#legacy PCB replacement

Explore tagged Tumblr posts

Text

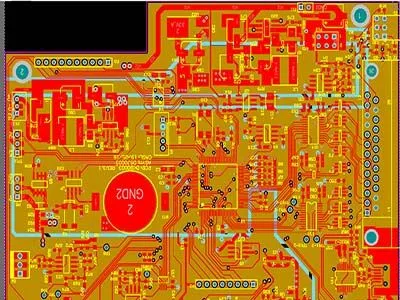

Grundy Partners RM-B PCB Card | High-Performance Industrial Control Board | Ram Automations

Discover the reliability and precision of the Grundy Partners RM-B PCB Card, a trusted component in many automation and industrial control systems. Whether you’re upgrading, repairing, or maintaining your equipment, this used but fully functional PCB card is the perfect fit for high-performance applications. Now available at Ram Automations, where we specialize in genuine and hard-to-find industrial and marine spare parts from the world’s top brands.

🛒 Buy Now: https://ramautomations.com/products/grundy-partners-rm-b-pcb-card-used

🌐 Explore Our Full Product Range: https://ramautomations.com

🔍 Product Highlights:

• Product Name: RM-B PCB Card • Brand: Grundy Partners • Condition: Thoroughly Tested & Verified • Type: Printed Circuit Board (PCB) • Application: Industrial Control & Automation Systems

This RM-B PCB Card by Grundy Partners is built to ensure the longevity, reliability, and stability of your industrial control setup. It handles signal transmission and circuit management tasks effectively, making it indispensable in automation processes. Even though it’s used, it’s been quality checked and remains highly efficient.

✅ Key Features:

✔️ Trusted quality by Grundy Partners ✔️ Designed for industrial-grade applications ✔️ Enhances operational accuracy and circuit performance ✔️ Thoroughly tested and quality assured ✔️ Ideal replacement for faulty or discontinued PCB cards ✔️ Part of advanced automation, monitoring, or PLC control systems

🏭 Ideal For:

• Manufacturing Units • Electrical & Automation Control Panels • Marine Equipment Controls • Power Distribution Systems • Factory Automation • Legacy Equipment Repairs • OEM Replacement for Existing Units

📦 Why Buy from Ram Automations?

At Ram Automations, we offer a massive inventory of industrial automation and marine equipment spare parts, including rare or discontinued models from over 1000+ trusted brands. Whether you’re searching for automation parts, PLCs, drives, transmitters, power supplies, or circuit boards like the Grundy Partners RM-B PCB Card, we deliver with quality, care, and global shipping options.

✔️ 100% Genuine & Tested Products ✔️ Competitive Pricing & Bulk Order Discounts ✔️ Worldwide Shipping & Timely Delivery ✔️ Reliable Technical Assistance ✔️ Hassle-Free Returns ✔️ Trusted by Engineers Worldwide

🔎 Applications of Grundy Partners RM-B PCB Card:

• Signal Processing • PLC Interfacing • Control Logic Processing • Automation Loop Control • Circuit Integration in Industrial Machinery • Equipment Maintenance for Manufacturing Plants

📽️ Watch to Learn:

In this video, we highlight the technical features and uses of the Grundy Partners RM-B PCB Card. Learn how this component functions within your automation system and why it’s a preferred solution among engineers and industrial professionals.

🔧 We also provide installation tips, use cases, and troubleshooting info to help you deploy it effectively in your setup.

💬 Let’s Connect:

If you have any questions about this PCB card or other industrial products, drop them in the comments! 👍 Like this video if it helped you 🔔 Subscribe to stay updated on automation components

#Grundy Partners RM-B#RM-B PCB Card#Grundy RM-B Board#industrial PCB card#automation spare parts#control panel board#signal interface card#used automation board#industrial control board#circuit board automation#industrial PCB module#OEM replacement PCB#automation system PCB#Ram Automations parts#marine PCB components#electrical control board#automation PCB card#PCB for industrial system#used PCB board#Grundy automation board#automation electronics#control signal processor#legacy PCB replacement#Grundy PCB module#printed circuit board#automation spares

1 note

·

View note

Text

The Importance of Keeping Spare Parts for Marine Systems

In manufacturing, marine, and industrial settings, downtime isn't merely a hassle - it's costly, disruptive, and occasionally hazardous. It doesn't matter if it's a faulty PLC, a blown relay, or a cracked sensor. The smallest part can cause entire processes to grind to a halt. That's why having spare parts for essential systems isn't just a best practice - it's a requirement.

In this blog, we’ll explore the key reasons why spare parts inventory is essential, what types of components should be prioritized, and how to manage them effectively to maintain productivity, safety, and profitability.

What Are Critical Systems?

Critical systems are the components of an industrial process that are essential to continued operation, safety, and compliance. These include:

• Automation and control systems (PLCs, HMIs)

• Power supply modules

• Sensors and instrumentation

• Valves, actuators, and solenoids

• Marine engine controllers

• Pressure and temperature monitors

The Actual Downtime Cost

• Unscheduled downtime costs the manufacturing sector an estimated $50 billion each year

• Each minute of stopped production in automotive or food production can cost thousands of dollars

• In nautical environments, breakdown of a navigation or ballast controller can postpone trips or attract penalties

These expenses are not merely economic—they also impact customer confidence, staff productivity, and obedience to safety protocols.

Why Spare Parts Matter?

Here's why having a well-stocked and well-maintained inventory of spare parts is crucial for any operation with critical systems:

1. Avoid Downtime

The most self-evident reason to carry spares is to minimize downtime. When a part fails and a replacement is available on-site, your maintenance crew can easily replace it and get back up and running—typically within hours or minutes rather than days.

Example:

A spare HMI panel that's conveniently sitting in your inventory can be put in place right away when the current one fails—instead of waiting 3–5 days for shipping or finding somewhere else.

2. Eliminate Long Lead Times

Certain parts, particularly legacy pieces or OEM-specific modules, are not easily obtained from the manufacturer or regional distributors. Lead times may be weeks to months, which severely disrupts.

By having used, tried, or even rebuilt spares in stock, you can avoid international supply chain delays and maintain smooth operations.

3. Ensure Safety & Compliance

Security-critical systems such as fire alarms, pressure sensors, gas sensors, and marine engine control systems are bound by safety regulations. Failure could see you facing legal risks, fines, or running your operations.

Having spare parts of the required nature means that you are able to recover these critical safety systems as quickly as possible and be within industry standards like ISO, IEC, or marine approvals.

4. Reduce Emergency Procurement Expenses

Emergency purchase of parts is always more costly. Express shipping, expedited buying, and panic purchasing can skyrocket costs.

Spare part planning assists you:

• To buy during less busy periods

• To compare suppliers and secure the best price

• To minimize premium charge for rush delivery

5. Legacy Equipment Support

Few facilities no longer operate older systems—such as Siemens S5 PLCs, Omron NT HMIs, or Mitsubishi relay logic circuits. These are good but no longer supported by manufacturers.

Used spare parts extend the lifecycle of this equipment and postpone expensive system overhauls or upgrades.

What Parts to Stock?

