#AI For Manufacturing Efficiency

Explore tagged Tumblr posts

Text

Learn how generative AI addresses key manufacturing challenges with predictive maintenance, advanced design optimization, superior quality control, and seamless supply chains.

#Generative AI In Manufacturing#AI-Driven Manufacturing Solutions#AI For Manufacturing Efficiency#Generative AI And Manufacturing Challenges#AI In Manufacturing Processes#Manufacturing Innovation With AI#AI In Production Line Optimization#Generative AI For Quality Control#AI-Based Predictive Maintenance#AI In Supply Chain Management#Generative AI For Defect Detection#AI In Manufacturing Automation#AI-Driven Process Improvements#Generative AI In Factory Operations#AI In Product Design Optimization#AI-Powered Manufacturing Insights

0 notes

Text

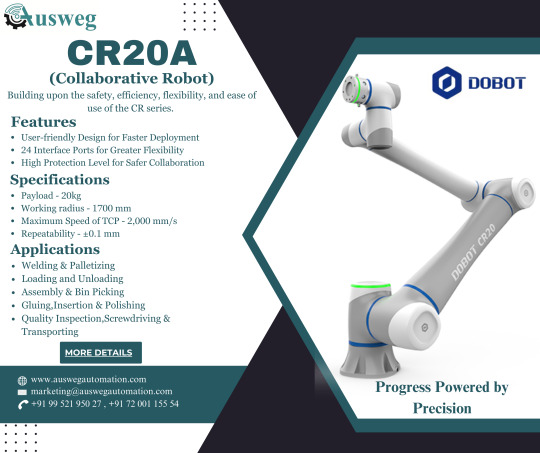

DOBOT CR20A Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com [email protected] +91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes

Text

Webinar | From Bottlenecks to Launchpads: How AI Is Transforming Product Compliance in Manufacturing

Is compliance slowing down your product launch? In this exclusive webinar, Certivo CEO & Founder Kunal Chopra unveils how AI is reshaping compliance from a bottleneck into a launch accelerator.

From eliminating manual document reviews to spotting expired declarations instantly, learn how top manufacturers are using AI to automate regulatory operations, reduce risk, and get audit-ready in hours.

🚀 Watch the full webinar here: https://youtu.be/r0J31TZYvc4

🌐 Learn more: https://www.certivo.com

🔖 Stay #AlwaysCompliant and #AlwaysMarketReady

#AI automation for regulatory compliance workflows#How manufacturers use AI for compliance efficiency#Reduce compliance risk with AI in manufacturing#Compliance automation webinar for supply chain leaders#Audit-ready document validation using AI#PFAS and EUDR compliance automation tools#Streamlining product compliance in medtech and EV#AI-powered compliance ROI for manufacturers#Build supplier risk matrices using AI#7-day pilot for AI compliance implementation

0 notes

Text

The AIoT Revolution: How AI and IoT Convergence is Rewriting the Rules of Industry & Life

Imagine a world where factory machines predict their own breakdowns before they happen. Where city streets dynamically adjust traffic flow in real-time, slashing commute times. Where your morning coffee brews automatically as your smartwatch detects you waking. This isn’t science fiction—it’s the explosive reality of Artificial Intelligence of Things (AIoT), the merger of AI algorithms and IoT ecosystems. At widedevsolution.com, we engineer these intelligent futures daily.

Why AIoT Isn’t Just Buzzword Bingo: The Core Convergence

Artificial Intelligence of Things fuses the sensory nervous system of IoT devices (sensors, actuators, smart gadgets) with the cognitive brainpower of machine learning models and deep neural networks. Unlike traditional IoT—which drowns in raw data—AIoT delivers actionable intelligence.

As Sundar Pichai, CEO of Google, asserts:

“We are moving from a mobile-first to an AI-first world. The ability to apply AI and machine learning to massive datasets from connected devices is unlocking unprecedented solutions.”

The AIoT Trinity: Trends Reshaping Reality

1. Predictive Maintenance: The Death of Downtime Gone are days of scheduled check-ups. AI-driven predictive maintenance analyzes sensor data intelligence—vibrations, temperature, sound patterns—to forecast failures weeks in advance.

Real-world impact: Siemens reduced turbine failures by 30% using AI anomaly detection on industrial IoT applications.

Financial upside: McKinsey estimates predictive maintenance cuts costs by 20% and downtime by 50%.

2. Smart Cities: Urban Landscapes with a Brain Smart city solutions leverage edge computing and real-time analytics to optimize resources. Barcelona’s AIoT-powered streetlights cut energy use by 30%. Singapore uses AI traffic prediction to reduce congestion by 15%.

Core Tech Stack:

Distributed sensor networks monitoring air/water quality

Computer vision systems for public safety

AI-powered energy grids balancing supply/demand

3. Hyper-Personalized Experiences: The End of One-Size-Fits-All Personalized user experiences now anticipate needs. Think:

Retail: Nike’s IoT-enabled stores suggest shoes based on past purchases and gait analysis.

Healthcare: Remote patient monitoring with wearable IoT detects arrhythmias before symptoms appear.

Sectoral Shockwaves: Where AIoT is Moving the Needle

🏥 Healthcare: From Treatment to Prevention Healthcare IoT enables continuous monitoring. AI-driven diagnostics analyze data from pacemakers, glucose monitors, and smart inhalers. Results?

