ITE provides various testing services, including MFL, Phased Array Ultrasonic, Time of Flight Diffraction, Helium Leak Testing, Radiography, Magnetic Particle Testing, Dye Penetrant Testing, Borescopic Inspection, Eddy Current Testing, Fugitive Emission Testing, Positive Material Identification, Stress Relieving, and more.

Don't wanna be here? Send us removal request.

Text

Top Advanced Non Destructive Testing Service in India

What is Non-Destructive Testing (NDT)?

Advanced Non-Destructive Testing refers to a range of techniques used to evaluate the properties of materials, components, and structures without causing any harm. The primary goal of NDT is to detect and evaluate defects, flaws, or irregularities that could compromise safety and performance. Unlike traditional methods that might require the destruction of the test sample, NDT allows for ongoing monitoring and inspection without affecting the item being tested.

Why Choose Advanced NDT Services?

While conventional NDT methods are valuable, advanced techniques offer enhanced capabilities, greater accuracy, and broader applications. At ITE, we specialize in advanced NDT services that leverage the latest technology to provide comprehensive and reliable inspections. Here’s why our advanced NDT services stand out:

1. Enhanced Accuracy

Advanced NDT methods utilize sophisticated equipment and algorithms to detect even the most subtle defects. Our state-of-the-art tools ensure precise measurements and detailed insights, minimizing the risk of missed anomalies.

2. Greater Sensitivity

Our advanced techniques are designed to identify smaller and more complex defects that traditional methods might overlook. This sensitivity is crucial for industries where safety and reliability are non-negotiable.

3. Real-Time Results

Many of our advanced NDT services provide real-time data, allowing for immediate analysis and decision-making. This capability is particularly valuable in critical situations where time is of the essence.

4. Broader Applications

From aerospace and automotive to construction and energy, our advanced NDT services are applicable across a wide range of industries. We tailor our approach to meet the specific needs of each sector, ensuring relevant and actionable results.

Our Advanced NDT Services

At ITE, we offer a comprehensive suite of advanced NDT services, each designed to address different inspection needs:

1. Ultrasonic Testing (UT)

Ultrasonic Testing uses high-frequency sound waves to detect internal flaws in materials. Our advanced UT systems provide precise measurements and can detect various types of defects, including cracks, voids, and weld quality issues.

2. Radiographic Testing (RT)

Radiographic Testing involves the use of X-rays or gamma rays to inspect the internal structure of materials. Our advanced RT services offer high-resolution imaging, allowing for the detection of intricate defects within thick materials.

3. Eddy Current Testing (ECT)

Eddy Current Testing is a technique that uses electromagnetic induction to detect surface and near-surface defects. Our advanced ECT systems provide rapid and accurate results, making them ideal for inspecting conductive materials.

4. Magnetic Particle Testing (MPT)

Magnetic Particle Testing involves the application of magnetic fields and iron particles to detect surface and near-surface discontinuities. Our advanced MPT methods enhance sensitivity and reliability, ensuring thorough inspections.

5. Acoustic Emission Testing (AET)

Acoustic Emission Testing monitors the release of energy from materials under stress. This method is highly effective for assessing the condition of structures under load and identifying potential failure points.

Why ITE?

Choosing ITE means partnering with a team of experts dedicated to delivering exceptional NDT services. Here’s why we are the preferred choice:

Expertise: Our team comprises highly skilled professionals with extensive experience in advanced NDT methods.

Technology: We invest in the latest technology to ensure the highest standards of accuracy and reliability.

Tailored Solutions: We understand that each industry and project has unique requirements. Our services are customized to meet your specific needs.

Commitment to Safety: We prioritize safety and quality in every inspection, ensuring that our findings contribute to the overall reliability and safety of your operations.

Conclusion

In the world of industrial inspection and maintenance, advanced Non-Destructive Testing is a game-changer, offering unparalleled accuracy and reliability. At ITE, we are committed to providing top-notch advanced NDT services across India, helping industries maintain the highest standards of safety and performance. Whether you’re in aerospace, automotive, construction, or any other sector, our advanced NDT solutions are designed to meet your unique needs and exceed your expectations.

For more information on how ITE can enhance your inspection processes with advanced NDT services, contact us today. Let us help you unlock the power of precision and ensure the integrity of your materials and structures.

For more details, please visit :-

Website :- https://www.itenoida.com/

Contact No. :- +91–9891174696, +91–9810059715

Email :- [email protected], [email protected]

1 note

·

View note

Text

Advanced Non Destructive Testing Services in India

Inspection & Testing Engineers (ITE) offers comprehensive Advanced Non-Destructive Testing (NDT) services in India, ensuring the highest standards of safety and quality. Utilizing cutting-edge technologies, ITE provides a range of NDT methods including ultrasonic testing, radiographic testing, magnetic particle testing, and eddy current testing. These techniques are essential for detecting flaws and irregularities in materials and structures without causing any damage, thereby ensuring reliability and longevity. ITE's skilled professionals are trained to handle intricate inspections in various industries such as aerospace, automotive, oil and gas, and construction. By leveraging advanced NDT methods, ITE helps clients maintain compliance with stringent regulatory standards, improve operational efficiency, and reduce downtime. With a commitment to excellence and innovation, ITE stands as a trusted partner for all non-destructive testing needs in India.

For more Information:-

Call:- +91-9891174696, +91-9810059715

Email:- [email protected], [email protected]

Address:- F 22-23, Site C, Surajpur Industrial Area UPSIDC, Surajpur, Greater Noida, 201306

0 notes

Text

Welding Inspection Services in Noida

Are You Looking For Welding Inspection Services Provider in India? Inspection & Testing. offers comprehensive welding inspection services. Their expert team ensures the highest quality and safety standards through rigorous testing and evaluation. Utilizing advanced techniques and equipment, they provide accurate assessments, helping industries maintain compliance and reliability in their welding processes, ensuring the integrity and durability of welded structures.

For more Information:- Call:- +91-9891174696, 9810059715, 9953489999 Email:- [email protected] Address:- F 22-23, Site C, Surajpur Industrial Area UPSIDC, Surajpur, Greater Noida, 201306

#Welding Inspection Services#Services Provider in India#Welding Inspection Services Provider#Welding Inspection Services Provider in Noida

0 notes

Text

Phased Array Ultrasonic Testing services in India

Phased Array Ultrasonic Testing (PAUT) services in India have gained significant popularity in recent years. PAUT is a non-destructive testing technique that uses ultrasonic waves to inspect materials for defects or flaws. It offers several advantages over traditional methods, making it a preferred choice for material testing in various industries.

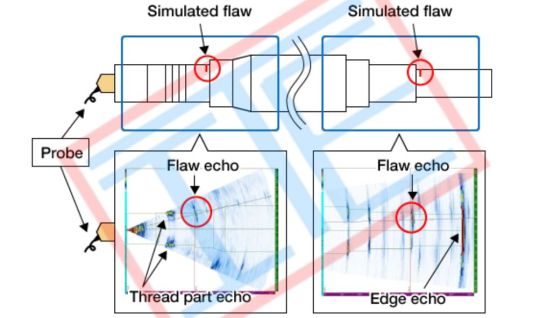

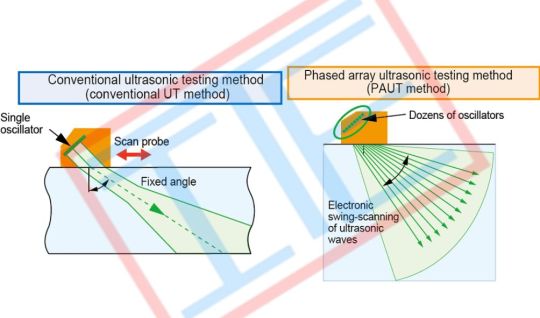

PAUT inspection involves the use of an array of ultrasonic transducers that can be electronically controlled to emit and receive ultrasonic waves at different angles. This allows for the creation of a detailed and accurate image of the material being tested. The ability to control the angle and focus of the ultrasonic waves makes PAUT testing highly versatile and effective in detecting both surface and subsurface defects.

One of the major benefits of PAUT testing is its speed and efficiency. With traditional ultrasonic testing methods, multiple scans are required to cover the entire area being inspected. However, with PAUT, multiple beams can be emitted simultaneously, covering a larger area in a single scan. This not only reduces the inspection time but also increases productivity and cost-effectiveness.

Another advantage of PAUT inspection is its ability to provide real-time imaging. The data collected from the ultrasonic waves can be displayed as a visual image, allowing for immediate analysis and interpretation. This real-time imaging feature enables faster decision-making and reduces the need for additional testing or re-inspection.

PAUT testing is widely used in various industries such as aerospace, oil and gas, power generation, manufacturing, and infrastructure. In the aerospace industry, PAUT is used for inspecting critical components such as aircraft wings, turbine blades, and engine parts. In the oil and gas industry, it is used for inspecting pipelines, storage tanks, and pressure vessels. In power generation, PAUT is used for inspecting boilers, turbines, and heat exchangers.

India has witnessed a significant growth in the demand for PAUT services due to its numerous advantages and applications. Several testing service providers in India offer PAUT inspection services to cater to the growing needs of industries. These service providers use advanced PAUT equipment and employ trained technicians who are proficient in operating and interpreting the results from PAUT systems.

When selecting a PAUT testing service provider in India, it is important to consider factors such as experience, expertise, and certifications. The service provider should have a proven track record in performing PAUT inspections and should be equipped with state-of-the-art equipment. Additionally, they should have a team of qualified technicians who are trained in conducting PAUT inspections and interpreting the results accurately.

In conclusion, PAUT inspection services in India have gained immense popularity due to their speed, efficiency, and accuracy. The ability to detect both surface and subsurface defects makes PAUT an ideal choice for material testing in various industries. With the growing demand for reliable non-destructive testing methods, PAUT is expected to continue being widely used in India's industrial sectors.

If you are looking for testing service in Delhi/NCR, India worldwide. Look no further now, contact us : +91-9810059715, +91-9953489999 . Our Address is F 22-23, Site C, Surajpur Industrial Area, UPSIDC, Greater Noida, 201306.

#paut inspection#paut testing#non destructive testing#ultrasonic testing equipment#material testing#stainless steel welding#steel welding

0 notes

Text

0 notes

Text

0 notes

Text

#software#software developer job#software development#software developers#it#Mechanical and Chemical Testing Services for Steel

0 notes

Text

Advanced Non-Destructive Testing (NDT) services have transformed the way metals and welds are inspected and evaluated for quality assurance. These services have revolutionized the processes, guaranteeing the safety and structural integrity of vital components without inflicting any harm or damage.

#software#software development#advanced Testing#advanced non-destructive testing#service provider#likeforlikes

1 note

·

View note