You don't have to stock every component in the world. Prioritize these categories:

High-Failure-Rate Parts

• Relays, fuses, contactors

• Sensors (proximity, temperature, pressure)

• Switches and connectors

Lead-Time Sensitive Parts

• Obsolete PLC modules

• Rare HMIs or PCBs

• Brand-specific control boards

Mission-Critical Components

• Power supplies

• Control relays

• Actuators and solenoids

• Marine control panels and regulators

Consumables

• Gaskets, seals, O-rings

• Valve kits and diaphragms

• Indicator lamps or display screens

0 notes

Text

Marck Industries: Trusted Manufacturer of Premium Elevator Spare Parts

Why Reliable Spare Parts Matter in Elevator Systems

Elevators are essential in modern buildings—transporting people and goods swiftly and safely. Downtime due to broken or worn-out parts isn’t just inconvenient—it can impact safety, building efficiency, and tenant satisfaction. That’s why having a dependable source of high-quality spare parts is vital.

What Sets Marck Industries Apart

1. Decades of Expertise

With years of experience in manufacturing elevator components, Marck Industries understands the stringent requirements of vertical transportation—ensuring every part is engineered for precision, durability, and compliance with international safety standards.

2. Comprehensive Product Portfolio

From mechanical to electrical systems, we supply a full range of elevator parts, including:

Controller boards & PCBs

Inverter and VFD units

Proximity switches & sensors

Door lock and safety gear

Brake assemblies & drums

Buffers, rollers, and pulleys

Cabin fixtures: buttons, display panels, handrails

3. Precision Manufacturing

Utilizing CNC machining, injection molding, and automated PCB assembly, each component is produced to exact tolerances—ensuring fit and function with OEM performance or better. Strict quality checks, including EN 81, ASME A17.1, and ISO audits, guarantee consistency.

4. Certified Quality & Safety

Marck operates with certifications to:

ISO 9001 Quality Management

CE marking and compliance

Adherence to EN (Europe) and ASME (North America) elevator safety codes

These credentials ensure safe, global-grade parts.

5. Custom Solutions & Adaptability

Recognizing that every elevator system is unique, Marck Industries excels in custom engineering—from tailored connectors and cables to complete PCB re-engineering—while maintaining cost and lead-time efficiency.

Benefits of Partnering with Marck Industries

Advantage

Impact

High Uptime & Quick Delivery

Minimize downtime with rapid part replacement and fast shipping

Competitive Pricing

Optimized production lowers costs without compromising quality

Global Support Infrastructure

Sales and technical teams available round-the-clock across regions

Extended Product Warranty

Confidence via long-term warranty and support packages

Serving Diverse Market Segments

Residential Buildings: Reliable replacements for passenger-lift maintenance.

Commercial Complexes: Durable components suited for high-traffic usage.

Industrial Facilities: Heavy-duty parts designed for freight and goods lifts.

OEM Collaborations: Contract manufacturing aligned with global elevator brands.

Quality Control & Testing Procedures

Each batch undergoes:

Incoming Material Inspection (IQC)

In-Process Monitoring (IPC)

Performance Testing: Load, endurance, vibration, and electrical tests

Final Audits & Certification

Partnering with Marck: How It Works

Initial Consultation Understand your system specs, OEM models, and usage patterns.

Quotation & Sample Approval We provide detailed proposals and offer test samples for validation.

Order & Production Ranging from small spare lots to mass production, with regular updates.

Technical & After-Sales Support Including troubleshooting, field assistance, and prompt RMA processes.

Ongoing Relationship We offer lifecycle support—even for legacy elevators requiring obsolete part replacements.

Elevate Your Operations with Marck Industries

Your elevator fleet deserves nothing less than reliable, certified parts that stand the test of time. Choose Marck Industries for precision, safety, and peace of mind—backed by technical excellence and global service reach.

Ready to discuss your parts needs? Contact our sales team or request a quote through the Marck Industries website today.

0 notes

Text

Expert Circuit Board Repair and Testing Services for Reliable Performance

Understanding the Importance of Circuit Board Repair

Circuit boards are the backbone of every modern electronic system, whether used in industrial machinery, medical devices, or complex automation systems. When they fail, production halts, and downtime becomes costly. That’s why professional circuit board repair is essential for businesses relying on sensitive and high-value electronic components. Instead of replacing entire systems, circuit board repair restores functionality, saving both time and resources.

Our Commitment to Precision and Quality

At Direct Turbine Control, we specialize in advanced circuit board testing and repair for a wide variety of control system boards. Our team of experienced engineers brings a deep understanding of board-level diagnostics and functional troubleshooting. Using precision tools and a data-driven approach, we identify even the most complex faults in PCBs and restore them to their optimal performance.

Advanced Circuit Board Testing Methods

Thorough and accurate testing is the foundation of every successful repair. Before beginning any repair work, our specialists perform complete circuit board testing and repair diagnostics. We utilize functional live testing panels to simulate real-world performance conditions. This ensures that each repaired board functions exactly as intended once it is reinstalled into your system.

We also offer component-level testing, signal tracing, and thermal imaging to detect cracks, shorts, corrosion, and other damage that often goes unnoticed without professional-grade equipment. This attention to detail is what sets us apart in the circuit board repair industry.

Restoring Circuit Boards to Like-New Condition

From power surges to age-related wear, circuit boards can fail for various reasons. Our repair process begins with a thorough inspection and cleaning, followed by identifying defective components. Each part is meticulously desoldered, replaced with OEM or high-quality equivalents, and soldered back with precision. After reassembly, we run complete tests to verify that all circuits are functioning properly.

By focusing on comprehensive circuit board repair instead of partial fixes, we deliver long-term reliability and reduce the likelihood of future system breakdowns.

Why Choose Direct Turbine Control for Circuit Board Repairs

Direct Turbine Control isn’t just another repair shop. Our facility is designed specifically for high-performance electronic component repair and testing. Our engineers are not only skilled but passionate about electronics and diagnostics. We invest heavily in advanced test benches, calibration equipment, and specialized tools that allow us to repair and validate boards from all major manufacturers.

This includes legacy boards that are no longer in production, giving you the confidence that even the most obsolete parts can be brought back to life. Our certified repair process ensures consistency, quality, and a performance guarantee you can count on.

Certifications and Quality Control

Our circuit board testing and repair services are backed by rigorous quality control protocols. We follow industry standards and provide full documentation for every board we serve. Clients can also opt for our Certification service, which verifies the genuineness and functionality of third-party control system components before installation. This helps prevent costly system failures and ensures you're getting the value you expect from your purchases.

Fast Turnaround and Customer-Focused Solutions

Time is a critical factor when a control system is down. We understand that every hour of downtime means lost productivity. That’s why our repair process is designed to be fast and efficient without compromising quality. Depending on complexity, most circuit board repair jobs can be completed and returned quickly, keeping your operations moving and avoiding extended disruptions.

In addition, our customer service team works closely with you to understand your specific system needs. From identifying faulty boards to advising on testing options, we guide you through every step of the process.

Cost-Effective Alternative to Replacement

Full system replacements can be expensive, especially for highly specialized or discontinued equipment. Circuit board testing and repair offers a practical and cost-effective alternative. Rather than investing in new boards, repairing existing ones extends their life and preserves your original system configuration. This is especially beneficial for businesses operating with unique or legacy equipment that may no longer be supported by manufacturers.

Industries We Serve

Our circuit board repair services support a wide range of industries, including:

Power generation and energy

Manufacturing and automation

Aerospace and defense

Marine and transportation

Medical and laboratory equipment

Whether you need repairs for turbine controls, PLCs, or custom electronics, Direct Turbine Control has the experience and infrastructure to handle it.

Expert Circuit Board Testing and Repair

If your business relies on electronic control systems, don’t let faulty boards slow you down. Trust Direct Turbine Control for fast, accurate, and professional circuit board testing and repair. Our expert technicians are ready to bring your boards back to life, reduce downtime, and improve system reliability. Contact us today to request a consultation or learn more about our services. Let us help you restore your equipment’s performance with expert-level circuit board repair.

