#SCADA Panel Board

Explore tagged Tumblr posts

Text

Digital VGA STN PCB Card | High-Performance Industrial Automation Module | Ram Automations

Level up your industrial and marine automation systems with the Digital VGA STN PCB Card, now available at Ram Automations. Designed for high-precision signal processing and industrial-grade visual outputs, this PCB card ensures seamless communication between your control hardware and visualization systems.

Built to support mission-critical automation environments, the Digital VGA STN PCB Card is ideal for upgrading your system’s display interfaces, ensuring clear communication, real-time monitoring, and system stability across industrial setups.

🛒 Buy Now: 👉 https://ramautomations.com/products/digital-vga-stn-pcb-card

🌐 Explore More Premium Industrial Products: 👉 https://ramautomations.com

🔧 Product Overview:

• 📦 Product Name: Digital VGA STN PCB Card • 🏢 Brand: Digital (Digital Equipment Corporation) • 🧩 Type: Printed Circuit Board (PCB) — VGA Signal and Display Interface Module • 📌 Condition: Fully Tested • 🛠 Applications: Factory floor systems, marine automation displays, process control panels, SCADA visualization, machine interfaces

✅ Key Features:

✔️ Genuine Digital Equipment Corporation board ✔️ High-quality VGA signal output for industrial monitors ✔️ Seamless integration into control and automation systems ✔️ Strong signal stability and display clarity ✔️ Reliable design for demanding industrial environments ✔️ Fully verified for performance and longevity

🏭 Ideal Applications:

✔️ Industrial visualization systems ✔️ Automation cabinets and control panels ✔️ Marine navigation displays ✔️ SCADA workstations ✔️ OEM equipment visualization ✔️ Factory production monitoring systems

Whether you’re upgrading your automation displays or maintaining OEM equipment, the Digital VGA STN PCB Card offers the best combination of durability, quality, and precision output.

🛠 Why Choose Ram Automations?

At Ram Automations, we stock tested, genuine, and hard-to-find industrial parts from over 1000 global brands, ready to ship worldwide.

✔️ 1000+ Global Brands in Inventory ✔️ Fully Tested, Reliable Automation Components ✔️ Fast Worldwide Delivery ✔️ Bulk and OEM Support Available ✔️ Expert Technical Assistance

📽️ In This Video You Will Learn:

🔎 Full Visual Overview of Digital VGA STN PCB Card ⚙️ How to integrate it into industrial visualization systems 📈 Applications in SCADA and process control ⚡ Why visualization modules are crucial for system monitoring 🌍 Benefits of trusted brands like Digital Equipment Corporation in industrial automation

📣 Subscribe and Stay Updated:

🔔 Subscribe to Ram Automations YouTube Channel for weekly videos featuring industrial spare parts, system integration tips, and rare automation components. 💬 Drop your questions in the comments — we respond fast! 👍 Like this video if you found it helpful

#Digital VGA STN PCB Card#VGA PCB Board#Industrial Display Module#Automation Visualization Card#SCADA Display Card#Industrial PCB for Displays#Ram Automations#Digital Equipment Corporation Board#Automation Visual Module#VGA Industrial Control Board#Marine Display Board#SCADA Panel Board#Factory Automation Display#VGA Signal Module#Automation Display Module#OEM Display Parts#Industrial Automation Board#Industrial Signal Processing#Industrial Electronics Board

1 note

·

View note

Text

Enhancing Industrial Automation with Intelligent HMI and Advanced LCD Display

In today’s smart manufacturing era, HMI (Human-Machine Interface) systems and industrial LCD display modules play a crucial role in enhancing automation and operational efficiency. The seamless integration of these components empowers real-time interaction and visual monitoring across complex industrial environments.

At the core of HMI systems lies the LCD Module Display—a vital component that ensures stable performance, even in challenging conditions. Whether it's a TFT LCD display, touch screen, or OLED panel, these display technologies provide clear, high-resolution interfaces for operators to control and monitor machinery.

Modern touch LCD screen technology has greatly improved HMI usability. The incorporation of lcd touch and touch display capabilities enables intuitive interaction, reducing human error and increasing responsiveness. With lcd driver boards supporting intelligent communication, the system can effortlessly connect with PLCs, SCADA, and other devices using protocols like Modbus and Ethernet.

Industrial applications require rugged solutions. TFT LCD screen and tft lcd module options are built for wide-temperature ranges, high brightness, and anti-interference performance—making them ideal for outdoor, factory-floor, and heavy-duty environments. Even lcd module old designs are being upgraded with lcd tft and lcd display modules to meet modern standards.

Among various manufacturers, Innolux display modules are recognized for their superior quality and reliability. These display modules are often deployed in HMI systems that demand long-term operation with minimal maintenance.

As AI and IoT technologies advance, the role of display lcd components becomes even more important. Next-generation panel lcd solutions will not only show data but also analyze trends, support predictive maintenance, and communicate alerts to reduce downtime.

From inch lcd screen variants tailored for compact control panels to large lcd panel systems for industrial dashboards, choosing the right display module can dramatically impact system performance and cost-efficiency.

In conclusion, the combination of smart HMI systems and high-performance lcd display screen technologies forms the foundation of modern industrial automation. Selecting premium LCD Module Display solutions with enhanced touch screen interfaces ensures increased productivity, streamlined control, and future-ready infrastructure.

Shenzhen Zhiyan Optronics Co., Ltd. (zylcdshop.com) is a trusted supplier of industrial and commercial display solutions. We specialize in high-performance LCD panels, touchscreen displays, and screen modules—delivered with expert support and competitive pricing.

#car touch screen control panel#touch panel pc#siemens touch panel#multi touch panel#lcd touch panel

0 notes

Text

GBM Industries – Haryana’s Leading Manufacturer of Powder Coating Plants

Founded in 1984 in Bahadurgarh, Haryana, GBM Industries has emerged as a frontrunner in the design and manufacturing of industrial ovens and surface finishing equipment. As an ISO 9001:2015 certified company, GBM stands for quality, innovation, and commitment to customer satisfaction.

With a strong presence in both Indian and international markets, GBM Industries specializes in custom-built powder coating plant solutions that meet the high demands of automotive, appliance, architectural, and general engineering industries. Built with advanced engineering, GBM’s powder coating systems are designed to deliver durability, cost-efficiency, and environmental friendliness—making them the go-to choice for high-performance applications in 2025 and beyond.

What is a Powder Coating Plant?

A powder coating plant is a complete system engineered to apply dry powder onto metal or conductive surfaces using electrostatic spray guns. The coated surface is then cured in an oven, producing a hard, smooth, and durable finish. Compared to traditional wet painting methods, powder coating is more efficient, environmentally safe, and long-lasting.

Why GBM Industries Leads the Powder Coating Industry

1. Trusted Legacy and Industry Experience

With nearly two decades of excellence, GBM Industries brings unmatched expertise to surface finishing systems. Their in-depth knowledge of industrial ovens and coating processes ensures every project is executed with precision, efficiency, and quality control.

2. Custom-Tailored Solutions

No two businesses are alike. GBM understands that each industry has unique coating needs, which is why they offer custom powder coating plant designs to fit space, production capacity, and technical specifications—whether it’s a batch-type plant for small-scale production or a fully automated conveyor-based system for continuous operations.

3. ISO-Certified Manufacturing Excellence

As an ISO 9001:2015 certified company, GBM adheres to strict quality management systems. Each plant is thoroughly tested to ensure flawless performance, safety, and long service life, even under demanding industrial environments.

