#wiring harness terminal

Text

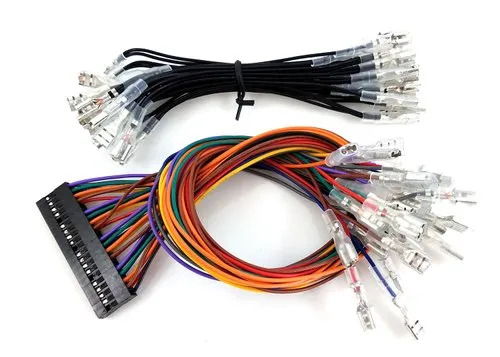

Wiring Harness Terminals & Sheet Metal Components Manufacturer in India

We Shubham Industries is a well-known name in Wiring Harness Terminals manufacturer in Delhi along with Sheet Metal Components Manufacturers in India. Read the full article for a better understanding of our precious products.

The terminals on the wiring harness are the areas where the wire terminates or is connected to other components.

Similar to wire harness connections, the type of termination needed will depend on the intended usage and may have different forms, sizes, and insulation requirements.

Non-insulated terminals are a more cost-effective solution when protection from temperature, moisture, or the environment is not absolutely necessary.

Importance of Wiring Harness

Since wire harnesses must be precisely made with specific application needs in mind, the wire harness design process may be quite customized.

Several wire harnesses need to be concealed in boxes, walls, or other limited spaces. Functionality and safety both depend on a high-quality design.

The extensive list of elements above demonstrates how environmental considerations must be made in wire harness designs.

Sheet Metal Components

Let’s discuss the sheet metal components as we mentioned above about the wiring harness now we are going to discuss the sheet metal components and their uses.

Sheet metal is used to make many different objects, including the bodywork of automobiles, trucks, and lorries, huge appliances, airplane fuselages, and wings, tinplate for tin cans, roofing for buildings (architecture), and many other things.

Iron sheets with laminated steel cores and other high magnetic permeability materials are used in transformers and other electric equipment.

#wiring harness#wiring harness terminal#wiring harness terminal manufacturer#sheet metal#sheet metal componets#sheet meta component manufacturer#manufacturer#supplier#engineering#automobile#auto parts

0 notes

Text

UPM heat shrink tubing, Versatility Insulation Protection Identification Connectivity

#shrink tubing#heat shrink#shrink terminator#shrink sleeve#upm heat shrink specialist#heat shrink connector#stress control tube#thin wall heat shrink#shrink breakout boot#shrink end cap#flame retardant#automotive wire harness

1 note

·

View note

Text

Exploring the World of Leading Wire Harness Innovators

Wire harness manufacturers play a crucial role in various industries, providing essential components that ensure seamless connectivity and electrical integration in a wide array of applications. These manufacturers design and produce intricate wire harness systems tailored to specific requirements, adhering to strict quality standards and industry regulations.

For More Information Please visit, top wire harness manufacturers

key aspects of wire harness manufacturing

Industry Overview : Wire harness manufacturers operate in a highly competitive and evolving industry. They serve sectors such as automotive, aerospace, electronics, telecommunications, and healthcare, among others. The demand for custom wire harness solutions continues to grow as industries advance technologically.

Customization and Design : One of the significant aspects of wire harness manufacturing is customization. Manufacturers work closely with their clients to understand their unique needs. This involves designing wire harnesses that meet specific requirements, including size, shape, number of wires, insulation materials, and connector types.

Quality Assurance: Quality is paramount in wire harness manufacturing. Manufacturers invest in state-of-the-art testing equipment and employ skilled technicians to ensure that each harness meets the required standards. Rigorous testing procedures are in place to check for electrical continuity, insulation resistance, and overall durability.

Materials and Components: Wire harnesses consist of various materials and components, including wires, connectors, terminals, tubing, and insulation materials. Manufacturers carefully select these components based on the application's requirements, taking into account factors such as temperature, voltage, and environmental conditions.

Compliance and Certification: Wire harness manufacturers adhere to industry standards and regulations to guarantee the safety and performance of their products. Compliance with standards such as IPC/WHMA-A-620 ensures that the manufactured harnesses meet the necessary criteria for reliability and functionality.

