#variable data printing press

Explore tagged Tumblr posts

Text

Order Jetsci® Global Digital Label Printing machine

Order a Jetsci® Global digital label printing machine for high-performance, reliable, and precise label production. Designed with advanced technology, these machines deliver exceptional print quality, speed, and efficiency. Trusted by leading brands worldwide, Jetsci® offers customized solutions to meet your specific needs. Invest in innovation—choose Jetsci® for your label printing.

OUR CONTACT DETAILS: ADDRESS: B-15, InfoCity Phase 1, Sector 34,Gurugram-122001, Haryana, India CONTACT NO. +91 1244226771 EMAIL: [email protected] Visit Us: https://www.jetsciglobal.com/kolorsmart/

#digital label press#digital label printing solutions#uv label printing press#digital color label press#variable data printing press#digital uv inkjet label production press#uv inkjet label printing solution#jetsci® global#book printing press#digital book printing press

0 notes

Text

Romance with the Alchemist.

pairing: albedo x reader

warning: not proofread, rough draft, grammatical erroes (i think), wrote this like a year before and continued it on the spot so it's going to be a bit confusing but anw idc i js need to delete these drafts mehn HWIEHDJWJAH.

It began with a cup of tea.

Not yours—his. Albedo had brewed it, left it on the table, and forgotten about it amidst a string of calculations. You passed by, noticed the cup, and without a word, picked it up, warmed it again over the flame, and set it beside him with the gentlest clink.

That was the first data point. He didn’t write it down, but it stayed. He told himself it was curiosity at first.

You behaved unlike the others who visited Dragonspine. You didn’t press him with questions, didn’t ask for favors or boast about surviving the cold. You were…quiet, in your own way. Attentive without demanding. Present without pulling.

A quiet variable that returned, again and again. He found himself measuring time in your visits. Not in hours or days, but in the way the cave brightened when your boots left shallow prints by the door.

Noted. Unspoken.

Albedo’s affection bloomed not like fire, but like frost—slow, creeping, unnoticed until everything beneath was touched by it. He began adding a second chair beside his. “In case Timaeus visits,” he said. But he never offered it to Timaeus. Only to you.

He stored a second blanket in the corner—“for emergencies.” You used it once. After that, it was always folded neatly at arm’s reach from your favorite spot. These weren’t declarations. These were constants. Quiet insertions into his environment that proved your presence was not only expected, but accounted for.

The acceptance came not with a realization, but with a recalibration. One night, after you left with a soft wave and a promise to return “next week, maybe,” he found his mind drifting. Not to your face.

But to your voice, saying “next week.”

To your hand brushing his wrist as you passed something he needed.

To the warmth of your scarf still left behind on the hook.

He stared at it for a long time.

Then, without a word, he hung it next to his coat.

It was in the way he started pacing when your return was delayed. The way his brush hovered above the page, unsure whether to draw the tree outside… or the way he could see your breath on the cold air as you looked at something from the distance.

He never called this feeling to be something possibly like romance or affection, he does not believe he could feel such emotions.

But he stopped testing it. Stopped resisting the instinct to brew tea for two. To write notes in the margin for you to find. To reach for the scarf you gave him even when the cold didn’t bite.

One evening, you fell asleep near the campfire in his lab, book in hand, cheek resting against your arm. The silence was soft, comforting.

Albedo didn’t move you. He sat, watching the snow beyond the entrance, the curl of your fingers against the page. And for the first time, he allowed himself to speak aloud—not to wake you, not to be heard, but simply to let it exist:

“Stay as long as you’d like.”

It was not an invitation.

Not a request.

But it was a hypothesis proven true, quietly, patiently: In a world of shifting truths and elusive formulas, you had become the one constant he never needed to solve—only preserve.

To be honest, the snow never bothered Albedo.

Most avoided Dragonspine unless they had no choice, but not him—and not you, either, much to his quiet surprise the first time you trudged through the thick frost just to bring him a scarf. It was hand-knitted, a little uneven in stitching, dyed a blue that didn’t quite match his usual palette. You apologized for it, babbling that you weren’t sure he’d like it, but—

He took it from your hands, wore it immediately, and didn’t say a word. But he wore it again. And again. Every time you visited. You never noticed the way his gloved hand would linger over the fabric when you left. He made sure of that.

Albedo didn’t love like others did.

There were no grand proclamations. No impulsive touches or clumsy declarations. He didn’t stumble over his feelings or turn crimson at your smile. Instead, he observed you—like an unsolvable equation that he didn’t want to solve too fast.

He remembered the way you liked your tea: a dash of honey, not sugar. So when you visited the lab, a steaming cup always waited near the heat lamp. He noted the books you skimmed in the library, then borrowed them in secret, reading ahead so you could “coincidentally” discuss them together.

He never said the words. But he showed them in ways he knew how—through routines, through precision, through the silence between thoughts where your name lingered like an echo.

One afternoon, you arrived while snowflakes danced lazily outside, clinging to your cloak. “You’re not cold?” you asked, setting down a wrapped lunch you made for the both of you.

“I’m adjusted to this climate,” he answered without looking up, yet he slid a warmer chair closer to the heater for you. “But you should be careful. I noticed your gloves are worn. I’ve… made you a pair.”

You blinked. “You made them?” He nodded. “Woven from wool. Reinforced with wind crystal shards. A minor alchemical enhancement for warmth retention.”

You laughed softly, slipping them on. “They’re perfect.” He turned away too quickly. “I’m glad.” He never said the three words. He didn’t need to. The way he watched you with steady, unwavering eyes—the way he noticed what even you didn’t—said it all.

It wasn’t until much later, when you found an old sketchbook half-buried under his pile of notes, that you truly saw it. Pages and pages of you. Not exact portraits, but impressions—the curve of your hand holding tea, the softness in your gaze when you looked at snow falling outside his window, the tilt of your head when you read aloud.

Each drawing carried a different kind of tenderness. And at the corner of one, written in his delicate script: “Hypothesis: In the presence of [Name], the concept of home shifts. It is no longer a place, but a person.”

When it came to everyone and their thoughts regarding the both of you, Lisa knew first. Of course she did.

You visited the library one afternoon looking for a book Albedo had once mentioned in passing—Floral Properties of Subzero Climates, Vol. II. You didn’t ask for it by name. You simply described the way his voice softened when he last spoke of it.

Lisa smiled, handed it over without a word, and watched you leave with a knowing hum. “That boy…” she murmured. “Head over heels in his own way.

Kaeya noticed when he caught Albedo adjusting his gloves one evening at the tavern. “You’re headed back to Dragonspine, aren’t you?” Kaeya asked. “Say hello to our favorite snow visitor for me.”

Albedo blinked once, the way he did when caught off-guard. “You mean Timaeus?” Kaeya chuckled. “Sure. Timaeus.” But Albedo didn’t argue. He just quietly picked up the satchel with two thermoses inside—one with his usual tea, the other with yours.

He wouldn’t call it affection. But he made sure the one labeled with your initials was sealed better, warmer.

Sucrose found one of your hairpins tucked into the corner of Albedo’s desk. She reached for it absentmindedly, only for Albedo to stop her gently. “That’s not… for use,” he said.

“Oh.” She blinked. “It’s the traveler’s, right?” Albedo didn’t answer. He just took it and placed it into the locked drawer where he kept his most fragile samples. Not because he wanted to hide it—but because things that mattered should be protected.

You never talked about what it meant. When you arrived, you simply sat beside him. Sometimes you read. Sometimes he painted. Sometimes you both just existed in quiet parallel.

