#PCB robotic designs

Explore tagged Tumblr posts

Text

The Role of Flexible PCB Design in Next-Generation Robotics

Robotics and automation are not buzzwords anymore. We all witness the latest flying robots, auto-balancing AGVs, and industrial heavy collaborative robots that are revolutionizing the way we work. But do you know that PCBs are the “brain” of these technology marvels?

With the exponential demand for robotics in every field, the demand for smaller, lighter, more flexible electronic components, especially flex PCBs, is rapidly increasing. According to the International Federation of Robotics, there was a 48% increase in professional service robot sales globally by 2022. In such a scenario, flexible printed circuit boards (PCBs) have become the cornerstone of this transformation. Their special construction and ability are crucial for addressing the design difficulties given by next-generation robotics.

This article will explore how flexible PCB design is transforming robotics and what that implies for PCB manufacture.

Why Robotics Need Flexible PCBs

Unlike conventional rigid PCBs, flexible PCBs are designed to bend and twist, which creates countless opportunities for integrating electronics into the intricate forms and motions needed for robotic applications. For robotics, where designs generally call for flexibility and durability, flex PCBs, which can manage movement and fit into small areas, are perfect.

Key Benefits of Flexible PCB Design for Robotics

Flex PCBs are specially designed to focus on some key benefits that are essential for robotics and complex electronic devices. Some of the noteworthy advantages are:

Adaptability: Flexible PCBs can fit the form of the robotic component, therefore enabling designers to create thinner, lighter systems without compromising performance.

Durability: For robots with moving parts, these boards are perfect since they can absorb stress created during motion and vibration.

Space optimization: By reducing the need for connectors and bulky wiring, flexible PCBs free up valuable space and reduce the weight of the robot.

Enhanced reliability: High-performance robotics depend on fewer sources of failure. Flex PCBs reduce the requirements of connectors and bulky wirings, and therefore, they improve the robot's reliability.

Applications of Flexible PCBs in Robotics

From simple consumer devices to sophisticated industrial machines, flexible PCBs are fast taking the stage in many different robotic applications. Here is where flexible PCB manufacturing is taking the front stage:

Wearable Robots: Wearable robots are used in medical and fitness applications, and they require lightweight, comfortable designs. Flex PCBs make it possible for these devices to bend and contour to the user's body.

Drones and autonomous vehicles: Autonomous cars and drones call for lightweight parts that can withstand stress from continuous motion and fit small areas. Flexible PCBs enable maximum efficiency and help to reduce weight.

Industrial robots: Flexible PCBs can withstand the wear and tear of motion without compromising on performance. Therefore, it becomes highly dependable without sacrificing space for robotics undertaking repetitive tasks.

Important Considerations in Robotics Flexible PCB Design

Flexible PCB design for robotics presents certain difficulties. These are some crucial elements to consider:

Selection of Materials

Flexibility, durability, and heat resistance depend on the selected materials; hence, they are quite important. Because of its heat resistance, flexibility, and durability, polyimide is a common choice for flexible PCB manufacture.

Thickness and Layer Count

The number of layers in a flex PCB might range from one to many. The design requirements for the robot will dictate the optimal balance between physical flexibility and usefulness since adding more layers can limit its adaptability.

Copper Traces and Bend Radius

Careful design of copper traces in a flexible PCB helps to prevent cracks or breakage. Ensuring that traces follow a specific bend radius can help maintain the board's integrity during movement.

Component Placement

During operations, robots experience shocks and vibrations, so it's crucial to strategically place components and reinforce areas prone to bending. This lowers the possibility of component failure in high-stress environments.

Final Thoughts: Embracing Flexible PCBs into Your Robotic Designs

As it offers the adaptability, longevity, and efficiency required for modern, complicated applications, flexible PCB design plays an obvious role in robotics. As a PCB manufacturer, you can broaden the capabilities of robotics by learning about and making use of flex PCBs.

Including flexible PCBs in robotic designs not only creates more space-efficient, robust machines but also helps you to be in front of a market where innovation is vital. Adaptable electronics will surely define the direction of robotics going forward; flexible PCB fabrication has the power to propel these developments ahead.

PCB Power is your one-stop solution, providing premium, durable PCBs to support all technological advancements such as RoboticsLooking for a reliable flex PCB manufacturer for your project? Email us at [email protected] or call us at +1(818) 886 8900. Read More: The Role of Flexible PCB Design in Next-Generation Robotics

0 notes

Text

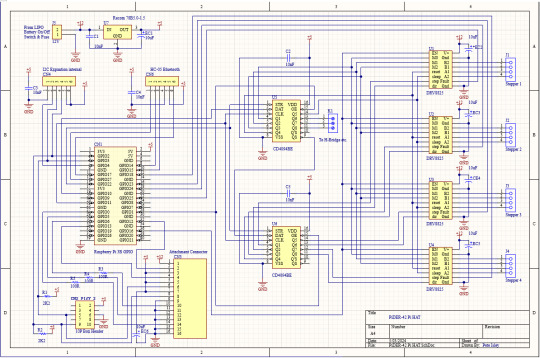

Today (Friday 3rd May 2024) I finally got the schematic of the matrix board plus a few improvements drawn out in the PCB CAD system ready for the next stage of laying out the board. I will probably ponder over this for a few weeks just in case I want to change or improve something else. Two of the signal lines on the attachment connector have been changed to include the I2C channel, as I feel that this could be a very useful communications link for any future attachments that we might need to provide for the robot. Also the DRV8825 driver modules provide a 'Fault' output pin that the previous drivers didn't have. So these four lines have been connected to the Pi for monitoring by the software. The two CD4094 shift register latches are loaded using the Pi's SPI interface and then all sixteen bits are latch simultaneously by a single line from the Pi. It is the most effective way to add lots of synchronised digital output lines to the Pi.

