#Manufacturing Automation Tools

Explore tagged Tumblr posts

Text

Knurling Tools Market Forecast to Reach $912.5 Million by 2035

Market Growth Overview

The global Knurling Tools market is projected to grow significantly, reaching $912.5 million by 2035, up from $416.1 million in 2024. This represents a compound annual growth rate (CAGR) of 7.4% over the forecast period (2024–2035). Growth is driven by rising demand in industrial precision tooling and automotive manufacturing.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/knurling-tools-market-research-report

Key Areas of Application

Knurling tools are essential in:

Automotive parts production

Jewelry design

Machinery and component manufacturing

Hardware and tool fabrication

The report highlights key opportunities across Tool Type, Material Composition, Design Variants, Technology Use, and Application Verticals.

Competitive Landscape Snapshot

The market is highly competitive, with several global and regional manufacturers actively innovating. Prominent players include:

CJWinter

Vardex

Accu Trak

Eagle Rock Technologies

Reed Machinery

Dorian Tool

Alvord-Polk

ISCAR

Ghring

Jiangsu Tiangong Tools

Forbes Precision Tools

Command Tooling Systems

Innovation in CNC-compatible knurling tools and durability-focused materials has been a key trend among these players.

Market Drivers and Emerging Opportunities

Growth is largely supported by:

Rising industrial automation

Expanding automotive and construction industries

Technological advancement in tool design and durability

Emerging opportunities include:

Entry into underpenetrated markets

Strategic partnerships for distribution

Customization of tooling systems for niche industrial needs

Core demand regions include the U.S., Germany, China, Japan, and India.

Regional Dynamics and Supply Chain Developments

North America and Asia Pacific remain at the forefront of market activity, fueled by high manufacturing activity and technological adoption. However, the market faces challenges, including:

Supply chain disruptions

High-precision manufacturing barriers

To mitigate risks and scale operations, firms are focusing on growth in Vietnam, Brazil, and South Africa to diversify their Total Addressable Market (TAM).

About DataString Consulting

DataString Consulting delivers end-to-end market intelligence services for businesses across B2B and B2C sectors. Our services include:

Tailored market research

Strategic consulting

Opportunity mapping

Business decision support

With a leadership team combining over 30 years of experience, we track and analyze over 15 high-growth industries globally to help businesses stay competitive.

#Knurling Tools Market#Industrial Tooling Market#Precision Tooling Industry#Automotive Manufacturing Tools#Metalworking Tools Market#Machine Component Production#Knurling Tools Forecast 2035#Tool Manufacturing Trends#Global Industrial Tools Report#Hardware Fabrication Tools#Tooling Industry Growth#Manufacturing Automation Tools#Construction Tool Market#CNC Tooling Solutions#Mechanical Tool Supply Chain#Asia Pacific Tool Market#U.S. Tool Manufacturing Industry#Emerging Markets in Tooling#Tooling Industry Opportunities#DataString Market Research

0 notes

Text

Top 5 DeepSeek AI Features Powering Industry Innovation

Table of Contents1. The Problem: Why Legacy Tools Can’t Keep Up2. What Makes DeepSeek AI Unique?3. 5 Game-Changing DeepSeek AI Features (with Real Stories)3.1 Adaptive Learning Engine3.2 Real-Time Anomaly Detection3.3 Natural Language Reports3.4 Multi-Cloud Sync3.5 Ethical AI Auditor4. How These Features Solve Everyday Challenges5. Step-by-Step: Getting Started with DeepSeek AI6. FAQs: Your…

#affordable AI solutions#AI automation#AI for educators#AI for entrepreneurs#AI for non-techies#AI for small business#AI in manufacturing#AI innovation 2024#AI time management#business growth tools#data-driven decisions#DeepSeek AI Features#ethical AI solutions#healthcare AI tools#no-code AI tools#Predictive Analytics#real-time analytics#remote work AI#retail AI features#startup AI tech

