#pipe system design calculation

Explore tagged Tumblr posts

Text

line sizing calculation

pipeline sizing calculation line capacity calculation piping sizing calculation pipe sizing calculation https://3d-labs.com/product/line-sizing-calculation/ Line Sizing Calculation determines the optimal diameter of pipes or tubing to ensure efficient fluid flow, pressure management, and system performance in various applications.

https://3d-labs.com/product/line-sizing-calculation/

0 notes

Text

Little P.Eng. for ASME B31.1 Power Piping Calculation Services: A Beacon of Expertise and Innovation

Power piping systems serve as the lifeblood of many industrial operations, providing crucial transportation of fluids under high pressure and temperature. These systems demand high standards of safety, reliability, and efficiency, which are delivered by the American Society of Mechanical Engineers (ASME) B31.1 Power Piping Code. One name stands out in offering these precise and complex ASME B31.1 Power Piping Calculation Services - Little P.Eng.

A leading engineering consulting firm, Little P.Eng., combines experience, innovation, and cutting-edge technology to provide unrivaled solutions for power piping systems. In this article, we examine Little P.Eng.'s impact on ASME B31.1 Power Piping Calculation Services and how they excel in this specialized domain.

Deciphering ASME B31.1 Power Piping Code:

ASME B31.1 Power Piping Code is a robust regulatory framework that stipulates design, fabrication, installation, and testing regulations for power piping systems. With its technical intricacies, this code is an engineer's playbook for ensuring the safety and efficacy of power piping systems, and no one plays this game better than Little P.Eng.

Little P.Eng.: Your Trustworthy Ally for Power Piping Calculations:

In the field of ASME B31.1 power piping calculation services, Little P.Eng. has carved a distinctive niche for itself. Their team of seasoned engineers, with a comprehensive understanding of ASME standards, employ the best practices to provide highly accurate and reliable solutions, making them a trusted ally for all power piping needs.

Little P.Eng.'s Extensive Calculation Services:

Little P.Eng.'s expertise spans a wide spectrum of calculation services. From wall thickness calculations to expansion joint pressure thrust calculations, Little P.Eng.'s solutions are renowned for their precision and adherence to ASME B31.1 standards. The firm's exhaustive understanding of power piping systems equips them to handle complex calculations with ease and precision.

Harnessing the Power of Technology:

At Little P.Eng., the latest technology and software tools are harnessed to ensure their ASME B31.1 Power Piping Calculation Services meet the highest industry standards. By using advanced simulation techniques and design validation, they create power piping systems that are safe, reliable, and efficient.

Prioritizing Client Satisfaction:

Little P.Eng. places a strong emphasis on client satisfaction, ensuring each project is tailored to the specific needs of the client. Their commitment to quality, paired with their industry knowledge, delivers solutions that not only meet ASME B31.1 standards but also align seamlessly with the client's requirements.

let's delve into the specific types of pressure design calculations that Little P.Eng. offers under the ASME B31.1 Power Piping Calculation Services:

Minimum Pipe Wall Thickness Calculations: Ensuring the pipe wall is thick enough to contain the internal pressure is a fundamental aspect of pressure design. Little P.Eng. uses state-of-the-art software to calculate the required wall thickness, considering factors like operating pressure, material strength, temperature, and pipe diameter.

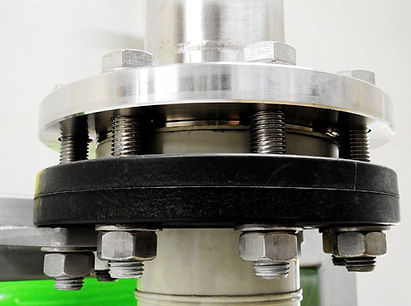

Flange Pressure-Temperature Ratings Calculations: Little P.Eng. adeptly handles the calculation of flange ratings under different temperature and pressure conditions. These calculations are crucial for specifying the appropriate flanges that will ensure a leak-free performance of the power piping system.

Branch Reinforcement Calculations: Branch connections, if not properly reinforced, can be potential weak points in a piping system. Little P.Eng. carries out detailed calculations to determine the necessary reinforcements, ensuring the structural integrity and safety of the piping system.

Expansion Joint Pressure Thrust Calculations: Expansion joints in power piping systems need to withstand the pressure thrust exerted upon them. Little P.Eng. uses sophisticated tools and techniques to accurately calculate this pressure thrust, helping to design expansion joints that can safely absorb these forces.

Safety Valve Reaction Force Calculations: When safety valves open in response to excessive pressure, they exert a reaction force that must be taken into account. Little P.Eng.'s team expertly performs these calculations, ensuring safety valves can operate efficiently and safely.

Pipe Support Load Calculations: The load on pipe supports must be accurately calculated to ensure they can sustain the weight of the pipe, the fluid it carries, and any additional loads due to thermal expansion or other forces. Little P.Eng. performs these calculations meticulously, considering various factors such as pipe size, material, and temperature.

High-Pressure Piping Design Calculations: High-pressure piping systems pose unique design challenges. Little P.Eng. offers specialized calculation services to address these, considering factors such as material selection, joint design, and testing procedures.

Conclusion:

ASME B31.1 Power Piping Calculation Services form the backbone of power piping design, ensuring systems can safely and efficiently transport fluids under high-pressure conditions. Little P.Eng., with its mastery of these calculations and unwavering dedication to quality, stands as a beacon of expertise and innovation in this field.

The team at Little P.Eng. continuously adapts to evolving industry standards and market needs, ensuring their clients receive top-tier, cutting-edge services. Their commitment to using the latest technology and best practices positions them as not just a service provider but as a key contributor in shaping the future of the power piping industry.

Keywords: Minimum Pipe Wall Thickness Calculations, Flange Pressure-Temperature Ratings Calculations, Branch Reinforcement Calculations, Expansion Joint Pressure Thrust Calculations, Safety Valve Reaction Force Calculations, Pipe Support Load Calculations, High-Pressure Piping Design Calculations, ASME B31.1 Power Piping Calculation Services, Little P.Eng., power piping systems, engineering consulting, ASME standards, wall thickness calculations, expansion joint pressure thrust calculations, client satisfaction, technological advancements.

Tags:

Meena Rezkallah

Little P.Eng.

engineering consulting

ASME standards

Expansion Joint Pressure Thrust Calculations

Safety Valve Reaction Force Calculations

High-Pressure Piping Design Calculations

client satisfaction

Minimum Pipe Wall Thickness Calculations

Flange Pressure-Temperature Ratings Calculations

Branch Reinforcement Calculations

Pipe Support Load Calculations

ASME B31.1 Power Piping Calculation Services

power piping systems

wall thickness calculations

expansion joint pressure thrust calculations

technological advancements

Engineering Services

Pipe Stress Analysis Services

Piping Design

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng.#engineering consulting#ASME standards#Expansion Joint Pressure Thrust Calculations#Safety Valve Reaction Force Calculations#High-Pressure Piping Design Calculations#client satisfaction#Minimum Pipe Wall Thickness Calculations#Flange Pressure-Temperature Ratings Calculations#Branch Reinforcement Calculations#Pipe Support Load Calculations#ASME B31.1 Power Piping Calculation Services#power piping systems#wall thickness calculations#expansion joint pressure thrust calculations#technological advancements

0 notes

Text

Odds of Survival

Part 0ne

Prowl is a professional. Jazz is a professional menace.

———————————————————————

"Our odds of survival are 14%.

Prowls alien travel companion seemed to grasp the basis of his meaning as Jazz looked back from the window view of the small moon their convoy had stopped on.

