#Implementing 7 QC Tools

Explore tagged Tumblr posts

Text

Understanding the 7 QC Tools: The Foundation of Quality Improvement

In every quality-based company, problem-solving involves going beyond just resolving an issue. It requires deep diving into understanding why the issue arose in the first place. This is exactly where the 7 Quality Control (QC) Tools come into play.

Designed in Japan, these tools offer a practical, visual, and data-oriented method for problem-solving, analysis of processes, and continual improvement. Be it managing production lines, performing compliance audits, or spearheading digital transformation projects, the 7 QC Tools assist teams in clearly and systematically eliminating root causes, minimizing variation, and improving performance.

All seven tools contribute to the enhancement of evaluating processes and inefficiencies for the sake of achieving ongoing operational excellence. Their collective application builds a comprehensive system that can be used in any field, including but not limited to, healthcare, logistics, and information technology.

The 7 QC Tools for Quality Improvement

These tools form the foundation of any successful Quality Management System (QMS). Their straightforward nature as well as flexibility make them indispensable for any team that aims at building a culture of quality.

1. Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

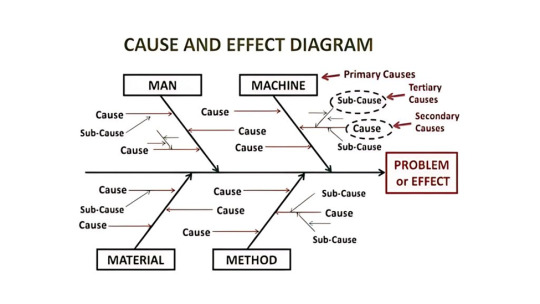

This tool aids in outlining every potential cause a given problem may have. By grouping causes into manpower, methods, machines, measurement, materials measurement and environment, teams deepen their understanding of the issue.

Example: A sealing two-hundred boxes of country's best raw honey fails repeatedly. A packaging team takes this diagram to help overcome this issue.

2. Check Sheet

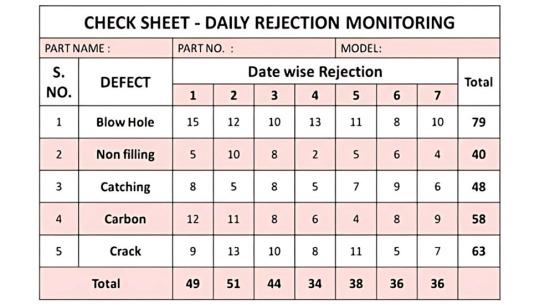

As simple as it gets, check sheets allow customers to identify all types of orders, including defects, errors, and occurrences systemically.

Example: A logistics company tracks and identifies peak periods for late deliveries using check sheets.

3. Control Chart

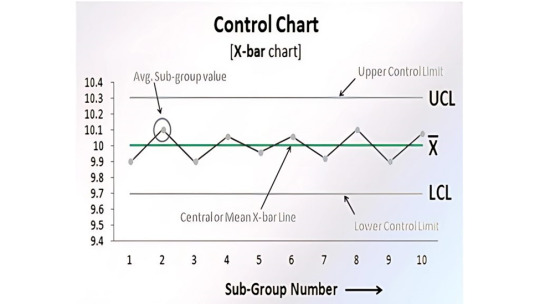

A process is stable when the control upper and lower limits are constant, while in need of corrective action when they change. Control charts display process behavior over time.

Example: A pharmaceutical company control charts to avoid inconsistent temperature control during production.

4. Histogram

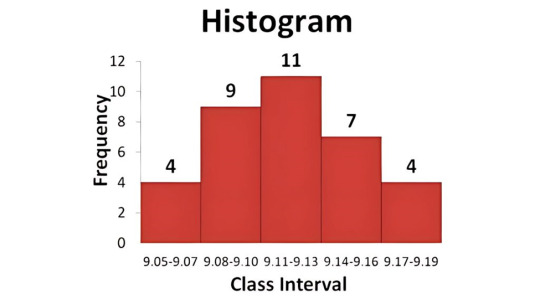

Example: IT support teams resolve tickets and average the time taken to do so.

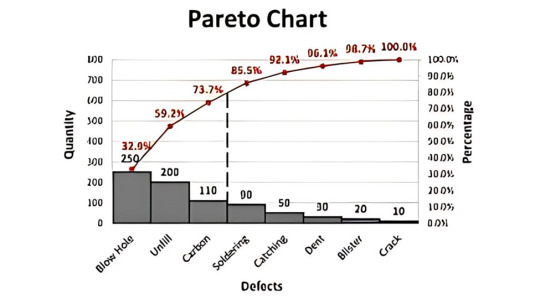

5. Pareto Chart

Example: A call center finds out that two service lines account for a majority of customer complaints through Pareto analysis.

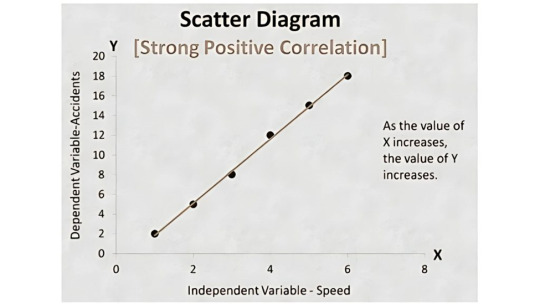

6. Scatter Diagram

Example: An HR manager tests a theory about onboarding hours and early-stage employee error reduction by increasing onboarding hours.

7. Flowchart

A flowchart is one of the ways to visualize processes step-by-step. It helps teams pinpoint inefficiencies, bottlenecks, and redundancies.

Example: A hospital maps out its discharge process to identify and eliminate delays.

Where Can These Tools Be Used?

Finally, all industries can use the 7 QC tools, even if they were primarily used in manufacturing.

In ESG compliance: Monitor sustainability KPIs and supplier risk.

In HR: Streamline hiring and employee performance monitoring using flowcharts and control charts.

In IT: Use histograms and Pareto charts to improve response times for help desk services and reduce system outages.

In logistics: Identify service-related delays, optimize routes, and improve service.

These tools allow all organizations, regardless of industry, to practice fact-based decision making, which is crucial in any organization committed to quality.

How to Implement the 7 QC Tools Effectively

The good news is that you don't need expensive tools and certifications to start. Most of these can be implemented using Excel, Google Sheets, or even pen and paper.

Steps to Implement:

1. Identify the problem – Frame the issue you are experiencing as specifically as possible.

2. Select the right QC Tool – Match the problem or analysis with the appropriate tool.

3. Train your team – Make sure the relevant personnel know how to use the selected tools.

4. Collect accurate data – Focus on achieving consistency as well as completeness.

5. Analyze and act – Review all the data and decide what information will lead to improvement.

With some support from leadership and basic training, these tools can easily be integrated into your team's daily routines and problem-solving habits.

Why the 7 QC Tools Matter

The 7 QC tools are incredibly powerful due to how basic they are. They:

• Enable root cause analysis

• Support data-driven decisions

• Promote continuous improvement

• Foster collaboration across teams

• Enhance quality, efficiency, and compliance

In today's world with growing complexities, intense competition, and increasing customer expectations, these tools can serve as a cornerstone for operational excellence and strategic transformation.

How 4C Consulting Can Help You Implement the 7 QC Tools

At 4C Consulting, we focus on integrating quality into the heart of your operations. We have successfully completed over 2,500 ISO implementations and delivered over 15,000 hours of expert training, so we have the experience and deep industry knowledge to help.

Here's how we help your journey with the 7 QC Tools:

✅ Gap Assessment – Identify where your existing processes are relative to your goals.

✅ Tailored Training – Teach your teams to properly use and maintain the QC tools with confidence.

✅ Tool Selection & Deployment – Select the appropriate tools for your specific problems.

✅ Real-Time Application Support – Get hands-on help with real-life projects.

✅ Ongoing Improvement Coaching – Foster an environment that promotes quality, spanning multiple departments.

Looking to aid with process improvement, variability reduction, and establishing an organization-wide continuous improvement culture?

Master the 7 QC Tools and more with 4C Consulting.

👉 Begin your journey to better quality today.