1 note

·

View note

Text

Robot girl, finally back online after a year and a half, looking at the newly outfitted soldering station. There's a lot more tools on it than there were when she last closed her eyes: Inspection microscopes, hot air reflow, EEPROM programmers, logic analyzers, thermal cameras and regulated power supplies. She starts to tear up when she sees the video history of her partner (and repairperson): months and months of electronic tutorials, starting simple ("what is a circuit?") and towards the end there's PCB design classes and CCC videos about reverse engineering secure processor firmware.

"You did all this, for me?" she asks, her voice sounding different from how she remembers it, lacking the stutterglitch and 8-bit audio harshness. Her partner smiles. "I thought I'd lost you... I couldn't live with that. I had to!"

She hugs them in a pile of spare parts, servos moving smoothly for the first time in decades, pressure sensors finally accurate enough to hold them without risk of crushing them.

Sometimes, love is stored in the soldering iron.

978 notes

·

View notes

Text

Hey robot enthusiasts! Nature meets technology in Short Circuit, an enamel pin collection inspired by the aesthetics of Printed Circuit Boards (PCB). 🤖🐺

All 12 of the above pins are funded and available designs to purchase by backing, in addition to:

And our current goal is less than €200 away from unlocking as well!

If you'd like any of these bot-boards as hybrid enamel pins or selective holographic vinyl stickers, check out the campaign on Backerkit! 💚✨

#robots#printed circuit board#pcb#sci fi art#enamel pins#pins#pintopia#pintopia 2025#wolf#cat#rat#leaf#goat#fox#eagle#flame#swan#butterfly#vampire squid#wave#paw#dragon#raven#my art#artists on tumblr

301 notes

·

View notes

Note

Never had a job where i had to be a soldering pinch hitter but it was my main college extracurricular, and agreed, it's good enrichment 👍

Hello! I'm also doing robotics engineering, but I'm still an undergrad. It's surprising how many robotics engineers I've found here, at least three. I'm (most likely) going into manufacturing after I graduate, but I think you're doing something different?

hello hello!! i admittedly do not know much about the industrial automation side of things -- my experience is largely with behavior/planning/controls for, basically, boxes on wheels that operate in environments with people in them (what you might call a "cobot", if you were a corporate tool. if you catch me on here posting about AMRs like thats a coherent concept please just shoot me)

might end up at an AV company at some point but they tend to be kind of large compared to the size of startup i prefer to work for. like, mostly i write software but i have one of those startup jobs thats sometimes like "hey, you know what end of a soldering iron is hot, right? we urgently need someone to put together some cables", my job title is the delightfully vague Roboticist II, and i've gotten my grubby little hands on just about every piece of the software stack at some point or another, and i think this is actually critical for my mental health because otherwise i'll get bored and burn out :p

#i was never any kind of robotics engineer but i hung out with them in college so following g-t's blog is nicely nostalgic <3#chatter#well mostly pcb design and manufacturing. wires are too wiggly. but yeah them too when needed

17 notes

·

View notes

Text

Timbug II published in Elektor, June 1980. This robot uses ultrasonics to trigger obstacle avoidance behaviour – a random back-off and turn. There are no photographs in the Elektor article so the photos show David Buckley's build of Timbug-II made in the style of other Elektor projects using acrylic sheet and pcb spacers. "The initial design requirements for this 'bug' were that it be able to 'see' objects in its path and take avoiding action. It should also be as inexpensive and as simple as possible. As the circuit was designed around the ever popular 555 timer IC, and the circuit shown here is the Mk II version, it is not difficult to realise how it came to be christened Timbug II. By using just four timer ICs and a handful of other components a quite 'intelligent' and lifelike animal can be made. Rather like a bat, the bug transmits a 'radar beam' of ultrasonic sound which will be reflected by any obstacle in its path. Once this reflected signal has been detected the bug will alter its course. It does this simply by reversing a short distance while turning to the left or right at the same time. If the path in front of the bug is now clear it will move straight ahead thereby avoiding any obstacle. If, however, another object is detected the bug will continue to 'wriggle its way out' by turning to the left and right alternately." – Elektor, June 1980.

39 notes

·

View notes

Text

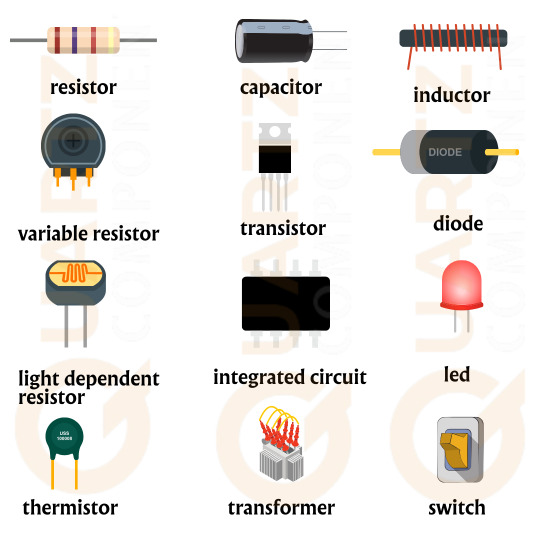

Electronics Components #components #electronics #engineering #electrical #arduino #electronic #innovation #design #robotics #electroniccomponents #raspberry #technology #manufacturing #industrial #gaming #school #learningbydoing #solar #bahrain #pc #pcb #budaiya #muhharaq #manama #engineeringforkids #saar #riffa #makersgonnamake #isatown #summerprogram

#Electronics Components#components#electronics#engineering#electrical#arduino#electronic#innovation#design#robotics#electroniccomponents#raspberry#technology#manufacturing#industrial#gaming#school#learningbydoing#solar#bahrain#pc#pcb#budaiya#muhharaq#manama#engineeringforkids#saar#riffa#makersgonnamake#isatown

