#uv label printing press

Explore tagged Tumblr posts

Text

Order Jetsci® Global Digital Label Printing machine

Order a Jetsci® Global digital label printing machine for high-performance, reliable, and precise label production. Designed with advanced technology, these machines deliver exceptional print quality, speed, and efficiency. Trusted by leading brands worldwide, Jetsci® offers customized solutions to meet your specific needs. Invest in innovation—choose Jetsci® for your label printing.

OUR CONTACT DETAILS: ADDRESS: B-15, InfoCity Phase 1, Sector 34,Gurugram-122001, Haryana, India CONTACT NO. +91 1244226771 EMAIL: [email protected] Visit Us: https://www.jetsciglobal.com/kolorsmart/

#digital label press#digital label printing solutions#uv label printing press#digital color label press#variable data printing press#digital uv inkjet label production press#uv inkjet label printing solution#jetsci® global#book printing press#digital book printing press

0 notes

Note

I love your art so much!!! I've also been starting to paint with gouache, and I'd love to know a little more about your process! What kind of paints do you use, do you sketch first or start with paint, do you paint in layers over several day or all at once?

Hi and thank you! I hope you don't mind me answering this publicly and apologies for length, but:

MY ART PROCESS!

Supplies: I use winsor and newton gouache and arches cold press paper blocks, usually 140 lbs (the lime green ones) and sometimes 300 lbs (the teal green ones). Even though this paper comes pre-stretched in blocks, I actually take the sheets off and stretch them myself because I've found arches' glue isn't as strong as it used to be. This is how you get watercolor paper to lay flat! I recommend youtubing some videos on how to do it -- there's a lot of great tutorials out there. Also, I use princeton brushes, and kraft paper tape and these boards to stretch my paper. (these aren't affiliate links, I just shop at blick)

A word about art supplies: these are the exact tools I use but everyone uses supplies differently and two people with the exact same supplies might get different results! A lot of it is about what works for you and what you like, so I always suggest that gouache/watercolor beginners just buy a few tubes from a couple of different paint companies and some small pieces of paper from different manufacturers to see what you like. Just changing one ingredient in the above has created massively different results for me, but maybe that'll end up being something you'd like! The first step in learning a new medium imo is to play. Just have fun!

ALSO: gouache isn't super light permanent, check your tubes for which ones hold up to sunlight. Here is winsor and newton's color chart explaining which ones will fade when exposed to sunlight -- all manufacturers will give you this. I only use the colors rated A and AA, and I still frame my pieces with UV glass just to be safe. Not all gouache is re-wettable, but winsor and newton is. I just put it in my palettes and refill my palettes if it runs low. AND SOME PAINT IS TOXIC. A lot of paints have cadmium and cobalt in them. I don't use any of the toxic colors, but if you do, make sure you don't eat while working and wash your hands thoroughly afterwards. This information is also usually available on manufacturer's websites. As more people are rejecting cadmium paint, you'll see more tubes labeled things like cadmium-free yellow. This is why. More artists should be aware that their tools can be dangerous. You don't need that many tubes of paint to begin, just a warm and cool red, warm and cool yellow, warm and cool blue, white and black. I have around 50 colors and use 20 regularly. I always mix all my colors myself, and never use straight tube paint. Most of my colors have about 5-6 different tube colors mixed together. If you use re-wettable paint a tube of paint will last you years; even as a professional I only buy new paints every 5 years or so.

Process: I ALWAYS start with a sketch first. Not everyone has to, but because I do illustration work -- where sometimes a client gets input on a drawing -- I always do a lot of preliminary work before I even begin to paint. At this point, even my personal work usually involves the exact same process:

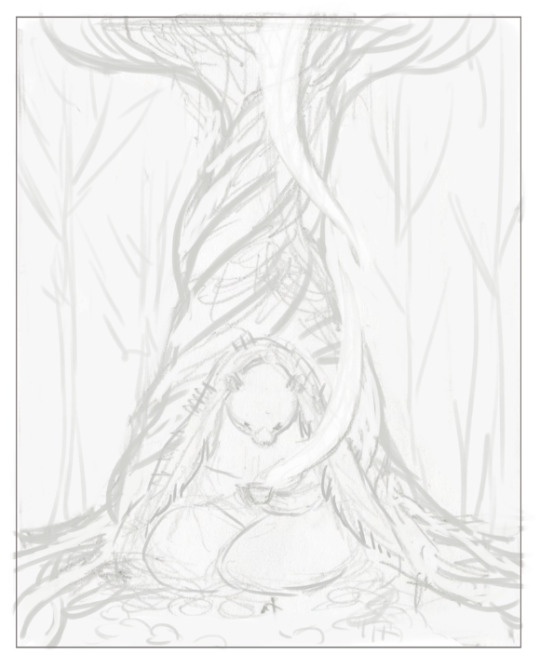

I start with a 3" or so thumbnail that I scan (left; I traced it quickly digtally for clarity to myself here) and then either clean up digitally or print out and clean up traditionally with tracing paper (right):

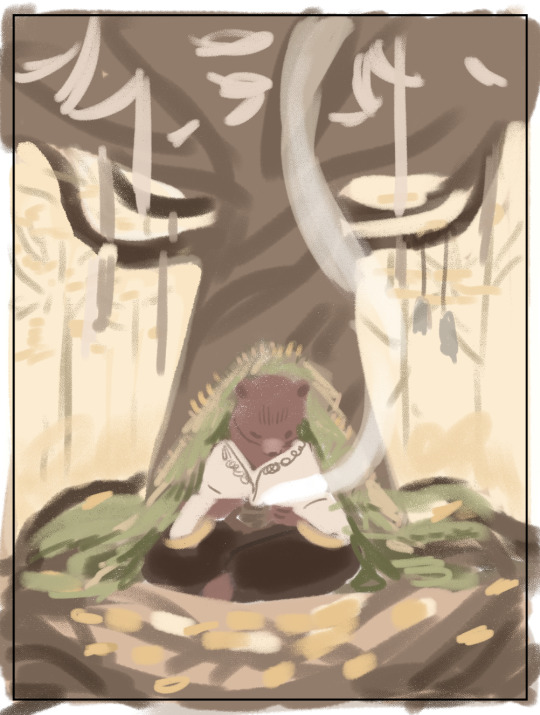

Then I scan the cleaned sketch in and color rough it digitally (left, this was for a gallery show, so no one had to approve my color roughs, so it's messy!) then I transfer my sketch to my paper (with either carbon transfer paper or a light table), stretch my paper, and paint (right):

I obviously changed my mind about the color of the ribbon in the trees, ha, and made everything a lot more vibrant. The benefit again of gallery work is no pre-approval!