2 notes

·

View notes

Text

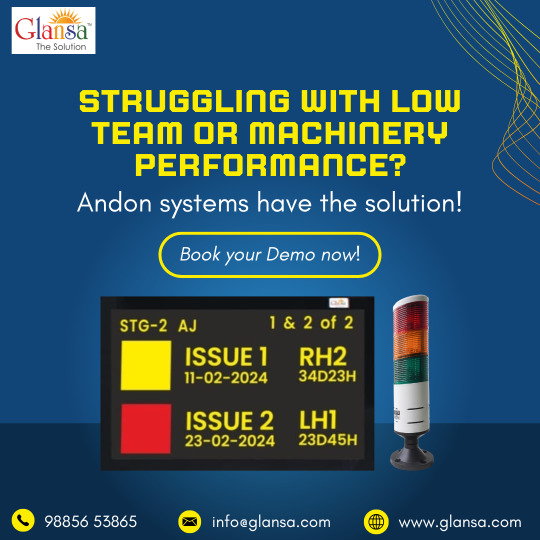

Andon Device: The Key to Real-Time Manufacturing Efficiency

In today's fast-paced manufacturing environment, efficiency, visibility, and rapid response are essential for success. One powerful tool that has helped many industries streamline operations is the Andon device—a real-time visual and audible alert system designed to signal issues on the production floor.

🔍 What Is an Andon Device?

An Andon device is a signaling mechanism used in lean manufacturing to indicate the status of a machine, process, or work area. Traditionally, it involves stack lights, displays, or alarms that notify operators and supervisors when immediate attention is required.

These alerts can be triggered by operators manually or automatically through sensors. The goal is to highlight problems in real time so they can be addressed before they escalate.

⚙️ Benefits of Using Andon Systems in Manufacturing

Real-Time Issue Detection Andon devices help teams identify issues the moment they occur—reducing downtime and avoiding large-scale disruptions.

Improved Communication Shop floor personnel, maintenance, and supervisors stay in sync, enabling faster responses and improved productivity.

Reduced Downtime With quick issue resolution, teams can prevent prolonged delays and keep operations running smoothly.

Data-Driven Insights Modern Andon systems can collect and analyze data to uncover recurring problems and support continuous improvement.

🌐 How Glansa's Andon Device Stands Out

Glansa's Andon solution is designed with IoT integration, wireless connectivity, and customizable alerts that suit any industrial setup. The system not only notifies users in real time but also integrates with existing ERP and MES systems to offer deeper insights and control.

Key Features:

Push-button or automatic triggers

LED displays and multi-color stack lights

Cloud-based analytics dashboard

Scalable for multiple production lines

📈 Why Every Smart Factory Needs an Andon System

In the era of Industry 4.0, smart factories depend on interconnected devices to maintain efficiency. Andon devices serve as a crucial part of this ecosystem by ensuring visibility and fast response across departments.

Whether you're running a high-speed assembly line or a custom manufacturing unit, implementing an Andon system can significantly reduce waste, enhance workflow, and improve overall operational control.

🔗 Learn More

To explore how you can implement an Andon system tailored to your operations, visit: 👉 https://glansa.com/andon/

#Andon device#Andon system#lean manufacturing tools#production monitoring#factory alert system#Glansa automation#smart manufacturing#Industry 4.0 tools#real-time production alerts

0 notes

Text

The AI Revolution: 10 Industries Being Transformed by AI

The relentless march of technology often brings about profound shifts, but few have been as sweeping and impactful as the current Artificial Intelligence (AI) revolution. Once confined to the realms of science fiction, AI has now permeated nearly every facet of our daily lives, quietly reshaping industries, redefining possibilities, and fundamentally altering how businesses operate. This isn’t…

#agricultural AI#agriculture AI tools#AI adoption#AI applications#AI benefits#AI challenges#AI evolution#AI for growth#AI impact on business#AI in agriculture#AI in banking operations#AI in cybersecurity#AI in education#AI in finance#AI in healthcare#AI in industries#AI in manufacturing#AI in media#AI in retail#AI in transportation#AI innovation#AI opportunities#AI revolution#AI solutions#AI strategy#AI-driven cyber defense#AI-driven insights#artificial intelligence transformation#automation#autonomous systems