#7 QC Tools#Seven Quality Control Tools#7 QC Tools for Quality Improvement#Implementing 7 QC Tools#7 QC Tools Examples#Quality Management Tools

1 note

·

View note

Text

Guide for Importers on Manufacturing Control

Efficient Manufacturing Control in China

1. Understand the Chinese Manufacturing Environment:

Diverse Ecosystem: China offers a vast range of manufacturers, from small workshops to large factories. This variety is beneficial but also poses challenges in ensuring consistent quality.

IP Concerns: Despite improvements, IP protection in China can be inconsistent, requiring robust measures to safeguard your innovations.

Regulatory Landscape: China’s complex and changing regulations make compliance crucial to avoid fines and reputational damage.

Quality Control: While quality has improved, some sectors still prioritize quantity over quality. Rigorous quality protocols are essential.

Labor & Costs: Labor costs are rising, pushing manufacturers toward automation. Infrastructure is robust, but supply chains can be disrupted by natural disasters or policy changes.

Government Policies: China’s government heavily influences manufacturing through policies and incentives, which can affect costs and market access.

2. Build a Strong Foundation:

Supplier Selection: Choose reliable suppliers through thorough due diligence, including factory visits and financial checks.

Clear Communication: Provide detailed specifications and maintain open communication to avoid misunderstandings.

Quality Management: Implement a Quality Management System (QMS) and conduct regular audits to ensure consistent product quality.

Strong Relationships: Develop long-term partnerships with suppliers to build trust and collaboration.

3. Implement Effective Control Strategies:

QA & QC: Establish a robust QA/QC framework to ensure consistent product quality.

Supplier Development: Invest in your suppliers’ capabilities to improve quality and efficiency.

Risk Management: Prepare for disruptions with backup plans and diversified suppliers.

Contractual Coverage: Clearly define product specifications and include IP protections in contracts.

Third-Party Verification: Use third-party inspections to ensure compliance and quality.

4. Manage Logistics & Supply Chain:

Transportation: Choose the best transport mode and routes to minimize costs and delays.

Warehousing & Inventory: Optimize warehouse locations and use management systems to track inventory.

Customs & Documentation: Ensure compliance with customs regulations and prepare accurate documentation.

Supply Chain Visibility: Use technology to monitor shipments and collaborate with suppliers.

Risk Assessment: Develop contingency plans for disruptions like natural disasters or strikes.

5. Overcome Common Challenges:

Language & Cultural Barriers: Hire experts to bridge gaps in communication and cultural understanding.

IP Protection: Secure your IP with patents, trademarks, and NDAs; monitor for infringements.

Regulatory Compliance: Stay updated on regulations and partner with local experts for compliance.

Supply Chain Disruptions: Diversify suppliers, maintain sufficient inventory, and use smart tools for monitoring.

6. Continuous Improvement:

Use data analytics to track trends and improve processes.

Regularly evaluate supplier performance and invest in employee training.

Embrace technology to enhance communication and efficiency.

7. Build a Culture of Quality:

Encourage employees to propose improvements.

Reward contributions to quality enhancement.

Focus on exceeding customer expectations.

Conclusion: Effective manufacturing control in China requires ongoing effort, attention, and adaptation. Invest in strong practices to improve product quality, reduce costs, protect your brand, and optimize your supply chain.

3 notes

·

View notes

Text

7 QUALITY CONTROL TOOLS FOR PROCESS IMPROVEMENT

“As much as 95 per cent of all quality-related problems in the factory can be solved with seven fundamental quantitative tools.”

-Kaoru Ishikawa, The inventor of Fishbone Diagram

In today’s customer-centric market, quality is an integral factor in the growth and sustainability of any business. Businesses go the extra mile to provide the best and excellent customer experience to ensure customer satisfaction. Hence, efficient quality management which has the highest impact on customer experience is one of the most essential features for any business.

Introduced by Kaoru Ishikawa, the seven basic tools of quality also known as 7QC tools are very effective in quality management and quality assurance process. So, businesses who want to ensure competitive and excellent quality of their products and services can utilize the proven 7QC tools for structuring a strategic plan for quality improvement.

LIST OF 7 QC TOOLS

Cause and Effect Diagram

Cause and Effect Diagram also known as Fishbone Diagram helps in identifying the potential causes of an effect or a problem. In addition to sorting ideas in respective categories, it also helps in understanding the areas of opportunity through effective brainstorming. Fishbone training empowers you to identify the potential cause in the problem.

Control Chart

Control charts are used to study how the processes have changed over a period of time. Further, by comparing current data to historical control limits, one could lead to the conclusion about whether the process variation is consistent as in under control or unpredictable as in out of the control due to being affected by special causes of variation.

Pareto Chart

Pareto Chart is based on the 80/20 rule where it shows the significant factors that have the highest impact on the identified problem.

Check Sheet

Check sheet is a structured process which helps to collect and analyzing data. It is an effective tool that can be for a variety of purposes.

Histogram

Histogram is commonly used a graph that shows the data and its frequency of distribution to help users identify each different value in a set of data occurs.

Scatter Diagram

Scatter diagram shows the relationship between two important factors i.e. pairs of numerical data, one variable on each axis to demonstrate the relationship.

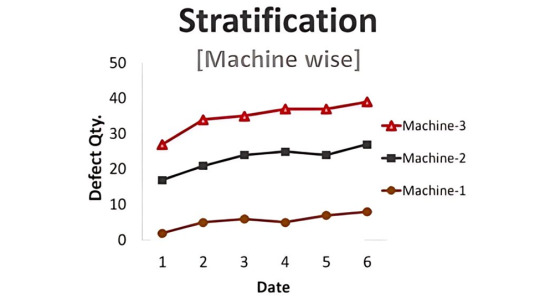

Stratification

Stratification also known as a flow chart or run chart is a technique that separates the data gathered from a variety of sources so that patterns can be seen i.e., the path an entity has taken through a defined process.

Utilizing the 7 QC tools in six sigma or quality management process helps in taking a systematic approach to identify and understand the risk, assess the risk, control fluctuation of product quality and accordingly provide solutions to avoid future defects.

WHEN SHOULD YOU USE 7 QC TOOLS?

7 QC tools can be carried out during the quality management, quality improvement process, six sigma implementation processes or even the regular PDCA cycle for the quality purpose for enhanced quality management.

In the first phase of measuring and identifying, Fishbone Diagram also known as cause and effect diagram, Pareto Chart and Control Chart can be utilized. In the next phases of assessment and analysis, Scatter Diagram, Histogram and Checklist can be carried out. The Control Chart can be utilized consistent quality improvement.

BENEFITS OF 7 QC TOOLS

The 7 QC tools are structured and fundamental instruments that help businesses improve their management and production process for achieving enhanced product quality.

From assessing and examining the production process, identification of key challenges and problems to controlling the fluctuation present in the product quality and providing solutions for prevention of defects in future, the easy to understand and implement, 7 QC tools are very effective. Some of the major business benefits of 7 QC tools are listed below.

Provides a more structured path for problem-solving and quality improvement

Easy to understand as well as implement yet extremely effective

A scientific and logical approach for problem-solving

Follows the 80/20 rule i.e. gain 80% result with 20% efforts

Improve the quality of product and services

Helps in identifying and analyzing problems during the process

Fishbone training aides in root cause analysis and problem-solving

Encourages team spirit and fosters a healthy culture

Identifies roots cause and solve it permanently

Enhance customer experience and customer satisfaction

Based on the data-driven process and customer-centric approach, 7 QC tools implementation is one of the most effective processes that too in the shortest amount of time.

4C team of certified professionals has provided 80+ implementation of 7 QC Tools and 120+ 7 QC Tools Training. By solving 200+ quality problems, 4C has empowered clients to reduce the 80% cost of poor quality. To accelerate your quality management process and reduce your cost of poor quality, contact our experts now.

#iso certification#iso certification consultants#iso consultancy#iso consultant#iso certificate online#iso certification in india

3 notes

·

View notes

Text

IATF 16949 Consultants: QC Tools Used in the Certification

In the competitive world of automotive manufacturing, quality is not something to strive for; it is imperative. Based on customer expectations, we must also ensure safety, reliability, and compliance with regulations. That’s where a globally recognized quality management standard designed specifically for the automotive sector comes into play in the form of IATF 16949.