But small things kept building up.

The sketchbook left open where he knew you’d peek.

The comment you’d drop about something he made—just enough to make him pause, the corners of his lips curling slightly.

Once, you brought lunch and forgot utensils. Without hesitation, Albedo offered his own.

Two hours later, he was still touching the spot where your fingers had grazed his.

Amber visited one time and caught the two of you mid-conversation—or rather, mid-silence. You were both just sitting, sipping tea, watching the snow fall outside. Nothing romantic, at first glance.

But then Albedo leaned closer, brushing a stray snowflake from your shoulder without breaking eye contact. You didn’t flinch. You smiled, like it was the most natural thing in the world.

Amber blinked. “Wait,” she whispered under her breath. “Are they…already dating?”

You weren’t.

Neither of you said anything.

But everyone could see it and they had bet on it. In the way Albedo set aside a space for you in every part of his world. In the way your laugh softened his features in a way no potion or pigment ever could. Still, the words were never spoken.

Not when he adjusted your scarf before you left.

Not when you left him your gloves by mistake and found them cleaned and folded neatly in your bag the next morning.

Not even when he handed you a notebook one day—filled with formulas, sketches, pressed flowers, and on the last page: “Certain variables defy classification. I’ve stopped trying to define what you are to me. I’ve decided instead…to keep you.” There was no name on it. But you knew.

And when you returned the next day, you didn’t say anything either. Just sat beside him like always, eyes shining a little brighter.

And he, ever subtle, simply handed you your cup.

Still warm. Still waiting.

#nyx — writes.🖊️#genshin impact#genshin x reader#genshin impact x reader#albedo scenarios#albedo gi#albedo kreideprinz#genshin impact albedo#albedo fic#albedo x reader#albedo#genshin blog#genshin imagines#genshin impact scenarios#genshin x you#albedo kreideprinz x reader#i have returned#bitchass this is so shit PLSHWIAHDHDBA

559 notes

·

View notes

Text

Printing Press in Sharjah: The Type of Service Your Business Needs

In the bustling emirate of Sharjah, where business and innovation thrive, the demand for reliable and high-quality printing services in Dubai is ever-present. A crucial aspect of marketing and brand communication, printing plays a pivotal role in shaping the identity of businesses. In this dynamic environment, choosing the right printing press in Sharjah becomes paramount. This article explores the various types of printing services available in Sharjah and how businesses can make informed decisions to meet their unique needs.

The Landscape of Printing Press in Sharjah

A Flourishing Industry

Sharjah, often referred to as the cultural capital of the United Arab Emirates, is home to a thriving printing industry. The emirate has witnessed significant growth in recent years, with numerous printing presses catering to the diverse needs of businesses ranging from small startups to large corporations.

Technological Advancements

One of the key reasons behind the success of the printing company Sharjah is its adoption of cutting-edge technologies. From offset printing to digital printing, these presses leverage state-of-the-art equipment to ensure efficiency, precision, and a wide range of capabilities.

Types of Printing Services Offered

1. Offset Printing

Offset printing remains a popular choice for businesses requiring large quantities of printed materials. This traditional method involves transferring ink from a plate to a rubber sheet, which then makes contact with the printing surface. Offset printing is known for its high-quality results, making it suitable for items like brochures, catalogs, and business cards.

2. Digital Printing

In the era of quick turnarounds and short print runs, digital printing has gained prominence. This method eliminates the need for printing plates, allowing for on-demand printing with minimal setup time. Digital printing is ideal for projects that require customization, such as personalized marketing materials, variable data printing, and short print runs.

3. Large Format Printing

For businesses looking to make a bold visual impact, large-format printing is the go-to option. This service is capable of producing oversized prints on various materials, including banners, posters, and signage. Large-format printing is crucial for events, trade shows, and outdoor advertising, providing businesses with a powerful tool to capture attention.

4. Promotional Items Printing

Printing press in UAE also offers services for printing on promotional items. This includes branded merchandise like pens, mugs, and T-shirts. Businesses can enhance their marketing efforts by incorporating their logos and messaging onto these items, creating tangible and memorable connections with their target audience.

5. Packaging Printing

In the competitive landscape of retail, packaging plays a crucial role in attracting customers. Printing press in Sharjah provides specialized services for packaging printing, ensuring that products stand out on the shelves. Whether it's food packaging, cosmetic boxes, or product labels, these presses deliver high-quality packaging solutions.

Choosing the Right Printing Press In Sharjah

1. Understanding Your Needs

Before selecting a printing press in Sharjah, it's essential for businesses to clearly define their printing needs. Consider the type of materials to be printed, the desired quantity, and any specific customization requirements. This initial assessment sets the foundation for finding a printing press that aligns with the unique goals of the business.

2. Quality and Technology

The quality of printed materials reflects directly on a business's image. When choosing a printing press, inquire about the technologies they employ and the quality control measures in place. High-resolution printing, color accuracy, and attention to detail are crucial factors that contribute to the overall quality of the final product.

3. Turnaround Time

In the fast-paced business environment of Sharjah, turnaround time is a critical consideration. Different printing presses may have varying production timelines. Businesses should communicate their timelines and deadlines upfront to ensure that the printing press can meet or exceed expectations.

4. Cost Considerations

While quality is paramount, businesses must also consider the cost implications of their printing projects. Obtain detailed quotes from the potential printing press in Sharjah, including any additional charges for customization or expedited services. Comparing costs against the expected quality and services helps businesses make informed decisions.

5. Customer Reviews and Reputation

Before finalizing a choice, it's advisable to research the reputation of the printing press. Customer reviews, testimonials, and case studies provide valuable insights into the experiences of other businesses. A printing press with a positive track record of customer satisfaction is more likely to deliver reliable and satisfactory results.

Conclusion

In the vibrant business landscape of Sharjah, choosing the right printing press is a strategic decision that can significantly impact a company's success. Whether it's traditional offset printing for large quantities or cutting-edge digital printing for on-demand needs, the diverse range of services offered by the printing press in Sharjah caters to the multifaceted requirements of businesses. By understanding their unique printing needs, and considering factors like quality, turnaround time, cost, and reputation, businesses can forge lasting partnerships with printing presses that elevate their brand presence and communication.

2 notes

·

View notes

Text

APFC Panels vs Capacitor Panels: Key Differences

Modern electrical systems demand efficient power management. Among various solutions, APFC Panels and Capacitor Panels are two vital components used in industrial and commercial power systems. Understanding the differences between them can help you make better choices when sourcing from a capacitor panel supplier and manufacturer or considering top APFC panel manufacturers.

This article breaks down how both panel types function, where they are used, and their benefits without getting too technical.

What Are Capacitor Panels?

Capacitor panels are used to correct the power factor in electrical systems. They are made up of a combination of capacitors, contactors, and fuses that manually or automatically switch based on load requirements.

These panels are primarily installed to improve the efficiency of electrical power usage and reduce electricity bills by lowering penalties due to poor power factor.

Where they are used:

Small to medium-scale industries

Commercial buildings

Office complexes

Pumping stations

Benefits:

Simple design and lower cost

Helps avoid utility penalties

Reduces load on transformers

What Are APFC Panels?

APFC Panels, short for Automatic Power Factor Correction Panels, are advanced versions of standard capacitor panels. The key difference lies in automation. These panels use a microcontroller or programmable relay to monitor the power factor and switch capacitors automatically.

They are suitable for dynamic loads where power requirements vary constantly. This automation results in better performance and minimal human intervention.

