#Embedded software

Explore tagged Tumblr posts

Text

I made an output agnostic logging framework for embedded devices that would work on anything as it's written only with standard C++ libs. In theory I could use it for linux or pis, lol. I made it because I kept having to write new handlers for serial, mqtt, uart, then having to like wire them all together without creating dependency loops or other issues - especially because I often work on meshes or online embedded devices that require multiple outputs. Now you just write your handler, tell it what tags to watch, and it'll log according to tag and log level. So you could write a serial debugging log handler when you're first making it. Then when you're done, disable it, and it'll stop outputting - but then later assign the serial debugging log tag to your MQTT handler and get all your debugging serial lines output to MQTT - then just disable it again when you're done. There's still some polish I need to put into it, it has some jank, some bugs, but it's working and neat. it's kind of neat.

39 notes

·

View notes

Text

VPX Chassis

The VPX Chassis offers a robust and scalable platform designed to meet the demanding needs of high-performance embedded computing applications. Built on the open VPX standard, these chassis are engineered for rugged environments and critical applications such as defense, aerospace, and industrial systems. They provide superior cooling, power distribution, and data communication to support high-bandwidth, real-time processing.

#embedded systems#backplanes#hardware#embedded#switches#embedded computing#embedded software#embedded microcontroller#chassissystems#california#openvpx#vpx

1 note

·

View note

Text

Project isn't working

Connect oscilloscope to check if it's generating the signal you expect

See a signal that makes absolutely no sense

Now you're even more confused than before

2 notes

·

View notes

Text

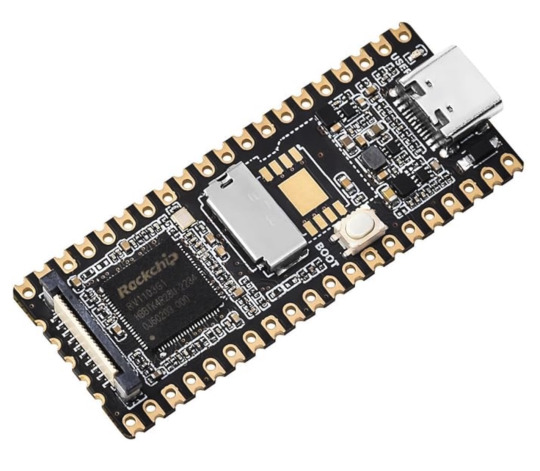

Linux Micro Development Board, Integrates ARM Cortex-A7/RISC-V MCU/NPU/ISP Processors

The LuckFox Pico represents a cost-effective Linux micro development board based on the Rockship RV1103 chip, which supplies a straightforward and efficient development platform for embedded system designers. It supports a variety of interfaces, including MIPI CSI, GPIO, UART, SPI, I2C, USB, and more. Developing applications is convenient, and debugging is quick.

3 notes

·

View notes

Text

Cybersecurity Glossary

Over the course of this year I have explained to colleagues and clients who’s roles are not in Cybersecurity what certain phrases or abbreviations mean. After I while I started to drop them into a word document so I could reuse them. Then I decided to make this post so I can easily share the explanations. There are bound to be things missing, please drop a comment if I have missed something and…

View On WordPress

#anonymisation#Attack Surface#authentication#BCP#Biometrics#Botnet#Compliance#Critical Infrastructure#cybersecurity#DDoS#DFIR#Embedded software#Encryption#Firewalls#GRC#ICS#IEC62443#Industrial Control System#IR#ISO27001#Malware#mfa#NIS2#Operational Technology#OSINT#OT#OT Security#PCI DSS#Penetration test#phishing

2 notes

·

View notes

Text

Thermal Simulation Tools Are Evolving—Is Your Workflow Keeping Up?

Simulation Is No Longer Optional

Designing electronics without thermal simulation today is like racing without a dashboard, you might keep moving, but you’ll miss the warning signs. With tighter enclosures, higher power densities, and diverse operating environments, thermal challenges aren’t just probable—they’re inevitable.