Key Features of GBM Powder Coating Plants

GBM Industries integrates the latest advancements in automation and energy efficiency, offering features such as:

Electrostatic Spray Guns (manual or automatic)

High-Efficiency Curing Ovens (electric, diesel, or gas fired)

Powder Recovery Booths for reduced wastage

Modular Pretreatment Systems with multi-tank setup

Overhead or Floor-Mounted Conveyor Systems

Advanced Control Panels with PLC/SCADA options

Environment-Friendly Operation with zero-VOC emissions

These systems are engineered to offer high throughput, minimal maintenance, and consistent coating qualit

Specification of GBM Powder Coating Plants

Coating Booth: MS/SS construction with cyclone-type recovery system

Spray Gun Type: Electrostatic (Manual / Automatic)

Curing Oven: Electric, Diesel, or Gas-fired – temperature up to 250°C+

Conveyor Type: I-Beam, Power & Free, Overhead, or Floor Conveyor

Pretreatment Line: 5 to 9 tank process with optional hot phosphating

Control System: Smart automation with PLC / SCADA-based control

Coating Thickness: 60–120 microns (standard)

Industries Served by GBM’s Powder Coating Plants

GBM’s powder coating plants are widely used across various sectors, including:

Automotive & Auto Parts – Wheels, bumpers, chassis, accessories

Home Appliances – Refrigerators, air conditioners, kitchen equipment

Architectural & Building Materials – Doors, windows, grills, railings

Electrical & Electronics – Distribution boards, control panels, enclosures

General Engineering & Hardware – Tools, storage units, office furniture

Each solution is designed for uniform finish, corrosion resistance, and long-term durability.

Environmental and Economic Benefits

Powder coating is the future of sustainable surface finishing. GBM’s systems are designed to:

Eliminate VOC emissions

Recycle unused powder through recovery booths

Reduce energy consumption through insulated ovens

Lower operational costs with minimal maintenance

In a world where sustainability and cost-efficiency are key, GBM's powder coating plants tick all the boxes.

Unmatched After-Sales Support

What truly makes GBM Industries the preferred partner is their comprehensive customer support:

On-site installation and commissioning

Technical training for operators

Scheduled maintenance and service

Spare parts supply and upgrades

This dedication ensures smooth operations and long-term ROI for clients.

Conclusion:

In the fast-paced world of industrial manufacturing, choosing the right partner for your surface finishing needs is critical. GBM Industries, with its proven track record, ISO-certified quality, and tailor-made powder coating plant solutions, is not just a manufacturer—it’s a strategic growth partner for your business.

Contact GBM Industries

Location: Bahadurgarh, Haryana, India Website: https://gbmindustries.com/Email: [email protected] Call: +91 9996055996

0 notes

Text

Top Bogie Hearth Furnace Manufacturers: Driving Industrial Heat Treatment Excellence

As industries evolve to meet growing demands for precision, durability, and energy efficiency, heat treatment processes have become more advanced than ever. At the center of these processes lies the bogie hearth furnace—a specialized thermal solution ideal for treating large and heavy metal components. Behind these reliable systems are bogie hearth furnace manufacturers, engineering firms that design, fabricate, and deliver custom heat treatment solutions built to last.

In this article, we dive into what makes a leading bogie hearth furnace manufacturer, the key features of these furnaces, and why selecting the right manufacturer can significantly impact your operations.

What is a Bogie Hearth Furnace?

A bogie hearth furnace is a type of batch furnace where the base (or bogie) is mounted on wheels and can be moved in and out of the heating chamber. This design simplifies the handling of large or awkwardly shaped components, allowing for quick loading and unloading.

The furnace is commonly used for:

Annealing

Stress relieving

Normalizing

Hardening

Tempering

Thanks to its versatility and capacity, it’s widely adopted across sectors like steel fabrication, aerospace, automotive, heavy engineering, and forging industries.

Why Choose Expert Bogie Hearth Furnace Manufacturers?

Not all furnaces are created equal. Leading bogie hearth furnace manufacturers combine advanced engineering with deep industry knowledge to offer furnaces that perform reliably over time and across demanding applications.

Here’s what to expect from top manufacturers:

1. Custom Engineering Based on Your Needs

Each industrial process is unique. Whether you’re dealing with castings, forgings, or welded structures, expert manufacturers offer:

Custom load capacities (up to 200 MT and beyond)

Heating options (electric, gas, or oil-fired)

Temperature ranges up to 1300°C

Adjustable heating zones and insulation materials

Customization ensures that your furnace delivers the most efficient results with the lowest energy expenditure.

2. High-Efficiency Insulation and Sealing

Energy efficiency is critical in heat treatment. Trusted manufacturers provide:

High-density ceramic fiber linings

Vacuum-formed ceramic boards or brick linings

Pneumatic soft-seal clamps to prevent cold air ingress These design features help reduce heat loss, improve uniformity, and extend the lifespan of the furnace.

3. Smart Controls & Automation

The best furnace manufacturers equip their systems with:

PLC-based control panels

SCADA integration

HMI touch interfaces

Thyristor-based heating control

These tools ensure precision, real-time monitoring, and process repeatability—ideal for industries with zero-tolerance for deviation.

4. Robust Mechanical Construction

A bogie hearth furnace often handles high loads and is exposed to extreme conditions. That’s why reliable manufacturers use:

Heavy-duty fabricated steel structures

Stainless steel baffles for uniform heat distribution

Roller rails and smooth-drive mechanisms for bogie movement

Durability isn’t optional—it’s the foundation of furnace performance.

5. Full Lifecycle Support

Beyond building the furnace, top manufacturers provide:

On-site commissioning and testing

Operator training

Preventive maintenance services

Rapid spare parts availability

This ensures your operation stays efficient and downtime is minimized.

JR FURNACE: India’s Trusted Bogie Hearth Furnace Manufacturer

With over 35+ years of thermal engineering expertise, JR FURNACE stands out among bogie hearth furnace manufacturers for its commitment to quality, innovation, and customer satisfaction.

Why industries choose JR FURNACE:

Bogie hearth furnaces with capacities up to 200 MT

Electric, oil-fired, and gas-fired options

Custom automation using PLC, SCADA, and HMI

Certified thermal uniformity (Class 2/Class 3)

Integrated forced cooling and atmosphere control (optional)

Sealed doors and bogie design for energy savings

We serve a wide array of industries, from defense to heavy fabrication, offering not just equipment but total heat treatment solutions.

Conclusion

The importance of partnering with the right bogie hearth furnace manufacturer cannot be overstated. Your choice directly impacts energy efficiency, product quality, maintenance costs, and long-term production success.

If you're looking for a solution that combines rugged performance with intelligent design and automation, trust JR FURNACE—where every system is crafted with precision, backed by service, and built to endure the demands of modern industry.

0 notes

Text

How to Select the Right PCC Panel for Your Industry

In today’s fast-paced industrial world, efficient power distribution is essential for operational reliability, safety, and scalability. One of the most critical components in any industrial electrical setup is the Power Control Center (PCC) Panel. These panels serve as the nerve center of power management systems, controlling and distributing electricity across various parts of the facility.

Choosing the right PCC panel can significantly impact your plant’s safety, productivity, and energy efficiency. Whether you are expanding an existing system or installing a new one, this guide will help you select the right PCC panel for your industrial needs. If you are looking for a trusted PCC Panel Manufacturer in Vadodara, Gujarat, or anywhere across India, this blog will also point you in the right direction.

What is a PCC Panel?

A Power Control Center (PCC) panel is a type of electrical distribution board that controls and distributes electrical power efficiently to various mechanical and electrical systems. It is usually installed in industries with high electricity loads, such as manufacturing plants, chemical processing units, food processing factories, and data centers.

The main purpose of a PCC panel is to:

Control power distribution

Protect electrical equipment from overload or short circuit

Monitor power consumption

Improve energy efficiency and safety

Key Factors to Consider When Selecting a PCC Panel

1. Understand Your Power Requirements

Before choosing a PCC panel, it is important to assess your facility's power load. Determine:

Total connected load

Peak load requirement

Future expansion plans

The PCC panel should be capable of handling the current load and accommodate future growth.

If you are not sure how to calculate this, a professional PCC Panel Supplier in Vadodara or Gujarat can assist you with a detailed load analysis and panel recommendation.

2. Compliance with Industry Standards

The PCC panel must comply with national and international safety standards such as:

IEC 61439

IS 8623

IP rating for dust and water protection

Working with a reputed PCC Panel Manufacturer in Gujarat or PCC Panel Supplier in India ensures your panels are manufactured with the highest quality standards and tested for performance, safety, and durability.