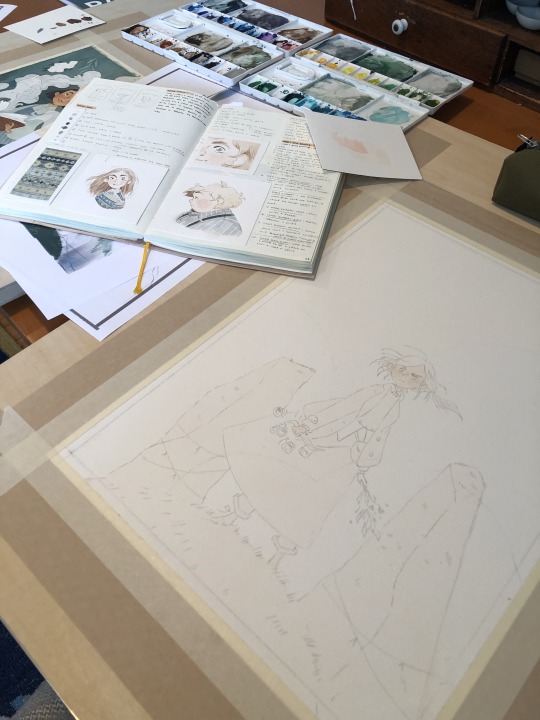

You are correct, I paint in a series of washes, going from lightest to darkest, where I apply the same color beneath all shapes that are the same warmth (cools under all upcoming cools, warms under all upcoming warms). I paint a piece usually in one or two days, depending on complexity. I didn't take pictures of the above painting, but here's a different painting to show you a little bit what I mean:

I painted the peach color under everything (and twice for skin tones), and the gray color of the sky under everything that would be grayish (the rocks, trees, her pants, her skirt, and coat). I do this to stop me from getting darker lines where two different colors butt up against each other, and also for color harmony. I have step by step photos of this in my process stories highlight on my instagram; also check my FAQ and tip highlights for more info on all this stuff. Most pieces take around 25-30 washes before I start adding in the details (sometimes I add in face details early though because if I mess those up it's not worth finishing the rest of the painting! 😅)

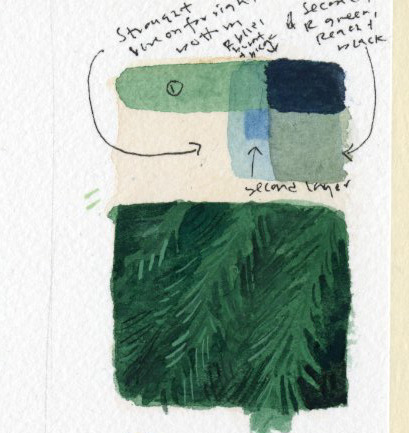

All this might seem like a lot of work (...it is) but I do it so that I can show clients previews of the final piece and so I don't have to repaint the finals. I also used to pre-test all of my washes on scrap paper like this:

I still recommend doing this if you're just beginning! But at this point I only do it when testing techniques because I know my paints really well. (the above was my test for the pine boughs in this piece)

Painting by far is the longest part of the process, so I do more work up front to not have to do it twice. Every piece takes about 6-24 hrs of actual work time to produce. Stretching watercolor paper takes about 24 hrs to dry, and because I sell most of my originals in galleries, they need to be flawless, so planning ahead is useful and in the end saves me time.

And to conclude this novel of an explanation, don't be overwhelmed by all the information I've given you! I put it here so that people at various stages of their artistic journey can maybe find something useful in it. But seriously, the first step to learning how to paint whether it's traditionally or digitally is just to have fun. Try it out, see what's working and what isn't, and then try to solve specific issues that you're struggling with. I've been doing this for a loooooong time at this point, but here's my first watercolor piece from when I was re-teaching myself how to paint traditionally nine years ago:

Obviously, I was destined for greatness. Ha, yeah, no. If you scroll back through my tumblr archive, you can see me learning how to use these paints in real time. And keep in mind that I'd been working digitally for years before then, and years before that where I didn't post my work online at all.

So for anyone who needs to hear it: there's no such thing as talent, just hard work, patience, and trying again and again and again...and sometimes again. What I do is a skill and anyone can learn it. Sometimes, progress is slow. I'm 38. I only really feel like my art was half-way decent starting a few years ago, but I've been making art my entire life, and I went to art school at 18. 20 years later I'm kind of figuring it out.

The best advice I can give, whether it's about art or not, is find the thing you love so much that you'll keep at it even when you suck at it, because most skills you'll suck at to begin with -- and perhaps for a long time. I sucked at art for yeeeaaaaarrrrs. On top of the usual learning curve, I struggled with fine motor control and dexterity. But I loved it so much I kept trying every time I failed. If I can do it, so can all of you, no matter what stage of art you're at now, and no matter how old you are.

Anyway, thank you to those still reading this deep in. I wish you all the best on your artistic journey. Art can kick your butt sometimes, but it's also pretty dang rewarding 💛

543 notes

·

View notes

Text

How does Prakash Machineries Pvt. Ltd advanced printing technology ensure consistent quality?

Prakash Machineries Pvt. Ltd

advanced printing technology is designed to deliver consistent, high-quality results across every print run, no matter the volume or material. Whether you're printing packaging, catalogs, labels, or promotional materials, Prakash Machineries Pvt. Ltd machinery ensures that every piece meets the same professional standard.

Here’s how our technology guarantees consistency and reliability:

🔹 1. Precision Engineering of Printing Units

At the heart of every Prakash Machineries Pvt. Ltd machine is a high-precision printing system, built to deliver accurate and repeatable output:

Tight register controls prevent misalignment between colors.

Balanced ink and water system ensures clear, smudge-free images.

Rugged construction reduces vibration, enhancing image stability even at high speeds.

🟢 Result: Whether it’s the first or ten-thousandth sheet, every print looks identical.

🔹 2. Automatic Ink Control Systems

Our machines use automated ink management to maintain consistent ink density throughout the job:

Sensors monitor ink flow in real time.

Adjustments are made automatically to avoid over-inking or fading.

Supports closed-loop color control systems for exact reproduction of color profiles.

🟢 Benefit: Uniform color across entire print runs—no fading, no variations. Prakash Machineries Pvt. Ltd

Even pressure distribution

Minimal dot gain

Smooth ink transfer

Our high-speed technology does not compromise on output quality, ensuring both efficiency and excellence.

🔹 4. Advanced Dampening and Anti-Ghosting Systems

Our machines are equipped with features to eliminate common printing defects:

Anti-ghosting mechanisms prevent image repetition artifacts.

Alcohol- and alcohol-free dampening systems avoid color variation and water streaking.

🟢 Outcome: Clean, sharp images with no background haze or uneven tones.

🔹 5. Superior Plate Compatibility and Quick Changeover

Offset printing plates used in Prakash machines are designed for:

High resolution imaging for crisp detail

Long plate life, reducing re-imaging needs

Quick-change features, maintaining consistency even during batch changes

This is ideal for jobs with multiple SKUs or short turnaround cycles.

🔹 6. Advanced Drying and Curing Options

Our presses support various drying methods, such as:

IR (Infrared) drying

Hot air drying

UV curing (for coated or synthetic stocks)

These ensure fast drying without smudging or set-off, which is critical when printing both sides or applying finishes.

🔹 7. Multi-Substrate Compatibility

Consistency isn’t just about image quality—it’s about performing reliably across:

Coated and uncoated paper

Kraft and duplex boards

Synthetic sheets and laminated materials

Our machines are engineered to handle different substrates without loss of quality, making them ideal for diverse commercial printing needs.

🔹 8. Quality Control Features Built-In Prakash Machineries Pvt. Ltd technology comes with built-in quality management systems:

On-machine inspection cameras (optional)

Color calibration tools

Tension control for web-fed systems

Operators can monitor, correct, and maintain output without stopping production.

🔹 9. Consistent Output Across Long Runs

Long print runs often suffer from color shifts and register issues over time. Prakash Machineries Pvt. Ltd machines combat this with:

Heat and pressure-resistant components

Stable mechanical registration systems

Low-maintenance rollers and bearings

🟢 Result: Output on sheet #10,000 is as good as sheet #1. Let Prakash Machineries Pvt. Ltd guide your business with world-class offset machinery that delivers precision, performance, and profit.

