#modular PLC design

Explore tagged Tumblr posts

Text

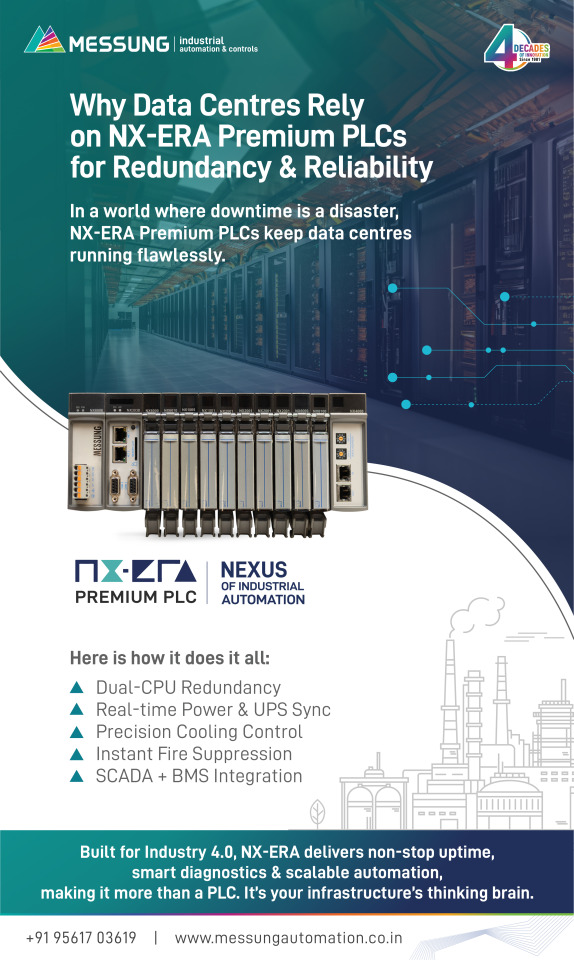

Why Data Centres Rely On NX-ERA Premium PLCs For Redundancy & Reliability

Data centres are the online headquarters of businesses today. Every click, transaction, login, or query is responded to via a data centre. In this hyper-connected world, downtime is more than a slowdown; it's a disaster.

Whether it is hosting cloud applications, running finance systems, or managing mission-critical enterprise data, data centres simply can't afford failure of control. That's why businesses often spend money on layers of redundancy, not merely power or cooling, but even on the thinking brain of their infrastructure: the Programmable Logic Controller (PLC).This is where Messung Industrial Automation's NX-ERA Premium PLCs come in as a strategic benefit, designed to provide unparalleled modular scalability, PLC redundancy, and seamless SCADA integration for control that's future-proof. For more information about NX-ERA Premium Plc visit us https://www.messungautomation.co.in/why-data-centres-rely-on-nx-era-premium-plcs-for-redundancy-reliability/

#data centres#Programmable Logic Controller (PLC)#PLC redundancy#SCADA integration#mini PLCs#Premium PLC#PLC controller#data centre automation#redundant PLC#high-speed PLC#modular PLC design#MODBUS TCP/IP#NX-ERA Premium PLCs#PLC architecture#PLC systems#Industry 4.0 PLC#AI-based decision systems

0 notes

Text

What is the installation space requirement and power consumption?

Planning for both production capacity and practical installation needs—namely, power consumption and floor space—is crucial when thinking about buying a square-bottom paper bag maker. Your factory layout, monthly operating expenses, and long-term scalability are all directly impacted by these two variables.

At Prakash Machineries Pvt. Ltd., we design our square-bottom paper bag machines to be Whether you’re running a large industrial setup or launching a small startup, our machines are built to integrate smoothly into your workspace without demanding major infrastructure upgrades.

In this guide, we explain the power and space requirements of our square-bottom paper bag machines and how you can prepare your facility for successful installation and operation.

⚡ Power Consumption: Designed for Energy Efficiency

Our machine is equipped with servo-driven motors, automated PLC controls, and energy-optimized components to ensure high productivity with minimal energy use. On average, the power consumption of our square-bottom paper bag-making machine falls between

✅ 10 kW to 14 kW per hour

(Depending on the machine model, size range, and optional attachments)

🔋 Breakdown of Power Usage:

Component Approximate Load Main motor (servo drive) 5–7 kW Vacuum pump 2–3 kW Gluing system & heater (if any) 1–2 kW Control panel and sensors 0.5–1 kW Optional attachments (printer, handle unit) 1–2 kW

This efficient power profile means that you won’t need industrial-scale electricity infrastructure to run the machine. Even for startups or medium-scale units, a standard 3-phase connection with a 20–25 HP (horsepower) supply is typically sufficient.

✅ Monthly Cost Estimate:

Assuming 8 hours/day of operation at an average of 12 kW/hr:

12 kW × 8 hours × 30 days = 2,880 kWh/month

At ₹8/kWh (approx. industrial rate in India), monthly electricity cost = ₹23,000

This makes our machine a cost-effective production solution, especially when you compare the high output capacity (up to 192,000 bags/day) with the low operational expense.

📐 Required Space for Installation

Our square-bottom paper bag machines are compact, modular, and engineered to occupy minimal floor space while still offering full production capabilities.

✅ Recommended Installation Area:

20 feet (L) × 8 feet (W) for standard machines 25 feet (L) × 10 feet (W) if optional units (e.g., printer, handle pasting) are included

🏭 Ideal Layout Plan Includes:

Machine footprint—main operational unit

Paper roll loading area—space for jumbo rolls (up to 1 m wide)

Bag collection table—output stacking and packing zone

Operator movement zone—minimum 3 ft clearance on each side

Electrical control cabinet—attached or wall-mounted

Optional space—for printer unit, handle applicator, or lamination feeder (if installed)

Our machines can be installed in a production unit as small as 500–600 sq. ft. You do not need a massive industrial hall. Even a startup with a moderate factory space can begin production seamlessly.

🛠️ Site Preparation Checklist

Before installation, ensure the following infrastructure is in place:

✔️ Electrical Requirements:

3-phase power connection (415V)

A stabilizer or UPS recommended for voltage fluctuation zones

Isolated circuit breaker and control panel for machine safety

✔️ Space & Foundation:

Flat, concrete floor surface (leveling required)

Dust-free, dry environment for optimal performance

Space for operators to safely move around machine

✔️ Ventilation & Safety:

Basic ventilation or exhaust fans (especially in hot climates)

Fire safety measures as per industrial compliance

Proper lighting for operator visibility

💡 Why This Matters to Your Business

Understanding your power and space needs in advance helps you

Avoid delays in installation

Ensure uninterrupted production

Optimize your floor plan for raw material, output, and manpower

Control operational costs with energy-efficient planning

This is especially crucial for startups, small businesses, or factories expanding capacity, where space and energy planning affect both short-term efficiency and long-term profitability.

🔧 Our Support Includes:

At Prakash Machineries Pvt Ltd, we don’t just deliver machines—we offer end-to-end installation support, including:

Pre-installation guidance (electrical, civil layout)

Custom floor plans for your site

On-site machine setup and calibration

Operator training and troubleshooting

Maintenance and after-sales service

🏁 Conclusion: Compact. Efficient. Installation-Ready.

Our square-bottom paper bag-making machines are designed to be energy-efficient and space-friendly—ideal for both high-output factories and compact manufacturing setups. With low power consumption (10–14 kW) and a compact footprint (under 250 sq. ft.), you can begin or scale up your paper bag production with minimal infrastructure investment.

📞 Plan Your Factory Setup With Us

Want help designing your factory layout? Need a customized installation guide for your plant? We’re here to help.

👉 Contact Prakash Machineries Pvt Ltd to get a personalized site layout, electrical requirement checklist, or expert consultation to prepare your facility for high-speed, efficient paper bag production.

#manufacturer#paper bag manufacturer#paper bag#paper#machines#flexo#v bottom#square bottom#alien stage#baking#bags#cake#chris sturniolo#cooking#critical role#dan and phil#delicious#breakfast#chocolate

1 note

·

View note

Text

Sand Washer Market Size, Anticipating Growth Prospects from 2033

According to recent analysis by Fact.MR, the global sand washer market is expected to grow from USD 1 billion in 2023 to USD 1.65 billion by 2033, at a compound annual growth rate (CAGR) of 5%.

Sand washers improve sand quality by removing contaminants like clay and silt. They work by separating dirt and debris from the water and sand mixture. Typically used alongside a filter for additional water purification, sand washers come in manual and electric varieties. Manual models use a brush to agitate the water, while electric machines use an impeller to mechanically spin the water in a drum.

For more insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=3177

Globally, the demand for sand washers is rising due to their diverse applications across industries like construction, mining, and electronics. Sand washers are employed alongside sand-making equipment to remove stone powder and other impurities from the sand produced.

