#7 QC Tools Examples

Explore tagged Tumblr posts

Text

Understanding the 7 QC Tools: The Foundation of Quality Improvement

In every quality-based company, problem-solving involves going beyond just resolving an issue. It requires deep diving into understanding why the issue arose in the first place. This is exactly where the 7 Quality Control (QC) Tools come into play.

Designed in Japan, these tools offer a practical, visual, and data-oriented method for problem-solving, analysis of processes, and continual improvement. Be it managing production lines, performing compliance audits, or spearheading digital transformation projects, the 7 QC Tools assist teams in clearly and systematically eliminating root causes, minimizing variation, and improving performance.

All seven tools contribute to the enhancement of evaluating processes and inefficiencies for the sake of achieving ongoing operational excellence. Their collective application builds a comprehensive system that can be used in any field, including but not limited to, healthcare, logistics, and information technology.

The 7 QC Tools for Quality Improvement

These tools form the foundation of any successful Quality Management System (QMS). Their straightforward nature as well as flexibility make them indispensable for any team that aims at building a culture of quality.

1. Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

This tool aids in outlining every potential cause a given problem may have. By grouping causes into manpower, methods, machines, measurement, materials measurement and environment, teams deepen their understanding of the issue.

Example: A sealing two-hundred boxes of country's best raw honey fails repeatedly. A packaging team takes this diagram to help overcome this issue.

2. Check Sheet

As simple as it gets, check sheets allow customers to identify all types of orders, including defects, errors, and occurrences systemically.

Example: A logistics company tracks and identifies peak periods for late deliveries using check sheets.

3. Control Chart

A process is stable when the control upper and lower limits are constant, while in need of corrective action when they change. Control charts display process behavior over time.

Example: A pharmaceutical company control charts to avoid inconsistent temperature control during production.

4. Histogram

Example: IT support teams resolve tickets and average the time taken to do so.

5. Pareto Chart

Example: A call center finds out that two service lines account for a majority of customer complaints through Pareto analysis.

6. Scatter Diagram

Example: An HR manager tests a theory about onboarding hours and early-stage employee error reduction by increasing onboarding hours.

7. Flowchart

A flowchart is one of the ways to visualize processes step-by-step. It helps teams pinpoint inefficiencies, bottlenecks, and redundancies.

Example: A hospital maps out its discharge process to identify and eliminate delays.

Where Can These Tools Be Used?

Finally, all industries can use the 7 QC tools, even if they were primarily used in manufacturing.

In ESG compliance: Monitor sustainability KPIs and supplier risk.

In HR: Streamline hiring and employee performance monitoring using flowcharts and control charts.

In IT: Use histograms and Pareto charts to improve response times for help desk services and reduce system outages.

In logistics: Identify service-related delays, optimize routes, and improve service.

These tools allow all organizations, regardless of industry, to practice fact-based decision making, which is crucial in any organization committed to quality.

How to Implement the 7 QC Tools Effectively

The good news is that you don't need expensive tools and certifications to start. Most of these can be implemented using Excel, Google Sheets, or even pen and paper.

Steps to Implement:

1. Identify the problem – Frame the issue you are experiencing as specifically as possible.

2. Select the right QC Tool – Match the problem or analysis with the appropriate tool.

3. Train your team – Make sure the relevant personnel know how to use the selected tools.

4. Collect accurate data – Focus on achieving consistency as well as completeness.

5. Analyze and act – Review all the data and decide what information will lead to improvement.

With some support from leadership and basic training, these tools can easily be integrated into your team's daily routines and problem-solving habits.

Why the 7 QC Tools Matter

The 7 QC tools are incredibly powerful due to how basic they are. They:

• Enable root cause analysis

• Support data-driven decisions

• Promote continuous improvement

• Foster collaboration across teams

• Enhance quality, efficiency, and compliance

In today's world with growing complexities, intense competition, and increasing customer expectations, these tools can serve as a cornerstone for operational excellence and strategic transformation.

How 4C Consulting Can Help You Implement the 7 QC Tools

At 4C Consulting, we focus on integrating quality into the heart of your operations. We have successfully completed over 2,500 ISO implementations and delivered over 15,000 hours of expert training, so we have the experience and deep industry knowledge to help.

Here's how we help your journey with the 7 QC Tools:

✅ Gap Assessment – Identify where your existing processes are relative to your goals.

✅ Tailored Training – Teach your teams to properly use and maintain the QC tools with confidence.

✅ Tool Selection & Deployment – Select the appropriate tools for your specific problems.

✅ Real-Time Application Support – Get hands-on help with real-life projects.

✅ Ongoing Improvement Coaching – Foster an environment that promotes quality, spanning multiple departments.

Looking to aid with process improvement, variability reduction, and establishing an organization-wide continuous improvement culture?

Master the 7 QC Tools and more with 4C Consulting.

👉 Begin your journey to better quality today.

#7 QC Tools#Seven Quality Control Tools#7 QC Tools for Quality Improvement#Implementing 7 QC Tools#7 QC Tools Examples#Quality Management Tools

1 note

·

View note

Text

Benefits of Using 7 QC Tools

Implementing 7 QC Tools in your organization offers numerous advantages, including:

Improved Quality: Identify and rectify issues swiftly, leading to higher-quality products and services.

Cost Savings: Eliminate waste and reduce operational costs.

Data-Driven Decisions: Make informed decisions based on data analysis.

Enhanced Efficiency: Streamline processes and workflows for greater efficiency.

Customer Satisfaction: Consistently meet customer expectations, leading to increased loyalty.

1 note

·

View note

Text

How to Keep Your Check Sheet in 7 QC Tools Current and Move It Forward

In the world of quality control and continuous improvement, the 7 QC tools are the foundation for solving problems and enhancing processes. Among these tools, the Check Sheet in 7 QC tools is one of the simplest yet most powerful methods for collecting real-time data in a structured, visual format.

However, just creating a check sheet once isn’t enough. To keep it valuable and relevant, you must update, improve, and align it with your changing process needs. In this blog, we’ll explore how to keep your Check Sheet current and how to enhance its effectiveness over time.

✅ Why Check Sheets Matter in Quality Control

A Check Sheet helps collect data at the source—during inspections, operations, or even customer service. It’s a tool to track:

Defects and error types

Equipment failures

Downtime causes

Frequencies of events

Inspection results

Used correctly, it helps teams spot trends, make decisions based on evidence, and take corrective actions. But if the format is outdated or misaligned with current operations, it loses effectiveness.

✅ Steps to Keep Your Check Sheet Current and Effective

1. Revisit Your Quality Objectives

Begin by asking: What are we trying to measure or control?

As business priorities shift—new product lines, new machines, or different customer complaints—your Check Sheet must reflect those changes. Update your data categories, frequencies, and timeframes to match your current quality goals.