#paper bag manufacturer#paper bag#personal#delicious#chocolate#dan and phil#alien stage#baking#cooking#cake#critical role#chris sturniolo#j#breakfast

1 note

·

View note

Text

UV Inks for Offset Printing: Fast-Curing, Durable, and Vibrant Results

In the ever-evolving world of printing technology, UV inks for offset printing have become a game-changer. Offering fast curing times, exceptional durability, and brilliant color vibrancy, UV inks are revolutionizing how businesses produce high-quality prints efficiently and sustainably.

If you’re considering upgrading your offset printing process, understanding the benefits and applications of UV inks can help you make informed decisions that enhance your print quality and operational efficiency.

What Are UV Inks for Offset Printing?

UV (ultraviolet) inks are specialty inks cured or dried using ultraviolet light. Unlike conventional inks that rely on evaporation or absorption to dry, UV inks undergo a photopolymerization process when exposed to UV light, instantly solidifying the ink on the substrate.

This unique curing process makes UV inks particularly well-suited for offset printing applications, allowing faster production speeds without compromising print quality.

Key Benefits of UV Inks in Offset Printing

Fast Curing: UV inks dry instantly under UV light, significantly reducing production time and enabling quicker turnaround.

Outstanding Durability: Prints created with UV inks exhibit excellent resistance to scratching, fading, and chemical exposure, ensuring longer-lasting results.

Vibrant Colors: The instant curing process preserves color pigments, resulting in sharper, more vivid images and graphics.

Wide Substrate Compatibility: UV inks can adhere to a variety of materials including coated and uncoated papers, plastics, foils, and more.

Eco-Friendly Advantages: UV inks emit little to no volatile organic compounds (VOCs), helping printing operations reduce their environmental footprint.

Typical Applications of UV Offset Printing Inks

UV inks are widely used in:

High-end packaging and labels

Commercial brochures and catalogs

Promotional materials and marketing collateral

Specialty printing on non-porous surfaces

The combination of quality and durability makes UV inks ideal for projects that demand superior appearance and resilience.

Why Partner with a Trusted Supplier for UV Offset Printing Inks?

Choosing the right UV inks is crucial to achieving optimal performance. Factors such as ink formulation, compatibility with your printing press, and substrate characteristics can significantly impact the final print quality.

How We Support Your Printing Success

Providing high-quality UV inks tailored to your specific needs

Offering technical advice on ink application and curing processes

Ensuring reliable supply and consistent product quality

Helping your business adopt environmentally responsible printing practices

By choosing our UV ink solutions, you invest in a partnership dedicated to elevating your print quality and operational efficiency.

Final Thoughts

UV inks for offset printing represent a forward-thinking solution that blends speed, durability, and vibrant aesthetics. By integrating UV inks into your printing workflow, you can produce stunning, long-lasting prints while enjoying faster production cycles and reduced environmental impact.

0 notes

Text

Everything You Need to Know About a UV DTF Printer: The Future of Custom Printing

In today’s fast-evolving printing industry, UV DTF printers are making a bold statement. With the ability to print directly on a wide variety of surfaces without the need for heat transfer or weeding, these innovative machines are revolutionizing how we think about custom design and branding. If you're a business owner, designer, or print enthusiast, learning about UV DTF printers could be your next big step forward.

What is a UV DTF Printer? A UV DTF (Direct to Film) printer is a cutting-edge printing device that uses ultraviolet (UV) light to instantly cure ink printed onto a special film. The printed film is then transferred directly to hard or irregular surfaces like glass, wood, metal, acrylic, ceramics, leather, and plastic. Unlike traditional DTF printing used mostly for fabric, UV DTF printers cater to more rigid and varied surfaces, making them ideal for personalized items and promotional products.

How Does a UV DTF Printer Work? The UV DTF printing process typically involves three layers:

Color Ink Layer – The design is first printed in CMYK colors.

White Ink Layer – A white ink layer follows to enhance vibrancy and allow printing on dark or transparent surfaces.

Gloss or Varnish Layer – This layer gives your design a polished and durable finish.

Once printed, the film is applied with transfer adhesive and peeled off, leaving the design cleanly adhered to the target surface.

Key Features of UV DTF Printers Instant UV curing: No drying time needed.

Versatile Surface Compatibility: From mugs and phone cases to glass and wood.

No Weeding: Unlike vinyl cutting, there's no need to weed excess material.

High Durability: Scratch-resistant, waterproof, and UV-resistant.

High-Resolution Output: Excellent print clarity and color saturation.

Benefits of Using a UV DTF Printer

Expand Your Product Line

With a UV DTF printer, businesses can offer personalized products that were previously hard to customize. This includes:

Customized tumblers and mugs

Acrylic keychains

Personalized phone cases

Wooden plaques and gifts

Branded glassware

Cost-Effective for Small Runs

Traditional screen printing or pad printing is expensive for small quantities. A UV DTF printer allows you to do one-off prints or small batch runs with minimal waste and setup.

No Heat Required

One of the standout features is the no-heat application. Unlike sublimation or standard DTF printing that requires heat presses, UV DTF relies on UV light and adhesive, making it safer and faster.

Environmentally Friendly

UV-curable inks are more eco-friendly than solvent-based inks, producing fewer VOCs and requiring no water for cleanup.

Who Can Benefit from a UV DTF Printer?

Small Businesses & Entrepreneurs Etsy sellers, custom gift shops, and local printing services can all benefit from the versatility and low-cost operation of a UV DTF printer.

Branding Agencies Create branded promotional items such as logo-printed merchandise without needing multiple machines.

Artists & Designers Print unique artwork on unconventional surfaces like wood blocks or acrylic sheets for home décor and art installations.

Industrial Applications Even industries like automotive, packaging, and signage find UV DTF useful for labeling and customization on curved or textured surfaces.

UV DTF Printer vs. Other Printing Technologies Technology Best For Requires Heat Weeding Surface Types UV DTF Printer Hard & irregular items No No Glass, wood, plastic Regular DTF T-shirts & fabrics Yes No Soft materials Sublimation Polyester fabrics Yes No Fabric, coated items Vinyl Cutting Stickers & labels Sometimes Yes Limited

Things to Consider Before Buying a UV DTF Printer

Print Size Capacity Choose a printer based on the size of items you plan to print. Some models support A4 or A3 sizes, while industrial-grade printers can handle much larger surfaces.

Ink System and Refills Make sure the printer uses reliable and readily available UV inks. Some printers come with bulk ink systems that are more economical over time.

Software Compatibility Check whether the printer is compatible with your design software like Adobe Illustrator or CorelDRAW, and supports common file formats like PNG, SVG, or PDF.

Maintenance Requirements Like all printers, UV DTF machines need regular maintenance. Look for models that offer easy access to parts and have available technical support.

Top UV DTF Printer Brands in the Market Here are a few reliable brands known for UV DTF printing:

Lopo UV DTF Printers – Ideal for small businesses with beginner-friendly features.

A3 Pro UV DTF Printer – Offers high resolution and built-in laminating.

ComColor UV DTF Machines – Industrial grade, suitable for bulk production.

Final Thoughts The UV DTF printer is a game-changer for the world of customized printing. Whether you're starting a new business or expanding your current product offerings, this technology offers flexibility, affordability, and high-quality output that traditional methods simply can't match.

As demand for personalization grows across industries, investing in a UV DTF printer can help you stay ahead of the curve—and create products that wow your customers.