Advanced Manufacturing Techniques : Modern wire harness manufacturing involves advanced techniques such as automated assembly, which enhances efficiency and precision. Computer Numerical Control (CNC) machines are employed for accurate cutting, stripping, and crimping of wires and connectors.

Supply Chain Management : Efficient supply chain management is crucial for timely production and delivery of wire harnesses. Manufacturers work closely with suppliers to source high-quality materials and components, ensuring a seamless flow of production.

Research and Development : Continuous research and development efforts drive innovation in the wire harness industry. Manufacturers invest in developing new materials, manufacturing processes, and technologies to improve the performance and longevity of wire harnesses.

Environmental Sustainability : Many wire harness manufacturers focus on sustainable practices, including the use of eco-friendly materials and recycling initiatives. Sustainability efforts contribute to reducing the environmental impact of manufacturing processes.

Conclusion

Wire harness manufacturers operate at the intersection of technology and precision engineering. Their commitment to quality, innovation, and customer satisfaction drives the industry forward, enabling seamless integration of electrical systems in various applications across the globe.

2 notes

·

View notes

Text

Cable Wire Harness

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Harness Braiding & Over Mold#Continuity & Hi-Pot Testing#Radio Frequency Testing#IPC 620 Standard#MIL SPEC Harness Standards#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

Wire Harness Components: Exploring the Building Blocks of Electrical Systems

In the realm of electrical engineering and connectivity, wire harnesses serve as unsung heroes, enabling the smooth transmission of power and signals across an array of industries. These vital components have become indispensable in modern applications, ensuring efficiency, reliability, and safety.

In this comprehensive guide, we delve into the world of wire harnesses, exploring their functionality, applications, and significance in various sectors.

For More Information Please visit, wiring harness manufacturers near me

What are Wire Harnesses?

A wire harness, also known as a cable harness or wiring assembly, is a bundled arrangement of multiple electrical wires or cables. These wires are bound together using various methods, such as tape, zip ties, or sleeves, to form a unified and organized unit. The purpose of a wire harness is to facilitate the efficient and tidy transmission of electrical signals, power, and data within complex systems.

Structure and Components:

Wire harnesses are designed to suit specific applications, and their structure can vary accordingly. Typically, a wire harness consists of the following components:

Wires/Cables: The core elements of a wire harness are the electrical wires or cables, which come in various gauges and types, depending on the application's requirements.

Connectors: Connectors are the crucial interface points that link the wire harness to other electrical components, devices, or systems.

Terminals: Terminals serve as the end points of individual wires, making electrical connections with connectors or other terminals.

Sleeves and Sheaths: To protect the wires from external elements and prevent damage, sleeves and sheaths are used as protective coverings.

Tapes and Labels: Tapes are utilized to bundle the wires together, while labels aid in identification and organization.

Applications in Different Industries:

Wire harnesses find extensive applications in numerous industries due to their efficiency and reliability. Some of the key sectors that heavily rely on wire harnesses include:

Automotive: In vehicles, wire harnesses are essential for transmitting electrical signals, power, and data to various components, such as engines, lights, sensors, and infotainment systems.

Aerospace: The aerospace industry uses wire harnesses to ensure secure and organized connectivity within aircraft, satellites, and spacecraft.

Electronics: From consumer electronics to industrial machinery, wire harnesses are crucial for connecting and powering electronic components.

Telecommunications: In the world of telecommunications, wire harnesses facilitate the smooth flow of data and power in network infrastructure.

Healthcare: Medical devices and equipment rely on wire harnesses to ensure precision and safety in their electrical connections.

Advantages of Using Wire Harnesses:

The adoption of wire harnesses brings forth several advantages:

Simplified Installation: Wire harnesses streamline the installation process by eliminating the need to deal with individual wires, reducing assembly time and errors.

Improved Reliability: Organized and secure connections enhance the overall reliability and performance of electrical systems.

Space-Efficient: Wire harnesses help conserve space, especially in compact devices and machinery.

Enhanced Safety: Properly insulated and protected wires reduce the risk of electrical hazards and ensure operator safety.

Conclusion:

Wire harnesses are the unsung heroes that play a vital role in ensuring seamless electrical connectivity across a myriad of industries. From automotive to aerospace, electronics to healthcare, these organized bundles of wires provide efficiency, reliability, and safety in diverse applications. As technology continues to advance, wire harnesses will remain a cornerstone of modern electrical engineering, contributing to innovation and progress across the globe.