The increasing need for clean building materials in civil construction projects and the widespread use of sand washers in wet process mining are key drivers of market growth. These devices are used to wash a variety of materials, including concrete, sand, manganese ore, and gold ore.

Key Takeaways from Market Study

The global sand washer market stands at a value of US$ 1 billion in 2023.

Global demand for sand washers is set to increase at a CAGR of 5% from 2023 to 2033.

Use of sand washers in quarry washing applications is predicted to increase at a CAGR of 5.1% over the decade.

Worldwide sales of sand washers are forecasted to reach US$ 1.65 billion by 2033.

The market in China is predicted to rise at 5.6% CAGR over the next ten years.

“Sand and stones produced from large-scale manufactured sand and stone crushing units have to be segregated and washed to produce highly marketable materials to be used in construction, for which, sand washers are required. For manufacturers of quarry washing sand washers, major profits are generated through aftermarket spares, services, and technical support,” says a Fact.MR analyst

Winning Strategy

Leading sand washer manufacturers are focusing on quality control, advanced technology integration, and adherence to product standards to boost revenue. They are heavily investing in R&D to develop innovative products and strengthen their market position. Key players are also emphasizing new developments, strategic collaborations, and efficient supply chain management to meet rising product demand.

To reduce environmental impact, many companies are introducing eco-friendly sand washers. This approach not only attracts new customers but also encourages existing ones to switch to more sustainable solutions.

Prominent producers are expanding their market share by prioritizing product innovation and strengthening partnerships, distribution networks, and regional presence.

For example:

In 2019, McLanahan launched the Modular Ultra-Wash, which has a capacity of 365 TPH and can produce two types of sand products.

In 2020, at CONEXPO-CON/AGG in Las Vegas, CDE Global introduced the 500 TPH ComboTM X900, specifically designed for the material processing industries in North and Latin America.

Key Companies Profiled

CDE Global Ltd.

Dernaseer Engineering Ltd.

Hydria Water

McLanahan

Powertrac Inc.

Propel Industries

Superior Industries, Inc.

The Weir Group PLC

Zhengzhou Unique Industrial Equipment Co., Ltd.

Key Segments of Sand Washer Industry Research

By Type:

Wheel

Spiral

By Capacity:

Below 50 T/H

50 to 100 T/H

101 to 150 T/H

151 to 200 T/H

201 to 300 T/H

Above 300 T/H

By Portability:

Stationary

Mobile

By Power Consumption:

Below 10 kW

10 to 25 kW

26 to 50 kW

51 to 100 kW

Above 100 kW

By End Use:

Quarry Washing

Ore Washing

Sand & Gravel Washing

Others

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

More Valuable Insights on Offer

Fact.MR, in its new offering, presents an unbiased analysis of the global sand washer market, presenting historical demand data (2018 to 2022) and forecast statistics for the period (2023 to 2033).

The study divulges essential insights on the market based on type (wheel, spiral), capacity (below 50 T/H, 50 to 100 T/H, 101 to 150 T/H, 151 to 200 T/H, 201 to 300 T/H, above 300 T/H), portability (stationary, mobile), power consumption (below 10 kW, 10 to 25 kW, 26 to 50 kW, 51 to 100 kW, ABOVE 100 kW), and end use (quarry washing, ore washing, sand & gravel washing), across five major regions of the world (North America, Europe, Asia Pacific, Latin America, and MEA).

𝐂𝐨𝐧𝐭𝐚𝐜𝐭: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

𝗗𝗶𝗱 𝘆𝗼𝘂 𝗸𝗻𝗼𝘄 𝘄𝗵𝗼’𝘀 𝘁𝗵𝗲 𝘂𝗻𝘀𝘂𝗻𝗴 𝗵𝗲𝗿𝗼 𝗯𝗲𝗵𝗶𝗻𝗱 𝗽𝗿𝗲𝗰𝗶𝘀𝗶𝗼𝗻 𝗺𝗼𝘁𝗶𝗼𝗻 𝗰𝗼𝗻𝘁𝗿𝗼𝗹 𝗶𝗻 𝗶𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗲𝘀 𝘄𝗼𝗿𝗹𝗱𝘄𝗶𝗱𝗲?

𝗜𝘁’𝘀 𝘁𝗵𝗲 𝗗𝗖 𝗗𝗿𝗶𝘃𝗲𝘀 𝗠𝗮𝗿𝗸𝗲𝘁.

DC drives are the backbone of applications demanding constant torque at low speeds—conveyors that never stall, hoists that lift safely, and extruders that shape materials flawlessly. Their straightforward design and lightning‑fast response help manufacturers minimize mechanical wear through smooth acceleration and deceleration, optimize energy use by precisely matching motor output to load demands, and boost safety with reliable braking and exact speed regulation.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗜𝗻𝘃𝗲𝗿𝘀𝘁𝗼𝗿𝘀 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀

For investors, DC drives offer a distinct opportunity within industrial automation: legacy plants worldwide are primed for retrofit waves as manual starters give way to intelligent drive systems; the ongoing automation surge in robotics, packaging lines, and material‑handling equipment underscores the need for ultra‑precise motion control; and high‑margin aftermarket revenues—from service contracts to spare‑parts sales—ensure steady, recurring income streams.

𝗞𝗲𝘆 𝗣𝗹��𝘆𝗲𝗿𝘀

ABB Ltd. – Innovator in modular DC‑drive platforms and retrofit solutions

Siemens AG – Provider of high‑performance DC drives with integrated safety features

Schneider Electric SE – Expert in energy‑efficient DC drives with advanced diagnostics

Rockwell Automation Inc. – Known for rugged drives and seamless PLC integration

Yaskawa Electric Corp. – Specializes in compact, high‑torque drives for robotics

Mitsubishi Electric Corp. – Supplier of reliable DC‑drive packages for heavy‑duty use

Toshiba Corp. – Offers drives with strong braking and regenerative capabilities

Nord Drivesystems GmbH – Focused on in‑line drive‑gearmotor assemblies for conveyors and mixers

Position your portfolio for the precision‑control revolution—DC drives are powering the next wave of smart manufacturing.

𝗖𝗼𝗻𝗰𝗹𝘂𝘀𝗶𝗼𝗻: 𝗣𝗼𝘄𝗲𝗿𝗶𝗻𝗴 𝗣𝗿𝗲𝗰𝗶𝘀𝗶𝗼𝗻 𝗮𝗻𝗱 𝗣𝗿𝗼𝗳𝗶𝘁𝘀

As industries embrace tighter process control and predictive maintenance, DC drives stand out for their unmatched torque performance, energy savings, and reliability—making them a strategic bet for long‑term industrial growth. By tapping into retrofit demand, the automation boom, and high‑margin aftermarket services, investors can drive both operational innovation and portfolio returns in this specialized segment.

#DCDrives#MotionControl#IndustrialAutomation#SmartManufacturing#PrecisionEngineering#EnergyEfficiency#Investing#FactoryAutomation#CleanTech#ElectricalDrives

0 notes

Text

How to Choose the Right X-Ray Inspection System for Your Production Line

In today's fast-paced and quality-driven manufacturing landscape, X-ray inspection systems have become essential for ensuring product integrity, regulatory compliance, and brand reputation. Whether you're in food processing, pharmaceuticals, electronics, or automotive manufacturing, choosing the right X-ray system for your production line is a critical investment decision.

However, with numerous configurations, technologies, and feature sets available, the selection process can be complex. This guide outlines the key factors to consider when choosing an X-ray inspection system that aligns with your operational goals and industry requirements.

1. Understand Your Inspection Objectives

Before evaluating specific models or vendors, start by clearly defining your inspection goals. Ask the following questions:

What types of foreign materials or defects are you trying to detect (metal, glass, bone, plastic, etc.)?

Are you inspecting for missing or broken components, fill levels, or structural integrity?

Is your primary objective regulatory compliance, consumer safety, or process control?

A well-defined objective helps narrow down the type of system you need, whether it's basic contaminant detection or advanced measurement capabilities.

2. Match System Capabilities with Product Characteristics

X-ray systems must be tailored to the specific properties of the product being inspected. Factors to consider include:

Product size and density: Denser products (e.g., cheese blocks or batteries) require higher energy levels or dual-energy systems for clearer imaging.

Packaging material: Metalized films and aluminum trays can affect detection performance; select systems designed to compensate for these materials.

Orientation and presentation: Are products flowing in bulk, in trays, or individually packaged? Choose between single-beam, multi-beam, or side-view systems accordingly.