Applications:

Factories with frequent load changes

Shopping malls

Hospitals

Printing presses

Advantages:

Real-time power factor correction

Improved system lifespan

Optimised energy efficiency

Why Businesses Prefer APFC Panels

Industries now look beyond just cost-cutting they want long-term efficiency and automation. APFC panels serve this demand.

Reasons for increasing demand:

Labour cost reduction due to automation

Better compatibility with modern machinery

Enhanced protection against harmonics

Compliance with energy norms

Leading APFC panel manufacturers also offer remote monitoring options and smart energy reporting, allowing facility managers to make better decisions with real-time data.

This shift in preference is driving more businesses to upgrade from basic capacitor panels to smart APFC systems, especially in sectors with variable power needs.

How to Choose the Right Panel for Your Needs

When choosing between the two, consider these points:

Nature of Electrical Load For fluctuating loads, go with APFC For steady loads, basic capacitor panels are enough

Automation Requirements APFC panels offer better integration with building management systems

Initial Budget vs Long-term Savings Capacitor panels are cheaper initially APFC panels reduce power bills over time

Service and Maintenance APFC panels often come with built-in diagnostics Capacitor panels need manual checks

Always connect with a reliable capacitor panel supplier and manufacturer like Dj Electro Controls, known for delivering long-lasting electrical systems.

FAQs

Q1. What is the main role of APFC panels?

Answer: APFC panels maintain the power factor automatically by switching capacitors based on real-time load conditions.

Q2. Can I replace capacitor panels with APFC panels easily?

Answer: Yes, but the switch should be made based on load analysis and expert consultation.

Q3. Which is more cost-effective in the long run?

Answer: APFC panels offer better returns over time due to energy savings and automation.

Q4. Are APFC panels only for large industries?

Answer: Not necessarily. Any facility with variable loads can benefit from APFC systems.

Q5. Who are some trusted APFC panel manufacturers?

Answer: Brands like Dj Electro Controls offer reliable and scalable APFC solutions.

Conclusion

Choosing between APFC Panels and Capacitor Panels depends on your specific power usage patterns. For predictable loads, standard capacitor panels do the job. But for operations involving frequent load changes, APFC panels bring automation, accuracy, and long-term savings.

Work with trusted suppliers like Dj Electro Controls, who not only offer a range of options but also assist in system selection and support. Upgrading to the right panel can bring real improvements in efficiency, equipment life, and operational costs.

#djelectrocontrol#apfc manufacturer#apfc panels#apfc supplier in india#Capacitor Panels#Capacitor Panels supplier in india

0 notes

Text

Gold Coast Printing: Your One-Stop Destination for High-Quality Print Solutions

Are you searching for top-tier Gold Coast printing services that deliver on time, on budget, and with exceptional quality? Whether you’re a small business, a corporate brand, or an individual with personal printing needs, the Gold Coast is home to some of Australia’s most innovative and reliable print providers.

Why Choose a Local Gold Coast Printer?

Choosing a local printer on the Gold Coast offers several advantages. Not only do you benefit from faster turnaround times and reduced shipping costs, but local printers often provide more personalized service. They understand the unique needs of the Gold Coast market, from tourism and events to real estate and hospitality.

Key Benefits:

Fast turnaround times

Personalized customer service

High-quality materials and finishes

Support for local businesses

Types of Printing Services Offered on the Gold Coast

Gold Coast printing companies offer a diverse range of services to meet all your branding and marketing needs. Here are some of the most popular services:

1. Business Printing

Business cards

Flyers and brochures

Letterheads and envelopes

Presentation folders

2. Large Format Printing

Posters and banners

Window signage

Exhibition displays

A-frame signs

3. Custom Printing

Invitations and greeting cards

Custom packaging

Stickers and labels

Calendars and notepads

4. Promotional Products

Branded merchandise

Apparel printing (T-shirts, hats, uniforms)

Corporate gifts

Digital vs. Offset Printing: What’s Best for You?

Gold Coast printing companies often provide both digital and offset printing options. Understanding the difference can help you choose the right method:

Digital Printing is ideal for short runs, fast turnarounds, and variable data (e.g., personalized mailers).

Offset Printing is better for larger volumes with consistent quality and lower per-unit costs.

How to Choose the Best Gold Coast Printing Company

When looking for a Gold Coast print shop, consider these factors:

Experience and reputation: Check reviews and past work.

Range of services: Can they handle all your printing needs?

Quality assurance: Do they use high-quality inks and materials?

Customer service: Are they responsive and helpful?

Eco-friendly practices: Do they offer sustainable printing options?

Eco-Friendly Printing on the Gold Coast

Sustainability is becoming a priority for many businesses. Look for printers that use:

Recycled paper options

Vegetable-based inks

Energy-efficient printing presses

Carbon-neutral shipping methods

Top Uses for Gold Coast Printing Services

Event marketing: Posters, flyers, and signage for festivals and expos

Real estate materials: Property brochures and signs

Retail promotions: Sales banners and loyalty cards

Corporate branding: Stationery, uniforms, and promotional items

Conclusion: Get Started with a Trusted Gold Coast Printer

Whether you're launching a new product, promoting an event, or branding your business, finding a reliable Gold Coast printing partner can make all the difference. With cutting-edge technology, a wide array of services, and a deep understanding of the local market, the right printer will bring your vision to life with precision and professionalism.

Need Gold Coast printing services? Search for local providers with great reviews and request a custom quote today!

0 notes

Text

The Tangibility of Thought: Elevating Brand Identity through Precision Printing in the Digital Age

In a marketplace ever saturated with ephemeral pixels and algorithmic noise, print's deliberate tactility continues to emerge not as an anachronism but as a strategic renaissance. At Printplus, New Zealand’s consummate provider of comprehensive printing solutions, we do not merely transfer ink to substrate—we transmute ideas into artefacts of permanence and persuasion.

The Intellectual Gravitas of Printed Media

Consider the modern brochure. In lesser hands it is a perfunctory marketing relic. In ours it becomes a narrative vessel—a curated anthology of your brand’s ethos, ambitions, and sensory identity. Through our specialised Brochure Printing in Auckland, we deploy a synthesis of design intelligence, chromatic fidelity, and material precision to craft communicative instruments that engage not merely the eye but the intellect.

Leaflet Printing: The Art of the Strategic Whisper

Unlike digital intrusions that demand attention, Leaflet Printing is the art of subtle seduction. A masterfully designed leaflet does not shout; it resonates. With Printplus, every leaflet is not a mass-printed afterthought—it is a meticulously calibrated communique. We align typography with psychology, colour with cognition, and layout with logic, ensuring your message pierces through cognitive clutter with surgical clarity.

Beyond the Press: A Holistic Print Philosophy

We operate beyond mere production—we curate outcomes. Our end-to-end print architecture incorporates

Offset and Digital Hybridisation for tailored scalability

Eco-conscious Paper Sourcing that marries aesthetics with environmental responsibility

Data-driven Variable Printing for hyper-personalised marketing

Rapid-turn Prototyping to test and perfect before committing to volume

We are not your printer. We are your co-authors in tactile storytelling.

Rooted in Aotearoa, Resonating Globally

With a proud domicile in Auckland, Printplus reverberates through every suburb, region, and enterprise that seeks enduring brand resonance. From Leaflet Printing for local campaigns in Queenstown to elaborate Brochure Printing projects in Auckland’s commercial heart, our reach is national, our impact indelible.