13 notes

·

View notes

Text

Pink Sweets is a beautiful disaster of a video game

Pink Sweets might be Cave's grodiest shmup and I love it so much. the game is a fucking mess that hates the player. thank you Shinobu Yagawa, nobody else does it like you, probably for good reason

he really made a game with the nastiest dynamic difficulty possible where it's only lowered when you lose a life and then said "y'know what? you don't get extra lives from getting points. you only get them by raising a completely different number, and that number goes down if you use your best weapon. also the number is invisible. because fuck you is why."

the game is so fucked that you had people wondering whether a glitch that let you get infinite lives that was in the first 3 revisions of the PCB was actually an intentional design decision to make it possible to beat this fucking nightmare

the world record run (on a version without the infinite lives glitch) jacks the difficulty up to max during the stage one boss by changing option formations as fast as possible and then plays basically the entire game there. also it's an hour and twenty minutes long in order to properly milk as many points as possible from every single boss and midboss.

even the visual aesthetic is complete nonsense. it keeps the elegant character art and rose theming from its predecessor Ibara, but replaces the military tanks and planes and vaguely steampunk flying machines and places them with. brightly colored toy robots, for some reason?

incredibly strange, hateful game. I love it.

10 notes

·

View notes

Text

To my fans looking for any potential updates, here's a special one :D

I've been planning to revamp the ProwCinnBlock trio into something new and much more interesting. The next album is an insanely new creative leap from my previous works and so I wanna reflect that change with the characters.

With that said, here's the new design for PCB Blockbuster, who finally looks like a robot rather than a box on a woman base body. They also have eyes so she's a lot more expressive, a detail that the previous design lacked for the worse.

I plan on working on Cinnimin next, then Prowler. Cinnimin I think will be an easy work, however Prowler I'm not entirely sure what to do yet, but we'll get there when we get there.

4 notes

·

View notes

Text

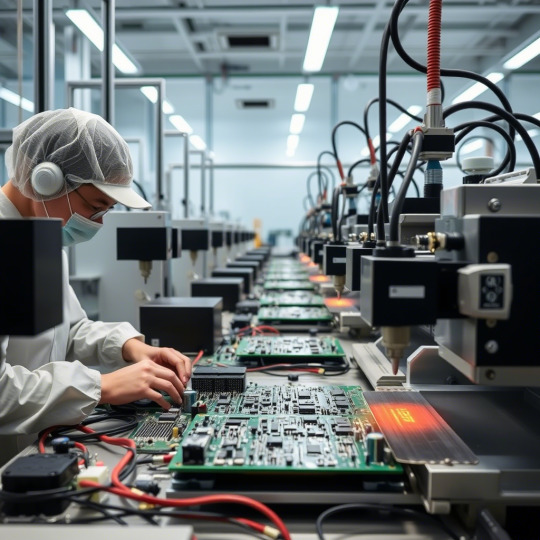

Experience high-speed, automated PCB assembly with advanced robotic soldering. Visit www.auckam.com for reliable EMS & hardware design services.

#PCBA#RoboticSoldering#ElectronicsManufacturing#EMS#PCBAssembly#SurfaceMountTechnology#SmartManufacturing#IoTDevices#IndustrialAutomation#ElectronicDesign#ContractManufacturing#HardwareEngineering#SmartElectronics#AuckamTechnologies

0 notes

Text

Global HVAC Duct-Cleaning Robots Market : Key Drivers, Significant Analysis And Future Scope

Global PCB Solid State Relays Market valued at USD X.X Billion in 2024 and is projected to reach USD X.X Billion by 2032, growing at a CAGR of X.X% from 2025 to 2032. Global PCB Solid State Relays Market: Significant Analysis The global PCB solid state relays market is experiencing robust growth driven by increasing adoption across diverse industries such as automotive, industrial automation, and consumer electronics. Advancements in semiconductor technology and the demand for reliable, compact, and energy-efficient switching solutions are key factors propelling market expansion. Projections indicate a steady CAGR over the next several years, fueled by rising investments in smart grid technologies and IoT integration. Additionally, the trend towards miniaturization and enhanced performance in electronic components further supports market momentum. Emerging applications in renewable energy and healthcare sectors offer new avenues for growth. Challenges related to high initial costs and thermal management are being addressed through innovation, enabling wider acceptance. Overall, the market outlook remains positive, with continuous improvements anticipated to drive adoption globally. Get the full PDF sample copy of the report: (Includes full table of contents, list of tables and figures, and graphs) @ https://www.verifiedmarketresearch.com/download-sample/?rid=368234&utm_source=Glob-VMR&utm_medium=261 Global PCB Solid State Relays Market Key Drivers Key drivers of the global PCB solid state relays market include the increasing need for efficient and durable switching devices in various electronic applications. The rise in automation and smart manufacturing processes has elevated demand for reliable relays that offer faster switching speeds and longer operational lifespans compared to traditional electromechanical relays. Additionally, growing awareness about energy conservation and the push for low-power consumption electronics encourage the use of solid state relays. The expanding automotive industry, with a focus on electric and autonomous vehicles, also fuels market growth. Moreover, the surge in consumer electronics requiring compact and silent operation components boosts demand. Continuous advancements in materials and circuit design further enhance performance, making PCB solid state relays an attractive choice across sectors. Global PCB Solid State Relays Market: Future Scope The future scope of the global PCB solid state relays market is promising, with substantial growth anticipated due to technological advancements and expanding applications. As industries increasingly adopt automation and digital solutions, the demand for compact, efficient, and reliable switching devices will grow significantly. Innovations in semiconductor materials and integration with smart technologies will enable improved relay performance and functionality. Additionally, emerging sectors such as renewable energy, electric vehicles, and healthcare instrumentation offer new growth opportunities. The ongoing trend toward miniaturization and multifunctional devices will further drive market expansion. Regional developments, particularly in Asia Pacific, will play a crucial role in shaping the market landscape. Overall, the future outlook suggests strong growth supported by increasing investments and evolving technological requirements. Refractive Optical Element Market Regional Analysis The Asia Pacific region holds a pivotal position in the refractive optical element market due to rapid industrialization and technological advancements. Growing demand from sectors such as telecommunications, consumer electronics, and healthcare fuels regional market growth. Countries in this region are investing heavily in research and development, improving manufacturing capabilities and adopting advanced materials. Increasing applications in augmented reality, virtual reality, and laser systems contribute to rising market opportunities. Additionally, expanding