3. Choose Between Manual and Automatic Operation

PCC panels come in manual, semi-automatic, and fully automatic variants. Depending on your plant’s operational requirements, you can choose the level of automation:

Manual panels are cost-effective and suitable for basic industrial setups.

Automatic panels offer remote control, real-time monitoring, and system diagnostics.

For large-scale or smart industrial facilities, opting for a panel from a PCC Panel Distributor in Gujarat offering automated control panels can increase operational efficiency.

4. Panel Design and Layout

A well-designed PCC panel should have:

Adequate ventilation

Segregated sections for control and power wiring

Easy accessibility for maintenance

Safety interlocks and protection relays

Always go for a PCC Panel Manufacturer in India that offers custom-designed panels tailored to your plant layout and operational flow.

5. Reliability and After-Sales Support

Choose a manufacturer or supplier that has a proven track record in delivering high-performance PCC panels. More importantly, ensure they offer:

Warranty and certification

On-site installation support

Regular maintenance services

Readily available spare parts

Trusted PCC Panel Suppliers in Vadodara often provide robust after-sales service and technical support to ensure minimal downtime for your plant.

6. Energy Monitoring and Smart Features

In the age of Industry 4.0, many facilities are switching to smart PCC panels that come integrated with:

Digital meters

SCADA systems

IoT connectivity

Data logging capabilities

These features allow real-time monitoring of energy usage and help in predictive maintenance. If you are investing for the long term, choose a PCC Panel Distributor in India offering advanced features that align with your energy management goals.

Why Location of the Manufacturer or Supplier Matters

While quality and features are paramount, working with a local manufacturer or distributor offers several advantages:

PCC Panel Manufacturer Vadodara

Vadodara, being a hub of engineering industries, houses several reputed PCC Panel Manufacturers in Vadodara who offer high-quality panels at competitive prices. Choosing a local manufacturer helps in:

Faster delivery

Easier site visits

Quicker support and maintenance

PCC Panel Supplier Gujarat

For companies operating across the state, a PCC Panel Supplier in Gujarat can provide region-wide support and faster installation. Gujarat has an excellent network of electrical component suppliers and skilled labor, making it ideal for industrial procurement.

PCC Panel Distributor India

When your operations are spread across the country, selecting a trusted PCC Panel Distributor in India with a national distribution network ensures consistent quality and service across all units.

Industries That Benefit from PCC Panels

Here are some industries where PCC panels play a critical role:

Manufacturing Plants: For controlling motors, conveyors, and machinery

Chemical & Pharma Units: For safe handling of high-power equipment

Textile Industry: For ensuring smooth operation of looms and dyeing machines

Food Processing Units: For hygiene-compliant energy systems

Steel & Metal Industries: For managing heavy-load machinery and furnaces

If your business falls under any of these categories, consulting with a PCC Panel Supplier in Gujarat or PCC Panel Manufacturer in India can help you find the perfect solution.

Benefits of Choosing the Right PCC Panel

Investing in the right PCC panel yields long-term benefits:

Increased Energy Efficiency: Reduced energy losses and operational costs

Improved Safety: Protection from electrical faults and hazards

Scalability: Easy expansion as business grows

Lower Downtime: Enhanced system reliability and minimal interruptions

Compliance: Meets legal and industry safety norms

Conclusion: Make an Informed Decision

Selecting the right PCC panel is not just a technical decision; it is a strategic investment in your business infrastructure. Always consider the load capacity, safety features, customization, smart capabilities, and local support when choosing your panel.

Partnering with a reputed PCC Panel Manufacturer in Vadodara, PCC Panel Supplier in Gujarat, or PCC Panel Distributor in India ensures that you receive top-quality products backed by excellent service and technical expertise.

Whether you are setting up a new industrial unit or upgrading an old one, make sure to consult with experienced suppliers and manufacturers who understand the nuances of your industry. A reliable PCC panel will not only enhance operational efficiency but also provide the safety and scalability your business needs for future growth.

Looking for a dependable PCC panel manufacturer or supplier? Choose one that offers proven expertise, certified products, and industry-specific solutions to keep your operations running smoothly and safely.

0 notes

Text

ARM Embedded Remote Controller for Weather Monitoring System

System Overview

A weather monitoring system requires real-time collection of various environmental parameters (e.g., temperature, humidity, wind speed, air pressure, rainfall) and efficient data processing and communication for remote monitoring and analysis. The ARMxy Embedded Remote Controller BL335ARMxy SBC realizes real-time data collection, remote monitoring and intelligent analysis of meteorological monitoring, and is widely used in automatic weather stations, agricultural monitoring, environmental monitoring, etc. with its industrial-grade design, rich interface configuration, and robust protocol support, serves as an ideal core device for building such systems.

Hardware Configuration Plan

Core Hardware Selection

Host Model: BL335B (supports 2 Y-series I/O boards for multi-sensor connectivity).

SOM Module: SOM335 (8GB eMMC + 1GB DDR3, ensuring large-capacity data buffering and processing).

Wireless Communication: Added 4G module (model BL335L) for reliable data transmission in remote areas.

Sensor and I/O Board Integration

Y-series I/O Boards:

Y31: 4-channel single-ended 0/4~20mA analog input for current-type temperature/humidity sensors.

Y33: 4-channel 0~10V analog input for voltage-type pressure sensors.

Y95: 4-channel PWM output + pulse counting for anemometer signal acquisition.

Y63: 4-channel RS485 for Modbus-compatible digital sensors (e.g., rain gauge).

Expandability: Use X-series I/O boards (e.g., X1) to expand RS485 interfaces for additional industrial protocol devices.

Environmental Adaptability

Mounting: DIN35 rail installation for outdoor cabinets or industrial control boxes.

Protection: IP30 dustproof design with custom waterproof housing for harsh weather.

Wide Temperature Range: Operates at -40°C to 85°C for stability in extreme environments.

Software Architecture and Functionality

OS and Development Tools

OS: Ubuntu 20.04, offering open-source toolchains and containerization support.

Development Frameworks:

Node-RED: Graphical programming for data flow logic (e.g., sensor data cleaning, threshold alerts).

Docker: Containerized deployment of MQTT/OPC UA data forwarding services for seamless cloud integration.

Protocol and Data Management

BLIoTLink Protocol Conversion:

Converts Modbus RTU (RS485 sensors) to MQTT for cloud platforms (e.g., Alibaba Cloud IoT).

Supports IEC104 protocol for integration with SCADA systems in meteorological stations.

Edge Computing and Storage:

SQLite for historical data storage; Python scripts for anomaly filtering.

Real-time edge calculations (e.g., average wind speed, temperature/humidity trends) to reduce cloud load.

Remote Maintenance and Monitoring

BLRAT Tool: Remote access for firmware updates or sensor configuration.

Watchdog: Auto-restart for failed services, ensuring 24/7 operation.

Typical Applications

Solar Farm Weather Stations: Monitor irradiance and wind speed to optimize PV panel angles.

Agricultural Networks: Collect soil moisture/temperature for smart irrigation systems.

Transportation Alerts: Upload real-time road icing data for intelligent traffic management.

Key Advantages

High Reliability: Passes GB/T EMC and IP30 tests for harsh industrial environments.

Flexible Expansion: 4000+ module combinations, compatible with diverse sensors and protocols.

Low-Cost Operation: BLRAT reduces on-site maintenance; edge computing minimizes bandwidth usage.

Implementation Recommendations

Sensor Calibration: Use Y-series AO outputs for periodic analog signal calibration.

Power Redundancy: 9-36V wide input voltage; deploy solar + lithium battery solutions.

Data Security: Enable Linux kernel encryption for secure data transmission.

The ARMxy BL335, with its high customization and industrial-grade performance, provides an end-to-end solution for weather monitoring systems—from data acquisition to cloud integration—empowering smart city and green energy initiatives.

0 notes

Text

NSIC Limited, New Delhi, provides job-focused training; eligibility varies, contact details available.