0 notes

Text

Running a small manufacturing biz? You don’t need chaos. You need systems. Try @mrpeasy and bring peace to your process. 👉 https://try.mrpeasy.com/omgitzlo #SponsoredProduct

#Business growth#cloud MRP#ERP#inventory software#manufacturing software#mrpeasy#productivity tools#small business tools#sponsored spotlight#streamline production#workflow automation

0 notes

Text

WorkSeer: The Smart SAP GTS Alternative for Modern Global Trade Compliance

In the rapidly evolving world of international commerce, agility, automation, and compliance are essential. Traditional, legacy systems like SAP GTS may have served well in the past, but today���s global trade demands a more flexible and intelligent approach. Enter WorkSeer — a next-generation cloud-based GTM system that’s transforming how businesses manage trade compliance.

What is WorkSeer?

WorkSeer is a modern, scalable trade compliance SaaS platform designed for importers, exporters, and logistics professionals. As a cloud-native GTM system, WorkSeer empowers companies to automate, optimize, and stay compliant in real time, without the high costs and rigidity of traditional enterprise solutions.

Why Choose WorkSeer Over SAP GTS?

Many businesses are now exploring a smarter SAP GTS alternative — and WorkSeer is quickly becoming the go-to choice. Unlike SAP GTS, which often requires heavy IT involvement and long implementation times, WorkSeer is:

Quick to Deploy – Get started in days, not months.

User-Friendly – No technical background required.

Cost-Effective – Predictable pricing with no surprise costs.

Fully Cloud-Based – Accessible from anywhere, anytime.

Leading the Way in Global Trade Compliance Automation

WorkSeer leverages the power of automation and artificial intelligence to deliver global trade compliance automation like never before. The platform helps businesses manage:

Restricted party screening

HTS & ECCN classification

Denied party list checks

Export license determination

Country-specific regulations

Document generation & retention

Through automation, WorkSeer eliminates manual errors, speeds up compliance workflows, and reduces regulatory risks — ensuring that every shipment clears customs smoothly and legally.

What Makes WorkSeer the Best Trade Compliance SaaS Solution?

As a trade compliance SaaS provider, WorkSeer offers:

Continuous Software Updates – Stay ahead of regulatory changes.

Data Security & Compliance – Meets global security standards.

Real-Time Dashboards & Reporting – Get full visibility into your trade operations.

AI-Powered Insights – Make smarter decisions, faster.

WorkSeer also integrates easily with popular ERPs and logistics platforms, enabling seamless communication between departments and partners.

The Future of Trade Compliance is in the Cloud

With ever-changing trade laws, rising operational costs, and increasing global competition, businesses can no longer afford to rely on outdated tools. A cloud-based GTM system like WorkSeer ensures your business is always connected, always compliant, and always one step ahead.

Conclusion: Make the Smart Switch to WorkSeer

If you're searching for an agile, automated, and intelligent SAP GTS alternative, WorkSeer is your answer. As a leading trade compliance SaaS solution, WorkSeer simplifies complex processes, reduces compliance risks, and empowers your team to scale confidently across borders.

Try WorkSeer Today – The Future of Global Trade Compliance is Now.

#global trade management#best GTM software for exporters#cloud-based GTM system#global trade compliance automation#SAP GTS alternative#trade compliance SaaS#GTM tool for manufacturers

0 notes

Text

#AI Tools#Entrepreneur#Business Growth#Future of Work#Technology#Local Business#Startup Strategy#Automation#manufacturer in mumbai

0 notes

Text

Supporting Robotics and Automation Rollouts with Industrial Estimating Services

Introduction Robotics and automation are revolutionizing industrial operations by boosting productivity, improving quality, and reducing labor costs. However, implementing these technologies requires significant investment and meticulous cost planning. Industrial estimating services play a pivotal role in supporting robotics and automation rollouts by providing detailed, accurate, and realistic cost estimates. These estimates help stakeholders make informed decisions and avoid budget overruns in complex automation projects.

Understanding the Cost Components of Robotics and Automation Robotics and automation projects involve a variety of cost elements beyond just the purchase price of equipment. Key components include:

Hardware costs: Robots, conveyors, sensors, controllers, and peripheral equipment.