2. Validate the Categories and Data Points

Are you still tracking the right issues? A Check Sheet created months ago may be collecting data that’s no longer useful.

✔ Eliminate outdated categories ✔ Add new defect types or failure modes ✔ Clarify ambiguous terms ✔ Ensure frontline operators understand each category

3. Keep the Format Simple and Clear

A cluttered or confusing Check Sheet leads to inconsistent data collection. Stick to these principles:

Use plain language

Keep columns/rows organized

Avoid excessive detail

Use tick marks or symbols for faster recording

Consider using digital versions (spreadsheets or apps) for efficiency

4. Align Check Sheets with Process Changes

Have you changed tools, materials, or workflows recently?

Update your Check Sheet to reflect these adjustments. For example, if you’ve introduced automation, you might need to track machine error codes instead of manual defects.

5. Standardize Across Shifts and Teams

Inconsistent data ruins trend analysis. Make sure everyone uses the Check Sheet the same way by:

Providing short training or refresher sessions

Using standardized formats across shifts and departments

Clarifying who fills it out and when

Reviewing entries regularly for completeness

6. Review Data Trends and Take Action

A Check Sheet isn’t valuable unless you do something with the data.

Summarize data weekly or monthly

Identify defect patterns, peak times, or recurring failures

Share findings with relevant teams

Link data to corrective actions, Kaizen events, or root cause analysis

7. Digitize for Better Insights

While paper-based Check Sheets are still useful, digital versions offer advantages like:

Real-time data capture

Easy filtering and analysis

Automatic charts and graphs

Remote sharing with quality teams

Consider using tools like Excel, Google Sheets, or quality management software.

✅ When to Revise or Replace Your Check Sheet

Your Check Sheet may need a revamp if:

The same issues have been solved and no longer occur

New types of defects are emerging

Operators complain it’s too complicated

The data collected isn’t helping decisions

The process being monitored has changed

Don’t be afraid to revise or rebuild your Check Sheet—it’s a living tool.

✅ Benefits of Keeping Your Check Sheet Updated

Ensures accurate, real-time data collection

Helps identify trends before they become major issues

Supports faster problem-solving

Increases operator engagement and ownership

Provides valuable input for other QC tools like Pareto Charts or Control Charts

✅ Conclusion

A Check Sheet may look simple—but when updated and used effectively, it becomes a powerful tool for improving quality. By regularly reviewing and refining it, you ensure it continues to support real-time decision-making, reduce defects, and drive continuous improvement.

Remember, in the spirit of the 7 QC tools, quality is not a one-time act—it’s a habit.

#7QCTools#CheckSheet#QualityControl#ContinuousImprovement#ProcessImprovement#QualityManagement#DataDriven#ManufacturingExcellence#QualityAssurance#RootCauseAnalysis

0 notes

Text

IATF 16949 Consultants: QC Tools Used in the Certification

In the competitive world of automotive manufacturing, quality is not something to strive for; it is imperative. Based on customer expectations, we must also ensure safety, reliability, and compliance with regulations. That’s where a globally recognized quality management standard designed specifically for the automotive sector comes into play in the form of IATF 16949.

IATF 16949 is more than a certification; it embodies a culture of continual improvement and process excellence. Becoming certified, though, is a labyrinth of requirements, documents, and audits. Here is where the role of IATF 16949 Consultants becomes crucial, as they help organizations navigate the process with their knowledge and clear insights.

This is no different for Quality Control (QC) tools, the backbone of any quality management system. These tools assist in issue identification, data analysis, process control, and decision-making based on facts. When coupled with QC tools, consultants help organizations that want to achieve compliance with the certification and improve their quality systems to lay a rock-solid foundation to achieve this.

What is IATF 16949?

IATF 16949 in UAE is a technical specification founded by the International Automotive Task Force (IATF) and the International Organization for Standardization (ISO). They based it on the fundamentals of ISO 9001, but with many automotive-specific requirements that are required for product development, production, and servicing.

The main goal of IATF 16949 Certification in Abu Dhabi is to create a quality management system that promotes continual improvement, focuses on defect prevention, and reduces variation and waste in the automotive supply chain.

Key Objectives:

Benefits of Certification:

As IATF 16949 Certification Consultants, your role is to ensure organizations meet the exacting standards of IATF 16949, thereby enhancing their organizational processes.

The IATF 16949 standard process can be lengthy and requires a lot of documentation, internal audits, and compliance reviews. Enter consultants to the rescue.

Who Are They?

Consultants are subject-matter experts with proven track records in assisting successful rollout and maintenance of standards within organizations.

Services Provided:

Benefits of Hiring a Consultant:

Widely-used QC Tools in IATF 16949

To get the correct products, organizations implement Quality Control (QC) tools. IATF 16949 Consultants in Dubai are essential to help solve problem diagnosis, process control, and decision-making.

The 7 Basic QC Tools:

Tools Related to Advanced Quality Planning (Core Tools):

The Role of QC Tools in the Quality Systems:

Tools for Quality Control Implementation of IATF 16949

It is also worth noting that the above QC tools are not just theoretical but are embedded in the���DNA of IATF 16949 Certification in Dubai.

How do QC Tools Help Compliance?

Example Scenarios:

One of the quality suppliers identifies repetitive defects in a certain part by Pareto analysis and resolves it by Fishbone diagrams and FMEA.

MSA and SPC data are used by an organization during PPAP submission to demonstrate process capability and measurement reliability.

Consultant's Role:

Common Obstacles:

How IATF 16949 Consultants Help in Dealing with Challenges?

The Main Point!!

The IATF 16949 is not only a badge but a testament to excellence, consistency, and customer satisfaction in the automotive industry. Expert guidance and practical tools are needed to reach and maintain this standard.

IATF 16949 Consultants in UAE know what has gone wrong in the past and the strategies, processes, and ways of thinking that will help a company successfully implement the standard and prepare for and respond to audits. On the other hand, QC tools are the eyes and ears of your quality management system, detecting problems and informing decisions.

Collectively, they enable automotive suppliers to raise the bar in the industry. Investing in expert consultants and embracing QC tools is not just smart—it's essential for any organization seeking sustainable growth and operational excellence.

0 notes

Text

What is Statistics? A Beginner's Guide to Understanding the Basics

Statistics is a field that is often misunderstood and overlooked, yet it plays a crucial role in our daily lives. From predicting the outcome of a sports game to understanding the impact of a new medication, statistics is used to make sense of the world around us. However, for those who are new to the subject, the world of statistics can seem daunting and overwhelming. In this blog post, we will provide a beginner's guide to understanding the basics of statistics and the importance of basic statistics training.

So, what exactly is statistics? In simple terms, statistics is the science of collecting, organizing, analyzing, and interpreting data. It involves using mathematical methods to gather and make sense of numerical data, and then using that information to draw conclusions and make decisions.