0 notes

Text

Panasonic DS2Y-S-DC5V Signal Relay – 5V DPDT 2A Compact Through Hole Relay

The Panasonic DS2Y-S-DC5V is a high-performance signal relay with a 5VDC coil and DPDT (2 Form C) contact configuration. With a 2A load capacity, it ensures fast and reliable switching for low-power circuits. Its compact through-hole design makes it ideal for densely packed PCBs in automation, instrumentation, and control systems. Though discontinued it remains in demand for replacement and legacy support.

Key Features:

Coil Voltage: 5VDC Contact Type: DPDT (2 Form C) Switching Power: 500VA / 440W Contact Rating: 2A @ 250VAC / 220VDC Fast Response: 4 ms operate / 3 ms release Mounting: Through Hole with PC Pins Temperature Range: -40°C to +70°C

📦 Bulk orders available – DM us or call to get the best price!

📞 Contact Today : +919810987429

📥 Enquire Now : [email protected]

#DS2YRelay#PanasonicRelay#5VRelay#SignalRelay#DPDTRelay#ThroughHoleRelay#ObsoleteRelay#LegacyComponent#CompactRelay#AutomationRelay#ElectricalRelay#PCBRelay#LowPowerRelay#ReplacementRelay#IndustrialRelay

0 notes

Text

Discover High-Precision DALE Electronic Components at Aeliya Marine

DALE is a name that comes to mind with reliability, accuracy, and innovation when it is about high-performance electronic components. With a reputation for manufacturing a broad spectrum of resistors, inductors, transformers, and other related passive components, DALE has for many years been an engineer’s favorite brand across the marine, industrial, aerospace, and defense industries.

At Aeliya Marine Tech, we’re committed to offering a dedicated range of DALE components, handpicked for quality, supply status, and compatibility with legacy and future-proof systems. Whether you need to undertake a system retrofit, build a control board, or replace a critical automation unit, DALE’s components provide the performance and reliability professionals expect.

About DALE A Respected Brand in Passive Electronics

DALE is a brand that was initially founded as Dale Electronics Inc., subsequently acquired and merged into Vishay Intertechnology, one of the world’s premier producers of discrete semiconductors and passive electronic components. Vishay Dale remains synonymous with high-reliability resistive components, constructed to the demanding standards demanded by critical markets.

DALE’s products are recognized for:

Extensive resistance ranges and close tolerances

Extended operating life

Resistance to heat and vibration

Military and aerospace-grade versions

These capabilities make DALE a trusted solution for high-performance, mission-critical applications where a minor component failure can have system-wide effects.

What Sets DALE Components Apart?

Precision Engineering DALE resistors and inductors are designed to provide precise performance under variable voltage, temperature, and load conditions.

High Power Ratings Most DALE components have high power ratings, so they’re perfect for tough industrial environments or heavy-duty control systems.

Military-Grade Reliability DALE components are often used in military hardware due to their compliance with MIL-STD and AEC-Q200 standards. They are rugged, stable, and resistant to environmental degradation.

Innovative Designs From wirewound resistors to thick and thin film technologies, DALE’s engineering continuously evolves to meet modern electronic challenges.

Popular DALE Product Categories at Aeliya Marine

At Aeliya Marine, you’ll find a broad selection of DALE components. Let’s explore the most sought-after categories:

1. Wirewound Resistors

DALE’s wirewound resistors are optimized for high-energy applications. These resistors support high wattage loads and possess superior heat resistance.

Features:

Power range: 1W to 250W+

In chassis-mount, radial, and axial leads available

Tinned or plated leads for solderability

Flameproof and non-inductive versions

Applications:

Braking systems

Motor drives

Power conversion units

Load testing

2. Thick Film & Thin Film Resistors

DALE manufactures thick film (low-cost, general-purpose) and thin film (precision, low-noise) resistors to suit various design requirements.

Thick Film:

Surface-mount technology (SMT)

Suitable for densely populated PCB layouts

Long-term resistance stability

Thin Film:

Tightly controlled tolerance (±0.1% or better)

Low TCR (Temperature Coefficient of Resistance)

Suitable for instrumentation and signal processing

3. Power Resistors

For industrial-level applications, DALE has high-power resistors with metal-case enclosures, heat sinks, and thermal management options.

Applications:

Inverters

Heavy equipment

UPS systems

Marine engine control

The resistors facilitate safe energy dissipation management in high-load applications without causing thermal damage to nearby components.

4. Inductors and Transformers

DALE’s line also encompasses inductors and transformers, standard and custom, for signal filtering, EMI suppression, and energy storage in switching power supplies.

Types:

Toroidal inductors

Common-mode chokes

SMD inductors

Due to their small size and dependable frequency characteristics, they are well-suited for marine electronics and embedded systems.

5. Specialty Components (Custom Assemblies)

DALE/Vishay also produces resistive networks and resistor arrays, custom. These assemblies conserve PCB space and enhance thermal distribution.

Used In:

Navigation electronics

Signal calibration systems

Control feedback loops

Why Select DALE Components from Aeliya Marine Tech?

At Aeliya Marine, we know that procuring the correct part is not merely a matter of availability — it’s a matter of accuracy, trust, and support. That’s why each DALE component we feature is thoroughly vetted and fully described.

Authenticity Verified Each of our DALE products is either brand new or inspected used/refurbished units. No clones, no generic alternatives — only the genuine article, by part number.

Product Description in Detail We offer complete specifications, images, datasheets (if available), and application insights to ensure you make an informed purchase.

Global Shipping at a Fast Pace We ship at a fast pace from our warehouse in Mumbai with global shipping support. From South Africa to Singapore, we ship quickly and efficiently.

Assistance from Qualified Technicians Having trouble determining the correct component or verifying compatibility? Our support team provides fast and knowledgeable help, ensuring your purchasing experience is seamless.

Key DALE Part Numbers You’ll Find at Aeliya Marine

Some popular DALE parts featured on our site include:

DALE RH-50 : A 50W aluminum housed power resistor, widely used in load and braking applications

DALE CMF55 Series : Precision metal film resistors with ultra-stable resistance

DALE RLR07C Series : MIL-spec resistors ideal for aerospace or naval systems

DALE NS5 Resistor Network : Multiple resistors in one package for PCB efficiency

DALE HL Series : Reliable power resistors with robust performance and high heat dissipation

Industries Dependent Upon DALE Products

DALE product lines benefit various industries such as:

Ship & Marine Automation

Ballast control

Engine room panels

Voltage conditioning

Alarm systems

Industrial Machine

Factory automation

Robotic drives

Power factor correction

Motor control panels

Aerospace & Defense

Avionics circuits

Signal tracking systems

Missile guidance boards

Energy & Power Systems

UPS and battery management

Solar inverter control

Grid feedback monitoring

Instrumentation & Measurement

Test equipment

Calibration systems

Oscilloscopes and signal analyzers

Top Reasons Engineers Rely on DALE

Tight Tolerances : Perfect for applications where accuracy to 0.01% is needed

High Voltage and Wattage Ratings : Ideal for high-power applications

Durability : Resists vibration, temperature change, and corrosive conditions

Global Standards Compliance : DALE components frequently comply with MIL, AEC, and IEC specifications

Long Product Lifecycle : Components that maintain consistency over years of service

Tips for Selecting the Proper DALE Resistor

Know Your Wattage Requirement : Always choose a resistor with a rating 2–3x above the expected power dissipation.

Match Tolerance to Application : For calibration circuits and signal paths, opt for ±0.1% or better.