New Post has been published on https://www.jobsarkari.in/nsic-limited-new-delhi-provides-job-focused-training-eligibility-varies-contact-details-available/

NSIC Limited, New Delhi, provides job-focused training; eligibility varies, contact details available.

The National Small Industries Corporation Limited offers job-oriented training programs in industrial automation and more. The training programs include Industrial Automation, Advance Industrial Automation with Mechatronics, loT-Internet of Things, Advance Embedded System with PCB & Circuit Designing, Embedded System using Development Boards, Electrical AutoCAD (2D & 3D), Electric Vehicle (EV) and Charging Stations, PCB and Circuit Designing, Solar Energy with PVSOL Software & Business Model, EDP on Solar Energy (Business Model), LED Light Repair & Manufacturing, CCTV Installation & Security Systems with PTZ Cameras, Advance Diploma in Electrician, Basic Electrician & Industrial Circuit, Industrial Circuits & Power House Maintenance, Home Appliance Repair & Maintenance, Industrial Electrical LT-Panels & Three Phase Wiring System, Air Conditioner (AC) PCB Repair, Industry 4.0 Using PLC Gateways, and Summer/Industrial Project Training. The eligibility for these programs is 8th/10th/12th/Graduate/Diploma/B.Tech. The training center is located in Okhla Industrial Estate, New Delhi and contact information can be found at the end of the document.

National Small Industries Corporation Limited offers job-oriented training programs.

The training programs cover various topics such as industrial automation, IoT, embedded systems, electrical AutoCAD, electric vehicle technology, solar energy, LED light repair, CCTV installation, and more.

The duration and fees for each training program vary.

Eligibility for the training programs includes 8th/10th/12th pass, graduate, diploma, or B.Tech.

NSIC Technical Services Centre is located in Okhla Industrial Estate, New Delhi.

National Small Industries Corporation Limited offers job-oriented training programs

Training programs provided by National Small Industries Corporation Limited

Programs focus on job-oriented skills

Opportunity to gain practical knowledge and enhance employability

Industrial Automation Training Programme

Duration: 2 months

Fee: Rs. 12,000

Topics covered: PLC, SCADA, HMI, VFD, DCS-Siemens

Advance Industrial Automation with Mechatronics Training Programme

Duration: 6 months

Fee: Rs. 30,000

Combination of industrial automation and mechatronics

Enhance skills in advanced automation technologies

IoT – Internet of Things Training Programme

Duration: 2 months

Fee: Rs. 12,000

Focus on Arduino and Communication technologies

Explore the potential of IoT in various industries

Advance Embedded System with PCB & Circuit Designing Training Programme

Duration: 3 months

Fee: Rs. 15,000

Learn advanced embedded system concepts

Gain skills in PCB and circuit designing

Electrical AutoCAD Training Programme (2D & 3D)

Duration: 1 month

Fee: Rs. 18,000

Develop proficiency in electrical AutoCAD software

Learn both 2D and 3D design techniques

Electric Vehicle (EV) and Charging Stations Training Programme

Duration: 2 days

Fee: Rs. 5,000

Focus on electric vehicle technology and charging infrastructure

Explore the future of sustainable transportation

Solar Energy with PVSOL Software & Business Model Training Programme

Duration: 2 months

Fee: Rs. 10,000

Learn about solar energy systems and PVSOL software

Understand the business aspects of solar energy

LED Light Repair & Manufacturing Training Programme

Duration: 1 month

Fee: Rs. 5,000

Develop skills in repairing and manufacturing LED lights

Explore the growing LED industry

CCTV Installation & Security Systems with PTZ Cameras Training Programme

Duration: 2 months

Fee: Rs. 10,000

Learn about CCTV installation and security systems

Gain expertise in PTZ cameras

Advance Diploma in Electrician Training Programme

Duration: 12 months

Fee: Rs. 28,000

Comprehensive training in electrician skills

Advanced diploma for professional growth

Basic Electrician & Industrial Circuit Training Programme

Duration: 6 months

Fee: Rs. 18,000

Fundamental training in electrician skills

Focus on industrial circuit maintenance

Industrial Circuits & Power House Maintenance Training Programme

Duration: 3 months

Fee: Rs. 10,000

Enhance skills in industrial circuit maintenance

Learn power house maintenance techniques

Home Appliance Repair & Maintenance Training Programme

Duration: 3 months

Fee: Rs. 10,000

Develop skills in home appliance repair and maintenance

Explore opportunities in the home appliance industry

Industrial Electrical LT-Panels & Three Phase Wiring System Training Programme

Duration: 2 months

Fee: Rs. 15,000

Focus on industrial electrical LT-panels and three-phase wiring system

Gain expertise in electrical panel installation and maintenance

Air Conditioner (AC) PCB Repair & Maintenance Training Programme

Duration: 3 months

Fee: Rs. 10,000

Learn AC PCB repair and maintenance techniques

Enhance skills in air conditioning technology

Industry 4.0 Using PLC Gateways Training Programme

Duration: 2 months

Fee: Rs. 15,000

Explore the concept of Industry 4.0 and its implementation with PLC gateways

Understand the future of automation in industries

Summer/Industrial Project Training Programme

Duration: Varies

Fee: G.S.T extra and Placement Assistance Available

Opportunity to work on summer or industrial projects

Gain hands-on experience in real-world scenarios

Summary of Job Oriented Training Programmes

National Small Industries Corporation Limited offers a range of job-oriented training programs in various fields.

Topics covered include industrial automation, IoT, embedded systems, electrical AutoCAD, electric vehicle technology, solar energy, and more.

Eligibility for the programs includes 8th/10th/12th pass, graduate, diploma, or B.Tech.

NSIC Technical Services Centre is located in Okhla Industrial Estate, New Delhi.

0 notes

Text

Liebherr PCB Card 925086914 0002555 0601004 | High-Quality Control PCB Board | Ram Automations

Enhance your machinery’s performance with the Liebherr PCB Card 925086914 0002555 0601004, available now at Ram Automations. This high-quality Printed Circuit Board (PCB) offers exceptional reliability, precision engineering, and durability for a wide range of industrial and marine applications.

Designed for maximum performance and efficiency, this Liebherr PCB Card ensures seamless integration with complex control systems, making it ideal for critical automation environments and high-demand applications.

🛒 Buy Now from Ram Automations 👉 https://ramautomations.com/products/pcb-card-925086914-0002555-0601004-liebherr-new

🌐 Explore 1000+ Genuine Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Liebherr • 🔹 Model: 925086914 / 0002555 / 0601004 • 🔹 Type: PCB Card • 🔹 Category: PCB Card / Industrial Electronics / Automation PCB • 🔹 Application: Industrial Automation, Marine Systems, Control Panels, Process Systems

✅ Key Features

✔️ Precision-engineered PCB for reliable performance ✔️ Seamless integration with industrial systems ✔️ High-quality materials and craftsmanship ✔️ Essential for complex machinery and automation units ✔️ Ideal for industrial, marine, and manufacturing environments

💡 Typical Applications

• Marine Electronic Control Systems • Industrial Automation Panels • SCADA and HMI System Boards • Heavy Equipment Automation • Process Automation Systems • Robotics Control Panels • Industrial Machinery Systems

🌟 Why Choose Ram Automations?

✅ 100% Genuine Products Only ✅ Best Prices with Worldwide Delivery ✅ Trusted Industrial Automation Supplier ✅ Large Inventory of Hard-to-Find Components

🛍️ Visit Us: https://ramautomations.com

In This Video You Will Discover:

🔎 Close-up View of Liebherr PCB Card 🔧 How It Integrates with Complex Systems 💡 Importance of High-Quality PCBs in Industrial Automation 🌐 Why Ram Automations is the Go-To Source for Industrial Parts

📣 Get Involved!