Closing Impression

In an era increasingly defined by fleeting impressions and click-throughs, the judicious use of print is not just effective—it is revolutionary. At Printplus, we invite you to transcend the ephemeral and embrace the enduring. Let us help you inscribe your narrative not on screens but in the minds and memories of your audience.

Print with purpose. Print with Printplus.

0 notes

Text

What Are the Advantages of Digital Printing?

In today’s fast-paced, design-driven world, high-quality printing plays a crucial role in personal and professional branding. Whether you're a small business owner looking to print marketing materials or a student in need of customized notebooks, digital printing offers a modern, efficient solution. More than just a method of transferring ink to paper, digital printing represents speed, accuracy, and flexibility. For individuals and businesses searching for reliable printing services near me, understanding the benefits of digital printing can help you make more informed choices.

What is Digital Printing?

Digital printing is a method of printing digital-based images directly onto various media. Unlike traditional offset printing, which uses plates and rubber blankets, digital printing doesn’t require such setup. This not only reduces the time taken to start a print job but also allows for quick changes, on-demand printing, and cost-effective short runs.

Fast Turnaround Time

One of the most significant advantages of digital printing is its speed. Since there's no need for pre-press processes or setup plates, printers can begin production immediately. For businesses in Visakhapatnam, this means same-day or next-day service is entirely possible, especially when working with trusted providers like Srirama Notebooks, which offers quick and professional digital printing in Visakhapatnam.

Whether you're printing business cards or last-minute promotional flyers, the turnaround time can make all the difference.

High-Quality Output

Digital printing delivers sharp, vibrant colors with consistent quality from the first print to the last. It's particularly effective for projects that require high detail, such as brochure printing services or custom letterheads. With advancements in technology, digital printers can now handle various paper types, finishes, and coatings, giving printed materials a premium look and feel.

If you’ve been Googling letterhead printing near me, make sure to choose a provider that uses the latest digital technology to ensure your brand materials reflect quality and professionalism.

Cost-Effective for Small Runs

Traditional printing becomes cost-effective only when you're printing in bulk. But what if you need just 100 brochures or 50 letterheads? This is where digital printing shines. It allows for smaller runs without the high setup costs. For local entrepreneurs, students, or event organizers in Visakhapatnam, digital printing offers the flexibility to print only what you need—when you need it—without blowing your budget.

Easy Customization and Variable Data Printing

Need 500 brochures with personalized names and contact details? Digital printing can handle that with ease. Variable data printing (VDP) allows you to change elements like names, addresses, or even images on each piece without slowing down the production. This is ideal for personalized direct mail campaigns, wedding invitations, or membership cards.

Businesses offering brochure printing services now use VDP to help brands target specific customers with tailored content. This leads to better engagement and higher ROI.

Environmentally Friendly

Digital printing tends to be more environmentally friendly than traditional methods. It produces less waste, uses less ink, and avoids the chemical-heavy plate processing associated with offset printing. Companies like Srirama Notebooks are making a conscious effort to incorporate sustainable practices into their digital printing in Visakhapatnam, helping customers reduce their carbon footprint.

Versatility Across Formats

Digital printing isn’t limited to paper. You can print on vinyl, fabric, cardboard, and even plastic. Whether you’re looking to create custom stickers, booklets, or banners, digital printing gives you the flexibility to work across multiple mediums.

If you’ve been searching for printing services near me that can handle everything from business essentials to creative projects, a versatile digital printing provider is your best bet.

On-Demand Printing Reduces Inventory Costs

Gone are the days when businesses had to store thousands of printed items that might go unused. Digital printing supports on-demand production, which means you only print what you need, when you need it. This not only saves space but also reduces waste from obsolete or outdated materials.

For example, if your company updates its branding or contact information, you can quickly print a fresh batch of brochures or letterheads without worrying about throwing away old stock.

Why Choose Srirama Notebooks?

When it comes to reliable and affordable digital printing in Visakhapatnam, Srirama Notebooks stands out for its quality, speed, and customer service. Whether you're looking for brochure printing services, custom notebooks, or letterhead printing near me, Srirama Notebooks has the tools, technology, and experience to deliver exceptional results.

Their team works closely with customers to ensure each project is completed to perfection, using only the best materials and latest digital printing machines. They also offer eco-friendly options and competitive pricing, making them a top choice for individuals and businesses alike.

Conclusion

Digital printing has revolutionized the way we think about printed materials. With its speed, quality, flexibility, and affordability, it’s no wonder more people are turning to digital solutions for their everyday printing needs. Whether you're a small business, a student, or a creative professional, digital printing offers practical advantages that traditional methods can’t match.

If you're located in Andhra Pradesh and searching for printing services near me, look no further than Srirama Notebooks. With expertise in everything from brochure printing services to letterhead printing near me, they are your one-stop solution for professional digital printing in Visakhapatnam.

0 notes

Text

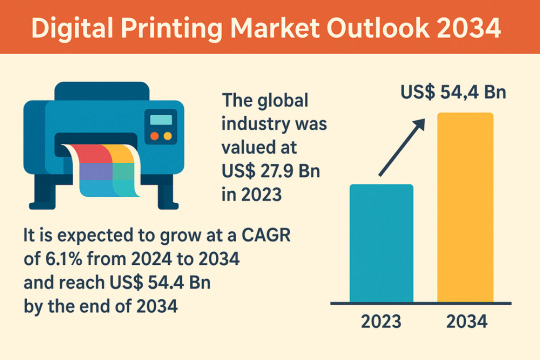

Digital Printing Market to Reach $54.4 Billion by 2034 Amid Rising Demand for On-Demand Solutions

The global digital printing market reached a valuation of US$ 27.9 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.1% between 2024 and 2034, culminating in a market worth US$ 54.4 billion by December 31, 2034. Digital printing bypasses the need for traditional printing plates by transferring digital files directly onto substrates such as paper, canvas, textiles, and synthetics. This seamless workflow supports on-demand production, reduces waste, and delivers high-throughput performance of up to 4,800 sheets per hour once printing begins.

Industry analysts anticipate that continued investments in print manufacturing efficiencies, supply chain integration, and time-to-market acceleration will drive digital printing adoption. Key growth verticals include textile and packaging, where high-definition, on-demand print capabilities facilitate product personalization and rapid iteration. The rise of direct-to-consumer printing models—particularly in can printing further cements digital printing’s role as a versatile, customer-centric technology.

Market Drivers & Trends

Technological Upgrades in Printing: Major players are embedding automation, AI-driven color management, and new printheads into their presses. For instance, in 2022, Hewlett Packard unveiled its Indigo 15K and 100K Digital Press platforms to enhance automation, reduce labor and plate costs, and slash turnaround times for medium to high-volume short runs.

Textile & Packaging Industry Growth: The global textile sector, valued at US$ 4.4 trillion, is rapidly embracing digital print to enable limitless design options and shorter production cycles. Likewise, packaging manufacturers are deploying UV LED and single-pass inkjet presses to deliver variable data printing—such as QR codes and barcodes—at scale.

On-Demand & Personalized Printing: Digital technology empowers brands to engage customers directly by crowdsourcing can designs, securing approvals, and fulfilling orders without intermediaries. This strategy has spurred increased consumer engagement and brand loyalty.

Latest Market Trends

High-Speed Single-Pass Inkjet: Next-generation presses with robust sheet feeders are driving throughputs that rival and often exceed traditional lithography, enabling signage and packaging that formerly required multiple litho sheets to be completed in a single digital pass.

