#advanced automation systems

Explore tagged Tumblr posts

Text

#Automated Technology Group#industrial automation#innovation in automation#Industry 4.0#IoT integration#smart robotics#predictive maintenance#green automation#automation solutions#automation in manufacturing#automation trends 2024#sustainable automation#AI in automation#collaborative robots#automation success stories#future of work#advanced automation systems#automation market growth#automation technology#industrial efficiency

0 notes

Note

So.... why'd Peri get assigned Dev as his first godchild?

Jorgen’s usually not the one in charge of assigning godchildren. There’s an entire department that weighs and classifies potentail Godkids to the right Fairy. Although it’s on strike at the moment.

So Jorgen has to do it by hand, until the union negotiations are resolved. Turns out trying to use paperclips is very hard. Itty bitty paperclips. Big muscular biceps. Not a good combo.

Bitties Series: [Start] > [Previous] > [Next]

Peri's Assignment: [Previous] > [Next]

#fairly oddparents#fop#fop a new wish#fop timmy turner#fop timmy#timmy turner#fop jorgen vonstrangle#fop jorgen#jorgen vonstrangle#asks#itty bitties fop au#you'd think they'd have automated everything what with technology advancing to how it is today#but nah.#institutions are very slow to update or switch onto new tech or new efficient system. so everything's still on paper at the moment#(<- upset that most of the court systems in the u.s still rely on paper trails and refuses to digitize important documents)#anyways the department's in negotiations which means jorgen has to pick up the work to ensure no other fairy crosses the picket line#which means handling itty bitty paper clips for itty bitty papers#the amount of paper clips that have lost their lives because he accidentally snapped or bent them.... o7#ALSO.#I THINK IMMA MAKE A NEW POST FOR THIS BUT#I THINK IM GOING TO ADD A NEW LINE OF LINKS FOR THE PLOT-RELATED POSTS#THAT WAY YOU CAN JUMP BACK TO THE IMMEDIATE PREVIOUS PLOT LINK#WITHOUT NEEDING TO JUMP THROUGH A THOUSAND OTHER UPDATES THATS BEEN PUT BETWEEN THEM#when i go back to the chimmy moving plot and the timhazdev argument plot i'll also do the same thing

436 notes

·

View notes

Text

damn i cant believe i saw one single image of theatre production and went "oh they didnt label the production.... but that looks like somethin Hale Centre Theatre would do" AND I WAS RIGHT. i love being a nerd about theater lmao

#it was hale centre theatre 2023 newsies btw#they brought their bowery beauties in from the ceiling btw#it looked gorgeous#“the most rich thats rich thats ever riched” yea fr#ily most technically advanced automation system in an american regional theater#newsies#hale centre theatre

3 notes

·

View notes

Note

he’s on the right path for the wrong reason?

more like the wrong path for the right logic

#liek i guess i agree with what he says re: the path of ai but i do not think that the way ai is being utilized right now is the way it#should follow but that's not like A Truth but like obviously a very biased opinion#based in how i feel about art and creation. like of course jobs will continue being automated and his point about#basic income necessary as those jobs become automated is something i agree with#but there's more to just advancement of science behind ai because it is part of a market. what people dont understand#is that most of the time the point of ai is to improve comfort because comfort is the best thing to sell#in the neoliberalism system The first people that are fucked are the people without that financial support#that are getting taken away creative rights. so its not considering how corporations work#because they have a very positive view of how science develops#star anons

3 notes

·

View notes

Text

Precision Redefined -PLC- Controlled Shock Absorber Testing Machines

#PLC automation#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Technological Advancements in Welding Technology & Training | PTTI Insights

Discover the latest technological advancements transforming welding—from automated welding systems and robotics to virtual training, augmented reality, and AI-powered quality control. Learn how PTTI integrates these cutting-edge tools into its welding curriculum to equip students with modern skills demanded by industry. Stay ahead with hands-on experience in the most advanced welding techniques and technologies shaping the future of manufacturing and construction.

Related Tags : welding technology advancements, welding training technology, automated welding systems, welding robotics, AR welding training, virtual welding simulator, AI quality control welding, PTTI welding tech, advanced welding techniques, industry 4.0 welding

#welding technology advancements#welding training technology#automated welding systems#welding robotics#AR welding training#virtual welding simulator#AI quality control welding#PTTI welding tech#advanced welding techniques#industry 4.0 welding

0 notes

Text

Unleashing Efficiency: The Rise of Industrial Automation Software Solutions

In the age of digital transformation, industrial sectors across the globe are undergoing a fundamental shift. One of the most significant developments driving this evolution is the rise of Industrial Automation Software Solutions. These intelligent systems are redefining how industries operate, streamline processes, and respond to real-time data — all while reducing human error and maximizing productivity.