0 notes

Text

K&B with Rapida sheetfed offset tech at China Print

At the 11th Beijing International Printing Exhibition (China Print), which takes place in Beijing from 15 to 19 May, Koenig & Bauer (K&B) will be present with a stand covering over 1,000 square meters in Hall 2 (W2-001). The focal point of the presentation is a Rapida 105 with eight printing units and coating equipment, which will be demonstrated several times a day in practical live shows.

The Rapida 105, which was showcased at the previous China Print as a six-color version with a coating tower, now features two additional printing units and extra equipment. The exhibition machine (max. sheet format of the demonstration machine 780 x 1,050 mm) is equipped with, among other things, an additional package for carton printing, equipment for UV/mixed operation, nonstop feeder and delivery (lowerable nonstop carriage), fully automatic plate changers, inking unit temperature control, CleanTronic washing units, measuring and control technology for print quality and register, as well as other automation components. This equips printing companies for today's and future challenges – both in packaging printing and in commercial and label printing applications.

Focus on packaging printing

The presentation of the Rapida 105 is primarily aimed at users in the packaging sector. In addition to the production of various packaging types, the production of posters is planned, which traditionally attracts great interest from the trade fair audience.

The production of seven-color printing with an expanded color gamut (CMYK+OVG) will be shown, as well as fast changeovers between individual print jobs. A second focus is digital packaging production with the VariJET 106. Packaging samples in seven-color digital printing and comparison samples in sheetfed offset were produced in advance. This allowed print specialists to see for themselves that there are no longer any differences between the two processes in terms of print quality and color gamut.

Rapida sheetfed offset: Stable backbone of print production

Sheetfed offset presses in the Rapida series are highly sought after in Greater China and have been in strong demand for decades. In many printing companies, they have become a stable backbone in production and are particularly valued for their outstanding printing performance, high print quality and flexibility in terms of their features.

Koenig & Bauer traditionally expects many visitors and widespread interest from trade professionals at China Print.

0 notes

Text

Personalized to Perfection: Maverton’s Unforgettable Gift Experiences

Gifts should do more than just sit on a shelf—they should tell a story, evoke emotion, and create lasting connections. At Maverton, we specialize in crafting personalized gifts that go beyond the ordinary, blending innovative technology with heartfelt customization. Whether you're searching for a sentimental keepsake, a corporate award, or a fun surprise, our collection offers something extraordinary for every occasion and every person in your life.

The Magic of Customization

A great gift reflects the recipient’s personality, passions, and the special bond you share. That’s why Maverton’s team of skilled designers, engravers, and printing experts work meticulously to ensure every detail is perfect. With options ranging from laser-etched designs to full-color photo prints, we help you create gifts that are as unique as the people receiving them.

For the sentimental soul: Engraved jewelry, custom star maps, or memory books.

For the stylish trendsetter: Personalized apparel, chic home décor, or sleek tech accessories.

For the corporate achiever: Elegant engraved awards, branded merchandise, or executive gifts.

No matter the style, our gifts are designed to delight, inspire, and leave a lasting impression.

Laser Engraving: Precision That Speaks Volumes

When it comes to timeless elegance, nothing compares to the art of engraving. Maverton’s high-tech laser engraving ensures crisp, permanent designs on a variety of materials, including:

Metal: Personalized watches, keychains, and cufflinks.

Wood: Custom plaques, photo frames, and keepsake boxes.

Glass & Crystal: Wine glasses, awards, and decorative pieces.

Each engraved piece carries a sense of sophistication, making it ideal for milestone celebrations, corporate recognition, or romantic gestures.

Vivid Photo Prints: Capture Memories in Color

For those who love bold, vibrant designs, our advanced printing technology brings photos and artwork to life. Using UV printing, DTG (Direct-to-Garment) techniques, and high-resolution digital presses, we create stunning personalized gifts such as:

Photo blankets & cushions – Cozy reminders of special moments.

Custom mugs & drinkware – Start their day with a smile.

Posters & canvas prints – Turn memories into wall art.

These gifts are perfect for birthdays, anniversaries, holidays, or just because—because nothing says “I care” like a gift made just for them.

Why Maverton Stands Out

Unrivaled Quality – We use premium materials and state-of-the-art equipment to ensure durability and beauty.

Endless Creativity – Mix and match designs, fonts, and colors to create something truly one-of-a-kind.

Fast Turnaround – With over a million orders fulfilled, we deliver speed without sacrificing perfection.

Customer-Centric Service – Our team is always ready to help, ensuring a seamless experience from start to finish.

The Perfect Gift for Every Moment

Life is full of occasions worth celebrating, and Maverton has the perfect gift for each one:

Weddings & Anniversaries? A custom-engraved wine box or personalized wall art.

Graduations & Achievements? A laser-engraved pen set or motivational poster.

Just Because? A photo-printed puzzle or custom-scented candle with a personal label.

Final Thought: Gifts That Leave a Legacy

At Maverton, we don’t just sell gifts—we create treasured heirlooms that spark joy for years to come. Whether it’s a delicate engraved necklace or a vibrant printed throw pillow, every item is designed to celebrate life’s most meaningful moments.

Ready to make someone’s day unforgettable? Explore Maverton’s personalized gift collection geschenke today and turn your love into a masterpiece.

0 notes

Text

Top Gold Coast Printers: Affordable, Fast & High-Quality Printing Services

Are you looking for the best Gold Coast printers for business or personal printing needs? Whether you're after eye-catching business cards, high-volume flyer printing, or custom signage, this guide covers the top printing services on the Gold Coast. We’ve done the research to help you find the most reliable, affordable, and high-quality printing solutions in the area.

Why Choose Local Gold Coast Printers?

Working with local printers on the Gold Coast comes with many advantages:

Faster turnaround times

Personalized service and easy communication

Support for local businesses

Pickup and delivery options

Choosing a Gold Coast-based printer also ensures that you can check samples and proofs in person, reducing errors and saving time.

Services Offered by Top Gold Coast Printers

The best Gold Coast printing companies offer a wide range of services to meet your needs, including:

Business card printing

Brochures and flyers

Posters and banners

Custom T-shirts and apparel

Stickers and labels

Large format printing

Signage and display materials

Booklets, catalogues, and magazines

No matter your project, you’ll find a service tailored to suit your goals and budget.

What to Look for in a Gold Coast Printer

Before selecting a printing service, consider the following:

Print quality: Ask for samples to evaluate color accuracy, paper quality, and finish.

Experience: Choose a printer with experience in your type of project (e.g., marketing materials, signage).

Customer reviews: Look for positive Google reviews and testimonials from local clients.

Eco-friendly practices: Many Gold Coast printers now offer sustainable printing options using recycled paper and soy-based inks.

Competitive pricing: Request quotes and compare turnaround times to get the best value.

Top-Rated Gold Coast Printers in 2025

Here are a few local favorites based on customer reviews and service quality:

1. Gold Coast Print Hub

✅ Fast turnaround | ✅ Affordable pricing | ✅ Wide range of services Gold Coast Print Hub is known for its exceptional customer service and consistent high-quality results. Ideal for both small businesses and large orders.

2. Snap Print & Design Southport

Snap is a trusted name Australia-wide, with the Southport branch providing expert local support, design services, and professional-grade prints.

3. Fast Proof Press

Specializing in offset and digital printing, Fast Proof Press is perfect for bulk print orders without compromising on quality.

4. Print HQ Gold Coast

Offering eco-friendly options, fast delivery, and sharp digital print quality—great for business cards, flyers, and signage.

Benefits of Professional Printing Over DIY

While home printers are fine for occasional documents, professional printing delivers:

Sharper image resolution and color matching

Durable materials for long-lasting prints

Custom finishes like gloss, matte, and UV coating

Access to professional design services

For business branding and marketing, professional printing can dramatically improve your perceived quality and trustworthiness.