2 notes

·

View notes

Text

Replace a wiring harness if an electrical connector melts or burns

Introduction: The heat from the electrical connector can melt or burn the insulation in a wire. If this happens, you need to replace the wiring harness as soon as possible.

Replace a Wiring Harness if an Electrical Connector Melt or Burn.

Patching a blown electrical connector can be a challenging task, but it’s important to do your research before starting. To help avoid any trouble down the road, follow these steps:

1. Look for an electrical diagram of the product you’re repairing or replacing. This will help you understand how the connector works and where potential problems may exist.

2. Remove all accessories from the system and store them away in a safe place. This includes cords, power adapters, and any other devices that may be used in the replacement process.

3. Connect one end of the new wiring harness to an appropriate terminal on the old connector and connect the other end to a power outlet or another ground terminal.

4. Place the old connector in a safe place and wait until it has cooled slightly (about 20 minutes). Then replace it with the new wiring harness.

5. reattach any accessories that have been removed during restoration or replacement, if necessary.

Replace a Wire Harness if It Burns.

If your electrical connector starts to melt or burn, you will need to replace it. Here are some tips on how to do this:

1. First, check the connector for any damage. If there is damage, it will need to be replaced.

2. Next, find a wire harness that Match Your Model and Year of Use. This can be difficult because the Harness may not be marked anywhere specific. To find a wire harness that matches your year of use and model, you can use this online search tool:

3. Once you have found a wire harness that matches your year of use and model, cut the wires off the old harness and place them into the new one. Be sure to match up all of the wires so they are properly connected.

4. Finally, reattach the power cord to the electrical outlet and turn on the appliances you need to stay plugged in while you work on fixing the problem with your wiring harness (like turning on a light).

Replace a Wire Harness if It Burns.

If a wire harness melts or burns, follow these steps to replace it:

1. Cut the harness cable off of the electrical connector.

2. Tie each end of the new wire harness together with a knot (or other strong tie) and place it back on the electrical connector.

3. Replace the electrical connector if it has been melted or burned down.

4. Check for any damage to the electrical connector and replace if necessary.

Conclusion

Replacement wiring harness if an electrical connector melts or burns can be a difficult task. However, if done correctly, it can prevent any damage to your equipment. By checking the electrical connector for damage and replacing it if necessary, you can keep your equipment running smoothly.

2 notes

·

View notes

Text

0 notes

Text

Improve Your Car Audio Experience with a High-Quality Crossover Audio Car

Improve Your Car Audio Experience with a High-Quality Crossover Audio Car

Are you tired of mediocre sound quality in your car? A crossover audio car can transform your driving experience by delivering crystal-clear highs and deep, resonant bass. This essential component separates the full-range audio signal into different frequency bands, ensuring each speaker performs optimally. Whether you're a casual listener or an audiophile, investing in a crossover audio car can make a significant difference.

What Is a Crossover Audio Car?

A crossover is a device that divides the incoming sound signal into distinct high, mid, and low frequencies. Each band is directed to the appropriate speakers, ensuring that the tweeters handle the highs, the midranges manage the middle frequencies, and the woofers produce the bass. This separation results in a balanced and immersive sound.

Key Features of a Crossover Audio Car

- Rated Power: A crossover for car capable of handling up to 200W can manage powerful sound signals without distortion.

- Crossover Points: An adjustable crossover point, such as 3000Hz, allows for precise tuning of the audio spectrum.

- Compact Design: A small form factor, like 120mm x 65mm, makes installation simple and space-efficient.

- Durability: Constructed to be lightweight yet robust, weighing around 380g per pair, ensuring longevity.

Technical Specifications and Installation Tips

To maximize the performance of your crossover audio car, consider the following technical details and installation guidelines:

- Filtering Characteristics: A 12dB/octave slope ensures smooth transitions between frequency bands.

- Connections: The crossover includes dedicated connections for amplifier input (+/-) and woofer/tweeter output (+/-).

- Installation: Begin by disconnecting the car battery for safety. Then, connect the crossover according to the manufacturer's instructions. Fine-tune the crossover points using a multimeter or oscilloscope if available.