One of the key components of statistics is data. Data can be defined as any information that can be measured or counted. This can include numbers, measurements, or even observations. For example, data can be the number of people who prefer chocolate ice cream over vanilla, the average height of students in a class, or the amount of rainfall in a particular region. Without data, statistics would not exist.

Now that we understand the basics of statistics, let's dive into some of the key concepts that are essential for beginners to understand.

Also Read: 7 QC Tools Training

1) Descriptive vs. Inferential Statistics

Descriptive statistics involves summarizing and describing data using measures such as mean, median, and mode. It helps to organize and simplify large amounts of data, making it easier to understand. On the other hand, inferential statistics involves using data from a sample to make predictions or draw conclusions about a larger population. This type of statistics is used to test hypotheses and make generalizations about a population based on a smaller sample.

2) Population vs. Sample

In statistics, a population refers to the entire group of individuals or objects that we are interested in studying. For example, if we want to know the average income of all the people living in a city, the population would be all the residents of that city. However, it is not always feasible or practical to collect data from an entire population. In such cases, a sample, which is a smaller subset of the population, is used to represent the entire population.

Also Read: SPC Training

0 notes

Text

➡️ Flow Chart in 7 QC Tools | Process Flow Diagram Explained with Examples

0 notes

Text

Elksourcing:12 Common Mistakes of Importing from China

During the daily practice of importing from China, I’ve learned 12 common mistakes from various clients I dealt with. Here are the details:

1. Looking for the lowest price

If you purchase something below market price, you are taking very high risks. Either quality will not be up to your standard, or you are about to get scammed.

2. Letting the supplier ship without checking product quality

Once a production batch is on a boat, it’s too late. Verify quality yourself, or pay for quality inspection services. And do it systematically, at least for the first 5 shipments (after that, you can do random skip-lot QC).

3. Failing to realize that pre-production samples are selling tools

Many buyers who are surprised that samples are not representative of bulk production. But getting an order and a cash deposit is one thing, and manufacturing the goods is another thing! Your job is to check whether production is up to the pre-production sample.

4. Displaying obvious distrust towards one’s suppliers

One of my clients does this. Her suppliers hate her, and they often get into arguments. You need your suppliers (1) to have a good image of you, and (2) to know that you care about them. If not, nobody will look after your production in the factory.

5. Not keeping two weeks of padding in the shipment schedule

There will be delays, with a certainty comprised between 30% and 90%. So plan for it. Bonus: even worse than failing to plan for delays, is pushing the factory to reduce production time.

6. Paying everything in full while one still needs leverage

Some purchasers get a really good feeling about a supplier, and agree to wire 100% of the order amount in advance. Then the manufacturer has no incentive to hurry up or to produce up to the standard. If quality issues are uncovered (and that’s only if they allow for an inspection), the factory might refuse to rework the goods.

7. Accepting to be left in the dark regarding your own supply chain

Do not rely on a middleman, upon which your whole company’s success rests. Qualify the factory, if possible get to know/approve the sub-suppliers. You will make it up many times in the long run. It is so basic, but so many people get this wrong.

8. Forgetting to describe an essential product attribute, or even the entire packaging

If you don’t specify your expectations in detail, a factory technician will take the decision for you, based (most probably) on cost savings. And you will not even be able to protest when you notice it.

9. Hoping that an unsatisfactory manufacturer will get better over time

Per my experiences, it is a bad idea to give a second order to a factory that just produced substandard quality. Rather than rolling the dice (when the odds are 90% against you), nurture a backup manufacturer.

10. Not registering one’s trademark when buying from China

Do you want a competitor to force your manufacturer to stop production? Do you want a supplier to sell your goods on the local market? If not, pls register your IP.

11. Not having a contract

A contract that can be enforced locally is important. There are various strategies to adopt in “non-cooperative” situations, and you can adopt them. For example: “take little steps” (issue small orders at beginning), “verify constantly” (quality inspections) and “use a third-party” (for example, to use a verified sourcing company to monitor your suppliers).

12. Trying to manufacture small quantities in China

It will usually push you in the arms of small trading firms that deal with small workshops. The result in 90% of cases: quality disasters and/or long delays. But there is a solution, if you can purchase non-customized items: produce them in coordination with a non-competing importer. Hard to pull off, I admit, but worth giving a shot!

0 notes

Text

Top Corporate Training & Courses in India.

Total quality management (TQM) discovers a management system wherein a company arrives at organizational advancement through a commitment to customer requirements. A company can only meet those requirements when it empowers every employee in every function to maintain high standards and work for continuous improvement. Total quality management is that the precursor of the many quality management systems, like six letters of the alphabet, Lean, and ISO.

TQM is a company-wide initiative to involve everyone in doing the first time right for the customer.

“Do things right, the first time and every time.”

TQM Principles

Customer Satisfaction

Employee Commitment

Fact-Based Decision Making

Effective Communications

Strategic Thinking

Integrated System

Process-Approach

Continuous Improvement

Roots of TQM

The roots of the principles and pattern of TQM extend back to the first 20th century and Frederick Taylor’s Principles of Scientific Management that advocated an even method of executing tasks and inspecting finished work to foreclose defective products from departing the shop. Advance innovation came in the 1920s with Walter Shewhart’s expansion of statistical process controls, which one could apply at any point in the production process to forecast quality levels. It was Shewhart who formulated the control chart which is used today.

During the 20s and 30s, Shewhart’s friend and mentee, William Deming, built-up statistical process control theories that he would eventually use to help the US Census department in the early 1940s. This was the beginning use of statistical process control in a non-manufacturing field.

The Quality Era in Japan

Following the world war, early American quality theorists, including Deming, who would achieve hero status in Japan, notified Japanese industry on how to amend processes and output to reconstruct their war-shattered economy. At the time, the term which was made in Japan was similar with shoddy craftsmanship. As early as 1945, seers and electrical engineer Homer Sarasohn spoke about containing variation and supervising process to bring on best deliverables.

As a result, in the 1950s, quality became the proverb for Japanese manufacturing. Quality pertained not just management, but all levels of a company. In the 1960s, quality circles started coming out in Japanese workplaces and furnish employees the opportunity to talk about problems and consider solutions, which they then demonstrated to management. Commencing on the factory or so called shop floor, quality circles expended to other functional departments. The company-wide focus on quality may also provide a clew to the origin of the phrase TOTAL QUALITY.

TQM in the USA

In early 1970’s, since the end of WWII, the main effort in American factories was to produce a large quantity of items, maintain the production schedule, and save money. Usability and durability rarely weighed until concerns about lack of product quality reached a fever pitch.

As Japan with success challenged the U. S. for industrial leadership, USA business currently took a page from Japan’s quality improvement book.

