#paut testing

Explore tagged Tumblr posts

Text

Phased Array Ultrasonic Testing services in India

Phased Array Ultrasonic Testing (PAUT) services in India have gained significant popularity in recent years. PAUT is a non-destructive testing technique that uses ultrasonic waves to inspect materials for defects or flaws. It offers several advantages over traditional methods, making it a preferred choice for material testing in various industries.

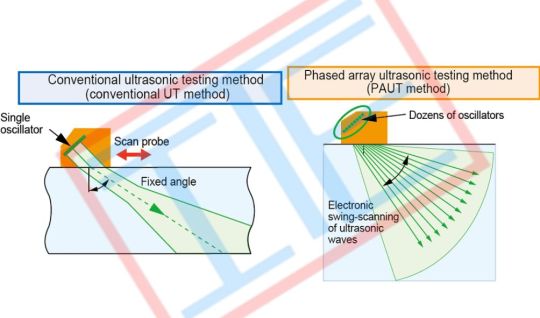

PAUT inspection involves the use of an array of ultrasonic transducers that can be electronically controlled to emit and receive ultrasonic waves at different angles. This allows for the creation of a detailed and accurate image of the material being tested. The ability to control the angle and focus of the ultrasonic waves makes PAUT testing highly versatile and effective in detecting both surface and subsurface defects.

One of the major benefits of PAUT testing is its speed and efficiency. With traditional ultrasonic testing methods, multiple scans are required to cover the entire area being inspected. However, with PAUT, multiple beams can be emitted simultaneously, covering a larger area in a single scan. This not only reduces the inspection time but also increases productivity and cost-effectiveness.

Another advantage of PAUT inspection is its ability to provide real-time imaging. The data collected from the ultrasonic waves can be displayed as a visual image, allowing for immediate analysis and interpretation. This real-time imaging feature enables faster decision-making and reduces the need for additional testing or re-inspection.

PAUT testing is widely used in various industries such as aerospace, oil and gas, power generation, manufacturing, and infrastructure. In the aerospace industry, PAUT is used for inspecting critical components such as aircraft wings, turbine blades, and engine parts. In the oil and gas industry, it is used for inspecting pipelines, storage tanks, and pressure vessels. In power generation, PAUT is used for inspecting boilers, turbines, and heat exchangers.

India has witnessed a significant growth in the demand for PAUT services due to its numerous advantages and applications. Several testing service providers in India offer PAUT inspection services to cater to the growing needs of industries. These service providers use advanced PAUT equipment and employ trained technicians who are proficient in operating and interpreting the results from PAUT systems.

When selecting a PAUT testing service provider in India, it is important to consider factors such as experience, expertise, and certifications. The service provider should have a proven track record in performing PAUT inspections and should be equipped with state-of-the-art equipment. Additionally, they should have a team of qualified technicians who are trained in conducting PAUT inspections and interpreting the results accurately.

In conclusion, PAUT inspection services in India have gained immense popularity due to their speed, efficiency, and accuracy. The ability to detect both surface and subsurface defects makes PAUT an ideal choice for material testing in various industries. With the growing demand for reliable non-destructive testing methods, PAUT is expected to continue being widely used in India's industrial sectors.

If you are looking for testing service in Delhi/NCR, India worldwide. Look no further now, contact us : +91-9810059715, +91-9953489999 . Our Address is F 22-23, Site C, Surajpur Industrial Area, UPSIDC, Greater Noida, 201306.

#paut inspection#paut testing#non destructive testing#ultrasonic testing equipment#material testing#stainless steel welding#steel welding

0 notes

Text

Phased Array Ultrasonic Testing: Benefits and Applications

Phased Array Ultrasonic Testing (PAUT) is an advanced non-destructive testing (NDT) technique that utilizes multiple ultrasonic elements and electronic time delays to create a focused beam of sound waves. This innovative technology allows for precise control over the angle, focal point, and depth of the inspection, resulting in highly detailed images. Such precision is crucial for identifying defects like cracks, voids, and inclusions within materials, ensuring the integrity and safety of critical components.

Comprehensive Inspection Capabilities

Phased Array Ultrasonic Testing excels in inspecting complex geometries and materials, making it invaluable in industries such as aerospace, oil and gas, and power generation. It is commonly employed for weld inspections, corrosion mapping, and flaw detection in metals and composites. The ability to generate real-time images enables inspectors to make immediate assessments, enhancing the efficiency of the inspection process.