infrastructure and government support for high-tech industries create a favorable environment for market expansion. The region��s cost-effective manufacturing and skilled workforce further attract global players to establish production hubs. These factors collectively drive significant growth in the Asia Pacific refractive optical element market, positioning it as a key contributor to the global industry. Download Full PDF Sample Copy of PCB Solid State Relays Market Report @ https://www.verifiedmarketresearch.com/download-sample/?rid=368234&utm_source=Glob-VMR&utm_medium=261 Key Competitors in the PCB Solid State Relays Market These companies are renowned for their broad product offerings, sophisticated technologies, strategic efforts, and robust market presence. Each competitor's primary advantages, market share, current events, and competitive tactics—such as collaborations, mergers, acquisitions, and the introduction of new products—are highlighted in the study. Omron TE Connectivity Sensata Technologies Celduc Relais Siemens ABB Rockwell Automation. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount/?rid=368234&utm_source=Glob-VMR&utm_medium=261 PCB Solid State Relays Market Trends Insights PCB Solid State Relays Market Trend Insights offers a thorough examination of the market's current and developing trends, providing insightful data-driven viewpoints to assist companies in making wise decisions. This study explores the major consumer trends, market forces, and technology developments influencing the sector. By Specifications By Load Type By Application By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/pcb-solid-state-relays-market/ Detailed TOC of PCB Solid State Relays Market Research Report, 2026-2032 1. Introduction of the PCB Solid State Relays Market Overview of the Market Scope of Report Assumptions 2. Executive Summary 3. Research Methodology of Verified Market Reports Data Mining Validation Primary Interviews List of Data Sources 4. PCB Solid State Relays Market Outlook Overview Market Dynamics Drivers Restraints Opportunities Porters Five Force Model Value Chain Analysis 5. PCB Solid State Relays Market, By Geography North America Europe Asia Pacific Latin America Rest of the World 6. PCB Solid State Relays Market Competitive Landscape Overview Company Market Ranking Key Development Strategies 7. Company Profiles 8. Appendix About Us: Verified Market Research®Verified Market Research® is a leading Global Research and Consulting firm that has been providing advanced analytical research solutions, custom consulting and in-depth data analysis for 10+ years to individuals and companies alike that are looking for accurate, reliable and up to date research data and technical consulting. We offer insights into strategic and growth analyses, Data necessary to achieve corporate goals and help make critical revenue decisions.Our research studies help our clients make superior data-driven decisions, understand market forecast, capitalize on future opportunities and optimize efficiency by working as their partner to deliver accurate and valuable information. The industries we cover span over a large spectrum including Technology, Chemicals, Manufacturing, Energy, Food and Beverages, Automotive, Robotics, Packaging, Construction, Mining & Gas. Etc.Having serviced over 5000+ clients, we have provided reliable market research services to more than 100 Global Fortune 500 companies such as Amazon, Dell, IBM, Shell, Exxon Mobil, General Electric, Siemens, Microsoft, Sony and Hitachi. We have co-consulted with some of the world's leading consulting firms like McKinsey & Company, Boston Consulting Group, Bain and Company for custom research and consulting projects for businesses worldwide. Contact us:Mr. Edwyne FernandesVerified Market Research®US:

+1 (650)-781-4080UK: +44 (753)-715-0008APAC: +61 (488)-85-9400US Toll-Free: +1 (800)-782-1768Email: [email protected]:- https://www.verifiedmarketresearch.com/ Global Gardening Equipment Market

0 notes

Text

Surface Mounting Technology (SMT): Revolutionizing Modern Electronics Assembly

Surface Mounting Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs). This revolutionary technology has transformed the way electronic devices are assembled, enabling smaller, faster, and more efficient products.

What is SMT?

SMT is a production technique where electronic components, known as Surface-Mount Devices (SMDs), are placed and soldered directly onto the surface of a PCB, as opposed to the older method of inserting components through holes (Through-Hole Technology).

How SMT Works: A Step-by-Step Overview

Solder Paste Application A stencil is used to apply solder paste to specific areas on the PCB where components will be mounted.

Pick and Place Robotic machines precisely pick up SMD components and place them onto the solder-paste-covered pads.

Reflow Soldering The assembled PCB is passed through a reflow oven. The heat melts the solder paste, securing the components in place as it cools and solidifies.

Inspection and Testing Automated Optical Inspection (AOI), X-ray inspection, and functional testing are used to ensure accuracy and reliability.

Benefits of SMT

Miniaturization SMT allows for smaller components, making compact device designs possible—ideal for smartphones, wearables, and medical devices.

Higher Component Density Components can be placed on both sides of a PCB, increasing functionality in a smaller area.

Faster Manufacturing SMT is highly automated, enabling high-speed production with fewer manual interventions.

Cost-Effective Lower labor costs and material waste result in reduced overall production expenses.

Improved Performance Shorter leads and tighter connections minimize signal distortion, making SMT suitable for high-frequency applications.