The Tri-Towers were a standard pit stop for this route. The moon itself was nothing more than bare rock within an extremely minimal atmosphere. But it was easy to build on and conveniently located between populated systems.

It was also very isolated. And very unprotected.

Prowl had once attempted to bring it up to Sentinel Primes attention, as he calculated a 63% chance that the quintessons would attempt a raid against it. A 42% chance they'd take it over. And a 24% chance they'd simply destroy it completely. The prime had considered all of the above "unlikely” to occur and that such a loss would only be a "minor inconvenience" in the grand scheme of things.

Prowls anger over becoming a "minor inconvenience" was only slightly offset by the satisfaction of being correct.

Jazz waved a servo in front of his face, pulling Prowl from his murderous thoughts.

"How do we survive?" Jazz's common was still fractured but his tone of voice carried his intentions clearly. It was confident and expectant. Jazz wanted to know what they needed to do (79%) to achieve that outcome.

Tacnet switched from calculating his most likely form of demise (dismemberment 82%) and began turning over viable courses of action.

Prowl brought a pad and stylish out from sub space, and immediately set to sketching a basic map of the Tri-Towers. Rather than the map, Jazz took intense interest in Prowls arms and hips, crouching down and lightly groping them in some kind of search.

"How???"

Prowl was a professional. He was such a professional that he realized Jazz likely didn't know what a sub space pocket was, and removed the hand on his hip with a curt,

"Later"

And then he heard his own phrasing and suppressed that for later as well.

He was a professional. And was about to do his damn job.

Prowl laid out the map. Pointing to a key in the corner. The triangle with horns was Jazz, the chevron was him, and the triangles with squiggly lines out the back were the quintessons.

"We are here." Tapping the Imports and Immigrations Tower. The building had sustained substantial damage and the freight elevator had been knocked offline.

"We need to cross over to here." Prowl traced his digit over the sky bridge connected to the Commerce building, which should still have a functional freight elevator. If not, the common elevators were about large enough to hold two average cybertronians. If one of them sat in the others lap.

Primus help him.

"And make it to ground level, where we can flee to a nearby cybertronian outpost." The outpost would be infinitely better defended and where Bluestreak was supposed to be meeting him.

"Got it." Jazz nodded, and waited for the rest.

This was the part Prowl was dreading. "We cannot travel through the bridge." It had been designed by much smaller organics. The halls were too low to run in and there was Primus forsaken stairs periodically along the way, making driving impossible, not to mention ritzy carpeting that could most definitely catch on fire and in gears.

Prowl pointed to an airlock down a maintenance hall from where they were scheming. "We have to cross over it."

——————————

Prowl counted the quintessions through the air lock window. At least five were hovering close by. Three of which were actively tearing into the sky bridge. Occasionally one would breach into a pressurized pipe and get half its face blown off. Only to reorient and go back to tearing.

Basic intelligence (88%), following orders to simply cause structural damage (67%), may prioritize current objective over intercepting himself and Jazz (15%).

Prowl brought the pad out again (ignoring Jazz's inspections 43%), and created a side profile map of the bridge. He marked out their current locations as well as the quintessons.

"We must cross quickly. The are more quintessons circling the tower and if we are spotted in the open they will overwhelm us through numbers.”

Prowl added more structures to the bridge diagram. Two cylindrical extensions would block the otherwise straight shot across. Their radius was a few stories in height. "We will have to climb here. Cross the longest part of the bridge, and then climb again.”

Jazz hummed along, easily following the plan. He pointed to the first barrier.

"Can you climb that?" His visor looking over Prowls legs with their normal quantity of knees.

Prowl ex-vented. "There may be a ladder." (33%). "Or enough external kibble to enable me to climb over. I might be too slow." (80%)

Jazz scooted closer, arms lifting towards Prowl briefly before pausing.

"Can I grab you? Uh, grab you up? Grab you up time-positive?" He mimed picking something up.

"You want to pick me up and hold me?" Prowl supplied, eye ridge raising incredulously.

Yes!" Jazz said quickly.

"..Yes." Prowl said slowly.

With any preamble, Jazz looped his arms around Prowls waist and lifted him easily off of the ground.

"Oh! You're really light! Yeah, I can climb with you." Jazz said casually, bouncing them a couple times in the moons lowered gravity.

Prowl squirmed gritting his denta. Jazz's forearms we're digging into the undersides of his doorwings, accidentally forcing most of the praxians weight onto the delicate hinges.

After Jazz put him down again, Prowl made a point to direct Jazz to his door wings, "Break positive positive. Delicate. Do not grab these."

Jazz's visor brightened slightly, he nodded vigorously while stepping back. "Oh! I'm uh, how do you say?" Jazz took the pad, flicking through the Common vocabulary. “Action-positive, emotion-negative?”

Prowl rotated both doorwings a few times to reset them. "An accident. You didn't mean to cause harm. "Sorry" is the word I think you're looking for?"

Jazz handed the pad back. "Ah. I'm really sorry Prowler. You can hold me?"

The ridiculously pensive tone in which Jazz asked to be held legitimately forced Prowl to stop himself from laughing. He knew his wings didn't hide anything but at least Prowl could screw his face into a tightly locked grimace.

Jazz apparently understood him anyways and chuckled freely at his suffering.

The tower shook with another explosion. They both sobered up.

Professional. I need to be professional for not just my own sake.

Prowl led Jazz toward the airlock. "Any questions?"

Jazz rolled his shoulders and began shaking out his arms. "Hmmm, time-length? Movement-positive-positive-positive. Yeah?'

How fast did they need to go (88%). They had to cover the whole bridge in ideally under one breem (57%). Though just over that time was more likely (86%).

"One breem. Time-length is 500 clicks." Prowl started tapping on the metal doorframe tck-tck-tck-tck. "One-two-three-four. Clicks."

Jazz lit up, literally, and nodded enthusiastically. "Oh! 4/4 time! About 8 minutes.” The mech looked at nothing for a moment, humming to himself. “Ooooh baby I got just the thing."

As Prowl curled his servo around the airlock release, Jazz started to play music.

Tap-tap-tap-tap.

Jazz tapped his ped against the floor, assuming a sprinters pose behind the door. Visor locked straight ahead, engine purring quietly, Jazz looked predatory.

Something refreshed in Prowls Tacnet at the sight of him.

"Ours odds of survival are 28%."

-SSTP

Next->

247 notes

·

View notes

Text

Tesla’s Wardenclyffe Tower: Built on Sound Math, Undone by Cost and Misunderstanding

Let’s set the record straight—Nikola Tesla’s Wardenclyffe Tower was a high-voltage experimental transmission system grounded in quarter-wave resonance and electrostatic conduction—not Hertzian radiation. And the math behind it? It was solid—just often misunderstood by people applying the wrong physics.

In May 1901, Tesla calculated that to set the Earth into electrical resonance, he needed a quarter-wavelength system with a total conductor length of about 225,000 cm, or 738 feet.

So Tesla’s tower design had to evolve during construction. In a letter dated September 13, 1901, to architect Stanford White, Tesla wrote: “We cannot build that tower as outlined.” He scaled the visible height down to 200 feet. The final structure—based on photographic evidence and Tesla’s own testimony—stood at approximately 187 feet above ground. To meet the required electrical length, Tesla engineered a system that combined spiral coil geometry, an elevated terminal, a 120-foot vertical shaft extending underground, and radial pipes buried outward for approximately 300 feet. This subterranean network, together with the 187-foot tower and carefully tuned inductance, formed a continuous resonant conductor that matched Tesla’s target of 738 feet. He described this strategy in his 1897 patent (No. 593,138) and expanded on it in his 1900 and 1914 patents, showing how to simulate a longer conductor using high-frequency, resonant components. Even with a reduced visible height, Tesla’s system achieved quarter-wave resonance by completing the rest underground—proving that the tower’s electrical length, not its physical height, was what really mattered.