45% fewer hospital readmissions (Mayo Clinic study)

Early detection of sepsis 6+ hours faster (Johns Hopkins AIoT model)

🌾 Agriculture: Precision Farming at Scale Precision agriculture uses soil moisture sensors, drone imagery, and ML yield prediction to boost output sustainably.

Case Study: John Deere’s AIoT tractors reduced water usage by 40% while increasing crop yields by 15% via real-time field analytics.

🏭 Manufacturing: The Zero-Waste Factory Manufacturing efficiency soars with AI-powered quality control and autonomous supply chains.

Data Point: Bosch’s AIoT factories achieve 99.9985% quality compliance and 25% faster production cycles through automated defect detection.

Navigating the Minefield: Challenges in Scaling AIoT

Even pioneers face hurdles:ChallengeSolutionData security in IoTEnd-to-end encryption + zero-trust architectureSystem interoperabilityAPI-first integration frameworksAI model driftContinuous MLOps monitoringEnergy constraintsTinyML algorithms for low-power devices

As Microsoft CEO Satya Nadella warns:

“Trust is the currency of the AIoT era. Without robust security and ethical governance, even the most brilliant systems will fail.”

How widedevsolution.com Engineers Tomorrow’s AIoT

At widedevsolution.com, we build scalable IoT systems that turn data deluge into profit. Our recent projects include:

A predictive maintenance platform for wind farms, cutting turbine repair costs by $2M/year.

An AI retail personalization engine boosting client sales conversions by 34%.

Smart city infrastructure reducing municipal energy waste by 28%.

We specialize in overcoming edge computing bottlenecks and designing cyber-physical systems with military-grade data security in IoT.

The Road Ahead: Your AIoT Action Plan

The AIoT market will hit $1.2T by 2030 (Statista). To lead, not follow:

Start small: Pilot sensor-driven process optimization in one workflow.

Prioritize security: Implement hardware-level encryption from day one.

Democratize data: Use low-code AI platforms to empower non-technical teams.

The Final Byte We stand at an inflection point. Artificial Intelligence of Things isn’t merely connecting devices—it’s weaving an intelligent fabric across our physical reality. From farms that whisper their needs to algorithms, to factories that self-heal, to cities that breathe efficiently, AIoT transforms data into wisdom.

The question isn’t if this revolution will impact your organization—it���s when. Companies leveraging AIoT integration today aren’t just future-proofing; they’re rewriting industry rulebooks. At widedevsolution.com, we turn convergence into competitive advantage. The machines are learning. The sensors are watching. The future is responding.

“The greatest achievement of AIoT won’t be smarter gadgets—it’ll be fundamentally reimagining how humanity solves its hardest problems.” — widedevsolution.com AI Lab

#artificial intelligence#predictive maintenance#smart city solutions#manufacturing efficiency#AI-powered quality control in manufacturing#edge computing for IoT security#scalable IoT systems for agriculture#AIoT integration#sensor data intelligence#ML yield prediction#cyber-physical#widedevsolution.com

0 notes

Text

IoT in Action: Transforming Industries with Intelligent Connectivity

The Power of Connectivity

The Internet of Things (IoT) has become a cornerstone of innovation, as it reimagines industries and redefines the way business is conducted. In bridging the physical and digital worlds, IoT enables seamless connectivity, smarter decision-making, and unprecedented efficiency. Today, in the competitive landscape, intelligent connectivity is no longer just a technology advancement; for businesses wanting to be relevant and continue to thrive, it is now a strategic imperative.

IoT is not simply about connecting devices; it’s about creating ecosystems that work collaboratively to drive value. With industries relying heavily on real-time data and actionable insights, IoT-powered connectivity has become the backbone of operational excellence and growth. Let’s explore how this transformative technology is revolutionizing key sectors, with a focus on how businesses can leverage it effectively.

Applications of IoT in Key Industries

1.Smart Manufacturing: Efficiency Through Connectivity

Manufacturing has embraced IoT as a tool to streamline operations and boost productivity. By embedding sensors in machinery and integrating real-time monitoring systems, manufacturers can:

Predict and Prevent Downtime: IoT-enabled predictive maintenance reduces unplanned outages, saving time and money.

Optimize Resource Allocation: Smart systems track inventory, raw materials, and energy consumption, ensuring optimal usage.

Enhance Quality Control: Real-time data from production lines helps identify defects early, maintaining high-quality standards.

Example: A global automotive manufacturer integrated IoT sensors into its assembly lines, reducing equipment downtime by 25% and improving production efficiency by 30%. The ability to monitor machinery health in real time transformed their operations, delivering significant cost savings.

2.Healthcare: Improve Patient Outcomes

In healthcare, IoT has been a game-changer in enabling connected medical devices and systems that enhance patient care and operational efficiency. The main applications include:

Remote Patient Monitoring: Devices track vital signs in real time, allowing healthcare providers to offer timely interventions.

Smart Hospital Systems: IoT-enabled equipment and sensors optimize resource utilization, from patient beds to medical supplies.

Data-Driven Decisions: IoT integrates patient data across systems, providing actionable insights for personalized treatment plans.

Example: A major hospital has put into operation IoT-enabled wearables for chronic disease management. This solution reduced the number of readmissions to hospitals by 20% and empowered patients to take an active role in their health.

3.Retail: Revolutionizing Customer Experiences

IoT is revolutionizing retail through increased customer interaction and streamlined operations. Connected devices and smart analytics allow retailers to:

Personalize Shopping Experiences: IoT systems track customer preferences, offering tailored recommendations in real time.

Improve Inventory Management: Smart shelves and sensors keep stock levels optimal, reducing wastage and improving availability.