Applications of SMT

Consumer Electronics: Smartphones, tablets, TVs, and laptops

Automotive Electronics: Sensors, infotainment systems, and control modules

Medical Devices: Pacemakers, diagnostic equipment, and monitoring tools

Telecommunications: Routers, modems, and base stations

Industrial Automation: PLCs, sensors, and control systems

Challenges in SMT

Thermal Management Smaller components generate heat that must be properly managed to avoid failure.

Component Handling Some ultra-small components can be difficult to place accurately and require advanced machinery.

Inspection Complexity With denser boards and finer pitches, defect detection becomes more challenging.

0 notes

Text

Why Should You Rely on Connector Wrenches for Precision and Safety?

Introduction to Connector Wrenches

Connector wrenches are essential tools engineered to simplify the tightening and loosening of connectors in a wide variety of electrical, electronic, and mechanical assemblies. Unlike generic wrenches, connector wrenches are specially designed to provide optimal torque control, ensuring secure connections without damaging delicate components. Their role is increasingly important in precision-driven industries, from telecommunications and aerospace to electronics manufacturing and data centers. The compact design and compatibility with hard-to-reach spaces make these tools a must-have for technicians and engineers working with connectors, sensors, cables, microcontrollers, and other sensitive components.

Why Are Connector Wrenches So Important?

Connector wrenches serve as the interface between quality installation and long-lasting performance. Whether assembling fiber optic cables or tightening RF connectors in communication equipment, these wrenches ensure a perfect fit and torque consistency, reducing the risk of signal loss or component failure.

Their significance extends across multiple fields:

In electronics, they provide careful application of pressure, preserving internal components.

In safety-critical environments, they prevent under-tightening or over-tightening, which can compromise functionality.

In thermal and high-frequency environments, they help maintain signal integrity and reduce potential system malfunctions.

With the rise in automated systems, robotics, and microelectronic devices, connector wrenches have become more refined, precise, and essential.

What Are the Key Features of a Connector Wrench?

Connector wrenches are built with attention to detail, functionality, and durability. The best models are manufactured using high-grade materials like stainless steel or anodized aluminum, and are compatible with various connector types and industry standards.

Key features include:

Ergonomic handles that provide a comfortable, anti-slip grip during repetitive tasks

Torque-limiting designs to prevent damage to sensitive terminals or threaded connectors

Slim or angled profiles to access connectors in tight or obstructed areas

Interchangeable heads to work with different connector sizes or standards

Non-magnetic materials to ensure safety in environments with magnetic-sensitive components like capacitors, sensors, and microprocessors

These design features make connector wrenches versatile for professionals working with thermal pads, controllers, contactors, and other high-performance equipment.

How Are Connector Wrenches Used in Industry?

Connector wrenches are utilized across several technical sectors where precise connectivity is essential. In telecommunications, for example, connector wrenches are commonly used to install coaxial or fiber connectors. In the aviation and aerospace industry, they’re instrumental in ensuring vibration-resistant terminations. In electronics, especially during PCB assembly or repair, connector wrenches help technicians maintain uniform pressure on connector housings, cable grips, and solderless terminals.

They are also integral in:

Automotive electronics installation and diagnostics

Sensor placement in industrial automation systems

Power connector setup in energy distribution equipment

Secure mounting of thermal systems involving heatsinks or fans

Connector wrenches not only streamline workflows but also improve the longevity and safety of complex systems.

What Types of Connector Wrenches Are Available?

There is a wide range of connector wrenches, each tailored for specific applications or connector types. Selecting the right wrench ensures compatibility and precision.

Common types include:

Fixed-head connector wrenches for specific connector sizes and types

Adjustable connector wrenches for handling multiple dimensions with one tool

Torque-limiting connector wrenches with calibrated mechanisms for consistent tightness

T-handle and L-handle styles that enhance torque application in confined spaces

Ratcheting connector wrenches for high-efficiency repetitive tasks

Insulated connector wrenches designed for working with electrical connectors in live circuits

Selecting the correct type ensures compatibility with connectors in tools, switches, safety modules, microcontrollers, and more.

Where Are Connector Wrenches Most Commonly Applied?

Connector wrenches are ubiquitous in various high-tech and industrial environments. Their ability to handle components without risking deformation makes them especially useful in sensitive electrical and data systems.

Typical applications include:

Networking installations involving coaxial, SMA, or fiber connectors

Aerospace electronic equipment where vibration-resistant assembly is vital

Medical devices requiring delicate yet firm connection fittings

Industrial automation systems incorporating sensors, thermal components, and fuses

Consumer electronics involving microprocessors, LEDs, and compact controllers

Renewable energy systems for secure connection of high-power terminals and capacitors

These tools are ideal for use during both installation and maintenance phases.

What Are the Benefits of Using the Right Connector Wrench?

Using the right connector wrench can enhance performance, increase safety, and reduce rework. As systems become increasingly compact and complex, the precision offered by connector wrenches becomes even more valuable.

Key benefits include:

Enhanced reliability of electrical and mechanical connections

Minimization of torque-related connector damage

Efficient installation and maintenance of components such as switches, thermal pads, and cables

Reduction in installation time and human error

Compliance with technical standards in regulated industries

The result is a cleaner, more stable connection with increased system performance and reduced maintenance costs.

How to Choose the Ideal Connector Wrench?

Choosing the right connector wrench depends on various factors such as the type of connector, environment, access space, and required torque.

Consider the following criteria:

Material durability and resistance to wear

Ergonomic design suited for extended use

Compatibility with specific connector types (e.g., SMA, N-Type, DIN)

Availability of torque control if precision is critical

Magnetic safety when working near microelectronics

Size and weight for ease of transport in fieldwork

Investing in a quality wrench tailored to your workflow can make all the difference in precision and efficiency.