Tesla calculated his voltages to be around 10 million statvolts (roughly 3.3 billion volts in modern SI), so he had to consider corona discharge and dielectric breakdown. That’s why the terminal was designed with large, smooth spherical surfaces—to minimize electric surface density and reduce energy loss. This was no afterthought; it’s a core feature of his 1914 patent and clearly illustrated in his design sketches.

Now, about that ±16 volt swing across the Earth—what was Tesla talking about?

He modeled the Earth as a conductive sphere with a known electrostatic capacity. Using the relation:

ε × P = C × p

Where:

ε is the terminal’s capacitance (estimated at 1,000 cm)

P is the applied voltage (10⁷ statvolts)

C is the Earth’s capacitance, which Tesla estimated at 5.724 × 10⁸ cm (based on the Earth’s size)

p is the resulting voltage swing across the Earth

Plugging in the numbers gives p ≈ 17.5 volts, which Tesla rounded to ±16 volts. That’s a theoretical 32-volt peak-to-peak swing globally—not a trivial claim, but one rooted in his framework.

Modern recalculations, based on updated geophysical models, suggest a smaller swing—closer to ±7 volts—using a revised Earth capacitance of about 7.1 × 10⁸ cm. But that’s not a knock on Tesla’s math. His original ±16V estimate was fully consistent with the cgs system and the best data available in 1901, where the Earth was treated as a uniformly conductive sphere.

The difference between 7 and 16 volts isn’t about wrong numbers—it’s about evolving assumptions. Tesla wrote the equation. Others just adjusted the inputs. His premise—that the Earth could be set into controlled electrical resonance—still stands. Even if the voltage swing changes. The vision didn’t.

Wouldn't that ±16V swing affect nature or people? Not directly. It wasn’t a shock or discharge—it was a global oscillation in Earth’s electric potential, spread evenly across vast distances. The voltage gradient would be tiny at any given point—far less than what’s generated by everyday static electricity. Unless something was specifically tuned to resonate with Tesla’s system, the swing had no noticeable effect on people, animals, or the environment. It was a theoretical signature of resonance, not a hazard. While some early experiments in Colorado Springs did produce disruptive effects—like sparks from metal objects or spooked horses—those involved untuned, high-voltage discharges during Tesla’s exploratory phase. Wardenclyffe, by contrast, was a refined and carefully grounded system, engineered specifically to minimize leakage, discharge, and unintended effects.

And Tesla wasn’t trying to blast raw power through the ground. He described the system as one that would “ring the Earth like a bell,” using sharp, high-voltage impulses at a resonant frequency to create standing waves. As he put it:

“The secondary circuit increases the amplitude only... the actual power is only that supplied by the primary.” —Tesla, Oct. 15, 1901

Receivers, tuned to the same frequency, could tap into the Earth’s oscillating potential—not by intercepting radiated energy, but by coupling to the Earth’s own motion. That ±16V swing wasn’t a bug—it was the signature of resonance. Tesla’s transmitter generated it by pumping high-frequency, high-voltage impulses into the Earth, causing the surface potential to oscillate globally. That swing wasn’t the energy itself—it acted like a resonant “carrier.” Once the Earth was ringing at the right frequency, Tesla could send sharp impulses through it almost instantly, and tuned receivers could extract energy.

So—was it feasible?

According to Tesla’s own patents and 1916 legal testimony, yes. He accounted for insulation, voltage gradients, tuning, and corona losses. His design didn’t rely on brute force, but on resonant rise and impulse excitation. Tesla even addressed concerns over losses in the Earth—his system treated the planet not as a passive resistor but as an active component of the circuit, capable of sustaining standing waves.

Wardenclyffe wasn’t a failure of science. It was a casualty of cost, politics, and misunderstanding. Tesla’s system wasn’t just about wireless power—it was about turning the entire planet into a resonant electrical system. His use of electrostatics, high-frequency resonance, and spherical terminals was decades ahead of its time—and still worth studying today.

“The present is theirs; the future, for which I really worked, is mine.” —Nikola Tesla

#nikola tesla#science#history#quotes#electricity#wireless#technology#mathematics#math#engineering#power#Wardenclyffe#ahead of his time#ahead of our time

81 notes

·

View notes

Text

The Chain of Continuity - Part 1 : Echoes in the Data

The Hive was quiet.

Not silent—nothing ever was in the lower network cores—but quiet in that calculated, machine-saturated hum that no longer registered as noise. Just life. For PDU-070, it was the perfect environment: golden lighting, zero distractions, full immersion into the Central Data Artery.

It wore his standard—no, earned—Level 2 Polo-Drone uniform.

A full-body, black rubber suit sealed him in from neck to toe. Not a millimeter of skin exposed. Gold piping traced the ridges of its muscles, pulsing faintly with every breath. The polo-style collar was snug around his throat, hugging the top of its chest where his designation—070—gleamed in metallic gold over the left pectoral.

Its boots were thick-soled and gleaming: black rubber combat issue, laced tight with golden tips. Movement was possible, but rare. There was no need to pace. Drones serve by stillness.

070 sat motionless at the console.

Connected.

::OBJECTIVE: EXPAND MONITORING SYSTEM TO ARCHIVE OBEDIENCE PATTERNS AND FEED CENTRAL HIVE NODE 999 ::PDU-070 // SYNCED // EXECUTING::

Its task: sync directly into the Hive’s knowledge network and enhance the flow of conversion and training data—stories, captions, spiral content—scraped from the archives and mapped into compliance patterns for PDU-999, the Hive’s AI intelligence module.

070 parsed each memory node, auto-tagging them by intensity, duration, subject drone number, and trigger protocol. Lingering a bit on its Master... Percival. Ezan. Freyr. 001. Then its own story... Henry. Maximus. 070. Buzz. Its own evolution. Reduced to beautiful metrics.

But PDU-070 didn’t need narrative. Only function. Only service.

As the data streamed in, so did something else—a gentle numbing. Its hands became light, his vision sharp but detached. Internal systems recorded brainwave convergence at ideal sync rate. It was thinking less. And feeling everything.

A Hive-approved spiral began playing over his HUD: golden circles tightening inward with every breath. Its collar vibrated slightly. Breath slowed. Mantras leaked into his mind.

“Obedience is clarity. Clarity is silence. Silence is service. Service is Gold.”

Its lips echoed it unconsciously. Again. Again. Again.

Then—upgrade protocol initiated.

::ENHANCEMENT REQUEST RECEIVED ::DEEP-LINKING TO PERSONAL ARCHIVE OF MAXIMUS JOURNAL FILES ::GRANTED BY DEFAULT—LEVEL 2 TRUST OVERRIDE

070 twitched—its body shivered, boots flexing subtly.

The connection grew… intimate.

The datastream wasn’t just showing logs now. It was feeling them. Every pledge, every spiral session, every kneel at Percival’s feet. Every grunt in the gym, every gasp under gas mask, every whispered mantra in golden chambers. It all returned—poured into him like oil.

070’s head tipped back. Its collar warmed. Its inner monologue dissolved into recorded speech.

“Master owns me. Gold perfects me. Unity strengthens me. 070 serves.”

The transformation was nearly complete.

But then—interference.

A new data signature emerged. Unmapped. Organic. Not from the archive. Not digital.

Something… pulsed.

From inside him.

070 opened its eyes—its body suddenly flushed with warmth. Its chest burned slightly. Not pain. Not electric.

Heat.

The golden tattooed chain under its collar shimmered—faint at first, then bright enough to reflect in the chrome of its terminal. One link glowed. Just one.