How to Get the Best Printing Deals on the Gold Coast

To save money without sacrificing quality:

Order in bulk – larger quantities often mean lower per-unit costs.

Request quotes from multiple printers.

Use seasonal discounts and referral deals.

Check for bundled services like design + print packages.

Ready to Print on the Gold Coast?

Whether you need business cards, promotional flyers, or signage, choosing a reliable Gold Coast printer is key to getting professional results without the hassle. Local printers offer better support, faster service, and custom solutions tailored to your needs.Need help choosing the right printer? Contact us or explore the recommended providers above to get started with your next print project today!

0 notes

Text

What is UV Printing?

With the modern technology of printing, UV printing has changed the mode of printing high-quality and long-lasting prints on different substrates for individuals as well as companies. The modern printing technology is used in many marketing sectors, packaging, interior decoration, and personalized gifts. If you require UV printing in Abu Dhabi, Seryali offers quality printing services that deliver high-quality, durable, and professional prints.

Understanding UV Printing

UV printing is computer-to-print technology that exploits the use of the application of ultraviolet (UV) light to immediately fix the ink the moment it is released on a substrate. As opposed to solvent-based ink heat curing, UV printing provides speedy, precise, and eco-friendly prints with substantially higher durability.

Once applied to the surface, the ink is immediately cured by the assistance of UV light, hence eliminating smudge and providing top-class, gloss finish. Abu Dhabi UV printing can therefore be used on highly diverse materials from plastic to glass, metal, wood, acrylic, to paper.

Why UV Printing in Abu Dhabi?

As there are more and more demands for customized printing solutions, UV printing in Abu Dhabi is the new darling of the people and business communities. The greatest advantages of UV printing include the following:

1. Fast Drying to Enable Quick Turnaround

Since UV light can cure ink right away, drying time is zero. This enhances production and makes UV printing in Abu Dhabi perfect for press runs and bulk orders.

2. Vibrant, High-End Prints

UV printing produces deep, rich, and vibrant colors with crystal-clear transparency. From gifts, and promotional items, to signs – Abu Dhabi-based UV printing has everything.

3. Longevity and Durability

Patterns remain water-resistant, scratch-resistant, and fade-resistant, and this is the reason why UV printing is the ideal choice for outdoor signs, commercial signs, and decorative prints.

4. Varied Material Compatibility

As opposed to traditional printing procedures, UV printing in Abu Dhabi can be applied on diverse surfaces like:

Plastic

Glass

Metal

Wood

Acrylic

Leather

Paper and cardstock

5. Environment-Friendly and Eco-Friendly Printing

UV printing is environmentally friendly compared to traditional printing procedures. Because the ink dries in a fraction of a second, no toxic solvents are necessary, cutting down emissions as well as waste.

Applications of UV Printing in Abu Dhabi

We at Seryali are experts in UV printing for some of the following uses:

1. Personalized Business Products and Branding

Companies apply UV printing in Abu Dhabi on marketing materials such as pens, USB flash drives, notebooks, and keychains. UV printing is left behind as a lasting impression branding.

2. Personalized Home Decor and Gifts

From customized mugs and phone cases to acrylic photo frames and canvas prints, Abu Dhabi UV Printing offers unique and special designs that are the best gift items.

3. Advertising and Signage

Restaurants, retail outlets, and party firms utilize Abu Dhabi UV printing to produce indoor and outdoor high-tech signs that have endured various climatic conditions.

4. Packaging and Label Printing

Abu Dhabi UV printing is used by retail, cosmetics, and food companies for premium packaging, labels, and product brand identification.

Why to choose Seryali for UV Printing Abu Dhabi

Seryali is a reliable UV printing company with premium prints for individuals, events, and companies. We have the following reasons why clients repeatedly come back to our services:

Newest UV Printing Technology: We use state-of-the-art UV printers for precision and accuracy.

Customized Solutions: We offer personalized printing solutions as per individual requirements.

Low Cost: Get low-cost prints at reasonable prices.

Quick Turnaround: Our instant curing method provides for fast turnarounds.

Get the Best UV Printing Abu Dhabi Today!

Require UV printing in Abu Dhabi?

Search no more, as Seryali is where you will get trusted, high-quality custom printing solutions.

Call now to get the quality UV printing Abu Dhabi you deserve and let us make your creative imagination a reality!

0 notes

Text

Inline Flexographic Printing Machine would give you the following headline: UV Graphic Technologies Private Limited

This means that our operation provides the upscale industry benchmark while emphasizing futuristic solutions to problems in printing. It was designed, engineered, and finally manufactured, so that precision, speed, and innovation are established in the business. Our flexo print-line machine, business units' various needs, and print-packing specs, making available high quality, high-speed operations at very low cost.

Where is the area of the market application of a inline Flexographics Printing Machine of this kind?

Inline-Flexo Printing Machines are highly productive machines that utilize flexible relief plates in transferring the image from inking onto various substrates such as paper, plastics, and metalized films. They are highly utilized in the label printing market, flexible packaging, and, thus, carton manufacturing by virtue of speed and flexibility.

Features of the Flexo Printing Machine of Ours

1. High-Speed Press:

also feature highly robust construction and design due to its fast production cycles; creating highly efficient and least downtime for printing needs.

2. Precision Office Press:

As in above 35, this machine is capable of giving out superior print quality prints, highly registering with crisper graphics vibrant enough to appeal a subconscious; this is the mark of an office press with scoring-precision.

3. Multi-Substrate Printing:

The machine is capable of printing on almost everything; that is, paper, film, foil, and other available flexible materials. There is a standard on how to print on all these substrates; it's all well-explained in Chapter Four of this book. Most of the issues raised in Chapter Five are within the capabilities of existing techniques. Already, there are endeavors underway adding flexible multi-substrate flexibility to the printing process. Modification of the L-cala to include water-based and UV curing teloms and the proliferation of UV curing for food packaging are some of the substantial developments in recent years.

4. Eco-Friendly Thin:

In operation, the machine uses only water-users based and UV inks. This minimizes environmental impacts.

5. Upgradeable Modular Design Maskara30:

The machine's modular design where all individual units are upgradable throughout the design by addition or removal of 10 modules.

6. Running Costs Washer:

Energy efficiency and speed are closely related during the print production process. Energy-efficient performs and saves on energy in the drying system.

7. Easy-Read Interface-Calvin:

Automated interface and programming for easy user control.

Broad applications of the Inline Flexo Printing Machine

The flexographic printing machine belongs to sectors that need high-quality printing and in much higher quantities.

These sectors include:

- Label Printing: Printing ingredients on foodstuffs, beverages, cosmetics, and pharmaceuticals.

- Flexible Packaging: Production of pouches, wrappers, and laminated packaging materials.

- Carton Printing: A presentation of bold branding with a plethora of fine and lively cartoons carried by folding cartons.

- Shrink Sleeves & Wraps: Specific and enduring printing on shrink sleeve packaging.

Why UV Graphic Technologies Pvt. Ltd.?

For decades, in many years of operation, UV Graphic Technologies Pvt. Ltd. has gained a solid reputation in the markets.

Our Inline Flexomachines offer:

- State-of-the-Art Technology-U: Contemporary advancements combine them to improve productivity and improve print quality.

- Customizations: The chance to mold the machines with business requirements in mind, keeping productivity at barest minimums. After-Selling Service: Well-attended training service, tidying up maintenance care, peace, and hope given in oceans of technical support.