Final Thoughts

Connector wrenches play a vital role in ensuring reliable, secure, and professional-grade connectivity across electronics, automation, communications, and industrial applications. As the demand for high-performance systems increases, the importance of using precise tools like connector wrenches becomes evident. These tools enhance system performance, improve safety, and prolong the lifespan of critical components.

Whether you're an electronics technician working with sensors and microcontrollers or an engineer installing power connectors and thermal solutions, connector wrenches are your trusted companion for clean, secure, and efficient assembly. Explore quality options from trusted brands and elevate your toolkit for modern-day applications.

0 notes

Text

Comprehensive Guide to PCB Board Design & Printed Circuit Assembly for Optimal Electronic Performanc

Compre

Modern electronics rely heavily on printed circuit boards (PCBs). Without well-designed PCBs and quality assembly, devices can become unreliable or fail prematurely. Whether you’re a designer or manufacturer, understanding how to create and assemble high-quality PCBs is crucial. This guide covers essential design principles, manufacturing methods, testing, and tips for better PCB performance.

Understanding PCB Board Design Fundamentals

The Role of PCB Design in Electronics Functionality

PCB design is the blueprint that shapes how your device works. It directly influences electrical signals, heat management, and overall durability. Poor design can lead to issues like signal interference or overheating, hurting the product's performance. Good design results in a more reliable, longer-lasting device that customers can count on.

Essential Components of a PCB Design

A PCB isn’t just a green board with some wires. It includes multiple elements such as:

Layers: These are the different sheets of the PCB, repeating signals or power.

Traces: Thin lines of copper that connect components.

Pads: Contact points for mounting parts like chips or resistors.

Vias: Small holes that link traces on different layers.

Components: Resistors, capacitors, ICs, and other parts attached to the board.

Each piece affects how well the circuit functions. Proper layout and placement ensure electrical signals flow smoothly and the device functions as intended.

Designing for Manufacturing (DFM) Best Practices

Designing with manufacturing in mind helps lower costs and speeds up production. Here are key tips:

Use standard component sizes and footprints.

Keep traces wide enough to handle current.

Avoid tiny vias or complex shapes that are hard to manufacture.

Place components logically to reduce assembly time.

Minimize the number of layers if possible. Fewer layers often mean lower costs.

These practices make it easier for factories to produce your design without errors or delays.

Types of Printed Circuit Boards and Their Applications

Rigid PCBs

Rigid PCBs are the most common type. They’re made of solid material, like fiberglass, that keeps the board stiff. You’ll find these in everything from computers to appliances. They’re reliable, cost-effective, and easy to handle during assembly.

Flexible and Rigid-Flex PCBs

Flexible PCBs bend and fold, fitting into small spaces inside devices. Rigid-flex combines both types, offering stiffness where needed and flexibility elsewhere. These are popular in wearable tech and smartphones, where space is tight.

High-Frequency and HDI PCBs

Special boards designed for fast signals — known as high-frequency PCBs — are used in radio, radar, and satellite systems. HDI (High-Density Interconnect) PCBs pack more components into less space, ideal for miniaturized electronics like medical devices or smartphones.

The Printed Circuit Assembly (PCA) Process

From Design to Production: Step-by-Step Overview

A typical PCA process includes:

Designing the circuit using CAD tools.

Verifying the design for errors.

Creating prototypes for testing.

Moving into full-scale manufacturing.

Assembling components via soldering.

At every step, quality checks are essential to prevent costly mistakes later.

Key Manufacturing Techniques

Surface-Mount Technology (SMT): Attaching components on the surface. It’s fast and suitable for high-volume production.

Through-Hole Assembly: Inserting pins into drilled holes. Best for parts needing full mechanical strength.

Automated Assembly: Robots place components quickly with high precision.

Manual Assembly: Used for small runs or complex parts, but slower.

Choosing the right method impacts the speed and quality of your PCB production.

Quality Control and Inspection

Regular inspections catch problems early:

X-ray Inspection: Checks hidden solder joints.

Automated Optical Inspection (AOI): Finds defects on the surface.

SPI (Solder Paste Inspection): Ensures correct solder paste volume.

Complying with standards like IPC-610 and IPC-2221 helps keep quality high and consistent.

Critical Factors Influencing PCB and PCA Quality

Material Selection for Durability and Performance

Choosing the right materials makes a difference:

Substrates like FR-4 are common but vary in quality.

Copper thickness affects current capacity.

Solder masks prevent shorts and corrosion.

Durable materials stand up to temperature, vibration, and environmental stress.

Design for Reliability

To keep your device working long-term:

Minimize electrical interference by proper grounding.

Manage heat by placing heat-sensitive parts away from heat sources.

Use clear labels and ample space for easy assembly and maintenance.

Good practice prevents failure and reduces warranty repairs.

Environmental Considerations

PCBs face many conditions:

Use conformal coatings to protect from moisture.

Choose vibration-resistant designs for mobile devices.

Select temperature-tolerant materials for harsh environments.

Designing for these factors enhances lifespan and performance.

Cost Optimization

Balancing quality with budget is key:

Use standard components rather than custom parts.

Avoid overly complex designs.

Optimize layout for easy assembly.

Good planning reduces waste and keeps costs in check.

Best Practices for PCB Design and Assembly Optimization

Design Tips for Ease of Assembly

Properly space components for automatic placement.

Use clear silkscreen labels to identify parts.

Keep copper traces away from component pads for easier soldering.

Simplicity saves time during manufacturing and reduces errors.

Enhancing Manufacturing Efficiency

Stick to standard footprints.

Avoid intricate shapes on copper traces.

Use consistent pad sizes and pad-to-component spacing.

This approach speeds up production and keeps quality high.