Know Thermal Placement : Power resistors require adequate heat sinking or air flow.

Utilize Exact Part Numbers : Numerous DALE resistors share common names always double-check series and suffixes.

Discover the Collection Today

Getting quality electronic components must be simple and at Aeliya Marine Tech, it is. Our DALE range is a single-source solution for :

Repair technicians bringing back marine control systems to life

Engineers seeking hard-to-find resistors

OEMs seeking reliable component suppliers

Ready to explore?

Click Here To View The Complete Dale Products Collection

#industrial equipment#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#marineautomationparts#automationmarineparts#partsmarineautomation#partsautomationmarine#automationparts#marineparts#automationmarine#marineautomation

0 notes

Text

Test Engineering in Industry 4.0: The Shift Towards Smart Manufacturing

Manufacturing has been revolutionized by Industry 4.0, where digital innovations seamlessly unite with traditional processes, resulting in a world where automation, precision, and data-driven decision making prevail. In this article, we will see how test engineering has progressed to meet the modern production challenges, leveraging the emerging advanced testing methods, stringent quality assurance, and smart automation practices that are propelling production systems worldwide for reliable, efficient, and innovative manufacturing today.

Evolution of test engineering

The field of test engineering has transformed over the past decades as industries embraced digital innovations. Sophisticated techniques have replaced traditional methods to maintain efficiency and reliability. Adapting to increasing product complexity and dynamic market requirements has been driven by the evolution in test engineering and management. In manufacturing systems where sensors, data analytics, and automation are integrated, rigorous testing has become critical to operational success. This shift not only improves product quality but also optimizes processes by pinpointing problems early in the production cycle. Today, engineers use integrated software tools to monitor performance, simulate, and validate results in real time. The industry has been committed to innovation and quality control, resulting in the continuous improvement of testing protocols that have led to safer, more reliable products. With a focus on modern test engineering practices, they are a cornerstone in the transition to a data driven manufacturing ecosystem. The legacy they left behind continues to inspire future advancements across sectors worldwide.

Digital transformation in manufacturing

Manufacturing has been transformed by digital transformation, which has combined advanced computational methods and conventional industrial practices. Automation and real time data analytics have made operational workflows faster, smoother and error free. A robust engineering design testing process is essential to ensure that digital systems meet high quality and performance requirements. Engineers leverage digital twins alongside simulation models and cloud computing to forecast system behavior across different operational scenarios before starting production. The proactive nature of this approach shortens equipment downtime while enhancing total operational efficiency. Digital transformation allows companies to optimize resources, monitor system integrity continuously, and be able to adapt to market fluctuations at high speed. The convergence of digital technologies in manufacturing not only speeds up the process of innovation but also improves quality assurance protocols, making manufacturing processes more efficient and sustainable. If we want to achieve operational excellence and be successful over the long term in a competitive landscape, modern testing methodologies need to be integrated. It underscores the revolutionary impact of technology in manufacturing efficiency and product integrity.

Integration of automation systems

Modern manufacturing has achieved unprecedented efficiency and consistency through the implementation of automation systems. Modern manufacturing relies on automated processes to manage complex operations previously handled by humans which leads to faster production cycles and reduced errors. A thoughtfully designed PCB design board becomes crucial when multiple automation components need to communicate because it enables smooth data exchange between sensors, actuators and controllers. The combination of hardware and software creates real-time monitoring capabilities that enable adaptive control systems which sustain optimal performance levels. Automation technologies enhance both workflow optimization and data-driven decision support systems. Smart manufacturing development continues to rely on intelligent machinery integration with robust control systems to enhance operational efficiency. The integration of these elements establishes a fundamental base for developing flexible production environments that offer scalable capabilities and resilience to market changes. The PCB design board will remain central to future automation progress as new innovative approaches improve system interoperability and operational efficiency.

Advancements in quality assurance

Recent advances in quality assurance have changed the manufacturing landscape, emphasizing precision and reliability. Modern testing methodologies are strategically integrated to consistently meet rigorous industry standards. This framework of test engineering and management stands as a cornerstone to this evolution, balancing process control with technological innovation. Quality assurance protocols are constantly refined through the application of advanced analytics and machine learning to detect anomalies and mitigate risks. The result has been dramatic reductions in production defects and increased overall production efficiency. Automated inspection systems and predictive maintenance are now used in quality control to forecast potential failures before they occur, guaranteeing sustained performance. This makes manufacturers better positioned to provide superior products at less waste and greater resource utilization in a competitive marketplace. Additionally, continuous improvement practices promote process transparency and reliability, which in turn creates an environment where test engineering and management principles enable decision making and innovation. This systematic approach leads to production operations with enduring quality and sustainability.

Innovations in engineering design

Catalyzed by innovative approaches in engineering design, manufacturing methodologies have evolved into an era of precision and adaptability. The importance of the engineering design testing process has been emphasized on structured frameworks to evaluate each prototype thoroughly. This paradigm allows engineers to simulate real world conditions, assess structural integrity, and optimize design parameters before production. In this dynamic landscape, collaboration among multidisciplinary teams is essential to leverage insights from different areas to uplift the overall product performance. Design innovations are not only functional but also allow for increased cost efficiency and environmental sustainability. Advanced software tools and simulation platforms further strengthen the reliability of design outcomes in modern manufacturing facilities. Thus, companies are able to manufacture innovative and robust products that meet market demands and raise the bar for industry standards through continuous improvement and rigorous testing protocols. The engineering design testing process is further reinforced with continuous feedback loops and iterative refinements to provide reliability and optimum product performance.

Future prospects and challenges

The upcoming era of smart manufacturing shows promise but simultaneously presents multiple obstacles to overcome. Technology advancements transform production processes while driving new problem-solving methods. The growing complexity of modern systems demands better integration between digital tools and automation frameworks. The success of modern systems depends heavily on well-engineered PCB design boards that maintain both operational reliability and effective connectivity. The future of manufacturing will benefit from artificial intelligence alongside augmented reality and predictive analytics to drive advanced process optimization. However, issues such as cybersecurity, data integrity, and scalability present ongoing hurdles. The industry needs to overcome these obstacles while sustaining dedication to quality standards and innovation. Strategic partnerships combined with ongoing research will shape the next manufacturing era through adaptable production systems and resilient manufacturing environments. Research and development investments will continue to resolve emerging issues while strengthening the PCB design board's role in connecting technological advancements to dependable manufacturing processes.

The convergence of technology, rigorous testing, and innovative design defines smart manufacturing. Test engineering has evolved to change production with efficiency and quality. Digital solutions and robust automation are still being embraced by industry professionals. Continuous progress and focused improvements assure the future of manufacturing, securing reliability and excellence in the production process in every phase, worldwide today.

0 notes

Text

Pakistan’s Road to Redemption: Can They Repeat Their 2017 Triumph?

Pakistan vs New Zealand to Kick Off the Tournament

The highly anticipated ICC Champions Trophy will commence with the opening match between Pakistan and New Zealand in Karachi on Wednesday. Returning after an eight-year hiatus, this prestigious tournament will feature the world’s top eight cricket teams battling for glory.

Three Weeks of Intense Cricket Action

Over the next three weeks, cricket fans will witness thrilling encounters as teams compete in one of the toughest tournaments, often compared to the World Cup. Hosted by Pakistan under a hybrid model, matches will be played in Rawalpindi, Karachi, Lahore, and Dubai.