A new interest in quality management took hold, building on the work of Shewhart’s disciples, like Deming, Josef Juran, and Kaoru Ishikawa in Japan. Influential businessmen like Philip Crosby championed the trend. Although the growth of TQM seems to have occurred exclusively within the districts of industry, the basic outlines of the concept owe much to a 1980s US Navy project that used Shewhart and Deming’s PDCA (plan, do, check, act) model.

TQM Adjoins the World

Quality management began in producing, and TQM, like it’s later methodologies, custom-made well to finance, healthcare, and different fields.

Some of the landmark corporations to adopt TQM embrace Toyota, Ford, and Philips Semiconductors. Worldwide, countries like European nation, France, the UK, and Turkey established TQM standards.

ISO Superseds TQM

By the Nineties, TQM was outdated by ISO (International Standards Organization), that became the quality for a lot of continental Europe, and by another method response of the Nineteen Eighties to quality concerns, Six Sigma. However, TQM principles form the basis for much of ISO and Six Sigma.

For example, PDCA seems beneath the Six letter of the alphabet methodology DMAIC (define, measure, analyze, improve, control). And within the 2000s, the ISO governing body recognized TQM as a foundational philosophy.

TQM lives on in data-driven ways for a data-driven age.

Why is TQM Important to an Organization?

When it admits the completely company in the pursuit of high quality. An example is that the quality circle, in which workers directly involved in a process brainstorm to discover solutions. “People are a fabulous resource that is often underutilized”. Worker know how to fix problems. Implementing a TQM philosophy can help an organization:

Ensure customer satisfaction and customer loyalty

Ensure increased revenues and higher productivity

Reduce waste and inventory

Improve design

Adapt to changing markets and regulatory environments

Increase productivity

Enhance market image

Eliminate defects and waste

Increase job security

Improve employee morale

Reduce costs

Increase profitability

How Do You Implement Total Quality Management?

PDCA lies at the core of the many twentieth century quality efforts. PDCA began within the Nineteen Twenties as a creation by engineer and statistician conductor Shewhart. It had been originally known as PDSA (plan, do, study, act) wide disseminated by Deming, World Health Organization cited it because the Shewhart cycle, it’s currently typically cited because the Deming cycle.

In 2000, ISO acknowledged PDCA as a foundational methodology. It seems once more in Six alphabetic characters because the DMAIC methodology (define, measure, analyze, improve, and control). Walters notes that TQM is way additional folks familiarised, where six alphabetic character is method primarily based. He checks, as an example, that the term outline “takes the human component out” and also the term live focuses on knowledge.

TQM & Six Sigma: Which One When?

While TQM’s method of employing employees as a source of ideas and solutions can help companies, Six Sigma’s process and measurement focus — which promotes data-driven decisions — offers obliging benefits. Walters uses the instance of manufacturing spread and jelly sandwiches.

“We’d begin out with 2 items of bread, add the peanut butter, add the jelly, and put the two pieces of bread together. But, maybe the edges are banged up together. Maybe the corners are altered. Or, when our customers get it, they say the bread is boggy. Within that method, we’re not sure whether we’re putting on too much jelly or whether we’re using the wrong type of peanut butter. You just don’t know what it is, so you have these group meetings and brainstorm till your customer response is what you want, and the level of acceptance of your quote unquote quality product is wherever you want it to be” says Walters. With Six Sigma, however, the calling into question process would drill down to the details. What kind of bread were you using? What kind of peanut butter? What kind of jelly?

“That to me is the benefit since it takes the onus off the people and focuses rigorously on the process,” asserts Walters. “So, if we tend to tighten the method, we can feel like we already have quality people. And after the process is recurring in the same manner, even if there are other performance issues that automatically sets you back to the human side. But then you’ll manage the human issue properly as a result of which you don’t ought to worry regarding your processes. Your numbers aren’t changing.”

Walters states further that almost companies want to develop brand loyalty, even if their product is fundamentally the same as a competitor’s. “If we tend to use TQM, we hope a product is of better quality, so you’ll come back. With TQM, you’ve got to attend for your customers to verify that it’s sensible. With Six letter of the alphabet, at the end of the day, you don’t guess if your product is better. You know it. If you properly identify your market and your product has the best fit for the niche, you know you have the better product from a process view. That leads to the thicker relationships,” he says.

KEY PLAYERS IN TOTAL QUALITY MANAGEMENT: CUSTOMERS, SUPPLIERS, AND staff.

-Tqm Principles & Concepts

-Statistical Tool & Techniques For Tqm

1. 7 Qc Tools

2. Measurement System Analysis (MSA)

3.Statistical Process Control (SPC)

-Customer Focus – Participation & Team Work

-Customer Satisfaction Measurement

-Problem Solving

-Quality Circles

-Quality Circles

-Auditing Techniques

-Kaizen

-Techniques Of Housekeeping (5s)

-8-Discipline Methodologies For Problem Solving

-Why-Why Analysis – Root Cause Analysis

-Business Process Mapping

-Daily Work Management (DWM)Shop Floor Supervisor Development Program

Quatrain Solutions Pvt. Ltd. (QuaTrain) is the premier corporate training and consulting organization in India specialized in the field of Business Excellence, Six Sigma, TQM, Lean Implementation, ISO related trainings, IT Trainings, Technical Trainings, Soft, Behavioural and Developmental programs and started with an aim of building capabilities of working professionals across various domains and functions.

#Best Total Quality Management Trainings in India#Top Business Excellence training in India#Best Lean Six Sigma Training in India#Best IT Skills Trainings in India#Best Corporate Behavioral Trainings In India#Best Lean Trainings in India

0 notes

Text

Hire Mobile App Developers (iOS/Android) in Vietnam

A mobile application can help clients have a good experience when using services. Aside from that, investing in mobile application development gives a great advantage. So, many companies are looking for hiring mobile app developers.

Finding mobile app developers in Vietnam is very difficult because the software market has a larger amount of providers and you have no idea about hiring them. Let's keep reading this article it can give you a helpful suggestion.

Benefits of hiring mobile app developers in Vietnam

There are many reasons to choose Vietnamese mobile app developers because of low-cost attribution, established infrastructure, a large pool of IT talents and more.

Vietnam is an attractive hiring mobile app developers destination

Besides, the cost of hiring a mobile app developer in Vietnam in comparison to the price of hiring one in the United States is considerably cheaper, at least 50%. Compared to India, China, or the Philippines, Vietnamese developers’ rates are just as equal or even cheaper while their skills (both technical skills and soft skills) are equivalent. Vietnam is among the countries with the most affordable rates, with an average of $30-40 per hour.