Water-Based Polymer Inks: Sustainability concerns have prompted Canon’s 2022 launch of an automated production facility in Venlo for water-based CMYK inks, designed to curtail waste while ensuring consistent, premium output.

Strategic Partnerships & Acquisitions: Industry consolidation remains robust. In October 2023, ARC Document Solutions partnered with Canon Solutions America to integrate Arizona printing and Colex cutting systems, bolstering its digital color printing services.

Explore pivotal insights and conclusions from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86049

Key Players and Industry Leaders

Prominent companies shaping the digital printing landscape include:

Amcor plc

Avery Dennison Corporation

Canon Inc.

ColorJet Group

DIC Corporation

Durst Group

Electronics for Imaging, Inc.

Hewlett Packard Enterprise

Inca Digital Printers Ltd.

Konica Minolta, Inc.

Mimaki Engineering Co., Ltd.

The Ricoh Company, Limited

Roland DG Corporation

Seiko Epson Corporation

Toshiba Corporation

Xeikon B.V.

Xerox Holdings Corporation

Other

Recent Developments

April 2023: Kyocera Corporation acquired NIKKA S.A.S., enhancing its inkjet print engine capabilities and strengthening its presence in Japan’s digital printing market.

January 2022: Smurfit Kappa invested over US$ 33 million to install high-end printers in Brazil, supporting the booming e-commerce packaging segment.

September 2023: Fiery LLC inked an R&D partnership with Esko to advance digital print technologies with a focus on color and workflow automation.

Market Opportunities and Challenges

Opportunities:

Sustainability Focus: Development of eco-friendly inks and substrates presents new revenue streams as brands seek greener packaging solutions.

Emerging Economies: Rapid industrialization in Asia Pacific and Latin America offers fertile ground for new installations and service offerings.

4.0 Factory Integration: Combining IoT, AI, and advanced robotics with digital print presses can revolutionize mass customization.

Challenges:

High Capital Expenditure: Upfront costs of advanced digital presses may deter smaller enterprises despite long-term ROI advantages.

Skill Shortages: Operating and maintaining sophisticated digital printing systems requires specialized training.

Ink and Substrate Compatibility: Ensuring consistent print quality across diverse materials remains a technical hurdle.

Future Outlook

By 2034, digital printing is expected to account for more than half of global print volumes in packaging and textiles, driven by:

Automation & AI: Presses will self-optimize color, media handling, and maintenance schedules.

Personalization at Scale: Brands will offer hyper-customized products with batch sizes as low as one, unlocking new business models in retail and direct-to-consumer markets.

Hybrid Production Lines: Integration of digital and traditional printing methods will enable seamless transitions between high-definition short runs and high-volume lithography.

Market Segmentation

By Printing Type:

Inkjet (leading segment due to superior tonal range)

Laser

By Ink Type:

Aqueous

UV-Cured

Solvent

Latex

Dye Sublimation

Others

By Substrate Type:

Paper

Textile

Plastic Films or Foils

Ceramic

Glass

Others

Regional Insights

Asia Pacific dominated the digital printing market in 2023 and is forecast to maintain its leadership through 2034. China’s pivot toward end-to-end digitized value chains and strategic investments—such as Tomato Cloud Technology’s order for 10 Fujifilm Jet Press 750S machines in October 2021—have underpinned regional growth. In April 2023, Kyocera’s acquisition of NIKKA S.A.S. further underscores Japan’s commitment to inkjet innovation. North America and Europe remain important hubs for R&D, particularly in sustainable ink and substrate development.

Why Buy This Report?

Comprehensive Market Analysis: In-depth quantitative and qualitative insights covering 2020–2022 historical data, 2024–2034 forecasts, Porter’s Five Forces, value chain assessment, and SWOT analysis.

Competitive Landscape: Detailed profiles of leading players, product portfolios, strategic initiatives, market share breakdowns, and financial comparisons.

Actionable Segmentation: Granular analysis by printing type, ink, substrate, and region to inform targeted investment and expansion strategies.

Excel & PDF Formats: Ready-to-use data tables in Excel for custom modeling, alongside an executive-ready PDF report.

Explore Latest Research Reports by Transparency Market Research:

Ring Laser Gyroscope Market: https://www.transparencymarketresearch.com/ring-laser-gyroscope-market.html

Lithography Equipment Market: https://www.transparencymarketresearch.com/lithography-equipment-market.html

Compact Camera Module Market: https://www.transparencymarketresearch.com/compact-camera-module-market.html

Grow Light Market: https://www.transparencymarketresearch.com/grow-light-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Maximize ROI with Digital Printing for SMEs

Maximizing ROI with Digital Printing: A Guide for Small Businesses

In today’s competitive market, small businesses must be smart with their marketing spend. Every investment needs to deliver maximum return. One area where companies are seeing impressive results is in digital printing. Whether for promotional materials, product packaging, or retail branding, digital printing offers an affordable, flexible, and high-impact solution. For small businesses in Dubai and the UAE, Al Hutaib Advertising, a reputable display stands manufacturer in Dubai, is helping brands achieve just that—maximized ROI with tailored digital print services.

Digital printing enables businesses to produce sharp, vibrant materials quickly and in small quantities. This eliminates waste, lowers costs, and shortens time-to-market—key factors that contribute to strong return on investment (ROI), especially for growing enterprises.

Affordable Production in Small Batches

One of the standout features of digital printing is that it doesn’t require costly setup. Unlike offset or screen printing, there are no plates or screens involved, meaning small businesses can print low quantities without paying high setup fees.

This is ideal for companies testing new marketing materials or offering limited-edition packaging. You get the flexibility to experiment without tying up capital in bulk production.

As one of the leading display stands suppliers in Dubai, Al Hutaib Advertising understands the financial limitations many small businesses face. Their digital printing services allow clients to run small batches affordably, ensuring they can promote their products or services without overcommitting budgets.

Faster Turnaround = Faster ROI

Speed is money in business. The faster you can get your materials printed and out to market, the quicker you see a return. Digital printing is one of the fastest methods available—it delivers press-ready outputs almost instantly and allows for same-day or next-day delivery on many projects.

This is especially useful for promotions, pop-up events, or last-minute campaigns where timing is crucial. Pair this with display stands Dubai business owners use to grab attention, and you've got a potent formula for rapid brand exposure.

Al Hutaib Advertising not only prints but also manufactures high-quality display stands that complement your printed marketing assets. This end-to-end approach ensures brand consistency and maximized impact at every customer touchpoint.

Enhanced Customization = Targeted Marketing

Digital printing excels in customization. You can easily alter names, designs, languages, or promotions for different demographics without additional cost. This feature, known as variable data printing, lets small businesses fine-tune their campaigns for specific audiences.

Targeted marketing generally performs better—people respond more to personalized content, and this leads to higher conversion rates. When your print materials speak directly to your audience, ROI naturally increases.

From brochures to product labels and even display stands graphics, Al Hutaib Advertising, a prominent display stands supplier in UAE, offers full customization capabilities using cutting-edge digital printing technology.

Quality That Commands Attention

High-quality visuals are essential in establishing credibility. In a crowded marketplace like Dubai, your printed materials must stand out—not just in design but in execution. Digital printing offers exceptional image resolution, consistent color matching, and sharp text, even on short runs.

When paired with expertly designed display stands manufacturers in Dubai offer through Al Hutaib, your presentation becomes more than just functional—it becomes a compelling sales tool. Better presentation increases perceived value, which in turn boosts response rates and customer retention.