Original Source: https://www.rvsglobe.com/phased-array-ultrasonic-testing-see-beyond-the-surface-benefits-and-applications-120

Integration with Other NDT Methods

For optimal results, PAUT is often integrated with other NDT methods. Combining PAUT with Time of Flight Diffraction (TOFD), for instance, offers a more comprehensive evaluation of material integrity. This integrated approach provides a robust framework for detecting and sizing defects, ensuring the highest standards of safety and reliability.

Cost-Effectiveness and Efficiency

While the initial setup cost for Phased Array Ultrasonic Testing equipment may be higher than traditional methods, the long-term benefits make it a cost-effective solution. The ability to perform thorough inspections quickly reduces downtime, which is crucial for industries where time is of the essence. Moreover, the detailed imaging capabilities minimize the need for multiple inspections, saving both time and resources. The efficiency of PAUT makes it an attractive option for industries looking to optimize their maintenance schedules and extend the lifespan of their assets.

Applications Across Various Industries

The applications of PAUT are vast and varied, extending across multiple industries. In the oil and gas sector, PAUT is utilized to assess the condition of pipelines and pressure vessels, ensuring their safe operation. The aerospace industry employs PAUT for the inspection of aircraft components, where even the smallest defect can have significant consequences. Additionally, the power generation industry uses PAUT to monitor the condition of turbines and other critical equipment, preventing catastrophic failures.

Enhanced Accuracy and Versatility

Phased Array Ultrasonic Testing stands out for its exceptional accuracy and versatility. Unlike conventional ultrasonic testing, PAUT uses multiple ultrasonic elements and electronic time delays to create a focused beam of sound waves. This method allows for precise control over the angle, focal point, and depth of the inspection, resulting in highly detailed images. This level of precision is crucial for identifying defects that might be missed by other testing methods, such as cracks, voids, and inclusions within a material.

Complementary NDT Techniques

In addition to PAUT, various complementary NDT services provide a holistic approach to material inspection. For instance, Infrared Thermography Services are used to detect surface and subsurface anomalies by measuring temperature variations. This non-contact method is particularly useful for identifying electrical and mechanical issues in a wide range of applications. When combined with PAUT, infrared thermography provides a comprehensive understanding of material integrity, ensuring the highest level of safety and performance.

Conclusion

Phased Array Ultrasonic Testing is a powerful tool in the field of non-destructive testing, offering unparalleled accuracy and versatility. The ability to inspect complex geometries and integrate with other NDT methods makes PAUT an essential technique for various industries. By adopting advanced inspection technologies like PAUT, industries can maintain high standards of quality and safety, ensuring the longevity and reliability of their critical assets.

0 notes

Text

What is Phased Array Ultrasonic Testing (PAUT)?

Introduction

When it comes to Non-destructive Testing (NDT) methods, Phased Array Ultrasonic Testing (PAUT) has emerged as a powerful and efficient technique.

Phased Array Ultrasonic Testing, as the name suggests, uses multiple transducers in an array inside the testing probe to manipulate the input ultrasonic beam by exciting them in various sequences that can be controlled digitally.

These Ultrasonic Transducers are made of piezoelectric materials that convert one form of energy to another to fulfill the probe's purpose.

Evolution of Non-destructive Testing and PAUT

Non-destructive Testing is an essential practice used to assess the integrity of materials and structures without causing any damage.

As industries advanced, the need for more sophisticated PAUT NDT Methods became evident.

This is where phased array ultrasonic testing came into play.

What is Phased Array Ultrasonic Testing (PAUT)?

Phased Array Ultrasonic Testing is a modern NDT Technique that utilizes multiple ultrasonic elements to inspect materials.

Unlike conventional Ultrasonic Testing Methods, which use a single transducer to send and receive waves, PAUT test employs an array of elements.

Phased Array Ultrasonic Testing, as the name suggests, uses multiple transducers in an array inside the testing probe to manipulate the input ultrasonic beam by exciting them in various sequences that can be controlled digitally.

These Ultrasonic Transducers are piezoelectric materials that convert one form of energy to another to fulfill the probes’ purpose.

The sequenced actuation of the transducers facilitates sectorial, depth, and linear scanning.

It can also be used in situations where conventional Ultrasonic Testing methods are used.

It can be used for checking wall thickness profiles and Weld Inspection, as well as inspections of Heat Affected Zones (HAZ), which makes it versatile and viable across industries like manufacturing, construction, petrochemicals, and aerospace.