Pakistan Hosts an ICC Event After Three Decades

For the first time since co-hosting the 1996 World Cup, Pakistan is hosting a major ICC event. The journey to organizing this tournament was challenging for the Pakistan Cricket Board (PCB), given the ongoing debate over the relevance of ODI cricket and the dominance of T20 leagues. The event has also been surrounded by geopolitical tensions and concerns over stadium preparations. However, as Pakistan and New Zealand’s captains step out for the toss, all off-field matters will fade into the background.

India are locked in and ready for the #ChampionsTrophy pic.twitter.com/db4Mfd6CUm — ICC (@ICC) February 18, 2025

India vs Pakistan: The Ultimate Blockbuster

The last time Pakistan won the Champions Trophy was in 2017, and they will aim to reclaim the title. While the opening match promises excitement, the real showdown will be on February 23, when India and Pakistan face off in a high-voltage clash. This encounter will spark emotions across borders, ignite memories, and set social media on fire.

India’s High Stakes: A Tournament of Legacy

For India, this tournament carries immense significance. Rohit Sharma and Virat Kohli, two stalwarts of modern cricket, are nearing the end of their ODI careers. A strong performance could define their legacy, while a poor outing might impact their Test careers.

Additionally, coach Gautam Gambhir faces scrutiny. Despite a good run against England at home, past defeats against New Zealand and Australia remain fresh. Winning the ICC Trophy could cement his position, while failure could lead to questions about his coaching tenure.

India last won an ODI title in the 2013 Champions Trophy under MS Dhoni’s captaincy. They will enter as strong title contenders, but a single bad session, like in the 2023 World Cup final, could derail their campaign.

Top Contenders for the ICC Champions Trophy 2025

Australia

The five-time World Cup winners and 2006 & 2009 Champions Trophy winners will be without key players like Pat Cummins, Mitchell Starc, and Josh Hazlewood. However, with Steve Smith leading the side, their championship pedigree remains intact.

England

While England’s squad has aging stars and inconsistent form, experienced players like Jos Buttler, Joe Root, and Liam Livingstone could shine. Meanwhile, young talents like Harry Brook and Ben Duckett could shape the team’s future.

New Zealand

The 2000 Champions enter a new era after the retirements of Trent Boult and Tim Southee. However, with Kane Williamson at the helm, they remain strong contenders. Kyle Jamieson replaces the injured Lockie Ferguson and could be a game-changer.

South Africa

Winners of the 1998 ICC Knockout Trophy, South Africa will aim to break their ICC title drought. Having reached the T20 World Cup final, they now seek to add an ODI trophy to their cabinet.

Pakistan

With a world-class fast-bowling attack and strong batters like Fakhar Zaman and Salman Ali Agha, Pakistan can be a formidable force. If they manage to stay composed against India, they could emerge as serious contenders.

Afghanistan

Afghanistan’s victories are no longer considered upsets. With match-winners like Rashid Khan (ICC’s Best ODI Cricketer of the Year), Azmatullah Umarzai, and Rahmanullah Gurbaz, they are capable of big surprises.

Bangladesh

Bangladesh has been a consistent presence in this tournament. Having caused upsets before, including in the 2007 ODI World Cup, they will aim to do it again.

Tournament Groups

Group A: India, Pakistan, Bangladesh, New Zealand

Group B: England, Afghanistan, Australia, South Africa

Past Champions

1998 – South Africa

2000 – New Zealand

2002 – India, Sri Lanka (Joint Winners)

2004 – West Indies

2006 – Australia

2009 – Australia

2013 – India

2017 – Pakistan

With a mix of historic rivalries, legendary players, and rising stars, the ICC Champions Trophy 2025 is set to deliver a spectacular cricketing experience.

0 notes

Text

The Art and Science of PCB Reverse Engineering: A Comprehensive Guide

In the world of electronics, understanding how a printed circuit board (PCB) works can be crucial for troubleshooting, innovation, and learning. PCB reverse engineering is a process that allows engineers, hobbyists, and researchers to dissect and comprehend the intricate designs of existing PCBs. Whether you're looking to replicate an old design, learn about advanced technologies, or modify existing hardware, PCB reverse engineering offers valuable insights and opportunities. In this blog post, we’ll explore the essentials of PCB reverse engineering, its benefits, and practical tips for getting started.

What is PCB Reverse Engineering?

PCB reverse engineering is the process of analyzing and deconstructing a PCB to understand its layout, design, and functionality. This typically involves examining the physical board and its components to recreate or modify the circuit’s schematic diagram and design files. The goal is to uncover the design details that are not readily available from the manufacturer, enabling you to replicate or improve the existing design.

Why Engage in PCB Reverse Engineering?

Learning and Education: For students and hobbyists, reverse engineering provides a hands-on way to learn about electronic circuit design, component functions, and board layout. It’s a practical method to understand how various components interact within a circuit.

Repair and Maintenance: When dealing with older or discontinued hardware, PCB reverse engineering can help in diagnosing faults and replacing faulty parts. This is particularly useful for repairing vintage electronics where original schematics are no longer available.

Innovation and Design: Engineers often use reverse engineering to analyze competitor products, understand their design choices, and find areas for improvement. By learning from existing designs, they can innovate and create better, more efficient products.

Legacy Support: Companies maintaining legacy systems may need to reverse engineer PCBs to continue providing support, upgrades, or replacements for outdated technology.

The PCB Reverse Engineering Process

Reverse engineering a PCB involves several steps, each requiring precision and careful analysis. Here’s a simplified overview of the process:

Disassemble the PCB

Carefully remove the PCB from its enclosure or casing. Use tools like tweezers and anti-static mats to handle the board and avoid damaging sensitive components.

Document the Board

Take high-resolution photographs of both the top and bottom layers of the PCB. These images will serve as reference material during the reverse engineering process. Ensure that the images are clear and well-lit.

Identify Components

Label and identify all components on the PCB. This includes resistors, capacitors, integrated circuits (ICs), and connectors. Use a multi meter or component tester to help identify and measure components if necessary.

Trace the Circuit

Use the photographs to trace the circuit connections. This involves mapping out the paths of electrical connections between components. Tools like PCB design software can assist in recreating the circuit schematic.

Create the Schematic Diagram

Based on your tracing, create a schematic diagram that represents the electrical design of the PCB. This step is crucial for understanding how the circuit functions and for making any modifications.

Design the PCB Layout

Once the schematic is complete, design a PCB layout that matches the original design. PCB design software can be used to create and refine the layout, ensuring that it accurately reflects the original board’s design.

Verify and Test

Before finalizing the design, verify that the recreated PCB functions as intended. Build a prototype and test it to ensure that it meets the required specifications and performs correctly.

PCB reverse engineering is a powerful technique for understanding and working with electronic circuits. Whether you’re aiming to repair vintage hardware, learn about circuit design, or innovate in the field of electronics, mastering the art of PCB reverse engineering can provide significant advantages. By following the steps outlined in this guide and utilizing the right tools, you can delve into the intricate world of PCB design and uncover the secrets behind your favorite electronic devices.

0 notes

Text

BBC SYNPOL CMA-32 GVT 360–5792 PCB Card | Industrial Automation Control Board | Ram Automations

Discover industrial reliability and precision with the BBC SYNPOL CMA-32 GVT 360–5792 PCB Card — now available at Ram Automations, your trusted global supplier of genuine industrial and marine automation spare parts. This Printed Circuit Board (PCB) is designed for seamless integration into legacy control systems where stability and performance are critical. Whether you’re maintaining a control cabinet, restoring a discontinued system, or replacing a failed board, this BBC SYNPOL PCB Card offers the solution you need.