3. Assess Line Speed and Throughput Requirements

Your production line’s speed is a key determinant of system performance. High-speed lines demand:

Fast image processing to avoid bottlenecks

Automatic rejection mechanisms tailored for product size and spacing

Robust synchronization with upstream and downstream equipment

Make sure the system’s frame rate and software can keep up with your highest throughput demands without compromising inspection accuracy.

4. Evaluate Detection Sensitivity and Accuracy

Different systems offer varying degrees of sensitivity. Choosing the right sensitivity level involves balancing detection performance with false rejection rates.

Look for systems that offer automatic calibration and tuning for optimal contrast and resolution.

Consider dual-energy or 3D X-ray technologies if you're inspecting complex products with overlapping features or varied densities.

Review test results or performance benchmarks for your specific application before purchasing.

5. Ensure Compliance with Industry Standards

If your operation falls under strict regulations—such as FDA, USDA, BRC, or IFS—ensure the X-ray system meets all relevant standards for:

Hygienic design and cleanability (especially in food and pharma)

Radiation shielding and operator safety

Audit trail and data logging for traceability

Working with vendors who understand your industry’s compliance landscape will save you time and mitigate risks.

6. Consider Integration and Future Scalability

The best X-ray system is one that fits seamlessly into your current production line and adapts to future needs. Key integration points include:

PLC connectivity and data exchange with MES or ERP systems

Remote monitoring and diagnostics for predictive maintenance

Modular designs that allow easy upgrades or line expansion

Choose systems with user-friendly interfaces, real-time analytics, and support for Industry 4.0 protocols to future-proof your investment.

7. Check Total Cost of Ownership (TCO)

Beyond the upfront cost, factor in ongoing expenses such as:

Maintenance and service contracts

Spare parts availability

Operator training and certification

Downtime and throughput efficiency

A slightly higher initial investment in a reliable, well-supported system often results in lower TCO over time.

Conclusion

Choosing the right X-ray inspection system is more than a technical decision—it’s a strategic move that influences product quality, operational efficiency, and brand integrity. By evaluating your inspection goals, product attributes, and production dynamics, you can select a system that not only meets your current needs but evolves with your business.

Invest wisely, and you’ll gain more than just detection capability—you’ll earn customer trust and long-term competitive advantage.

0 notes

Text

hydraulic cylinder piston

Top Hydraulic Equipment Manufacturers in India: Power Packs, Cylinders & Centrifuge Solutions

Introduction to Hydraulic Solutions in Industrial Applications

Hydraulic systems are the lifeline of numerous industries such as manufacturing, energy, pharmaceuticals, and food processing. From powerful cylinders and compact power packs to innovative lifting solutions like centrifuge bag lifting devices, hydraulic technology has transformed how industries operate in India and globally.

Hydraulic Power Pack Manufacturers in Gujarat

Gujarat has emerged as a leading hub for hydraulic power pack manufacturing due to its robust industrial infrastructure and skilled engineering talent.

Features of Gujarat-Based Manufacturers

Use of modular and compact designs

Integration with IoT and automation

Pressure capacities ranging from 20 to 700 bar

Reliable cooling systems and filtration units

Key Industries Served

Machine Tools

Steel & Metal Processing

Marine & Offshore

Injection Molding

Gujarat’s manufacturers are known for delivering cost-effective yet durable power packs designed for 24/7 industrial operations.

Hydraulic Cylinder Manufacturers in Maharashtra

Maharashtra hosts some of the most advanced hydraulic cylinder manufacturing units in the country. Cities like Pune and Mumbai lead in OEM collaboration and product innovation.

Technology Used

CNC Machining for high-precision barrels

Honing machines for smooth bore finishes

Induction hardening for long piston rod life

Load testing under high pressure conditions

Custom Solutions for OEMs

Maharashtra-based manufacturers offer bespoke cylinder solutions tailored for construction equipment, mining machines, and heavy-duty applications.

Centrifuge Bag Lifting Device: Revolutionizing Industrial Safety

The centrifuge bag lifting device is a critical innovation in industries where solid-liquid separation is performed using centrifugal force, such as in pharmaceuticals, chemicals, and food production.

How It Works

This hydraulic system lifts heavy filter bags out of the centrifuge safely using:

Twin hydraulic cylinders

Electric or manual pump control

Stainless steel or anti-corrosive materials

Integrated safety interlocks

Benefits in Process Industries

Minimizes manual handling risks

Reduces bag replacement downtime

Increases operator safety

Ensures compliance with GMP and HACCP standards

Hydraulic Cylinder Manufacturers in New Delhi

Delhi NCR is gaining ground in precision engineering, with manufacturers offering standard and telescopic hydraulic cylinders for versatile applications.

Design Innovations

Space-saving telescopic cylinders

Double-acting and single-acting types

Compact high-pressure cylinders

Multi-stage lifting systems

Compliance & Standards

Manufacturers adhere to international standards like:

ISO 6020/1, 6022

CE and RoHS compliance

In-house 100% testing and inspection reports

Hydraulic Power Pack Manufacturers in New Delhi

With a growing demand in automation and robotics, Delhi’s hydraulic power pack industry has embraced integrated, efficient, and smart hydraulic solutions.

Compact & High-Efficiency Units

Oil-immersed motor-pump combinations

Built-in valve assemblies

Low noise and energy-efficient options

Integration with Automation Systems

SCADA and PLC compatibility

Load-sensing and pressure-compensated pumps

Wireless monitoring via mobile or web apps

Key Factors to Consider When Choosing a Manufacturer

Quality & Certifications

ISO 9001:2015 and ISO 14001:2015

BIS mark for safety and performance

In-house R&D labs

After-Sales Support

On-site installation and training

24/7 helpline and AMC plans

Spare parts availability

Export Potential of Indian Hydraulic Equipment

India is becoming a global supplier of hydraulic systems, exporting to:

Middle East

Southeast Asia

Europe (via CE-certified units)

Africa (for infrastructure projects)

Indian manufacturers offer competitive pricing, shorter lead times, and excellent customization support, making them highly sought after in international markets.

🔧 Frequently Asked Questions (FAQs)

1. What is the difference between a hydraulic power pack and a hydraulic cylinder?

A hydraulic power pack is a self-contained unit supplying pressurized fluid to operate machinery, while a hydraulic cylinder converts this pressure into mechanical force.

2. Which is the best region in India for hydraulic manufacturing?

Gujarat, Maharashtra, and New Delhi are leading regions known for their advanced manufacturing capabilities and global exports.

3. How does a centrifuge bag lifting device enhance safety?

It eliminates manual lifting of heavy bags, reducing injury risks and ensuring compliance with industrial safety standards.

4. Can hydraulic systems be customized for specific industries?

Yes. Leading manufacturers offer tailor-made designs based on application-specific requirements such as pressure ratings, cylinder stroke, fluid type, etc.

5. What maintenance do hydraulic power packs need?

Routine oil change, filter cleaning, leak checks, and pressure testing are key to long service life.

6. Are Indian hydraulic components exported?

Absolutely. Indian manufacturers export globally due to competitive prices, international certifications, and quality assurance.

Conclusion

India's hydraulic equipment industry is advancing rapidly with manufacturers in Gujarat, Maharashtra, and New Delhi offering world-class solutions for power packs, cylinders, and specialized lifting devices like centrifuge bag lifters. Whether you need compact units for automation or heavy-duty components for industrial setups, the Indian market provides reliable, innovative, and cost-effective options.

hydraulic cylinder in mumbai

Hydraulic Power Pack Manufacturers in Hyderabad

Hydraulic Power Pack Manufacturers in Gujarat

Hydraulic Cylinder Manufacturers in Maharashtra

Centrifuge Bag Lifting Device

Hydraulic Cylinder Manufacturers in New Delhi

Hydraulic Power Pack Manufacturers in New Delhi

Hydraulic Power Pack Manufacturers in Mumbai

Hydraulic Cylinder Manufacturers in Pune

Hydraulic Power Pack Manufacturers in Pune

hydraulic power pack

hydraulic cylinder

power pack

hyd cylinder

hydraulic cylinder price

hydraulic cylinder components

hydraulic cylinder piston

hyd cyl

hydraulic cy

hydraulic cylinder and piston

hydraulic piston cylinder price

hydraulic cylinder

hyd cylinder

hydraulic cy

#hydraulic cylinder in mumbai#Hydraulic Power Pack Manufacturers in Hyderabad#Hydraulic Power Pack Manufacturers in Gujarat#Hydraulic Cylinder Manufacturers in Maharashtra#Centrifuge Bag Lifting Device#Hydraulic Cylinder Manufacturers in New Delhi#Hydraulic Power Pack Manufacturers in New Delhi#Hydraulic Power Pack Manufacturers in Mumbai#Hydraulic Cylinder Manufacturers in Pune#Hydraulic Power Pack Manufacturers in Pune#hydraulic power pack#hydraulic cylinder#power pack#hyd cylinder#hydraulic cylinder price#hydraulic cylinder components#hydraulic cylinder piston#hyd cyl#hydraulic cy#hydraulic cylinder and piston#hydraulic piston cylinder price