Post-Assembly Testing and Validation

Once assembled, testing is crucial:

Conduct functional testing to verify operation.

Use burn-in tests to detect early failures.

Carry out long-term stress tests for durability.

Thorough testing ensures your product withstands real-world use.

Collaborating with Proven PCB Manufacturers

Choose manufacturers with:

Certifications like IPC-6012 or ISO 9001.

Experience in your specific PCB type.

Good communication and ability to meet deadlines.

Partnering with reliable suppliers reduces risks and improves final product quality.

Case Studies and Real-World Examples

Some companies have achieved great results by focusing on PCB design. For example, an electronics firm reduced their device failure rate by improving trace routing and component placement. Conversely, poor design choices, such as crowded traces, led to short circuits and costly recalls. Learning from these stories highlights the importance of meticulous planning and quality control.

Conclusion

Creating a high-performance PCB, from design to assembly, is essential for reliable electronics. Focus on good design practices, choose the right materials, and work with experienced manufacturers. Regular testing and inspection help catch issues before products hit the market. As technology advances, keep an eye on trends like miniaturization and high-frequency PCBs. Staying current ensures your designs remain competitive and durable. Quality now means better devices, happier users, and fewer headaches later.

0 notes

Text

Precision and Automation Redefined: Robotic Soldering Station in India – Powered by Ascomp Inc

As the demand for high-speed, precision-based electronics manufacturing continues to grow, manual soldering is no longer sufficient for maintaining consistency, safety, and throughput. Enter the robotic soldering station in India, a powerful innovation that brings automation to one of the most critical steps in PCB assembly. At Ascomp Inc, we supply cutting-edge robotic soldering solutions built for modern Indian factories—designed to enhance productivity, reduce human error, and ensure flawless results.

What is a Robotic Soldering Station?

A robotic soldering station is an automated machine equipped with programmable arms, temperature-controlled soldering tips, and precise motion control systems. It is used to automate repetitive soldering tasks on circuit boards, connectors, and terminal blocks.

Unlike traditional hand soldering, robotic soldering offers:

Consistent solder joints

Reduced operator fatigue

Greater speed and throughput

Lower rework and rejection rates

Better control over temperature and solder feed

Whether you're running a high-volume SMT line or a mid-scale EMS setup, a robotic soldering station in India delivers unmatched accuracy and repeatability.

Key Features of Ascomp Inc’s Robotic Soldering Systems

🤖 Multi-axis robotic arm for precise solder point control

🔥 Temperature-controlled iron tip with programmable profiles

🎯 Vision system and sensors for auto-alignment and inspection

💡 Custom jig fixtures to suit different PCB layouts

🛠️ Automated solder feeding system for consistent wire delivery

⚙️ User-friendly programming interface for custom routines

We also offer fume extraction integration and ESD-safe construction to meet electronics industry safety standards.

Ideal Applications

Our robotic soldering stations are suited for:

SMT and through-hole component soldering

Wire-to-board connections

Connector pin soldering

LED assemblies

Fine-pitch PCB assemblies

Automotive and EV electronics

Telecom and defense equipment manufacturing

Whether you're automating a high-speed production line or improving quality in low-volume, high-precision builds, Ascomp Inc has a model that fits your needs.

Why Invest in Robotic Soldering?

✅ Higher throughput with minimal manual intervention

✅ Lower training and labor costs

✅ Repeatable quality across thousands of units

✅ Fewer operator-related defects

✅ Improved traceability and data logging

It’s not just a tool—it’s a productivity multiplier for forward-thinking electronics manufacturers.

Why Choose Ascomp Inc?

📦 Ready stock of robotic soldering machines in India

🔧 Pre-sales guidance and post-installation support

💼 Integration with existing conveyor or workbench setups

🖥️ Training and programming assistance

🔄 Availability of spare parts and maintenance contracts

🛠️ Proven track record with EMS companies and R&D units

Our solutions are scalable, reliable, and fully customizable based on your board layout and workflow.

#RoboticSolderingIndia#AscompInc#PCBAssemblyTools#ElectronicsAutomationIndia#SMTProductionIndia#AutomatedSolderingStation#IndustrialSolderingRobot#SolderingAutomation#ESDCompliantSoldering#PrecisionElectronicsIndia

0 notes

Text

Electronics Go Dense, EMI Filters Grow Strong: Global Market Forecast to 2031

The global EMI filters market was valued at USD 274.5 Mn in 2022 and is projected to expand at a CAGR of 4.1% from 2023 to 2031, reaching USD 392.1 Mn by 2031. As industries worldwide move toward high-frequency operations and increasingly dense electronics ecosystems, electromagnetic interference (EMI) filters have become essential in ensuring signal integrity and operational stability across critical applications.

Market Overview: EMI filters play a vital role in safeguarding electronic devices and systems from the detrimental effects of electromagnetic interference. These filters block unwanted high-frequency signals while allowing desired currents to pass, thereby maintaining the reliability of mission-critical electronic equipment across industries such as telecommunications, automotive, aerospace, and consumer electronics.

As digital transformation accelerates across sectors, the complexity of electronic systems and their exposure to interference sources have surged, further boosting demand for sophisticated EMI filtering technologies.

Market Drivers & Trends

1. Surge in Electronic Device Usage: With growing adoption of smartphones, laptops, IoT devices, and wireless communication systems, the likelihood of EMI-related disruptions has increased. EMI filters ensure smooth functionality and extend the lifespan of sensitive electronic components.

2. Expansion of Telecommunication Networks: The rollout of 5G infrastructure, along with increasing data traffic and device density, has heightened the need for robust EMI solutions. Telecommunication operators are now heavily investing in high-performance EMI filters to maintain signal clarity and reduce latency.