Modern Mechanical & Thermal Design workflows are evolving fast. Simulation tools have become more intelligent, more accessible, and more essential. The real question is: has your workflow kept up with the change?

Why Thermal Simulation Is Getting Smarter

A few years ago, thermal simulations were mostly post-layout activities. Now, they’re integrated earlier in the design phase, sometimes even during concept development.

What’s driving the change:

Compact form factors with high power loads

Multi-board systems generating localized heat

Demands for silent (fanless) cooling

More design teams working remotely and asynchronously

These pressures make it critical to simulate heat flow, temperature gradients, and component interactions early in the process. That’s where Mechanical & Thermal Design takes center stage.

What Modern Tools Bring to the Table

Today’s simulation platforms aren’t just about running heat maps. They’re smarter, faster, and often integrated with your PCB and CAD tools.

Here’s what’s new:

Intuitive interfaces for 3D airflow modeling

Real-time co-simulation with mechanical CAD

Faster meshing algorithms that don’t need expert tweaking

Cloud-based options for collaborative work

With these features, Mechanical & Thermal Design is no longer siloed—it becomes a fluid part of the product design journey.

The Cost of Outdated Workflows

Still relying on spreadsheets, ballpark guesses, or legacy simulation methods? You’re likely leaving performance and time on the table.

Outdated approaches can lead to:

Over-engineered cooling systems (cost and space waste)

Missed hot spots that cause long-term failures

Design delays due to thermal issues in late-stage testing

Modern Mechanical & Thermal Design practices use simulation not just to fix problems but to prevent them from happening in the first place.

Early Simulation = Fewer Surprises

Integrating thermal simulation during early mechanical concepting avoids cascading design changes later. Whether you're using passive cooling, forced airflow, or heat sinks, the earlier you simulate, the better your decisions.

Benefits of early-stage thermal simulation:

Faster time-to-market

Smaller, more efficient enclosures

Fewer physical prototypes

Tighter collaboration between electrical and mechanical teams

Thermal modeling is now a strategic step in the Mechanical & Thermal Design process—not just a safety check.

Real-World Integration Tips

If your team is moving toward integrated simulation, here are a few quick tips:

Model real-world conditions: Include surrounding components, airflow paths, and mounting orientations.

Use 3D board models: Import IDF/STEP files to ensure geometry is accurate.

Validate against extremes: Simulate worst-case power and ambient temperature scenarios.

Involve mechanical engineers early: They understand enclosure constraints that affect cooling.

These strategies help you get the most from your Mechanical & Thermal Design simulations.

Why It Matters More Than Ever

Products are getting smaller, hotter, and expected to last longer. Your mechanical and thermal considerations need to evolve just as fast.

It’s no longer about just surviving temperature—it’s about:

Meeting performance targets

Achieving compliance

Extending product lifespan

Delivering consistency in every unit shipped

All of which are tied to one core capability: how strong your Mechanical & Thermal Design workflow really is.

Final Thoughts

Thermal simulation tools are not only evolving, they’re becoming essential allies in creating better products. If you’re still waiting until the end of a project to think about cooling, you're already behind.

It’s time to treat Mechanical & Thermal Design not as a checklist item, but as a dynamic, simulation-driven pillar of your product development process.

FAQs

Q1: Do I need thermal simulation if my design isn’t high-power?A: Yes. Even low-power devices in enclosed spaces can overheat. Thermal simulation helps avoid risk early.

Q2: Can mechanical and thermal simulations be done in the same tool?A: Many modern platforms offer co-simulation, streamlining Mechanical & Thermal Design into a single environment.

Q3: How often should thermal simulations be run during a project?A: Ideally at multiple stages—during initial layout, after major component shifts, and before prototyping.