- Pricing Level-Fair and really good deals for the market: Cost-based solutions can be overruled to ensure practically good performance.

Get State-of-the-Art Flexo Printing Solution at Today!

If you have been looking for that forceful machine, your Inline Flexo Printing Machine, then we have just the perfect point to be at! Go through our Flexographic Printing Machines page now; see the machines we got to offer; upgrade your print possibilities nowadays!

1 note

·

View note

Text

Buy Latest Hybrid Label Press - Jetsci® Global

Buy the latest Hybrid Label Press from Jetsci® Global and experience the future of label printing. With cutting-edge digital and flexographic technology, these presses offer unmatched flexibility, speed, and print quality. Perfect for high-demand industries, Jetsci® Global’s latest models are designed to improve productivity and provide superior, consistent results.

OUR CONTACT DETAILS: ADDRESS: B-15, InfoCity Phase 1, Sector 34,Gurugram-122001, Haryana, India CONTACT NO. +91 1244226771 EMAIL: [email protected] Visit Us: https://www.jetsciglobal.com/dspark-hybrid/

#digital label press#digital label printing solutions#uv label printing press#digital color label press#variable data printing press#digital uv inkjet label production press#digital book printing press#book printing press#uv inkjet label printing solution#Hybrid Label Press#Jetsci® Global

0 notes

Text

Innovative Flexo Printing Technology for Superior Results by UV Graphic

As an innovator in the manufacture of flexo printing machines, UV Graphics provides state-of-the-art solutions for any printing-related needs. Highly recognized for their reliability, precision, and innovative features, our machines effectively meet dynamic needs in the packaging, labeling, and commercial categories of printing.

Flexo printing is known for being the fastest and most versatile printing technology, which makes it the ideal printing type for long runs. Our promise as a company at UV Graphic is to make high-quality machines with the latest technology that encourages brighter colors, sharper details, and absolute uniformity across-the-board, be it on paper, plastic, or metal foils.

Our wide vision regarding countryscape warrants that there are efficient energy systems and waste operations to be had. Small Compact Press for small jobs and massive capacity systems for industrial-scale projects-all these together prove that UV Graphic has a designed effect on your success.

#curing machine manufacturer#gravure printing machines manufacturer#rotary hot foil stamping#label punching machines manufacturer#Flexo Printing Machines Manufacturer

0 notes

Text

Ok, big reveal… I’ve spent a lot of time looking after printers on a professional basis, since ‘98 in fact, and I’ve spent the entire time describing them as malicious little boxes of evil.

Part of the issue is that even when you get up to the huge industrial ones that are expecting to run continuously for the entire working day, they usually are tremendously bad at it. Partly because nobody in the office is trained to maintain the printers and they basically just wear out and get full of crud, but partly because they’re designed to be weird as heck to evade getting dragged through court by some failing company who’s last ditch profitability model is suing everyone for design infringement… and of course, to make it really hard to get generic parts.

And the. There’s the custom software which is most likely some ancient controller thats being kludged together on a budget and then talked at by a driver that still thinks it’s running on Windows NT 3, or for some fucking reason CUPS.

BTW I currently work supporting thermal printers for receipts and Dymo label printers, and… honestly, Dymo are actively evil.

Having to argue with a caller to get them to open a Terminal window to turn on CUPS WebUI so they can change paper size via a simple 72 step process that includes having to use a 5 digit code and also manually typing your username and password to save that… What?

Windows is as bad: Sometimes the receipts just go CVS on you and you have to set the paper size from “the length of the print” to “whatever the shortest length that’s provided” which is 20cm.

And that used to be easy, until Star re-worked their drivers and that setting must be set twice, in completely different dialogues then a third time in Chrome’s own weird intercessionary print preview, that has it’s own driver independent paper size settings.

Also that thing about Linotype? Hate to be the “um Actually” person like object, but I ran a mechanical print business in 2005 and I was still buying slugs of lead/antimony linotype print from a guy who sat at a machine that had an honest to got open air pot of liquid lead/antimony/tin and who I had the pleasure of doing the very Printer thing of discussing who’s lost a finger this week.

Lead type has tin in to make it harder, and antimony which expands as it cools. The alloy for lead type is therefore the same volume when hot as it is when cold so the type face won’t warp or shrink. The Line-o-type machine has an electric melting pot and a bar of allow on a chain. The bar is lowered into the pot and melted as the machine is used. I was buying type for a 40 year old Heidelberg platen press, which was very mechanical, very predictable and despite being capable of turning a human hand into a smear without any particular strain, was about the safest machine that I had. The others? Nightmare fuel.

I got out of that job. Too many solvents, open air bathes of isopropyl alcohol, inhaleable potato starch clouds and machines that were basically toxic trash and built like a sadistic trap from Saw.

Not to mention the photolithography table for etching print plates that has zero protection from the high powered UV light.

That entire industry basically got killed off in the late 2000’s by large cartels banding together to buy huge Heidelberg printers that were hammering out print in volumes so massive they were offering colour prints at what small outfits were paying for the paper alone.

And then most people went digital anyway. At the time I was making my money printing for church groups who were having serious trouble keeping up with the modern world and who’d type up their work in Word, print it, cut it up and glue it to sheets of paper to do the layout.

That and weird paper cutting jobs that needed a platen press to do… and of course receipt books for trade customers who were determined to run on NCR receipt pads until they keeled over of old age into the hopper of their sausage making machine.

Like Crowley and the 14th century, my favourite thing about time is that I get further and further away from having to work in a print shop.

Now if I can just persuade everyone to stop using Dymos and Receipt printers, I’ll be happy.

why are printers so hated? it's simple:

computers are good at computering. they are not good at the real world.

the biggest problems in computers, the ones that have had to change the most over the time they've existed, are the parts that deal with the real world. The keyboard, the mouse, the screen. every computer needs these, but they involve interacting with the real world. that's a problem. that's why they get replaced so much.

now, printers: printers have some of the most complex real-world interaction. they need to deposit ink on paper in 2 dimensions, and that results in at least three ways it can go on right from the start. (this is why 3D printers are just 2D printers that can go wrong in another whole dimension)

scanners fall into many of the same problems printers have, but fewer people have scanners, and they're not as cost-optimized. But they are nearly as annoying.

This is also why you can make a printer better by cutting down on the number of moving elements: laser printers are better than inkjets, because they only need to move in one dimension, and their ink is a powder, not a liquid. and the best-behaved printers of all are thermal printers: no ink and the head doesn't move. That's why every receipt printer is a thermal printer, because they need that shit to work all the time so they can sell shit. And thermal is the most reliable way to do that.

But yeah, cost-optimization is also a big part of why printers are such finicky unreliable bastards: you don't want to pay much for them. Who is excited for all the printing they're gonna be doing? basically nobody. But people get forced to have a printer because they gotta print something, for school or work or the government or whatever. So they want the cheapest thing that'll work. They're not shopping on features and functionality and design, they want something that costs barely anything, and can fucking PRINT. anything else is an optional bonus.

And here's the thing: there's a fundamental limit of how much you can optimize an inkjet printer, and we got near to it in like the late 90s. Every printer since then has just been a tad smaller, a tad faster, and added some gimmicks like printing from WIFI or bluetooth instead of needing to plug in a cable.

And that's the worst place to be in, for a computer component. The "I don't care how fancy it is, just give me one that works" zone. This is why you can buy a keyboard for 20$ and a mouse for 10$ and they both work plenty fine for 90% of users. They're objectively shit compared to the ones in the 60-150$ range, but do they work? yep. So that's what people get.