How to Install a Crossover Audio Car

- Disconnect the Battery: Always start by disconnecting the negative terminal of your car battery for safety.

- Remove Old Speakers: Carefully remove your existing speakers and wiring harness.

- Install the Crossover: Connect the crossover to your head unit and speakers according to the manufacturer's instructions.

- Adjust Settings: Fine-tune the crossover points using a multimeter or an oscilloscope if available.

- Test the System: Play various types of music to ensure each speaker is working correctly and sounds balanced.

Benefits of Using a Crossover Audio Car

A high-quality crossover audio car, such as the 200W Crossover Car Audio, can significantly enhance your car audio system. Its robust design and advanced engineering ensure every note is delivered with precision and clarity, making your driving experience more enjoyable.

Exploring Different Types of Crossovers

While 2-way crossovers are popular, some enthusiasts prefer a 3-way crossover car audio for even finer control over midrange frequencies. Additionally, "audio crossover car" and "car crossover audio" models offer similar benefits but may vary in terms of specifications and compatibility.

Why Choose a Reliable Crossover Audio Car?

If you're looking to improve the sound quality in your car, a crossover audio car is the perfect choice. Its robust design and advanced engineering ensure every note is delivered with precision and clarity, enhancing your driving enjoyment. Whether you're commuting to work or taking a long road trip, a well-engineered crossover can make your music sound as good as it does in a concert hall.

Conclusion

Investing in a crossover is a smart choice for anyone who values high-fidelity sound in their vehicle. Whether you're a casual listener or an audiophile, a well-engineered crossover can make your music sound as good as it does in a concert hall. Don't settle for mediocre sound quality—upgrade to a crossover audio car today and experience the difference!

Read the full article

0 notes

Text

Harness Test Probes

View 30 suppliers of wiring harness test probes, allowing electrical contact without entering the terminal. For detecting the correct length and straightness of flat pins, view all coda system, Qualmax-M, probe star. For any query, write to us at [email protected]. For more information visit https://bit.ly/3RiysVg

0 notes

Text

What is EPlan? An Overview of Its Functionality and Applications

EPlan is a powerful software solution designed for electrical engineering, offering a comprehensive suite of tools to automate and optimize the design process of electrical control systems, fluid power systems, and cable harnesses. Developed by EPlan Software & Service GmbH & Co. KG, it is widely used across various industries, including automotive, energy, manufacturing, and building automation, to create detailed schematics, wiring diagrams, and documentation with high precision and efficiency. Lets understand what is EPlan, its application, functionalities, and many more in details.

Functionality of EPlan

EPlan’s core functionality revolves around its ability to streamline the planning, designing, and documenting of complex electrical systems. Here’s a closer look at some of its key features:

1. Schematic Design

EPlan allows engineers to create detailed electrical schematics that serve as the blueprint for control systems. The software offers a wide range of symbol libraries, predefined templates, and automated functions that significantly reduce the time and effort needed to produce accurate and standardized schematics. These schematics can include wiring diagrams, panel layouts, and PLC (Programmable Logic Controller) configurations.

2. Automation and Standardization

One of the standout features of EPlan is its capacity to automate repetitive tasks. By using macros and standard libraries, users can automate the generation of common circuit elements and configurations, ensuring consistency across projects and reducing the potential for errors. This automation not only speeds up the design process but also allows for easy updates and modifications to existing designs.

3. Interdisciplinary Integration

EPlan supports interdisciplinary collaboration, integrating with other engineering tools and software platforms. This capability is crucial in environments where electrical, mechanical, and fluid power systems must be designed in harmony. EPlan facilitates the exchange of data between different departments, ensuring that all aspects of a project are aligned and that any changes in one area are reflected across the board.

4. 3D Design and Visualization

EPlan includes robust 3D design tools that allow users to visualize their electrical systems within a three-dimensional space. This feature is particularly useful for panel building and cabinet layout, enabling engineers to see how components will fit together in the real world. The 3D visualization also helps in identifying potential issues, such as spatial conflicts or incorrect placements, before the manufacturing stage.

5. Project Management and Documentation

EPlan excels in project management and documentation. The software automatically generates comprehensive documentation for each project, including part lists, terminal diagrams, and assembly instructions. This documentation is essential for manufacturing, installation, and maintenance, ensuring that all stakeholders have access to the necessary information at every stage of the project.