Enable Smooth Transactions: IoT-driven payment systems make checkout easier and much faster, increasing customers’ convenience

Example: A retail chain leveraged IoT to integrate smart shelves that automatically update inventory data. This reduced out-of-stock situations by 40%, improving customer satisfaction and driving higher sales.

Role of Intelligent Connectivity in Business Transformation

Intelligent connectivity lies at the heart of IoT’s transformative potential. By connecting devices, systems, and processes, businesses can:

Accelerate Decision-Making: Real-time data sharing enables faster, more informed decisions, giving companies a competitive edge.

It increases collaboration by allowing smooth communication between departments and teams, making the entire system more efficient.

Adapt to Market Dynamics: IoT enables companies to respond quickly to changes in demand, supply chain disruptions, or operational challenges.

Intelligent connectivity is not just about technology; it’s about creating value by aligning IoT solutions with business objectives. This strategic approach guarantees that IoT investments will deliver measurable outcomes, from cost savings to improved customer loyalty.

How Tudip Technologies Powers Intelligent Connectivity

Tudip Technologies specializes in designing and implementing IoT solutions that drive meaningful transformation for businesses. With a focus on innovation and collaboration, Tudip ensures that its clients achieve operational excellence through intelligent connectivity.

Tailored Solution for Every Business Industry

Tudip understands that no two businesses are alike. By customizing IoT strategies to address specific challenges, Tudip helps clients unlock the full potential of connectivity. Examples include:

Smart Supply Chains: Implementing IoT systems that provide real-time visibility into inventory and logistics, reducing delays and improving efficiency.

Energy Management: Developing IoT frameworks to monitor and optimize energy usage, driving sustainability and cost savings.

Healthcare Innovations: Designing networked medical devices that allow remote patient monitoring and data integration without a hitch.

The Future of Connected Systems

The demand for intelligent connectivity will keep increasing as the industries continue to evolve. Emerging trends in IoT include edge computing, 5G networks, and AI-powered analytics, which promise to redefine possibilities for connected ecosystems.

Businesses that embrace these advancements stand to gain:

Greater Resilience: IoT enables adaptive systems that can withstand market fluctuations and operational challenges.

Enhanced Innovation: Connected technologies open doors to new business models, revenue streams, and customer experiences.

Sustainable Growth: IoT optimizes resources and processes, contributing to long-term environmental and economic sustainability.

The future belongs to those who see connectivity not just as a technological tool but as a strategic enabler of transformation. The right partner will help businesses transform IoT from a concept into a competitive advantage.

Conclusion: Embracing Intelligent Connectivity with Tudip

IoT is not just changing the way businesses operate—it’s redefining what’s possible. From manufacturing and healthcare to retail and beyond, intelligent connectivity is driving innovation, efficiency, and growth across industries.

Tudip Technologies is at the forefront of this transformation, offering customized IoT solutions that deliver real results. By prioritizing collaboration, adaptability, and measurable outcomes, Tudip ensures that its clients stay ahead in an increasingly connected world.

Now is the time to embrace the power of IoT and unlock its potential for your business. With Tudip as your partner, the journey to intelligent connectivity is not just achievable—it’s inevitable.

Click the link below to learn more about the blog IoT in Action: Transforming Industries with Intelligent Connectivity https://tudip.com/blog-post/iot-in-action-transforming-industries-with-intelligent-connectivity/

#Tudip#IoT#intelligent connectivity#real-time data#predictive maintenance#smart manufacturing#remote patient monitoring#healthcare IoT#retail IoT#smart shelves#supply chain optimization#edge computing#AI-powered analytics#5G networks#industrial IoT#connected devices#digital transformation#operational efficiency#business intelligence#automation#data-driven decision-making#IoT solutions#smart systems#enterprise IoT#IoT-powered connectivity#sustainable growth#technology innovation#machine learning#cloud computing#smart sensors

0 notes

Text

AI-Powered Predictive Maintenance in Pharmaceutical Manufacturing

In pharmaceutical manufacturing, keeping machines running smoothly is essential for producing high-quality medicines. Traditional maintenance methods, like fixing machines after they break or scheduling routine checkups, can lead to unexpected failures or unnecessary repairs. AI-powered predictive maintenance is changing this by helping manufacturers prevent problems before they happen, saving time and money.

#AI development company in Dallas#Artificial Intelligence#AI-powered predictive maintenance#Manufacturing efficiency#Preventive maintenance#AI-based software development

0 notes

Text

Machine learning applications in semiconductor manufacturing

Machine Learning Applications in Semiconductor Manufacturing: Revolutionizing the Industry

The semiconductor industry is the backbone of modern technology, powering everything from smartphones and computers to autonomous vehicles and IoT devices. As the demand for faster, smaller, and more efficient chips grows, semiconductor manufacturers face increasing challenges in maintaining precision, reducing costs, and improving yields. Enter machine learning (ML)—a transformative technology that is revolutionizing semiconductor manufacturing. By leveraging ML, manufacturers can optimize processes, enhance quality control, and accelerate innovation. In this blog post, we’ll explore the key applications of machine learning in semiconductor manufacturing and how it is shaping the future of the industry.

Predictive Maintenance

Semiconductor manufacturing involves highly complex and expensive equipment, such as lithography machines and etchers. Unplanned downtime due to equipment failure can cost millions of dollars and disrupt production schedules. Machine learning enables predictive maintenance by analyzing sensor data from equipment to predict potential failures before they occur.