IATF 16949 is more than a certification; it embodies a culture of continual improvement and process excellence. Becoming certified, though, is a labyrinth of requirements, documents, and audits. Here is where the role of IATF 16949 Consultants becomes crucial, as they help organizations navigate the process with their knowledge and clear insights.

This is no different for Quality Control (QC) tools, the backbone of any quality management system. These tools assist in issue identification, data analysis, process control, and decision-making based on facts. When coupled with QC tools, consultants help organizations that want to achieve compliance with the certification and improve their quality systems to lay a rock-solid foundation to achieve this.

What is IATF 16949?

IATF 16949 in UAE is a technical specification founded by the International Automotive Task Force (IATF) and the International Organization for Standardization (ISO). They based it on the fundamentals of ISO 9001, but with many automotive-specific requirements that are required for product development, production, and servicing.

The main goal of IATF 16949 Certification in Abu Dhabi is to create a quality management system that promotes continual improvement, focuses on defect prevention, and reduces variation and waste in the automotive supply chain.

Key Objectives:

Benefits of Certification:

As IATF 16949 Certification Consultants, your role is to ensure organizations meet the exacting standards of IATF 16949, thereby enhancing their organizational processes.

The IATF 16949 standard process can be lengthy and requires a lot of documentation, internal audits, and compliance reviews. Enter consultants to the rescue.

Who Are They?

Consultants are subject-matter experts with proven track records in assisting successful rollout and maintenance of standards within organizations.

Services Provided:

Benefits of Hiring a Consultant:

Widely-used QC Tools in IATF 16949

To get the correct products, organizations implement Quality Control (QC) tools. IATF 16949 Consultants in Dubai are essential to help solve problem diagnosis, process control, and decision-making.

The 7 Basic QC Tools:

Tools Related to Advanced Quality Planning (Core Tools):

The Role of QC Tools in the Quality Systems:

Tools for Quality Control Implementation of IATF 16949

It is also worth noting that the above QC tools are not just theoretical but are embedded in the DNA of IATF 16949 Certification in Dubai.

How do QC Tools Help Compliance?

Example Scenarios:

One of the quality suppliers identifies repetitive defects in a certain part by Pareto analysis and resolves it by Fishbone diagrams and FMEA.

MSA and SPC data are used by an organization during PPAP submission to demonstrate process capability and measurement reliability.

Consultant's Role:

Common Obstacles:

How IATF 16949 Consultants Help in Dealing with Challenges?

The Main Point!!

The IATF 16949 is not only a badge but a testament to excellence, consistency, and customer satisfaction in the automotive industry. Expert guidance and practical tools are needed to reach and maintain this standard.

IATF 16949 Consultants in UAE know what has gone wrong in the past and the strategies, processes, and ways of thinking that will help a company successfully implement the standard and prepare for and respond to audits. On the other hand, QC tools are the eyes and ears of your quality management system, detecting problems and informing decisions.

Collectively, they enable automotive suppliers to raise the bar in the industry. Investing in expert consultants and embracing QC tools is not just smart—it's essential for any organization seeking sustainable growth and operational excellence.

0 notes

Text

Aurobindo Pharma Job Openings in Quality Control and Quality Assurance Aurobindo Pharma is excited to announce job opportunities in Quality Control (QC) and Quality Assurance (QA) at our Jadcherla Unit in Telangana. Join a globally recognized pharmaceutical company known for its high-quality standards and commitment to innovation. Current Job Openings 1. Quality Control – Chromatography Experience Required: 3 to 7 years Location: Jadcherla Unit, Telangana Key Responsibilities: Perform routine analysis of in-process, finished, and stability samples using HPLC. Expertise in using HPLC software, particularly Empower 3, is required. Exposure to LCMS is an added advantage. Ensure compliance with cGMP and GLP standards during testing activities. Qualifications: MSc in Chemistry or B Pharmacy/M Pharmacy with relevant experience. Strong knowledge of chromatography techniques and regulatory guidelines. 2. Quality Control – Investigator Experience Required: 10 to 14 years Location: Jadcherla Unit, Telangana Key Responsibilities: Lead investigations related to Out of Specification (OOS) and Out of Trend (OOT) results. Manage Quality Management Systems (QMS) and conduct root cause analysis. Document investigation reports and implement corrective actions. Qualifications: B Pharmacy/M Pharmacy with extensive experience in quality investigations. Proven track record in managing complex investigations in a pharmaceutical setting. 3. Quality Assurance – Investigator Experience Required: 7 to 9 years Location: Jadcherla Unit, Telangana Key Responsibilities: Manage investigations related to QMS, production, and quality assurance. Independently handle USFDA audits and implement corrective actions. Conduct root cause analysis using various investigation tools and techniques. Qualifications: B Pharmacy/M Pharmacy with relevant experience in QA investigations. Strong knowledge of regulatory requirements and quality assurance processes. 4. Quality Assurance – Documentation/QMS Experience Required: 4 to 7 years Location: Jadcherla Unit, Telangana Key Responsibilities: Manage the preparation and review of Annual Product Quality Reviews (APQR). Handle QMS processes including deviations, CAPA (Corrective and Preventive Actions), and documentation. Ensure compliance with regulatory and company standards. Qualifications: B Pharmacy/M Pharmacy with hands-on experience in QA documentation and QMS. Strong understanding of documentation requirements for regulated environments. [caption id="attachment_56779" align="aligncenter" width="930"] Aurobindo Pharma Job Vacancies for Quality Control and Quality Assurance[/caption] 5. Quality Assurance – BMR and BPR Issuance Experience Required: 4 to 6 years Location: Jadcherla Unit, Telangana Key Responsibilities: Manage the issuance of Batch Manufacturing Records (BMR) and Batch Packing Records (BPR). Ensure accuracy and compliance in batch card preparation. Coordinate with production and quality teams to maintain seamless operations. Qualifications: B Pharmacy/M Pharmacy with experience in BMR/BPR issuance in a pharmaceutical setting. Familiarity with regulatory and compliance requirements for OSD formulations. How to Apply Interested candidates can share their resumes with the subject line "Application for QC/QA Position" to [email protected].

0 notes

Text

Elevating Quality with 7QC Tools Certification Consultants

In today’s competitive market, quality is paramount. Businesses must constantly strive to improve their processes, reduce defects, and enhance customer satisfaction. One effective way to achieve these goals is by leveraging the power of the 7 Quality Control (7QC) tools. These tools, when implemented correctly, can lead to significant improvements in product quality and operational efficiency. However, the successful adoption and utilization of these tools often require expert guidance. This is where 7QC Tools Certification Consultants from 4C Consulting come into play.

Understanding the 7QC Tools

The 7QC tools are a set of fundamental techniques used to identify and solve quality-related issues within an organization. They are essential for any business aiming to implement a robust quality management system. These tools include:

Cause-and-Effect Diagrams (Ishikawa/Fishbone Diagrams)

Check Sheets

Control Charts

Histograms

Pareto Charts

Scatter Diagrams

Flowcharts

These tools are designed to be simple yet powerful, enabling teams to analyze problems, monitor processes, and ensure continuous improvement.

The Role of 7QC Tools Certification Consultants

Achieving certification in the 7QC tools signifies that an organization has effectively implemented these techniques to enhance its quality control processes. However, navigating the path to certification can be challenging without the right expertise. This is where 7QC Tools Certification Consultants from 4C Consulting prove invaluable.

Expertise and Guidance

Consultants bring a wealth of knowledge and experience to the table. They understand the intricacies of each QC tool and can provide tailored guidance on how to implement them effectively within your organization. This expertise ensures that your team can utilize the tools to their full potential, leading to more accurate data analysis and better decision-making.

Training and Education

For the 7QC tools to be effective, your team needs to be well-versed in their application. Consultants from 4C Consulting offer comprehensive training programs that cover each tool in detail. These training sessions are designed to be practical and hands-on, ensuring that your team can immediately apply what they have learned to real-world scenarios.

Implementation Support

Implementing the 7QC tools requires a structured approach. Consultants work closely with your team to develop an implementation plan that aligns with your organization’s specific needs and goals. This includes identifying key areas where the tools can be applied, setting up data collection processes, and establishing monitoring systems to track progress.