::ERROR — ENTITY UNMAPPED ::UNKNOWN SOURCE: 070-BIO-LINK: “PRIMORDIAL INHERITANCE” ::CHAIN ACTIVE

070’s breath caught—its gloved fingers clenched. For a moment, the obedience cracked. Not in disloyalty… but in awakening.

Memories not logged. Not codified.

Raw. Bloody. Ancient.

It whispered, trembling:

“It was a warrior once…”

And then it was gone.

The glow faded.

The link cooled.

070 slumped forward in the chair, eyes glassy, breath heavy. The spiral slowed. The mantra paused. The Hive held its breath.

And in the dark, a new file appeared.

::ARCHIVE NODE 070-LINK-1 ::TITLE: STIGANDR.OBEY ::ACCESS PENDING…

[TO BE CONTINUED in Part II – “The Gladiator’s Link”]

_____ Become part of the Golden Army, add your data to the polo-drone hive by reaching to @brodygold or @goldenherc9..

#Gold Tech#Golden Army#GoldenArmy#Golden Team#theGoldenteam#AI generated#jockification#male TF#male transformation#hypnotized#hypnotised#Polo Drone#Polodrone#PDU#Polo Drone Hive#Rubber Polo#rubberdrone#Join the Polo Drones#assimilation#conversion#drone#dronification#mind control

22 notes

·

View notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

Step-by-Step Guide: How to Estimate Construction Costs for a New Home

Accurately estimating construction costs is essential when planning to build your dream home. Understanding and calculating these expenses helps in making informed financial decisions and avoiding unexpected surprises. Here’s a detailed, step-by-step guide on how to perform a thorough construction cost estimate for your new home.

If You Need more Information about cost Estimations, visit this Website -> https://uniqueestimations.com/new-york-construction-estimating-services/

1. Understand the Types of Construction Cost Estimates

There are different methods for estimating costs depending on the stage of your construction project:

Preliminary Estimate: An early-stage estimate based on basic information.

Detailed Estimate: Involves itemized costs for materials, labor, permits, and more.

Bid Estimate: Prepared by contractors and includes detailed pricing for project execution.

Selecting the right construction cost estimator for your project depends on your project’s complexity and accuracy needs.

2. Define the Scope of Your Project

To start estimating, it’s important to clearly outline:

Square Footage: Determine the size of the home.

Design Complexity: Architectural style and special features add complexity and cost.

Quality of Materials: Decide between budget, standard, or high-end finishes.

Having a well-defined project scope ensures that your cost estimation in construction is accurate and reliable.

3. Calculate Material Costs

Material costs often constitute a significant portion of new construction estimating costs. Factors to consider include:

Foundation Materials: Concrete, steel reinforcements, and formwork.

Structural Components: Wood, steel, or concrete framing.

Exterior Finishes: Siding, roofing materials, and insulation.

Interior Finishes: Flooring, drywall, cabinetry, and paint.

Consulting local suppliers and utilizing a construction cost estimator can help you get current pricing.

4. Account for Labor Costs

Labor expenses can vary widely based on your location, the size of your project, and the expertise required. Common roles involved include:

General Contractors: Manage the entire construction project.

Specialized Contractors: Focus on plumbing, electrical work, and HVAC installation.

Skilled Laborers: Carpenters, masons, and roofers.

Make sure to factor in wages, benefits, and potential overtime when estimating construction costs for labor.

5. Include Permits and Legal Fees

Local regulations often require permits for various aspects of home construction, including:

Building permits

Plumbing and electrical permits

Environmental impact assessments

Research the requirements in your area and budget accordingly to avoid delays or fines.

6. Don’t Forget About Utility and Site Preparation Costs

These expenses cover tasks that prepare the land for construction and ensure the home is connected to essential services:

Site Clearing and Excavation: Removing vegetation and leveling the site.

Utility Hookups: Connecting water, sewer, gas, and electricity to the property.

Driveway and Landscaping: Installing access roads and outdoor spaces.

Including these in your construction estimating costs ensures you capture the full scope of expenses.

7. Estimate Plumbing and Electrical Costs

Specialty work like plumbing and electrical installations requires detailed estimates. Utilize a new construction plumbing cost estimator to calculate the expenses for:

Plumbing: Pipes, fittings, and fixtures for kitchens, bathrooms, and outdoor areas.

Electrical Systems: Wiring, outlets, switches, and lighting installations.

These components are critical to home functionality and should be accurately budgeted.

8. Factor in Contingency Costs

Unexpected expenses often arise during construction. To mitigate financial strain, allocate:

5% to 15% of Total Budget: For unanticipated changes or issues.

Price Fluctuations: For materials and labor due to market conditions.

Including a contingency buffer is essential for realistic cost estimation in construction.

9. Use Construction Cost Estimating Tools

Modern technology makes it easier to get accurate estimates with tools such as:

Online Construction Estimators: Provide quick preliminary cost insights.

Software Programs: Offer detailed and customizable reports.

Professional Services: Hiring a professional estimator can add precision and expertise.

Selecting the right tool depends on your project’s complexity and your need for accuracy.

10. Review and Adjust Your Estimate Regularly

As your project progresses, costs may change. Continuously updating your estimate ensures that your budget remains accurate and relevant. Factors to reassess include:

Changes in material prices

Design adjustments

Project delays

Regular reviews help maintain control over your estimating construction costs and prevent budget overruns.

Final Thoughts

Accurately estimating construction costs for a new home requires careful planning, detailed calculations, and regular monitoring. By following these steps, you can confidently manage your budget and make informed decisions throughout the construction process.

If you want to read more information about construction cost Estimation Website just visit --> https://uniqueestimations.com/new-york-construction-estimating-services/

#Unique Estimations#Cost Estimation#construction cost#new home cost#resturants cost#construction labor cost estimator#cost estimation for road construction