0 notes

Photo

MPR 10000 ALUMINUM CORNER PRESS MACHINE - https://www.aluminyumcuyuz.com/haberler/sektorel-haberler/mpr-10000-aluminum-corner-press-machine/ - Aluminium Machinery for Aluminium Market, Aluminium Profile Machining Center, Double Head Cutting Machine, 4 axis CNC, 5 Axis CNC, Facade Notching Saws, Double Mitre Saws This machine is a corner press machine that was first designed to make frames from wide aluminum profiles, such as modular panel facade profiles and wide sliding frames.One of the best features it has is the PLC control unit and pressure-adjustable hydraulic print heads and the front locking block, thanks to which it provides the opportunity and advantage to make perfect and solid corner joints.Especially thanks to the print head tabs that can be shifted axially based in October in addition to the front and back, to make additional special knives in series such as frame profiles of modular panel joinery with thermal insulation it can print on profiles with a height of 25cm without having to.In addition, thanks to the automatic internal locking mechanism with double headstock, the frame supports the profiles to be made in October in a very practical way without making special apparatus, allowing us to make a more robust printing.The hydraulic print heads with a power of 100 bar cover the angular and dimensional cutting errors in joinery. features: – Electro-welded monolithic steel upper and lower body that provides maximum rigidity and precision. -Max, who can connect. Profile height: 300mm -The top knife is max. printing point height: 250mm – Hydraulic control with double foot pedals that provides simultaneous and error-free printing – adjustable Pressing pressure force up to 100 bar – Print heads with Decoupling between 25-60mm from the edge of the corner wedge – Easily adjustable measuring heads with millimeter scale – Hydraulic locked, down-up profile internal support blocks (h:200mm) -3 sets (6 pcs) printing tabs (3, 5, 7mm thick) – Profile V-support blocks adjusted by the wrist, maximum 90 mm -2 Pcs vertical pneumatic profile holder -2 axial rotatable profile support arms, – Working height: 950 mm· * Track support blocks – Axially adjustable adjustable printheads (for insulated wings) – Automatic, hydraulic movable, double-stage internal support block -1 PLC Controlled, timer adjusted cycle setting Hydraulic adjustment device that allows printing on profiles with wall thickness up to 5mm Hydraulic motor (1.2kW) (100bar max.) MPR 10000 ALUMINUM CORNER PRESS MACHINE yazısı ilk önce Mecanica - Alüminyum Profil Kesme ve İşleme Makine ve Otomasyon Teknolojileri üzerinde ortaya çıktı.

0 notes

Text

Why Fiber Optic Splitters Are the Backbone of Modern FTTH Networks

A fiber optic splitter distributes optical signals from a single source to many users. This device supports point-to-multipoint connections in FTTH networks. The fiber optic splitter 1x2, fiber optic splitter 1x8, multimode fiber optic splitter, and plc fiber optic splitter all provide reliable, passive signal delivery.

Key Takeaways

Fiber optic splitters share one high-speed internet signal with many users, making networks efficient and reliable. Using splitters lowers costs by reducing cables, installation time, and power needs, simplifying network setup and maintenance. Splitters allow easy network growth by adding more users without major changes, supporting both small and large deployments.

Fiber Optic Splitter Fundamentals

What Is a Fiber Optic Splitter? A fiber optic splitter is a passive device that divides a single optical signal into multiple signals. Network engineers use this device to connect one input fiber to several output fibers. This process allows many homes or businesses to share the same high-speed internet connection. The fiber optic splitter does not require power to operate. It works well in both indoor and outdoor environments. How Fiber Optic Splitters Work The fiber optic splitter uses a special material to split light signals. When light enters the device, it travels through the splitter and exits through several output fibers. Each output receives a portion of the original signal. This process ensures that every user gets a reliable connection. The splitter maintains signal quality, even as it divides the light. Note: The efficiency of a fiber optic splitter depends on its design and the number of outputs. Types of Fiber Optic Splitters Network designers can choose from several types of fiber optic splitters. The two main types are Fused Biconical Taper (FBT) splitters and Planar Lightwave Circuit (PLC) splitters. FBT splitters use fused fibers to split the signal. PLC splitters use a chip to divide the light. The table below compares these two types: Type Technology Typical Use FBT Fused fibers Small split ratios PLC Chip-based Large split ratios Each type offers unique benefits for different FTTH network needs.

Fiber Optic Splitter Roles and Benefits in FTTH Networks

Efficient Signal Distribution A fiber optic splitter enables a single optical signal to reach many users. This device divides the light from one fiber into several outputs. Each output delivers a stable and high-quality signal. Service providers can connect multiple homes or businesses without installing separate fibers for each location. This approach ensures efficient use of network resources. Tip: Efficient signal distribution reduces the need for extra cables and equipment, making network management easier. Cost Savings and Simplified Infrastructure Network operators often choose a fiber optic splitter to lower costs. By sharing one fiber among many users, companies save on both material and labor expenses. Fewer cables mean less digging and less time spent on installation. Maintenance becomes simpler because the network has fewer points of failure. The passive nature of the splitter also eliminates the need for electrical power, which further reduces operational costs. Key cost-saving benefits include: Lower installation expenses Reduced maintenance needs No power requirements Scalability and Flexibility for Network Growth Fiber optic splitters support network growth with ease. Providers can add new users by connecting more output fibers to the splitter. This flexibility allows networks to expand as demand increases. The modular design of splitters fits both small and large deployments. Service providers can upgrade or reconfigure the network without major changes to the existing infrastructure. Technical Features for Modern Deployments Modern fiber optic splitters offer advanced features that meet today’s network demands. These devices maintain signal quality even when splitting the light into many outputs. They resist environmental changes such as temperature and humidity. Splitters come in different sizes and configurations, including rack-mounted and outdoor models. This variety allows engineers to select the best option for each project. Feature Benefit Passive operation No external power needed Compact design Easy installation High reliability Consistent performance Wide compatibility Works with many network types Real-World FTTH Application Scenarios Many cities and towns use fiber optic splitters in their FTTH networks. For example, a service provider may install a 1x8 splitter in a neighborhood. This device connects one central office fiber to eight homes. In apartment buildings, splitters distribute internet to each unit from a single main line. Rural areas also benefit, as splitters help reach distant homes without extra cables. Note: Fiber optic splitters play a key role in delivering fast and reliable internet to both urban and rural communities. A fiber optic splitter helps deliver fast, reliable internet to many homes. Network providers trust this device for its efficiency and cost savings. As more people need high-speed connections, this technology remains a key part of modern FTTH networks. Reliable networks depend on smart solutions like fiber optic splitters.

FAQ

What is the typical lifespan of a fiber optic splitter? Most fiber optic splitters last over 20 years. They use durable materials and require little maintenance in both indoor and outdoor environments. Can fiber optic splitters affect internet speed? A splitter divides the signal among users. Each user receives a portion of the bandwidth. Proper network design ensures everyone gets fast, reliable internet. Are fiber optic splitters difficult to install? Technicians find splitters easy to install. Most models use simple plug-and-play connections. No special tools or power sources are needed. By: Eric Tel: +86 574 27877377 Mb: +86 13857874858 E-mail: [email protected] Youtube: DOWELL Pinterest: DOWELL Facebook: DOWELL Linkedin: DOWELL Read the full article

0 notes

Text

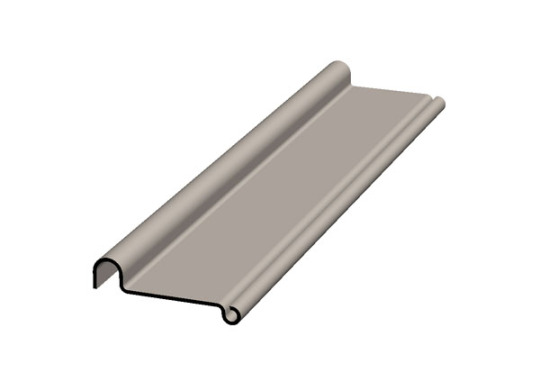

Transforming Sheet Metal with JUGMUG’s Super L Bottom Roll Forming Technology

In today’s fast-paced and quality-focused manufacturing world, the demand for highly precise, efficient, and reliable forming machines is at an all-time high. One such technological marvel that stands out in the domain of roll forming is the Super L Bottom Roll Forming Machine, especially when crafted by industry pioneers like JUGMUG Roll Forming. Known for their dedication to quality, durability, and engineering precision, JUGMUG has revolutionized the way sheet metal is transformed into structurally vital components using their advanced Super L Bottom Roll Forming Machines.