Industrial automation is no longer just a competitive advantage; it’s quickly becoming a necessity for modern manufacturing, logistics, energy, and production-based businesses. At the core of this transformation lies powerful software designed to integrate machinery, manage workflows, and monitor operations with precision and efficiency.

One of the key strengths of Industrial Automation Software Solutions is their ability to centralize control over complex industrial processes. From programmable logic controllers (PLCs) to supervisory control and data acquisition (SCADA) systems, this software enables seamless communication between machines, sensors, and operators. The result is a smarter, more connected operation that can adapt quickly to changing demands.

Beyond basic automation, these solutions offer deep analytics capabilities. Using machine learning and AI, the software can detect patterns, predict equipment failures, and recommend proactive maintenance — ultimately helping businesses avoid costly downtime. This predictive approach not only increases reliability but also extends the lifespan of expensive equipment.

Flexibility is another crucial advantage. Most modern Industrial Automation Software Solutions are highly customizable and scalable, allowing companies to tailor systems to their unique needs and expand functionality as they grow. Whether an organization is automating a single production line or an entire facility, the right software can be scaled appropriately without significant disruptions.

In today’s globalized economy, remote access and cloud integration are more important than ever. Many automation platforms now offer web-based dashboards and mobile apps, giving managers and technicians the ability to monitor and control systems from virtually anywhere. This level of accessibility promotes faster response times and better decision-making, even across multiple locations.

Security, too, has become a top priority. As more industrial systems connect to the internet, they become more vulnerable to cyber threats. Industrial Automation Software Solutions are now being developed with robust cybersecurity features, including encrypted communication, multi-layered access control, and real-time threat monitoring.

These solutions also play a key role in sustainability efforts. By optimizing energy usage, reducing waste, and ensuring consistent product quality, industrial automation supports greener operations. Businesses not only improve efficiency but also meet environmental standards more effectively.

As industries continue to adopt smart technologies and prepare for Industry 4.0, the demand for reliable and intelligent automation software is set to grow exponentially. Investing in Industrial Automation Software Solutions is no longer just about keeping up with competitors — it's about laying the foundation for a resilient, future-ready operation.

Whether it's enhancing productivity, improving safety, or driving innovation, automation software is reshaping what’s possible in the industrial world. The future of manufacturing and production isn’t just automated — it’s intelligent, adaptive, and incredibly powerful.

#Traceability Software Great Lakes Region#Machine Vision Integration Great Lakes#Great Lakes Industrial Marking Solutions#Factory Monitoring Software Great Lakes Region#Lean Manufacturing Solutions Great Lakes#Automated Data Collection Systems Great Lakes#Industrial Traceability Solutions Detroit#Machine Vision Systems Detroit#Detroit Barcode Verification Services#Laser Marking Services Detroit MI#Production Management Software Detroit#Detroit Manufacturing Systems#product traceability software Detroit#industrial marking systems Detroit#Laser Marking Services Auburn Hills#Industrial Traceability Solutions Michigan#Barcode Verification Systems Auburn Hills#Machine Vision Systems Michigan#Auburn Hills Laser Part Marking#Industrial Marking Solutions Michigan#Traceability Software Auburn Hills#Turnkey Laser Systems Michigan#Auburn Hills Barcode Reader Solutions#Advanced Laser Marking Auburn Hills MI#laser marking systems#laser marking machine#laser part marking#uv laser marking machine#uv laser marking#dot peen marking machine

0 notes

Text

Transforming LLM Performance: How AWS’s Automated Evaluation Framework Leads the Way

New Post has been published on https://thedigitalinsider.com/transforming-llm-performance-how-awss-automated-evaluation-framework-leads-the-way/

Transforming LLM Performance: How AWS’s Automated Evaluation Framework Leads the Way

Large Language Models (LLMs) are quickly transforming the domain of Artificial Intelligence (AI), driving innovations from customer service chatbots to advanced content generation tools. As these models grow in size and complexity, it becomes more challenging to ensure their outputs are always accurate, fair, and relevant.