6. Data Consistency and Reusability

With EPlan, data consistency is maintained throughout the project lifecycle. The software’s centralized database ensures that all project data is stored in a single location, reducing the risk of discrepancies. Additionally, EPlan’s data management capabilities allow users to reuse design elements and modules across different projects, enhancing efficiency and promoting best practices.

Applications of EPlan

EPlan’s versatility makes it applicable across a broad range of industries and use cases. Some of the primary applications include:

1. Industrial Automation

In industrial automation, EPlan is used to design the electrical systems that control machinery and production lines. The software’s ability to integrate with PLC programming tools and its support for creating detailed wiring diagrams make it invaluable in this sector. Engineers can design, simulate, and document the control systems that keep factories running smoothly.

2. Energy and Power Distribution

EPlan is widely used in the energy sector for the design and management of power distribution systems. The software helps engineers create detailed plans for substations, switchgear, and other critical infrastructure components. EPlan’s robust documentation features ensure that all aspects of power distribution are accurately captured and easily accessible for maintenance and troubleshooting.

3. Automotive Industry

In the automotive industry, EPlan is employed to design and document the electrical systems of vehicles, including wiring harnesses, control units, and sensor networks. The software’s ability to handle complex systems and its support for 3D visualization are particularly beneficial in this context, allowing engineers to ensure that every component fits and functions as intended.

4. Building Automation

EPlan is also used in building automation to design and manage the electrical systems that control lighting, HVAC (Heating, Ventilation, and Air Conditioning), and security systems. The software’s integration capabilities ensure that these systems can be designed in conjunction with other building systems, leading to more efficient and effective building management solutions.

Conclusion

EPlan is a comprehensive tool that significantly enhances the efficiency and accuracy of electrical engineering projects. Its rich feature set, combined with its ability to integrate with other systems and disciplines, makes it a vital resource for engineers across various industries. Whether it’s automating repetitive tasks, managing complex data, or ensuring interdisciplinary collaboration, EPlan provides the functionality needed to meet the challenges of modern electrical design.

0 notes

Text

Wiring Harness Terminals & Sheet Metal Components Manufacturer & Supplier in India

Terminals for Wiring Harnesses

We Shubham Industries is well known name in Wiring Harness Terminals manufacturer in Delhi along with Sheet Metal Components Manufacturer in India. Read full article for better understand of our precious products..

The terminals on the wiring harness are the areas where the wire terminates or is connected to other components.

Similar to wire harness connections, the type of termination needed will depend on the intended usage and may have different form, size, and insulation requirements.

Non-insulated terminals are a more cost-effective solution when protection from temperature, moisture, or the environment is not absolutely necessary.

Terminals for Wiring Harnesses

Automotive wiring harnesses terminals must be precisely made with specific application needs in mind, the wire harness design process may be quite customized.

Several wire harnesses need to be concealed in boxes, walls, or other limited spaces. Functionality and safety both depend on a high-quality design.

The extensive list of elements above demonstrates how environmental considerations must be made in wire harness designs.

Top Sheet Metal Components

Sheet metal is used to make many different objects, including the bodywork of automobiles, trucks, and lorries, huge appliances, aeroplane fuselages, and wings, tinplate for tin cans, roofing for buildings (architecture), and many other things.

Iron sheets with laminated steel cores and other high magnetic permeability materials are used in transformers and other electric equipment.

Sheet metal is metal that has undergone industrial processing to create thin, flat pieces. Sheet metal is one of the fundamental components used in metalworking, and it may be bent and cut into a variety of shapes.

As opposed to portions thicker than 6 mm (0.25 in), which are referred to as "plate," such as "plate steel," a form of structural steel, very thin sheets are referred to as "foil" or "leaf." There are wide variations in thickness.

