#Autonomous Mobile Robots Demand

Explore tagged Tumblr posts

Text

Autonomous Mobile Robots (AMRs) Market Size, Revenue Share, Drivers & Trends Analysis, 2024–2030

The Autonomous Mobile Robots Market was valued at USD 1.7 billion in 2023 and will surpass USD 5.2 billion by 2030; growing at a CAGR of 16.9% during 2024 – 2030. the Autonomous Mobile Robots (AMRs) market has seen significant growth, driven by advancements in robotics, artificial intelligence (AI), and machine learning. AMRs, which can navigate and perform tasks without direct human intervention, are transforming industries by enhancing efficiency, reducing costs, and improving safety. This blog explores the current state of the AMRs market, key trends, and future prospects.

Autonomous Mobile Robots are a type of robot that can perform various tasks in diverse environments, from warehouses and manufacturing floors to hospitals and retail spaces. Unlike traditional automated guided vehicles (AGVs), which require predefined paths and external guidance, AMRs use sensors, cameras, and AI to understand their surroundings, make decisions in real-time, and navigate dynamically within a space.

Read More about Sample Report: https://www.intentmarketresearch.com/request-sample/autonomous-mobile-robots-amrs-market-3605.html

Market Growth and Drivers

The AMRs market is experiencing rapid expansion, with a compound annual growth rate (CAGR) expected to exceed 20% over the next few years. Several factors contribute to this growth:

E-commerce Boom: The rise of e-commerce has led to an increased demand for efficient and flexible logistics solutions. AMRs help in automating warehouse operations, handling goods, and optimizing supply chains, making them indispensable in the fast-paced world of online retail.

Labor Shortages and Rising Costs: In many industries, labor shortages and rising wages are pushing companies to seek automated solutions. AMRs offer a viable alternative, performing repetitive tasks like material handling, inventory management, and transportation more cost-effectively than human labor.

Technological Advancements: Continuous improvements in AI, machine learning, and sensor technologies are enhancing the capabilities of AMRs. These advancements allow robots to operate in increasingly complex environments, boosting their adoption across various sectors.

Safety and Compliance: AMRs are designed to work alongside humans safely, reducing the risk of workplace accidents. In environments like healthcare, where precision and hygiene are critical, AMRs can perform tasks such as disinfection and delivery, minimizing human contact and contamination risks.

Key Trends Shaping the AMRs Market

Industry-Specific Solutions: As the AMRs market matures, we are witnessing the development of industry-specific solutions. For instance, in healthcare, AMRs are used for patient monitoring, medication delivery, and even surgical assistance. In manufacturing, they are employed for assembly line automation and quality control.

Integration with IoT and Big Data: The integration of AMRs with Internet of Things (IoT) devices and big data analytics is creating smarter, more connected environments. By collecting and analyzing data from their surroundings, AMRs can optimize their operations, predict maintenance needs, and adapt to changing conditions in real-time.

Collaborative Robots (Cobots): The rise of collaborative robots, or cobots, is another significant trend. Cobots are designed to work alongside human workers, assisting with tasks that require precision, strength, or endurance. This collaboration not only enhances productivity but also reduces the workload on human employees.

Expansion into New Markets: While logistics and manufacturing have been the primary markets for AMRs, their application is expanding into new areas such as agriculture, hospitality, and defense. In agriculture, for example, AMRs are used for tasks like crop monitoring, harvesting, and soil analysis.

Ask for Customization Report: https://www.intentmarketresearch.com/ask-for-customization/autonomous-mobile-robots-amrs-market-3605.html

Challenges and Future Outlook

Despite the promising growth, the AMRs market faces challenges, including high initial investment costs, regulatory hurdles, and the need for ongoing technological development. Ensuring that AMRs can operate safely and efficiently in diverse environments, particularly in industries with stringent regulations, remains a critical challenge.

Looking ahead, the future of the AMRs market is bright. As technology continues to advance, we can expect to see more sophisticated and versatile AMRs that can handle increasingly complex tasks. The integration of AMRs with other emerging technologies like 5G, edge computing, and autonomous vehicles will further propel the market forward.

Conclusion

The Autonomous Mobile Robots market is at the forefront of a technological revolution, reshaping how industries operate. From enhancing efficiency in warehouses to improving patient care in hospitals, AMRs are proving to be invaluable assets in the modern world. As the market continues to grow, driven by innovation and the need for automation, AMRs will play an increasingly important role in the future of work.

#Autonomous Mobile Robots#Autonomous Mobile Robots Size#Autonomous Mobile Robots Growth#Autonomous Mobile Robots Demand

0 notes

Text

The Role of AI in Enhancing Autonomous Mobile Robot Capabilities

An autonomous mobile robot (AMR) is a multipurpose, self-contained robot that can move around and carry out activities in dynamic surroundings without assistance from a human. AMRs can map their environment, make judgments in real time, and adjust to changing situations since they are outfitted with sophisticated sensors, cameras, and artificial intelligence. These autonomous mobile robots are commonly utilized for duties like material handling, inventory management, and patient care in sectors including manufacturing, logistics, and healthcare. Their independence boosts productivity, lowers personnel expenses, and increases security in intricate settings.

#autonomous mobile robot demand#autonomous mobile robot share#autonomous mobile robot trend#autonomous mobile robot size

0 notes

Text

Autonomous Mobile Robots Market Estimated To Witness Growth Due To Rising Demand From Logistics And Warehousing Industries

The global autonomous mobile robots market is estimated to be valued at US$ 3.41 Bn in 2024 and is expected to exhibit a CAGR of 3.1% over the forecast period 2024 to 2031, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: The key driver explained from the heading is the rising demand from logistics and warehousing industries. The growing e-commerce sector has placed significant pressure on logistics and warehousing companies to expedite and streamline operations. Autonomous mobile robots help in automating material handling tasks which reduces operational costs and improves productivity for warehouse and logistics companies. Additionally, AMRs ensure safer working environments by eliminating risks associated with manual material handling. This factor is further driving their adoption across industries. Furthermore, continuous technological advancements are making AMRs more affordable and efficient. Emergence of IoT and AI-enabled AMR solutions is also fueling market growth over the forecast period. SWOT Analysis Strength: Autonomous mobile robots are highly efficient as they can operate 24/7 without breaks. They perform repetitive and routine tasks with high accuracy reducing the scope of human errors. Their programming makes them consistent in task performance. Weakness: High initial investment costs are required for deployment of autonomous mobile robots. Technical glitches and system failures can disrupt workflow. Lack of dexterity and adaptability are limitations as they cannot handle unpredictable situations or tasks requiring human judgment. Opportunity: Increased labor costs and shortage of labor is driving many industries to adopt robotics solutions. The logistics and warehousing sector offers huge growth opportunity for autonomous mobile robots for applications like transportation and sorting. Growth of e-commerce will further boost demand. Threats: Concerns around job losses can increase resistance from labor unions. Delay in development of technologies like advanced sensing, AI and 5G networks can hamper full potential of autonomous mobile robots. Changes in government regulations regarding robotics can affect adoption plans of some companies. Key Takeaways The global autonomous mobile robots market growth is expected to witness high growth over the forecast period owing to benefits like improved efficiency and reduced costs. The market size is estimated to reach US$ 3.41 Mn in 2024 from US$ 1.23 Mn in 2019, indicating a CAGR of around 3.1% during the period. Regional analysis:

North America currently dominates the market attributed to rapid technological advancement and increasing investments by prominent players in the region. Asia Pacific is anticipated to be the fastest growing market led by countries like China, Japan and India. With growing industrialization and manufacturing hub status, the APAC autonomous mobile robots market is projected to witness a CAGR of over 4% during the forecast period. Key players:

Key players operating in the autonomous mobile robots market are Sanofi, Pfizer, Inc., Novartis AG., B. Braun Melsungen AG, Fresenius Medical Care, Medtronic, Preservation Solution Inc., TransMedics, Inc., Organ Recovery Systems, and Transonic Systems Inc. These key players are focused on new product launches and partnerships to strengthen their market position.