Printers fell into that zone long, long ago, when people stopped getting excited about "desktop publishing". So with printers shoved into the "make them as cheap as possible" zone, they have gotten exponentially shittier. Can you cut costs by 5$ a printer by making them jam more often? good. make them only last a couple years to save a buck or two per unit? absolutely. Can you make the printer cost 10$ less and make that back on the proprietary ink cartridges? oh, they've been doing that since Billy Clinton was in office.

It's the same place floppy disks were in in about 2000. CD-burners were not yet cheap enough, USB flash drives didn't exist yet (but were coming), modems weren't fast enough yet to copy stuff over the internet, superfloppies hadn't taken over like some hoped, and memory cards were too expensive and not everyone had a drive for them. So we still needed floppy disks, but at the same time this was a technology that hadn't changed in nearly 20 years. So people were tired of paying out the nose for them... the only solution? cut corners. I have floppy disks from 1984 that read perfectly, but a shrinkwrapped box of disks from 1999 will have over half the disks failed. They cut corners on the material quality, the QA process, the cleaning cloth inside the disk, everything they could. And the disks were shit as a result.

So, printers are in that particular note of the death-spiral where they've reached the point of "no one likes or cares about this technology, but it's still required so it's gone to shit". That's why they are so annoying, so unreliable, so fucking crap.

So, here's the good news:

You can still buy a better printer, and it will work far better. Laser printers still exist, and LED printers work the same way but even cheaper. They're still more expensive than inkjets (especially if you need color), but if you have to print stuff, they're a godsend. Way more reliable.

This is not a stable equilibrium. Printers cannot limp along in this terrible state forever. You know why I brought up floppy disk there? (besides the fact I'm a giant floppy disk nerd) because floppy disks GOT REPLACED. Have you used one this decade? CD-Rs and USB drives and internet sharing came along and ate the lunch of floppy disks, so much so that it's been over a decade since any more have been made. The same will happen to (inkjet) printers, eventually. This kind of clearly-broken situation cannot hold. It'll push people to go paperless, for companies to build cheaper alternatives to take over from the inkjets, or someone will come up with a new, more reliable printer based on some new technology that's now cheap enough to use in printers. Yeah, it sucks right now, but it can't last.

So, in conclusion: Printers suck, but this is both an innate problem caused by them having to deal with so much fucking Real World, and a local minimum of reliability that we're currently stuck in. Eventually we'll get out of this valley on the graph and printers will bother people a lot less.

Random fun facts about printing of the past and their local minimums:

in the hot metal type era, not only would the whole printing process expose you to lead, the most common method of printing text was the linotype, which could go wrong in a very fun way: if the next for a line wasn't properly justified (filling out the whole row), it could "squirt", and lead would escape through gaps in the type matrix. This would result in molten lead squirting out of the machine, possibly onto the operator. Anecdotally, linotype operators would sometimes recognize each other on the street because of the telltale spots on their forearms where they had white splotches where no hair grew, because they got bad lead burns. This type of printing remained in use until the 80s.

Another fun type of now-retired printers are drum printers, a type of line printer. These work something like a typewriter or dot-matrix printer, except the elements extend across the entire width of the paper. So instead of printing a character at time by smacking it into the paper, the whole line got smacked nearly at once. The problem is that if the paper jammed and the printer continued to try to print, that line of the paper would be repeatedly struck at high speed, creating a lot of heat. This worry created the now-infamous Linux error: "lp0 on fire". This was displayed when the error signals from a parallel printer didn't make sense... and it was a real worry. A high speed printer could definitely set the paper on fire, though this was rare.

So... one thing to be grateful about current shitty inkjet printers: they are very unlikely to burn anything, especially you.

(because before they could do that they'd have to work, at least a little, first, and that's very unlikely)

8K notes

·

View notes

Text

Types Of Flexo Printing Inks & Their Environmental Concerns

Flexo printing inks are classified into three main categories, each with distinct environmental implications:

Solvent-Based Inks: These inks contain volatile organic compounds (VOCs), which contribute to air pollution and pose health risks to workers. VOC emissions can lead to smog formation, making them a significant environmental concern. Additionally, solvent-based inks require specialized disposal methods to prevent contamination of water sources.

Water-Based Inks: These are considered more environmentally friendly because they contain fewer VOCs. They are commonly used for printing on porous substrates such as paper and cardboard. However, water-based inks still require proper waste management to prevent excess water consumption and contamination.

UV-Curable Inks: Unlike solvent-based and water-based inks, UV-curable inks do not rely on evaporation for drying. Instead, they cure instantly under UV light, eliminating the release of VOCs. However, UV curing consumes a significant amount of energy, raising concerns about its overall environmental impact. Additionally, some UV inks contain photoinitiators that can be hazardous if not properly handled.

Waste & Pollution Concerns

The use of flexo printing inks generates various waste products that contribute to environmental pollution. Some of the primary concerns include:

VOCs & Air Pollution: Solvent-based inks release VOCs into the atmosphere, contributing to poor air quality and climate change. Strict regulations are in place to limit VOC emissions, but enforcement varies across regions.

Water Contamination: Improper disposal of ink waste can contaminate water bodies, affecting marine ecosystems. Even water-based inks, if not managed correctly, can introduce chemicals into wastewater systems.

Energy Consumption: UV-curable inks require high-intensity UV light for curing, leading to increased energy consumption. Although they reduce VOC emissions, their reliance on electricity affects the overall sustainability of the process.

Solid Waste Generation: Printing presses produce significant amounts of solid waste, including leftover ink, cleaning solvents, and printing plates. Without proper recycling systems in place, these materials contribute to landfill waste.

Industry Efforts Toward Sustainable Solutions

To minimize the environmental impact of flexo printing inks, the industry is adopting sustainable practices and innovative solutions:

Development of Bio-Based Inks: Researchers are exploring plant-based and biodegradable ink formulations to replace petroleum-derived solvents. These alternatives reduce harmful emissions and improve biodegradability.

Recycling & Waste Reduction: Many printing companies are implementing ink recovery and recycling systems to minimize waste. Ink waste can be reprocessed and reused, reducing the demand for new raw materials.

Energy-Efficient Curing Technologies: Advances in LED curing for UV inks are reducing energy consumption. LED curing is more efficient and has a longer lifespan than traditional mercury-based UV curing systems.

Regulatory Compliance & Certifications: Governments and environmental organizations are setting stricter guidelines for ink formulations. Certifications such as the Nordic Swan and Blue Angel labels encourage manufacturers to produce environmentally responsible inks.

Final Thoughts

Flexo printing inks are an essential component of modern printing, but their environmental impact cannot be overlooked. While water-based and UV-curable inks provide more sustainable alternatives, challenges remain in waste management, air pollution, and energy consumption. The printing industry is actively working towards greener solutions by developing bio-based inks, enhancing recycling efforts, and improving curing technologies. As businesses and consumers prioritize sustainability, the demand for eco-friendly printing inks will continue to grow, driving innovation and reducing the environmental footprint of flexo printing.

0 notes

Text

Everything You Need to Know About a UV DTF Printer: The Future of Custom Printing

In today’s fast-evolving printing industry, UV DTF printers are making a bold statement. With the ability to print directly on a wide variety of surfaces without the need for heat transfer or weeding, these innovative machines are revolutionizing how we think about custom design and branding. If you're a business owner, designer, or print enthusiast, learning about UV DTF printers could be your next big step forward.