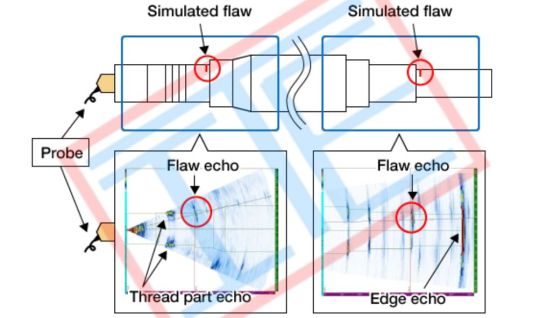

The input Ultrasonic Testing Procedure of the phased array ultrasonic testing apparatus is made to sweep across the testing subject and hence pick up on deformities that would have been missed by a conventional single-beam PAUT ultrasonic testing device that produces a singular directed beam.

How does PAUT Work?

In PAUT Inspection, each element in the array can be controlled individually.

By altering the timing and amplitude of the signals sent to each element, the ultrasonic waves can be focused, steered, and scanned electronically.

This allows for greater flexibility in inspecting complex geometries and varying materials.

#non-destructive testing#ndt testing#ndt techniques#ndt methods#ndt#ndt technique#PAUT#Phased Array Ultrasonic Testing

0 notes

Text

꧁. ͡์‾❦้้ͼ𝕯𝖆𝖗𝖐𝖑𝖔𝖛𝖊 โ္ৡั ًً꧂:

Cerita Lucah Melayu:

Kerana Seluar Track

Aku Lina. Aku masih belajar di sebuah kolej swasta. Aku suka memakai seluar track dan paling best kalau tak pakai seluar dalam. Semuanya sebab ada cerita sebenarnya kenapa aku suka pakai seluar track. Macam ni ceritanya bermula.

Aku tinggal bersama mak bapak aku dan adik beradik aku di sebuah taman perumahan. Masa tu aku masih sekolah Tingkatan 4. Walau pun masih sekolah tapi body aku memang mengancam. Bentuk body aku yang macam orang dewasa menarik minat ramai lelaki terutamanya peha dengan bontot.

Masa tu aku masih tak matang sangat jadi tak tahu sangat nafsu lelaki ni macam mana. Budak-budak lagi la katakan. Sampai la satu hari tu aku pergi la ke kedai beli kelapa parut. Tengah tunggu akak mamak tu parut kelapa, datang la sorang brader ni nak beli rokok.

Bila aku tengok dia, dia pun tengok aku. Bila dia tengok aku aku pun tengok dia. Kami senyum. Lepas tu dia datang dan tegur aku. Kami pun berkenalan. Namanya Zack. Kerja kat kilang elektronik sebagai tecnician.

Kami lama-lama jadi couple. Dia selalu bawak aku keluar naik motor dia. Apa yang aku perasan bila aku bonceng motor dia mesti ramai driver yang tengok aku. Rupanya gaya aku naik motor tu memang daring habis. Melentik lebih-lebih lagi kalau aku pakai kain uniform sekolah. Memang nampak gebu la peha dengan bontot aku yang montok ni. Tapi Zack ni biasa-biasa je bila kita orang jumpa.

Sampai la satu hari ni aku balik dari hari sukan sekolah. Pakai t-shirt dengan seluar track je, untuk Zack ambik aku balik dari sekolah dan kita orang lepak kat taman tasik. Masa lepak-lepak tu Zack asyik tengok je peha aku. Lepas tu dia asyik tenung je kelengkang aku. Lepas tu lama-lama dia dah mula usap-usap peha aku. Makin lama makin lain macam. Aku tak kisah sangat sebab aku pun suka.

Lama-lama Zack pegang cipap aku. Dia gosok-gosok tangan dia kat cipap aku sampai aku stim. Aku memula tu malu tapi stim punya pasal lama-lama aku sendiri cum. Aku peluk Zack sebab sedap sangat.

Lepas tu aku tanya Zack kenapa suka tengok peha aku. Zack cakap sebab cantik dan seksi. Aku tak faham sebab takkan la pakai seluar track pun boleh kira seksi. Aku pun tak kisah sangat la. Tapi lepas tu aku sengaja nak test Zack.

Kami jumpa lagi pada hari yang lain dan aku sengaja pakai seluar track lagi. Sekali lagi Zack asyik tengok je peha dan cipap aku. Lepas tu Zack asyik suruh aku jalan ke sana la ke situ la. Rupa-rupanya dia nak tengok bontot aku. Aku pun sengaja la mengada-ngada la kat Zack supaya dia gosok cipap aku lagi macam hari tu sampai cum.