Software costs: Licensing, integration platforms, programming, and updates.

Installation and integration: Engineering design, system integration, and commissioning.

Training and change management: Educating staff and adjusting operational processes.

Maintenance and support: Ongoing servicing, spare parts, and software upgrades.

Cybersecurity: Protecting automated systems from vulnerabilities.

Regulatory compliance: Ensuring adherence to safety and industry standards.

Accurately estimating these diverse costs is essential for comprehensive budgeting.

How Industrial Estimating Services Add Value Industrial estimating services bring specialized expertise in cost analysis tailored to the unique challenges of robotics and automation:

Detailed cost breakdowns: They separate costs into granular categories to ensure no aspect is overlooked.

Technology-specific expertise: Familiarity with current robotics technology pricing trends and vendor offerings.

Integration complexity assessment: Evaluating the technical challenges and associated costs of merging new automation with legacy systems.

Risk and contingency planning: Accounting for uncertainties such as installation delays, technology obsolescence, and vendor reliability.

Total cost of ownership: Considering long-term expenses beyond initial acquisition, including maintenance and software renewals.

Benchmarking: Using data from similar projects to validate estimates and identify potential cost savings.

Addressing Challenges Unique to Automation Projects Robotics and automation projects face unique cost estimation challenges, such as:

Rapid technology evolution: Hardware and software prices can fluctuate quickly due to innovation cycles.

Customization needs: Many automation solutions require custom programming or adaptations, increasing costs.

Interoperability: Ensuring compatibility between new robots and existing control systems can be complex.

Workforce impact: Budgeting for retraining or reassigning employees affected by automation.

Cybersecurity investments: Growing concerns over industrial network vulnerabilities require dedicated budgeting.

Industrial estimating services use scenario planning and risk analysis to manage these challenges proactively.

The Role of Estimating Software and Tools Modern estimating services leverage software tools to improve precision and efficiency in automation project cost estimation:

Parametric estimating: Using statistical models based on project parameters to predict costs.

Cost databases: Access to up-to-date vendor pricing and historical data specific to automation equipment.

3D modeling and digital twins: Simulating automation workflows to identify hidden costs and optimize layouts.

Collaborative platforms: Facilitating communication between engineers, vendors, and estimators to refine budgets.

These tools help generate transparent, data-driven estimates.

Case Study: Automation in a Manufacturing Plant A manufacturing company planned to automate a packaging line with robotic arms and vision systems. The industrial estimating service conducted a detailed cost assessment, covering equipment purchase, system integration, and workforce training. By identifying hidden costs such as specialized safety enclosures and software licenses, the estimate prevented budget shortfalls. The company successfully deployed the automation system on schedule and within budget, realizing productivity gains quickly.

Conclusion As robotics and automation continue to transform industry, the importance of precise cost estimating grows. Industrial estimating services enable successful rollouts by providing comprehensive, accurate, and realistic budgets that account for the complexities of automation projects. Their expertise helps organizations navigate uncertainties, optimize investment decisions, and maximize the value of automation initiatives.

For industrial operations looking to embrace robotics, partnering with a skilled estimating service is a critical step toward achieving cost-effective and efficient automation adoption.

#robotics cost#automation budgeting#industrial estimating#automation rollout#integration costs#technology pricing#software licensing#workforce training#cybersecurity budgeting#system commissioning#project risk#cost breakdown#parametric estimating#digital twins#industrial automation#maintenance costs#vendor pricing#scenario planning#cost optimization#legacy systems#change management#industrial robotics#manufacturing automation#total cost of ownership#estimating software#project budgeting#contingency planning#technology upgrades#estimating tools#automation projects

0 notes

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

Automated welding can reduce errors by up to 𝟕𝟎%!