🔔 Subscribe for Automation & Electronics Updates 👍 Like to Show Support for Quality Electronics 💬 Comment Your Queries — We’re Happy to Help! 🛒 Visit our Online Store: https://ramautomations.com

#Liebherr PCB Card#PCB Card for Automation#Industrial PCB Card#Automation PCB Card#Marine Control PCB#Automation System Board#Ram Automations#Control Panel PCB Card#Process Control PCB#Marine Automation Electronics#Industrial Electronic PCB#Automation Equipment PCB Card#Marine Systems PCB Card#Factory Automation Parts#Robotics Control Panel Card#Data Transmission PCB Card#PLC Control PCB Card#High Quality PCB Card#SCADA System PCB Card#Electronic Connectivity PCB Board

1 note

·

View note

Text

Key Features of Industrial LCD Panels

1.Ruggedized Construction:

Reinforced glass or polycarbonate front panels resist scratches, impacts, and chemical exposure.

IP65/IP67-rated enclosures protect against dust, water jets, and temporary submersion.

Wide operating temperature ranges (-20°C to +70°C) ensure reliability in freezing or scorching environments.

2.Enhanced Visibility & Readability:

High-brightness TFT LCD display modules (up to 1,500 nits) combat glare from direct sunlight.

Anti-glare & anti-reflective coatings reduce reflections, improving visibility in bright conditions.

Wide viewing angles (178°) maintain clarity from multiple perspectives, crucial for control rooms and factory floors.

3.Longevity & Low Maintenance:

50,000+ hour LED backlight lifespans minimize downtime and replacement costs.

Fanless cooling systems prevent dust buildup and mechanical failures.

Resistant to UV radiation, salt fog, and oil exposure, ideal for marine, mining, and oil & gas applications.

4.Seamless Integration & Customization:

Modular LCD driver boards support RS-232, RS-485, HDMI, and Ethernet interfaces for easy PLC, SCADA, and IoT connectivity.

Touch LCD screen options (resistive, capacitive, or projected capacitive) enable intuitive human-machine interaction.

Custom sizes (3.5" to 24") and aspect ratios fit specific machinery, kiosks, or control panels.

At Shenzhen Zhiyan Optronics Co., Ltd. (zylcdshop.com), we provide trusted, performance-driven LCD screen solutions tailored to your requirements, all at factory-direct pricing.

#lcd panel#lcd touch panel#lcd screen#touch screen#lcd module#Plastic injection machine LCD#lcd modules#touch panel#Industrial Computer Accessories#for sharp industrial monitor model#LCD Monitors

0 notes

Text

Leading technology training Provider in UAE & KSA

IIPD Global (Institute of Innovation Professional Development Global) is a training center known for offering a diverse range of technical and professional development programs. With a commitment to helping individuals and companies realize their full potential and make a positive impact within their respective organizations, IIPD Global has established itself as a top-notch institution in the field of education and skills development.

Overview

IIPD Global, short for the Institute of Innovation and Professional Development Global, is a renowned training center specializing in cutting-edge technical and professional development programs. Founded with the mission to empower individuals and organizations to reach their full potential and create a positive impact, IIPD Global has become a trusted destination for skill enhancement and education.

Programs Offered

IIPD Global offers a wide array of training courses across various domains, ensuring that learners have access to the latest knowledge and expertise. Some of the key areas covered by their programs include:

Industrial Automation: IIPD Global provides training in areas such as PLC (Programmable Logic Controller), SCADA (Supervisory Control and Data Acquisition), HMI (Human Machine Interface), VFD (Variable Frequency Drive), and Control Panel design.

Building Management System: Their courses cover DDC (Direct Digital Control), ELV (Extra-Low Voltage) systems, UPS (Uninterruptible Power Supply), and HVAC (Heating, Ventilation, and Air Conditioning) systems.

Specialized Fields: IIPD Global offers training in specialized areas like KNX (a standardized network communications protocol), IIOT (Industrial Internet of Things), Oil & Gas, and MEP (Mechanical, Electrical, and Plumbing).

Energy Management and Renewables: With a focus on sustainability, IIPD Global provides training in energy management and renewable energy technologies.

Power Electronics and Instrumentation & Control: Their programs encompass power electronics and instrumentation techniques, essential in various industries.

Facility Management and Operation & Maintenance: IIPD Global equips individuals with the skills needed for efficient facility management and operation, including maintenance practices.

Digital Marketing: In the realm of digital marketing, IIPD Global offers training in Search Engine Optimization (SEO), Paid Advertising, and YouTube marketing strategies.

Innovation and Development: IIPD Global fosters innovation and development by providing courses that enable individuals and organizations to stay ahead in the ever-evolving business landscape.

And More: The institution continually updates its course offerings to stay aligned with industry trends and demands, ensuring that learners receive the most relevant and up-to-date education.

Collaboration

IIPD Global has forged strategic partnerships with several prestigious organizations and institutions to enhance the quality and reach of its training programs. These collaborations include:

PECB (Professional Evaluation and Certification Board): IIPD Global is proud to partner with PECB, a leading certification body for various international standards, to offer globally recognized certifications to its learners.

CompTIA: As a partner of CompTIA, a renowned provider of IT certifications, IIPD Global provides comprehensive training in IT and cybersecurity, ensuring that learners are well-prepared for the demands of the technology industry.

KNX Association: IIPD Global collaborates with KNX Association, a global leader in home and building control standards, to provide training in KNX technology, empowering individuals to excel in the field of smart building automation.

Cernexus: The partnership with Cernexus enhances IIPD Global's offerings in innovation and development, allowing learners to stay at the cutting edge of technology and business trends.

GINI: By partnering with GINI, IIPD Global strengthens its position in the field of digital marketing, ensuring that learners receive top-notch training in SEO, paid advertising, and YouTube marketing.

TÜV Rheinland: IIPD Global's collaboration with TÜV Rheinland, a globally recognized certification body, underscores its commitment to quality and compliance in various industries.

In addition to these partnerships, IIPD Global is proud to be approved by two respected regulatory authorities:

KHDA (Knowledge and Human Development Authority), Dubai: IIPD Global's approval from KHDA in Dubai signifies its commitment to meeting the educational standards and requirements set by the Dubai government, ensuring the quality of its programs.

TVTC (Technical and Vocational Training Corporation), Saudi Arabia: Approval from TVTC in Saudi Arabia reflects IIPD Global's dedication to delivering high-quality vocational and technical training that aligns with the standards and needs of the Saudi Arabian workforce.

These collaborations and approvals solidify IIPD Global's reputation as a reliable and respected institution, further enhancing its ability to empower individuals and organizations with the skills and knowledge they need to excel in today's competitive global landscape.

Learn More: https://www.iipdglobal.com/

0 notes

Text

An Interview

It was March 2020 I had started giving interviews for internship. why you may ask. why an internship? it was because I wasn't getting any job and every company was asking for experience. Now from where should I get the experience because I had a BE degree and an M.Tech. degree and no experience so I decided to get some experience via internship. I applied for many internships and gave many interviews also but all in vain.

Then I found an internship position open at Pranab Mukherjee Foundation. I applied there and then I was asked to write an article on the topic "Dams are temples of modern India: Agree or disagree" I wrote it and after a few days on the 12th of March I got a call that my interview is scheduled on 13th at 11:30 a.m. I reached the interview venue at 11:15 a.m. and I was asked to wait; then, after some time I was called in for the interview. I went there and the interviewer asked me to come in and sit, I sat and he started asking me questions, he was mostly interested in my solar related project which I did during my BE so he was asking questions about solar panels and its connections which I answered and there were some questions whose answers I knew but at that time it just didn't strike my mind e.g. what is the full form of SCADA? AND I WAS LIKE HOW CAN I FORGET THIS! He also took my typing test which, I feel, I must have done fairly well. And in the end, he said you will get a call in two-three days.

On 14th I had train for home and on 20th I had to return. I didn't get any call till 19th which was already 6 days since my interview (I thought I am not selected that's why not getting call) so I decided to stay at home for a few more days and I cancelled my return ticket of 20th.

But...

I got a call on 20th from Pranab Mukherjee Foundation that I have been selected for the internship and that I have to join on 25th. I was regretting, why did I cancel my ticket? So I booked another ticket of 24th and then on 21st Modi Ji came on TV asking citizens for Janata curfew on 22nd so my family members asked not to go to Delhi but I didn't cancel my ticket but the situation of COVID was worsening and I wasn't allowed to board my train on 24th and on 24th night Modi Ji came on TV (again!) and announced that there will be a 21 day lock down in India starting from 25th.