#automitive wiring harness terminal#wiring harness terminal#wiring harness terminal manufacturer#wiring harness terminal manufacturer in Delhi#wiring harness terminal manufacturer in India#automotive#auto parts#Sheet Metal Components#Sheet Metal Components manufacturer#Sheet Metal Components manufacturer in Delhi#Sheet Metal Components manufacturer in India

0 notes

Text

#cut heat shrink#heat shrink factory#shrink technology#shrink tube#shrink sleeve#shrink connector#shrink terminator#assorted kit#red heat shrink#black shrink tube

Union Polymer Material Co.,Ltd.(hereinafter referred to as UPM) is engaged in the R&D, production and sales of heat-shrinkable insulation products, expandable braided sleeve and other functional polymer materials. Focus on providing coverage protection solutions for system components to achieve insulation, waterproof, wear-resistant, impact resistance, color coding, binding, electromagnetic shielding, identification and other functions. The products are mainly used in automobile, military industry, aerospace, telecommunication, electric power, electronics, shipbuilding and other fields.

Products got ISO 9001:2015,IATF 16949:2016,GJB 9001C-2017,ISO 14001:2015,ISO 45001:2018 approval and comply with GJB,CE,UL224,UL486D,CCS,ABS,DNV.

Let's shrink the world together. Let's choose Union Polymer.Contact Lily at upolymer dot com or upmheatshrink at gmail dot com to customized your heat shrink products.

#shrink tubing#heat shrink#upmheat shrink#shrink technology#shrink sleeve#shrink connector#wraparound tube#wire insulation#shrink terminator#assorted kit#red heat shrink#black shrink tube#cable protection#cable assembly#wire harness

0 notes

Text

What is an Electrical Wire Harness

In the maze of modern electronics and electrical applications, streamlining connectivity while ensuring safety and reliability is of paramount importance. This is where an electrical wire harness comes into play, and we, as a leading professional electrical wire harness manufacturer, stand at the vanguard of crafting these pivotal components.

The Vital Role of Electrical Wire Harnesses:

An electrical wire harness is essentially an ensemble of wires or cables that transmit electrical power or signals. Consider it the circulatory system of any electrical system, an organized set of wires, terminals, and connectors that run throughout the device to relay information and electric power. Wire harnesses consolidate multiple cables into a single, manageable bundle, which significantly mitigates the risk of a short and protects the wires from environmental factors and abrasion.

Precision Engineering for Superior Quality

Crafting an electrical wire harness is no trivial task; it requires precision, attention to detail, and a comprehensive understanding of electrical systems. As a specialist electrical wire harness manufacturer, we take pride in our ability to engineer products that are bespoke to each client’s requirements. Our wire harnesses are the epitome of quality and reliability, designed to withstand rigorous use in a myriad of environments.

Employing state-of-the-art technology, our manufacturing process addresses every aspect of wire harness construction wire cutting, stripping, and assembly to the insertion of terminals and the application of seals and sheaths. Each harness is diligently crafted to ensure that it not only fits the specs but exceeds performance expectations time and time again.

A Commitment to Innovation

Leading the industry as a professional manufacturer comes with the responsibility to innovate constantly. Our dedication to research and development ensures that we stay at the forefront of new technologies and emerging needs in the electrical wire harness space. By integrating the latest design techniques and exploring novel materials, we refine our products to offer clients superior solutions that cater to evolving technological landscapes.

We balance the fine line between innovation and practicality, providing wire harnesses that deliver optimal functionality while also paving the way for future advancements in the electronics and electrical sectors.

Our Production Capabilities

Quality production can only be achieved with the right tools and facilities. Our advanced manufacturing infrastructure is the backbone of our world-class harness production. The factory spans a vast area, allowing us to take on projects of all sizes while maintaining impeccable quality control. Our production lines are equipped with the finest machinery, operated by skilled technicians trained to handle the intricacies of wire harness assembly.

Our streamlined processes are not just about efficiency; they are about consistency and precision. This translates to wire harnesses that perform as intended every single time they are integrated into a client’s system.

After-Sales Support You Can Rely On

Delivering an excellent product is only half of the equation for customer satisfaction. We are deeply committed to providing comprehensive after-sales support that ensures your experience with our products is flawless from start to finish. Our dedicated support team is always at hand to respond to queries, provide guidance, and offer any necessary assistance post-purchase to maintain the integrity and performance of your wire harness setup.

Partner with a leader in the field that prioritizes precision, innovation, and customer satisfaction. Allow us to be the driving force behind your next project with top-tier electrical wire harnesses that are unmatched in quality and performance. Trust us to connect the dots, electrify your endeavours, and ensure the seamless operation of your electrical systems with unparalleled attention to detail and dedication.