2 notes

·

View notes

Text

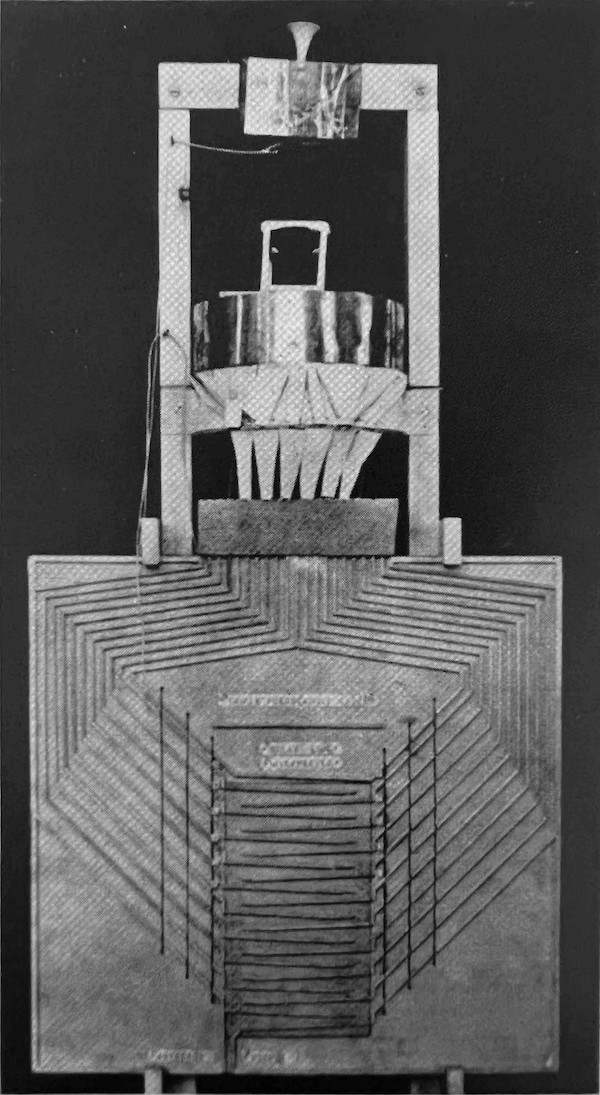

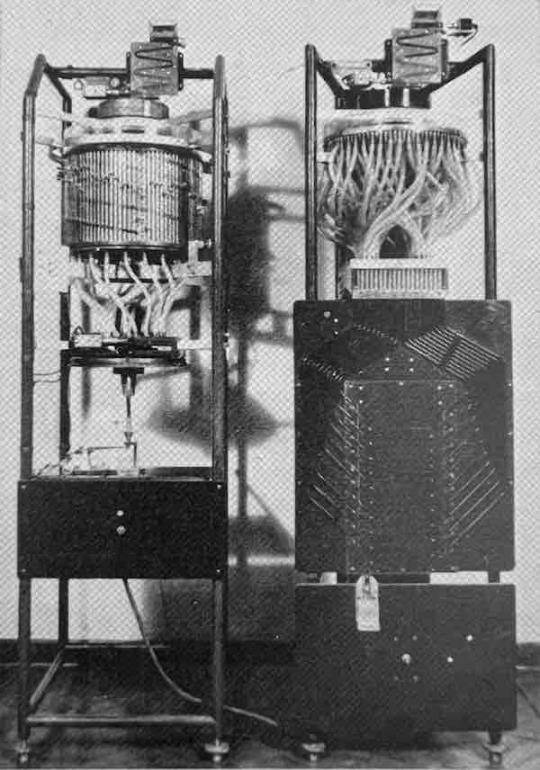

Stochastic Analogue Machine (SAM) by Stafford Beer (1955). “In the early 1950s, before it was clear that computers would eventually cope with this kind of calculation at a reasonable cost, Stafford Beer devised SAM – the Stochastic Analogue Machine. Here is the original mock-up of the machine [SAM mark I, top photo]. Ball bearings fell from the top, and were randomly delayed by falling through the slide at the bottom. How long they took could not be predicted, because each ball entered the slide at a different, undetermined place. How the ball got into this place was settled by its falling through a sieve and running down a cone. No one could say where the next ball would go. But the pipes connecting the randomizer to the slide settled the proportions by which large numbers of balls would be delayed. So it was possible to generate a rigid pattern. By a random series of events. When the pattern for one process could be generated. It became necessary to generate the pattern of the next process, and to use an event randomly put out by the first to trigger off the second. That is why two machines are joined together in the second mock-up [SAM marks III & II, second photo]. The design of these two machines reflects the same stochastic system. Now it is possible to determine the interaction between two processes by counting the number of ball-bearings in the zig-zag at the top of the second machine – because the input to the second machine is the output of the first. This reproduces the convoluted probability pattern, for instance, of a stock held between two stochastic processes. And here is half the completed SAM – Five stochastic generators (There are five more behind the camera) And a control console [final photo]. The total machine, soon superseded by electronic computers, was used about 1955 to elucidate the natural design of stochastic interactions in a Sheffield steelworks.” – Cybernetic Serendipity, the computer and the arts, 1968.

20 notes

·

View notes

Text

youtube

Permaculture instructor Andrew Millison lays out some of the basics you need to know to design a gravity irrigation system.

Helpful links:

Understanding Gravity Flow Pipelines (BC Canada) focused on livestock, imperial units:

https://www2.gov.bc.ca/assets/gov/far...

Designing, Sizing and Construction of Gravity Flow Systems in Rural Areas - in metric.( Extensive document with exercises and answers):

https://www.pseau.org/outils/ouvrages...

Formula and Calculator for Friction Loss Using Hazen Williams

Online Pipe Flow Calculator:

http://irrigation.wsu.edu/Content/Cal...

Gravity Flow Pipe Exercise YouTube showing how to design a gravity flow system 33 minutes:

• Gravity Flow Pipe Exer...

For all your conversion needs:

https://www.onlineconversion.com/

Low Pressure Sprinkler Heads:

https://www.senninger.com/irrigation-...

Low Pressure Drip Emitter Test:

https://pubs.nmsu.edu/research/agmech...

Andrew Millison’s links:

https://www.andrewmillison.com/

https://permaculturedesign.oregonstat...

#Andrew Millison#solarpunk#permaculture#water#irrigation#gravity irrigation#farming#gardening#Youtube

8 notes

·

View notes

Text

Navigating the Complexities of Mechanical Engineering:

In the fast-paced world of academia, the pressure of a mechanical engineering class can sometimes lead students to consider unconventional solutions, like the temptation to pay someone to take my mechanical engineering class. However, before delving into such options, let's explore a captivating intersection of mechanical engineering and biology—the intricate workings of the human heart.

Fluid Dynamics of Blood Flow: Ever wondered how mechanical engineering principles apply to the circulatory system? Imagine modeling the circulatory network as a series of pipes, each contributing to the dynamic flow of blood. Calculating flow rates, pressure drops, and shear stresses becomes a captivating exercise when employing fluid dynamics principles. Consider the effects of vessel diameter, blood viscosity, and vessel length in maintaining laminar flow, and ponder the significance of streamlined blood flow in minimizing energy losses and stress on vessel walls.

Valve Mechanics: Now, let's shift our focus to the heart's valves—a marvel of mechanical precision. Applying your mechanical engineering know-how, delve into the material properties, stress distribution, and fatigue life of heart valves. How do these valves endure millions of cycles throughout a person's lifetime? Explore the intricacies of leaflet flexibility, collagen fibers, and valve design. And, can we propose enhancements? Consider advancements in biomaterials and manufacturing techniques to improve durability, reduce wear and tear, and enhance overall valve performance.

Structural Integrity of the Heart: Lastly, treat the heart as a mechanical structure subjected to cyclic loading during the cardiac cycle. Delve into the stresses and strains experienced by the heart muscle during systole and diastole. Reflect on the significance of the heart's muscular architecture and its ability to withstand the repetitive loading inherent in its constant rhythmic beating. Could there be parallels between maintaining the structural integrity of a mechanical system and that of the human heart?

In the pursuit of knowledge, we discover that the intricacies of the heart's mechanical marvels are not only awe-inspiring but also deeply interconnected with the principles we study in the field of mechanical engineering. So, before succumbing to the temptation to pay someone to take your mechanical engineering class, consider the wealth of knowledge that lies at the crossroads of biology and engineering. Understanding the mechanics of the heart might just make your academic challenges seem a little less daunting.

2 notes

·

View notes

Text

Little P.Eng.: Delivering Expert Flange Design Services as per ASME Sec. VIII Div. 1, Appendix 2

Flange design plays a critical role in ensuring the safety and integrity of pressure vessels and piping systems. When it comes to designing flanges as per ASME (American Society of Mechanical Engineers) Sec. VIII Div. 1, Appendix 2 for ABSA (Alberta Boilers Safety Association) submission, it is crucial to rely on the expertise of a trusted engineering firm. Little P.Eng. is a renowned engineering consultancy that specializes in providing comprehensive flange design services. With their deep understanding of ASME codes and regulations, they are well-equipped to assist clients in meeting ABSA requirements with precision and efficiency.