0 notes

Text

A Comprehensive Guide for Embedded Software Development for Medical Devices

As a reality check, the embedded software development life cycle of a medical device is not only challenging, but it is also sophisticated in regard to the value proposition it presents to the healthcare payers and patients. Consequently, as the field of medicine continuous to evolve, these tools become more complex as their operations are managed by embedded software which needs to be integrated with the system in a way that guarantees safe and effective operation. This in-depth tutorial will guide you through the development embedded software for medical devices and all regulatory considerations that must be addressed.

Grasping the Regulatory Framework

Manufacturers of medical devices will always be bound by the numerous laws from the Federal Drug Administration (FDA) concerning effectiveness and safety of medical devices. Starting March 2023, the FDA began restricting submissions of Software Bill of Materials (SBOM) unless there was a set cybersecurity strategy. By October 2023 the FDA started refusing to accept submission of devices that had cyber security problems.

The regulatory landscape requires manufacturers to:

Implement a risk-based approach to software design and testing Conduct thorough validation of software functionality and security

Ensure devices can detect and respond to security incidents

Establish processes for monitoring and reporting security issues

Conduct ongoing testing throughout the device's lifecycle

Key Components of Embedded Medical Device Software

Hardware-Software Integration

In medical devices, embedded systems must achieve full intergration of hardware parts and software. This is necessary to guarantee that the medical devices operate as needed and that safety regulations are satisfied.

Real-Time Operating Systems (RTOS)

Many medical devices use Real-Time Operating Systems because they require some degree of waiting time to perform an important task. Such OS’s are essential in time-sensitive operations. For embedded medical devices, RTOS frameworks like FreeRTOS and Zephyr are routinely deployed.

Software Architecture

The structure has to be modular, so that later maintenance, testing, and validation would be easier. That also helps meet regulatory standards because tracking requirements to be enacted is simplified.

Read Also: Integrating Hardware and Software in Embedded Systems Development

The Development Process

Establishing a Regulatory Strategy Early

Prior to commencing any developmental work, formulate and put in writing a regulatory strategy that is aligned with the device's capabilities and goals. This becomes particularly critical in the case of Software as a Medical Device (SaMD), wherein modifying software becomes relatively easier than changing a hardware component.

Selecting the Right Development Team

Select the relevant personnel from the software policy team having working knowledge in cyber security, more so, if drastic changes are anticipated post initial launch of the product. Engage the services of engineers specialized in software development of medical devices as they have working knowledge of the required documentation for the device regulatory processes.

Programming Languages and Tools

Common languages used in embedded medical device development include:

C: Efficient and suitable for low-level memory management

C++: Provides object-oriented features for complex systems

Assembly: For performance-critical applications requiring direct hardware access

Rust: Offers memory safety features for developing secure systems

Implementing Security by Design

Security is not an add-on but a fundamental aspect of medical device software development. The FDA requires manufacturers to:

Conduct secruity risk assessments to identify potential vulnerabilities

Implement security controls to mitigate identified risks

Design software to be resilient against potential attacks

Ensure the ability to detect and respond to security incidents

Testing and Validation

Comprehensive Testing Approach

Testing should cover every aspect of the software, including:

Unit testing for individual components

Integration testing for combined components

System testing for the entire device

Performance testing under various conditions

Security testing to identify vulnerabilities

Documentation Requirements

Thorough documentation is essential for regulatory compliance. This includes:

Design specifications

Risk assessments

Test protocols and results

Validation reports

User manuals and technical documents

Post-Market Requirements

Getting regulatory clearance is just the beginning. Once your device is on the market, you must:

1. Maintain annual Establishment Registration

2. List your device(s)

3. Implement and maintain Quality Management System (QMS) processes

4. Document changes to software and assess regulatory impact

5. Be prepared for FDA audits

6. Run postmarket cybersecurity processes including periodic penetration tests and vulnerability scans

7. Conduct postmarket surveillance

8. Produce Unique Device Identifiers for new versions

Managing Software Updates

Yes, you can update your software after FDA clearance, and in fact, the FDA expects you to provide cybersecurity updates. However, significant changes may require a new 510(k) submission, possibly including new clinical or performance data.