0 notes

Text

0 notes

Text

H A L C Y O N: Tokio Rhapsody

L O G 3

After playing a game of mahjong, which he utterly lost, Joss excused himself and finally made his way upstairs. Feeling tired Joss kicked open the door and while still walking towards the bed he started chugging the bottle of vodka. His eyes narrowed at the pleasure bots in sleep mode. “Adonis mode, eh? That’s a hard pass thank you very much.” He walked over to the terminal and changed the body type to normal. Satisfied he closed the door and started to undress. He had

milky off-white skin adorned with old battle wounds. He laid on the bed and activated the male and female bots from their operations panel near their backsides.

The female bot had soft features and raven black hair . She was wearing a pastel see-through nighty whose trim was adorned with faux pink fur, while the male wore a gray mesh jockstrap and harness. The female straddled his side kissing him deeply while her hands slowly crept down his broad shoulders, then to his backside and finally within him while the male removed Joss’s briefs slowly and aroused him leaving a trail of saliva cascading down from the bed-sheets to the floor. Suddenly their eyes went red, which Joss immediately took notice of, and then in a jerking motion, their hands folded back revealing a pair of long blades ready to impale the gumshoe. Joss rolled back just in time to see the bots stab each other.

The bots unphased sheathed their blades as Joss said, “it’s not polite to use teeth you know!” Confused the bots cocked their heads and Joss sighed. Then the female bot changed form into that of an arachnid with her head dangling whose visage was akin to Munch’s ‘The Scream’ while the male bot changed form into that of a golem with spikes covering his hardened skin. Popping his knuckles Joss said, “Alright bitches…let’s boogie!” The bots launched evasive maneuvers attacking from both the rear and aerial directions, but Joss avoided the assault with a single step then having noticed their weak spots applied a barrage of precise blows to areas where the

transformations originated. A spray of hydraulic fluid soaked the floor. The male bot grabbed the bottle of vodka with the intent of turning it into a razor-sharp implement, but Joss quickly snatched it away saying, “the booze…really? Today’s bots have no self-respect,” and slung it back on the bed. Again, the duo launched towards Joss with their blades, but the gumshoe easily deflected the strikes. Pinning down the female bot he used the male bots blade and pierced her cranium. Just as quickly his left hand in the shape of a mantis claw grabbed the male bots throat and ripped with such force that the head propped in the air for a few moments and then finally

plummeted with a loud thud. Their eyes went from red to pale blue, pale blue to milky white, and finally colorless.

Quickly he dressed and made his way towards the door. Stopping himself he grabbed the bottle of vodka and chugged the remains and tossed it on the bed. Walking into the foyer with his gun

ready Xian laughed, “Oh, it seems my bots failed. What a pity,” while revealing a garrote wire, “I don’t have much time to play, Joss, so let’s make this quick.” She rushed at him so fast that the paintings on the walls fell from their frames but as if time slowed down Joss pressing his hands on her shoulders propelled himself over her with a single flip and shot off a few rounds in her left arm. Responding in turn with her right arm she threw a dagger which grazed his chiseled face. The two rushed at each other throwing a series of blows with the final connecting with both Joss and Xian. Joss laughed as blood trickled down his cheek. Her face red Xian said, “You won’t be

laughing for long,” while waving the shot glass. “Oh, you poisoned it. I am hardly concerned doll face,” he replied. Tossing the glass in his face and using the chance to charge at him with her laser blade she nearly stabbed him in the chest. Deflecting the tip of the blade against her right arm Xian fell to the ground in agony. “Are we done?” Joss said as he pulled out a set of energy shackles. Kicking herself back a few inches she back-flipped and, in the process, connected with Joss sending him back a step or two. Realizing she was outclassed Xian jumped out the window and seemingly disappeared into the fog of night. “I got to stop drinking with strange women,”

Joss grumbled.

To Be Continued...

Copyright © 2024 All Rights Reserved. By Dhyrek Grigorieva.

#cyberpunk novel#atmopunk#capitalist dystopia#indie works#lgbt author#lgbt pride#vaporwave aesthetic#cyberpunk horror

0 notes

Text

0 notes