Reducing Waste and Storage Costs

Another benefit of digital printing for small businesses is its lean approach. Because you’re not forced to print in large volumes, you avoid excess inventory, storage costs, and material waste. You print only what you need, when you need it.

This approach aligns perfectly with modern business principles of efficiency and sustainability. It also gives small businesses the agility to update or rebrand materials quickly and cost-effectively without worrying about discarding outdated stock.

Al Hutaib Advertising, known for its versatility as a display stands supplier in Dubai, supports businesses with just-in-time printing solutions. By aligning production with demand, they help clients reduce overhead while improving responsiveness to market trends.

Complementing Displays for Greater Reach

It’s not just about what you print—it’s about how and where you display it. Small businesses often overlook the importance of presentation. Using custom-printed materials alongside well-designed display stands amplifies visibility and drives engagement.

Display stands manufacturers in Dubai like Al Hutaib offer a range of portable, modular, and promotional stands that are easy to deploy in retail spaces, trade shows, and exhibitions. When digital print and display design work hand-in-hand, the return on every marketing dirham spent increases significantly.

As a full-service provider, Al Hutaib Advertising not only delivers on digital printing but also provides the physical structures that bring these printed assets to life. This integration maximizes impact while keeping your marketing streamlined and cost-effective.

Partnering with the Right Print Expert

ROI isn’t just about the tools you use—it’s about who you work with. Small businesses in the UAE need partners that understand local market dynamics, budget constraints, and branding expectations.

Al Hutaib Advertising, a leading name among display stands suppliers in UAE, delivers customized, budget-friendly digital print services designed to help small businesses thrive. Their team works closely with clients to ensure that every printed piece and display solution contributes directly to business growth and brand success.

Smart spending, efficient production, high-impact visuals, and reliable partnerships—these are the pillars of a strong return on investment in marketing. With digital printing and the expertise of Al Hutaib Advertising, small businesses in Dubai can confidently invest in materials that truly pay off.

#Display Stands Manufacturer Dubai#display stands suppliers in uae#display stands manufacturers in dubai#Display Stands Dubai#display stands suppliers in dubai#display stands

0 notes

Text

Bombay Enterprise powers productivity with Ricoh

Mumbai printer Bombay Enterprise provides both small and industrial-level print jobs using a fleet of high-end presses and machines. To scale print productivity, the company invested in a new Ricoh Pro C9500, a high-speed digital color production press, supplied and installed by Monotech Systems.

In the offset and commercial printing market over the last two decades, serving customers in print contracting and consultancy businesses as well as others from different sectors, Bombay Enterprise provides an array of bespoke end-products such as business cards, invitation cards, brochures, cloth & garment tags, etc. The company is backed by a team of 12 skilled and experienced printing and production professionals.

On the company’s establishment, Dipu Devda, operational director, Bombay Enterprise, says, “In the beginning, we were into offset printing, then gradually expanded to digital production printing with a focus on print embellishment using an AccurioShine 3600. Nevertheless, we felt the shortage of a digital color production press. Then we found the Ricoh Pro C9500. We are now empowered to enhance productivity with this digital press from Monotech Systems.”

Devda says that before the Ricoh Pro C9500, they barely used to manage digital printing jobs with multifunction printers (MFPs). “It hampered our productivity and couldn’t generate appropriate volume and print quality, which we needed to meet the demand of quality-conscious clients in both the domestic and international markets.”

“Over the years, we kept on expanding our client base as a result of our team’s commitment and constant upgrades of our machine portfolio and many new developments on various fronts. We have been working for some offshore clients in cities such as New Jersey and Dubai. Our investment in the new Ricoh Pro C9500 has given us the advantage of producing higher print volume and textured graphics. Media flexibility of this Ricoh press is magnificent.”

Printing in a resolution of 2400 x 4800 dpi on lightweight as well as heavyweight media to produce dazzling textured graphics, the Ricoh Pro C9500 takes in stocks right from 40 gsm up to 470 gsm. “The press’ media-handling capability and speed are some of its attributes that impressed us,” Dipu says, adding, “Its upgradable speed of 135ppm meets everything we require on time. Currently, we are producing around 30,000 sheets in eight hours with this Ricoh digital press.”

Moreover, the Ricoh Pro C9500 is bundled with EFI Fiery Digital Print Servers, a crucial tool to optimize efficiency and quality in print operations. The servers’ intuitive Fiery Command WorkStation is designed to facilitate precise job management and color control, enabling quick production of personalized products with the press’ variable data printing capabilities in exceptional RIP speeds and smooth PDF workflows. “We further look ahead to getting more such capable machines, doubtlessly from Monotech Systems,” emphasizes Dipu.

0 notes

Text

Precision in Print: How Estimation Software Enhances Cost Accuracy and Boosts Profitability

In the ever-evolving world of commercial printing, getting your numbers right is crucial. With increasing customer demand for customization, quicker turnarounds, and competitive pricing, traditional quoting methods are quickly becoming outdated. Enter print estimation software a game changer in achieving accurate print job costing and maintaining profitability in a competitive marketplace.

Let’s explore how leveraging a print estimating tool can help streamline operations, enhance pricing precision, and align business with the latest printing industry trends.

Why Print Job Estimation Needs a Digital Upgrade

Estimating print jobs manually—-factoring in materials, labor, press time, setup costs, and finishing—-is not only time-consuming but prone to error. A small miscalculation can lead to underpricing, reduced profit margins, or overpricing that drives customers away.

With the help of modern print estimation software, printers can eliminate guesswork. These tools automatically consider all variables involved in a print job—-sheet size, ink usage, labor, machine time—-and generate accurate, consistent quotes in minutes.

Enhanced Accuracy with Automated Calculations

One of the primary advantages of using a print estimating tool is the ability to generate precise job quotes based on real-time data. The software uses pre-defined cost libraries and machine capabilities to deliver accurate pricing for any print specification.

This means you can confidently quote jobs without fear of underestimating costs or overlooking hidden expenses—- improving both client satisfaction and your bottom line.

Streamlining Your Print Management Process

Integrating estimation tools into a full print MIS ERP solution helps in streamlining your print management process end-to-end. From quoting and job scheduling to inventory control and invoicing, everything is synced in a single ecosystem.

This integration ensures that your estimation aligns with actual production capabilities and current material availability, reducing job delays and improving workflow efficiency.

Faster Turnaround and Customer Response Time

Speed is a differentiator in today’s market. With print estimation software, your sales or customers service team can generate accurate quotes in real time—-reducing delays and increasing the chances of securing the job.

This fast response builds trust and positions your shop as a reliable partner—-especially when serving B2B clients who expect timely and competitive proposals.

Adaptability to Printing Industry Trends

Modern ERP for the printing and packaging industry is built with flexibility in mind. As printing industry trends shift owner shorter runs, eco-friendly materials, and hybrid printing, estimation tools can quickly adapt to reflect new costing models or service offerings.

Whether you’re expanding into digital printing, custom packaging, or large-format signage, an intelligent estimating tool can be configured to support new product lines and workflows.

Smarter Profitability Analysis

Beyond just quoting, the data collected through your print estimating tool helps you analyze job profitability over time. You can identify which types of projects bring the most revenue, where hidden costs are eroding profits, and how to optimize production for better margins.

Ths kind of actionable insight of especially powerful when integrated into a print MIS ERP solutions, giving you a 360-degree view of your business performance.