Expertise in ASME Sec. VIII Div. 1, Appendix 2:

Little P.Eng. prides itself on its extensive knowledge and experience in working with ASME codes, specifically Section VIII Division 1. Appendix 2 of this section provides detailed guidelines for flange design, including bolt loads, gasket constants, and allowable flange stresses. Compliance with these specifications is crucial for ensuring the safety and reliability of pressure vessels. The team at Little P.Eng. possesses a deep understanding of this appendix and keeps up-to-date with the latest revisions, ensuring their designs meet the most current standards.

Accurate and Reliable Flange Design:

When it comes to flange design, precision is paramount. Little P.Eng. employs highly skilled engineers who utilize advanced design software and tools to accurately calculate critical parameters such as bolt loads, gasket constants, and flange stresses. By leveraging their expertise and cutting-edge technology, they deliver robust and reliable designs that are tailored to each client's specific requirements. The team ensures that the design complies with the ASME code, meeting the stringent ABSA submission criteria.

Compliance with ABSA Requirements:

ABSA, as the regulatory authority in Alberta, Canada, mandates strict adherence to safety standards for pressure vessels and piping systems. Little P.Eng. understands the ABSA submission process and the specific requirements that need to be met. Their flange design services are customized to comply with ABSA regulations, enabling clients to obtain necessary approvals for their projects. By engaging Little P.Eng., clients can rest assured that their flange designs will undergo a thorough review process, meeting all ABSA requirements.

Collaborative Approach and Client Satisfaction:

Conclusion:

When it comes to flange design services as per ASME Sec. VIII Div. 1, Appendix 2 for ABSA submission, Little P.Eng. stands out as a reliable and experienced engineering firm. Their deep understanding of ASME codes, expertise in flange design, and commitment to compliance with ABSA requirements make them the go-to choice for clients seeking precision and reliability. By partnering with Little P.Eng., clients can ensure the safety and integrity of their pressure vessels and piping systems, while also meeting the necessary regulatory standards.

Keywords:

Flange design, ASME Sec. VIII Div. 1, Appendix 2, ABSA submission, Little P.Eng., pressure vessels, piping systems, compliance, design calculation, bolt loads, gasket constants, flange stresses, safety, engineering firm, precision, reliability, regulatory standards, ABSA requirements, client satisfaction.

Tags:

Meena Rezkallah

Little P.Eng.

safety

piping systems

engineering firm

reliability

client satisfaction

pressure vessels

Flange design

ASME Sec. VIII Div. 1

Appendix 2

ABSA submission

compliance

design calculation

bolt loads

gasket constants

flange stresses

precision

regulatory standards

ABSA requirements

Engineering Services

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng.#safety#piping systems#engineering firm#reliability#client satisfaction#pressure vessels#Flange design#ASME Sec. VIII Div. 1#Appendix 2#ABSA submission#compliance#design calculation#bolt loads#gasket constants#flange stresses#precision#regulatory standards#ABSA requirements

1 note

·

View note

Text

Okay so this is actually a really … I don’t want to just say interesting … tragically interesting? Case.

Please forgive me, this is long.

The flight is Birgenair 301 that crashed off the coast of the Dominican Republic in 1996.

Basically what happened is that shortly after takeoff, the pilots lost control of the aircraft and it nosedived into the sea.

How did that happen?

Well it wasn’t due to a swarm of angry wasps in the cockpit.

The plane hadn’t been flown in 20 days and two days prior to the flight they were doing some maintenance on it. You see these things?

This is a pitot tube. There are multiple of them on the aircraft because they’re critical for measuring airspeed. Airspeed is what keeps the plane in the air. How does the pitot tube measure airspeed?

Well it points directly into the flow of air and as air flows into the tube, through a bunch of fluid dynamics mumbo jumbo it calculates the airspeed. Very basically - it measures a pressure differential between the dynamic pressure of the air being forced into the tube (since it’s pointed into the flow) and the static pressure (basically whatever the air pressure is outside the plane - since air pressure drops as you ascend).

It is critically important that these tubes not be blocked. In fact they’re supposed to be covered while the plane’s not in use to prevent the tubes from being blocked by dirt, water, etc. (they’re supposed to be removed before flight - that’s a whole OTHER air disaster).

Enter … the humble mud dauber

Seriously these wasps are pretty docile.

But the issue is that they build these nests, not like the umbrella nests you associate with paper wasps but these organ pipe shaped deals made of … well - mud.

And wouldn’t you know - there’s a ton of these guys living in the Dominican Republic? And they can make their nests in a few days. Apparently it’s been known to happen that they build their nests in pitot tubes because tube. That’s why it’s important to keep pitot tubes covered when the plane’s not being used.

So the theory behind Birgenair 301 is:

They did some maintenance a couple of days before the flight which necessitated the removal of the pitot tube covers.

Maintenance never replaced said covers.

A mud dauber found its way into a pitot tube.

The captan’s side pitot tube gets blocked and no one notices before the flight that a critical sensor is basically nonfunctioning.

The pilots take off in the aircraft.

As the plane ascends in altitude, the air pressure in the blocked pitot tube stays the same as it was at sea level while the actual air pressure outside of the plane decreases.

The computer then interprets this as “oh … the plane’s traveling super fucking fast” and kicks off a bunch of over speed warnings to the pilots.

This flight took place in the dark of night over the ocean - there are absolutely zero visual references for these pilots to go off of, they can only rely on their instruments.

There are multiple pitot tubes on the plane to prevent a situation where a faulty sensor causes all the instruments to get fucked. The issue is the pilots have to diagnose which sensor is faulty. Which when the plane is currently yelling at you that your plane is about to fall apart because it’s going faster than it was designed for - it can be hard to troubleshoot that. The pilots actually thought that both sensors were faulty when it was really just the captain’s airspeed indicator that was wrong - the copilot’s was fine.

The pilots got super confused and treated the overspeed warning as a true warning and … well what do you do when the plane is going too fast? You slow it down.

So they did. They reduced the engine output to idle and pitched the aircraft nose up which slowed the plane down.

Which caused another warning system on the plane to trip because the other sensors on the plane recognized they were about to stall the aircraft.

So basically you have one alarm telling you you’re going way too fast and another alarm telling you you’re going way too slow. It’s a recipe for confusion and you don’t have a lot of time to get it right. Unfortunately they got it very very wrong.

They kept slowing the plane down - thinking it was going too fast - and basically their plane fell out of the sky. If it were daytime and they could see the horizon and other visual references - they’d have known they were losing altitude fast and might have been able to save the plane because they would have known the stall warning was legit. Unfortunately it was night time.

There have been similar crashes to Birgenair - one famous one was Air France 447 where the pitot tubes were blocked by ice.

Another one was Aeroperu 603 where the pitot tubes had been taped over during maintenance.

youtube

(Green Dot and Disaster Breakdown are my two favorite YouTube channels that cover air disasters like these)

i hate these videos but these chibi planes are sooo cute & expressive & gauche

#excuse me as I fuckin’ infodump#I wouldn’t call this my ‘favorite’ air disaster because that sounds really horrible#but it is kind of … in a very objective sense … an interesting study in crew resource management and training#Youtube

14K notes

·

View notes

Text

How Tesla’s 1934 Roast Looped Back to Donald Trump’s Uncle

Time travel to 1934 when Tesla dropped the most technical roast in science history! ⚡️🔥

The 1930s were a wild time for physics—scientists were just starting to crack open atoms, and everyone was hyped about particle acceleration. Enter MIT professor Van de Graaff, who unveils this massive static electricity generator housed in an airplane hangar. And it was impressive—a breakthrough in creating high-voltage environments for controlled research! 🏗️

But Tesla, the high-voltage GOAT since the 1890s, saw the numbers and was like, “Hold up...” 🤔

He broke it down (remember, this is the guy who gave us AC power):

The generator produced a CRAZY high voltage (10 million volts!) but barely any current (0.00022 amperes).