What is a UV DTF Printer? A UV DTF (Direct to Film) printer is a cutting-edge printing device that uses ultraviolet (UV) light to instantly cure ink printed onto a special film. The printed film is then transferred directly to hard or irregular surfaces like glass, wood, metal, acrylic, ceramics, leather, and plastic. Unlike traditional DTF printing used mostly for fabric, UV DTF printers cater to more rigid and varied surfaces, making them ideal for personalized items and promotional products.

How Does a UV DTF Printer Work? The UV DTF printing process typically involves three layers:

Color Ink Layer – The design is first printed in CMYK colors.

White Ink Layer – A white ink layer follows to enhance vibrancy and allow printing on dark or transparent surfaces.

Gloss or Varnish Layer – This layer gives your design a polished and durable finish.

Once printed, the film is applied with transfer adhesive and peeled off, leaving the design cleanly adhered to the target surface.

Key Features of UV DTF Printers Instant UV curing: No drying time needed.

Versatile Surface Compatibility: From mugs and phone cases to glass and wood.

No Weeding: Unlike vinyl cutting, there's no need to weed excess material.

High Durability: Scratch-resistant, waterproof, and UV-resistant.

High-Resolution Output: Excellent print clarity and color saturation.

Benefits of Using a UV DTF Printer

Expand Your Product Line

With a UV DTF printer, businesses can offer personalized products that were previously hard to customize. This includes:

Customized tumblers and mugs

Acrylic keychains

Personalized phone cases

Wooden plaques and gifts

Branded glassware

Cost-Effective for Small Runs

Traditional screen printing or pad printing is expensive for small quantities. A UV DTF printer allows you to do one-off prints or small batch runs with minimal waste and setup.

No Heat Required

One of the standout features is the no-heat application. Unlike sublimation or standard DTF printing that requires heat presses, UV DTF relies on UV light and adhesive, making it safer and faster.

Environmentally Friendly

UV-curable inks are more eco-friendly than solvent-based inks, producing fewer VOCs and requiring no water for cleanup.

Who Can Benefit from a UV DTF Printer?

Small Businesses & Entrepreneurs Etsy sellers, custom gift shops, and local printing services can all benefit from the versatility and low-cost operation of a UV DTF printer.

Branding Agencies Create branded promotional items such as logo-printed merchandise without needing multiple machines.

Artists & Designers Print unique artwork on unconventional surfaces like wood blocks or acrylic sheets for home décor and art installations.

Industrial Applications Even industries like automotive, packaging, and signage find UV DTF useful for labeling and customization on curved or textured surfaces.

UV DTF Printer vs. Other Printing Technologies Technology Best For Requires Heat Weeding Surface Types UV DTF Printer Hard & irregular items No No Glass, wood, plastic Regular DTF T-shirts & fabrics Yes No Soft materials Sublimation Polyester fabrics Yes No Fabric, coated items Vinyl Cutting Stickers & labels Sometimes Yes Limited

Things to Consider Before Buying a UV DTF Printer

Print Size Capacity Choose a printer based on the size of items you plan to print. Some models support A4 or A3 sizes, while industrial-grade printers can handle much larger surfaces.

Ink System and Refills Make sure the printer uses reliable and readily available UV inks. Some printers come with bulk ink systems that are more economical over time.

Software Compatibility Check whether the printer is compatible with your design software like Adobe Illustrator or CorelDRAW, and supports common file formats like PNG, SVG, or PDF.

Maintenance Requirements Like all printers, UV DTF machines need regular maintenance. Look for models that offer easy access to parts and have available technical support.

Top UV DTF Printer Brands in the Market Here are a few reliable brands known for UV DTF printing:

Lopo UV DTF Printers – Ideal for small businesses with beginner-friendly features.

A3 Pro UV DTF Printer – Offers high resolution and built-in laminating.

ComColor UV DTF Machines – Industrial grade, suitable for bulk production.

Final Thoughts The UV DTF printer is a game-changer for the world of customized printing. Whether you're starting a new business or expanding your current product offerings, this technology offers flexibility, affordability, and high-quality output that traditional methods simply can't match.

As demand for personalization grows across industries, investing in a UV DTF printer can help you stay ahead of the curve—and create products that wow your customers.

0 notes

Text

Flexo automation and the shift to digital and hybrid labels

The pressure-sensitive label industry in India continues to grow as packed and labeled products in numerous types of containers, formats, and sizes multiply. Every food and snack product is available in various exotic and localized flavors. You can now buy packs of Hershey’s chocolates filled with California almonds with guava and Mexican chilli flavor, or Hershey’s Exotic Dark blueberry and acai flavored centers. Also, you can find Mazan chocolate cubes filled with paan flavour and many other products in the market with a variety of localized flavors including Kurkure packs with ‘UP Taste.’ In short, the number of SKU’s of pouches and labeled containers have substantially multiplied.

It is no longer about flexo versus digital versus flexo. At the Labelexpo India in 2022, the European plate and roller manufacturers said that ‘digital is the death of flexo.’ To bolster their views they pointed to challenges such as print density, banding, and handling newer substances – a virtual laundry list of difficulties with digital label production.

Digital printing has found its place in various label applications, especially when personalization, variable data, and shorter print runs are required. Flexo holds significant advantages in terms of cost-effectiveness in large-volume production runs and printing on certain materials and increasingly for short-run flexible packaging, especially with the widespread availability of locally manufactured presses.

Managing shorter print runs is challenging for flexo converters, considering the cost of creating printing plates, time-consuming press set-up, and set-up waste. Adding flexo units to a digital module in a hybrid configuration, or investing in a digital roll-to-roll press alongside established flexo lines has helped converters adopt a more sustainable ‘print-on-demand’ business model for shorter-run labels and packaging.

Hybrid printing can be a more sustainable and economical approach. “The flexo technologies being retrofitted with add-on features to a digital press are referred to as hybrid,” explained Ajit Bharadwaj of Vinsak. “Features such as variable data printing, foiling, stamping, die-cutting, and more automated features are increasingly in demand among converters. Reducing avoidable print waste saves both converters and brands money and reduces the need to handle excess printed stock,” he said.

Parwez Izhar, senior vice president of the printing cylinders business at UFlex shares that the Indian packaging industry is witnessing a surge in smart packaging that features technologies such as track-and-trace systems integrated into labels and packaging including RFID, NFC, QR codes, holograms, and more.

Izhar explains that approximately 20% of the gravure market share has shifted to flexo, primarily due to its cost-effectiveness and faster turnaround time. He says, “In the label industry, both flexo and digital are gaining ground, and with the increasing demand for short-run jobs, converters are also turning to digital.”

“However, converters are not focusing on just one approach, they are thinking about growth. Many opt for both technologies—if they have flexo, they add digital. Converters recognize the demand for a premium look and feel, so the future lies in hybrid technologies that can meet all the quality, volume, and variable data requirements,” Izhar adds.

The automated flexo presses that include hybrid LED UV systems, die-cut units, pre-register, auto-register, movable turn bar, lam and relam units, peal and seal kits, and foiling stations for labels, shrink sleeves, and flexible packaging are increasing in global demand. Faridabad-based Multitec’s mid-web flexo presses can print on various substrates including thin and extensible materials with capability ranging from 10 microns up to 450 microns at 200 meters a minute with impressive registration and low setup wastage.

Multitec generally leads the industry in new technology adoption and implementation with 40% of its manufacturing being exported. Amit Ahuja, managing director of Multitec explained, “The growing short-run demand is creating a market space for digital. This does not pose any threat to veteran flexo users – but the future is in the hybrid production of labels together with the increasing demand for more automation features and quicker and more precise make-ready solutions.”

0 notes