Strategic planning around feature development is crucial. Consider creating key features that FDA needs to evaluate in version 1.0, then have your engineering team work on version 1.1 features while waiting for FDA review.

Best Practices for Success

Optimize code for performance, power consumption, and memory usage

Implement robust error handling mechanisms

Reuse code when possible to reduce development time

Provide thorough documentation for maintainability

Perform comprehensive testing to ensure code meets requirements

Raise sufficient funding for clinical performance validation, non-clinical testing, software documentation, and cybersecurity.

Conclusion

A greener tomorrow starts with better healthcare today, and embedded software for medical devices is at the forefront of this transformation. By integrating robust security measures, following regulatory guidelines, and implementing best development practices, manufacturers can create safe, effective medical devices that enhance patient care while maintaining compliance.

Let's build smarter, develop better, and create medical devices that care for both patients and healthcare providers. The truth is, embedded software development for medical devices is complex but essential for advancing healthcare technology and improving patient outcomes.

0 notes

Text

#Embedded Software Development Services#Embedded Software#Embedded Operating System#Embedded Firmware Development

0 notes

Text

Redefine Customer Engagement with AI-Powered Application Solutions

In today’s digital landscape, customer engagement is more crucial than ever. ATCuality’s AI powered application redefine how businesses interact with their audience, creating personalized experiences that foster loyalty and drive satisfaction. Our applications utilize cutting-edge AI algorithms to analyze customer behavior, preferences, and trends, enabling your business to anticipate needs and respond proactively. Whether you're in e-commerce, finance, or customer service, our AI-powered applications can optimize your customer journey, automate responses, and provide insights that lead to improved service delivery. ATCuality’s commitment to innovation ensures that each AI-powered application is adaptable, scalable, and perfectly aligned with your brand’s voice, keeping your customers engaged and coming back for more.

#digital marketing#seo services#artificial intelligence#seo marketing#seo agency#seo company#iot applications#amazon web services#azure cloud services#ai powered application#android app development#mobile application development#app design#advertising#google ads#augmented and virtual reality market#augmented reality agency#augmented human c4 621#augmented reality#iot development services#iot solutions#iot development company#iot platform#embedded software#task management#cloud security services#cloud hosting in saudi arabia#cloud computing#sslcertificate#ssl

1 note

·

View note

Text

🚀 Power Your Devices with Cutting-Edge Embedded Software! 🌐

Our team at SMAC Software specializes in developing reliable and high-performance embedded software solutions, custom-designed to optimize functionality and enhance device efficiency across industries.

✅ Tailored Firmware & Software ✅ High Performance & Reliability ✅ Scalable Solutions ✅ Industry-Specific Expertise

Ready to bring your devices to life with seamless software integration? Let’s get started! 🔋💡

Read more at https://smacsoftwares.com/embedded-software-development/

#smacsoftwares#embedded software#iotsolutions#Firmware Development#DeviceOptimization#SmartSolutions#EmbeddedSystems

0 notes

Text

My worker firmware works! It flashed itself over, now just to add some roll back, security, and validation features. But effectively this means I never have to plug in another ESP32 to send them firmware. I can just tell them to post to MQTT from the worker firmware for logging and post the firmware binary to my local file server. This makes my life so much easier while building out this mesh of meshes multi-protocol com lib. Hell yeahhh

#trans#queer#transgender#tech#esp32#maker#computer#programming#c++#arduino#embedded software#firmware

8 notes

·

View notes

Text

Rotary Encoders | Elma Electronic

Our famous "Swiss Click Indexing System" featured on all our rotary encoders epitomizes great switching feel. Elma’s engineering services can also customize our standard offerings to suite your individual requirements, even in small quantities.