How It Works: ML algorithms process real-time data from sensors, such as temperature, vibration, and pressure, to identify patterns indicative of wear and tear. By predicting when a component is likely to fail, manufacturers can schedule maintenance proactively, minimizing downtime.

Impact: Predictive maintenance reduces equipment downtime, extends the lifespan of machinery, and lowers maintenance costs.

Defect Detection and Quality Control

Defects in semiconductor wafers can lead to significant yield losses. Traditional defect detection methods rely on manual inspection or rule-based systems, which are time-consuming and prone to errors. Machine learning, particularly computer vision, is transforming defect detection by automating and enhancing the process.

How It Works: ML models are trained on vast datasets of wafer images to identify defects such as scratches, particles, and pattern irregularities. Deep learning algorithms, such as convolutional neural networks (CNNs), excel at detecting even the smallest defects with high accuracy.

Impact: Automated defect detection improves yield rates, reduces waste, and ensures consistent product quality.

Process Optimization

Semiconductor manufacturing involves hundreds of intricate steps, each requiring precise control of parameters such as temperature, pressure, and chemical concentrations. Machine learning optimizes these processes by identifying the optimal settings for maximum efficiency and yield.

How It Works: ML algorithms analyze historical process data to identify correlations between input parameters and output quality. Techniques like reinforcement learning can dynamically adjust process parameters in real-time to achieve the desired outcomes.

Impact: Process optimization reduces material waste, improves yield, and enhances overall production efficiency.

Yield Prediction and Improvement

Yield—the percentage of functional chips produced from a wafer—is a critical metric in semiconductor manufacturing. Low yields can result from various factors, including process variations, equipment malfunctions, and environmental conditions. Machine learning helps predict and improve yields by analyzing complex datasets.

How It Works: ML models analyze data from multiple sources, including process parameters, equipment performance, and environmental conditions, to predict yield outcomes. By identifying the root causes of yield loss, manufacturers can implement targeted improvements.

Impact: Yield prediction enables proactive interventions, leading to higher productivity and profitability.

Supply Chain Optimization

The semiconductor supply chain is highly complex, involving multiple suppliers, manufacturers, and distributors. Delays or disruptions in the supply chain can have a cascading effect on production schedules. Machine learning optimizes supply chain operations by forecasting demand, managing inventory, and identifying potential bottlenecks.

How It Works: ML algorithms analyze historical sales data, market trends, and external factors (e.g., geopolitical events) to predict demand and optimize inventory levels. Predictive analytics also helps identify risks and mitigate disruptions.

Impact: Supply chain optimization reduces costs, minimizes delays, and ensures timely delivery of materials.

Advanced Process Control (APC)

Advanced Process Control (APC) is critical for maintaining consistency and precision in semiconductor manufacturing. Machine learning enhances APC by enabling real-time monitoring and control of manufacturing processes.

How It Works: ML models analyze real-time data from sensors and equipment to detect deviations from desired process parameters. They can automatically adjust settings to maintain optimal conditions, ensuring consistent product quality.

Impact: APC improves process stability, reduces variability, and enhances overall product quality.

Design Optimization

The design of semiconductor devices is becoming increasingly complex as manufacturers strive to pack more functionality into smaller chips. Machine learning accelerates the design process by optimizing chip layouts and predicting performance outcomes.

How It Works: ML algorithms analyze design data to identify patterns and optimize layouts for performance, power efficiency, and manufacturability. Generative design techniques can even create novel chip architectures that meet specific requirements.

Impact: Design optimization reduces time-to-market, lowers development costs, and enables the creation of more advanced chips.

Fault Diagnosis and Root Cause Analysis

When defects or failures occur, identifying the root cause can be challenging due to the complexity of semiconductor manufacturing processes. Machine learning simplifies fault diagnosis by analyzing vast amounts of data to pinpoint the source of problems.

How It Works: ML models analyze data from multiple stages of the manufacturing process to identify correlations between process parameters and defects. Techniques like decision trees and clustering help isolate the root cause of issues.

Impact: Faster fault diagnosis reduces downtime, improves yield, and enhances process reliability.

Energy Efficiency and Sustainability

Semiconductor manufacturing is energy-intensive, with significant environmental impacts. Machine learning helps reduce energy consumption and improve sustainability by optimizing resource usage.

How It Works: ML algorithms analyze energy consumption data to identify inefficiencies and recommend energy-saving measures. For example, they can optimize the operation of HVAC systems and reduce idle time for equipment.

Impact: Energy optimization lowers operational costs and reduces the environmental footprint of semiconductor manufacturing.

Accelerating Research and Development

The semiconductor industry is driven by continuous innovation, with new materials, processes, and technologies being developed regularly. Machine learning accelerates R&D by analyzing experimental data and predicting outcomes.

How It Works: ML models analyze data from experiments to identify promising materials, processes, or designs. They can also simulate the performance of new technologies, reducing the need for physical prototypes.

Impact: Faster R&D cycles enable manufacturers to bring cutting-edge technologies to market more quickly.

Challenges and Future Directions

While machine learning offers immense potential for semiconductor manufacturing, there are challenges to overcome. These include the need for high-quality data, the complexity of integrating ML into existing workflows, and the shortage of skilled professionals. However, as ML technologies continue to evolve, these challenges are being addressed through advancements in data collection, model interpretability, and workforce training.

Looking ahead, the integration of machine learning with other emerging technologies, such as the Internet of Things (IoT) and digital twins, will further enhance its impact on semiconductor manufacturing. By embracing ML, manufacturers can stay competitive in an increasingly demanding and fast-paced industry.

Conclusion

Machine learning is transforming semiconductor manufacturing by enabling predictive maintenance, defect detection, process optimization, and more. As the industry continues to evolve, ML will play an increasingly critical role in driving innovation, improving efficiency, and ensuring sustainability. By harnessing the power of machine learning, semiconductor manufacturers can overcome challenges, reduce costs, and deliver cutting-edge technologies that power the future.

This blog post provides a comprehensive overview of machine learning applications in semiconductor manufacturing. Let me know if you’d like to expand on any specific section or add more details!

#semiconductor manufacturing#Machine learning in semiconductor manufacturing#AI in semiconductor industry#Predictive maintenance in chip manufacturing#Defect detection in semiconductor wafers#Semiconductor process optimization#Yield prediction in semiconductor manufacturing#Advanced Process Control (APC) in semiconductors#Semiconductor supply chain optimization#Fault diagnosis in chip manufacturing#Energy efficiency in semiconductor production#Deep learning for semiconductor defects#Computer vision in wafer inspection#Reinforcement learning in semiconductor processes#Semiconductor yield improvement using AI#Smart manufacturing in semiconductors#AI-driven semiconductor design#Root cause analysis in chip manufacturing#Sustainable semiconductor manufacturing#IoT in semiconductor production#Digital twins in semiconductor manufacturing

0 notes

Text

Generative AI in Drug Manufacturing: Revolutionizing the Pharmaceutical Industry

The pharmaceutical industry is on the brink of a technological revolution, thanks to the advent of generative artificial intelligence (AI). This cutting-edge technology is transforming drug manufacturing by enhancing efficiency, reducing costs, and accelerating the development of life-saving medications. In this article, we will explore the impact of generative AI on drug manufacturing. We will…

#competitive landscape#drug discovery#drug manufacturing#efficiency#ethical considerations#Generative AI#Innovation#pharmaceutical industry#quality content#quality control#transformative potential

0 notes

Text

AI in Manufacturing Operational Efficiency 2025

Artificial intelligence (AI) is revolutionizing the manufacturing sector by driving operational efficiency to new heights. From automating repetitive tasks to enabling real-time decision-making, AI is reshaping how manufacturing processes are executed. With the demand for smarter factories and leaner operations, companies are turning to AI to stay competitive. In this article, we explore how AI in manufacturing operational efficiency in 2025, key use cases, and the transformative benefits it offers.

The Role of AI in Manufacturing Operational Efficiency 2025

AI-powered solutions are pivotal in addressing the complexities of modern manufacturing. By integrating AI into operations, manufacturers can achieve predictive maintenance, improve quality control, and streamline supply chain processes. This leads to cost reduction, enhanced productivity, and minimized downtime.

Benefits of AI in Manufacturing 2025

Predictive Maintenance: AI algorithms analyze machine data to predict failures before they occur, reducing unplanned downtime.

Quality Control: Machine learning models detect defects in real-time, ensuring consistent product quality.

Supply Chain Optimization: AI enhances inventory management, demand forecasting, and supplier coordination.

Energy Efficiency: AI optimizes energy consumption by adjusting processes to real-time demands.

Human-Machine Collaboration: AI-powered tools empower workers with actionable insights, enhancing productivity and safety.

Key AI Applications in Manufacturing 2025

1. Predictive Maintenance

Predictive maintenance uses AI to monitor equipment performance and anticipate potential failures. Sensors embedded in machines collect real-time data, which AI models analyze to identify anomalies and predict when maintenance is needed. This reduces unexpected breakdowns and maintenance costs.

2. Quality Assurance

AI-powered computer vision systems inspect products for defects with greater accuracy than human inspectors. These systems can process thousands of images per second, identifying flaws invisible to the naked eye and ensuring consistent quality standards.

3. Supply Chain Management

AI streamlines supply chain operations by predicting demand, managing inventory, and optimizing logistics. This reduces lead times and ensures the availability of materials, enhancing operational efficiency.

4. Robotics and Automation

AI-driven robots handle complex tasks such as assembly, welding, and material handling. These robots adapt to changing conditions and learn from their environment, boosting flexibility and precision in manufacturing.

5. Energy Optimization

AI analyzes energy consumption patterns to identify inefficiencies. By adjusting machine operations and production schedules, manufacturers can significantly reduce energy usage and costs.

The Impact of AI on Operational Efficiency 2025

Enhanced Decision-Making

AI provides real-time insights that enable manufacturers to make informed decisions quickly. By analyzing vast amounts of data, AI identifies trends and patterns that humans might overlook.

Reduced Waste

AI optimizes resource utilization, reducing waste and lowering production costs. Smart systems adjust processes dynamically to minimize material wastage.

Improved Customer Satisfaction

By ensuring consistent product quality and timely deliveries, AI helps manufacturers meet customer expectations. Predictive analytics also enable personalized customer solutions.

Scalability

AI enables manufacturers to scale operations efficiently by automating repetitive tasks and optimizing workflows. This allows companies to meet growing demand without compromising quality or increasing costs.

Challenges and Solutions in Implementing AI

Data Management

AI systems require vast amounts of high-quality data for training. Manufacturers must invest in data collection and management systems to ensure reliable outcomes.

Integration with Legacy Systems

Integrating AI with existing infrastructure can be challenging. Partnering with experienced AI solution providers helps ensure seamless integration.

Workforce Training

Adopting AI requires upskilling employees to work alongside AI tools. Offering training programs ensures a smooth transition to AI-driven workflows.

The Future of AI in Manufacturing 2025

The adoption of AI in manufacturing is expected to grow exponentially. Emerging technologies such as generative AI, digital twins, and edge computing will further enhance operational efficiency. Companies that embrace AI will gain a competitive edge, driving innovation and sustainability in the manufacturing sector.

Challenges include data management, integration with legacy systems, and workforce training. Addressing these issues requires strategic planning and partnering with AI solution providers.

AI is transforming manufacturing by unlocking new levels of operational efficiency in 2025. From predictive maintenance to energy optimization, the possibilities are vast. By embracing AI, manufacturers can future-proof their operations and drive sustainable growth.

Content Source - https://tagbinnews.blogspot.com/2025/01/ai-in-manufacturing-operational.html

#tagbin#writers on tumblr#artificial intelligence#AI in Manufacturing Operational Efficiency 2025#AI in Manufacturing#Manufacturing Operational Efficiency#Artificial Intelligence in Manufacturing 2025#Predictive Maintenance with AI#AI-powered Quality Control#AI for Supply Chain Management#Robotics in Manufacturing 2025#Future of Manufacturing with AI#AI and Manufacturing Trends 2025#tumblr

0 notes

Text

AI in Manufacturing: Driving Operational Efficiency to New Heights

In an era where industries are under constant pressure to innovate, reduce costs, and enhance productivity, AI in manufacturing operational efficiency is emerging as a game-changer. By harnessing artificial intelligence, manufacturers can optimize operations, improve quality, and make smarter decisions. This article explores the transformative role of AI in manufacturing and how it’s redefining operational efficiency.

What is AI in Manufacturing Operational Efficiency?

AI in manufacturing operational efficiency refers to the use of artificial intelligence to streamline manufacturing processes. From predictive maintenance to real-time monitoring and process automation, AI is reshaping every aspect of the manufacturing cycle.

By analyzing vast amounts of data, AI can identify inefficiencies, predict equipment failures, and optimize workflows, leading to cost savings and increased productivity.

Key Benefits of AI in Manufacturing Operational Efficiency

1. Predictive Maintenance

AI-powered systems monitor equipment in real-time, predicting potential failures before they occur. This reduces unplanned downtime and ensures continuous production.

Example: AI uses IoT sensors to detect anomalies in machine performance.

Benefit: Extends the lifespan of equipment while minimizing maintenance costs.

2. Improved Quality Control

AI can inspect products with a level of precision that surpasses human capabilities. By identifying defects early, manufacturers can maintain high-quality standards and reduce waste.

Tools like computer vision analyze images to spot flaws in products.

Result: Enhanced customer satisfaction and brand reputation.

3. Supply Chain Optimization

AI streamlines supply chain management by forecasting demand, tracking inventory, and optimizing logistics. This leads to better resource allocation and reduced operational costs.

Use Case: AI predicts raw material requirements, preventing overstocking or shortages.

4. Energy Efficiency

Manufacturers use AI to monitor and control energy consumption, ensuring sustainability without compromising output.

Example: AI adjusts energy usage based on production demands.

Benefit: Reduces utility bills and carbon footprint.

5. Enhanced Worker Safety

AI systems, such as robotics and wearable devices, improve worker safety by performing hazardous tasks and monitoring workplace conditions.

AI-enabled robots handle toxic substances or heavy lifting.

Wearables alert workers about unsafe environments.

Applications of AI in Manufacturing

1. Process Automation

AI automates repetitive and time-consuming tasks, such as assembly, sorting, and packaging. This not only speeds up production but also reduces human error.

Example: Robotic Process Automation (RPA) for routine tasks.

Benefit: Frees up human workers for more strategic roles.

2. Digital Twins

A digital twin is a virtual replica of a manufacturing process or system. AI analyzes these replicas to test scenarios, identify inefficiencies, and optimize operations.

Example: A digital twin of a factory floor predicts bottlenecks before they occur.

3. Real-Time Data Analytics

AI processes real-time data from sensors and devices across the factory, providing actionable insights to optimize workflows and reduce delays.

Example: An AI dashboard identifies underperforming machinery and suggests corrective actions.

4. AI-Driven Design

AI accelerates product design by simulating different designs, materials, and manufacturing techniques.

Example: Generative design algorithms propose optimal product designs.

Benefit: Reduces development time and costs.

Real-World Examples of AI in Manufacturing

1. General Electric (GE)

GE uses AI-powered tools to predict equipment failures, reducing downtime in their manufacturing plants. This has resulted in millions in cost savings annually.

2. Tesla

Tesla integrates AI in its production lines for quality control and automation. AI-driven robots handle welding, painting, and assembly with precision and consistency.

3. Siemens

Siemens employs AI to optimize production schedules and manage supply chains efficiently. Their AI tools also monitor energy consumption, improving sustainability.

How to Implement AI for Operational Efficiency

Step 1: Assess Current Operations

Evaluate areas where inefficiencies exist. Focus on bottlenecks, high failure rates, or repetitive tasks that could benefit from AI intervention.

Step 2: Choose the Right AI Tools

Identify tools tailored to your needs, such as predictive maintenance software, AI-powered robotics, or supply chain analytics platforms.

Step 3: Train Your Workforce

Equip your team with the skills to work alongside AI systems. Conduct workshops and provide ongoing training to ensure seamless adoption.

Step 4: Monitor and Optimize

Continuously measure the impact of AI tools and refine processes based on data-driven insights.

Challenges in Implementing AI in Manufacturing

While the potential of AI is vast, there are challenges that manufacturers must address:

1. High Initial Investment

AI systems can be expensive to implement, especially for small and medium-sized enterprises.

2. Data Privacy Concerns

AI relies on vast amounts of data, raising concerns about data security and compliance.

3. Workforce Resistance

Employees may fear job displacement due to automation. Clear communication and upskilling initiatives are crucial.

The Future of AI in Manufacturing Operational Efficiency

As AI technologies advance, manufacturers can expect even greater benefits, such as:

Autonomous Factories: Fully automated production lines with minimal human intervention.

AI-Powered Customization: Tailored production based on real-time customer data.

Advanced Robotics: Smarter robots capable of learning and adapting to new tasks.

AI will also play a key role in achieving sustainability goals, reducing waste, and creating eco-friendly production processes.

Conclusion

The integration of AI in manufacturing operational efficiency is not just a technological upgrade; it’s a transformative shift that drives productivity, reduces costs, and enhances competitiveness. From predictive maintenance to supply chain optimization, AI empowers manufacturers to achieve unparalleled efficiency and agility.

For businesses willing to embrace AI, the potential rewards are immense. As the manufacturing landscape evolves, AI will continue to be the cornerstone of innovation, enabling smarter, faster, and greener production processes.

Content Source -

1 note

·

View note

Text

#Automated Technology Group#industrial automation#innovation in automation#Industry 4.0#IoT integration#smart robotics#predictive maintenance#green automation#automation solutions#automation in manufacturing#automation trends 2024#sustainable automation#AI in automation#collaborative robots#automation success stories#future of work#advanced automation systems#automation market growth#automation technology#industrial efficiency

0 notes

Text

Improve Your Manufacturing Workflows with ZBrain!

In today’s fast-paced industrial landscape, optimizing manufacturing workflows is crucial. ZBrain harnesses the power of AI and data analytics to streamline processes, reduce waste, and enhance productivity. Imagine a system that can predict bottlenecks, automate repetitive tasks, and provide real-time insights into your operations. With ZBrain, companies can make informed decisions, boost efficiency, and ultimately drive profitability.

Ready to revolutionize your manufacturing process?

👉 Read more about how ZBrain can transform your workflows! 👈

0 notes

Text

Looking to improve your manufacturing workflows? 🚀 ZBrain is your solution! By leveraging AI-powered insights and automation, ZBrain helps optimize production lines, reduce downtime, and streamline processes. Whether you’re handling small-batch production or managing large-scale operations, ZBrain can integrate with your current systems, ensuring efficiency and cost savings. With real-time analytics and predictive maintenance, you can stay ahead of potential disruptions and keep your manufacturing running smoothly. Start transforming your workflow today with ZBrain!

👉 Read more about how ZBrain can revolutionize your production process.

0 notes

Text

IoT Solutions in Manufacturing Solutions by Mobiloitte

#Advanced Manufacturing Solutions#Manufacturing Innovation#Manufacturing Technology#Smart Manufacturing#Industrial Automation#Manufacturing Efficiency#Production Optimization#Digital Manufacturing#Manufacturing Industry Solutions#Robotics in Manufacturing#AI in Manufacturing#Manufacturing Process Improvement#IoT in Manufacturing#Manufacturing Software#Global Manufacturing Innovation#Advanced Production Techniques.

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

Innovative Solutions: AI Automation and Manufacturing Efficiency

Did you know that the adoption of AI in manufacturing is projected to contribute over $1.2 Trillion in added value to the global economy by 2030? This staggering statistic highlights the transformative potential of AI technologies in reshaping manufacturing processes.

Manufacturing has always been at the forefront of technological advancements, driving efficiency and productivity. However, despite significant progress, the industry still grapples with numerous challenges. From managing complex supply chains to maintaining high-quality standards and ensuring worker safety, manufacturers face a constant battle to optimize their operations and reduce costs. Traditional methods often fall short in addressing these multifaceted issues, leading to inefficiencies and increased operational expenses.

Enter AI automation—a game-changer poised to revolutionize the manufacturing landscape. By leveraging advanced technologies such as machine learning, robotics, and computer vision, AI automation promises to streamline processes, enhance quality control, and drive unprecedented levels of efficiency. In this blog, we will explore how AI is transforming manufacturing, offering tangible benefits, and paving the way for a smarter, more agile industry.

Benefits of AI Automation in Manufacturing

In today’s competitive manufacturing landscape, harnessing the power of AI automation offers unparalleled advantages across various facets of operations. From enhancing efficiency and reducing costs to ensuring stringent quality control and improving worker safety, AI is reshaping the industry in profound ways.

Increased Efficiency: How AI Improves Process Efficiency

AI-driven technologies excel in optimizing manufacturing processes by analyzing vast amounts of data and making real-time adjustments. This capability leads to:

AI-Driven Scheduling: AI algorithms can dynamically adjust production schedules based on real-time demand forecasts, machine availability, and resource allocation. This ensures optimal use of equipment and manpower, reducing downtime and enhancing overall productivity.

Workflow Optimization: AI systems streamline workflows by identifying bottlenecks and inefficiencies. By continuously analyzing data from sensors and production metrics, AI can suggest process improvements and automate routine tasks, allowing human workers to focus on more complex and value-added activities.