And that is how I lost my first and only opportunity of an internship to COVID lockdowns.

But why was this interview so special for me?

To answer this, let me introduce you to my interviewer Dr. Krishna Kant Paul.

Dr. K. K. Paul is a former IPS officer who served as police commissioner of Delhi for more than 3 years. He was a member of UPSC for almost 6 years. He also has experience of working in IB and RAW. He then went on to become governor of Northeastern states Meghalaya, Manipur, Mizoram, Nagaland and also Uttarakhand.

Getting interviewed by such a personality was an honour for me and clearing the interview was way beyond my explanation & that is why this interview is one of the most memorable moments of my life.

0 notes

Text

Hot asphalt batching plant – components and features.

All Tech Group is a manufacturer ofhot asphalt batching plants. We have successfully exported many machines of different capacities. This blog is about our recent installation of a 260 tph asphalt mixer and about its components and features. All Tech Group manufactures top quality asphalt batch plants with focus on quality and service. The equipment is designed to be working for long time without breakdown. The use of quality brought out items in the manufacturing enables us to offer the best quality.

Stringent quality norms are followed at each manufacturing stage. In the end, the equipment is sand blasted prior to application of paint. This process allows us to get a plant that is more finished and better looking. When higher quality components are used, the machine tends to perform better. Each component is designed with care, and it works in tandem with other units for a trouble free performance. Better- and high-quality raw materials = better quality and performance.

Components of hot asphalt batching plant 260 tph

All the components of the hot asphalt batching plant are important and crafted with precision. Since this is a tower type batch asphalt plant of 260 tph the components are bigger compared to the other smaller plants of 60 tph, 100 tph, 120 tph or even the 160 tph plants. The components are modular means the plant is easily broken down into different small components for easy installation. This also facilitates easy transportation of the full plant. The key components of this machine are listed as below:

Image:-

Batch mix plant suppliers

-

All tech group

5 bin cold aggregate feeder.

Primary vibrating screen and slinger conveyor.

Drying drum

Fuel efficient air atomization burner.

Bag filter with pre-separator

Filler silo with elevator

Hot aggregate elevator

5 deck vibrating screen

5 deck hot bins

Mixing unit

Weighing scales for filler, aggregates and bitumen on tower of hot asphalt plant.

Bitumen storage tanks with thermic heating unit.

Fuel tank for drum burner.

Control panel system

Features of hot asphalt batching plant (asphalt mixer) of 260 tph capacity

There are many strong advantages of All Tech Group hot asphalt batching plant. The asphalt mixer of 260 tph is designed to perform with precision. It is manufactured to produce quality hot mix asphalt as per the desired mix recipe. Some of them are under:

The 5-bin feeding unit is with adjustable push up roller for easy alignment.

The corrugated auxiliary belt avoids material wastage at the site.

Drum unit is supported by EN 350 forged rings.

Bigger trunnion rollers for better drum support.

Low noise air atomization burner

Proven and fuel efficient burner compliments the drum

Hot elevator with dual chain design for prolonged life.

5 or 6 screening decks – upon request of customer

Larger screening area for uninterrupted production.

Bigger hot bins for storing sufficient quantity of aggregates into separate compartments.

Hot bins are thermally insulated for heat retention.

Mixer is supplied by BHS. It is of 3500 kgs. Capacity.

Stringent and proven design of mixer that works smooth.

Aggregate scale size is 4500 kgs.

Filler scale size is 450 kgs.

Image:- A

sphalt Batch mix plant manufacture

-

All Tech Group

Bitumen scale size is 300 kgs.

Bag filter with larger filtration area.

Bag filter has high cleaning efficiency.

Bag house is thermally insulated to keep the bags away from moisture.

Exhauster is heavy and bigger.

It is equipped with a variable frequency drive for efficient operation.

Foreign filler silo provided is of 60 m3 capacity.

Four bitumen tanks of 50 tons each provided with the plant.

Bitumen tanks are heated by a 700,000 thermic heater.

Control cabin is double storey with 2 PC’s on the top floor and all the control boards on the bottom floor.

Both the floors are air conditioned.

High technology cabin with user friendly software.

PLC with SCADA and with Siemens HMI.

Fuel tanks provided are 2 in number for using 2 different fuels. Each tank is of 24,000 liters.

Platform railings and ladders are of high quality with diamond shaped grating and anti-slip design.

Duct line comes with an improved design which is now maintenance free. It also allows free flow of gases.

Some advantages of All Tech Group hot asphalt batching plant, 260 tph

All Tech Group asphalt mixing plantshave proven their advantages and worth with more than 140 installations in 5 years. Below are some of the advantages of the All Tech Grouphot asphalt batching plant of 260 tph. The higher level of acceptance with customers is a proof of our quality product. The higher number of units is also a testimony of low maintenance, better after sales support, low fuel consumption, more savings and superior overall performance.

Few of the core benefits of asphalt mixers by All Tech Groupare as below:

● Structure: Overall structure is heavy with the plant tower unit girders being wider compared to the competition.

It’s advantage: It aids in getting more stability to the machine. The equipment can withstand harsh weather. The machine life will not be affected even after several re-installations.

0 notes

Text

Solar Electricity - Green Future of India - Hartek Group

In 2018, the sunlight based power industry saw a 24% expansion in its y-o-y limit augmentations, while hydropower saw 2% and wind energy saw a 10% expansion). Although a greater part of the sunlight based limit increases were overwhelmed by Asia, new business sectors like Brazil, Saudi Arabia, Egypt, Spain and Latin America saw significant development.

The wonderful upsurge in private investment in the force area in India and the public authority's pushed on sustainable power is in a state of harmony with the nation's sun oriented overdrive in quest for the 100-GW focus for sunlight based undertakings, there are obstructing issues like delicate abrogation of UBER ventures. China's strategy move, feed-in-tax cut in Japan, and approaches requiring of expenses and obligations on sun oriented energy industry in India restricted sun based area development in 2018, yet the sunlight based area is relied upon to ricochet in 2019.

With the delicate cycle getting pace in FY 2019-20, we have a great deal to anticipate this year. Seeking after a 40-GW focus on, the public authority is additionally good to go to give a major push to the housetop section through positive arrangements like net metering.

Solar Power is India's Green Future as it presents an extraordinary occasion to eliminate non-renewable energy source and its developing costs while changing the nation with mechanical, social, and monetary development. The fate of sun based energy in India generally relies upon accomplishing the goal-oriented sun based force age focus of 100 GW by 2022. With the combined sun oriented limit going up to 36.36 GW, as on June 30, 2019, the market conclusion is perky in view of the record number of establishments.

We accept that by 2030, India's sun oriented industry is ready to develop incredibly. The nation will require $250bn in environmentally friendly power energy assets from 2023 to 2030. Speculation open door for over $30bn every year is required to come up in the following decade, as indicated by the Economic Survey.

Significantly, India is running the world's biggest sustainable power program. Sunlight based force generation holds the way in to the phenomenal development India needs to enlist to get to the wizardry figure of 100 GW. Fuelling the ever-developing requirements of for all intents and purposes the wide range of various key areas, the force area shapes the foundation of our quickly extending economy. Since manageability is at the core of all advancement endeavours coordinated towards building a New India, the nation is targeting expanding the portion of renewables in the complete introduced power ability to half by 2030 with a significant piece coming from sunlight based energy. This is on top of another element of Vision 2030 which anticipates India as a contamination free country with green environs and blue skies. Inexhaustible sources by and large and sunlight based force specifically can have a significant effect here as a significant wellspring of energy flexibly.

It is appropriate to make reference to here that around 40% of the force limit introduced in India this year is sun oriented. Hard and fast endeavours at changing the energy blend are in progress. In the Indian sun powered market, pretty much every passing delicate has vowed to convey less expensive power. The sun powered industry is entering a time of cost productivity, because of advances in innovation and serious offering. Sunlight based force duties in India have plunged to a record low of Rs 2.44 per unit, which will push interest incredibly.