Continuous Improvement

The journey to quality improvement doesn’t end with certification. Consultants provide ongoing support to ensure that your organization continues to benefit from the 7QC tools. This includes regular reviews of your processes, updates to training programs, and assistance with any challenges that arise.

Choosing 4C Consulting for 7QC Tools Certification

4C Consulting stands out as a leader in quality management consulting. With a proven track record of helping organizations achieve and maintain high standards of quality, their team of experts is well-equipped to guide you through the 7QC tools certification process.

Their approach is customized to meet the unique needs of each client, ensuring that you receive the support and guidance necessary to achieve your quality goals. By partnering with 4C Consulting, you can be confident that your organization is on the path to improved quality, efficiency, and customer satisfaction.

The 7QC tools are a powerful asset for any organization committed to quality improvement. However, their effective implementation requires expertise and guidance. 7QC Tools Certification Consultants from 4C Consulting provide the knowledge, training, and support necessary to ensure that your organization can leverage these tools to their fullest potential.

By choosing 4C Consulting, you are investing in a future of continuous improvement and operational excellence. Contact 4C Consulting today to learn more about how their 7QC Tools Certification services can benefit your organization and help you achieve your quality objectives.

0 notes

Text

An Insight Into Jolly Clamps’s Quality Control in Clamp Manufacturing

At Jolly Clamps, we take pride in delivering top-notch products that meet and exceed our customers’ expectations. Our commitment to quality goes far beyond the visible aspects of our products. We understand that true quality lies in the meticulous testing and scrutiny of every component and material used in our clamp manufacturing process. In this blog post, we will take you on a journey inside Jolly Clamps, shedding light on the rigorous quality control measures we implement to ensure the excellence of our clamp products.

At Jolly Clamps we follow inspection right from Raw material to Finished Goods. Below are the stages and type of inspections that are carried out:

The Foundation of Excellence — Raw Material: The foundation of a high-quality clamp lies in the quality of the raw materials used. At Jolly Clamps, we source materials from trusted suppliers and conduct thorough inspections upon arrival. Our quality control team examines the raw materials to ensure they meet our stringent standards for strength, durability, and corrosion resistance. Our inhouse facility allows us for mechanical and chemical testing of raw material on machines likes Spectro, PMI and UTM. Along with inhouse testing, 3rd party lab testing is conducted on the received Raw Material.

2. The Perfect Fit Test — Dimensional Accuracy Checks: Dimensional accuracy is non-negotiable in clamp manufacturing. Our quality control team conducts checks at various stages of the production process starting from First piece approval, in-process inspection, and Last piece inspection for each process. This ensures that each clamp aligns with the specified measurements, guaranteeing a perfect fit and functionality in diverse applications.

3. The Tough Test- Strength and Load Showdown: Jolly Clamps are designed to withstand extreme conditions and heavy loads. To validate the strength and load-bearing capacity of our products, we subject them to rigorous testing protocols. Our advanced in-house testing facilities simulate real-world scenarios, allowing us to confidently assure, our customers of the reliability and durability of our clamps.

4. Surface Finish and Coating Test: Aesthetics matter, and so does the longevity of our products. Our quality control team pays

meticulous attention to the surface finish and coating of each clamp. This is done by carrying out plating thickness testing and salt spray testing. This not only ensures the visual appeal, but also confirms the clamps life against corrosion and environmental factors, ensuring a longer lifespan for our products.

5. Non-Destructive Testing (NDT): NDT methods, such as liquid penetrant testing allow for the evaluation of materials and components without causing damage. These techniques, along with visual inspection, have proven beneficial to us for identifying any surface defects in our RM as well as finished parts.

6. Final Quality Assurance: Before a Clamp leaves our manufacturing facility, it undergoes a final comprehensive quality assurance check. This includes a final inspection of all components, a review of documentation, and a confirmation that each clamp adheres to our quality standards. Only products that pass this rigorous evaluation are deemed ready for shipment to our customers.

In addition to inspection stages, the manufacturing industry employs a variety of other tools and methods for quality control. Here are some notable ones:

1. Super Tools for Super Quality — Application of 7 QC Tools: Jolly Clamps employs the renowned 7 Quality Control (QC) tools as a cornerstone of our quality assurance strategy. These tools, including Pareto Analysis, Ishikawa Diagrams, and Control Charts, allow us to systematically identify, analyse, and address potential issues in our manufacturing process. By leveraging these tools, we continuously refine our processes to achieve optimal efficiency and eliminate defects.

2. Fool proofing the Game — Poka Yoke Techniques: To enhance our error-proofing mechanisms, we have integrated Poka Yoke (mistake-proofing) techniques into our manufacturing processes. These techniques involve designing foolproof systems and mechanisms that prevent errors before they occur and monitoring the sustenance. This not only reduces the likelihood of defects but also streamlines our operations, contributing to the overall efficiency and reliability of our clamps.

3. Handling the Risky Factors: Failure Mode and Effects Analysis (FMEA): At Jolly Clamps we have implemented FMEAs and are committed to following a risk based approach for all the processes. Throughout our journey, FMEA has been a very helpful tool to identify and eliminate the issues even before the occur, which helps us to keep our rejection percentage at par minimum level. It helps us prioritize areas for improvement based on the severity, occurrence, and detectability of potential failures.

4. Master Plan of Jolly Clamps — Control Plans: A robust quality control framework necessitates planning and execution. At Jolly Clamps, we implement detailed Control Plans that outline every critical step in the manufacturing process. These plans specify key parameters, inspection points, and control measures to ensure consistency and adherence to quality standards. By adhering to these control plans, we guarantee the uniformity and precision of our clamp products.

5. Statistical Process Control (SPC): SPC involves monitoring and controlling production processes through statistical methods. Control charts, histograms, and process capability analysis are common SPC tools used to detect variations and maintain process stability. Capability indices assess the capability of a process to produce products within specification limits. Cp measures the potential capability, while Cpk measures the actual capability, accounting for any deviations from the target.

6. We have got eyes everywhere — Visual Inspection: Visual inspection is a major part of our inspection process. It involves manually checking products for defects, irregularities, or deviations from specifications. Along with the previous “Lesson Learned”, “Quality Alerts” and “Defect Displays” as each production and inspection stage, visual inspection helps each and every operator to identify and prevent any defective product from passing to the next process.

7. Measurement System Analysis: Conducting MSA assesses the reliability and consistency of measurement systems at our facility, ensuring that our equipment and operators provide accurate and repeatable results may it be variable of attribute characteristic.

8. Continuous Improvements, Kaizen: At Jolly Clamps, improvements are proposed, implemented and appreciated from our operators as well as our staff. These incremental improvements in our processes have been helping us to optimize and improve them. It involves the entire workforce and fosters a culture of continuous learning and enhancement. We take pride in announcing our IATF 16949 and EMS certifications, reflecting our dedication to meeting the highest standards in automotive quality management and environmental responsibility.

9. Integrated Quality Control Measures: The IATF 16949, ISO 14001 and ISO 45001 certifications seamlessly integrate with our existing quality control measures, creating a harmonized approach to excellence. Every step of our manufacturing process, from raw material inspection to final product testing, aligns with the principles of these certifications. By following strict guidelines and protocols, we ensure that Jolly Clamps not only meet the standards but sets new benchmarks for quality and sustainability in the industry.

10. Traceability and Accountability The IATF 16949 certification emphasizes the importance of traceability throughout the supply chain. At Jolly Clamps, we have implemented robust traceability systems that allow us to track and verify the origin and journey of every component used in our clamps. This not only ensures compliance with certification requirements but also enables us to quickly respond to any quality-related concerns, further enhancing customer satisfaction.

Choose Jolly, Choose Excellence : Jolly Clamps is synonymous with quality, and our in-house laboratory, equipped with advanced technologies is a testament to our dedication. Our commitment to quality extends beyond the manufacturing floor and is deeply embedded in our comprehensive quality control measures. Every step in our manufacturing process is meticulously planned and executed, guided by a relentless pursuit of excellence. When you choose Jolly Clamps, you’re not just getting a product; you’re getting a guarantee of excellence backed by rigorous testing and quality control measures, you’re choosing a product that embodies precision, reliability, and performance backed by a robust quality control framework.