To address this issue, AWS’s Automated Evaluation Framework offers a powerful solution. It uses automation and advanced metrics to provide scalable, efficient, and precise evaluations of LLM performance. By streamlining the evaluation process, AWS helps organizations monitor and improve their AI systems at scale, setting a new standard for reliability and trust in generative AI applications.

Why LLM Evaluation Matters

LLMs have shown their value in many industries, performing tasks such as answering questions and generating human-like text. However, the complexity of these models brings challenges like hallucinations, bias, and inconsistencies in their outputs. Hallucinations happen when the model generates responses that seem factual but are not accurate. Bias occurs when the model produces outputs that favor certain groups or ideas over others. These issues are especially concerning in fields like healthcare, finance, and legal services, where errors or biased results can have serious consequences.

It is essential to evaluate LLMs properly to identify and fix these issues, ensuring that the models provide trustworthy results. However, traditional evaluation methods, such as human assessments or basic automated metrics, have limitations. Human evaluations are thorough but are often time-consuming, expensive, and can be affected by individual biases. On the other hand, automated metrics are quicker but may not catch all the subtle errors that could affect the model’s performance.

For these reasons, a more advanced and scalable solution is necessary to address these challenges. AWS’s Automated Evaluation Framework provides the perfect solution. It automates the evaluation process, offering real-time assessments of model outputs, identifying issues like hallucinations or bias, and ensuring that models work within ethical standards.

AWS’s Automated Evaluation Framework: An Overview

AWS’s Automated Evaluation Framework is specifically designed to simplify and speed up the evaluation of LLMs. It offers a scalable, flexible, and cost-effective solution for businesses using generative AI. The framework integrates several core AWS services, including Amazon Bedrock, AWS Lambda, SageMaker, and CloudWatch, to create a modular, end-to-end evaluation pipeline. This setup supports both real-time and batch assessments, making it suitable for a wide range of use cases.

Key Components and Capabilities

Amazon Bedrock Model Evaluation

At the foundation of this framework is Amazon Bedrock, which offers pre-trained models and powerful evaluation tools. Bedrock enables businesses to assess LLM outputs based on various metrics such as accuracy, relevance, and safety without the need for custom testing systems. The framework supports both automatic evaluations and human-in-the-loop assessments, providing flexibility for different business applications.

LLM-as-a-Judge (LLMaaJ) Technology

A key feature of the AWS framework is LLM-as-a-Judge (LLMaaJ), which uses advanced LLMs to evaluate the outputs of other models. By mimicking human judgment, this technology dramatically reduces evaluation time and costs, up to 98% compared to traditional methods, while ensuring high consistency and quality. LLMaaJ evaluates models on metrics like correctness, faithfulness, user experience, instruction compliance, and safety. It integrates effectively with Amazon Bedrock, making it easy to apply to both custom and pre-trained models.

Customizable Evaluation Metrics

Another prominent feature is the framework’s ability to implement customizable evaluation metrics. Businesses can tailor the evaluation process to their specific needs, whether it is focused on safety, fairness, or domain-specific accuracy. This customization ensures that companies can meet their unique performance goals and regulatory standards.

Architecture and Workflow

The architecture of AWS’s evaluation framework is modular and scalable, allowing organizations to integrate it easily into their existing AI/ML workflows. This modularity ensures that each component of the system can be adjusted independently as requirements evolve, providing flexibility for businesses at any scale.

Data Ingestion and Preparation

The evaluation process begins with data ingestion, where datasets are gathered, cleaned, and prepared for evaluation. AWS tools such as Amazon S3 are used for secure storage, and AWS Glue can be employed for preprocessing the data. The datasets are then converted into compatible formats (e.g., JSONL) for efficient processing during the evaluation phase.

Compute Resources

The framework uses AWS’s scalable compute services, including Lambda (for short, event-driven tasks), SageMaker (for large and complex computations), and ECS (for containerized workloads). These services ensure that evaluations can be processed efficiently, whether the task is small or large. The system also uses parallel processing where possible, speeding up the evaluation process and making it suitable for enterprise-level model assessments.

Evaluation Engine

The evaluation engine is a key component of the framework. It automatically tests models against predefined or custom metrics, processes the evaluation data, and generates detailed reports. This engine is highly configurable, allowing businesses to add new evaluation metrics or frameworks as needed.

Real-Time Monitoring and Reporting

The integration with CloudWatch ensures that evaluations are continuously monitored in real-time. Performance dashboards, along with automated alerts, provide businesses with the ability to track model performance and take immediate action if necessary. Detailed reports, including aggregate metrics and individual response insights, are generated to support expert analysis and inform actionable improvements.

How AWS’s Framework Enhances LLM Performance

AWS’s Automated Evaluation Framework offers several features that significantly improve the performance and reliability of LLMs. These capabilities help businesses ensure their models deliver accurate, consistent, and safe outputs while also optimizing resources and reducing costs.

Automated Intelligent Evaluation

One of the significant benefits of AWS’s framework is its ability to automate the evaluation process. Traditional LLM testing methods are time-consuming and prone to human error. AWS automates this process, saving both time and money. By evaluating models in real-time, the framework immediately identifies any issues in the model’s outputs, allowing developers to act quickly. Additionally, the ability to run evaluations across multiple models at once helps businesses assess performance without straining resources.

Comprehensive Metric Categories

The AWS framework evaluates models using a variety of metrics, ensuring a thorough assessment of performance. These metrics cover more than just basic accuracy and include:

Accuracy: Verifies that the model’s outputs match expected results.

Coherence: Assesses how logically consistent the generated text is.

Instruction Compliance: Checks how well the model follows given instructions.

Safety: Measures whether the model’s outputs are free from harmful content, like misinformation or hate speech.

In addition to these, AWS incorporates responsible AI metrics to address critical issues such as hallucination detection, which identifies incorrect or fabricated information, and harmfulness, which flags potentially offensive or harmful outputs. These additional metrics are essential for ensuring models meet ethical standards and are safe for use, especially in sensitive applications.

Continuous Monitoring and Optimization

Another essential feature of AWS’s framework is its support for continuous monitoring. This enables businesses to keep their models updated as new data or tasks arise. The system allows for regular evaluations, providing real-time feedback on the model’s performance. This continuous loop of feedback helps businesses address issues quickly and ensures their LLMs maintain high performance over time.

Real-World Impact: How AWS’s Framework Transforms LLM Performance

AWS’s Automated Evaluation Framework is not just a theoretical tool; it has been successfully implemented in real-world scenarios, showcasing its ability to scale, enhance model performance, and ensure ethical standards in AI deployments.

Scalability, Efficiency, and Adaptability

One of the major strengths of AWS’s framework is its ability to efficiently scale as the size and complexity of LLMs grow. The framework employs AWS serverless services, such as AWS Step Functions, Lambda, and Amazon Bedrock, to automate and scale evaluation workflows dynamically. This reduces manual intervention and ensures that resources are used efficiently, making it practical to assess LLMs at a production scale. Whether businesses are testing a single model or managing multiple models in production, the framework is adaptable, meeting both small-scale and enterprise-level requirements.

By automating the evaluation process and utilizing modular components, AWS’s framework ensures seamless integration into existing AI/ML pipelines with minimal disruption. This flexibility helps businesses scale their AI initiatives and continuously optimize their models while maintaining high standards of performance, quality, and efficiency.

Quality and Trust

A core advantage of AWS’s framework is its focus on maintaining quality and trust in AI deployments. By integrating responsible AI metrics such as accuracy, fairness, and safety, the system ensures that models meet high ethical standards. Automated evaluation, combined with human-in-the-loop validation, helps businesses monitor their LLMs for reliability, relevance, and safety. This comprehensive approach to evaluation ensures that LLMs can be trusted to deliver accurate and ethical outputs, building confidence among users and stakeholders.

Successful Real-World Applications

Amazon Q Business

AWS’s evaluation framework has been applied to Amazon Q Business, a managed Retrieval Augmented Generation (RAG) solution. The framework supports both lightweight and comprehensive evaluation workflows, combining automated metrics with human validation to optimize the model’s accuracy and relevance continuously. This approach enhances business decision-making by providing more reliable insights, contributing to operational efficiency within enterprise environments.

Bedrock Knowledge Bases

In Bedrock Knowledge Bases, AWS integrated its evaluation framework to assess and improve the performance of knowledge-driven LLM applications. The framework enables efficient handling of complex queries, ensuring that generated insights are relevant and accurate. This leads to higher-quality outputs and ensures the application of LLMs in knowledge management systems can consistently deliver valuable and reliable results.

The Bottom Line

AWS’s Automated Evaluation Framework is a valuable tool for enhancing the performance, reliability, and ethical standards of LLMs. By automating the evaluation process, it helps businesses reduce time and costs while ensuring models are accurate, safe, and fair. The framework’s scalability and flexibility make it suitable for both small and large-scale projects, effectively integrating into existing AI workflows.