The sun oriented industry has seen fast development over the most recent couple of years and is relied upon to develop considerably more in coming years. To energize the move from ecologically hindering wellsprings of energy to cleaner options, the public authority has been assuming a functioning part by presenting a few motivators, for example, GBIs, capital and interest appropriations, which are probably going to lessen the reliance on ordinary energy and increment reception of sun based force.

These measures include setting up a few little sun based activities on desolate land and presenting sun oriented water siphons.

To additionally support the appropriation of sun oriented force, a large number of welcome activities have been as of late presented by the public authority, which has been invited over the business. This remembers the burden of BIS principles for sun oriented imports, other than guaranteeing adherence to the nature of items rather than simple value benefits. Another welcome advance in the idea note delivered by the MNRE proposes the improvement of 10 GW of assembling limit over a time of five years, which centres on both poly-silicon and wafer assembling to make incorporated silica-to-modules bundles and moderate independent bundles or mixes.

Perhaps the greatest preferred position of sun oriented force is the capacity to keep away from the governmental issues and cost instability that is progressively describing petroleum product markets. While the costs of petroleum derivatives have expanded, the per watt cost of sunlight based energy creation has more than divided in the previous few years, and is set to turn out to be significantly less expensive soon as better innovation and economies of scale become effective. The primary advantage of utilizing sun based boards to create power is that they don't deliver any naturally inconvenient ozone harming substances.

Renewables represent a sizeable portion of the force limit augmentations, featuring the critical venture streaming into the sun oriented area specifically. No big surprise, India has arisen as the third biggest sun powered market universally. Be that as it may, we actually have far to go to turn into a worldwide sun based superpower like China and US.

To accomplish the objective, India needs weighty interest in coming years. A significant portion of it must be raised inside the nation, as the sustainable area could so far just pull in an unfamiliar direct speculation (FDI) worth $7.5 billion over the most recent 18 years (2000-2018), as per a report by the India Brand Equity Foundation.

The sunlight based area can quicken its development by zeroing in on assembling and supporting home-grown sun based board fabricating industry with sizeable speculations. This will assist India with scaling more noteworthy statures like China, which entered unfamiliar business sectors by undermining their market costs. By staying at work past 40 hours on its sun based board producing limit, China had the option to help its own solarisation, ring in incomes from sends out and make occupations. India needs to follow a comparable guide.

We have to get on the home-grown assembling front. Different endeavours by the Solar Energy Corporation of India (SECI) to draw in offers for the improvement of the between state transmission framework for sunlight based force departure have gone to no end. Sun based force age must be in a state of harmony with the development in bandwidths inferable from clearing difficulties, else we might be in for a stoppage.

control relay panels, Leading EPC company in substations, Largest roof top solar company, Top rooftop solar installers in india, solar EPC, Package substation, Power distribution products, HV & EHV substations, Power system EPC, Medium voltage panel, SCADA & automation, Largest rooftop solar project, Manufacture electrical switchboard panels,best roof top solar company in chandigarh, best roof top solar company in Punjab, rooftop solar panels,rooftop solar companies, rooftop solar company in india, solar panel chandigarh, solar roof top solutions, substation epc contractors in india, smart city power distribution, Top EPC Companies in India, smart infrastructure, future of solar industry, Control & relay panels, solar panel installation, power system, rooftop solar system, solar roof top system, rooftop solar companies in india, Transformer manufacturers, solar rooftop panel, smart cities, rooftop panel, rooftop solar panel installation, solar panel installation cost, solar rooftop system, Rooftop Solar, Indian solar industry, Electrical Substations, solar panel cost, elecricity distubution, electrical power generation, electric panel manufacturer, renewable energy, solar electricity, Advantages of solar, LT panels, Switchgear, smart grid, GIS Substations, HT panels, Compact substation, portable solar power, roof solar panel cost, electric power systems, solar power system, home solar power, solar roofing tiles, top power companies in india, electrical power, smart city technology, fuel, roof solar panels, electrical power, power solar system, Made in India Solar Company , Solar Roof Top, solar panel for home price

#solar panel for home price#Made in India Solar Company#power solar system#fuel#smart city technology#top power companies in india#solar roofing tiles#home solar power#solar power system#electric power systems#roof solar panel cost#portable solar power#Compact substation#HT panels#GIS Substations#smart grid#Switchgear#LT panels#Advantages of solar#solar electricity#renewable energy#electric panel manufacturer#electrical power generation#elecricity distribution#solar panel cost#epc company#rooftop solar#epc companies#Electrical Substations#Solar Roof Top

0 notes

Text

Powering Change In Electricity Distribution And Energy Management

The world of power distribution and energy management is growing in complexity as it confronts old problems, new challenges, varied energy sources and multiple applications emerge every day. Yet, it is also clear that today, electrical power drives modern civilisation. Efficient and safe distribution including energy management and power quality monitoring is critical for providing industrial and building facilities with power.

Messung understands this requirement of the Indian market and is committed to providing reliable, intelligent and world-class solutions for the Power Monitoring and Distribution sector. Messung has tied up with global players and market leaders for their cutting-edge products and technology such as busbar systems, Class A power quality analysers, residual current monitoring devices, online UPS, active harmonic filters and electrical panel components. The comprehensive portfolio is complemented by Messung’s own expertise in automation and engineering. The outcome is a range of custom-made and application-specific solutions that are transforming power distribution and energy management across industries and infrastructure.

Messung’s expertise spans three broad segments:

Distribution & Control: The power distribution panel is an essential component of every electricity supply system. These boards feed electrical power to different circuits that provide protective and efficient fuse and circuit breakers for every circuit and can be accessed with simplicity in case of an electrical fault.

Increasing levels of automation make this an exciting field for Messung to operate in. With its decades of experience in PLC-based automation, Messung provides smart power distribution control panels with automation products like PLC, HMI and Scada along with Wohner’s ‘s special Busbar systems as per IEC 61439 standards.

Messung offers total low voltage power distribution control systems by studying the automation requirements of the customer and proposing an efficient, cost effective solution.

Messung’s turnkey solutions are Industry 4.0-compatible, smart Cloud-based solutions to provide IOT features for “Any time Anywhere” supervisory and control features.

Messung also provides end-to-end support to ensure that the customers application – be it a machine tool or a water treatment plant – is completely automated. Messung’s team provides programming, engineering, training and documentation services as a part of the total deliverables.

Control Panels: Messung offers a single source solution for custom-made and application-based control panels to suit customer needs.

Messung provides “Control Panel Solutions” to a wide arena of applications like water and waste water treatment plants, sugar machinery, plastic extrusion, printing, pharmaceutical, automotive assembly and testing lines, electro plating, boilers, material handling, furnaces, mechanical and hydraulic press and other similar applications in different industry verticals.

Messung provides smart electrical distribution control systems with all types of advanced electronic instruments, components and programmable logic controllers. Customers are assured the latest technology and all interfacing/inter connections as per global industry standards.

Messung makes these control panel solutions using their state-of-the-art fabricated MS or Aluminum panels and world class switch gears as per the standardization of the end user. Besides Messung also puts in their NX-ERA PLC, Busbar products from Wöhner, international grade HMIs, energy meters and cloud interfaces. All control panel designs made by Messung are as per the latest technologies. Using high-end design software, they are able to provide good quality documentation for easy and accurate maintenance and servicing.

From design and development (Engineering) for electrical and instrumentation process control through manufacturing of all types of PLC & MCC Control Panels, with availability of Factory Acceptance Test facility and commissioning service support at site, Messung ensures on-time delivery of fully wired Control Panels

Energy Management: Electrical Energy is the primary need of any industry. By implementing proper Energy Management systems, Power Quality Monitoring and Analysis including Residual Current Monitoring, users can greatly benefit from enhanced up-time of machines, reduced tariff and penalties, and improved profits.