🛒 Order Now: 👉 https://ramautomations.com/products/bbc-synpol-cma-32-gvt-360-5792-pcb-card-used 🌐 Explore Our Full Catalog: https://ramautomations.com

🔍 Product Overview

• 📦 Model: CMA-32 GVT 360–5792 • 🏢 Brand: BBC SYNPOL • 🧩 Type: PCB Control Card • 🧾 Condition: Tested and Verified • ⚙️ Function: Signal routing, control interfacing, automation logic • 📍 Applications: Industrial PLC systems, control cabinets, marine automation units, legacy control systems

✅ Why This PCB Is a Great Choice

✔️ Genuine BBC SYNPOL product ✔️ Perfect fit for legacy systems ✔️ Fully tested and quality assured ✔️ Ideal for discontinued or obsolete installations ✔️ Supports long-term operation of industrial systems ✔️ Cost-effective and dependable replacement solution

🏭 Ideal For

✔️ Factory automation repair ✔️ OEM panel retrofits ✔️ Marine and shipboard control systems ✔️ Power plant systems ✔️ Process automation platforms ✔️ Industrial cabinet refurbishment ✔️ Obsolete PCB replacement

Extend the life of your equipment with this BBC SYNPOL CMA-32 GVT 360–5792 PCB, and avoid expensive upgrades or full replacements. Ram Automations provides support for both current and legacy automation technologies.

🌐 Why Ram Automations?

With access to 1000+ global brands, Ram Automations offers rare, genuine, and tested industrial parts. From power supplies and control boards to discontinued automation modules, we provide critical parts to engineers, integrators, and MRO professionals worldwide.

✔️ 1000+ Brands in Stock ✔️ Used and Legacy Components ✔️ Global Delivery Options ✔️ OEM & Bulk Discounts Available ✔️ Friendly Expert Support Team

📹 In This Video You Will Learn:

🔎 Product walkthrough of the BBC SYNPOL PCB ⚙️ Use cases in industrial and marine systems 🛠️ How to integrate the board into your system 💡 What makes legacy parts essential for MRO teams 📦 Why buying from Ram Automations is a smart investment

📣 Connect with Us

👍 Like this video if it helped 💬 Comment below for product questions 🔔 Subscribe for new weekly videos featuring industrial & marine spares

#BBC SYNPOL CMA-32#BBC PCB Card#CMA-32 GVT 360-5792#Industrial PCB Board#Automation Control Card#Marine PCB#Used Control Board#Signal Routing PCB#Legacy Automation Card#Ram Automations#BBC Automation#Marine Control System PCB#Obsolete PCB Replacement#Industrial Panel Board#Industrial Control Board#PLC Control PCB#Marine Power Control#Tested PCB Card#BBC SYNPOL Module#Factory Automation PCB#BBC Panel Module#Marine PCB Used#BBC Control Electronics

1 note

·

View note

Text

Enhancing Industrial Automation with the Simac C.S.I. 4969/09 PCB Card

In the realm of industrial automation, the efficient operation of machinery and control systems relies heavily on the integration and functionality of various electronic components. Among these, the Simac C.S.I. 4969/09 PCB card stands out as a critical element for improving automation processes. This article delves into the features, advantages, and applications of the Simac C.S.I. 4969/09 PCB card, highlighting its role in modern industrial environments.

Overview of the Simac C.S.I. 4969/09 PCB Card:

The Simac C.S.I. 4969/09 PCB card is a high-performance printed circuit board designed for use in industrial automation systems. Known for its robustness and versatility, the C.S.I. 4969/09 integrates seamlessly into a variety of automation setups, providing essential functions such as signal processing, communication interfacing, and control logic. Its design reflects the demands of industrial environments, ensuring reliable performance under rigorous conditions.

Key Features:

Advanced Signal Processing: The C.S.I. 4969/09 is equipped with advanced signal processing capabilities that enhance the accuracy and reliability of data transmission. This feature is crucial for applications where precise control and monitoring of industrial processes are required.

Robust Construction: The PCB card is built to withstand the harsh conditions typical of industrial environments. Its durable construction ensures longevity and reliable operation, even in settings with high temperatures, electrical noise, and mechanical vibrations.

Versatile Integration: Designed for flexibility, the C.S.I. 4969/09 can be integrated into a wide range of automation systems. It supports various communication protocols and interfaces, making it suitable for diverse applications across different industries.

Enhanced Connectivity: The card provides robust connectivity options, facilitating seamless communication between different components of an automation system. This ensures smooth data exchange and coordination between legacy and modern equipment.

Ease of Installation: The C.S.I. 4969/09 is designed for user-friendly installation. Its straightforward mounting and connection processes help minimize setup time and reduce the risk of errors during installation.

Low Maintenance Requirements: With minimal maintenance needs, the C.S.I. 4969/09 allows for uninterrupted operation of industrial systems. Its reliable performance reduces the frequency of maintenance checks and associated downtime.

Advantages of Using the Simac C.S.I. 4969/09 PCB Card

Improved Operational Efficiency: By enhancing signal processing and communication capabilities, the C.S.I. 4969/09 contributes to overall operational efficiency. Its ability to handle complex data and commands ensures that industrial processes run smoothly and efficiently.

Increased System Compatibility: The versatility of the C.S.I. 4969/09 allows for easy integration with both older and newer automation systems. This compatibility is essential for businesses looking to modernize their operations without discarding existing equipment.

Enhanced Reliability: The card’s robust construction and reliable performance enhance the dependability of industrial automation systems. Reduced risk of failure translates to improved system uptime and productivity.

Cost-Effective Solution: The C.S.I. 4969/09 offers a cost-effective solution for upgrading and maintaining industrial automation systems. Its ability to interface with various equipment helps businesses avoid the costs associated with complete system replacements.

Scalability: The card supports scalable automation solutions, allowing businesses to expand and upgrade their systems as needed. This flexibility ensures that the automation infrastructure can grow in line with operational demands.

Applications in Industrial Automation

The Simac C.S.I. 4969/09 PCB card is suitable for a wide range of applications in industrial automation:

Manufacturing Control Systems: In manufacturing environments, the card can be used to control machinery and processes, ensuring precise operation and coordination of equipment.

Process Monitoring: The card’s advanced signal processing capabilities make it ideal for monitoring industrial processes. It enables real-time data collection and analysis, facilitating prompt response to operational changes.

Remote Monitoring and Control: The C.S.I. 4969/09 can be integrated into remote monitoring systems, allowing operators to oversee and control equipment from distant locations.

Integration with SCADA Systems: The card supports integration with Supervisory Control and Data Acquisition (SCADA) systems, providing a critical link between field devices and central control stations.

Legacy System Upgrades: For businesses with existing analog or older digital systems, the C.S.I. 4969/09 offers a means to upgrade and integrate these systems with modern automation technologies.

Conclusion:

The Simac C.S.I. 4969/09 PCB card is a vital component for enhancing industrial automation systems. Its advanced features, robust construction, and versatile integration capabilities make it a valuable asset for businesses looking to optimize their automation processes. By improving signal processing, connectivity, and system compatibility, the C.S.I. 4969/09 helps ensure efficient and reliable operation in demanding industrial environments. As industries continue to evolve and embrace new technologies, the C.S.I. 4969/09 stands out as a key player in bridging the gap between legacy systems and modern automation solutions.

0 notes

Text

PCB Clone Services: Precision in Reproduction

What is PCB Cloning?

PCB Clone is the process of creating an exact replica of an existing printed circuit board (PCB). This service is essential when you need to reproduce a board for which the original design files are unavailable. PCB cloning involves reverse engineering the board to generate the necessary data for manufacturing a duplicate.