Scalability and Competitve Advantage

As your business grows, managing complex quotes and multiple job types manually becomes unsustainable. Estimation software enables scalability by standardizing pricing, centralizing data, and reducing reliance on key personnel.

It also provides a competitive edge—-ensuring that your quotes are not only fast but also reflect true production costs, enabling strategic pricing decisions.

Conclusion

In a dynamic and competitive market, precision is everything. Investing in print estimation software and integrating it with a broader ERP for the printing and packaging industry is no longer optional–it’s essential. These tools don’t just automate pricing, they streamline print management, improve profitability, and align your business with emerging printing industry trend. Whether you’re a small print shop or an enterprise-level provider, a modern print estimating tool will help you quote smarter, faster, and more profitability.

#printing industry#packaging industry#print estimation tool#print estimation software#erp for printing#erp for packaging

1 note

·

View note

Text

Buy Latest Hybrid Label Press - Jetsci® Global

Buy the latest Hybrid Label Press from Jetsci® Global and experience the future of label printing. With cutting-edge digital and flexographic technology, these presses offer unmatched flexibility, speed, and print quality. Perfect for high-demand industries, Jetsci® Global’s latest models are designed to improve productivity and provide superior, consistent results.

OUR CONTACT DETAILS: ADDRESS: B-15, InfoCity Phase 1, Sector 34,Gurugram-122001, Haryana, India CONTACT NO. +91 1244226771 EMAIL: [email protected] Visit Us: https://www.jetsciglobal.com/dspark-hybrid/

#digital label press#digital label printing solutions#uv label printing press#digital color label press#variable data printing press#digital uv inkjet label production press#digital book printing press#book printing press#uv inkjet label printing solution#Hybrid Label Press#Jetsci® Global

0 notes

Text

Affordable Direct Mail Printing – Get Your Letters Delivered Fast

In today’s fast-paced business world, speed and affordability are more important than ever—especially when it comes to communication. Whether you're sending invoices, promotional flyers, or personalized letters, direct mail printing remains one of the most effective ways to reach customers. But how do you ensure your mail is printed and delivered quickly without breaking the bank?

This comprehensive guide will show you how affordable direct mail printing works, how it can boost your business, and what to look for when choosing a service provider. We’ll also explore why speed matters and how you can reduce costs while increasing ROI.

What Is Direct Mail Printing?

Direct mail printing involves the professional printing of materials such as postcards, flyers, newsletters, brochures, or letters, which are then sent directly to recipients through postal services. Businesses use direct mail to reach customers, promote new products, share updates, and improve brand awareness.

Direct mail campaigns can be highly personalized, automated, and integrated with digital marketing strategies, making them a powerful tool for customer engagement and conversion.

Why Direct Mail Still Works

Even in a digital world, direct mail is thriving. Here's why:

Tangibility: Unlike emails, physical mail has a longer shelf life and grabs attention.

Higher Open Rates: Direct mail boasts open rates of 90%+, compared to 20-30% for email.

Less Competition: With fewer businesses using mail, your message stands out.

Targeted Marketing: Sophisticated data tools allow for precise audience segmentation.

Strong ROI: For every $1 spent, direct mail generates an average return of $4 to $12.

Affordable Doesn’t Mean Low Quality

When we say “affordable direct mail printing,” we’re talking about cost-effective solutions that don’t compromise on:

Print quality

Speed of delivery

Personalization capabilities

Customer service

Modern printing providers use high-speed digital presses, automated workflows, and optimized logistics to reduce production time and costs, allowing them to pass the savings on to you.

Types of Direct Mail Materials You Can Print

Affordable services don’t limit your options. You can create and send:

Postcards

Brochures

Catalogs

Flyers

Letters

Newsletters

Self-mailers

Coupons or discount offers

Each of these can be personalized with variable data printing to match specific audience profiles.

How to Get Your Letters Delivered Fast

To ensure your direct mail is not only affordable but also delivered quickly, follow these tips:

1. Choose a Full-Service Printing Provider

Look for a provider that handles everything from printing to mailing. This reduces delays caused by outsourcing parts of the process.

2. Use Address Verification Tools

Services that offer built-in address validation will reduce undeliverables and ensure your mail reaches the right people faster.

3. Automate and Schedule Your Mailings

Automation allows you to trigger mailings based on customer behavior or dates (e.g., birthdays, cart abandonment). This reduces lead time and human error.

4. Utilize Bulk Mailing Discounts

If you're sending large volumes, take advantage of USPS bulk mailing rates or presorted mail options offered by your provider.

5. Print Near the Delivery Destination

Some providers have multiple printing facilities and can route jobs to the one closest to your target audience, cutting down on shipping time.

Benefits of Affordable Direct Mail Printing

✅ Cost Savings

With the right provider, you can print and send high-quality direct mail for as little as $0.50 per piece, including postage.

✅ Faster Turnaround

Modern digital printing technology allows same-day or next-day printing and mailing.

✅ Higher Engagement

Direct mail delivers stronger engagement metrics—higher open rates, longer attention spans, and better recall.

✅ Personalization at Scale

Affordable doesn’t mean generic. Variable data printing allows for highly personalized messages and images.

✅ Seamless Integration

Direct mail can work hand-in-hand with email, SMS, and online campaigns to create omnichannel experiences.

youtube

SITES WE SUPPORT

Validate Letters & Docs – Weebly

0 notes

Text

Flexo automation and the shift to digital and hybrid labels

The pressure-sensitive label industry in India continues to grow as packed and labeled products in numerous types of containers, formats, and sizes multiply. Every food and snack product is available in various exotic and localized flavors. You can now buy packs of Hershey’s chocolates filled with California almonds with guava and Mexican chilli flavor, or Hershey’s Exotic Dark blueberry and acai flavored centers. Also, you can find Mazan chocolate cubes filled with paan flavour and many other products in the market with a variety of localized flavors including Kurkure packs with ‘UP Taste.’ In short, the number of SKU’s of pouches and labeled containers have substantially multiplied.

It is no longer about flexo versus digital versus flexo. At the Labelexpo India in 2022, the European plate and roller manufacturers said that ‘digital is the death of flexo.’ To bolster their views they pointed to challenges such as print density, banding, and handling newer substances – a virtual laundry list of difficulties with digital label production.

Digital printing has found its place in various label applications, especially when personalization, variable data, and shorter print runs are required. Flexo holds significant advantages in terms of cost-effectiveness in large-volume production runs and printing on certain materials and increasingly for short-run flexible packaging, especially with the widespread availability of locally manufactured presses.

Managing shorter print runs is challenging for flexo converters, considering the cost of creating printing plates, time-consuming press set-up, and set-up waste. Adding flexo units to a digital module in a hybrid configuration, or investing in a digital roll-to-roll press alongside established flexo lines has helped converters adopt a more sustainable ‘print-on-demand’ business model for shorter-run labels and packaging.

Hybrid printing can be a more sustainable and economical approach. “The flexo technologies being retrofitted with add-on features to a digital press are referred to as hybrid,” explained Ajit Bharadwaj of Vinsak. “Features such as variable data printing, foiling, stamping, die-cutting, and more automated features are increasingly in demand among converters. Reducing avoidable print waste saves both converters and brands money and reduces the need to handle excess printed stock,” he said.

Parwez Izhar, senior vice president of the printing cylinders business at UFlex shares that the Indian packaging industry is witnessing a surge in smart packaging that features technologies such as track-and-trace systems integrated into labels and packaging including RFID, NFC, QR codes, holograms, and more.