Get more insights on this topic: https://www.newsstatix.com/the-autonomous-mobile-robots-market-growth-is-propelled-by-increasing-demand-for-automation-in-warehouses/

#Autonomous Mobile Robots#Autonomous Mobile Robots Market#Autonomous Mobile Robots Market size#Autonomous Mobile Robots Market share#Autonomous Mobile Robots Market demand#Autonomous Mobile Robots Market analysis

0 notes

Text

Industrial Explosive Market Trends, Drivers, Restraints, Analysis and Forecast by 2034

According to a new industry analysis by Fact.MR, the global industrial explosive market is anticipated to be worth US$ 13.82 billion in 2024 and grow at a 6.3% CAGR from 2024 to 2034. Mining businesses use industrial explosives as a more practical and cost-effective alternative to mechanical excavation methods.

The market is expected to rise steadily due to the mining industry's increased demand for explosives. Furthermore, the rise of the mining industry is expected to fuel the industrial explosive market growth. The development of semi-automated explosive delivery systems is the outcome of key players' strategic agreements and quick technological advancements.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐂𝐨𝐩𝐲 𝐨𝐟 𝐓𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.factmr.com/connectus/sample?flag=S&rep_id=10096

Key Takeaways from Market Study:

The global industrial explosives market is expected to grow at a CAGR of 6.3% till 2034.

The market is expected to reach $25.45 billion by the end of 2034.

The market in the United States is expected to reach $1.83 billion by 2024.

China will account for 55.4% of the East Asian market in 2024.

Revenue from industrial explosive sales in Japan is expected to reach $1.02 billion by 2024.

The East Asia market is expected to grow at a CAGR of 6.5% till 2034.

Regional Analysis:

North America has developed as one of the most profitable regions for mining industry participants, owing to the presence of major worldwide mining and construction firms. India is a significant player in the South Asian industrial explosives market.

China is expected to account for 55.4% of the industrial explosive market in East Asia by 2024. China, a major manufacturer of metal and coal in the globe, has a thriving building industry. Furthermore, the country's demand for industrial explosives had skyrocketed as mining activity surged and the infrastructure sector expanded dramatically.

Category-wise insights

There are two types of explosives accessible on the market: bulk and packaged, with 56.3% and 43.7% market shares, respectively. Mining activities rely on explosives to break and construct a way through the hard rocks beneath the Earth's surface, hence the mining sector is a major user of industrial explosives. The worldwide mining business is impacted by rising demand for earth metals and minerals.

New government-sponsored exploration programs around the world are also driving the mining industry's growth. As end-use sectors expand, demand for industrial explosives is expected to rise steadily.

Competitive Landscape

The industrial explosive market is dominated by Orica Limited Exsa S.A., Eurenco SA, Enaex S.A., AEL Mining Services Ltd., Austin Powder Company, Irish Industrial Explosives Ltd., Solar Industries, LSB Industries, and BME Mining.

In October 2022, Orica Limited announced its acquisition of Axis Mining Technology. This transaction will provide the company with chances for growth in the mining value chain.

To address mining challenges in deep, complex places, Enaex S.A., a prominent explosives manufacturer, successfully demonstrated remote, robotic, and autonomous explosive loading in April 2022.

Read More: https://www.factmr.com/report/industrial-explosive-market

Segmentation of Industrial Explosive Market Research

By Type :

Bulk Explosives

Packaged Explosives

By End Use :

Mining

Construction

By Region :

North America

Western Europe

Eastern Europe

Latin America

East Asia

South Asia & Pacific

Middle East & Africa

Explore More Related Studies Published by Fact.MR Research:

Explosive Detection Technology Market: The global explosive detection technology market size has been forecast by Fact.MR to expand at a CAGR of 6.5% over the next ten years. As a result, the market is expected to increase from a value of US$ 8.56 billion in 2024 to US$ 16.07 billion by the end of 2034.

Mobile Explosive Manufacturing Unit Market: The global mobile explosive manufacturing unit (MEMU) market size has been calculated at a value of US$ 392.2 million in 2024, as revealed in a new study published by Fact.MR. Projections are that the market will expand at 5.6% CAGR to reach US$ 676.3 million by the end of 2034.

𝐀𝐛𝐨𝐮𝐭 𝐅𝐚𝐜𝐭.𝐌𝐑

We are a trusted research partner of 80% of fortune 1000 companies across the globe. We are consistently growing in the field of market research with more than 1000 reports published every year. The dedicated team of 400-plus analysts and consultants is committed to achieving the utmost level of our client’s satisfaction.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Optimizing Supply Chains with AI: From Demand Forecasting to Logistics

In the dynamic global economy of mid-2025, supply chains are no longer linear, predictable pipelines. They are complex, interconnected ecosystems constantly buffeted by geopolitical shifts, climate events, evolving consumer demands, and technological advancements. Navigating this volatility with traditional methods is like steering a supertanker with a rowboat oar. This is where Artificial Intelligence (AI) steps in, transforming supply chains from reactive operations into intelligent, self-optimizing networks.

AI is not just a buzzword; it's the GPS for modern supply chains, enabling real-time adaptability, enhanced resilience, and unprecedented efficiency from the initial whisper of demand to the final mile of delivery.

The Imperative for AI in Supply Chains

The sheer volume of data generated across a supply chain – from sales figures and inventory levels to shipping routes, weather patterns, and geopolitical news – is overwhelming for human analysis. AI and Machine Learning (ML) algorithms are uniquely positioned to process and analyze this extensive, high-dimensional data in real-time, deriving insights and solutions that humans simply cannot identify due to the scale and complexity of variables involved.

Companies that have embraced AI are already seeing significant returns on investment through:

Reduced forecast errors (up to 50%)

Improved inventory management (up to 15% better)

Lower operational costs (e.g., 20-35% reduction in transportation and inventory holding costs)

Faster response to disruptions

Let's explore how AI is revolutionizing key areas of the supply chain:

1. Precision Demand Forecasting: Predicting Tomorrow's Needs Today

Historically, demand forecasting relied on historical sales data and statistical averages, which often fell short in volatile markets. AI has transformed this:

Beyond Historical Data: AI models analyze vast datasets, including historical sales, real-time market trends, consumer sentiment from social media, economic indicators, promotional activities, and even external factors like weather patterns or current events.

Unmatched Accuracy: By recognizing subtle patterns and correlations invisible to human eyes, AI-driven forecasts significantly reduce prediction errors. This means less overstocking (reducing holding costs and waste) and fewer stockouts (improving customer satisfaction and preventing lost sales).

Dynamic Adaptability: AI models continuously learn and adjust forecasts based on new data, allowing businesses to respond swiftly to unexpected demand fluctuations, viral trends, or sudden shifts in consumer behavior. Generative AI is even being explored for scenario planning, modeling the impact of specific events like recessions or natural disasters on demand.

2. Intelligent Inventory Optimization: The Right Stock, Always

Maintaining optimal inventory levels is a delicate balance. Too much ties up capital and incurs holding costs; too little leads to stockouts and dissatisfied customers. AI provides the intelligence needed:

Real-Time Balance: AI analyzes sales patterns, lead times, supplier performance, and demand forecasts to recommend precise inventory levels across multiple warehouses and distribution centers.

Automated Replenishment: AI-powered systems can automate procurement and replenishment schedules, ensuring that raw materials and finished goods are available exactly when and where they're needed.

Reduced Bullwhip Effect: By providing better visibility and more accurate predictions throughout the chain, AI helps dampen the "bullwhip effect," where small demand fluctuations at the retail end amplify into massive swings further up the supply chain.

3. Streamlined Warehousing and Production: Smart Operations

Inside the warehouse and on the factory floor, AI is driving automation and efficiency:

Warehouse Orchestration: AI optimizes warehouse layouts, directs autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) for efficient pick paths and material transport. It can even orchestrate interactions between human workers and robots for augmented efficiency.

Predictive Maintenance: AI analyzes sensor data from machinery and equipment to predict potential failures before they occur. This enables proactive maintenance, minimizing costly downtime and ensuring continuous production.

Production Optimization: AI optimizes master production schedules by analyzing production data, resource availability, and demand. This leads to more efficient resource allocation, reduced waste, and increased customer fulfillment levels.

