers from inside your processes ★A great starting point for further activity and so much more.... #vsm #valuestreammapping #plantmanager #culture https://www.instagram.com/p/B4UjsaggKPT/?igshid=8wvhtm256ql9

0 notes