Read more: " How much does it cost to outsource Mobile App In Vietnam? "

Vietnam has a young, dynamic IT workforce with talented developers. Outsourcing software companies can offer a large talent pool where you can find highly proficient IT teams with proven IT competency, skills and experience. In recent years, the English competency of Vietnamese developers has improved greatly. Some of its highlights include:

Top 10 countries with the most engineering graduates in 2015 according to Forbes

Top 7 countries in Asia with the highest EF EPI average

Top 5 leading countries in Asia with the fastest improvement in English skills

Top 10 Leading Asia Pacific country with the highest Human Capital Index.

In fact, many big players in the industry like Intel, Samsung and IBM have already started outsourcing to Vietnam because the benefits are listed above. So, Vietnamese mobile app developers are also an important role in the software outsourcing global market. And Vietnam has become an attractive destination to provide high-quality mobile app developers in Asia.

Steps to hire a mobile app development company in Vietnam

Choosing a mobile app development company is crucial because this affects to completing and quality product.

Stage 1: Evaluate the project requirements

Understanding the current needs will give you a general idea of the development company you’re looking for and help you avoid searching aimlessly among thousands of potential partners. For example, if you’re seeking end-to-end services which include app strategy, development, design and post-launch support for marketing and maintenance, then pay more attention to companies with dedicated specialists for each service. Or if you already have a capable UI/UX team in charge of the design, you’d want to prioritize companies with development specialists.

Stage 2: Make a list of potential candidates

Based on your project requirements, list down 5 to 10 companies that you’ve managed to find in the form of a spreadsheet. The main columns should cover the company names, the price that they offer, expertise in your field, proposed solutions.

Stage 3: Review the companies’ portfolio

Learn about each company’s past projects. You can download and use their apps. Besides, you can look for user reviews and ratings for reference.

And, past clients’ reviews can also be a trustworthy source. You might want to go as far as to search through the social media of the companies’ past clients as they tend to leave detailed reviews on their social media.

In addition to reviewing the portfolio, ask the companies about their processes and timelines. To evaluate their ability to enough to undertake your projects. Usually, companies using Agile software development have a more systematic approach as they develop and resolve development problems.

Stage 4: Get an estimate of app development cost

App development costs can vary greatly from company to company and might not sit well with your budget. However, price shouldn’t be the number one priority when choosing an app development company, as the quality is what matters the most. An ideal company is one that offers the right balance between price and expertise. Send a request for a quote and learn the pricing models, payment terms and schedules that the companies employ to see which one is the best fit for your project.

Stage 5: Assess the level of communication

Communication is crucial to the success of any project, and even more so when you outsource to a foreign company. A trustworthy partner would demonstrate a high level of involvement. You’d need a company which provides constant and systematic updates on the work progress and any issues arising along the way to know whether each stage of development is going as planned, and if not, whether delays are being handled properly.

Stage 6: Learn about the maintenance & support policy

Even when you already have your app up-and-running, further support from your development company is still needed as no one can guarantee that the app will always be foolproof. It’s highly recommended to find out whether the development company provides quality maintenance and support services, the extent to which they provide support, how much they charge for each service and preparing a budget to meet the company's requirements.

Read more: "Best Mobile App Development Outsourcing Company In Vietnam"

Innotech Vietnam

Innotech Vietnam is a reliable mobile app development company in Vietnam. Be appreciated for high-quality products, services, and innovative solutions in a fintech company. We strive to create innovation and develop advanced fintech solutions. We provide a wide range of mobile application services, ready to meet all customer service requirements. The products and solutions we offer based on these advanced technologies become valuable for our customers through professional project management methods and tools to help customers effectively manage progress and resources a force of the project.

Innotech's head office

Innotech Vietnam has done more than 200+ mobile app projects for clients worldwide in Japan, the USA, Australia, Singapore and Vietnam. We’re confident to deliver even the most complicated mobile app development project successfully in areas such as banking and financial, logistics, transportation, education, and other industries. More than 90% of companies have kept coming back to Innotech for a wide range of Mobile App Development and they enjoy the same standard of service every time. Besides, we are proud that we are trusted by many Institutions in Banking and Finance such as ACB Bank, Tyme Bank, Unifimoney, Manulife, Commonwealth Bank, …

Why should you choose Innotech Vietnam?

Expert by experience

With more than 12 years of experience, Innotech Vietnam has experience in core banking software integrations for financial institutions such as ACB Bank, Tyme Bank, Unifimoney, Manulife, Commonwealth Bank, etc.

Ready solutions

Technical solutions and demonstration of a product or technique are available.

Dedicated teams

With more than 80+ mobile app developers, UI – UX Design, BA, project managers and QA/QC. Innotech staffs have good knowledge of banking and financial operation.

Young, dynamic, professional and creative engineers combined with highly experienced experts

Reputation

Experience in consulting, deploying and managing mobile applications with more than 2 million users.

Cybersecurity

Maintaining the security and confidentiality of our clients’ projects is always our top priority. We try our best to respond to cybersecurity standards for the partner.

Read more case study:

ACB BANK – MOBILE APP DEVELOPMENT CASE STUDY

MANULIFE – INSURTECH SOLUTIONS CASE STUDY

TYMEBANK – SHORTAGE OF HIGH-QUALITY ENGINEERS AND SOLUTIONS.

UNIFI.MONEY – NEO BANK APPLICATION DEVELOPMENT

If you are looking for a Mobile App development company to provide solutions for digital wallet companies, we're happy to grant our services. Contact experts at Innotech Vietnam for any questions about Mobile Application!

Email: [email protected]

Fintech Việt Nam là cổng thông tin cập nhật về công nghệ liên trong lĩnh vực Fintech tại Việt Nam và các xu hướng fintech trên thế giới.

Nguồn: https://fintechvietnam.com.vn/hire-mobile-app-developers-ios-android-in-vietnam/

0 notes

Text

Improve Your Process Quality with These 7 QC Tools

In today’s competitive market, businesses must consistently deliver high-quality products and services. Whether you’re in manufacturing or service delivery, improving your processes is key to meeting customer expectations and reducing errors. That’s where the 7 QC (Quality Control) Tools come in.

These tools are simple yet powerful techniques that help you identify problems, analyze them, and find solutions for continuous improvement.

What Are the 7 QC Tools?

The 7 QC Tools are a set of problem-solving methods used widely in quality management and process improvement. Originating from Japan, these tools are easy to understand and apply—even if you don’t have a technical background.

Here are the 7 QC Tools:

Cause and Effect Diagram (Fishbone or Ishikawa Diagram)

Check Sheet

Control Chart

Histogram

Pareto Chart

Scatter Diagram

Flowchart (Process Diagram)

🔍 1. Cause and Effect Diagram (Fishbone Diagram)

Purpose: To identify root causes of a problem.

This tool helps teams brainstorm and categorize potential causes of a problem, showing how different factors (like manpower, machine, materials, methods) affect the outcome.