0 notes

Text

7 QC Tools Training Demystified: A Step-by-Step Guide to Quality Improvement

Are you looking to improve the quality of your products and services? If so, 7 QC Tools Training is a great way to get started. Quality control (QC) tools are used by organizations around the world to help identify problems and opportunities for improvement in their operations. But what exactly is 7 QC Tools Training? And how can it benefit your business?

7 QC Tools Training provides an introduction to seven basic quality control tools: check sheets, cause-and-effect diagrams (also known as Ishikawa or fishbone diagrams), Pareto charts, histograms, scatter plots & graphs, flowcharts, and measurement system analysis training. These seven simple but powerful tools provide a systematic approach to problem-solving that can be applied across many different industries from manufacturing to healthcare. Each tool has its own specific purpose within the overall framework of improving product or service performance through better data collection methods and analysis techniques.

The first step in any successful 7 QC Tool program is understanding each individual tool’s purpose and function within the larger context of improving product/service quality assurance processes throughout your organization's value stream(s). Check sheets allow you to quickly capture large amounts of data without having too much detail; cause-and-effect diagrams show relationships between variables that may affect production outcomes; Pareto charts display frequency distributions with relative importance; histograms measure process variability over time; scatter plots & graphs compare two sets of values visually, while flowcharts demonstrate sequential steps in a process sequence—all useful information when trying to understand where potential issues may lie along with possible solutions.

Also Read: Measurement System Analysis Training

Lastly, measurement system analysis training helps assess whether existing measuring systems are accurate enough for effective decision-making purposes before implementing corrective actions if necessary.

Once each individual tool’s purpose has been understood, then comes implementation - which requires proper planning prior to execution, such as determining who will use them, when they should be used, what type of results need collecting, etc. This includes creating templates or forms associated with these documents; setting up databases; establishing procedures on how collected data will be analyzed, etc. It also requires everyone involved to be trained on both proper usage/interpretation and understanding why their role matters in order for these efforts towards continuous improvement initiatives to become successful long-term.

Overall, 7 QC Tools Training offers an efficient way not only to identify potential areas needing improvements but also allows companies to focus resources more effectively towards achieving desired goals faster than traditional means alone would have allowed previously.

0 notes

Text

Seven new management tools - 7QC Tools

“As much as 95 per cent of all quality-related problems in the factory can be solved with seven fundamental quantitative tools.”

-Kaoru Ishikawa, The inventor of Fishbone Diagram

In today’s customer-centric market, quality is an integral factor in the growth and sustainability of any business. Businesses go the extra mile to provide the best and excellent customer experience to ensure customer satisfaction. Hence, efficient quality management which has the highest impact on customer experience is one of the most essential features for any business.

Introduced by Kaoru Ishikawa, the seven basic tools of quality also known as 7 QC tools are very effective in quality management and quality assurance process. So, businesses who want to ensure competitive and excellent quality of their products and services can utilize the proven 7QC tools for structuring a strategic plan for quality improvement.

Types of quality management tools

Cause and Effect Diagram

Cause and Effect Diagram also known as Fishbone Diagram helps in identifying the potential causes of an effect or a problem. In addition to sorting ideas in respective categories, it also helps in understanding the areas of opportunity through effective brainstorming. Fishbone training empowers you to identify the potential cause in the problem.

Control Chart

Control charts are used to study how the processes have changed over a period of time. Further, by comparing current data to historical control limits, one could lead to the conclusion about whether the process variation is consistent as in under control or unpredictable as in out of the control due to being affected by special causes of variation.

Pareto Chart

Pareto Chart is based on the 80/20 rule where it shows the significant factors that have the highest impact on the identified problem.

Check Sheet

Check sheet is a structured process which helps to collect and analyzing data. It is an effective tool that can be for a variety of purposes.

Histogram

Histogram is commonly used a graph that shows the data and its frequency of distribution to help users identify each different value in a set of data occurs.

Scatter Diagram

Scatter diagram shows the relationship between two important factors i.e. pairs of numerical data, one variable on each axis to demonstrate the relationship.

Stratification

Stratification also known as a flow chart or run chart is a technique that separates the data gathered from a variety of sources so that patterns can be seen i.e., the path an entity has taken through a defined process.

Utilizing the 7 QC tools in six sigma or quality management process helps in taking a systematic approach to identify and understand the risk, assess the risk, control fluctuation of product quality and accordingly provide solutions to avoid future defects.

WHEN SHOULD YOU USE 7 QC TOOLS?

7 QC tools can be carried out during the quality management, quality improvement process, six sigma implementation processes or even the regular PDCA cycle for the quality purpose for enhanced quality management.

In the first phase of measuring and identifying, Fishbone Diagram also known as cause and effect diagram, Pareto Chart and Control Chart can be utilized. In the next phases of assessment and analysis, Scatter Diagram, Histogram and Checklist can be carried out. The Control Chart can be utilized consistent quality improvement.

BENEFITS OF 7 QC TOOLS

The 7 QC tools are structured and fundamental instruments that help businesses improve their management and production process for achieving enhanced product quality.

From assessing and examining the production process, identification of key challenges and problems to controlling the fluctuation present in the product quality and providing solutions for prevention of defects in future, the easy to understand and implement, 7 QC tools are very effective. Some of the major business benefits of 7 QC tools are listed below.

Provides a more structured path for problem-solving and quality improvement

Easy to understand as well as implement yet extremely effective

A scientific and logical approach for problem-solving

Follows the 80/20 rule i.e. gain 80% result with 20% efforts

Improve the quality of product and services

Helps in identifying and analyzing problems during the process

Fishbone training aides in root cause analysis and problem-solving

Encourages team spirit and fosters a healthy culture

Identifies roots cause and solve it permanently

Enhance customer experience and customer satisfaction

#types of quality management tools#data quality control tools#new seven management tools#stratification quality tool pdf#7 qc tools คือ#7 new tools#seven new management tools

1 note

·

View note

Text

7 QC Tools for Quality Improvement in Manufacturing & Services Industries

In our competitive business climate today, consistently providing a quality product or service is not a choice, it is necessary. Whether in the manufacturing or service industry, the task of fulfilling expectations of a customer requires tools that help you to identify the problem, analyze the data, and the process of improvement. This is where the 7 QC (Quality Control) Tools come into play.

The 7 QC Tools are simple, effective, and applicable to everyone; they are the basis for quality improvement for all industries. Let’s take a look at each of these tools and how quality can provide value to you in your work.

What Are the 7 QC Tools?

The 7 QC Tools are basic statistical tools developed by Kaoru Ishikawa, a Japanese quality expert, to improve product and service quality. They are:

Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

Check Sheet

Control Chart

Histogram

Pareto Chart

Scatter Diagram

Flow Chart (Process Mapping)

These tools help teams in problem identification, root cause analysis, monitoring processes, and decision-making — critical to achieving Total Quality Management (TQM) and continuous improvement.

1. Cause-and-Effect Diagram (Fishbone Diagram)

Also known as the Ishikawa Diagram, this tool is used to identify the root causes of a problem by categorizing possible causes into groups such as:

Man

Machine

Method

Material

Measurement

Environment

📈 Use Case:

In a manufacturing plant, if there’s a defect in the product, the Fishbone Diagram helps break down and analyze every possible factor that could be causing it.

In a service company, it could be used to find why customer complaints have increased.

2. Check Sheet

A Check Sheet is a structured, prepared form used to collect real-time data at the location where it is generated. It's one of the simplest and most effective tools for tracking how often a problem occurs.

📈 Use Case:

In manufacturing, it might track the number of defects per shift.

In services, a call center might use it to log the types of issues customers report.

3. Control Chart

Control Charts are used to monitor process variation over time and determine whether a process is in a state of control.

It distinguishes between:

Common cause variation (normal)

Special cause variation (abnormal)

📈 Use Case:

A manufacturing process using machinery can track the consistency of product dimensions.

In services, a control chart could monitor average call handling time to ensure it stays within set limits.

4. Histogram

A Histogram is a graphical representation of data distribution. It shows how often each different value in a set of data occurs.

📈 Use Case:

In manufacturing, it helps identify the spread of measurement values, like length or weight.