#promotechindia#europe#indian#WeldingAutomation#SmartManufacturing#FutureOfWelding#MetalFabrication#AutomatedWelding#weldingautomation#welding#roboticwelding#metalfabrication#manufacturing#weldingequipment#weld#weldingrobot#automation#robotics#weldingmachine#migwelding#arcwelding#automationsolutions#cobot#tools#universalrobots#advancedwelding#migweld

0 notes

Text

How Predictive Analytics and AI Are Transforming Sustainable Compliance Management

Discover how sustainable compliance management is evolving with AI in compliance management and predictive analytics in manufacturing. Learn how manufacturers can proactively meet sustainability and regulatory compliance goals using intelligent tools that reduce emissions, improve reporting accuracy, and automate workflows. This blog explores real-world case studies, implementation steps, and how environmental compliance software helps organizations stay audit-ready while aligning with environmental targets. From reducing violations to boosting operational efficiency, predictive technologies are reshaping the future of compliance for forward-thinking manufacturers.

#Sustainable compliance management strategies#Predictive analytics in manufacturing compliance#AI tools for environmental compliance#Benefits of AI in compliance management#How to implement sustainable compliance solutions#Environmental compliance software for manufacturers#Using AI to meet sustainability goals#Predictive analytics for reducing compliance risks#Real-time audits using AI in manufacturing#Regulatory compliance automation with AI

0 notes

Text

Glansa Solutions specializes in smart factory technologies, including advanced Andon devices for real-time production monitoring. Our customizable Andon systems help manufacturers reduce downtime, improve shop floor communication, and support lean manufacturing processes. Trusted by industries like automotive, electronics, and FMCG.

#Andon Device#Glansa Solutions#Lean Manufacturing Tools#Industrial Automation#Smart Factory Systems#Shop Floor Monitoring#Real-Time Alert System#Production Efficiency

0 notes

Text

Why KOKA Books Is the Ideal Accounting Solution for Dairy Manufacturers

Dairy manufacturing involves much more than just processing milk. From tracking raw milk procurement and inventory to managing daily transactions, job work, wastage, and GST compliance, without automation, the risk of errors, delays, and inefficiencies increases significantly.

With solutions customized specifically for the dairy industry, Koka Books Accounting Software simplifies and streamlines every step of the process. Let’s explore why KOKA Books Is the Ideal Accounting Solution for Dairy Manufacturers

KOKA Books Accounting Software

Koka Books is built to handle the unique challenges of dairy businesses. From tracking milk procurement and managing inventory to recording job work and automating GST billing, it keeps your operations smooth and error-free. 1. Milk Procurement and Supplier Management

Dairy businesses often work with multiple milk suppliers and face daily rate changes. Koka Books simplifies this by allowing you to:

Record supplier-wise milk purchases

Apply variable rates based on quality (Fat/SNF)

Manage payments, advances, and outstanding balances

2. Inventory Management for Raw and Processed Goods

From raw milk and cultures to packed products like paneer, butter, and ghee; dairy inventory is complex. Koka Books allows:

Real-time tracking of stock

Batch-wise inventory management

Alerts for expiry-sensitive products

3. Production and Job Work Tracking

Whether you're processing in-house or outsourcing tasks like packaging, Koka Books lets you:

Create and manage job work orders

Track materials issued and finished goods received

Calculate production cost per batch

4. GST-Compliant Invoicing

Dairy businesses often work with mixed GST rates (e.g., on milk vs. processed products). Koka Books simplifies compliance by:

Generating GST-ready invoices instantly

Applying correct HSN codes and tax rates automatically

Exporting GSTR reports for easy filing

5. Sales and Distribution Insights

Stay on top of orders from distributors, retailers, and direct customers with tools like:

Route-wise and customer-wise billing

Daily sales report

Credit and payment tracking

6. Easy Reporting and Business Dashboard

Koka Books gives you real-time insights with:

Real-time profit and loss reports

Daily, monthly, and product-wise performance summaries

A dashboard to monitor cash flow, stock, and receivables

Conclusion:

For dairy manufacturers, accounting is about controlling cost, maximizing margins, and keeping operations smooth. Koka Books Accounting Software is designed with your industry in mind, offering the tools you need to manage procurement, production, billing, and compliance - all in one place.

If you're looking to simplify your accounting and scale your dairy business, Koka Books is the solution you've been waiting for.