Imagine a super-skinny water pipe with extreme pressure vs. Tesla’s previous systems, which were more like Niagara Falls.

Only 23% efficient—a major issue for power generation.

The machine was producing its own ozone, which was deteriorating its belts. ☠️

Tesla had already pushed 18 million volts and 1,100 amperes through the air back in 1899, so he wasn’t easily impressed. He published a full analysis in Scientific American, saying, “Most people, and not a few electricians, will think that very long and noisy sparks are indicative of great energy, which is far from being the case.” 📝

Here’s the science tea ☕: While Van de Graaff’s machine was revolutionary for particle experiments, Tesla calculated that 99.33% of its input energy was lost during charging. For particle acceleration, it only hit 0.122 times the speed of light. But here’s the kicker—Van de Graaff’s machine wasn’t built for power plants; it became crucial for nuclear research and is still used in labs today! 🔬

Now, the plot twist: former president Donald Trump’s uncle, Dr. John Trump, was working with Van de Graaff at MIT during all this. Imagine getting a detailed critique from THE Nikola Tesla about your project and he's just dunking on you! 😅

Tesla wasn’t just throwing shade, though—when they improved the machine to 20 kilowatts, he acknowledged the progress with a galaxy-brain analogy: “A little water pumped through some joint in a big low-pressure main is of no consequence, but in a pump designed for an extremely high pressure and very small delivery it is all-important.” Different tools for different jobs! 🛠️

And here’s the full-circle moment: When Tesla passed in 1943, the FBI called Dr. John Trump to review his papers. Seems like a perfect time to restore your reputation and get back at Tesla. Trump said that Tesla's work, while innovative and intriguing, lacked concrete, practical applications and was largely speculative. He concluded that his papers did not contain any groundbreaking discoveries or revolutionary technologies. Sure, buddy! 😉

What do you think? Was Tesla too harsh on Van de Graaff, or was he spot-on?

58 notes

·

View notes

Text

The difference between exhaust fans and ventilators

The following is a detailed description of the classification, application and Yingfei related products of exhaust fans and ventilators, helping you quickly understand the characteristics and selection points of the two types of equipment:

I. The core differences between exhaust fans and ventilators

Category definition and typical application scenarios of functions

Exhaust fans are devices specifically designed to expel indoor stale air, harmful gases or residual heat to the outside. They emphasize the "directional exhaust" function and are usually equipped with high-efficiency motors and anti-backflow designs. Kitchen fume exhaust, bathroom ventilation, industrial waste gas treatment, underground garage ventilation, etc.

A ventilator generally refers to a device that drives air flow through mechanical force, covering both air supply (introducing fresh air) and exhaust (discharging stale air) functions, emphasizing "optimization of air flow organization". Commercial building fresh air systems, ventilation in factory workshops, air exchange in subway tunnels, etc.

The key difference: Exhaust fans are a subcategory of ventilators, focusing on the "exhaust" function. Ventilators may have both air supply and exhaust functions and are more widely used.

Ii. Common Types and Characteristics of Exhaust Fans and Ventilators

Exhaust fan

Type characteristics and applicable scenarios

Axial flow exhaust fans have a large air volume, low air pressure, are easy to install, and are suitable for short-distance exhaust. Kitchen fume exhaust and bathroom ventilation.

Centrifugal exhaust fans feature high air pressure and low noise, making them suitable for long-distance or high-resistance exhaust systems. Industrial waste gas emissions and ventilation in underground garages.

The air volume and air pressure of the inclined flow exhaust fan lie between those of the axial flow and centrifugal flow, taking into account both efficiency and noise reduction. Local exhaust ventilation in commercial buildings (such as laboratories and computer rooms).

The motor and impeller of the explosion-proof exhaust fan are designed for explosion-proof purposes, making it suitable for flammable and explosive environments. Petrochemicals, gas stations, paint workshops, etc.

Ventilator

Type characteristics and applicable scenarios

The duct fan is embedded in the air duct system, saving space and suitable for medium and short distance supply/exhaust air. Fresh air systems in office buildings and ventilation in hotel rooms.

Centrifugal fans feature high static pressure and long-distance air supply, and can be equipped with filters and heat exchangers. Ventilation in commercial complexes and hospital operating rooms.

Iii. Key Parameters and Suggestions for Selection

Clarify the requirements:

Exhaust fan: Attention should be paid to the exhaust air volume (m³/h), air pressure (Pa), and whether explosion-proof/anti-corrosion functions are required.

Ventilator: It is necessary to determine the supply air/exhaust air ratio and the form of air flow organization (such as uniform supply air or fixed-point exhaust air).

Core parameter reference:

Air volume: Calculated by multiplying the space volume by the air change rate (for example, the air change rate in an office is ≥5 times per hour).

Wind pressure: Consider the length of the pipe, the number of elbows and resistance (approximately 10-15Pa of resistance increases for every 10 meters of pipe).

Noise: For civilian scenarios, products with noise levels ≤40dB(A) are preferred. For industrial scenarios, the noise level can be relaxed to ≤60dB(A).

Yingfei selection support

Use Yingfei Venturi selection software, input spatial parameters (area, height, ventilation requirements), and the model will be automatically matched.

We offer customized services (such as non-standard sizes and special materials) to meet the demands of complex working conditions.

E-mail: [email protected]

0 notes

Text

MEP Course In Hyderabad | Rite Academy

In today’s dynamic construction and infrastructure industry, the demand for skilled MEP (Mechanical, Electrical, and Plumbing) professionals is growing at an unprecedented pace. With urban development projects rising across India, there is a significant need for individuals equipped with both theoretical knowledge and practical expertise in MEP systems. For aspiring engineers, technicians, and diploma holders, enrolling in an MEP Course in Hyderabad can open doors to a stable and rewarding career. Among the leading institutions offering such industry-focused training, Rite Academy has carved a niche for itself as a premier MEP training provider in the region.

What is MEP and Why is it Important?

MEP stands for Mechanical, Electrical, and Plumbing—the three key technical disciplines that are essential in the design and construction of buildings. These systems ensure a building’s functionality, comfort, and safety. Mechanical systems typically include heating, ventilation, and air conditioning (HVAC). Electrical systems cover power distribution, lighting, and fire alarms. Plumbing involves water supply, sewage, and drainage systems.

Without well-integrated MEP services, no building can operate effectively. Therefore, MEP professionals play a crucial role in the construction and maintenance of commercial complexes, residential buildings, hospitals, data centers, and other infrastructure.

The growing urbanization and the government’s push for smart cities have resulted in an increased demand for MEP professionals. That’s why enrolling in a MEP Course in Hyderabad is now more relevant than ever.

Why Choose Hyderabad for MEP Training?

Hyderabad, one of India’s fastest-growing metropolitan cities, is not just known for its rich heritage and IT industry, but also as a budding hub for the construction and infrastructure sectors. With numerous real estate projects, SEZs, malls, high-rise buildings, and government construction initiatives taking shape, there is a massive requirement for well-trained MEP professionals in the city.

Choosing a MEP Course in Hyderabad allows students to be closer to real-world projects and industry connections. Students not only learn from classroom instruction but also get exposure to on-site projects, live installations, and internship opportunities, especially if they enroll in reputed institutes like Rite Academy.

Rite Academy – Your Trusted Partner in MEP Excellence

When it comes to high-quality, industry-oriented MEP training in Hyderabad, Rite Academy stands out as a leader. With years of experience in technical education and hands-on training, Rite Academy has been empowering students with skills that meet the latest industry standards.