4. Dynamic Logistics and Route Optimization: Smarter Deliveries

The movement of goods is often the most complex and costly part of the supply chain. AI revolutionizes logistics:

Dynamic Route Planning: AI algorithms analyze real-time traffic conditions, weather forecasts, road closures, delivery windows, and even vehicle capacity to identify the most efficient delivery routes. This reduces fuel consumption, transportation costs (by up to 22%), and delivery times.

Real-Time Shipment Visibility: AI integrates data from IoT sensors, GPS, and cloud platforms to provide end-to-end visibility of shipments. It can flag potential delays, temperature fluctuations, or unexpected route changes, enabling proactive intervention and improved customer communication.

Autonomous Logistics: While still evolving, AI-powered autonomous trucks and drones are set to revolutionize freight transportation, promising reduced human error, increased safety, and further optimization of delivery times.

Challenges and the Road Ahead

Despite the immense promise, integrating AI into supply chains isn't without its challenges:

Data Readiness: AI thrives on high-quality, integrated data. Breaking down data silos and establishing robust data governance frameworks are crucial prerequisites.

Talent Gap: A shortage of professionals skilled in AI, machine learning, and data analytics within the supply chain sector remains a barrier.

Integration Complexity: Seamlessly integrating AI solutions with existing legacy ERP and planning systems requires careful planning and execution.

Ethical Considerations: Ensuring fairness, transparency, and accountability in AI decision-making (e.g., route optimization that doesn't disproportionately impact certain communities).

Conclusion

In 2025, AI is no longer an optional upgrade for supply chain management; it's a fundamental necessity for survival and growth in an increasingly unpredictable world. By leveraging AI from the precision of demand forecasting to the dynamic optimization of logistics, businesses can transform their supply chains into intelligent, resilient, and highly efficient engines of progress. Those that embrace this transformation will not only navigate disruptions with greater ease but will also unlock unprecedented levels of competitive advantage, profitability, and customer satisfaction. The future of supply chain management is undeniably intelligent, and it's here now.

#technology#artificial intelligence#ai#gen ai#supply chain security#supplychain#supply chain attacks

0 notes

Text

Powering the Future: AI and Machine Learning Development Services Driving Business Growth

In today’s fast-paced, digital-driven world, AI and machine learning development services are revolutionizing how businesses operate. From improving efficiency to unlocking deep data insights, organizations across industries are leveraging these technologies to spark innovation and enable smarter, faster decision-making.

Among the core branches of artificial intelligence, machine learning (ML) stands out as one of the most transformative. It empowers systems to learn from data, identify trends, and make decisions with little to no human input. Unlike traditional rule-based software, machine learning algorithms evolve over time by processing more data, becoming more accurate and intelligent as they go.

How Machine Learning Actually Works

At its core, machine learning is about learning from data—just like humans learn from experience. Here’s a simplified look at how machine learning systems are developed:

Data Collection: The journey starts by collecting data from sources like IoT sensors, business applications, web platforms, or internal tools.

Data Preprocessing: This data is cleaned and structured so it’s usable for training machine learning models.

Model Selection: Based on the business goal—be it forecasting, segmentation, classification, or optimization—a suitable ML algorithm is chosen.

Training the Model: The algorithm is trained using historical data to recognize patterns and relationships.

Model Evaluation: Developers validate the model using test data to ensure its performance is accurate and reliable.

Deployment: Once refined, the model is integrated into real-world systems, from cloud platforms to mobile applications.

Ongoing Learning: With continuous data input, the model can be retrained over time, improving accuracy and adaptability.

Major Types of Machine Learning

Understanding the main categories of machine learning helps businesses select the right method for their use cases:

Supervised Learning: Models are trained with labeled data, learning from known outcomes. This is ideal for tasks like credit scoring, demand forecasting, or spam detection.

Unsupervised Learning: Here, the model explores unlabeled data to discover patterns. It’s used in customer segmentation, trend analysis, and market research.

Reinforcement Learning: The algorithm learns by interacting with its environment, adjusting actions based on feedback. It's widely used in robotics, gaming, and autonomous driving systems.

Real-World Applications Across Industries

Businesses in virtually every sector are investing in AI and machine learning development services to solve complex challenges and create value:

Healthcare: From early diagnosis and drug discovery to personalized treatment plans, AI is improving patient care and operational workflows.

Retail & E-Commerce: Machine learning powers personalized shopping experiences, dynamic pricing, and supply chain forecasting.

Finance: ML models help detect fraud, automate risk assessment, and drive algorithmic trading.

Manufacturing: Predictive maintenance, real-time quality control, and process optimization are driven by AI.

Transportation & Logistics: AI ensures smarter route planning, demand forecasting, and autonomous delivery vehicles.

Why AI and Machine Learning Development Services Are Essential

Here are key reasons companies are integrating AI into their operations:

Data-Driven Decisions: AI analyzes massive datasets quickly, delivering actionable insights for faster and more informed decision-making.

Higher Efficiency: Automating time-consuming tasks minimizes human error and accelerates productivity.

Customer Personalization: From product suggestions to AI-powered support, businesses create more relevant and engaging experiences.

Cost Reduction: Automation reduces labor costs, downtime, and operational waste—leading to long-term financial gains.

Real-Time Monitoring: Businesses gain the ability to detect issues or opportunities as they happen, enhancing agility.

Security & Compliance: AI detects anomalies and threats, strengthening cybersecurity and compliance across systems.

Scalability: AI systems grow effortlessly with the business, managing more data and users without sacrificing performance.

Emerging Trends Shaping the AI Landscape

The future of AI is being shaped by innovative advancements, including:

Edge AI: AI models are increasingly deployed on local devices for real-time, low-latency processing, reducing dependence on the cloud.

Explainable AI (XAI): As AI becomes central to critical decisions, there’s a rising demand for models that explain their outcomes clearly and transparently.

Autonomous Business Automation: AI is moving beyond task-level automation to manage entire workflows across enterprise systems.

AI for Cyber Defense: Advanced models are being trained to anticipate, detect, and respond to cybersecurity threats in real-time.

Ethical AI Development: With regulatory pressure mounting, responsible AI development practices—focusing on fairness, transparency, and accountability—are becoming the norm.

Choosing the Right AI Development Partner

Success in AI implementation heavily depends on partnering with the right development team. Here’s what to consider:

Industry Experience: Choose a partner that understands your specific business domain and operational needs.

Technical Skillset: Look for teams skilled in top frameworks like TensorFlow, PyTorch, Keras, and Scikit-learn.

Customized Solutions: Off-the-shelf tools may not fit your business. Opt for partners who offer tailored AI models and applications.

Scalable Infrastructure: Ensure they can build and support scalable solutions that grow with your business.

End-to-End Support: Post-deployment services like model tuning, updates, and maintenance are essential for long-term success.

Why Rytsense Technologies?

At Rytsense Technologies, we specialize in crafting high-performance AI and machine learning development services tailored to your organization’s goals. From building predictive models to automating workflows and designing intelligent applications, we bring strategic insight and technical excellence to every project.

Our approach combines innovation, reliability, and ethical AI practices to ensure your business stays ahead in the rapidly evolving digital landscape.

Want to Learn More?

👉 To dive deeper into AI and machine learning development services, be sure to check out the extended guide linked below. Read the Full Blog Here

0 notes

Text

Asia-Pacific Warehouse Automation Market Size Accelerating Supply Chain Transformation Across the Region

In the ever-evolving landscape of logistics and supply chain management, the Asia-Pacific Warehouse Automation Market is rapidly emerging as a strategic enabler for businesses seeking speed, precision, and cost-efficiency. From robotics to AI-powered inventory systems, warehouse automation is revolutionizing storage and distribution centers across the region.

According to the Asia-Pacific Warehouse Automation Market Report, the market is expected to witness impressive growth through 2032, driven by surging e-commerce demand, technological advancements, and increasing pressure on logistics providers to reduce turnaround times.

What is Warehouse Automation?

Warehouse automation involves the use of advanced technology—including robotics, AI, machine vision, IoT sensors, and software systems—to automate storage, retrieval, sorting, packaging, and inventory tracking processes. It helps reduce manual labor, increase throughput, and enhance supply chain visibility.