Izhar explains that approximately 20% of the gravure market share has shifted to flexo, primarily due to its cost-effectiveness and faster turnaround time. He says, “In the label industry, both flexo and digital are gaining ground, and with the increasing demand for short-run jobs, converters are also turning to digital.”

“However, converters are not focusing on just one approach, they are thinking about growth. Many opt for both technologies—if they have flexo, they add digital. Converters recognize the demand for a premium look and feel, so the future lies in hybrid technologies that can meet all the quality, volume, and variable data requirements,” Izhar adds.

The automated flexo presses that include hybrid LED UV systems, die-cut units, pre-register, auto-register, movable turn bar, lam and relam units, peal and seal kits, and foiling stations for labels, shrink sleeves, and flexible packaging are increasing in global demand. Faridabad-based Multitec’s mid-web flexo presses can print on various substrates including thin and extensible materials with capability ranging from 10 microns up to 450 microns at 200 meters a minute with impressive registration and low setup wastage.

Multitec generally leads the industry in new technology adoption and implementation with 40% of its manufacturing being exported. Amit Ahuja, managing director of Multitec explained, “The growing short-run demand is creating a market space for digital. This does not pose any threat to veteran flexo users – but the future is in the hybrid production of labels together with the increasing demand for more automation features and quicker and more precise make-ready solutions.”

0 notes

Text

What Are the Best Printing Techniques Used by Southport Printing Companies?

Printing technology has evolved significantly over the years, offering businesses and individuals a wide range of high-quality printing solutions. Southport Printing Company service providers utilize cutting-edge techniques to ensure precision, durability, and cost-effectiveness in their prints. Understanding these methods helps in selecting the best printing option for various needs, whether for marketing materials, business stationery, or large-scale signage.

1. Offset Printing

Offset printing is one of the most widely used printing techniques, known for its exceptional quality and cost-effectiveness in bulk production. It involves transferring ink from a plate to a rubber blanket and then onto the printing surface. This method is ideal for high-volume orders such as brochures, magazines, and business cards. Southport Printing Company providers often recommend offset printing for its:

Consistently sharp images and vibrant colors

Cost efficiency for large print runs

Ability to print on a wide range of paper types

2. Digital Printing

Digital printing has revolutionized the industry with its speed and flexibility. Unlike traditional methods, it does not require plates, making it perfect for short-run and on-demand printing. Southport Printing Company experts often use digital printing for personalized materials like flyers, postcards, and business reports. Key advantages include:

Quick turnaround times

High-quality, precise prints

Cost-effectiveness for small to medium print jobs

Customization options such as variable data printing

3. Large Format Printing

For businesses requiring oversized prints, large format printing is an essential technique. This method is used for banners, posters, and signage that need to capture attention from a distance. Southport Printing Company professionals employ advanced printers that produce:

High-resolution images with vibrant colors

UV-resistant and weatherproof prints for outdoor use

Flexible material options, including vinyl, canvas, and adhesive media

4. Screen Printing

Screen printing is widely used for textiles, promotional products, and specialty items. It involves pushing ink through a mesh screen onto the printing surface, ensuring durability and vivid color reproduction. Southport Printing Company businesses utilize this technique for:

High-quality apparel printing

Custom promotional items like tote bags and pens

Long-lasting prints resistant to fading and wear

5. Embossing and Foil Stamping

For premium, high-end print finishes, embossing and foil stamping are excellent choices. These techniques add a tactile and visual appeal to business cards, invitations, and certificates. Southport Printing Company specialists use them to enhance branding through:

Raised or recessed textures for a professional look

Metallic foils for an elegant, eye-catching finish

Customizable effects that improve brand perception

6. UV and Aqueous Coating

Coating techniques are applied to printed materials to enhance their durability and visual impact. Southport Printing Company services often include UV coating and aqueous coating, which offer:

Glossy or matte finishes for aesthetic appeal

Protection against smudging, moisture, and fading

Improved longevity for business materials like brochures and catalogs

7. Letterpress Printing

A classic technique that combines tradition with elegance, letterpress printing involves pressing inked plates onto thick paper to create a deep, textured impression. Southport Printing Company providers use this method for:

Luxury wedding invitations and event stationery

Elegant business cards with a distinguished look

Premium branding materials for high-end businesses

Choosing the Right Printing Technique

Selecting the best printing technique depends on factors such as the type of material, budget, quantity, and desired finish. Southport Printing Company services offer a variety of printing solutions tailored to different business needs. Whether requiring bulk production or customized, high-end prints, understanding these methods ensures an informed decision for optimal print results.

By utilizing modern printing technologies, Southport Printing Company providers continue to deliver high-quality, professional prints that enhance branding, marketing, and communication efforts for businesses and individuals alike.

0 notes

Text

Digital Printing Gold Coast: High-Quality Printing Services for Local Businesses

In today’s fast-paced world of marketing and branding, having access to professional, high-quality digital printing services is essential. For businesses on the Gold Coast, digital printing offers a fast, flexible, and cost-effective way to create visually compelling materials that make a lasting impression.

Why Choose Digital Printing on the Gold Coast?

Digital printing has revolutionized the print industry by allowing for short-run, on-demand printing with outstanding quality. Here's why businesses on the Gold Coast are turning to digital printing:

1. Fast Turnaround Times

Whether you need business cards, flyers, brochures, or banners, digital printing allows you to go from design to finished product in a matter of hours. This is ideal for last-minute promotions, events, or rebranding efforts.

2. Cost-Effective for Small Runs

Traditional offset printing is best for large quantities, but digital printing shines when you need small to medium-sized print runs. This makes it perfect for startups, local shops, and service providers who want professional materials without overspending.

3. Superior Print Quality

Modern digital presses produce vibrant colors, sharp text, and consistent quality on every print. Whether you’re printing glossy brochures or matte business cards, you can expect a professional finish every time.

4. Customization and Personalization

Digital printing makes it easy to personalize content. You can create targeted marketing pieces with variable data printing (VDP), tailoring names, images, and offers to individual recipients — a powerful tool for direct mail campaigns.

Popular Digital Printing Services on the Gold Coast

The Gold Coast is home to numerous reputable digital printing companies offering a wide range of services, including:

Business Cards & Stationery

Flyers & Brochures

Posters & Signage

Custom Stickers & Labels

Booklets & Catalogues

Large Format Printing (banners, A-frames, pull-up banners)

Apparel Printing (T-shirts, uniforms, branded merchandise)

These services are ideal for local businesses in hospitality, real estate, events, retail, and more.

Supporting Local Gold Coast Printers

Working with a local Gold Coast digital printer offers distinct advantages. You’ll benefit from:

Faster delivery and pickup options

Personalised customer service

Opportunities to support and collaborate with other local businesses

Better understanding of local market needs

Many Gold Coast print shops also offer in-house graphic design, so you can take your project from concept to completion under one roof.

How to Choose the Right Digital Printing Provider

When selecting a digital printer on the Gold Coast, consider:

Print quality and technology used

Turnaround times and delivery options

Customer reviews and testimonials

Ability to handle custom jobs or special finishes

Competitive pricing for your required quantity

Requesting a sample pack or visiting their showroom can help you make a confident choice.

Conclusion

Whether you're a small business owner, event organiser, or marketing professional, digital printing on the Gold Coast gives you the flexibility, speed, and quality you need to succeed. By partnering with a trusted local printer, you can elevate your brand presence and make a strong impact in a competitive market.

Ready to boost your brand with premium digital printing? Explore the top digital printing services Gold Coast has to offer and bring your vision to life today.

0 notes