What is Super L Bottom Roll Forming?

The Super L Bottom Roll Forming process is a continuous metal forming technique where a long strip of metal—typically steel or aluminum—is passed through a series of precisely aligned rollers to create an “L” shaped profile with enhanced bottom support. These profiles are widely used in shelving systems, support brackets, metal racking, cable trays, wall partitions, and more.

What sets the Super L Bottom design apart is its structural strength and ease of integration into modular systems. It ensures better weight distribution, superior rigidity, and enhanced support—all critical elements in industrial and commercial applications.

JUGMUG Roll Forming: Pioneering Perfection

With decades of expertise in designing and manufacturing roll forming machinery, JUGMUG Roll Forming has carved a strong niche in the Indian and global sheet metal forming industry. Their machines are not just tools—they are engineering solutions that offer long-term reliability, low maintenance, and high output, making them the first choice of manufacturers across multiple industries.

Key Features of JUGMUG’s Super L Bottom Roll Forming Machine

Precision Engineering Every JUGMUG machine is built with premium-grade components, CNC machined parts, and hardened rollers to ensure unmatched forming accuracy and durability. The Super L Bottom profiles produced are consistent in dimensions, angles, and thickness, reducing material wastage and rework.

Customizable Profile DesignJUGMUG understands that one size doesn’t fit all. Their Super L Bottom Roll Forming Machines are fully customizable to cater to specific profile shapes, sizes, thickness ranges, and punch hole patterns based on your unique production requirements.

High-Speed ProductionTime is money in manufacturing. JUGMUG machines operate at high linear speeds without compromising on quality. Whether you need a few hundred meters or large-scale continuous production, these machines deliver exceptional throughput.

Robust StructureBuilt with heavy-duty frames and industrial-grade material handling systems, JUGMUG’s machines are designed for long-term stability, minimal vibration, and zero deviation under heavy loads.

Servo-Based Precision FeedingFor operations that require punching or notching, JUGMUG integrates servo feeders that ensure exact distance control between holes or cutouts. This is especially useful for profiles that need to be pre-punched before forming.

PLC-Controlled AutomationJUGMUG machines come with intelligent PLC control systems and touch-screen HMIs for user-friendly operation, real-time production monitoring, and error detection.

Energy Efficient With smart motor controls and energy-saving designs, these machines consume less power per meter of production, offering long-term savings and sustainability.

Applications of Super L Bottom Profiles

The profiles produced by JUGMUG’s Super L Bottom Roll Forming Machines are vital components across numerous sectors:

Electrical & Cable Trays: For supporting wiring and cable networks in commercial buildings and factories.

Racking & Storage Systems: Used in warehouses, retail shelves, and logistic racks due to their high load-bearing capacity.

Partition Wall Frames: In prefabricated structures, these profiles are perfect for wall and ceiling partitions.

Construction & Infrastructure: Used in temporary fencing, formwork systems, and scaffold supports.

Solar Mounting Systems: The L Bottom profile provides strength and compatibility for solar panel frameworks.

Why Choose JUGMUG for Your Roll Forming Needs?

Unmatched Industry Experience With years of innovation and successful client partnerships, JUGMUG brings unparalleled expertise and reliability to every machine they build.

End-to-End Support From consultation and design to installation, training, and after-sales service, JUGMUG offers complete technical support and maintenance assistance.

Strong R&D Capabilities The team at JUGMUG constantly invests in research and development to adapt to new industry trends, materials, and automation technologies.

Proven Track Record With a vast list of satisfied customers across India and abroad, JUGMUG Roll Forming has consistently proven their capability to deliver world-class solutions that stand the test of time.

In-House Manufacturing All JUGMUG machines are manufactured in-house using advanced machining, welding, and quality control systems. This ensures timely delivery, consistent build quality, and complete control over every component.

Conclusion

As industries continue to demand better strength, higher precision, and faster production in sheet metal forming, JUGMUG Roll Forming stays ahead of the curve with its Super L Bottom Roll Forming Technology. These machines are more than just equipment—they’re enablers of innovation, productivity, and long-term growth for manufacturers.

Whether you're upgrading from older systems or entering the roll forming business for the first time, JUGMUG’s solutions guarantee performance that transforms not just metal—but your entire business process.

For more details, demos, or quotations, contact JUGMUG Roll Forming today and step into the future of sheet metal forming.

0 notes

Text

Why Data Centres Rely on NX-ERA Premium PLCs for Redundancy & Reliability

Data centres are the online headquarters of businesses today. Every click, transaction, login, or query is responded to via a data centre. In this hyper-connected world, downtime is more than a slowdown; it's a disaster.

Whether it is hosting cloud applications, running finance systems, or managing mission-critical enterprise data, data centres simply can't afford failure of control. That's why businesses often spend money on layers of redundancy, not merely power or cooling, but even on the thinking brain of their infrastructure: the Programmable Logic Controller (PLC).This is where Messung Industrial Automation's NX-ERA Premium PLCs come in as a strategic benefit, designed to provide unparalleled modular scalability, PLC redundancy, and seamless SCADA integration for control that's future-proof.

The Challenge: When Control Systems Become the Weak Link

Power? Backed up. Cooling? Redundant. However, what about the control systems controlling these vital components?

Standard or mini PLCs lack the sophistication needed to handle the mission-critical data centres' demand. One logic mistake or hardware malfunction can take down numerous systems, usually with SLA fines, reputation damage, and monetary loss.

What is required is a Premium PLC solution that guarantees:

High-speed, deterministic control

Hardware and logic level redundancy

Modern SCADA and BMS integration

Scalability as the data centre grows

The Solution: NX-ERA Premium PLCs, Control that Never Sleeps

Built to provide dependable, high-availability automation, our NX-ERA provides much more than your average PLC controller. Let's break down what makes NX-ERA the top choice for data centre automation:

Built with Redundancy: Always On, Always Watching

Designed with a redundant PLC, NX-ERA runs on two CPUs - one primary and one hot-standby. They are mirroring each other in real time. If the main unit fails because of power problems, software glitches, or hardware malfunction, the standby takes over immediately, with no downtime. This degree of PLC redundancy is mission-critical to sustain:

Continuous HVAC and precision cooling

Real-time UPS and power distribution management

Live fire detection and suppression procedures

Integrated High-Speed PLC Performance

NX-ERA is a high-speed PLC with processing power for complex, distributed systems. With event sequencing, real-time I/O update, and determinism support, it ensures that each action is done with precision and accuracy. It's like having a control system that can anticipate trouble before it occurs.

Modular PLC architecture for changing infrastructure

In contrast to fixed systems, our NX-ERA boasts a modular PLC design wherein you can introduce new elements, such as I/O racks, processors, or server room sensors, without having to reconfigure or replace the original configuration. This is necessary in contemporary data centres where growth is ongoing.

Centralised Command SCADA Integration

NX-ERA enables smooth SCADA integration via MODBUS TCP/IP and lets you:

Monitor system health through central dashboards

BMS and environmental management system integration

Allow predictive maintenance and compliance monitoring

Custom logic event-based fire alarms

This turns your PLC controller into the eyes and ears of your operation, reporting, responding, and recording in real time.

NX-ERA in Action: Where It Delivers Inside a Data Centre

Contemporary data centres are precision ecosystems. Every subsystem, power, cooling, and fire protection, has to work in a very sophisticated unison. And NX-ERA Premium PLCs are the invisible heroes, directing all the elements to work together in precision, in complete synchrony and faultlessly.

Let's observe how NX-ERA extends operational excellence to the most critical automation domains:

Precision Environmental & Cooling Management

Maintaining the right temperature and humidity is not just about extending equipment life; it's about performance reliability and data integrity. Any slight discrepancy can cause server throttling, random shutdown, or damage due to condensation. NX-ERA exercises close control over:

CRAC units and air handlers: Thermal hotspots are averted by continuous feedback loops and high-speed actuation.

Chilled water distribution and airflow systems: Adaptive logic keeps cooling in phase with current server loads.

Humidity control: Essential in helping prevent electrostatic discharge and hardware long-term health.

What is special about NX-ERA in this regard is that it can perform environmental control logic with microsecond accuracy, supplemented with real-time data monitoring and logging for auditing, regulatory compliance, and AI-driven optimisation.

UPS Control & Power Synchronisation

Uninterruptible Power Supply (UPS) systems are only as good as the logic behind them. Our NX-ERA functions as a moderator, synchronising among multiple PDUs, UPS systems, and switchgear units. It ensures:

Seamless power source transitions during outages or load fluctuations

Real-time load balancing to avoid overloads and maintain energy efficiency

Phase synchronisation for harmonised energy supply between server halls

Where basic PLCs can lag or lose a beat during transitions, NX-ERA's high-speed PLC architecture anticipates power shifts and actively synchronises systems to absorb the impact, critical in Tier III and Tier IV data centres where downtime is not an option.