#Dairy Accounting Software#Milk Procurement Management#Dairy Inventory Tracking#Dairy Business Automation#Koka Books Accounting#GST Software for Dairy#Accounting for Dairy Manufacturers#Job Work Tracking Dairy#Production Costing Software#Accounting Tools for Dairy Industry

0 notes

Text

Boost manufacturing efficiency with the ABE20550 - Twin Spindle Expansion Honing Machine! Designed for industries like automobile, aerospace, and oil & gas, it ensures precision and faster cycle times with twin spindles and auto wear compensation. 👉 Learn more: https://medium.com/@ramya10muralidharan/enhancing-manufacturing-efficiency-with-the-abe20550-twin-spindle-expansion-honing-machine-1259ae2cee8c

#business#honing manufacturer#honingmachine#manufacturer#100 days of productivity#HoningMachineManufacturer#abhifineproducts#industries#products#manufacturers#supplier#Expansion Honing Machine#Honing Machine#Honing Tools#Honing Fixtures#Automation#automobile#aerospace#oil and gas#Hydraulic#Pneumatics

0 notes

Text

How Data Analytics Enhances IoT Development for Smarter Business Solutions

#Introduction:#The combination of data analytics and the Internet of Things (IoT) is opening the door to more intelligent and effective business solutions#businesses can collect#evaluate#and act on real-time data#which improves customer experiences#lowers operating costs#and streamlines decision-making. This blog will discuss how data analytics enhances IoT development to provide more intelligent solutions a#Understanding the Core of IoT and Data Analytics#IoT Development involves creating systems and devices that communicate with each other over the internet#collecting data to automate processes and respond to changing environments. Sensors embedded in IoT devices capture enormous volumes of dat#from environmental conditions and machinery performance to user behavior and logistics data. However#this raw data alone has limited value until it’s processed and analyzed.#This is where Data Analytics comes into play. By analyzing IoT data#businesses can derive actionable insights#identifying trends#patterns#and anomalies. Data Analytics converts unstructured data into meaningful information#enabling businesses to make data-driven decisions.#The Role of Data Analytics in IoT Development for Smarter Solutions#Data Analytics is not just an add-on to IoT but a transformative element that enhances the functionality and intelligence of IoT solutions.#Real-Time Monitoring and Predictive Maintenance#Predictive Maintenance is crucial in sectors like manufacturing and energy#where machine downtime can lead to significant losses. IoT sensors embedded in machinery continuously collect data#which Data Analytics processes to predict equipment failures before they happen. This predictive approach minimizes disruptions#extending machinery life and reducing repair costs.#Enhanced Decision-Making Through Data Visualization#For organizations#it’s vital to not only collect data but also interpret it effectively. Advanced Data Analytics provides data visualization tools that trans#easily understandable formats. These insights enable business leaders to make quicker

0 notes

Text

Valuing Intellectual Property | A New Challenge for Industrial Estimating Services

Introduction As industrial sectors evolve through digitalization, automation, and innovation, intellectual property (IP) has become one of the most valuable assets within a project. From proprietary software and patented designs to custom manufacturing processes and smart technologies, IP is reshaping how value is created and assessed. However, traditional industrial estimating services—built around physical materials, labor, and equipment—are now faced with a complex challenge: how to accurately estimate the cost and value of intellectual property within industrial projects.

This emerging frontier calls for a redefinition of scope in industrial estimating services, expanding their role to account for intangible assets that drive both performance and competitive advantage.

Why IP Matters in Industrial Cost Estimation In many modern industrial developments, especially in high-tech manufacturing, advanced energy systems, and Industry 4.0-enabled factories, intellectual property comprises a significant portion of overall value. For instance:

A custom automation algorithm embedded in a robotics line

Proprietary energy-efficiency systems in a chemical plant

Secure software platforms for controlling distributed manufacturing

These IP-driven elements often represent a large portion of R&D investment and are critical to long-term operational efficiency. An accurate estimate must include not just the cost to implement or license such assets but also the potential risk, return, and lifecycle value they bring.