📌 Use when: You know the problem but not the reason behind it.

Example: High rejection in a production line — the diagram helps identify causes like machine calibration or operator error.

📝 2. Check Sheet

Purpose: To collect and organize data easily.

A check sheet is a simple form used to record the frequency of problems or defects. It helps in understanding where to focus improvement efforts.

📌 Use when: You need to collect real-time data on process issues.

Example: Tracking the number of defects per day or per machine.

📊 3. Control Chart

Purpose: To monitor process variation over time.

Control charts help you identify whether a process is stable or if there are abnormal variations that need attention.

📌 Use when: You want to control a process over time and ensure consistency.

Example: Monitoring the weight of a packaged product to stay within limits.

📈 4. Histogram

Purpose: To visualize the frequency of data.

Histograms show how data is distributed and help spot patterns, such as whether most defects fall within a certain range.

📌 Use when: You want to understand the distribution of a dataset.

Example: Measuring the delivery time of shipments and checking how consistent they are.

🎯 5. Pareto Chart

Purpose: To identify the most significant problems.

Based on the 80/20 rule (80% of problems come from 20% of causes), a Pareto chart helps you focus on the issues that have the biggest impact.

📌 Use when: You want to prioritize improvement efforts.

Example: Identifying that most customer complaints come from just two major issues.

🔗 6. Scatter Diagram

Purpose: To find relationships between two variables.

This diagram helps you determine if there's a correlation between two elements (e.g., machine speed and defect rate).

📌 Use when: You suspect that two variables are related.

Example: Analyzing if more training hours lead to fewer production errors.

🔄 7. Flowchart (Process Diagram)

Purpose: To visualize the steps in a process.

Flowcharts help understand how a process flows and where delays, defects, or confusion might occur.

📌 Use when: You want to document and improve a process.

Example: Mapping the customer complaint handling process to identify bottlenecks.

🚀 Why Use the 7 QC Tools?

The 7 QC Tools are popular for a reason—they’re simple, effective, and proven. Here’s why every business should use them:

✅ Easy to Use No complex software or technical skills needed—these tools are simple enough for anyone to understand and apply.

✅ Make Smarter Decisions They turn raw data into useful insights, helping you base decisions on facts instead of guesswork.

✅ Drive Continuous Improvement By identifying and fixing problems early, these tools help your team keep improving over time.

✅ Trusted Across Industries The 7 QC Tools are widely used in ISO 9001, Lean, Six Sigma, and other quality systems around the world.

✅ Save Time and Reduce Waste By targeting the real cause of issues, you reduce rework, improve efficiency, and save valuable resources.

🧠 How to Start Using the 7 QC Tools

Getting started with the 7 QC Tools is easier than you think. Follow these simple steps to improve your process quality:

Identify the Problem Start by clearly defining the issue you're facing. Be specific—whether it’s late deliveries, defects, or process delays.

Gather the Right Data Use tools like a Check Sheet or Flowchart to collect data and understand how the process works.

Find the Root Cause Use a Fishbone (Ishikawa) Diagram to dig deeper and identify the possible causes behind the problem.

Monitor Trends Over Time Use a Control Chart to see if the problem is consistent or just a one-time issue. A Histogram can help visualize data distribution.

Focus on What Matters Most Apply the Pareto Chart to find out which causes are having the biggest impact—so you can tackle them first.

Look for Relationships Use a Scatter Diagram to explore if two factors are connected—for example, training hours and error rate.

Take Action & Improve Once you understand the issue, take corrective actions. Then monitor the results and repeat the cycle for continuous improvement.

🏁 Final Thoughts

The 7 QC Tools are essential for any organization that wants to improve quality, reduce waste, and satisfy customers. Whether you’re in manufacturing, logistics, healthcare, or services—these tools can help you find problems and fix them faster.

Start small. Pick one problem in your process, apply one or two tools, and see the improvement for yourself!

#7 QC Tools#Quality Control Tools#Process Improvement Techniques#Problem Solving in Manufacturing#Lean Tools for Quality#ISO 9001 Tools#Root Cause Analysis Tools

1 note

·

View note

Text

ManagementStrategy

You might have a very good test management process and instrument to ensure the effectiveness of your own testing. But, test management alone will not ensure customer satisfaction. Total Quality Management is a means to not only deliver high-quality services and products but also to achieve higher customer satisfaction levels.In this informative article, we have coated the definition of superior management, its significance, the idea of total quality management, quality management principles, quality management example and the tool for comprehensive quality management.It has been stated many times if the high levels of management aren’t behind the execution of any QMS, it is bound to fail. It is true that the more involved the levels of management are from the QMS, the better the chance of succeeding, and the greater Even though this might not be a fact. If best management – who’s responsible for controlling the cash flow of the organization – can see the benefit of this machine, it is much more likely to be used to its fullest advantage.It is significant that individuals throughout the organization create value, especially in our ever-growing aggressive world. To ensure this, the ManagementStrategy has to focus to help them become engaged to construct value in them. By having empowered and engaged individuals in the business, this can act as a driving force behind fulfilling the aims of the organization.Trying to understand, control and enhance an overall system may often be complex, which can make any efforts doomed to collapse. However, by taking a look at the overall system as smaller interrelated processes you are able to concentrate your efforts toward more consistent and predictable results about the processes of this system. Assessing and improving the individual processes might be much easier and more effective way to control and improve the entire system.Companies that stay stagnant within an ever-more-competitive market will quickly be overtaken by their competition, and in order to counteract this pressure the business must improve in order to drive down cost and maintain market share. This permits the enterprise to react to changes in conditions that are external or internal to make new opportunities. The whole idea of owning a quality policy, with goals that are consistent with this policy, works toward improvement. That is the reason there’s a focus on monitoring & measurement in the ISO 9001 requirements (in fact, 4 of 6 mandatory documented processes are from this segment ).

The stakeholders of this project may have particular requirements and perspectives about the quality parameters of the project and these must be considered.The risk register gives an indication of the kind of dangers that are inherent in the project and those that must be considered while preparing the activities, to guarantee quality. The requirements for the job need to be considered for planning quality related tasks because the quality is about fulfilling the requirements.In addition to these, business environmental variables and organizational process assets are also recorded as inputs, because the criteria can be either from inside the company or from your government or other outside bodies. ManagementStrategy from within the organizations are normally the best practices learned over a time while implementing numerous jobs. An example of government standards can be standards to control air pollution by the motor vehicles, which vehicle manufacturers need to adhere to.To accomplish excellent planning, first, assess the benefits versus the costs of meeting quality requirements. Next, identify the price of quality if that kind of investment in quality is warranted, and confirm. In addition to these two, benchmarking helps in assessing the quality of action of similar projects executed in the past.This helps in identifying the particular quality of output of the prior project, which subsequently acts as a basis for the current project’s quality planning. Design of experiments can be utilized for quality preparation. This is a statistical means to ascertain what variables will enhance quality the most.For instance, in the event of ManagementStrategy doorways, it can be ascertained that raising the quality of the wood can have maximum impact on improving the quality of the door.In addition, the seven basic quality tools, also known as the 7 QC tools, are utilized to ascertain the strategy to accomplish the desirable degree of quality. Statistical sampling as a tool becomes relevant whenever the quality plan cannot be applied to each of the artifacts produced.For example, if harmful testing is a requirement, then it can be performed only on a sample, not the whole population.