#embedded software#embedded#electronicssolution#california#hardware#electronics#IncrementalEncoder#DefenseElectronics#EncoderTechnology#CompactEncoders#AbsoluteEncoder#backplanes#embedded systems

0 notes

Text

Understanding Embedded Computing Systems and their Role in the Modern World

Embedded systems are specialized computer systems designed to perform dedicated functions within larger mechanical or electrical systems. Unlike general-purpose computers like laptops and desktop PCs, embedded systems are designed to operate on specific tasks and are not easily reprogrammable for other uses. Embedded System Hardware At the core of any embedded system is a microcontroller or microprocessor chip that acts as the processing brain. This chip contains the CPU along with RAM, ROM, I/O ports and other components integrated onto a single chip. Peripherals like sensors, displays, network ports etc. are connected to the microcontroller through its input/output ports. Embedded systems also contain supporting hardware like power supply circuits, timing crystal oscillators etc. Operating Systems for Embedded Devices While general purpose computers run full featured operating systems like Windows, Linux or MacOS, embedded systems commonly use specialized Real Time Operating Systems (RTOS). RTOS are lean and efficient kernels optimized for real-time processing with minimal overhead. Popular RTOS include FreeRTOS, QNX, VxWorks etc. Some simple devices run without an OS, accessing hardware directly via initialization code. Programming Embedded Systems Embedded Computing System are programmed using low level languages like C and C++ for maximum efficiency and control over hardware. Assembler language is also used in some applications. Programmers need expertise in Microcontroller architecture, peripherals, memory management etc. Tools include compilers, linkers, simulators and debuggers tailored for embedded development. Applications of Embedded Computing Embedded systems have revolutionized various industries by bringing intelligence and connectivity to everyday devices. Some key application areas include: Get more insights on Embedded Computing

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Embedded Computing#Embedded Systems#Microcontrollers#Embedded Software#Iot#Embedded Hardware#Embedded Programming#Edge Computing#Embedded Applications#Industrial Automation

0 notes

Text

ARD1939 - SAE J1939 Protocol Stack Code for Arduino and ESP32

ARD1939 is a powerful and efficient embedded system C code designed to bring SAE J1939 protocol support to popular development boards, including the Arduino Uno, Mega2560, Due, and ESP32. This pre-compiled solution ensures seamless integration, eliminating the need for complex setup or manual coding—it works right out of the box.

0 notes

Text

Navigating Through the Depths of Embedded Software: Testing and Verification Strategies

In the complex realm of technology, Embedded Systems serve as the quiet foundation, driving a variety of devices from intelligent gadgets to automotive systems. At the core of these systems lies the embedded software, the unseen power coordinating smooth operation. However, ensuring the dependability and strength of this software is not a simple task. Step into the domain of Embedded Systems Testing and Verification, where BlockVerse Infotech Solutions emerges as a beacon of expertise and ingenuity.

In a time where flawless performance is a must, the importance of thorough testing and verification strategies cannot be overstressed. BlockVerse Infotech Solutions acknowledges this necessity and offers a comprehensive method tailored to tackle the distinctive challenges presented by embedded software.

Initially, understanding the complexities of the embedded environment holds great importance. BlockVerse utilizes a combination of white-box and black-box testing methods to explore deep within the software’s internal operations while replicating real-world situations. This detailed approach ensures not only functional accuracy but also deals with performance, reliability, and security concerns.

Moreover, Blockverse utilizes cutting-edge tools and techniques to simplify the testing process. From automated test frameworks to model-based testing, each tool is utilized with precision to optimize efficiency without compromising quality. By utilizing virtual platforms and emulation, BlockVerse enables thorough testing across various hardware configurations, preventing compatibility issues proactively.

However, testing alone does not guarantee the integrity of embedded software. Verification, the process of confirming that the software meets predefined requirements, is equally crucial. BlockVerse adopts a varied verification approach covering code reviews, static analysis, and formal methods. By scrutinizing every line of code and adhering to industry standards, BlockVerse guarantees compliance with strict quality benchmarks.