Key Categories of Intellectual Property in Industrial Settings Understanding how IP appears in industrial projects is essential for accurate estimation. Common categories include:

Patents: Inventions or processes owned or licensed by the project owner

Trade Secrets: Confidential formulas or methods applied during production

Software and Algorithms: Custom-coded tools used in automation and process control

Design Rights: Proprietary architectural or engineering designs

Licenses and Royalties: Payments made to third parties for the use of protected IP

Each of these categories demands unique valuation methods and estimation strategies that differ from traditional capital expenditures.

Challenges in Estimating IP Costs Valuing IP in industrial settings is inherently complex due to:

Intangibility: Unlike steel or labor hours, IP has no physical form and often lacks clear benchmarks.

Variable Cost Structures: Licensing fees, development costs, and long-term support vary widely by industry and supplier.

Lifecycle Uncertainty: IP might evolve or become obsolete quickly, adding estimation risk.

Confidentiality: Many IP assets are guarded by NDAs or corporate secrecy, limiting estimator access.

As a result, industrial estimating services must blend financial modeling, legal review, and technical expertise to deliver accurate assessments.

Approaches to Integrating IP into Estimates To manage these complexities, forward-thinking estimating services apply several strategies:

Cost-Based Estimation: Involves calculating the original R&D or development costs and applying a markup based on projected use.

Market-Based Valuation: Uses comparative licensing or sales data for similar IP assets, when available.

Income-Based Modeling: Projects future cash flows generated by the IP (e.g., operational savings, productivity gains) and discounts them to present value.

Expert Collaboration: Engaging IP lawyers, technology consultants, and accountants to accurately categorize and value protected assets.

Case Example: Estimating an Advanced Robotics System A manufacturing client planned to install a robotics line powered by proprietary AI software developed in-house. While the hardware had clear market prices, the software’s value was harder to define. The industrial estimating service worked with internal developers and finance experts to model the cost of development, anticipated efficiency savings over ten years, and licensing potential if the software was reused across other sites.

By incorporating both direct and indirect value contributions, the estimate provided a holistic picture that helped justify a higher upfront investment.

Benefits of IP-Savvy Estimating Industrial clients gain several advantages when IP is accurately included in estimates:

More Realistic Budgets: Avoids underbudgeting by recognizing the full cost of IP integration or licensing.

Stronger Business Cases: Supports ROI projections for innovation-driven projects.

Better Risk Assessment: Helps identify where IP exposure (e.g., licensing dependencies) may affect project costs.

Investor Appeal: Demonstrates comprehensive valuation, which is critical for attracting investment in innovation-heavy projects.

New Tools and Trends As the demand grows, some industrial estimating platforms are adapting to include IP modeling features:

Digital Asset Registries: Help track owned or licensed IP within the project scope.

AI-Powered Valuation Engines: Use historical and market data to suggest value ranges.

Blockchain for IP Tracking: Ensures provenance and licensing status of digital IP in complex supply chains.

These innovations indicate that IP valuation is becoming a mainstream requirement in industrial estimating practices.

Limitations and Ongoing Development Despite advances, valuing IP remains a partly subjective exercise. The uniqueness of each asset and the lack of standard benchmarks can introduce variability. Moreover, legal changes—such as patent law shifts or tax implications—can alter value significantly.

Estimating services must remain adaptive, continuously updating models and methodologies to reflect both technical and legal developments.

Conclusion The rise of intellectual property as a strategic asset in industrial projects is reshaping the landscape for estimating services. No longer confined to bricks, pipes, and wires, estimators must now navigate code, algorithms, and trade secrets. By embracing this challenge, industrial estimating services not only improve budget accuracy but also elevate their strategic role in capital planning and innovation management. The result is a more holistic view of project value—one that aligns with the digital age.

#industrial estimating#intellectual property#IP valuation#industrial projects#cost estimation#IP assets#software cost#patent cost#innovation budgeting#intangible assets#ROI modeling#licensing fees#proprietary software#automation IP#manufacturing IP#trade secrets#digital asset valuation#tech integration#income-based estimation#market-based estimation#IP in construction#software estimation#R&D cost#risk analysis#estimating strategy#lifecycle cost#future-proofing#estimating service tools#high-tech estimating#cost planning

0 notes