Fire Detection & Suppression Integration

When safety is not negotiable, response time is paramount. NX-ERA has real-time fire detection integration with intelligent logic chains that coordinate:

Smoke, temperature, and gas detector sensor integration

Alarm signalling through audio-visual signals

Release logic for chemical or inert gas extinguishing agents

But here's the surprise: NX-ERA performs these life-safety functions without affecting other automation tasks. Fire suppression systems may initiate in one area, yet cooling, power, and access control systems continue uninterrupted in other zones.

Shutdown-Free Maintenance: Redundancy in Action

All PLC systems will eventually need maintenance, but taking down operations to make it happen? That's a luxury no contemporary data centre can afford. NX-ERA avoids this inconvenience with live-switching redundancy:

You can upgrade firmware, replace I/O modules, or perform diagnostics on the main PLC.

In the meantime, the secondary PLC continues the automation uninterrupted.

After maintenance is finished, the jobs reverse, without any effect on operations.

This is redundancy in practice, not on paper, but in everyday ops. It's the way Redundant PLC logic makes scheduled downtime a non-event.

Business Benefits Over Engineering Specs

NX-ERA is more than just an upgrade to technology; it is an enabler for business. Here is how it immediately impacts operational and financial KPIs:

Uptime Confidence: Meets even the strictest SLAs with real-world dependability, minimising risk of penalties and guaranteeing service continuity.

Cost Efficiency: Avoids the enormous cost of downtime—lost business, manual intervention, and recovery of the system—and optimises energy usage with intelligent logic.

Compliance-Ready: With NX-ERA's thorough logging, audit trails, and snapshots of environmental data, ISO, ASHRAE, and Tier certifications are simple to comply with.

Future-Proofing: Built with Industry 4.0 PLC capabilities, such as remote access PLC capabilities, analytics, and diagnostics that become increasingly smarter with your infrastructure.

This is intelligent automation systems delivering tangible return on investment, not in years, but in months

The Road Ahead: Industry 4.0 Compliant, Future-Ready

NX-ERA is designed for the future by predicting the needs of tomorrow's data centre architecture today.

Designed for Edge computing applications where distributed processing is paramount

Smart analytics tools that are AI-enabled, performance optimisation compliant

Remote diagnostics and control, allowing for predictive maintenance anywhere

Integrates perfectly with AI-based decision systems, positioning your business for the next decade

As the business shifts towards smart control systems, NX-ERA is leading the way—not just prepared but already ahead.

Conclusion: Trust NX-ERA for Control that Never Compromises

Trust drives data centres. Trust that each byte is secure. Trust that there's uninterrupted uptime. Trust that operations persist, no matter what. NX-ERA Premium PLCs are designed for this trust.

Where time matters, every control logic matters. And that's where NX-ERA sets the pace: redundant PLCs, real-time SCADA integration, and modular PLC architecture for the intricacies of the future. We don't merely create control systems at Messung Industrial Automation. We create trust.

FAQs

In what way is NX-ERA different from standard PLC controllers?

NX-ERA is a High-availability Premium PLC that is suitable for high-availability environments. It accommodates redundant configurations, modular scalability, and advanced SCADA integration, as opposed to basic or micro-PLCs.

What is the method of NX-ERA's PLC redundancy?

NX-ERA has dual CPUs (main and standby). If the main fails, the standby takes over at once, with zero downtime or loss of data.

Is NX-ERA compatible with the current data centre infrastructure?

Yes. With MODBUS TCP/IP and SCADA-ready capabilities, NX-ERA is easily compatible with all control systems and BMS.

Is NX-ERA able to support small and large-scale data centres?

In fact. Its modular PLC design allows for effortless scaling, from small server rooms to multi-hall Tier IV data centres.

Does NX-ERA support Industry 4.0 PLC features?

Yes, it also has remote access, diagnosis, data logging, and intelligent analytics capabilities, and therefore is fully Industry 4.0-compatible.

#data centres#Programmable Logic Controller (PLC)#PLC redundancy#SCADA integration#mini PLCs#Premium PLC#PLC controller#data centre automation#redundant PLC#high-speed PLC#modular PLC design#MODBUS TCP/IP#NX-ERA Premium PLCs#PLC architecture#PLC systems#Industry 4.0 PLC#AI-based decision systems

0 notes

Text

Automation Robotic System & Solution and Roller Conveyor Supplier: Enhancing Manufacturing Efficienc

The Rise of Automation Robotic Systems & Solutions

Automation robotic systems have revolutionized the way industries operate. These systems encompass a range of robotic arms, automated guided vehicles (AGVs), and collaborative robots (cobots) designed to perform tasks traditionally handled by human workers. The primary benefits include increased throughput, enhanced accuracy, and improved safety conditions.

Implementing an Automation Robotic System & Solution involves a comprehensive approach, including system design, integration, and maintenance. manuel insert conveyor These systems are tailored to specific manufacturing processes—be it assembly, packaging, or material handling. They help reduce labor costs, minimize errors, and ensure consistent quality output.

Conveyor Systems: The Backbone of Material Handling

Conveyor systems are integral to efficient manufacturing workflows. Among various types, Roller Conveyor Supplier services stand out due to their durability, versatility, and ease of maintenance. Roller conveyors facilitate the smooth movement of items across production lines, warehouses, and distribution centers.

A reliable Roller Conveyor Supplier offers a wide range of products, including gravity roller conveyors, powered roller conveyors, and flexible modular systems. These conveyors can be customized to suit different load capacities, sizes, and operational environments. Their importance is especially evident in high-volume production lines where continuous, reliable transfer of goods is critical.

Manual Insert Conveyors and Their Role

While automation is prevalent, manual insert conveyors still hold relevance in many settings. These systems allow operators to manually place components onto the conveyor, combining human oversight with mechanical efficiency. Manual insert conveyors are particularly useful in scenarios requiring delicate handling, quality inspection, or customized assembly.

Integrating Manual Insert Conveyor systems with robotic automation enhances overall productivity. They serve as a flexible interface between manual tasks and automated processes, ensuring seamless workflows and reducing bottlenecks.

PLC Programming & Electrical Control System

Central to the success of automated systems and conveyor solutions is robust PLC Programming & Electrical Control System. Programmable Logic Controllers (PLCs) are industrial computers that control machinery operations through tailored software programs. They enable precise control over robotic arms, conveyor speeds, sensors, and safety interlocks.

Designing effective PLC programming involves developing logic sequences that coordinate multiple devices, respond to sensor inputs, and execute safety protocols. Electrical control systems encompass wiring, sensors, actuators, and human-machine interfaces (HMIs). Together, they ensure the smooth and safe operation of complex automation systems.

Integration for Optimal Efficiency

The synergy between Automation Robotic System & Solution, Roller Conveyor Supplier products, Manual Insert Conveyor, and PLC Programming & Electrical Control System creates a cohesive automation environment. For instance, a manufacturing line might incorporate robotic arms performing assembly tasks, conveyor belts transporting parts, and manual insert stations for quality checks—all managed by a centralized PLC system.

This integrated approach results in faster production cycles, higher quality standards, and reduced operational costs. Moreover, it offers scalability, allowing facilities to adapt to changing demands or expand their production capacity with minimal disruption.

Conclusion

Embracing automation and conveyor solutions is essential for modern manufacturing success. By partnering with reliable Roller Conveyor Supplier services and implementing advanced PLC Programming & Electrical Control System, companies can achieve higher efficiency, better quality, and greater flexibility. Whether deploying Automation Robotic System & Solution or integrating manual and automated conveyor systems, the key lies in seamless design and precise control.

For more information on top-quality conveyor systems, automation solutions, and control systems, visit for visual aids or consult industry specialists who can tailor solutions to your specific needs. Investing in these technologies paves the way for a smarter, more productive future in manufacturing.

0 notes

Text

Automatic Shot Blasting Machines: Features & Benefits

Introduction to Automatic Shot Blasting Machines

At Airo Shot Blast Equipments, we specialize in designing and manufacturing automatic shot blasting machines that transform surface preparation into an efficient, precise, and cost-effective process. These machines offer unmatched consistency in cleaning, strengthening, and finishing metal surfaces, catering to industries that demand high-volume productivity with minimal manual intervention.

Whether you're in automotive, aerospace, construction, shipbuilding, or metal fabrication, our automatic shot blasting machine deliver superior results by removing scale, rust, paint, and other contaminants, while enhancing the surface texture for coating adhesion or aesthetic improvement.