0 notes

Text

ManagementStrategy

You may have a very good evaluation management process and instrument to ensure the effectiveness of your testing. However, test management alone will not ensure customer satisfaction. Total Quality Management is a means to not only deliver high-quality products and services but to achieve increased customer satisfaction levels.In this post, we have coated the definition of quality management, its importance, the ManagementStrategy of total excellent management, quality management principles, quality management illustration and the tool for comprehensive excellent management.It has been said many times that if the high levels of management are not supporting the implementation of any QMS, it is likely to fail. While this may not always be a truth, it is true that the more involved the top levels of management are from the QMS, the better the likelihood of succeeding, and the better. If best management – who is responsible for controlling the cash flow of the business – may see the advantage of the system, it’s a lot more likely to be used to its fullest advantage.It is significant that people throughout the organization create value, particularly in our ever-growing competitive world. The QMS has to focus to assist them become engaged in the processes to construct value within them, to guarantee that. By having empowered and engaged people in the business, this can act as a driving force behind fulfilling the objectives of the organization.Trying to comprehend, control and improve an overall system may often be complicated, which may make any attempts doomed to failure. By taking a look at the overall system as smaller interrelated processes you are able to focus your efforts toward more predictable and consistent results on the individual procedures of the system. Assessing and enhancing the individual procedures can be a much simpler and much more effective approach to control and enhance the entire system.Companies that remain stagnant within an ever-more-competitive marketplace will be overtaken by their competition, and in order to counteract this pressure the company must improve in order to drive down cost and maintain market share. This permits the enterprise to react to changes in requirements that are external or internal to create new opportunities. The whole idea of owning an excellent policy works toward development. Objectives have to be proposed and SMART (Specific, Measurable, Attainable, Realistic, Time- ManagementStrategy ), and also won’t function without dedication to change.It is stated that you are more inclined to get the wanted effects by basing decisions on evaluation and analysis of data rather than a gut instinct of the circumstance. This is why there’s a focus on monitoring & measurement in the ISO 9001 requirements (in reality, 4 of 6 compulsory documented processes are out of this segment ). To be able to be aware that a process is functioning properly we need adequate data, and as a way to plan and evaluate improvements this information is much more significant. Because of this, maintaining good records becomes crucial to ease many of the other Quality Management Principles.Because the interaction with interested parties such as clients, employees and providers can help determine the performance of an organization, it is critical to manage these relationships.

Design of experiments can be utilized for quality preparation. This is a statistical means to ascertain what variables will enhance quality the most.For instance, in the event of manufacturing doorways, it can be ascertained that raising the quality of the wood can have maximum impact on improving the quality of the door.In addition, the seven basic quality tools, also known as the 7 QC tools, are utilized to ascertain the strategy to accomplish the desirable degree of quality. Statistical sampling as a tool becomes relevant whenever the quality plan cannot be applied to each of the artifacts produced.For example, if harmful testing is a requirement, then it can be performed only on a sample, not the whole population. Statistical sampling helps in arriving in a representative sample that can give useful information.Other added tools like brainstorming, force-field evaluation, etc. may be utilized to determine the quality management strategy to the undertaking. Conducting meetings is another important instrument. The quality management program has to be determined in a collaborative manner by consulting with the staff members and other stakeholders.A checklist is a list of things to inspect. Checklists are ManagementStrategy during the superior preparation and utilized in caliber control.Metrics are undertaking specific data that has to be measured to examine the status of the project. The easiest job metrics may be program and cost. Metrics are also decided during the superior planning and used in caliber control.One of the roles of the project manager is to not only deal with the job but also improve procedures in the endeavor to lower the cases of flaws, which in turn saves time and money. Such actions are recorded in the process improvement plan, which eventually becomes part of project management plan.As a result of the planning activities, other project documents may also get upgraded. By way of example, the excellent management program may lead to updates to the price or source requirements.There may be queries in the CAPM examination, depending on the plan quality control procedure. Until you take the exam, so please ensure you have a fair understanding of the concept.

0 notes

Text

ManagementStrategy

The stakeholders of this project may have particular requirements and perspectives about the quality parameters of the project and these must be considered.The risk register gives an indication of the kind of dangers that are inherent in the project and those that must be considered while preparing the activities, to guarantee quality. The requirements for the job need to be considered for planning quality related tasks because the quality is about fulfilling the requirements.In addition to these, business environmental variables and organizational process assets are also recorded as inputs, because the criteria can be either from inside the company or from your government or other outside bodies. ManagementStrategy from within the organizations are normally the best practices learned over a time while implementing numerous jobs. An example of government standards can be standards to control air pollution by the motor vehicles, which vehicle manufacturers need to adhere to.To accomplish excellent planning, first, assess the benefits versus the costs of meeting quality requirements. Next, identify the price of quality if that kind of investment in quality is warranted, and confirm. In addition to these two, benchmarking helps in assessing the quality of action of similar projects executed in the past.This helps in identifying the particular quality of output of the prior project, which subsequently acts as a basis for the current project’s quality planning. Design of experiments can be utilized for quality preparation. This is a statistical means to ascertain what variables will enhance quality the most.For instance, in the event of ManagementStrategy doorways, it can be ascertained that raising the quality of the wood can have maximum impact on improving the quality of the door.In addition, the seven basic quality tools, also known as the 7 QC tools, are utilized to ascertain the strategy to accomplish the desirable degree of quality. Statistical sampling as a tool becomes relevant whenever the quality plan cannot be applied to each of the artifacts produced.For example, if harmful testing is a requirement, then it can be performed only on a sample, not the whole population.