The Role of PCB Clone Services

PCB Cloning Service are vital in scenarios where you need an identical copy of an electronic circuit board. Whether it’s for replacing obsolete hardware, producing additional units, or creating backups, these services ensure precision in reproduction.

How PCB Cloning Works

1. Initial Analysis

The cloning process begins with a detailed analysis of the original PCB. This includes examining the board’s layout, components, and circuitry. Engineers carefully inspect every detail to ensure accurate replication.

2. Reverse Engineering

After the initial analysis, the reverse engineering phase begins. Engineers trace the circuitry, identify components, and create a schematic of the board. This step is crucial in understanding how the PCB functions.

3. Schematic Capture and Layout Design

Once the reverse engineering is complete, a schematic diagram is created. This diagram serves as a blueprint for the new board. Engineers then use specialized software to design a PCB layout that matches the original.

4. Prototyping and Testing

Before full-scale production, a prototype of the cloned PCB is manufactured. This prototype undergoes rigorous testing to ensure it functions exactly like the original board. Any necessary adjustments are made during this phase.

5. Mass Production

Once the prototype passes all tests, the PCB is ready for mass production. The final product is an exact clone of the original board, ready for use in any application.

Benefits of PCB Cloning Services

• Obsolete Hardware Reproduction: Clone services are ideal for replicating outdated circuit boards, ensuring continued operation of legacy systems.

• Cost-Effective: Cloning is often more cost-effective than redesigning a PCB from scratch.

• Fast Turnaround: PCB cloning services can quickly produce duplicates, reducing downtime for critical systems.

Challenges in PCB Cloning

PCB cloning, while beneficial, is not without its challenges. Complex multilayer boards, proprietary components, and encrypted firmware can complicate the cloning process. Skilled engineers are essential to navigate these obstacles and deliver an accurate clone.

Choosing the Right PCB Clone Service

When selecting a Clone PCB Service, consider factors such as experience, technology, and the ability to handle complex projects. A reliable service provider will ensure that your cloned PCBs meet the highest standards of quality and performance.

Conclusion

PCB cloning services play a crucial role in the electronics industry. Whether for preserving legacy systems or producing additional units, these services provide a reliable solution for duplicating PCBs with precision. With the right expertise, PCB cloning ensures that your electronic systems continue to function smoothly, regardless of the challenges posed by outdated or unavailable designs.

0 notes

Text

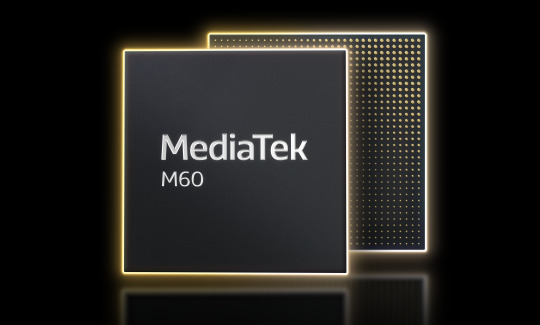

New MediaTek 5G RedCap technology transforms connectivity

MediaTek 5G RedCap technology

MediaTek, which makes has introduced its The company solutions, which will allow them to provide 5G technology download speeds as well as impressive power efficiency to a wide variety of Internet of Things equipment.

The previously the RedCap software modem technology and chipset family have been introduced by MediaTek as part of the company’s efforts to accelerate the migration to 5G-NR for consumer, corporate, and industrial IoT applications.

MediaTek T300 chipset series

MediaTek has announced that it would be extending its line of modems and chipsets to enable 5G RedCap. This announcement was made possible by MediaTek’s industry experience in 5G connection. The new solutions, the M60 modem IP and the MediaTek T300 chipset series, will make it simple for MediaTek to ease the transition to 5G-NR for a wide variety of applications. These applications include things like wearables, lightweight augmented reality devices, IoT modules, and devices built with edge artificial intelligence in mind.

RedCap, an abbreviation that stands for “reduced capability,” is an initiative that aims to bring the advantages of 5G to non-traditional radio (NR) consumer, corporate, and industrial devices. RedCap promises to bring dependability for devices that have minimal bandwidth needs by fully using the movement of 5G networks to the Standalone (SA) network architecture. This will offer many of the advantages of 5G without the expense and complexity of standard 5G solutions. RedCap will take full use of the evolution of 5G networks to the SA network design.

As stated by JC Hsu, Technical Senior Vice President at MediaTek, “Our 5G RedCap solutions constitute an important aspect of our objective to make accessible 5G, allowing consumers with the ability to maximize the efficiency of component while delivering devices capable of supporting 5G spanning a range of purposes and a range of price points.” “Our customers now have the ability to deliver 5G-enabled devices from a range of applications and a range of price points,” he said.

“The migration to 5G RedCap will replace legacy 4G/LTE solutions, offering significantly better power efficiency and more reliable user experiences when compared to leading edge 5G eMMB modem solutions and legacy 4G LTE Cat 4 and Cat 6 devices.”

The MediaTek T300 series is pioneering new territory in the 5G RedCap area since it is the world’s first single die solution for 5G RedCap that utilizes a 6nm Radio Frequency System-On-Chip (RFSOC) architecture. This RFSOC will enable marketers to build creative designs for corporate, industrial, consumer, augmented reality (AR), and data-card applications, allowing them to profit on the burgeoning RedCap market.

The MediaTek T300 series incorporates a single-core Arm Cortex-A35 in a substantially more compact PCB area. This is made possible by the extremely efficient TSMC 6nm process, which was used to build the series. The MediaTek T300 series is capable of supporting data transfer speeds of up to 122 Mbps in the uplink direction and 227 Mbps in the downlink direction.

The T300 series and the M60 5G modem IP both satisfy the 3GPP R17 standard and combine MediaTek’s industry-leading power efficiency with coverage upgrades and exceptionally low latency. Furthermore, the two of these products have been compatible using 5G networks. The The substance M60 is able to give users up to 70 percent reduction in energy consumption in compared to competitive 5G eMBB technologies and as much as seventy-five percent power savings in comparing to 4G LTE network solutions. This is possible via the incorporation of MediaTek’s UltraSave 4.0 semiconductor and the minimization of needless paging receptions.

To continue to address the constantly evolving relationship needs and standards, MediaTek’s The company solution are bringing about an exciting new era of efficiency, stability, and savings in expenses for devices with 5G RedCap capabilities across the consumer, businesslike, and industrial markets. Samples of devices included in the Broadcom T300 category will be accessible throughout the first half of 2024, and commercial samples will be available in the second half of the same year.