Messung offers modern Janitza products which have a wide range of applications and allow customers to implement a comprehensive installation of Class A power quality energy meters, varieties of energy measuring devices with Ethernet IP, Modbus, Profibus, Profinet, M-Bus protocol interfaces as per IEC 61000-2-4.

Alarms and push notifications including watchdog features as per EN 50160 and IEC 61000-2-4 provide solutions to customers, right up to individual departments in the industry to tightly monitor the usage and quality of the power at the most local level.

With intelligent hardware and software, Messung’s customised solutions enable power conservation, optimise power consumption, improve quality of power. By leveraging the power of IoT, Messung ensures connectivity and real-time data analyses for prompt & informed decision making.

Messung has also tied up with Fuji Electric Consul Neowatt for their market-leading range of online UPS and Active Harmonic Filters. These power conditioning and power back-up products enable Messung’s solutions to support critical and sensitive equipment in various industrial, commercial and data centre applications.

Conclusion

Messung is a leading power distribution control panel manufacturer dedicated to improving the quality of life and the environment through the use of innovative electrical products and technologies, and has partnered with international leaders to offer advanced solutions in electrical engineering.

Messung partners with OEMs and end users to deliver the most efficient solutions: best-in-class products that build world-class smart electrical distribution control panels; custom-built busbar panels for safe and compact installations as per IEC 61439 standards; and end-to-end solutions for power distribution & control, automation and Cloud-based energy management.

Integrating strategy and technical consulting expertise with deep domain knowledge and real-world experience, Messung helps homes, businesses, institutions and OEMs achieve increased energy efficiency, improved productivity, greater safety and higher profits.

#electrical panel components#smart power distribution control panels#Busbar systems as per IEC 61439 standards#low voltage power distribution control systems#smart electrical distribution control systems#Busbar products#power distribution control panel manufacturer#smart electrical distribution control panels#busbar panels#power distribution & control#Cloud-based energy management#electrical power distributor

0 notes

Text

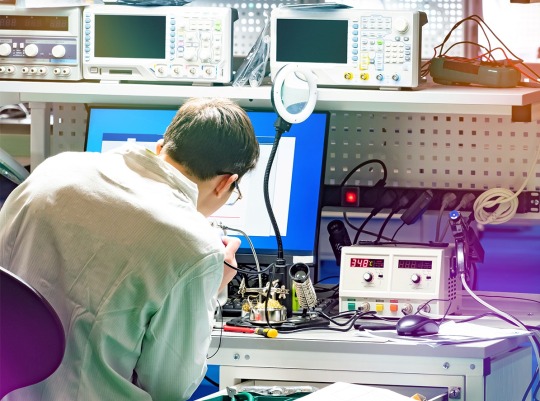

TURNKEY SOLUTIONS FOR TEST & MEASURING ENVIRONMENTS - TO ENHANCE EASE, SAFETY AND PRODUCTIVITY

Electronics and the electronic laboratory environment are characterized by continuous and dramatic innovation since the 1980s. There has been rapid and remarkable development in the range and complexity of electronic components and devices, matched by complementary changes and growth in the laboratory environment.

As electronics get smaller, more complex and sensitive, laboratory systems have had to keep pace, with advances in testing equipment, furniture, infrastructure and techniques.

TEST & MEASURING Electronics manufacturing, testing and quality control need test and measuring equipment and ergonomic environments that are flexible, versatile and safe. Hence Messung brings the future of modern workplace systems for R&D labs, testing labs, calibration centers, training and didactic centres, etc. spread across the Indian electronic industry. Messung's innovative, modular & customised laboratory furniture systems, and intelligent test & measurement solutions are designed to improve efficiency while offering user comfort.

Messung also offers expert capabilities for designing and executing complete laboratory solutions and setups or Training center setups. ESD furniture, testing equipment & instrumentation, computers, storage systems, harmonics-free power supplies, server rooms with UPS and air-conditioners - whatever the customer needs as per his application, Messung delivers the complete infrastructure from concept to commissioning.

Messung’s most important offering in this Domain are world-class, cost-effective solutions for Research and Development Laboratories (R&D Labs), Training and Didactic Centres, Calibration Stations for instrumentation, and complete setups for Assembly, Testing and Quality Control for large and medium electronic manufacturing units.

R&D Labs

Most electronic manufacturing companies have their own R&D labs for PCB design, prototype building, EMI-EMC testing, etc. These activities call for specific requirements such as ESD work surfaces, instrumentation racks or panels, computer monitors, connection to power supplies, Digital Multi Meters, Function Generators with high level specifications, and noise free highly stable Power supplies. Messung provides the entire infrastructure for such R&D labs, with fail-proof electrostatic discharge protection, proper ergonomics and flexibility to adapt to evolving needs.

Messung also offers ESD shelves, ESD drawer cabinets, ESD storage racks & cupboards, along with all the instrumentation and equipment.

Training & Didactic Centres

For Industrial and educational institutes focusing on Digital/Analog/IOT Technology, Messung helps set up world-class training & didactic centres in tune with future needs. Messung provides fully equipped didactic workstations and labs empowered with customised electronic products, simulators, oscilloscopes and other instrumentation; custom-designed user interfaces; training collaterals and assessment tools.

Messung specialises in preparing Training and Didactic stations for Industrial Automation, Building Automation, Process Automation, Instrumentation Automation for testing and quality control, Energy Management with top quality products for Power Quality Analysis and Supervisory Scada. We have specialised solutions for creating training for students in Home Automaton, Lighting Controls, HVAC Controls including BMS, Fire and Safety, Access Control and CCTV/Surveillance Controls.

Messung also offers to make dedicated Didactic and Training solutions for specific needs of Colleges, Universities, and Corporate Training centres.

Calibration Centres

All general purpose and precision measurement instruments and sensors require periodic calibration, compulsorily. The end user has to keep records of all the calibrations done so that it becomes part of their Quality Control manual and guarantees. Calibration minimises any measurement uncertainty by ensuring the accuracy of each and every test equipment and sensors. Whether it is calibration of instruments or calibration of various sensors and actuators, along with their ESD-safe furniture, Messung offers suitable electronic equipment and Software that are necessary to make the calibration as required by the Industry standard.

Based on the level of accuracy and functionality specified, Messung custom-designs and delivers the complete setup for calibration stations. We specialise in making these calibration stations for the Pharmaceutical, Chemical, Fertiliser and Oil & Gas industries.

Electronic Assembly & Testing

Messung provides modular, world-class work stations, trolleys and racks specially designed and manufactured to meet the functional and ergonomic requirements of Electronic Circuit Board Assembly, Cables, End Product Assembly, Service & Repair.

We have all the facilities to make the “Bed of nails” equipment and jigs to make testing and quality control suitable for large and medium quantity production setups.

We provide complete solutions for testing & measuring, rework and end of line testing in Automotive, Telecom, Defense, Pharmaceutical, FMCG and other industries.

ABOUT MESSUNG

Established in the year 1981, Messung Global Connect Pvt. Ltd. is a leading ESD chair supplier and ESD products manufacturer of world-class workplace technology solutions in India. The range includes ESD safe laboratory chairs, ESD cleanroom chairs, antistatic workbenches, ESD tables, ESD racks & trolleys, ESD stools and ESD mats. Messung also has a range of products for Cleanroom production including cleanroom chairs and clean room stools.

At its world-class Technology Centre in Pune, Messung continuously innovates and tests their products for design, quality and finish. So you're assured high quality, ergonomic industrial furniture with ESD protection as per global standards - for user health and productivity.

Today, with its decades of industry experience and in depth knowledge of the electronics industry in particular, Messung's scope has expanded to offer the complete package for modern laboratory and training centres. Messung's Test & Measuring solutions are providing a safe, ergonomic and efficient work environment across industry verticals that include Defense, Automotive, Education, Telecom, FMCG, Pharma and others.

#ESD chair supplier#ESD safe laboratory chairs#antistatic workbenches#ESD tables#Cleanroom production#cleanroom chairs#clean room stools#Test & Measuring solutions#Electronic Circuit Board Assembly#electrostatic discharge protection#test and measuring equipment

0 notes