To wrap up, embedded software plays a crucial role in modern technology, and its reliability is crucial. With BlockVerse Infotech Solutions leading the way, navigating the intricacies of Embedded Systems Testing and Verification becomes more than just a challenge; it transforms into an opportunity to enhance performance, improve reliability, and propel innovation forward.

#embedded systems#what is embedded system#embedded software#computer hardware#embedded operating system#embedded system design#remote iot software#edge computing and iot#iot development company#Cloud computing in IOT

0 notes

Text

ASIC vs FPGA: When and Why to Transition with Confidence

When you're developing a complex product or system, choosing the right technology is critical. One of the most common questions in hardware development is this: should you go with an FPGA or invest in a custom ASIC?

It’s not always an obvious choice. Both options serve different purposes, and depending on your goals, the right time to transition from FPGA to ASIC could make all the difference.

Let’s break it down in a way that’s easy to follow—no jargon overload, just clarity.

FPGA First: Why It’s the Go-To for Early Development

FPGAs (Field-Programmable Gate Arrays) are incredibly flexible. They’re reprogrammable, ideal for prototyping, and perfect when you’re still figuring things out.

Need to make fast changes? FPGAs let you tweak your logic on the fly.

Not ready to commit? They allow you to test before locking anything down.

Tight deadlines? FPGAs help get a proof of concept out the door fast.

Many teams start with FPGAs, validate their design, then look at next steps. That’s where ASIC Design, Verification and Validation becomes important.

ASIC: The Custom, Scalable Option

ASICs (Application-Specific Integrated Circuits) are built for one purpose—and they’re built to last. You don’t reprogram them. You don’t tweak them later.

But what you get in return is powerful:

Optimized performance

Lower power consumption

Smaller physical size

Full ownership of the design

It’s a deeper investment, but when paired with proper ASIC Design, Verification and Validation, it pays off long-term—especially when your product is stable, and you’re scaling up.

So, When Do You Make the Switch?

Transitioning from FPGA to ASIC isn’t just a tech decision—it’s strategic. Here are a few indicators the time might be right:

Your Design Is StableIf you’re no longer iterating on logic and the architecture is firm, ASIC may be a smart move.

You Need Higher PerformanceASICs are tailored for speed and efficiency. When performance limits your growth, it might be time.

You're Scaling Up ProductionASICs are great for high-volume products. With solid ASIC Design, Verification and Validation, your design is ready for mass deployment.

Power or Space Is TightThink wearables, medical devices, or aerospace—where power and size matter. ASICs shine here.

Not Sure Yet? Do This First

Before jumping in, use the FPGA as a platform to refine your design. Let your team test features, debug systems, and gather data.

Meanwhile, consult with experts who specialize in ASIC Design, Verification and Validation. They’ll help you determine if your current logic and requirements are ready for the transition.

ASIC Design, Verification and Validation: What It Involves

When you move into ASIC territory, you’ll hear a lot about this phase. It’s not just a technical checklist—it’s the heart of your transition.

Design: Converting your tested FPGA logic into an optimized ASIC layout

Verification: Ensuring your ASIC behaves exactly as expected—before manufacturing

Validation: Real-world testing, proving the chip performs in your target environment

Repeatable success here relies on strong planning and attention to detail. This is where experienced teams in ASIC Design, Verification and Validation really make a difference.

Final Thoughts

Both FPGA and ASIC have their place. The key is knowing when to transition—and doing it with confidence. With careful planning, clear goals, and robust ASIC Design, Verification and Validation, your move from prototype to product can be smooth, scalable, and future-ready.

FAQs

Q1: Can I skip FPGA and go straight to ASIC?A: Technically yes, but most teams prefer starting with FPGA to minimize risk and catch issues early.

Q2: How long does ASIC development take?A: It varies depending on complexity, but a strong ASIC Design, Verification and Validation strategy can help streamline the process.

Q3: Is ASIC always better than FPGA?A: Not necessarily. FPGA has advantages in flexibility and speed of iteration. ASIC excels when performance, efficiency, and scale are priorities.

0 notes