Key Market Drivers

E-Commerce Boom in Asia-Pacific

The explosive growth of online shopping in countries like China, India, Japan, and Southeast Asia has significantly increased demand for faster, more efficient fulfillment operations. Warehouse automation is no longer optional—it’s a competitive necessity.

Advancements in Robotics and AI

Autonomous Mobile Robots (AMRs), robotic arms, and AI-enabled picking systems are optimizing labor-intensive warehouse tasks. These innovations improve accuracy and minimize operational errors.

Industrial Modernization & Smart Logistics

As part of Industry 4.0 initiatives, major APAC economies are upgrading legacy logistics infrastructure. Automation plays a vital role in creating smart warehouses that are agile, data-driven, and scalable.

Rising Labor Costs & Shortages

With labor shortages becoming more common and wages on the rise, automation offers a sustainable solution to maintain productivity without increasing overheads.

Market Segmentation

By Component: Hardware (conveyors, AGVs, robotic arms), Software (WMS, analytics), and Services

By End-User: E-commerce, food & beverage, pharmaceuticals, automotive, retail, and 3PL

By Country: China, Japan, South Korea, India, ASEAN countries, and Australia

Major Trends Shaping the Market

1. Autonomous Mobile Robots (AMRs)

Unlike traditional AGVs, AMRs use AI and sensor fusion to navigate dynamically in unstructured environments—ideal for fast-paced warehouses.

2. Cloud-Based WMS

Warehouse Management Systems hosted on the cloud allow for real-time visibility, scalability, and integration with ERP and e-commerce platforms.

3. Predictive Maintenance

IoT-enabled sensors on automated equipment now predict system failures before they occur, minimizing downtime and repair costs.

4. Green Warehousing

Sustainability goals are prompting investment in energy-efficient automation systems and smart lighting to reduce carbon footprint.

Key Challenges

High Initial Investment: ROI is substantial, but upfront CAPEX for automation hardware and software integration can deter smaller players.

Integration Complexity: Blending old infrastructure with new automated systems can be technically challenging without the right expertise.

Cybersecurity Risks: As operations become digitized and connected, cybersecurity becomes a crucial aspect of warehouse management.

Trending Report Highlights

Explore more high-growth markets shaping the future of automation and electronics:

4D Technology Market

Micro-Electro-Mechanical System (MEMS) Market

Security Screening Market

Solid State Cooling Market

Projector Lamp Market

Infrared Detector Market

With e-commerce exploding and customer expectations reaching new highs, the Asia-Pacific Warehouse Automation Market is set for transformative growth. From robotics and smart software to fully integrated logistics ecosystems, automation is helping companies stay competitive in a fast-paced economy.

By automating their warehouse operations, businesses in Asia-Pacific can improve accuracy, reduce costs, and meet the growing demands of modern commerce—one intelligent system at a time.

0 notes

Text

Inductive Proximity Sensor Market Drivers Fueling Growth Across Key Industries

The global inductive proximity sensor market is witnessing robust growth due to the rapid adoption of automation technologies across manufacturing, automotive, and industrial sectors. These sensors are integral to non-contact detection applications, offering durability, accuracy, and efficiency in harsh operating environments.

Increasing Automation in Manufacturing

One of the most significant drivers for the inductive proximity sensor market is the growing trend of industrial automation. Smart factories are becoming the norm, particularly in developed economies, where manufacturers are focusing on enhancing productivity and reducing operational costs. Inductive proximity sensors are key components in robotic arms, conveyor systems, and automated quality checks, where contactless and reliable sensing is crucial. The increasing use of Industry 4.0 technologies and Internet of Things (IoT) in production lines is further accelerating demand.

Surge in Automotive Applications

The automotive sector is another major contributor to the growth of inductive proximity sensors. These sensors are widely used in systems such as anti-lock braking systems (ABS), parking assistance, automatic gearboxes, and engine control units. As automotive OEMs increasingly focus on improving vehicle safety and performance, the adoption of inductive sensors is scaling rapidly. The shift towards electric vehicles (EVs) also presents a fresh avenue for sensor integration, especially in battery management systems and autonomous driving technologies.

Growing Demand from Consumer Electronics

The proliferation of smart consumer electronics—such as smartphones, smart home devices, and wearables—has created a new layer of demand for inductive proximity sensors. These sensors are favored for their compact size, low maintenance, and long operational life. In mobile phones, they are used for screen on/off functions, while in smart appliances, they ensure responsive and seamless user interfaces.

Advancements in Sensor Technology

Ongoing innovations in sensor design and materials have made inductive proximity sensors more versatile and robust. Improved sensing ranges, miniaturization, enhanced electromagnetic compatibility, and better resistance to dust, moisture, and chemicals are expanding their use in challenging environments. These technological advancements are also opening new opportunities in aerospace, medical devices, and energy sectors where reliability and precision are critical.

Increased Investment in Industrial Infrastructure

Government policies encouraging smart infrastructure, especially in Asia-Pacific and Europe, are indirectly driving demand for inductive proximity sensors. Initiatives like “Make in India,” China’s “Made in China 2025,” and Europe’s focus on digital manufacturing are encouraging investment in modernizing industrial equipment. These developments rely heavily on sensor-based systems to ensure safety, efficiency, and predictive maintenance—further reinforcing market expansion.

Rising Focus on Safety and Predictive Maintenance

With industrial safety standards becoming more stringent, companies are turning to sensor technologies to prevent accidents and reduce unplanned downtimes. Inductive proximity sensors are widely used in monitoring the condition and position of moving parts in machinery, enabling predictive maintenance strategies. This ensures cost-effectiveness, longer equipment life, and reduced downtime, making sensors an essential part of modern industrial setups.

Regional Market Dynamics

Asia-Pacific dominates the global inductive proximity sensor market, driven by its manufacturing prowess, rising automation in countries like China, Japan, South Korea, and India, and a strong presence of key electronics and automotive manufacturers. North America and Europe are also significant contributors, with mature industrial automation and automotive sectors. Emerging economies in Latin America and the Middle East are gradually embracing smart technologies, creating long-term growth potential.

Conclusion

The inductive proximity sensor market is being propelled by a convergence of factors including industrial automation, automotive innovation, and smart technology integration. With continuous technological upgrades and the growing need for contactless sensing solutions, the market is set to witness sustained growth in the coming years. Manufacturers and industry players who leverage these trends will be well-positioned to capitalize on evolving market opportunities.

0 notes

Text

Key Automotive Technologies: ADAS, IoT, and Autonomous Vehicles

The global automotive industry is undergoing a radical transformation with the emergence of advanced technologies. From intelligent safety systems to fully autonomous vehicles, innovations such as ADAS (Advanced Driver Assistance Systems), IoT (Internet of Things), and AI-driven automation are reshaping the way we drive. For students pursuing the B.Tech Mechanical Automobile Engineering ADYPU program, this is an exciting time to be part of an industry where technology meets mobility. As one of the Best Universities for Automotive Engineering, ADYPU provides the right platform for students to explore, innovate, and thrive in this rapidly evolving space.

ADAS – Making Driving Safer and Smarter

Advanced Driver Assistance Systems (ADAS) have become essential features in modern vehicles. These systems use sensors, cameras, radar, and artificial intelligence to support drivers and enhance road safety. Features such as lane-keeping assist, adaptive cruise control, automatic emergency braking, and blind-spot detection are now common in high-end vehicles and are rapidly entering the mass market.

Students enrolled in the Best Automobile Engineering Course in Pune at ADYPU gain in-depth knowledge of the electronics, control systems, and software that power ADAS. Through hands-on training and industry-aligned coursework, they are equipped to design, simulate, and implement safety technologies that reduce human error and prevent accidents. This makes ADAS a critical area for anyone planning a career in automobile engineering & design.

IoT in Automobiles – Connecting Cars to the World

The Internet of Things (IoT) has opened up a new world of connectivity in the automotive sector. Smart vehicles can now communicate with each other, with traffic infrastructure, and with mobile devices. From real-time diagnostics and predictive maintenance to connected infotainment and remote vehicle monitoring, IoT enhances both user experience and operational efficiency.