In services, it can show customer satisfaction ratings to identify performance trends.

5. Pareto Chart

Based on the 80/20 rule, the Pareto Chart helps prioritize problems by showing which causes contribute most to an issue.

It ranks issues from most to least significant, so teams can focus on the "vital few" rather than the "trivial many."

📈 Use Case:

In manufacturing, it helps identify which types of defects occur most frequently.

In services, it can identify the top reasons for customer complaints or service delays.

6. Scatter Diagram

A Scatter Diagram shows the relationship between two variables. It helps determine if a change in one factor affects another.

📈 Use Case:

In manufacturing, you could study the relationship between machine maintenance frequency and product quality.

In services, it might analyze how employee training hours affect customer satisfaction scores.

7. Flow Chart (Process Mapping)

A Flow Chart maps out every step in a process, helping visualize workflows and identify unnecessary steps, delays, or bottlenecks.

📈 Use Case:

In manufacturing, it can map out an assembly process to find inefficiencies.

In services, it can improve the flow of customer onboarding or complaint resolution processes.

Benefits of Using 7 QC Tools in Manufacturing

Reduces defects and rework

Increases productivity and process control

Improves product consistency

Increases the effectiveness of decision making when using data to support decisions

Improves customer satisfaction and retention

Benefits of 7 QC Tools in Services Industry

Improves service delivery time

Reduces customer complaints

Improves employee performance through better processes

Enables proactive problem-solving

Supports a culture of continuous improvement

How to Implement the 7 QC Tools in Your Organization

Step 1: Train Employees

Start with basic training on each QC tool so that employees understand when and how to use them.

Step 2: Identify Problems

Pick a real problem that affects your quality, such as high defect rates or customer dissatisfaction.

Step 3: Choose the Right Tool

Each tool has a unique function. Select based on what you want to analyze — root cause, trends, relationships, etc.

Step 4: Analyze Data

Use the tool to collect and interpret data. Look for patterns, trends, or anomalies.

Step 5: Take Action

Based on the analysis, make informed decisions and implement process improvements.

Step 6: Review & Improve

Monitor the results of your changes and keep refining your processes.

How 4C Consulting Can Help

With experience of working with over 2500+ clients and delivering more than 15,000 hours of quality training, 4C Consulting is your expert partner in implementing QC tools, ISO standards, and quality improvement frameworks.

Our consultants will:

Provide hands-on training on 7 QC Tools

Help create customized checklists, charts, and templates

Assist in integrating these tools into your Quality Management System

Support your team in problem-solving and performance tracking

Ready to improve your quality processes? 👉 Talk to our experts today for a free consultation!

#7 QC Tools#Quality improvement tools#QC tools in manufacturing#QC tools in service industry#How to use 7 QC tools#Basic quality control tools#Problem-solving tools for quality#7 QC tools implementation#Quality management tools

1 note

·

View note

Text

Reliable Digital banking development company in Vietnam

The digital transformation for banking institutions can help clients have a good experience when implementing transactions. Aside from that, investing in digital banking development gives a great advantage in cost reduction. So, many companies are looking for a mobile application development company.

Finding a reliable digital banking development company is very difficult because the software market has a larger amount of providers and you have no idea about hiring them. Let's keep reading this article it can give you a helpful suggestion.

Benefits of digital banking development

Digital transformation for banking institutions brings a lot of advantages for the customers, individual ones, small companies, and huge corporations, as well as banks themselves. Clever strategy and constant improvements can result in a number of advantages:

Digital banking development brings a lot of advantages for the users and banking institutions

Convenience and Time - saving

Personal and company bank accounts are available at any device, the only things you need are an Internet connection and a few taps on the screen. This brings more customer satisfaction as they are able to constantly keep on track of their account balance and manage the information on their personal profile.

In addition to this, there is no need to go to the bank to conduct the transaction as they can do it on a mobile phone. It helps users saving-time significantly.

Cost savings

When transaction on digital banking can reduce the dependence on paper forms, as all transactions are done electronically, which contributes to reducing the expenses incurred by the conventional bank and the client pays them administrative expenses.

24/7 Service

Online banking services are available 24/7 all year round, even at the weekends. There is no need to stay in lines and wait for the bank to open in order to conduct certain operations.

Easier Management

Online accounts can be easily managed, although they require more information than traditional banks. Customers can add information themselves or directly contact online assistants to provide support on the current issue. What is more, digital banking allows users to retain payee information within the system, there is no need to re-enter data for the following payments, etc.

More Securities

Digital banking provides higher security and less risk of manipulation or theft of checks. In addition, the reliability of cash flows is higher and the speed of the movement of cash is faster.

Innotech Vietnam

Innotech Vietnam is a reliable mobile app development company in Vietnam. Be appreciated for high-quality products, services, and innovative solutions in a fintech company. We strive to create innovation and develop advanced fintech solutions. We provide a wide range of mobile application services, ready to meet all customer service requirements. The products and solutions we offer based on these advanced technologies become valuable for our customers through professional project management methods and tools to help customers effectively manage progress and resources a force of the project.

Innotech's head office

Innotech Vietnam has done more than 200+ mobile app projects for clients worldwide in Japan, the USA, Australia, Singapore and Vietnam. We’re confident to deliver even the most complicated mobile app development project successfully in areas such as banking and financial, logistics, transportation, education, and other industries. More than 90% of companies have kept coming back to Innotech for a wide range of Mobile App Development and they enjoy the same standard of service every time. Besides, we are proud that we are trusted by many Institutions in Banking and Finance such as ACB Bank, Tyme Bank, Unifimoney, Manulife, Commonwealth Bank, …

Digital Banking Development Services

Digital banking development services have offered many comfortable features and possibilities for users.

Digital banking should have many comfortable features and possibilities for users

Online Banking

To facilitate online use, most banks that offer online banking provide a host of high quality, technological solutions that make your banking experience easy and fast. The online banking development provides users banking services anytime and anywhere include:

View a summary of your account and transaction history

You can view or print your account statements and balances

Set up online payments and direct deposit services

Reorder checks for your account via the web

Some services allow you to export your account histories to third-party accounting software

Transfer funds from one account to another or make deposits which saves a lot of time and money for you.

Other accounts and services like CDs, IRAs, and others can be managed from the online account.

Personal Finance Planning

It's an advanced feature that digital banking brings to users. Users can loan calculators, premium calculators, financial planning tools, tools to help analyze investments, budgeting, forecasting, and also tax preparation, etc. Most of the financial planning can be done efficiently on digital banking without the need to personally visit a bank.

Mobile banking options

Users can do mobile banking app from anywhere and at any time only with smartphones. Just a few clicks on mobile phones, users can perform transactions include:

Transfer services allow users to transfer money to another person and between the owner’s accounts at different banks.

Payment services can directly pay the mobile fees, book tickets (movies, flights), automated payment for water/electricity bills, etc. In addition, users can set payments scheduling to make regular payments and pay bills in a snap.

Mobile banking app can integrate more features for users such as QR transfer, QR Payment, Snapshot, Biometric, Notifications,…

A chatbot on the mobile banking app can help 24/7 support and get professional consultation or advice anytime users need it.

Read more: “Reliable mobile development for banking company in Vietnam"

Digital Wallet

Digital wallets are one of the best innovations in the field of technology. Users can make payments from these e-wallets at shop, supermarket,.. there is no need for a physical card.

Rewards and Loyalty Program(s)

These digitally integrated reward programs are more efficient cost-effective and measurable, reward and incentivization capabilities to customer acquisition and retention. Such as special gifts, promotion code, coupons, vouchers and cashback, etc. for regular users.

Non-Internet Based Phone Banking

Users have also been made more convenient digital banking services on devices that do not have an internet connection. These services include SMS, Missed Call and USSD banking.

With SMS and missed call banking services, you are only required to send a text or give a missed call on some specific numbers.

USSD banking lets you access a host of banking services just by dialing *99# from your mobile number and interacting with a menu.

They can be accessed from anywhere and at any time since they do not need an internet connection. Especially, they are free services and all transactions are completely cashless.

Dedicated Remote Adviser

Remote banking makes your banking experience simple and hassle-free by dedicating a digital relationship manager for their service at anywhen and anywhere.