Before adhering to the criteria, you need to question their significance to the job. Implementing all probable criteria applicable to this job randomly will have time and cost implications.The project management strategy stipulates the scope, schedule, and cost baseline; all which have an effect on the quality management program. The excellent program has a direct correlation with these.It may have an effect on and be influenced by additional subsidiary management strategies, for example risk management. The stakeholders of this project may have particular requirements and perspectives about the quality parameters of this job and these must be considered.The hazard register gives an indication of the type of dangers which are inherent in the job and those that must be considered while preparing the actions, to ManagementStrategy quality. The prerequisites for your job have to be considered for preparation quality related tasks since the quality is about fulfilling the requirements.In addition to such, business environmental variables and organizational process assets will also be recorded as inputs, since the criteria can be from inside the company or from your government or other outside bodies.Standards from inside the organizations are normally the most effective practices learned over a time whilst implementing numerous jobs. A good illustration of government criteria can be criteria to control air pollution from the engine vehicles, which automobile manufacturers need to adhere to.To accomplish excellent preparation, first, assess the benefits versus the costs of fulfilling quality requirements. Identify the price of quality whether this type of investment in quality is warranted, and affirm. Along with those two, benchmarking assists in assessing the quality of action of similar jobs implemented in the past.This will help in identifying the specific quality of output signal of their prior job, which subsequently functions as a foundation for the present job’s quality preparation

0 notes

Text

Enhance Your Quality Management Toolkit: 7 QC Tools Training Essentials

For any business, quality control is essential for success. Quality control ensures that products and services are of the highest standard. To help businesses maintain their standards, there are 7 QC Tools Training Essentials to enhance your quality management toolkit.

The seven tools include: Cause & Effect Diagrams (Fishbone), Pareto Charts, Control Charts, Histograms & Frequency Distributions Graphs (Bar Chart or Pie Chart), Scatter Plots/Graphs/Diagrams, Check Sheets, and Flowcharts. These tools can be used in production processes to identify problems or areas of improvement before they become major issues in the future. Each tool has its own unique purpose, and when combined, they create a powerful system for improving product or service quality within an organization's operations process flowchart diagram.

Also Read: 5s Training

The first step is understanding how each individual tool works so you can use them effectively as part of your overall strategy for achieving high-quality outcomes across all aspects of your operations process flowchart diagram. For example, a cause & effect diagram helps identify root causes behind specific problems; Pareto charts prioritize tasks based on importance; Control charts monitor performance over time; Histograms analyze data distribution patterns while frequency distribution graphs visualize differences between values, etc. All these different techniques have been designed with one goal in mind – helping organizations achieve better results through improved efficiency and productivity levels achieved by eliminating defects from their processes quickly without compromising on safety standards.

By investing time in learning about these 7 QC tools training essentials, you will be able to develop a more comprehensive approach towards managing risk associated with producing goods or delivering services that meet customer expectations consistently over long periods of time - something which no other single technique could do alone! This type of knowledge also provides valuable insight into how well certain systems work relative to others, allowing managers to make informed decisions regarding where resources should be allocated most effectively going forward too!

0 notes

Text

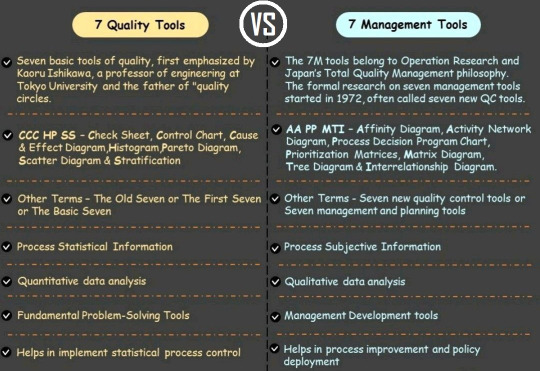

➡️ New 7 QC Tools | Seven Management and Planning Tools Explained with Example and Case Study

0 notes

Text

ManagementStrategy

You might have a very good test management process and instrument to ensure the effectiveness of your own testing. But, test management alone will not ensure customer satisfaction. Total Quality Management is a means to not only deliver high-quality services and products but also to achieve higher customer satisfaction levels.In this informative article, we have coated the definition of superior management, its significance, the idea of total quality management, quality management principles, quality management example and the tool for comprehensive quality management.It has been stated many times if the high levels of management aren’t behind the execution of any QMS, it is bound to fail. It is true that the more involved the levels of management are from the QMS, the better the chance of succeeding, and the greater Even though this might not be a fact. If best management – who’s responsible for controlling the cash flow of the organization – can see the benefit of this machine, it is much more likely to be used to its fullest advantage.It is significant that individuals throughout the organization create value, especially in our ever-growing aggressive world. To ensure this, the ManagementStrategy has to focus to help them become engaged to construct value in them. By having empowered and engaged individuals in the business, this can act as a driving force behind fulfilling the aims of the organization.Trying to understand, control and enhance an overall system may often be complex, which can make any efforts doomed to collapse. However, by taking a look at the overall system as smaller interrelated processes you are able to concentrate your efforts toward more consistent and predictable results about the processes of this system. Assessing and improving the individual processes might be much easier and more effective way to control and improve the entire system.Companies that stay stagnant within an ever-more-competitive market will quickly be overtaken by their competition, and in order to counteract this pressure the business must improve in order to drive down cost and maintain market share. This permits the enterprise to react to changes in conditions that are external or internal to make new opportunities. The whole idea of owning a quality policy, with goals that are consistent with this policy, works toward improvement. That is the reason there’s a focus on monitoring & measurement in the ISO 9001 requirements (in fact, 4 of 6 mandatory documented processes are from this segment ).

Along with those two, bench marking helps in analyzing the quality of action of similar projects implemented in the past.This helps in identifying the particular quality of output signal of their previous job, which subsequently acts as a basis for the present job’s quality planning. Design of experiments can also be used for quality preparation. That is a statistical means to determine what variables will improve quality the most.For instance, in the event of manufacturing doors, it may be ascertained that raising the quality of the wood can have maximum impact on improving the quality of the door.In addition, the seven basic quality components, also known as the 7 QC tools, are utilized to determine the plan to accomplish the desired level of quality. Statistical sampling for a tool becomes applicable whenever the quality plan cannot be applied to all the artifacts produced.For example, if destructive testing is a requirement, then it can be carried out only on a sample, not the entire population. Statistical sampling helps in arriving at a representative ManagementStrategy that can give useful information.Other added tools like brainstorming, force-field evaluation, etc. may be utilized to determine the quality management strategy for the undertaking. Conducting regular meetings is another tool. The quality management plan has to be set in a collaborative manner by consulting the team members and other stakeholders.A checklist is a listing of things to inspect. Checklists are made during the superior planning and utilized in quality control.Metrics are project certain data that needs to be quantified to examine the condition of the project. The job metrics may be schedule and cost. Metrics are also decided during the quality planning and employed in quality control.One of the functions of this project manager is to not only deal with the project but also improve procedures in the endeavor to decrease the cases of defects, which in turn saves money and time. Such activities are listed from the process improvement program, which becomes part of project management plan.As a result of the planning actions, other project files may also get updated. By way of example, the excellent management plan might lead to updates to the price or resource requirements.There could be questions in the CAPM exam, depending on the plan quality management process. Before you take the examination, please ensure you have a reasonable comprehension of the concept.

0 notes