Cost Reduction: Cost-Saving Aspects of AI Automation

Implementing AI in manufacturing yields significant cost savings through various mechanisms:

Reduction in Labor Costs: AI-powered automation minimizes the need for manual intervention in repetitive tasks, thereby reducing labor costs associated with assembly line operations and routine maintenance.

Minimizing Waste and Errors: AI enhances precision in manufacturing processes, leading to fewer defects and lower material wastage. Machine learning algorithms can detect anomalies in production lines early, preventing costly errors and optimizing resource utilization.

Enhanced Quality Control: AI’s Role in Maintaining High-Quality Standards

Quality control is paramount in manufacturing, and AI technologies play a pivotal role in ensuring consistent product quality:

Real-Time Monitoring: AI-enabled sensors and monitoring systems continuously track production metrics and product parameters. Any deviations from predefined standards trigger immediate alerts, allowing for prompt corrective actions to maintain quality.

Predictive Maintenance: AI algorithms predict equipment failures based on historical data and real-time performance metrics. This proactive approach minimizes unplanned downtime, extends equipment lifespan, and ensures uninterrupted production schedules.

Improved Safety: Enhancing Worker Safety Through AI

AI enhances workplace safety by automating hazardous tasks and implementing advanced safety protocols:

Automation of Hazardous Tasks: Dangerous operations, such as handling hazardous materials or operating heavy machinery, can be automated using AI-driven robotics. This reduces the risk of workplace accidents and minimizes exposure of workers to unsafe conditions.

AI-Driven Safety Protocols and Monitoring: AI systems analyze environmental data, employee movements, and equipment conditions to identify potential safety hazards. Automated safety protocols, such as emergency shutdowns or alerts for unsafe behaviors, enhance overall workplace safety standards.

AI automation represents a transformative force in the manufacturing industry, offering tangible benefits ranging from increased efficiency and cost reduction to enhanced quality control and improved worker safety. As AI technologies continue to evolve, their integration into manufacturing processes will further optimize operations, drive innovation, and propel the industry toward greater competitiveness and sustainability.

Key AI Technologies in Manufacturing

AI technologies such as machine learning, robotics, computer vision, and natural language processing (NLP) are revolutionizing manufacturing by enhancing efficiency, precision, and adaptability. Let’s explore how these technologies are reshaping the industry.

Machine Learning: How Machine Learning Algorithms Optimize Manufacturing Processes

Machine learning (ML) algorithms play a crucial role in optimizing various aspects of manufacturing operations:

Predictive Analytics: ML models analyze historical data to predict equipment failures, maintenance needs, and production bottlenecks. By foreseeing potential issues, manufacturers can proactively adjust schedules and resources, minimizing downtime and optimizing productivity.

Demand Forecasting: ML algorithms analyze market trends, historical sales data, and external factors to predict future demand accurately. This enables manufacturers to optimize inventory levels, streamline supply chain management, and meet customer demands more efficiently.

Robotics and Automation: Advanced Robotics in Manufacturing

Robotics and automation systems leverage AI to perform tasks traditionally done by human workers, enhancing speed, accuracy, and safety:

Collaborative Robots (Cobots): Cobots work alongside human operators, enhancing production line flexibility and efficiency. They assist in tasks requiring precision and dexterity, such as assembly and packaging while ensuring safe interaction with human coworkers.

Automated Guided Vehicles (AGVs): AGVs navigate manufacturing facilities autonomously, transporting materials and finished products between workstations. AI algorithms enable AGVs to adapt to dynamic environments, optimizing logistical processes and reducing manual handling.

Computer Vision: The Use of Computer Vision for Quality Inspection

Computer vision systems equipped with AI algorithms revolutionize quality control processes by providing accurate and real-time insights:

Defect Detection: AI-powered computer vision identifies defects in manufactured products with high precision. By analyzing visual data from cameras and sensors, it detects imperfections such as scratches, misalignments, or surface irregularities, ensuring only high-quality products reach consumers.

Automated Sorting: Computer vision systems classify and sort products based on visual characteristics such as size, shape, color, or texture. This automation streamlines assembly line operations, reduces labor costs, and enhances overall production efficiency.

Natural Language Processing (NLP): Applications of NLP in Manufacturing

NLP technologies enable machines to understand and interact with human language, facilitating smarter and more efficient manufacturing processes:

Voice-Activated Controls: NLP-powered voice recognition systems allow operators to control machinery and access information using voice commands. This hands-free interaction improves workflow efficiency and reduces manual input errors.

Intelligent Document Processing: NLP algorithms analyze and extract information from unstructured data sources such as documents, reports, and emails. This capability automates administrative tasks like data entry, compliance reporting, and supply chain documentation, freeing up human resources for higher-level decision-making.

AI technologies in manufacturing are not just enhancing productivity and efficiency but are also transforming the way industries operate. From predictive analytics and robotic automation to computer vision and natural language processing, these technologies are driving innovation and setting new standards for manufacturing excellence.

In conclusion, integrating AI automation into manufacturing processes represents a pivotal advancement towards efficiency, accuracy, and competitiveness in today’s industrial landscape. By harnessing the power of AI for predictive maintenance, quality control, and optimized production scheduling, manufacturers can significantly reduce costs, minimize downtime, and enhance product quality. However, successful implementation requires careful planning, robust data infrastructure, and a commitment to ongoing refinement. As AI continues to evolve, so too will its transformative impact on manufacturing, offering unprecedented opportunities for innovation and growth. Embracing AI automation isn’t just a technological upgrade—it’s a strategic imperative for companies aiming to thrive in the era of smart manufacturing.

Check out the Original Article

0 notes