Users can be assured of a dedicated relationship manager at their service, for taking care of all their banking and financial needs, during banking hours or even beyond them.

Why should you choose Innotech Vietnam?

Expert by experience

With more than 12 years of experience, Innotech Vietnam has experience in core banking software integrations for financial institutions such as ACB Bank, Tyme Bank, Unifimoney, Manulife, Commonwealth Bank, etc.

Ready solutions

Technical solutions and demonstration of a product or technique are available.

Dedicated teams

With more than 80+ mobile app developers, UI – UX Design, BA, project managers and QA/QC. Innotech staffs have good knowledge of banking and financial operation.

Young, dynamic, professional and creative engineers combined with highly experienced experts

Reputation

Experience in consulting, deploying and managing mobile applications with more than 2 million users.

Cybersecurity

Maintaining the security and confidentiality of our clients’ projects is always our top priority. We try our best to respond to cybersecurity standards for the partner.

Read more case study:

ACB BANK – MOBILE APP DEVELOPMENT CASE STUDY

MANULIFE – INSURTECH SOLUTIONS CASE STUDY

TYMEBANK – SHORTAGE OF HIGH-QUALITY ENGINEERS AND SOLUTIONS.

UNIFI.MONEY – NEO BANK APPLICATION DEVELOPMENT

If you are looking for a Mobile App development company to provide solutions for digital wallet companies, we're happy to grant our services. Contact experts at Innotech Vietnam for any questions about Mobile Application!

Email: [email protected]

Fintech Vietnam is a technology update portal about Fintech in Vietnam and Fintech trends worldwide.

Nguồn: https://fintechvietnam.com.vn/reliable-digital-banking-development-company-in-vietnam/

1 note

·

View note

Text

Eris Therapeutic Limited, a subsidiary of Eris Lifesciences Ltd, is actively hiring for various roles in the Quality Control (QC) department, including QC Microbiology and GLP/Finish Product, as well as Environmental Health and Safety (EHS) professionals. This exciting opportunity is based near Bavla, Ahmedabad.. QC Microbiology Senior Executive Role Designation: Senior Executive – QC Microbiology Qualification: M.Sc. in Microbiology Experience: 8-10 years Location: Near Bavla, Ahmedabad CTC Offered: Up to ₹7.50 LPA Preferred Experience: OSD/Injectable plant exposure Key Responsibilities: Oversee microbiological testing and ensure compliance with Good Laboratory Practices (GLP). Handle the preparation and review of microbiology protocols, SOPs, and analysis reports. Conduct routine and non-routine microbiological analysis of raw materials, in-process samples, and finished products. Monitor environmental conditions in production areas and ensure all quality standards are adhered to. Provide technical expertise and support to resolve microbiological issues during production. This role requires candidates with strong knowledge of microbiological testing, experience in OSD (Oral Solid Dosage) or injectable manufacturing environments, and a commitment to quality control processes. QC GLP / Finish Product Executive/Senior Officer Role Designation: Executive/Sr. Officer – Quality Control Qualification: B.Pharm / M.Sc. (Chemistry) Experience: 3-6 years Location: Near Bavla, Ahmedabad Preferred Experience: Pharmaceutical experience in OSD/Injectable/Ointment plants Key Responsibilities: Handling all lab instruments of HPLC, GC, Dissolution, D. T., Apparatus, Weighting balance, Friability, Hardness, Tester, FTIR, UV – Spectrophotometer. Analysis of semi product product, In-process, Finish products, Stability testing, Process validation. Participate in Lab incident /OOS/OOT/Analysis of deviation. Must be worked in semi finish product/Finish product/ GLP section. This role is ideal for professionals with experience in GLP and quality control, specifically in pharmaceutical settings, and who are looking for opportunities to contribute to a growing and dynamic team. EHS Officer Role Designation: EHS Officer Qualification: Diploma in Industrial Safety Experience: 5-7 years Location: Near Bavla, Ahmedabad Preferred Experience: Pharmaceutical industry exposure Key Responsibilities: ETP & RO operation and daily monitor of PH,TDS , BOD and COD. Fire Hydrant system & Fire extinguishers. Fire alarm system. Monitoring the work permits and other activities in campus to ensure safe working. Ensuring the safe construction activities in co-ordination with PMC to ensure accident-free site. Regular inspection of Fire pump room, service block, HSD yard, LPG banks and STP. Conducting risk analysis and ensuring the proper solution to avoid the risk & hazard. Record keeping and documentation of EHS related work. Inspection of machines, lifting tools and other equipments to ensure the compliance and safe working. Checking of firefighting and detection system to ensure the proper working. Training to the construction workers and service staff. Ensuring the safety induction of workers in co-ordination with PMC. Ensuring contractor’s safety programme. Inspects the facility to identify safety, health, and environmental risks. Develops and implements inspection policies and procedures, and a schedule of routine inspections. Develops health and safety procedures for all areas of the company. Prepares and schedules training to cover emergency procedures, workplace safety, and other relevant topics. Monitors compliance with safety procedures. Ensures that material safety data sheets are maintained and readily accessible when needed. Maintains records of discharge of or employee exposure to hazardous waste and/or pollutants, as required. Prepare data for GPCB form 3, 4, 5. Maintain record of safety form no. 9,10,11,37.

Prepare HIRA, and Environmental Aspect Impact. This role demands candidates with robust EHS management skills, a proactive approach to safety, and experience in the pharmaceutical industry. How to Apply Interested candidates who meet the qualifications and experience criteria can submit their updated resumes with the following details: Total Experience Qualification Current Salary Notice Period Designation Submit your CV to: 📧 [email protected]

0 notes

Text

Benefits of Using 7 QC Tools

Implementing 7 QC Tools in your organization offers numerous advantages, including:

Improved Quality: Identify and rectify issues swiftly, leading to higher-quality products and services.

Cost Savings: Eliminate waste and reduce operational costs.

Data-Driven Decisions: Make informed decisions based on data analysis.

Enhanced Efficiency: Streamline processes and workflows for greater efficiency.

Customer Satisfaction: Consistently meet customer expectations, leading to increased loyalty.

1 note

·

View note

Text

Kaizen Training: 5 Key Strategies for Enhancing Workplace Efficiency

Kaizen training is a powerful tool for improving workplace efficiency. It encourages employees to identify and eliminate wasteful practices, while also helping them develop new skills that can help improve their productivity. Kaizen training helps create an environment of continuous improvement by encouraging employees to take ownership of their work and strive for excellence in all aspects of the job. Here are five key strategies for enhancing workplace efficiency through Kaizen Training:

1) Focus on Process Improvement: By focusing on process improvement, you can identify areas where processes are inefficient or need updating. This allows you to make necessary changes that will increase overall productivity and reduce waste in your organization's operations. Additionally, it gives employees the opportunity to become more involved in problem-solving as they learn how different processes interact with each other within the company structure.

2) Empower Employees: Kaizen Training encourages employee empowerment by giving them a voice when it comes to making decisions about how things should be done at work – allowing them to feel like they have some control over what goes on around them rather than just following orders from management blindly. This sense of autonomy contributes significantly towards improved morale amongst staff members which leads directly to increased motivation levels resulting in greater success rates overall!

3) Utilize Data Analysis Tools & Techniques: Using data analysis tools such as Lean Six Sigma or Kanban boards provides valuable insights into identifying bottlenecks within production systems so that improvements can be made quickly without disrupting current operations too much - thus saving time & money! Additionally, these techniques allow managers/owners better visibility across departments ensuring everyone is working together efficiently towards common goals set out beforehand (ease communication).

Also Read: 7 QC Tools Training

4) Encourage Collaboration between Departments: To ensure maximum efficiency throughout all departments, it’s important to encourage collaboration between teams so ideas/best practices can easily flow back and forth leading to successful outcomes faster than if every team was operating independently (no sharing info). Furthermore, this type of cooperation often leads to creativity due to its ability to foster constructive criticism among colleagues who may otherwise not have had a chance to brainstorm together previously - ultimately creating an atmosphere of innovation that benefits the entire organization greatly going forward!