Read more on Govindhtech.com

1 note

·

View note

Text

MediaTek Expands its Product Portfolio for 5G RedCap Support

The arrival of 5G RedCap tech has certainly given rise to new tech innovations in the way of software and hardware, and a lot of manufacturers have deemed it wise to invest in research and development towards adoption and support for modern 5G solutions. With that being said, MediaTek recently announced that it was expanding its portfolio of modems and chipsets to include 5G RedCap support, in the form of the M60 modem IP and MediaTek T300 chip series. With these new hardware advancements, MediaTek hopes that it will be easier to facilitate the transition to 5G-NR for different applications for require long-lasting and efficient battery life, such as wearable devices, light-weight AR hardware, IoT modules, and devices built with edge AI in mind. JC Hsu, Corporate Senior Vice President at MediaTek states: “Our RedCap solutions are a significant part of our mission to democratize 5G, providing our customersthe ability to optimize components and deliver 5G-enabled devices from a range of applications and arange of price points. The migration to 5G RedCap will replace legacy 4G/LTE solutions, offering significantly better power efficiency and more reliable user experiences compared to leading edge 5G eMMB modem solutions and legacy 4G LTE Cat 4 and Cat 6 devices.” For those unfamiliar with the term, RedCap is short for "reduced capability," and is designed to give NR consumers the benefits of 5G, such as enterprise solutions and industrial devices. RedCap makes use of more modern 5G networks and is developed to be optimized for devices with low bandwidth requirements, with lesser costs and complexities involved. MediaTek says that its T300 series is the world's first 6nm Radio Frequency System-on-chip solution that's designed to work with RedCap, and will allow brands to fully utilize the advantages of the growing RedCap adoption within different industries and such. It's built on TSMC's 6nm process and integrates a single-core Arm Cortex-A35 in a more compact PCB area. Additionally, the T300 is capable of supporting up to 227 Mbps downlink and 122 Mbps uplink data rates. With that in mind, MediaTek adds that both the T300 series and M60 will support with 3GPP R17 standard, and are developed to be power efficient with low latency. They're also equipped with MediaTek’s UltraSave 4.0 technology; the M60 in particular offers up to a 70% reduction in power consumption compared to similar 5G eMBB solutions, and up to 75% power savings compared to 4G LTE solutions. In terms of market availability, MediaTek says that T300 series devices will be sampled in the first half of 2024, with commercial samples in the second half of 2024. Read the full article

1 note

·

View note

Text

HOW ATE HELPS IN RAPID TEST EXECUTION? - TMCS India

Testing a range of electric equipment in several industries, such as defense and aerospace, automotive, and industrial automation, requires effective data gathering and a diagnostic instrument called an ATE. In addition to guaranteeing that end users of electronic equipment obtain products that work and function as intended, ATE is directly responsible for ensuring they are not put in danger.

The market for automated test equipment was estimated to be worth USD 6.87 billion in 2020. From 2021 to 2028, it is anticipated to rise at a CAGR of 3.3%. Automated Test Equipment (ATE) usage in the semiconductor and automotive industries is fueling the expansion. This growth is driven by the number of connected devices and consumer electronics, as well as an increase in the firm’s focus on quality improvement and end-to-end testing solutions.

How is ATE Beneficial?

The terms “device under test” (DUT), “unit under test” (UUT), or “equipment under test” (EUT) is typically used to describe the device whose characteristics the ATE evaluates. ATE test a lot of the electronic gadgets that are in use today since they have so many benefits:

Faster and more accurate tests: Since manual testing depends on the test engineer’s efficiency and expertise, the results’ speed and accuracy are only as good as the test engineer’s capabilities.

Reduced test and cycle times: ATE’s capability in troubleshooting provides test and cycle time uniformity. This automation factor thus reduces work for engineers.

Reduction or prevention of data input errors: Making mistakes is part of human nature. If there are no equipment-related technical problems, ATE always gets it right. It thus helps in maintaining accuracy.

Use of available engineering resources efficiently and cost-effectively: Engineers may concentrate on the periodic testing issues rather than manually executing the tests using ATE. This results in the more efficient and economical use of engineering resources.

ATE Spotlight: National Instruments (NI):

Due to the lifesaving, mission-critical, and safety-critical electronics used in military aircraft, ships, ground vehicles, weaponry, missile launch, radar, and wireless communication systems, the aerospace and defense sectors are major consumers of ATE.

For crucial national security and safety reasons, these equipments must be evaluated more thoroughly than electronics used in other businesses. As a result, testing and validation before deployment consume a significant amount of time and money for aerospace and defense businesses.

Before being fielded by the DoD, almost everything from a missile launch system to the avionics systems on the newest fighter aircraft is evaluated and validated by aerospace and military industries, lowering the possibility of a launch failure or a Mayday crisis during a flight.

Devices tested by ATE include integrated circuits (ICs), printed circuit boards (PCBs), hard disk drives (HDDs), electronic systems, and line-replaceable units (LRUs) that support aircraft, spacecraft, and satellites – a family of technologies known as avionics.

TMCS’s expertise in ATE services:

India is one of the leading military forces in the world. This self-reliant initiative has accelerated the defense industry’s growth considerably in the past few years and this demand is constantly increasing. ATE Testing equipment exports are encouraged by the Make in India program and the industrial environment.

With years of legacy and constant research, TMCS, the NI Partner has developed the expertise to work on the test system requirements with NI, PLC, and Embedded solutions.

With these testing solutions, TMCS has assisted defense organizations in importing substitute options. TMCS’s vast experience in communication protocols on different hardware platforms for serial data bus communication, standardized power interface, environmental design, testing, and much more has helped them achieve excellence and success.

With these testing solutions, TMCS has assisted defense organizations in importing substitute options. TMCS’s vast experience in communication protocols on different hardware platforms for serial data bus communication, standardized power interface, environmental design, testing, and much more has helped them achieve excellence and success.

1 note

·

View note

Text

Discover Trusted Cegelec Automation Components at Aeliya Marine Tech

In today’s fast-paced industrial and marine sectors, reliability, durability, and performance are not just desired they’re required. When it comes to sourcing trusted automation components, Cegelec stands out as a pioneer in electrical and control system engineering. At Aeliya Marine Tech, we bring you a wide collection of Cegelec automation parts, sourced with care and offered with confidence.

About Cegelec : Excellence in Electrical Engineering

Cegelec, a name synonymous with innovation, is a global leader in delivering integrated industrial and automation solutions. Known for designing high-quality control systems and electrical components, Cegelec serves a wide range of sectors including marine, oil & gas, manufacturing, power distribution, and industrial automation.

Their components are built to perform under tough conditions and are often used in mission-critical applications. From marine vessels to process plants, Cegelec products are trusted by professionals who can’t afford failure.

What You’ll Find in Aeliya Marine’s Cegelec Collection

At Aeliya Marine Tech, our curated Cegelec product listings include :

PCB Interface Boards

Control System Cards

Input/Output (I/O) Modules

Power Supply Boards

Relay Units

Signal Converters

Marine-Grade Automation Parts

All components are either brand new or used in excellent tested condition. We understand the importance of quality and functionality, which is why our team ensures that each product is carefully inspected before listing.

Why Choose Used or Refurbished Cegelec Parts?

Many companies are shifting toward sustainable and cost-effective alternatives — and that’s where used and refurbished automation components play a key role. Here’s why :

Significant Cost Savings

Immediate Availability

Reduced Downtime

Environmentally Friendly

Ideal for Legacy System Repairs

Whether you’re sourcing replacements for obsolete Cegelec models or expanding your current automation setup, Aeliya Marine’s offerings deliver the perfect balance of price and performance.

Why Aeliya Marine is the Right Choice

With over a decade of experience in the industrial and marine automation market, Aeliya Marine Tech Pvt. Ltd. is a globally trusted supplier. Our strength lies not just in our inventory but in our service, support, and product knowledge.

Here’s what sets us apart :

Worldwide Shipping

Huge Inventory of Marine & Industrial Components

Accurate Product Listings with Detailed Specifications

Secure Payment Options

Responsive Customer Support

Easy Return Policies

Each product page includes images, specifications, reference numbers, and shipping details so that customers can make informed purchasing decisions.

Visit the Cegelec Product Collection

If you’re ready to upgrade or maintain your systems with Cegelec automation parts, head over to our collection today.

#Cegelec Automation#Cegelec PCB Card#Cegelec Control Systems#Marine Automation Parts#Industrial Automation India#Aeliya Marine Tech#Used Automation Components#Cegelec India Suppliers

0 notes