Key Features of Automatic Shot Blasting Machines

1. Fully Automated Operation

Our machines are engineered for complete automation. With PLC-based control systems, they allow seamless operation from loading to blasting and unloading. This not only reduces the requirement for manual labor but also ensures uniform blasting quality across batches.

Touch-screen HMI

Remote diagnostics and operation

Self-regulating blasting cycles

Fault-detection alerts and auto-shutdown safety

2. High-Efficiency Blast Wheels

The blast wheel assembly is the heart of any shot blasting machine. We incorporate high-speed, wear-resistant blast wheels designed for optimal abrasive flow and high-impact force. These robust wheels provide:

Maximum blasting efficiency

Reduced energy consumption

Minimal wear and tear

3. Abrasive Recycling System

Every Airo automatic machine comes equipped with an intelligent abrasive recovery and cleaning system. The used abrasive is collected, filtered, and recycled with minimal waste, which drastically reduces the cost of operation and improves environmental compliance.

Magnetic separators

Vibrating screens

Dust collection filters

Auto-refill mechanisms

4. Precision Workpiece Handling

From rollers, hangers, skew rollers to rotating drums, our machines provide flexible workpiece handling options to accommodate various shapes, weights, and sizes. Precision-engineered handling systems maintain consistent speed and distance, ensuring even exposure to the abrasive stream.

5. Rugged and Modular Construction

Built with abrasion-resistant manganese steel liners, the blast chambers and critical zones are designed to withstand extreme operational stress. Our modular machine design allows easy maintenance, part replacement, and future expansion or automation upgrades.

Heavy-duty frame

Corrosion-resistant surface coating

Minimal downtime design

Types of Automatic Shot Blasting Machines We Offer

1. Hanger Type Automatic Shot Blasting Machine

Designed for delicate and complex parts, these machines use rotating hooks to expose all surfaces uniformly. Ideal for:

Castings

Forgings

Welded structures

For more information visit URL - https://www.sandblastingmachine.in/hanger-type-shot-blasting-machines

2. Roller Conveyor Type Shot Blasting Machine

Optimized for plates, structural steel profiles, and beams, these machines utilize synchronized roller conveyors for linear, continuous processing.

Best for shipyards and steel fabrication

High throughput

Minimal floor space usage

3. Tumble Type Automatic Shot Blasting Machine

Perfect for small and medium-sized components such as fasteners and die-cast parts. The drum rotates to ensure complete abrasive exposure while protecting parts from damage.

4. Table Type Shot Blasting Machine

Equipped with a rotating turntable, this model suits flat and heavy components. With multiple blast wheels and variable speed rotation, the machine provides uniform surface treatment.

5. Spinner Hanger Type

Combining rotation and swinging motion, this variant delivers exceptional performance for components requiring 360-degree coverage, including automotive suspension parts and gear housings.

Benefits of Using Automatic Shot Blasting Machines

1. Consistent Quality and Precision

With computerized controls and pre-set parameters, automatic machines deliver repeatable blasting quality, eliminating human errors. This is especially critical for industries that demand high precision surface finishing before painting, coating, or welding.

2. Increased Productivity

Automatic systems enable continuous operation, significantly reducing turnaround time. With rapid blast cycles and integrated loading/unloading, businesses experience a dramatic increase in production efficiency.

3. Cost Reduction

Despite a higher initial investment, these machines offer long-term cost savings through:

Lower labor requirements

Reduced abrasive usage due to recycling

Minimal part rework

Lower energy consumption per unit

4. Worker Safety and Environment Compliance

By eliminating the need for manual blasting, these machines create a safer workplace. Integrated dust collectors and enclosures ensure compliance with international health and environmental regulations.

5. Minimal Maintenance and Downtime

Equipped with predictive maintenance alerts, easily accessible service points, and durable components, our machines minimize unplanned downtime and extend equipment life.

6. Scalable and Customizable Solutions

We understand that each application is unique. Our engineers tailor the machine configuration to match the client's specific blasting requirements, available space, and production flow. Upgrades for robotic integration, vision systems, and IoT analytics are also available.

Applications Across Industries

Our automatic shot blasting machines are trusted by industry leaders worldwide for applications including:

Surface cleaning of castings and forgings

Preparation for painting and powder coating

Stress relief in welded assemblies

Rust and scale removal from structural steel

Texture creation on stainless steel sheets

Industries served:

Automotive and OEMs

Aerospace

Steel fabrication

Railway components

Defense and shipbuilding

Why Choose Airo Shot Blast Equipments

At Airo Shot Blast Equipments, we deliver more than machines — we deliver complete blasting solutions. Our reputation is built on innovation, performance, and customer satisfaction.

Decades of expertise in abrasive blasting technology

ISO-certified manufacturing processes

Pan-India installation and service support

Export-ready machines meeting global standards

Comprehensive training and after-sales support

Conclusion

Automatic shot blasting machines have redefined surface preparation across multiple industries. With Airo Shot Blast Equipments, you're not just investing in equipment — you're investing in efficiency, consistency, and unmatched productivity. Our machines are engineered to meet your current needs while being adaptable for future demands.

Let our team help you select the right automatic shot blasting solution tailored to your applications. Connect with us today and elevate your surface treatment process to global standards.

#Shot Blasting#Shot Blasting Machine#Airo Shot Blast#Automatic Shot Blasting Machines#Shot Blasting Machines

1 note

·

View note

Text

Modernizing Legacy Control Systems: Moving from Obsolete to Optimized with Xytel India

In today’s fast-paced world of process automation, R&D, and real-time decision-making, relying on outdated control systems is like driving a modern car with a 90s engine — it’ll move, but not without limitations. For pilot plants and test units, where precision, safety, and data integrity are critical, legacy control systems are often the weakest link.

These systems weren’t built for today’s connected, digital-first workflows. The result? Slower innovation, reduced reliability, and increasing operational risks.

That’s exactly where Xytel India makes a difference — by offering a practical, strategic path to revamp outdated control systems and align them with modern-day expectations.

The Challenges of Legacy Control Systems in Real-World Operations

Legacy control systems often evolve from equipment that once led the industry — but they’re no longer keeping pace with current demands. Let’s break down the issues that many teams working in refining, petrochemicals, or R&D face every day:

1. Poorly Designed PLC Logic Creates Unpredictable Control Loops

Over time, custom-coded or undocumented PLC logic becomes hard to maintain. Diagnosing faults turns into guesswork, tuning is inconsistent, and every small change can introduce new problems. Without stable loops, your system reacts instead of responds — impacting overall process performance.

2. Disjointed HMI/SCADA Limits Situational Awareness

Legacy systems often use standalone HMIs or outdated SCADA tools that restrict real-time monitoring, trend analysis, and alarm management. Operators end up working with partial visibility, which affects both efficiency and safety.

3. Outdated Instruments Lack Self-Diagnostics

Many older field instruments — like temperature and flow sensors — can’t self-diagnose or alert operators to drift and failures. This leads to unnoticed performance degradation, avoidable downtime, and missed opportunities for predictive maintenance.

4. Data Gaps Undermine R&D Consistency

For R&D teams, inconsistent or manually logged data makes it hard to validate test results or repeat experiments. Without unified, time-stamped data records, key insights get lost — and so does trust in the results.

Xytel India’s Perspective: Why Upgrading Your Control System Is a Must

At Xytel India, we’ve seen firsthand how aging control infrastructure can hold back even the most innovative teams. Revamping isn’t just about swapping old hardware — it’s about restoring confidence, improving reliability, and enabling smarter operations.

That’s why we developed XY-MAT, a fully automated FCC catalyst testing rig built from the ground up to overcome every challenge of legacy systems. But our approach isn’t limited to one product — it’s a broader philosophy we apply across pilot plant control revamps.

How Xytel India Transforms Legacy Systems into Future-Ready Platforms

Here’s how we help pilot plants modernize without disrupting core operations:

Standardized PLC Logic with Modular Design

We replace outdated, ad-hoc logic with structured, documented programs using ladder logic or function blocks. This makes troubleshooting easier, updates safer, and control sequences more predictable — whether you’re controlling feed injection or regeneration cycles.

Integrated HMI & SCADA for Complete Visibility

Forget fragmented control panels. We implement modern HMI and SCADA platforms that give operators real-time insight, historical trends, and intuitive alarm tracking — all accessible locally or remotely.

Smart Instrumentation with Built-In Diagnostics

Our systems include intelligent field devices — transmitters, controllers, and positioners — with self-calibration, drift detection, and predictive failure alerts. This helps teams take action before problems become downtime.

Reliable, Centralized Data Logging

We ensure every process variable is digitally logged and synced in one system. Whether it’s temperature, flow rate, or pressure — your data is accurate, organized, and analytics-ready, making regulatory audits or R&D validations a breeze.