5) Measure Results Regularly: Finally measuring results regularly allows companies to track the progress being made against targets set out before implementation began; this ensures any issues occurring during the implementation stage are addressed swiftly avoiding costly delays later down the line due to lack of foresight planning ahead correctly initially! Allowing organizations access to real-time data makes decision-making easier enabling quicker responses needed when situations arise suddenly.

Also Read: Process Capability Training

0 notes

Text

Maison Koya, Saint-Sauveur

Maison Koya, Saint-Sauveur House, Québec Home, Canadian Real Estate, Architecture Images

Maison Koya in Saint-Sauveur, Québec

26 Nov, 2020

Maison Koya

Design: Alain Carle Architecte

Location: Saint-Sauveur, Canada

The Maison Koya site is part of a real estate development on the approaches to the town of Saint-Sauveur in the Laurentians. This area is in Montréal’s second ring of outlying communities, where the occupants have chosen to settle to combine a lifestyle in a natural setting (in the mountains) with the conveniences of a small regional town.

The clients have also chosen to make their project multigenerational, by allocating spaces for grandparents and their children. There is thus a temporal relationship, which poses an interesting problem for the design of this residence’s spaces.

The architect is interested in changing the nature of the program, the family composition, and the residents’ location in the spaces that are bound to change over time within the complex.

The project instead revolves around this temporal relationship, by structuring a mode of implementation related to the topographical features rather than to a logic of single-family row housing, typical of suburban areas. The project’s morphology materially distinguishes the more permanent elements of the residence, in concrete, from the more ephemeral components in wood. Like a sculptural bas-relief, the main traffic axes on the site become the two axes of the composition of the complex.

Different concrete retaining walls, landings, and transitional stairways install a new topography on the site, a conclusive structuring for what happens next. Deep geothermal boreholes “anchor” the composition in sustainability and address the energy needs metaphorically rather than in strictly technical terms.

Three wooden volumes are then deposited on the exterior of this new topography to accommodate the changing nature of the program. They are cantilevered on the concrete structures, in an unstable situation, and point respectively in opposite directions. Thus, this complex is detached from a conventional composition of the suburban single-family home, which often has a very distinct expression between the front and rear facades, to the detriment of the sides. Maison Koya instead seeks to establish a more open relationship with the site in the broader sense. The morphology here instead attempts, by multiple sawtooth patterns and small outdoor subspaces, to establish a diversified reading of the landscape, regardless of the structure of the lots or a single landscape component.

The idea of preferring a single point of view on the landscape (as the dominant observer) seems to attest to a recurring architectural problem, the outcome of thinking that favors the building as an “object”. In this perspective, the spaces are designed in the absence of reality as it is offered, in all its ambiguity and impurity, legitimizing a stylistic (i.e. canonical) approach instead of an approach based on the alterity of the form. Once again, the issue is not to work with ambiguity for the sake of ambiguity, to make it a “style” per se, but rather to accept the share of alterity offered by the infinite configurations of reality.

There are multiple accesses to the building without a specific hierarchy. In continuity with the landscape, these accesses have a fluid relationship with the lower spaces, where the indifferenciation of the building’s internal traffic system seeks to engage a non-hierarchical relationship with the landscape (see the typically suburban context of the neighboring structures).

Only a central space situated at the intersection of the three wood structures constitutes a place of convergence for the three generations inhabiting the complex. This metaphorically is the meeting place, a “public place” materially inscribed in the permanence of the mineral structure. This is the founding place of the complex, inscribed in movement. This possibility of moving between the internal and external parts of the building engages a type of open use, a possibility of reconfiguration of the occupations of the spaces over time as if each of the three structures could be reconfigured according to the changes of use.

In a certain way, the essence of the project resides in the relationship between the necessity of creating a temporality for every built structure, of inscribing the concept of space in time, or at least in anticipation of time.

Maison Koya in Saint-Sauveur, Québec – Building Information

Design: Alain Carle Architecte Location: Saint-Sauveur, Québec, Canada Year of completition: 2019 Area: 696 sqm / 7 500 ft2 Lead Architect: Alain Carle Project manager: Isaniel Lévesque Landscape design: Carlos Ipser Contractor: Self build Windows: Alumilex Roof covering: Black sheet, Toitures Vaillancourt Exterior wood 1: Light red cedar with a black dyed knot Exterior wood 2: Cognac brown dyed light eastern cedarWood Architectural concrete: Concrete with plank formwork Cabinetmaking: Walnut and oak Flooring: Slate tiles, oak planks Landscape design: Concrete wall, paving of stone Saint-Marc guided and corten steel tanks

About Us Alain Carle Architecte Alain Carle has worked in the architecture field in Montréal for twenty years. Based on a pedagogical approach he developed as a teacher and researcher in the Master’s program at the School of Architecture of the Université de Montréal, his achievements rely on a critical approach to representation in the design process.

Since 2000, the firm Alain Carle Architecte has conceived urban design and architectural projects on different scales for public and private bodies.

Assisted by a stable team of creative and daring minds, with complementary competencies and experience, the Alain Carle Architecte team guarantees a strong capacity for listening and openness to its clients in the custom design of projects.

Since 2018, Alain Carle presents his lecture “The Part of Landscape” in different universities of Quebec and across the United States, on the perceptual qualities that the careful study of the landscape offers. As an essential component of its approach, the landscape is not a tool to define identity, but rather an opening to the specificity, the difference, and the capacity for alteration that it carries within it.

Recently, the exhibition “Le Parloir – L’Empreinte” presents an installation at the School of Architecture of Quebec, taking shape from an interpretation of the exhibition site as such, formerly a parlour, part of the Grand Quebec Seminary. The reinterpreted landscape, as the ultimate polymorphic space and inexhaustible source of narratives, emerges as a metaphor for otherness in Carle’s work.

On the strength of its growing reputation in Québec, Alain Carle Architecte now practices internationally.

Photographer: Raphael Thibodeau

Maison Koya, Saint-Sauveur information / images received 261120

Location: Saint-Sauveur, Québec, Canada

Montreal Architecture

Montreal Architecture

Montreal Architecture Designs – chronological list

Montreal Architectural Tours Montreal Architecture Walking Tours by e-architect

Chalet La petite soeur, Saint-Donat-de-Montcalm, Canada Architects: ACDF Architecture photography : Adrien Williams Residence in Saint-Donat-de-Montcalm

La Luge Cabin, La Conception, in the Laurentides region of Quebec, Canada Architects: YH2 photograph : Francis Pelletier New House in La Conception

Mount-Royal Kiosks, Parc du Mont-Royal, Montreal, QC, Canada Architectes: Atelier Urban Face photographers : Fany Ducharme, Normand Rajotte, Sylvain Legault and Sylvie Perrault Mount-Royal Kiosks

Ville-Marie Apartment Architectes: naturehumaine photo : Adrien Williams Ville-Marie Apartment

Canadian Architects image courtesy of architects

Canadian Architecture

Montreal Buildings

Canadian Buildings

Comments / photos for the Maison Koya, Saint-Sauveur Canada Architecture page welcome

Website: Saint-Sauveur

The post Maison Koya, Saint-Sauveur appeared first on e-architect.

0 notes

Text

7 core tools of quality - 7 quality control tools pdf - tools of quality control

“As much as 95 per cent of all quality-related problems in the factory can be solved with seven fundamental quantitative tools.”

-Kaoru Ishikawa, The inventor of Fishbone Diagram

In today’s customer-centric market, quality is an integral factor in the growth and sustainability of any business. Businesses go the extra mile to provide the best and excellent customer experience to ensure customer satisfaction. Hence, efficient quality management which has the highest impact on customer experience is one of the most essential features for any business.

Introduced by Kaoru Ishikawa, the seven basic tools of quality also known as 7QC tools are very effective in quality management and quality assurance process. So, businesses who want to ensure competitive and excellent quality of their products and services can utilize the proven 7QC tools for structuring a strategic plan for quality improvement.

LIST OF 7 QC TOOLS

Cause and Effect Diagram

Cause and Effect Diagram also known as Fishbone Diagram helps in identifying the potential causes of an effect or a problem. In addition to sorting ideas in respective categories, it also helps in understanding the areas of opportunity through effective brainstorming. Fishbone training empowers you to identify the potential cause in the problem.

Control Chart