3. Technological Advancements in Filter Design: The incorporation of AI in filter design enables the creation of optimized, application-specific EMI filters. These intelligent systems can model complex interactions and tailor filter responses accordingly, improving performance and reducing design time.

Latest Market Trends

Miniaturization and Integration: With device footprints shrinking, manufacturers are designing compact EMI filters that can be seamlessly integrated into PCBs and electronic systems.

RoHS-Compliant and Sustainable Filters: In response to global sustainability mandates, eco-friendly and RoHS-compliant EMI filters are gaining traction.

Application-Specific Customization: The market is seeing a shift toward customized EMI filter solutions to meet diverse needs across verticals such as electric vehicles (EVs), data centers, and smart homes.

Key Players and Industry Leaders

The EMI filters market features a moderately fragmented competitive landscape, with several key players vying for technological leadership. Prominent companies include:

Astrodyne TDI Corporation

Captor Corporation

CTS Corporation

EMI Solutions, Inc.

Exxelia Group

KEMET Corporation

Knowles Precision Devices, Inc.

KYOCERA AVX Components Corporation

Microwave Filter Company Inc.

Murata Manufacturing Co., Ltd

Oxley Group

Schaffner Holding AG

Spectrum Control Inc.

TDK Corporation

TE Connectivity Ltd.

Other Key Players

These companies focus on expanding product portfolios, developing application-specific solutions, and forming strategic alliances to consolidate their market positions.

Download now to explore primary insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85982

Recent Developments

January 2024 – TDK Corporation launched the B84742AR725 series*, single-phase EMC/EMI filters for AC and DC applications, optimized for compactness and performance.

December 2022 – Astrodyne TDI introduced RP695H DC EMI filters to support high-performance EV fast-charging stations, aligning with the global shift toward sustainable transport.

June 2022 – Schaffner released the FN2500 / FN2640 EMC filter series, specifically designed for robotics and data center rack applications.

Market Opportunities

Rise in EV Penetration: As electric vehicles become mainstream, there is increasing demand for EMI filters that can operate in high-voltage environments and reduce noise in sensitive EV electronics.

Growth of Smart Cities and IoT: The proliferation of connected devices, sensors, and automation systems is creating new avenues for EMI filter deployment.

Defense and Aerospace Demand: Advanced electronic warfare systems, avionics, and radar technologies require highly reliable EMI shielding, creating robust demand in the defense sector.

Future Outlook

The EMI filters market is poised for steady and sustainable growth over the coming years. Emerging technologies such as 6G, AI-integrated systems, and high-speed edge computing will create intricate electronic environments that necessitate more advanced and adaptable EMI solutions. Manufacturers will continue investing in miniaturization, energy efficiency, and design automation to stay competitive.

Asia Pacific is expected to remain the market leader due to its thriving electronics manufacturing base and the ongoing deployment of next-gen telecom networks. Meanwhile, North America and Europe will benefit from rapid adoption of EVs, smart grids, and aerospace innovations.

Buy this Premium Research Report and gain expert perspectives and analysis -

Market Segmentation

By Type:

Band Pass Filters

High Pass Filters

Notch Filters

Low Pass Filters (leading segment)

By Filter Type:

LC

CL

T

Pi Filters (dominant due to impedance matching capabilities)

Others

By End-use Industry:

Consumer Electronics

Industrial

IT and Telecommunication

Aerospace and Defense

Automotive

Healthcare

Others

Regional Insights

Asia Pacific held a dominant market share of 38.8% in 2022, attributed to:

Booming electronics manufacturing in China, Japan, South Korea, and India

Growing investment in smart infrastructure, telecom networks, and defense

Rapid deployment of 5G and IoT devices

North America is also expected to witness significant growth, supported by:

Advanced aerospace and automotive sectors

Innovation in telecommunications and EV infrastructure

Europe continues to prioritize EMI compliance in industrial automation, while emerging economies in South America and the Middle East are gradually integrating EMI solutions as part of their digital transformation strategies.

Why Buy This Report?

Detailed market forecast and analysis through 2031

In-depth segmentation and cross-comparison across regions and industries

Profiles of key companies with strategic insights

Emerging opportunities and investment landscapes

Access to historical data and projections in PDF and Excel formats

Includes Porter’s Five Forces, Value Chain Analysis, and Key Trend Mapping

Frequently Asked Questions (FAQs)

Q1. What is the projected value of the EMI filters market by 2031? A: The EMI filters market is expected to reach US$ 392.1 Mn by 2031.

Q2. What is driving the EMI filters market growth? A: Growth is fueled by the expansion of 5G networks, increased usage of electronic devices, and rising adoption of electric vehicles.

Q3. Which region holds the largest market share? A: Asia Pacific, with 38.8% share in 2022, dominates the global market.

Q4. Which segment leads by filter type? A: The Pi filter segment leads due to its flexibility in impedance matching and high-frequency EMI suppression.

Q5. Who are the key players in this market? A: Leading players include TDK Corporation, Schaffner Holding AG, Astrodyne TDI Corporation, KYOCERA AVX, and Murata Manufacturing Co., Ltd.

Q6. Which end-use industry is seeing the highest EMI filter adoption? A: IT and Telecommunication, followed closely by Automotive and Consumer Electronics.

Explore Latest Research Reports by Transparency Market Research: High-Integrity Pressure Protection System (HIPPS) Market: https://www.transparencymarketresearch.com/high-integrity-pressure-protection-system-market.html

Piezoelectric Devices Market: https://www.transparencymarketresearch.com/piezoelectric-device-market.html

Energy Harvesting for Small Sensors Market: https://www.transparencymarketresearch.com/energy-harvesting-for-small-sensors-market.html

Gas Sensors Market: https://www.transparencymarketresearch.com/gas-sensors-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes