#Autodesk Inventor Course

Explore tagged Tumblr posts

Text

Exploring the Capabilities of Autodesk Inventor

Introduction to Autodesk Inventor Training

Autodesk Inventor is a powerful computer-aided design (CAD) software used widely across industries for mechanical design, simulation, and visualization. Whether you're a student, a budding engineer, or a seasoned professional, learning Autodesk Inventor can significantly enhance your ability to create precise and innovative design solutions. In the fast-paced world of engineering and manufacturing, CAD software like Autodesk Inventor is indispensable. It not only helps in drafting and modeling complex designs but also simulates real-world application of these designs, thus saving time and resources in prototyping. As industries continue to lean towards automation and precision, skills in such high-demand software become crucial.

This article provided by Multisoft Systems aims to guide both newcomers and experienced users through the depths of Autodesk Inventor training. From basic functionalities and certification processes to advanced techniques and industry applications, we'll cover everything you need to master this sophisticated tool.

Overview of Autodesk Inventor

Autodesk Inventor is a leading 3D CAD (computer-aided design) software developed by Autodesk, widely recognized for its comprehensive tools that enable precision in mechanical design, simulation, and documentation. Primarily used for product design and engineering, Inventor incorporates an intuitive and robust set of tools for 3D mechanical design, documentation, and product simulation. Innovative by design, it supports advanced 3D modeling, assembly, and drawing creation, which are crucial for modern engineering workflows.

Autodesk Inventor uses parametric modeling techniques, allowing engineers to create and explore a complete product before it’s built. Its digital prototyping capabilities enable the design and testing of products in a completely virtual environment, reducing the need for physical prototypes and helping to speed up the product development cycles.

Autodesk Inventor Training

Parametric Modeling: Central to Inventor is its parametric modeling engine, which allows users to quickly create and modify their designs by working with geometric and dimensional constraints.

Assembly Modeling: Inventor excels in its ability to handle complex assemblies. Users can define the exact fit and function between assembled parts to simulate real-world performance.

Drawing Creation: It automates part and assembly drawings, reducing errors and providing the necessary tools to generate detailed, more accurate mechanical drawings.

Simulation and Analysis: The software offers advanced simulation tools to test how a product will perform under real-world conditions. This includes stress analysis, dynamic simulation, and the ability to optimize materials and mass properties.

Integrated CAD/CAM Integration: Inventor seamlessly integrates with Autodesk’s CAM solutions, streamlining the workflow from CAD design to CAM manufacturing.

Importance of CAD Software in Modern Engineering

CAD software like Autodesk Inventor certification plays a pivotal role in the engineering sector today. The capabilities of CAD systems have revolutionized the way industries design and manufacture products. Here are some of the critical benefits and importance of CAD software in modern engineering:

Enhanced Productivity: CAD software significantly speeds up the design process by providing extensive tools that automate many of the tasks traditionally done by hand. This leads to faster completion of projects and increased productivity.

Improved Quality of Design: CAD systems provide engineers with the ability to examine their designs under various parameters and conditions, not feasible with traditional methods. This detailed analysis helps in refining designs and enhancing the quality of the final products.

Documentation and Visualization: Good documentation is crucial in engineering, and CAD software excels at creating detailed drawings that can be used for manufacturing and installation. Additionally, the ability to visualize and animate designs helps non-technical stakeholders understand complex engineering concepts.

Cost Efficiency: By using CAD software, significant cost savings can be achieved. The need for physical prototypes, often expensive and time-consuming to produce, is reduced as CAD allows complete testing and analysis of a product in a virtual environment.

Standardization of Design: CAD software helps maintain design standards. Companies can create their own custom design workflows in the software, ensuring that all products meet prescribed quality standards and regulatory compliance.

The evolution of CAD software has been a cornerstone in the transformation of engineering practices across all industries. Tools like Autodesk Inventor not only facilitate increased efficiency and precision in product design but also push the envelope of what can be achieved in modern engineering.

Interface Basics

The interface of Autodesk Inventor is meticulously organized to support efficiency and ease of use. Key components of the interface include:

Ribbon: At the top of the interface, the Ribbon contains all the tools and commands categorized into tabs such as Home, Assemble, View, and Manage. Each tab is further divided into panels that group related tools and functionalities together.

Browser: On the left side of the screen, the Browser acts as the control center for your design. It lists all the components, features, constraints, and other elements in your project, allowing quick navigation and modifications.

Modeling Window: This is the central area where you create and manipulate your 3D models. It provides a dynamic view of the work in progress.

ViewCube: Located in the upper-right corner of the modeling window, the ViewCube is a quick navigation tool that lets users rotate and orient the view of the 3D model in the workspace.

Quick Access Toolbar: This is a customizable toolbar at the top of the window, where you can add your most-used commands for easy access.

Status Bar: At the bottom, the status bar displays helpful information about the selected tool or feature, aiding in precision and decision-making during design.

Key Tools and Their Uses

Autodesk Inventor offers a variety of tools that cater to different aspects of 3D modeling and design:

Sketch Tools: Used for creating 2D shapes that serve as the foundational elements of 3D models. Tools include Line, Circle, Rectangle, and more, along with constraints and dimensions to define exact geometries.

Extrude and Revolve: These are basic 3D tools that transform 2D sketches into 3D objects by extending or rotating the sketch profile.

Assembly Tools: Used for defining the relationships between different parts in a mechanical assembly, such as constraints that mimic real-world mechanical connections (e.g., hinge, slider, mate).

Fillets and Chamfers: These tools are used for adding rounded or angled edges to the model, which are crucial for both aesthetics and manufacturing.

Measure and Inspect: Essential for checking distances, angles, and tolerances within the model to ensure precision and functional design.

Advanced Techniques in Autodesk Inventor

As engineers and designers become more proficient with Autodesk Inventor, they often seek to leverage more advanced techniques to further enhance their productivity and the sophistication of their designs. These techniques involve complex modeling strategies, the use of advanced simulation tools, and the customization and automation of workflows through APIs. Here’s a deeper look into each of these areas:

1. Complex Modeling Strategies

Advanced modeling in Autodesk Inventor allows for the creation of more intricate and refined designs that can handle specific engineering challenges:

Adaptive Components: Design parts that can automatically adjust based on changes to other parts or assemblies. This is particularly useful in modular designs where changes propagate through related components.

Multi-Body Design: Use a single part file to create complex parts that are composed of several bodies, which can later be saved as separate parts or combined to form a single unit. This strategy simplifies the management of complex models.

Surface and Mesh Modeling: Enhance the ability to model complex surfaces or to incorporate 3D scans into the design process. Inventor's tools allow for detailed refinement of surfaces and the repair of mesh models, essential for high-quality surface finishes.

iLogic: Inventor includes iLogic, a tool that provides rule-based design automation for driving design changes and configurations. By setting up rules, engineers can automate repetitive tasks and ensure that their designs adhere to predefined standards and parameters.

2. Using Advanced Simulation Tools

Inventor’s simulation tools enable designers to test, validate, and optimize their CAD models within the software environment, reducing the need for physical prototypes:

Finite Element Analysis (FEA): Perform advanced FEA to understand the stresses and deformations of parts under various conditions. Inventor’s integration with Autodesk Nastran enhances these capabilities, offering a range of additional simulations like nonlinear and dynamic analysis.

Motion Analysis: Use the dynamic simulation tools to calculate the forces and motions in moving components within an assembly. This analysis helps in understanding how all parts of an assembly interact with each other, identifying potential wear and failure points.

Optimization Tools: Leverage parameter optimization tools that automatically modify design parameters to meet specified objectives and constraints, such as minimizing weight while maintaining structural integrity.

3. Customization and Automation through API

The Application Programming Interface (API) in Autodesk Inventor opens a vast field of possibilities for customization and automation:

Custom Add-Ins and Macros: Develop custom add-ins and macros that integrate directly into the Inventor interface. These can automate routine tasks, add new functionalities, or integrate Inventor with other software tools used within the company.

User Interface Customization: Tailor the Inventor workspace to better fit company workflows or personal preferences, which can improve efficiency and ease of use.

Interfacing with Other Applications: Use the API to establish data exchange and functionality sharing between Inventor and other applications, such as ERP systems or custom engineering tools, creating a more integrated and efficient workflow environment.

Advanced techniques in Autodesk Inventor online training enable users to push the boundaries of design and analysis, leading to more innovative solutions and efficient production processes. By mastering complex modeling strategies, utilizing advanced simulation tools, and harnessing the power of customization through APIs, engineers can significantly enhance their capabilities in product development and manufacturing optimization.

Conclusion

Autodesk Inventor stands as a pivotal tool in modern engineering, offering a blend of powerful 2D and 3D design functionalities, sophisticated simulation capabilities, and extensive customization options through its API. Its intuitive interface and robust toolset empower engineers to craft detailed, accurate models, while advanced features like adaptive components and iLogic automation streamline the design process. By mastering Autodesk Inventor training, professionals can significantly enhance their productivity, optimize design workflows, and push the boundaries of innovation in product development. Autodesk Inventor is not just software; it's a gateway to transforming ideas into reality in the engineering world. Enroll in Multisoft Systems now!

0 notes

Text

Improve Revit & Civil 3D Productivity with Naviate Tools

Revit Add-In, Naviate tools are designed to improve productivity when working with Revit and Civil 3D. Get access to a range of convenient features that allow for faster modeling and design. Streamline your workflow and reduce time spent on tasks with Naviate tools from Symetri.

#Revit Add-In#Inventor#Autodesk Inventor#BIM 360 Docs#Inventor Nastran#BIM Consulting#Civil 3D#Revit Training Courses#AEC Collection

0 notes

Text

🕌✨ Bakrid Mubarak from DOT Institute – Trichy’s No.1 CAD Training Center! ✨🕌

Learn CAD. Build Your Future. Enroll This Eid.

📚 Top CAD Courses with Bakrid Festive Offers 🎁 AutoCAD | SolidWorks | CATIA | Creo | Ansys | Fusion 360 | NX CAD | Autodesk Inventor

📍 Location: Near Chathiram Bus Stand, Trichy 🌐 Website: www.dotinstitute.co.in 📞 Call: +91 999 42 99 879

🌙 Celebrate the spirit of sacrifice and self-growth this Eid al-Adha. At DOT Institute, we empower you to design your career with industry-ready CAD skills in Mechanical, Civil, and Electrical Design. Whether you’re a diploma student or an engineering graduate, this is the right time to start.

🎉 Bakrid Special: Get UP TO 30% OFF!

✔️ Apply before 15th June 2025 ✔️ Join flexible regular/weekend batches ✔️ Get certified with 100% placement guidance

💡 Inspired by Dr. A.P.J. Abdul Kalam

"Great dreams of great dreamers are always transcended." Let your dreams take shape at DOT Institute – where engineering excellence begins.

🏆 Why Choose DOT Institute?

Ranked #1 for CAD Training in Trichy

Expert Mentors in CAD/CAM Software

Internship & Career Support

Near top city zones: Thillainagar, Woraiyur, Srirangam, Central Bus Stand, Lalgudi

Address: 12A, 3rd Floor, Periyasamy Tower, Chathiram Bus Stand, Trichy – 620002 Phone: +91 99942 99879 | +91 75980 09444 | +91 75980 10444 Email: [email protected] Website: www.dotinstitute.co.in

https://www.dotinstitute.co.in

#Bakrid2025#BakridOffer#CADTrainingTrichy#AutoCADIndia#SolidWorksCourse#CreoDesign#CATIAIndia#DrAPJKalam#MuslimEngineer#MechanicalCAD#CivilDesign#EidMubarak#DOTInstituteTrichy#TrichyEducation#EngineeringCoursesTrichy

0 notes

Text

The Impact of Industry 5.0 on Mechanical Engineering

Industry 5.0 represents a significant shift in the manufacturing landscape, bringing with it a wave of technological advancements that are reshaping the way mechanical engineering operates. This new era is characterized by the integration of digital technologies, automation, and data exchange in manufacturing processes, leading to a more interconnected and efficient industry. The impact of Industry 5.0 on mechanical engineering is profound, influencing various aspects of design, production, and maintenance in the field. One key area where Industry 5.0 is making a substantial impact on mechanical engineering is in the realm of design innovation. With the advent of advanced software tools and simulation technologies, engineers now have access to powerful resources that enable them to create more complex and optimized designs. The use of computer-aided design (CAD) software, for instance, allows engineers to visualize and test their designs in a virtual environment before physical prototyping, leading to faster iteration cycles and improved product quality. This emphasis on design innovation is crucial in a competitive market where speed to market and product differentiation are key factors for success. Also Read-: Basic Guide to Autodesk Inventor and How Does It Work? Top 10 Courses to Join After Mechanical Engineering Open-Source CAD Software for Linux Operating System Moreover, Industry 5.0 is revolutionizing the production processes in mechanical engineering through the adoption of smart manufacturing technologies. The integration of Internet of Things (IoT) devices, robotics, and artificial intelligence (AI) in manufacturing facilities is enabling a higher degree of automation and efficiency. Smart factories equipped with interconnected sensors and actuators can collect real-time data on production processes, enabling predictive maintenance, reducing downtime, and optimizing resource utilization. This shift towards smart manufacturing not only enhances productivity but also improves the overall quality and consistency of manufactured products. In addition to design and production, Industry 5.0 is also transforming the way maintenance and servicing are approached in mechanical engineering. The implementation of predictive maintenance strategies, enabled by the Internet of Things and machine learning algorithms, allows engineers to anticipate equipment failures before they occur. By analyzing data from sensors embedded in machinery, maintenance schedules can be optimized, reducing unplanned downtime and extending the lifespan of critical assets. This proactive approach to maintenance not only saves costs but also enhances operational reliability and safety in industrial settings. Also Read-: Best Mechanical Design Software 2024 Best 2D CAD Drafting software of 2024 FreeCAD Integration with KiCAD Furthermore, Industry 5.0 is driving collaboration and connectivity across the mechanical engineering ecosystem. The concept of the digital twin, a virtual representation of a physical product or system, is gaining traction in the industry, enabling engineers to simulate and monitor the performance of assets in real-time. This digital twin technology facilitates cross-functional collaboration between design, production, and maintenance teams, fostering a more integrated and agile approach to engineering projects. By leveraging digital twins, engineers can streamline communication, identify potential issues early on, and make data-driven decisions throughout the product lifecycle. In conclusion, the impact of Industry 5.0 on mechanical engineering is multifaceted, encompassing design innovation, smart manufacturing, predictive maintenance, and collaborative practices. As the industry continues to embrace digital transformation, mechanical engineers are presented with new opportunities to enhance efficiency, quality, and sustainability in their work. By leveraging the latest technologies and embracing a holistic approach to engineering processes, professionals in the field can navigate the challenges and seize the benefits of Industry 5.0 to drive innovation and competitiveness in the evolving manufacturing landscape. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Revolutionizing Design: Autodesk Dublin's Innovative Solutions

At Symetri we work with you to tailor digital BIM, product design and lifecycle solutions to help you work smarter and do more with less. As a trusted partner for our customers, we constantly seek to challenge people to work smarter for a better future. With our expertise, leading-edge technology and services we always strive to enable our customers to gain an increased competitive advantage. That’s why our partnerships are long lasting. Symetri is Ireland’s preferred trusted Autodesk Partner with offices in Autodesk Dublin & Limerick.

#Autodesk Inventor#Autodesk Revit#Autodesk Vault#BIM 360#BIM Ireland#Bim Collaborate Pro#BIM Course#Autodesk Dublin#Autodesk Ireland#Autocad Course

0 notes

Photo

BIM Ireland

Autodesk BIM 360 connects people, data and workflows throughout the building construction lifecycle to save time, reduce risk, & mitigate errors in construction projects. Procad is the leading BIM provider throughout Ireland, offering free BIM Consultation’s to get you started on your BIM journey.

#Autodesk Inventor#Autodesk Fusion 360#BIM360#Revit Courses#Autocad LT#Autodesk Ireland#Autocad Courses Dublin#Autodesk Vault#Autodesk Construction Cloud#Autodesk BIM 360

0 notes

Video

tumblr

Best Training Institute for Engineering & CAD Courses in Dubai

Edoxi Training Institute is a pioneering name in the Dubai region that is renowned for offering advanced and quality job-focused hands-on training courses across a wide range of fields and domains. https://www.edoxitraining.com

0 notes

Text

Autodesk Inventor Training Online Certification course

Enhance your 3D design skills with Autodesk Inventor Training Online Certification by Multisoft Systems. Learn advanced modeling techniques, simulation, and more. Get certified and boost your career in mechanical design. Enroll now!

0 notes

Text

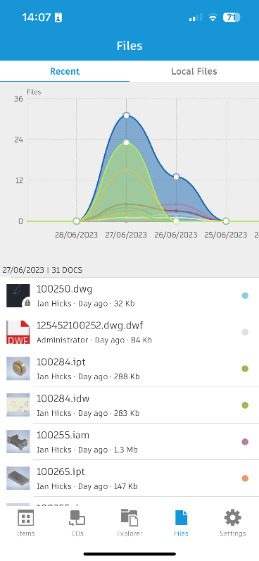

Did you know you can now access Autodesk Vault on your mobile?

What is Vault Mobile?

Vault mobile allows Autodesk Vault Professional users to access their Vault on mobile devices and tablets, making it convenient for teams that need access from anywhere. This functionality was limited to licenced versions of the Vault only; however, since the 2024 update, users without a licence can now access Vault data as a read-only user. Data can still be consumed, searched, and marked up when away from the office, offering a great alternative to the web client.

Who can use it?

Using the read-only mode, users can review Vault data through the app, create local mark-ups, which can be shared through smartphone applications, download files & exclusive to Vault mobile search using QR & Barcodes. The fully licenced user, however, can take part in lifecycle workflows, ECO creation and upload data directly from their mobile device, anything they can currently do with Vault desktop but on a mobile device.

How do you Connect?

Users can connect either through a local network connection when connected to the same network as Vault or through the Vault getaway services when away from the office, making it truly mobile. This means vault data can be accessed anywhere in the world, whether onsite with a client or on the shop floor with your team.

Vault mobile can be found on both iOS and Android Appstore. Please reach out to Symetri for a demo or support around Autodesk Vault.

Contact us via email or telephone.

0345 370 1444

#AutoCAD course#AutoCAD training#CAD Training#CAD training course#BIM Training#Revit courses#Revit training#Revit training courses#Infodrainage#Autodesk Infodrainage#Innovyze Infodrainage#Autodesk Nastran#Autodesk inventor Nastran#Inventor#Autodesk Inventor#Revit Add-In#Naviate#Oculo#Revit#Autodesk revit#Autodesk vault add in#Autodesk Vault#Autodesk Support#Autodesk Takeoff#Twinmotion for Revit#Twinmotion#Twinmotion revit#BIM 360#BIM 360 Docs#Civil 3D

0 notes

Photo

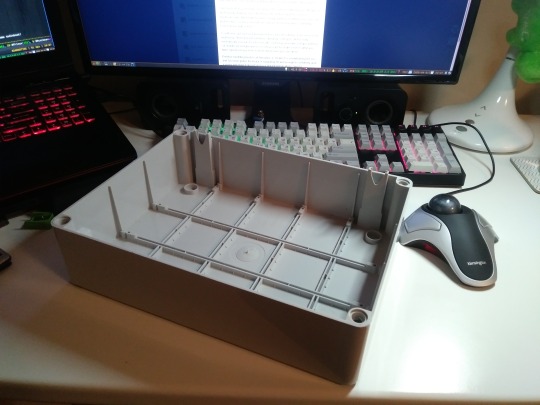

FreeCAD is surprisingly good, not just for an Open Source CAD package, but for a CAD package in general. I’ve used a lot of CAD packages and the learning curve wasn’t really any slower than when I went from Solid Edge (bleh) to Autodesk Inventor (<3).

The sketch constraints engine isn’t as powerful as the one in Inventor or Solidworks but it’s not ~bad~, you just need to be a little more explicit. Those counterbored screw holes were actually super easy, because I just applied them over the fillet on the corners and they snapped into place perfectly. A little more work and I’ll have this box down.

FreeCAD does call extruding “padding” which is unacceptable, obviously :P

I ain’t even a fancy mechanical engineer, the last time I did any real CAD was in my first-year drawing course that they make all the engineers, even us electricals, take. Admittedly I’ve been using parametric modellers ever since my brother (who is a fancy mechanical engineer) let me borrow his Solid Edge license key in high school.

I could never get my head around primitives based modelling, it just seems loose and messy. Sketching and extruding, sweeping, cutting etc. all feel really mechanically visceral. It’s a lot more like machining, you make a shape and then cut chunks out and glue pieces on until you get the shape closer to what you want, repeat until you hone in all the dimensions you care about.

Primitive modelling tends to all take place in 3D which is overwhelming (for me) and I’ve never gotten the knack of navigating 3D well enough to confidently grab a vertex and move it around and trust that it’ll end up where I want it.

13 notes

·

View notes

Photo

ALTERNATE RELIC MEDALLIONS

Here are all the medallions for the Alternate Relic fan comic. Under the cut, I'll list what they are, and what they say on the edges.

Mind- "Do not forget the past, for it is has made you who you are, but do not let it control you, and keep you from achieving your potential." Earth- "Stand your ground to all adversity, and you shall not be moved." Fire- "Channel the raging inner flames." Spirit- "In life, or death, the Spirit shall persevere." Light- "Nothing can dim the light that shines from within." Dream- "A dream is a world of your imagination, but remember to awaken to reality." Heart- "Strength of heart will carry you through the hardest of trials." Forest- "The mystery of the woods are tranquil, yet hold danger." Wind- "The winds of change are unknown, but always chart your own course." Time- "The past cannot change, the present unknown, and the future not set in stone." Water- "Let the waves wash over you, and it shall guide you." Shadow- "Remember that Darkness lingers in every heart." Destiny- "All things lead to one point, though the destination is meaningless without the journey. It is fate."

Made with Autodesk Inventor.

Fonts used in this piece are credited in the credits section of our Tumblr.

~Cizzle

#3d model#medallion#zelda#legend of zelda#dragon ball#kingdom hearts#crossover#fan comic#web comic#fan fiction#art#fan art#zelda au#digital art#gaming#kingdom hearts au#dragon ball au#tns art#ocarina of time#mind#earth#fire#spirit#light#dream#heart#forest#wind#time#water

5 notes

·

View notes

Text

Autodesk, Inc. is a design software & services company offering customers productive business solutions through various technology products and services. It operates through four segments: Platform Solutions & Emerging Business; Architecture, Engineering & Construction; Manufacturing and Media & Entertainment. With Academy Class, you can learn to utilise these software systems to further your career. We offer 3DS Max, Autodesk Courses , Fusion 360, Inventor, BIM., Maya, Navisworks and Revit courses! Do live, online, instructor-led training or in-class, depending on your preference.

0 notes

Text

The Influence of Environmental Regulations on Mechanical Engineering

Environmental regulations play a crucial role in shaping the landscape of mechanical engineering practices. As the world becomes increasingly aware of the impact of industrial activities on the environment, governments and regulatory bodies have implemented stringent measures to mitigate these effects. In the realm of mechanical engineering, these regulations have significant implications on various aspects of design, production, and operation. One of the key areas where environmental regulations have a direct impact is in the design phase of mechanical engineering projects. Engineers are now required to consider environmental factors right from the initial stages of product development. This includes assessing the environmental impact of materials used, energy consumption during operation, and end-of-life disposal considerations. Designing products that are energy-efficient, recyclable, and have a minimal carbon footprint has become a priority for mechanical engineers in compliance with these regulations. Also Read-: Basic Guide to Choosing ISO or ASME Standard for 2D Drawing Meaning of PN and DN in Valves Basic Guide to UC Bearing Number Designation Moreover, the manufacturing processes in mechanical engineering have also been influenced by environmental regulations. Strict emission standards and waste disposal regulations have compelled industries to adopt cleaner and more sustainable manufacturing practices. This has led to the development of innovative technologies and processes that reduce pollution, minimize waste generation, and optimize resource utilization. From implementing green manufacturing techniques to utilizing renewable energy sources, mechanical engineers are at the forefront of driving sustainable practices in the industry. In addition to design and manufacturing, environmental regulations have also impacted the operational aspects of mechanical engineering systems. Maintenance practices, energy management, and overall system efficiency are now scrutinized under the lens of environmental sustainability. Mechanical engineers are tasked with optimizing the performance of systems to reduce energy consumption, minimize emissions, and ensure compliance with regulatory standards. This shift towards eco-friendly operations has not only led to cost savings for industries but has also contributed to a cleaner and greener environment. Also Read-: Basic Guide to Autodesk Inventor and How Does It Work? Top 10 Courses to Join After Mechanical Engineering Open-Source CAD Software for Linux Operating System Furthermore, the integration of environmental considerations into mechanical engineering projects has spurred innovation and creativity within the industry. Engineers are constantly seeking novel solutions to meet regulatory requirements while maintaining high standards of performance and reliability. This has resulted in the development of advanced technologies such as smart sensors for energy monitoring, predictive maintenance systems for improved efficiency, and eco-friendly materials for sustainable construction. Overall, the influence of environmental regulations on mechanical engineering is undeniable. It has transformed the way engineers approach design, manufacturing, and operation of mechanical systems, driving a shift towards sustainability and environmental responsibility. By embracing these regulations and incorporating eco-friendly practices into their work, mechanical engineers are not only meeting compliance standards but also contributing to a healthier planet for future generations. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Autodesk Fusion 360

Autodesk Fusion 360 is a cloud-based 3D modelling, CAD, CAM, CAE and PCB software platform for product design and manufacturing. It connects your entire product development process in a single cloud-based platform that works on both Mac and PC. It combines industrial and mechanical design, simulation, collaboration and machining in a single package.

#Autocad LT#Autodesk Construction Cloud#Autocad Course#Autodesk Inventor#Revit Courses#Revit Course#Autodesk Revit#Autodesk Dublin#BIM Ireland#Revit Training Courses#Autodesk Fusion 360#BIM Course#Autocad#BIM Consultation#Autodesk BIM 360#Bim Collaborate Pro#Autodesk 360 Docs#Autodesk360 Docs#BIM 360#Autodesk Software#Autodesk Docs#Autodesk Ireland#Autodesk Vault#Autocad Courses#Autodesk Build

0 notes

Photo

Revit Course

This online Revit course takes participants through the basics of Revit Architecture Essentials, to a point where candidates are competent using its commands and tools.

#BIM Course#Autodesk Ireland#Autocad Course#BIM360#BIM 360#Autodesk Construction Cloud#Autodesk BIM 360#Autocad LT#Autodesk Inventor#Autodesk Fusion 360

0 notes

Text

AutoCAD

AutoCAD is a commercial computer-aided design (CAD) and drafting software application. Developed and marketed by Autodesk, AutoCAD was first released in December 1982 as a desktop app running on microcomputers with internal graphics controllers. Before AutoCAD was introduced, most commercial CAD programs ran on mainframe computers or minicomputers, with each CAD operator (user) working at a separate graphics terminal. AutoCAD is also available as mobile and web apps. AutoCAD is primarily used for 2 Dimensional drawings, and even though 3D modeling is available in AutoCAD other computer-aided design software like Fusion 360, Inventor and Solidworks are preferred in 3D modeling.

AutoCAD is used in industry, by architects, project managers, engineers, graphic designers, city planners and other professionals. It was supported by 750 training centers worldwide in 1994.

Are you searching for the best AutoCAD training institute in Noida? APPWARS TECHNOLOGIES Pvt Ltd. is the top place and it’s easy to enroll for the course. We offer a certified training and once you receive the certificate you will find it easy to apply for better jobs. Once you complete the training we will help you join your dream job. We give you excellent job placement support and it gives you the confidence to achieve success. Life thus becomes easy and we are here to give you support. Thus, you will get rid of all the worries and you will get a clear idea of why it’s good to join our institute.

Now, it’s time to join the AutoCAD classes. We conduct online certification training program helps you know the importance of the training program. We help you learn how to create 2D and 3D models and even you will get a clear idea of how to customize the apps. Thus, you will get an idea how we arrange the best AutoCAD training in Noida and it helps you explore better career opportunities. Once you join the AutoCAD classes you will get an idea of why we are recognized as the top AutoCAD training in Noida.

Are you planning to join our online AutoCAD training? It’s easy to choose our online AutoCAD classes and we will be glad to support you. You may join the regular classes or weekend classes and we are always here to help you with the best solutions. You can join one-to-one or corporate training and we will help you handle industry works. Also, you can join fast track classes and we will bring the best experience.

Finally, you will comprehend how how our institute gains popularity. We come up as one of the leading AutoCAD training institutes in Noida. We make it easy to find good jobs and you will explore a great profession.

0 notes