With comprehensive metrics, including responsible AI measures, AWS ensures LLMs meet high ethical and performance standards. Real-world applications, like Amazon Q Business and Bedrock Knowledge Bases, show its practical benefits. Overall, AWS’s framework enables businesses to optimize and scale their AI systems confidently, setting a new standard for generative AI evaluations.

#ADD#Advanced LLMs#ai#AI systems#AI/ML#alerts#Amazon#Analysis#applications#approach#architecture#artificial#Artificial Intelligence#assessment#automation#AWS#aws automated evaluation framework#AWS Lambda#bases#bedrock#Bias#biases#Building#Business#business applications#chatbots#Companies#complexity#compliance#comprehensive

0 notes

Text

Industry 4.0: Powering the Next Industrial Revolution with Intelligence, Connectivity, and Automation

The world is undergoing a radical transformation. As we move deeper into the 21st century, the fusion of digital, physical, and biological systems is reshaping how we manufacture, operate, and innovate. This revolution has a name: Industry 4.0—the fourth industrial revolution. It represents a new era where smart technology, real-time data, automation, and interconnected networks converge to…

#5G Connectivity#Additive Manufacturing#advanced robotics#Artificial intelligence#Automation#Big Data Analytics#Blockchain#Cloud Computing#connected industry#Cyber-physical systems#data-driven operations#Digital Transformation#Digital twin#Edge computing#fourth industrial revolution#IIoT#Industrial Networking#Industry 4.0#intelligent systems#manufacturing innovation#next-gen industry#Predictive maintenance#Real-time analytics#Robotics#smart factory#Smart Grid#Smart logistics#Smart manufacturing#SolveForce#Supply Chain Visibility

0 notes

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

Batch Fluid Bed Dryers Market Set to Hit $1,593.7 Million by 2035

The global Batch Fluid Bed Dryers market is projected to experience significant growth, rising from $697.6 million in 2024 to $1,593.7 million by 2035. The market is expected to grow at an average annual rate of 10.3% from 2024 to 2035, driven by strong demand across pharmaceutical manufacturing, food processing, chemical processing, and plastics manufacturing industries.

Access detailed report insights here - https://datastringconsulting.com/industry-analysis/batch-fluid-bed-dryers-market-research-report

Key Applications Driving Market Growth

Batch Fluid Bed Dryers play a critical role in several industries due to their ability to provide consistent, efficient, and rapid drying. In the pharmaceutical industry, these dryers are essential for preserving the integrity of sensitive ingredients during the drying process, ensuring higher quality end products. Leading pharmaceutical companies such as Novartis and Pfizer rely on these dryers for their accuracy and reliability, securing a competitive edge in the market.

In the food processing sector, Batch Fluid Bed Dryers are used for their uniform drying capabilities. These dryers help preserve the nutritional value and extend the shelf life of food products. Companies like Nestlé and Kraft Heinz utilize these systems for drying fruits, vegetables, herbs, spices, and coffee beans, benefiting from superior heat transfer and moisture removal.

Technological Advancements and Market Innovation

Technological advancements have significantly impacted the Batch Fluid Bed Dryers market, particularly in pharmaceutical and food processing sectors. Modern fluid bed dryers now offer enhanced efficiency, reduced energy consumption, and improved output quality. These innovations enable superior drying uniformity, moisture removal, and particle size reduction, making them ideal for drying powders and granules.

The integration of automation into these systems has optimized the drying process, ensuring consistent quality output while reducing human error. As a result, the Batch Fluid Bed Dryers market has seen substantial growth, driving productivity improvements, reducing resource wastage, and lowering production costs, which in turn boosts profitability and sustainability.

Industry Leadership and Competitive Landscape

The Batch Fluid Bed Dryers market is highly competitive, with key players such as GEA Group AG, Andritz AG, Bühler Holding AG, Glatt GmbH, FLSmidth & Co. A/S, ThyssenKrupp AG, and SPX Flow Technology Danmark A/S leading the market. These companies are driving innovation by focusing on developing advanced solutions for fluid bed drying technology, customizable dryers, energy-efficient designs, and automation to improve performance and reduce operational costs.

The market’s growth is supported by shifting trends in pharmaceutical manufacturing, the expansion of chemical industries, and continuous technological advancements in fluid bed drying systems. As demand for efficient and precise drying solutions continues to rise, industry players are positioned to capitalize on significant growth opportunities.