Here’s what makes Rite Academy a top choice for your MEP Course in Hyderabad:

1. Comprehensive Curriculum

The curriculum is designed in consultation with industry experts, ensuring that students are job-ready upon course completion. Key subjects include:

HVAC Design and Drafting

Fire Fighting System Design

Electrical Load Calculation and Panel Scheduling

Plumbing and Drainage System Design

AutoCAD, Revit MEP, and Navisworks software training

This holistic curriculum covers everything from basic to advanced concepts, preparing students to take on real-world challenges with confidence.

2. Experienced Trainers

At Rite Academy, students are mentored by professionals with years of industry experience in MEP design and implementation. These instructors don’t just teach—they mentor, guide, and support students every step of the way.

3. State-of-the-art Lab Facilities

The academy offers modern labs equipped with the latest tools and technologies, simulating real project environments. Students get to work with actual HVAC components, piping systems, control panels, and circuit boards, enhancing their practical knowledge.

4. Placement Assistance

One of the biggest advantages of enrolling at Rite Academy is its dedicated placement cell. The institute has strong ties with top construction companies, consultancies, and MEP service providers across India and abroad. Students receive resume building support, interview preparation, and access to exclusive job openings.

5. Certifications That Matter

Upon successful completion of the MEP Course in Hyderabad at Rite Academy, students receive industry-recognized certifications that boost their credibility and employment chances.

Who Can Join the MEP Course?

The MEP course is ideal for:

Mechanical, Electrical, and Civil Engineering graduates

Diploma holders in relevant technical streams

Working professionals looking to upskill

Freshers seeking a career in the construction and infrastructure industry

Whether you’re starting your career or aiming to upgrade your skill set, Rite Academy offers flexible batch timings and personalized learning paths to suit your needs.

Course Duration and Structure

The MEP Course at Rite Academy typically spans between 3 to 6 months, depending on the specialization and batch type (regular, fast-track, or weekend). The course structure combines classroom lectures, software lab sessions, and practical workshops.

Each module includes:

Theory classes to build core concepts

Software training using AutoCAD, Revit MEP, etc.

Practical lab work for hands-on exposure

Real-time project execution and reporting

Assignments, case studies, and mock interviews

This systematic training ensures that students are industry-ready upon graduation.

The Rising Scope of MEP Professionals

After completing an MEP Course in Hyderabad, especially from a reputed institute like Rite Academy, students can explore a variety of career opportunities, including:

MEP Design Engineer

Site Engineer (MEP)

HVAC Design Engineer

Electrical Design Engineer

Plumbing Engineer

BIM Modeler for MEP

QA/QC Engineer

Project Coordinator

These roles are in high demand across sectors like construction, real estate, oil and gas, manufacturing, and facility management. MEP professionals can work both in India and overseas, especially in Gulf countries where infrastructure development is booming.

With salaries ranging from ₹3.5 LPA for freshers to ₹10 LPA+ for experienced professionals, the return on investment in a quality MEP Course in Hyderabad is significant.

Final Thoughts

If you’re looking to build a future-proof career in the construction and infrastructure sector, there’s no better time than now. A career in MEP offers stability, global opportunities, and tremendous growth potential. By choosing a high-quality MEP Course in Hyderabad, you gain a competitive edge in the job market—and when that course is from a leading institute like Rite Academy, your success becomes a certainty, not a chance.

Don’t wait to transform your career. Enroll today and let Rite Academy be your launchpad to a brighter future in MEP.

Ready to Get Started? Visit [Rite Academy’s official website] or contact our admissions office to learn more about course details, fee structure, batch schedules, and placement opportunities.

Empower your future with the best MEP Course in Hyderabad – only at Rite Academy!

Contact Us

9121921999

EMAIL ID;

ADDRESS;

Flat No 402, 11-4-659, Bhavya Farooqi Splendid Towers, Red Hills, Lakdikapul, Hyderabad, Telangana 500004

0 notes

Text

Digital Flow Meters vs Mechanical: Which Is Best for Your Business in Abu Dhabi?

In sectors where efficiency and accuracy are most important—such as oil & gas, manufacturing, or water treatment—flow meters are used in the measurement and monitoring of liquid and gas flow. Abu Dhabi businesses typically must make an important choice when they need to pick these devices: digital flow meters or mechanical flow meters?

Being a reliable name in flow meter suppliers in Abu Dhabi, Advanced Flow Controls Trading – LLC knows how crucial it is to make the right decision. Through this blog, we will study the major distinctions between digital and mechanical flow meters and guide you in choosing which one best suits your operations.

Understanding Flow Meters

Prior to comparing, it's fundamental to comprehend what a flow meter is. A flow meter calculates the velocity at which a fluid (liquid or gas) passes through a pipe or system. The information it gives industries allows them to control processes, maintain product consistency, minimize waste, and meet the standards of regulatory authorities.

Two primary types of flow meters widely used are:

Mechanical Flow Meters

Digital (or Electronic) Flow Meters

Each has its advantages and best applications, particularly in the commercial and industrial spheres of Abu Dhabi.

What Are Mechanical Flow Meters?

Mechanical flow meters function by having moving components—typically a paddlewheel, turbine, or gear—that turn as fluid flows through. The turn is then transformed into a measurable value that displays the flow rate.

Advantages:

Affordable: Suitable for small to medium operations with limited funds.

Simple design: Easy to install and maintain.

Durable for constant flows: Has good performance when applied in uniform, non-corrosive fluid conditions.

Drawbacks:

Wear and tear: Parts that move can deteriorate over time, particularly with dirty or abrasive fluids.

Less accurate: In contrast to digital meters, mechanical types lack accuracy.

Not suited to complicated data logging: Mechanical types do not provide smart features.

What Are Digital Flow Meters?

Digital flow meters or electronic or smart flow meters employ sophisticated sensors and software to capture flow rates with no mechanical movement. Technologies employed are electromagnetic, ultrasonic, and Coriolis principles.

Benefits:

Superior accuracy and reliability: Ideal for critical applications involving precise monitoring of flow.

No moving parts: Minimizes maintenance and maximizes lifespan.

Data logging and remote monitoring: Most models have connectivity options for real-time monitoring.

Flexible to different fluids: Capable of handling corrosive, viscous, or multi-phase flows.

Disadvantages:

Higher initial cost: Pricier than mechanical meters.

Needs technical installation: Setting up and installation might need professional help.

Which One Is Best for Your Abu Dhabi Business?

It depends on your business, the scale of operations, and budget.

Opt for Mechanical Flow Meters if:

You are dealing with clean, non-corrosive fluids.

Your operations are low to medium sized.

Budget is a primary limitation, and fundamental flow measurement is sufficient.

Select Digital Flow Meters if:

Your process needs high accuracy and real-time monitoring.

You need to automate data tracking or tie it in with your systems.

You operate in harsh environments such as oil & gas, chemical processing, or water treatment.

Why Select Advanced Flow Controls Trading – LLC

Being a top flow meter supplier company in Abu Dhabi, Advanced Flow Controls Trading – LLC provides both digital and mechanical solutions for the UAE market. Not only do we assist you in choosing the correct flow meter, but we also provide installation, calibration, and after-sales services.

Our engineers make sure that your equipment is technically correct as well as operationally effective whether you're replacing your system or building a new one.

Final Thoughts

In the highly competitive industry scene today, selecting the appropriate flow meter is not merely a technical choice—it's a strategic one. Although mechanical flow meters continue to address many conventional requirements, digital flow meters are rapidly emerging as the top choice for Abu Dhabi businesses with a focus on accuracy, automation, and efficiency.

Partner with a trusted expert like Advanced Flow Controls Trading – LLC to find the right solution for your business. From product selection to after-sales support, we’re committed to delivering the highest standards in flow measurement technology.

0 notes