It’s More Than Technology — It’s a Partnership

What truly sets Xytel India apart is our hands-on engineering involvement. We don’t just install and walk away — we work alongside your team to:

Audit current system inefficiencies

Optimize control sequences and interlocks

Add redundancy where needed

Train your operators on new platforms

Fully test every component before handover

Our upgrades are modular and scalable. Whether you’re looking to modernize one test unit or your entire control suite, we tailor our approach to your specific needs.

A Safer, Smarter Plant Begins with a Control System Revamp

Old control systems aren’t just inefficient — they can pose real risks to safety, data quality, and operational continuity. The cost of inaction can be far greater than the investment in modernization.

With Xytel India, you can expect:

Stable, repeatable R&D processes

Stronger operator confidence

Fewer manual interventions and errors

Complete, actionable data for decision-making

A future-ready control platform built for efficiency and safety

0 notes

Text

HDPE, PP, PVC, ABS Article Plastic Scrap Washing Plant in Kanpur

R Mech Machine LLP is a prominent Manufacturer, Exporter, and Supplier of HDPE, PP, PVC, ABS Article Plastic Scrap Washing Plant in Kanpur, Uttar Pradesh, India. We have established our manufacturing facility in Ahmedabad, Gujarat, India. A plastic scrap washing plant is an industrial facility with machinery and technology to clean and process HDPE, PP, PVC, and ABS scraps. The plant removes contaminants like dirt, labels, glue, and other impurities, resulting in clean plastic flakes or pellets ready for recycling or reuse. Our advanced washing systems thoroughly clean, sort, and recycle plastic waste, producing high-quality recycled raw materials efficiently. With efficiency, sustainability, and cost-effectiveness, our plants empower industries to transform plastic waste into valuable, reusable resources. Our washing plants efficiently process diverse plastic scraps, maximizing recovery, improving material quality, and reducing environmental impact. Features of HDPE, PP, PVC, ABS Article Plastic Scrap Washing Plant: High Washing Efficiency: Thorough cleaning with minimal water and energy consumption. Multi-Layer Cleaning: Includes pre-wash, hot wash, friction wash, and dewatering. Robust Construction: Made from corrosion-resistant stainless steel and durable materials. Automated Operation: PLC-based control for easy monitoring and management. Modular Design: Flexible configurations to suit different scrap types and volumes. Energy-Efficient Motors: Low power consumption while maintaining high throughput. Wastewater Treatment: Integrated solutions for eco-friendly water management. Uses of HDPE, PP, PVC, ABS Article Plastic Scrap Washing Plant: • Plastic recycling plants • Waste management facilities • Plastic manufacturing units • Environmental protection agencies • Municipal solid waste processors • Industrial scrap processors • Exporters of recycled plastic materials FAQs: What types of plastic scraps can your washing plants handle? A: Our plants are designed for HDPE, PP, PVC, ABS, and mixed plastic scrap processing. Can the plant process mixed plastic waste? A: Yes, we have multi-polymer washing plants designed to handle mixed plastic scrap efficiently. What is the quality of the output after washing? A: The output consists of clean, contaminant-free plastic flakes suitable for high-quality recycling. Can the washing plant remove labels and adhesives? A: Yes, our multi-stage friction washing process effectively removes labels, glue, and other contaminants. R Mech Machine LLP is a HDPE, PP, PVC, ABS Article Plastic Scrap Washing Plant in Kanpur, Uttar Pradesh including other locations Lucknow, Ghaziabad, Agra, Meerut, Varanasi, Prayagraj, Bareilly, Aligarh, Moradabad, Saharanpur, Gorakhpur, Noida, Firozabad, Jhansi, Muzaffarnagar, Mathura-Vrindavan, Ayodhya, Rampur, Shahjahanpur, Farrukhabad-Fatehgarh, Budaun, Maunath Bhanjan, Hapur, Etawah, Mirzapur-Vindhyachal, Bulandshahr, Sambhal, Amroha, Hardoi, Fatehpur, Raebareli, Orai, Sitapur, Bahraich, Modinagar, Unnao, Jaunpur, Lakhimpur, Hathras, Banda, Pilibhit, Barabanki, Khurja, Gonda, Mainpuri, Lalitpur, Etah, Deoria, Ghazipur, Sultanpur, Azamgarh, Bijnor, Sahaswan, Basti, Chandausi, Akbarpur, Ballia, Tanda, Greater Noida, Shikohabad, Shamli, Awagarh, Kasganj. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

#Agra#Ahmedabad#Akbarpur#Aligarh#Amroha#Awagarh#Ayodhya#Azamgarh#Bahraich#Ballia#Banda#Barabanki#Bareilly#Basti#Bijnor#Budaun#Bulandshahr#Chandausi#Deoria#Etah#Etawah#Exporter#ExporterofHDPEPPPVCABSArticlePlasticScrapWashingPlant#ExporterofHDPEPPPVCABSArticlePlasticScrapWashingPlantinKanpur#Farrukhabad-Fatehgarh#Fatehpur#Firozabad#Ghaziabad#Ghazipur#Gonda

0 notes

Text

Isolated DC DC Converter: Efficient Power Solutions by Campus Component

In the realm of modern electronics, efficient power management is crucial to ensuring optimal performance and longevity of devices. An isolated DC DC converter plays a pivotal role in achieving this efficiency by providing electrical isolation between input and output, enhancing safety and improving system design flexibility. Whether you are designing industrial controls, medical devices, or telecommunications equipment, understanding how these converters work and their applications can help you make better choices. This article will explore everything you need to know about isolated DC DC converters, their types, benefits, and how to select the right one.

What is an Isolated DC DC Converter?

An isolated DC DC converter is an electronic circuit that converts one level of DC voltage to another while maintaining electrical isolation between its input and output. This isolation is achieved using a transformer, which separates the electrical paths but allows energy to transfer via electromagnetic induction. These converters are vital in applications where the system requires galvanic isolation to prevent noise, ground loops, or safety hazards.

The design and structure of these converters make them ideal for sensitive and high-reliability environments. Unlike non-isolated converters, which share a common ground, isolated types can protect both the system and the user.

How Do Isolated DC DC Converters Work?

At the core, an isolated DC DC converter functions by first converting the DC input into an AC signal using a high-frequency oscillator. This AC signal then passes through a transformer, providing isolation, and is finally rectified and filtered to generate the desired DC output.

The transformer serves a dual purpose:

Voltage Scaling: Changes the voltage level according to the turn ratio.

Isolation: Prevents direct electrical connection between input and output.

This approach allows for a compact design that delivers high efficiency, reduced electromagnetic interference (EMI), and safe operation across various voltage ranges.

Key Features of Isolated DC DC Converters

Electrical Isolation Provides galvanic separation between input and output, improving safety.

Wide Input Voltage Range Often designed to handle varying input voltages, useful in battery-powered or industrial systems.

High Efficiency Most models operate above 85% efficiency, reducing heat generation and power loss.

Compact Size Miniaturized versions are available, ideal for applications with space constraints.

Thermal Management Many modules include features for efficient heat dissipation or over-temperature protection.

Types of Isolated DC DC Converters

1. Flyback Converters

Common in low- to medium-power applications. Known for simplicity and cost-effectiveness.

2. Forward Converters

Suitable for higher power needs, offering better regulation and efficiency.

3. Push-Pull Converters

Used in medium to high-power applications with symmetrical switching to reduce ripple.

4. Half-Bridge and Full-Bridge Converters

Advanced designs used in high-power industrial or telecom systems requiring tight regulation.

Applications of Isolated DC DC Converters

Industrial Automation: Ensures safety and reliability in PLCs, sensors, and controllers.

Medical Devices: Provides critical isolation in patient-connected equipment.

Telecommunications: Maintains signal integrity in remote powering of devices.

Electric Vehicles (EVs): Manages power in battery management and motor control systems.

Renewable Energy Systems: Helps in transferring power from panels to storage units safely.

Benefits of Using an Isolated DC DC Converter

Safety: Prevents accidental shocks and damage due to voltage spikes.

Noise Reduction: Isolates sensitive circuitry from noisy power sources.

System Reliability: Protects the system from failures in connected parts.

Design Flexibility: Allows for modular designs and mixed voltage levels.

Improved Performance: Stabilizes output voltage despite fluctuating input conditions.

Choosing the Right Isolated DC DC Converter

When selecting an isolated DC DC converter module for your application, consider the following factors:

Input and Output Voltage: Match your system's voltage requirements.

Power Rating: Choose a module with sufficient wattage for your load.

Isolation Voltage: Ensure it meets safety standards for your application.

Efficiency: Higher efficiency reduces thermal issues.