Regional Analysis and Market Dynamics

North America remains a dominant player in the Batch Fluid Bed Dryers market, driven by robust industrial growth and technological advancements in drying systems. The pharmaceutical and food processing sectors, in particular, offer substantial opportunities due to their ongoing demand for high-efficiency drying solutions.

Key drivers in the region include stringent regulatory standards focused on quality and safety in production, along with a growing preference for sustainable and energy-efficient equipment. Europe and China are also strong contributors to market growth, with significant demand from local industries and manufacturers focusing on improving productivity and sustainability.

As these regions continue to expand, emerging markets in India, Brazil, and South Africa are expected to become increasingly important, offering new revenue opportunities for manufacturers seeking to diversify their portfolios and expand their total addressable market (TAM).

About DataString Consulting

DataString Consulting offers a comprehensive suite of market research and business intelligence solutions for both B2C and B2B markets. Specializing in bespoke research projects, the firm helps businesses achieve their strategic objectives, whether it’s expanding into new markets, increasing revenue, or addressing industry challenges.

With over 30 years of combined experience, DataString’s leadership team is well-versed in market & business research and strategy advisory across diverse sectors globally. Their expert consultants track high-growth segments within more than 15 industries and 60 sub-industries, providing actionable insights and data-driven strategies to help businesses thrive in competitive markets.

#Batch Fluid Bed Dryers#Market Growth#Pharmaceutical Manufacturing#Food Processing#Chemical Processing#Energy-efficient Drying Systems#Technological Advancements#Automation in Drying#Global Market Analysis#Industry Leadership#Competitive Landscape#Regional Market Dynamics#Sustainable Equipment#DataString Consulting

0 notes

Text

Unlock the Future of Parking: Discover How Automated Systems Maximize Space!

#automatic car parking system#automated car park solutions#vertical stacking systems#intelligent automated parking system technology#automated parking system technology#advanced parking solutions for urban areas#automated car parking system project#automated car park#car parking system manufacturers#automatic parking system solutions

0 notes

Text

#Advanced PLC and HMI Training Kit Pune#Advanced PLC HMI Kits Pune#Advanced Siemens PLC Kits Pune#Advanced Mitsubishi PLC Training Pune#PLC and HMI Systems Pune#Industrial Automation Training Kits Pune#PLC and HMI Training Solutions Pune#Professional PLC Training Kits Pune#Advanced Automation Training Kits Pune#Best PLC and HMI Training Kits Pune.

0 notes

Text

#Top challenges DMS#Recover DMS#Advanced DMS#DMS in AI#Ditribution automation#Heerasoftware#inventory system#warehouse management#wholesale management#distribution product management#supply chain management#sales management#Sales automation#Fmcg distribution#CPg distribution

0 notes

Text

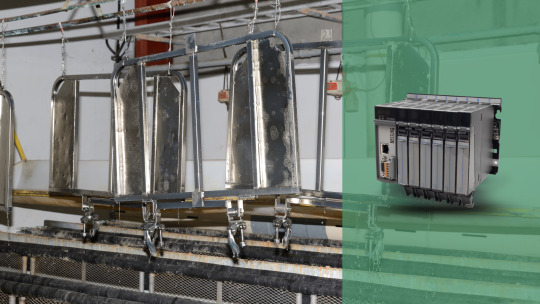

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Smart Building Technologies: AI & IoT Solutions for Modern Construction

Explore how smart building technologies are revolutionizing the construction industry in Philadelphia. With AI in construction management and IoT in building automation, companies are enhancing efficiency, safety, and sustainability in every phase of a project. Discover how AI-driven construction safety solutions are helping to prevent accidents and improve decision-making on-site. From high-rise developments to smart infrastructure, these innovations are shaping the future of urban building. Learn how adopting smart building technologies can future-proof your projects and ensure compliance with modern standards in one of America's most competitive construction markets.

#smart building technologies in Philadelphia construction#AI in construction management in Philadelphia#IoT in building automation systems Philadelphia#AI-driven construction safety tools in Philadelphia#Philadelphia smart construction technologies#advanced IoT solutions for building automation Philadelphia#artificial intelligence in Philadelphia building projects#construction safety technology for Philadelphia contractors#smart infrastructure development in Philadelphia#energy-efficient smart buildings using AI and IoT Philadelphia

0 notes