The Top Mechanical & Automotive Engineering Degree at ADYPU covers IoT applications in depth. Students work on live projects that include sensor integration, telematics, cloud computing, and cybersecurity. The B.Tech Mechanical Automobile Engineering ADYPU curriculum ensures that students understand not only the hardware but also the software and networking aspects that power connected vehicles. As this technology becomes standard, professionals skilled in automotive IoT are in high demand across industries.

Autonomous Vehicles – Engineering the Future of Mobility

One of the most exciting developments in the automotive world is the rise of autonomous or self-driving vehicles. These vehicles rely on a combination of sensors, AI, machine learning, and high-precision mapping to navigate without human input. While fully autonomous cars are still in testing phases, semi-autonomous features are already available and expanding rapidly.

ADYPU prepares its students to be leaders in this space. Through the Best University for Automotive Engineering, students explore concepts such as artificial intelligence, machine vision, robotics, and vehicular communication. The Admissions Open – B.Tech Automobile Engineering program at ADYPU is tailored to provide exposure to these cutting-edge technologies, ensuring that students graduate with the skills to innovate in a world heading toward automation.

Why ADYPU is the Right Choice for Automotive Tech Enthusiasts

With a future-oriented curriculum, experienced faculty, and industry partnerships, ADYPU is recognized as the Best Automobile Engineering Course in Pune. The B.Tech Mechanical Automobile Engineering ADYPU program offers a blend of theory and practical learning, ensuring students gain the technical know-how and problem-solving skills required in today’s competitive job market.

For those aspiring to build a strong career in automobile engineering & design, ADYPU stands as a trusted academic partner. With Admissions Open – B.Tech Automobile Engineering, now is the time to take a step toward becoming part of the next generation of automotive innovators.

Conclusion: Drive the Future with ADYPU

Technologies like ADAS, IoT, and autonomous driving are not just transforming vehicles—they’re transforming careers. Pursuing the Top Mechanical & Automotive Engineering Degree at ADYPU empowers students to shape the future of mobility with confidence and creativity. If you’re passionate about automobiles and innovation, the B.Tech Mechanical Automobile Engineering ADYPU program is your gateway to a thrilling and impactful career in the automotive world.

0 notes

Text

Forget Big Tech—These Electronics Manufacturing Companies Are Building the Future

While the spotlight often shines on major tech brands, the true engines of innovation are working behind the scenes electronics manufacturing companies. These organizations don’t just follow technology trends; they enable them. From the circuitry inside your smartphone to mission-critical aerospace systems, these companies are laying the groundwork for the technologies shaping our future.

In 2025, their role has never been more pivotal. As industries rapidly evolve with AI, automation, electric mobility, and smart infrastructure, electronics manufacturers are becoming strategic partners—not just suppliers—for innovation-driven businesses across the globe.

The Real Power Behind Modern Innovation

Every groundbreaking product, whether it’s a wearable health monitor or an autonomous vehicle sensor, begins as a concept. But transforming that concept into a functional, scalable, and reliable product requires the precision and expertise of an electronics manufacturing company.

These companies specialize in more than just PCB assembly. They provide end-to-end solutions that include:

Design for Manufacturability (DfM)

Prototyping and product development

Surface mount technology (SMT)

Box-build and final assembly

Functional testing and quality assurance

Supply chain and lifecycle management

Their impact is not just technical—it’s strategic. By helping clients reduce time-to-market, lower production costs, and ensure product reliability, these manufacturers become long-term innovation partners.

Key Trends Driving Electronics Manufacturing in 2025

The world of electronics manufacturing is undergoing rapid transformation. Here are some of the trends defining the industry this year:

1. Smart Factories & Industry 4.0

Automation is no longer optional. Electronics manufacturers are adopting robotics, IoT sensors, and AI-powered monitoring systems to create smart production lines. These enhancements improve accuracy, reduce downtime, and boost productivity.

2. Sustainable Manufacturing Practices

Environmental concerns are shaping every industry, and electronics is no exception. Today’s leading manufacturers are investing in eco-friendly components, energy-efficient machinery, RoHS compliance, and circular economy practices to meet global sustainability goals.

3. Miniaturization & Multi-Layer Integration

With the growing demand for compact, high-performance electronics—especially in wearables, medical devices, and IoT—manufacturers are pushing the limits of miniaturization. Techniques like high-density interconnect (HDI) and 3D packaging are becoming standard.

4. Localized Manufacturing Ecosystems

Global disruptions have taught businesses the value of supply chain resilience. Many electronics companies are now establishing regional manufacturing hubs to reduce dependency on offshore suppliers and ensure faster delivery.

5. Customization & Low-Volume Precision Manufacturing

In sectors like healthcare, aerospace, and defense, there’s a rising demand for low-volume, high-mix manufacturing. Electronics companies are adapting with modular production lines and flexible processes that support mass customization without compromising quality.

Why Choosing the Right Electronics Manufacturer Matters

In 2025, the gap between a good electronics manufacturer and a great one is significant—and the impact is measurable. Businesses must assess their manufacturing partners based on several critical parameters:

Technical Capabilities: Do they support high-speed SMT, advanced packaging, or RF/wireless assembly?

Certifications & Compliance: Are they certified for ISO 9001, IATF 16949, ISO 13485, or AS9100?

Design Support: Can they offer DfX (Design for Excellence) insights that improve cost and manufacturability?

Scalability: Are they equipped to take a prototype into high-volume global production?

Quality Control Systems: Do they have in-house testing, real-time defect tracking, and traceability?

Sustainability & Compliance: Are they aligned with environmental standards like RoHS, WEEE, and REACH?

When businesses align with the right manufacturer, they gain more than just a vendor—they gain a technology partner.

Industries Transforming Through Electronics Manufacturing

The reach of electronics manufacturing extends far beyond consumer gadgets. Key industries depending on high-performance electronics in 2025 include:

Automotive & EV: Battery management systems, power inverters, and autonomous driving modules

Medical Devices: Diagnostic equipment, wearable health monitors, implantable electronics

Industrial Automation: Controllers, sensors, robotics, machine vision systems

Telecommunications: 5G infrastructure, fiber optics, network hardware

Aerospace & Defense: Radar systems, flight control units, communications hardware

IoT & Smart Devices: Home automation, environmental monitoring, security systems

Each sector brings unique requirements for reliability, durability, regulatory compliance, and design complexity—requirements top electronics manufacturers are well equipped to meet.

What to Expect from the Future of Electronics Manufacturing

The evolution of electronics manufacturing is far from over. In the coming years, expect even greater integration between physical manufacturing and digital intelligence. Technologies such as digital twins, blockchain-based supply chain traceability, and AI-powered defect prediction are poised to redefine the industry.

Moreover, as the demand for electronics grows exponentially across emerging markets and advanced economies alike, manufacturers that invest in agility, automation, and talent development will lead the next era of innovation.

Conclusion: Behind Every Breakthrough Is a Trusted Electronics Manufacturer

In a hyper-connected, fast-paced world, electronics manufacturing companies are the invisible force enabling progress. They are the ones converting complex ideas into practical, scalable realities. And in 2025, they are more critical than ever.

Whether you’re a startup developing a new smart device or a global enterprise optimizing your supply chain, partnering with the right electronics manufacturer will define your success.

Ready to Partner with Leading Electronics Manufacturers?

FindingMFG connects you with verified, certified, and experienced electronics manufacturing companies around the world. Post your RFQ, evaluate capabilities, and accelerate your production journey with trusted partners.

0 notes

Text

Ecommerce Fulfillment in the USA: Trends and Technologies You Can’t Ignore in 2025

As the ecommerce industry surges ahead in 2025, the way products are stored, packed, and delivered has undergone a massive transformation. The rise of omnichannel retail, hyper-personalization, and same-day delivery expectations are forcing retailers and logistics providers in the USA to rethink and refine their fulfillment strategies. Staying competitive means embracing the latest technologies and evolving trends that are shaping the future of ecommerce fulfillment.

Smart Warehousing: The Foundation of Efficient Fulfillment

Modern ecommerce success begins with intelligent warehousing solutions. In 2025, smart warehouses are not just automated—they’re data-driven ecosystems that anticipate demand, optimize inventory, and reduce operational overhead.

Robotics and Automation: Fulfillment centers are integrating autonomous mobile robots (AMRs) and robotic picking systems to streamline operations, cut labor costs, and speed up order processing. Major players like Amazon and Walmart are setting benchmarks by operating fully automated hubs.

AI-Powered Inventory Management: Artificial intelligence analyzes sales data, seasonal trends, and market signals to fine-tune stock levels. Overstock and stockouts are drastically reduced, ensuring higher customer satisfaction and lower holding costs.

IoT and Real-Time Tracking: With Internet of Things (IoT) devices embedded across warehouses, operators can now monitor temperature, humidity, shelf life, and movement in real time—key for sensitive goods like perishables and pharmaceuticals.

Micro-Fulfillment Centers: Meeting Urban Demand Faster

Micro-fulfillment centers (MFCs) are compact, automated warehouses strategically located within urban hubs. As consumer demand shifts to same-day or even one-hour delivery, MFCs are becoming crucial to ecommerce logistics.

Urban Warehousing: Retailers are repurposing underutilized real estate—like malls and abandoned big-box stores—into MFCs. This places inventory closer to high-density customer zones, minimizing delivery times.

Hybrid Fulfillment Models: Combining dark stores (retail locations converted into non-customer-facing fulfillment centers) with traditional retail creates hybrid models that balance foot traffic with online fulfillment capabilities.

Integration with Delivery Networks: These centers are tightly integrated with last-mile delivery providers, enabling a seamless flow of goods from shelf to doorstep.

Last-Mile Delivery Innovations: Speed Meets Sustainability

The last mile is the most expensive and complex part of ecommerce logistics. In 2025, a range of innovations is redefining the economics and environmental impact of last mile delivery in the USA.

Electric and Autonomous Vehicles: Logistics companies are investing heavily in electric delivery vans, autonomous drones, and sidewalk robots. These reduce emissions and allow for 24/7 delivery in cities with strict vehicle regulations.

Crowdsourced Delivery Networks: Uber-style models for package delivery are expanding. Using local couriers through gig-economy platforms increases flexibility and reduces fixed costs.

Smart Route Optimization: AI and machine learning algorithms calculate real-time delivery routes based on traffic, weather, and customer availability, reducing delivery windows and boosting customer satisfaction.

Omnichannel Fulfillment: Bridging Online and Offline Experiences

Consumers expect seamless experiences whether they shop online or in-store. Omnichannel fulfillment strategies enable retailers to blur the lines between digital and physical retail.

Buy Online, Pick Up In-Store (BOPIS): This model has matured with retailers enhancing curbside pickup systems, offering lockers, and reducing wait times through better order tracking.

Ship-from-Store Fulfillment: Physical stores double as fulfillment hubs. Retailers use local inventory to ship orders faster and reduce warehousing costs.

Unified Inventory Visibility: Integrated systems provide real-time inventory updates across all channels. This prevents stock discrepancies and empowers consumers with accurate product availability information.

AI and Predictive Analytics: The Brain of Fulfillment

Artificial intelligence is the linchpin of next-gen ecommerce fulfillment. It empowers decision-making at every level of the supply chain.

Demand Forecasting: AI crunches vast amounts of data to anticipate what products will sell, where, and when. This leads to smarter purchasing, stocking, and placement decisions.

Dynamic Pricing and Promotions: Inventory levels are now tied to pricing strategies. When stock runs low or demand spikes, prices auto-adjust to optimize profit margins and sales velocity.

Customer Experience Optimization: AI predicts preferred delivery times, analyzes feedback, and customizes communications—driving loyalty and reducing cart abandonment.

Sustainable Fulfillment: Going Green Is No Longer Optional

Eco-conscious consumers in 2025 are holding brands accountable. Fulfillment operations must be optimized for sustainability, not just speed.

Eco-Friendly Packaging: Recyclable, compostable, and reusable packaging is becoming standard. Many brands are eliminating single-use plastics and switching to minimalistic designs.

Carbon Neutral Logistics: Companies are partnering with carbon offset providers and using green logistics networks to reduce the environmental impact of deliveries.

Reverse Logistics for Returns: Streamlining the returns process—using reusable packaging and consolidated pickup points—reduces emissions and enhances the post-purchase experience.

Third-Party Logistics (3PL) and Fulfillment-as-a-Service

Outsourcing fulfillment to specialized third-party logistics providers is now a key strategy for scalable ecommerce growth in the USA.

Flexible Fulfillment Infrastructure: 3PLs provide warehousing, packing, and shipping services without the capital investment. This is ideal for startups and rapidly scaling businesses.

API Integrations with Ecommerce Platforms: Top 3PLs offer seamless integrations with Shopify, WooCommerce, Amazon, and others—automating order flow and tracking.

Value-Added Services: From kitting and subscription box assembly to branded packaging, 3PLs now offer bespoke services that enhance the customer experience.

Fulfillment Technologies You Must Watch in 2025

The ecommerce fulfillment ecosystem in 2025 is supported by cutting-edge tech that transforms how goods move across the supply chain.

Blockchain for Supply Chain Transparency: Retailers use blockchain to track product origin, movement, and authentication, especially in high-value industries like luxury and electronics.

Digital Twins for Warehouse Simulation: These virtual models of warehouses allow logistics managers to simulate operations, test layouts, and predict bottlenecks before making real-world changes.

Voice and Vision Systems: Voice-directed warehousing and computer vision systems are enabling hands-free operations and improving pick accuracy.

Warehouse-as-a-Service (WaaS): Startups and SMEs can now rent warehouse space on demand, just like cloud computing, to scale quickly without capital expenditure.

In 2025, ecommerce fulfillment in the USA is defined by speed, intelligence, sustainability, and scalability. Retailers and logistics providers that adopt emerging technologies and align with the latest trends will gain a decisive edge in a highly competitive landscape. The future belongs to those who innovate their fulfillment strategies to deliver not just products, but exceptional customer experiences.

For original post visit: https://www.eastbostonnews.com/ecommerce-fulfillment-in-the-usa-trends-and-technologies-you-cant-ignore-in-2025

0 notes

Text

Robotics Crawler Camera System Market Size, Share, Trends, Forecast & Growth Analysis 2034

Robotics Crawler Camera System Market is rapidly transforming inspection and surveillance across a variety of high-risk and hard-to-reach environments. Valued at $360.8 million in 2024, this market is projected to reach $1.49 billion by 2034, registering a compelling CAGR of 15.5%. These robotic systems — equipped with high-resolution cameras, remote controls, and rugged mobility ��� are becoming indispensable in sectors like oil & gas, wastewater management, nuclear facilities, and construction. By reducing the need for manual inspection in dangerous settings, these systems not only enhance safety but also improve operational efficiency and data accuracy.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS33208

Market Dynamics

Several key factors are driving the robust momentum of this market. The foremost among them is the growing demand for automation in industrial inspection. With aging infrastructure and increasing safety mandates, industries are turning to robotic crawler systems for routine checks and emergency assessments. Moreover, smart technologies such as artificial intelligence (AI) and autonomous navigation are now being integrated into these systems, allowing for real-time analysis and predictive maintenance.

Municipal applications, particularly sewer and pipeline inspection, are also fueling demand. As urbanization increases, cities are investing in smart infrastructure, making crawler cameras essential tools in managing complex underground networks. Despite the strong growth trajectory, the market faces barriers like high initial costs, complex integration with existing infrastructure, and limited skilled labor for operation and maintenance. However, advancements in AI-driven analytics and wireless technology are expected to ease these challenges in the coming years.

Key Players Analysis

The competitive landscape is marked by innovation and strategic collaborations. Market leaders like Deep Trekker, CUES Inc., and Envirosight are consistently pushing technological boundaries by developing more agile, intelligent, and high-definition systems. Mini-Cam, Subsite Electronics, and Insight Vision are other notable players focusing on enhancing user interface and camera clarity for field operations.

Emerging entrants such as SuperDroid Robots and UAV Robotix are creating a buzz with autonomous and AI-enabled crawler systems tailored for niche applications. Strategic mergers, like Robocam Systems’ acquisition of InspectionTech, are reshaping the market by consolidating capabilities and accelerating product innovation. The ongoing investments in R&D reflect a strong commitment by players to address pain points such as adaptability and battery efficiency.

Regional Analysis

North America leads the global Robotics Crawler Camera System Market, with the United States spearheading adoption across oil and gas, utilities, and municipal sectors. Its strong regulatory framework and focus on infrastructure modernization are central to its dominance.

Europe holds the second-largest market share, with countries like Germany and the United Kingdom investing heavily in automation and smart infrastructure. Stringent environmental and safety regulations further drive the adoption of crawler camera systems in critical sectors.

Asia-Pacific is experiencing accelerated growth, thanks to industrialization in China, India, and Japan. Government-backed smart city initiatives and infrastructure upgrades are creating ripe opportunities for market expansion. In the Middle East & Africa, countries such as Saudi Arabia and the UAE are leveraging robotic camera systems for oil pipeline inspection, while Latin America, led by Brazil and Mexico, is gradually increasing adoption, spurred by urban development projects.

Recent News & Developments

The market has recently seen some impactful developments. Boston Dynamics announced a high-profile collaboration with a European utility to deploy advanced crawler systems for pipeline inspections, improving safety and minimizing downtime. iRobotics launched a new AI-powered camera system for the oil and gas sector, capable of predictive damage detection.

In a major consolidation move, Robocam Systems acquired InspectionTech, aiming to scale operations and expand their market reach. Furthermore, new U.S. regulations have been introduced to standardize robotic usage in hazardous settings, prompting manufacturers to realign their product designs. A significant $50 million investment in a start-up focused on autonomous robotic crawlers signals growing investor confidence in the sector.

Browse Full Report : https://www.globalinsightservices.com/reports/robotics-crawler-camera-system-market/

Scope of the Report

This report delivers an in-depth analysis of the Robotics Crawler Camera System Market, covering technological trends, competitive strategies, regulatory impact, and market forecasts through 2034. Key market segments include push and motorized crawlers, HD and PTZ cameras, and advanced technologies such as AI integration and autonomous navigation.

It also investigates core applications across industrial tanks, sewers, municipal pipelines, and nuclear facilities, while evaluating emerging demand for portable and vehicle-mounted systems. The report highlights strategic moves including partnerships, product launches, R&D investments, and regional expansions, equipping stakeholders with the insights necessary to navigate this high-growth market. #roboticscrawler #infrastructureinspection #smartrobotics #aiinrobotics #sewerinspection #pipelineinspection #roboticcameras #urbaninfrastructure #hazardousworksolutions #automatedinspection

Discover Additional Market Insights from Global Insight Services:

Printed Circuit Board Market : https://linkewire.com/2025/05/22/printed-circuit-board-market/

Asset Integrity Management Market : https://linkewire.com/2025/05/22/global-asset-integrity-management-market/

Medical Sensors Market : https://linkewire.com/2025/05/22/medical-sensors-market-2/

Smart Factory Market : https://linkewire.com/2025/05/22/smart-factory-market-5/

Wearable Sensors Market : https://linkewire.com/2025/05/22/wearable-sensors-market/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Logistics Robots Market

As global commerce becomes faster and more complex, the Logistics Robots Market is rapidly emerging as a cornerstone of modern supply chains. From smart warehouses to last-mile delivery, robotics is redefining how goods move, sort, and ship in today’s hyperconnected world.

📦 Driving Forces Behind the Growth

Several key factors are propelling this market forward:

E-commerce Expansion: The explosive growth of online shopping demands faster, more accurate fulfillment, pushing companies to automate their warehouses with robotic systems.

Labor Shortages: Increasing difficulty in recruiting and retaining warehouse staff is driving investment in autonomous solutions.

Technological Advancements: Progress in AI, machine vision, and IoT has made robots smarter, safer, and more efficient than ever.

Need for Operational Efficiency: Robotics significantly reduces human error, improves order accuracy, and enhances throughput in high-demand environments.

🔗 𝐆𝐞𝐭 𝐑𝐎𝐈-𝐟𝐨𝐜𝐮𝐬𝐞𝐝 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐟𝐨𝐫 𝟐𝟎𝟐𝟓-𝟐𝟎𝟑𝟏 → 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐍𝐨𝐰

⚙️ Market Applications & Impact

Logistics robots are now deployed across multiple sectors, including:

Retail & E-commerce: Automating picking, packing, and sorting in fulfillment centers.

Manufacturing & 3PL: Enhancing supply chain efficiency and minimizing downtime.

Healthcare & Pharmaceuticals: Ensuring precise handling and transport of sensitive materials.

Food & Beverage: Supporting cold chain logistics and timely deliveries.

These robots range from autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) to robotic arms and drones, depending on the specific task and environment.

🌍 Global Outlook

The Asia-Pacific region leads in both production and deployment, with major contributions from China, Japan, and South Korea. However, North America and Europe are rapidly catching up, driven by investments in smart warehousing and Industry 4.0 initiatives.

As of 2025, the Logistics Robots Market is projected to grow at a double-digit CAGR, with billions in revenue expected over the next five years. With scalability, precision, and speed at the core of logistics innovation, robots are becoming not just a luxury but a necessity for competitive global operations.

🔖 Key Takeaway

Logistics robots are no longer futuristic tools — they are today’s answer to tomorrow’s supply chain challenges. Companies that embrace automation will not only cut costs but also gain a strategic edge in an increasingly on-demand economy.

0 notes

Text

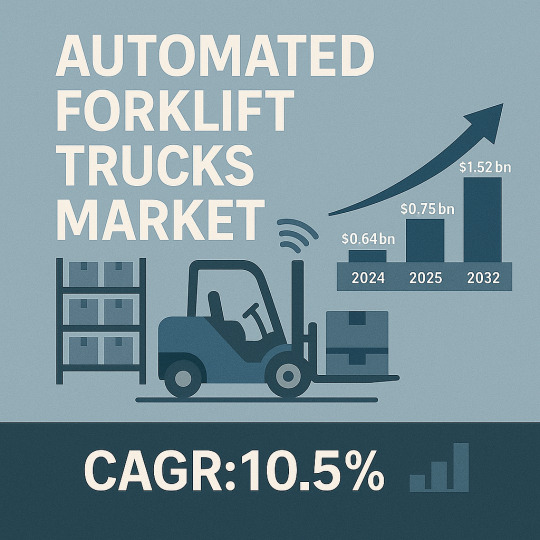

Automated Forklift Trucks Market Size, Trends & Forecast 2032

🚜🤖 The global automated forklift trucks market size was valued at USD 0.64 billion in 2024 and is projected to grow from USD 0.75 billion in 2025 to USD 1.52 billion by 2032, showcasing a healthy CAGR of 10.5% during the forecast period. 🌏 Asia Pacific dominated with a 37.5% share in 2024, reflecting rapid industrial automation and smart warehousing trends.

📌 Key Market Insights:

Market Size (2024): USD 0.64 billion

Forecast Size (2032): USD 1.52 billion

CAGR (2025–2032): 10.5%

Dominant Region: Asia Pacific held 37.5% in 2024

Growth Drivers: Rising demand for efficient material handling, labor cost savings, AMR navigation tech (Laser, Magnetic, Vision Guided), and booming e-commerce & F&B sectors.

🚀 Market Trends: Automated forklift trucks, also known as autonomous mobile robots (AMRs), are revolutionizing transportation, storage, assembly, and packaging in industries like automotive, food & beverage, and e-commerce. Expect more pallet movers, counterbalance, outriggers, and reach trucks with smarter navigation and IoT integration.

👉 Full report: https://www.fortunebusinessinsights.com/automated-forklift-trucks-market-102617

0 notes

Text

Autonomous Robots Market Future Trends, Growth, Key Factors, Manufacture Players, Opportunities Analysis by 2033

The autonomous robots market size is projected to achieve a value of approximately US$ 2,561.0 million by 2023, and it is anticipated to surpass US$ 6,175.0 million by 2033. This growth will be driven by a compound annual growth rate (CAGR) of approximately 9.2% between 2023 and 2033.

The autonomous robots market in Japan is set to experience robust growth with a healthy CAGR, aiming to secure a market share of 15.8% by the year 2023. Japan held the top position as the largest global exporter of robots, both in terms of shipment value and the quantity of units in operation. Remarkably, Japan boasts a robot density of 364 robots per 10,000 employees, a figure equivalent to that of Germany. Furthermore, Japan stands as the preeminent producer of robots worldwide, with a substantial 47% of the world's robots being manufactured in Japan.

Download a Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=8267

The Emergence of Autonomous Robots:

Autonomous robots, frequently referred to as self-driving or self-operating robots, represent machines with the ability to perform tasks and make decisions autonomously, devoid of human intervention. These robotic systems have discovered applications across a wide spectrum of industries, ranging from manufacturing and logistics to healthcare, agriculture, and even space exploration. Their capacity to enhance efficiency, productivity, and safety renders them indispensable in our ever-evolving world.

Key Insights from the Report:

The recently published report on the autonomous robots market furnishes valuable perspectives on the factors propelling its remarkable expansion:

Escalating Demand for Automation: Industries are increasingly embracing automation to streamline operations and curtail labor costs. Autonomous robots lead this automation wave, as they operate tirelessly, consistently, and without fatigue.

Technological Advancements: Progress in artificial intelligence, computer vision, and sensor technologies has significantly augmented the capabilities of autonomous robots. They can now navigate intricate environments, adapt to changing circumstances, and collaborate more effectively with human counterparts.

E-commerce and Logistics: The rapid growth of e-commerce and the demand for efficient last-mile delivery solutions have catalyzed the adoption of autonomous delivery robots. These robots are revolutionizing the parcel delivery process, rendering it quicker and more convenient for consumers.

Healthcare Transformation: In the healthcare sector, autonomous robots contribute to patient care, medication delivery, and even surgical procedures. They play a pivotal role in sanitation and cleaning protocols, particularly in response to the challenges posed by the COVID-19 pandemic.

Agriculture and Sustainability: Autonomous robots are instrumental in precision agriculture, where they optimize crop management, reduce the reliance on pesticides, and boost yields. This not only enhances food production but also fosters sustainable farming practices.

Space Exploration: Autonomous robots are venturing into outer space, undertaking missions on distant planets and celestial bodies. They play a critical role in data collection, experimentation, and the groundwork for future human exploration.

Competitive Landscape

In its report, Fact.MR has profiled several leading companies operating in the autonomous robots market. These companies include ABB, AMS, Inc., ANYbotics AG, Augean Robotics, Inc., BlueSkye Automation, Clearpath Robotics, Inc., DJI, Fetch Robotics, MHS Global, Mouser Electronics, Inc., Move Robotic Sdn Bhd, Skydio, Inc., Teradyne Inc., and Waypoint Robotics Inc.

ABB, following its acquisition of mobile robot firm ASTI Mobile Robotics in 2021, has unveiled its inaugural line of autonomous mobile robots, which bear the newly renamed branding.

In a separate development in 2022, The Advanced Institute of Science and Technology (ASTI) is actively engaged in the development of a robot capable of detecting plant diseases, thereby assisting farmers in enhancing crop yields. This artificial intelligence (AI) robot is currently being trialed in a banana plantation, where it detects and identifies diseased plants at their earliest stages of infection.

Such pioneering applications of autonomous robots and the integration of cutting-edge robotic technology are expected to open new revenue streams for manufacturers in this industry.

Segmentation of Autonomous Robots Industry Research

By Type :

Collaboration Robots

Inventory Transportation Robots

Scalable Storage Picking Robots

Automatically Guided Vehicles (AGV)

By Technology :

Programmable

Non-programmable

Adaptive

Intelligent

By Payload :

Less than 500 kg

500 -1000 kg

1000-1500 kg

1500 -2000kg

Above 2000 kg

Autonomous Robots Market by Application :

Packaging

Palletizing

Material handling

Painting

Welding

Assembly

Inspection

Cutting

Dispensing

By End-Use Industry :

Aerospace and Defense

Automotive

Chemicals & Materials

Electrical & Electronics

Food and Beverage

Healthcare

Mining & Oil & Gas

Retail & e-Commerce

Logistics & Warehousing

Packaging

Others

By Region :

North America

Latin America

Europe

East Asia

South Asia and Oceania

Middle East & Africa

Get Customization on this Report for Specific Research Solutions: https://www.factmr.com/connectus/sample?flag=RC&rep_id=8267

Future Outlook:

The report suggests that the autonomous robots market is set for explosive growth in the coming years. Factors such as increased investment in research and development, the development of more sophisticated AI algorithms, and the expansion of their applications across various industries will be key drivers of this growth.

Check Out More Related Reports:

Arc Welding Equipment MarketDrone Bridge Inspection Services MarketPalletizing Robot Market

Contact: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

#Autonomous Robots Market#Autonomous Robots Market Size#Autonomous Robots Market Share#Autonomous Robots Market Forecast#Autonomous Robots Market Growth

1 note

·

View note

Text

Micro LLMs and Edge AI: Bringing Powerful Intelligence to Your Devices

Artificial Intelligence has undeniably permeated every facet of our digital lives, from personalized recommendations to sophisticated content generation. Yet, much of this intelligence has traditionally resided in distant cloud data centers, requiring constant internet connectivity and raising concerns about privacy and latency. As we navigate mid-2025, a quiet revolution is underway: the proliferation of Micro LLMs and Edge AI, empowering devices to become intelligent, autonomous, and remarkably efficient without constant cloud reliance.

This paradigm shift isn't just about convenience; it's about making AI more private, faster, cheaper, and universally accessible, transforming everything from your smartphone to industrial sensors into powerful, on-demand intelligent systems.

The Limitations of Cloud-Centric AI

While cloud computing provides immense processing power, it comes with inherent drawbacks for many real-world AI applications:

Latency: Sending data to the cloud, processing it, and receiving a response introduces delays. For real-time applications like autonomous vehicles, robotics, or instant voice commands, even milliseconds matter.

Privacy Concerns: Transmitting sensitive personal or proprietary data to remote servers raises significant privacy and security questions.

Bandwidth & Cost: Constant data streaming to and from the cloud consumes considerable bandwidth and can accrue significant costs, especially for large-scale IoT deployments.

Offline Functionality: Cloud-dependent AI ceases to function without an active internet connection, limiting its utility in remote areas or during network outages.

Understanding the Core Concepts: Edge AI and Micro LLMs

To overcome these challenges, two interconnected technological advancements are taking center stage:

Edge AI: This refers to the deployment of AI algorithms and machine learning models directly on "edge devices" – the physical devices where data is generated. Think smartphones, smart cameras, industrial sensors, wearables, or autonomous vehicles. Instead of sending all raw data to the cloud for processing, Edge AI enables intelligent computation to happen locally, at the "edge" of the network.

Micro LLMs (and TinyML): These are highly optimized, significantly smaller versions of Large Language Models (LLMs) and other AI models, specifically designed to run efficiently on resource-constrained edge devices. Techniques like quantization (reducing numerical precision), pruning (removing unnecessary connections in a neural network), and knowledge distillation (training a smaller model to mimic a larger one) allow these models to deliver powerful AI capabilities with minimal memory, processing power, and energy consumption. TinyML is a broader term encompassing the entire field of running very tiny machine learning models on microcontrollers.

The Power of On-Device AI: Key Benefits

The synergy of Micro LLMs and Edge AI unlocks a wealth of advantages:

Enhanced Privacy: By processing data on the device itself, sensitive information never leaves the local environment, significantly reducing privacy risks and aiding compliance with data protection regulations.

Ultra-Low Latency: Decisions are made in milliseconds, as data doesn't need to travel to and from the cloud. This is critical for applications requiring immediate responses.

Reduced Bandwidth & Cost: Less data needs to be transmitted, leading to substantial savings on bandwidth and cloud infrastructure costs.