Zack macam faham. Cipap aku pun digosok-gosok tangan Zack sampai la aku terkangkang-kangkang cum dalam seluar track. Basah kelengkang aku. Lepas tu Zack mintak aku berdiri depan dia. Lepas tu Zack menyangkung belakang aku. Dia pegang-pegang bontot aku. Lepas tu dia cium bontot aku. Lepas tu dia sembam muka dia kat bontot aku. Aku dengar Zack sedut nafas kuat-kuat. Aku tunduk biar bontot lagi tonggek.

Zack buka zip seluar. Dia tunjuk aku konek dia. Dah keras. Dia berdiri belakang aku. Dia lancap sambil tengok bontot aku. Lepas tu dia peluk aku dari belakang. Zack letak konek dia kat celah bontot aku. Dia suruh aku tonggeng.

Lepas tu dia geselkan konek dia kat celah bontot aku. Bila aku toleh kat konek dia ada air jernih dah keluar dan basahkan seluar track aku. Aku lentikkan lagi bontot aku. Zack tampar manja bontot aku berkali-kali. Sedap jugak. Bergegar bontot aku dalam seluar track yang sendat tu. Zack tekan konek dia lepas tu dia mengerang sambil paut pinggang aku.

Aku lepas tu rasa konek dia bergerak-gerak kat celah bontot aku. Aku pun toleh. Terkejut aku bila tengok dia dah terpancut air mani yang putih dan pekat kat bontot aku. Banyak gila yang berpalit atas seluar track aku. Zack tekan-tekan lagi sampai la dia puas.

275 notes

·

View notes

Text

Ensuring Weld Quality: Advanced Ultrasonic Testing Methods

In the world of welding, ensuring the quality and integrity of welds is crucial. One of the most effective ways to inspect welds is through ultrasonic testing, which uses high-frequency sound waves to detect imperfections. This blog explores advanced ultrasonic testing methods for welding inspection, highlighting their benefits and applications in the UK.

Introduction to Ultrasonic Testing

Ultrasonic testing for welding involves high-frequency sound waves to detect flaws in welds. This non-destructive testing (NDT) method effectively identifies internal and surface defects without damaging the material.

Why Ultrasonic Testing for Welding?

Accuracy: Provides precise detection of internal flaws.

Non-Destructive: Does not damage the material being inspected.

Versatility: Suitable for a wide range of materials and thicknesses.

Advanced Ultrasonic Testing Techniques

Advanced ultrasonic testing techniques have revolutionised the NDT industry, providing unprecedented levels of accuracy and efficiency. Below are some of the most advanced testing techniques used in the industry:

1. Phased Array Ultrasonic Testing (PAUT)

PAUT is an advanced technique that uses different ultrasonic elements and electronic time delays to create a sweeping beam. This method provides a detailed image of the weld, allowing for precise identification of defects.

Benefits:

High-resolution and detailed images

Faster inspection times

Improved defect characterisation

2. Time-of-Flight Diffraction (TOFD)

TOFD is another complex ultrasonic testing method that uses the time taken by sound waves to travel and diffract around defects to detect and size flaws accurately.

Benefits:

High accuracy in defect sizing

Effective for detecting both surface and subsurface defects

Reduced operator dependency

3. Automated Ultrasonic Testing (AUT)

AUT involves automated systems that perform ultrasonic inspections. This method enhances the consistency and repeatability of inspections, making it ideal for large-scale projects.

Benefits:

Consistent and repeatable results

Increased inspection speed

Reduced human error

Applications of Ultrasonic Testing in the UK

Ultrasonic testing is widely used in the UK across different industries to provide safety and integrity to critical infrastructure. Here are some key applications of ultrasonic testing in the UK.

1. Oil and Gas Industry

In the UK, the oil and gas industry rely heavily on ultrasonic testing for welding to ensure the integrity of pipelines and other critical infrastructure. PAUT and TOFD are commonly used to inspect welds in pipelines, ensuring they are free from defects that could lead to failures.

2. Aerospace Industry

The aerospace industry requires the highest levels of safety and reliability. Ultrasonic testing methods are used extensively to inspect welds in aircraft components, ensuring they meet strict safety standards.

3. Construction and Infrastructure

Ultrasonic testing plays a crucial role in the construction industry, particularly for inspecting welds in bridges, buildings, and other structures.

Advantages of Advanced Ultrasonic Testing Methods

Check out the advantages of advanced ultrasonic testing methods over traditional approaches.

1. Enhanced Accuracy

Advanced ultrasonic testing methods provide higher accuracy in detecting and sizing defects than traditional methods.

2. Increased Efficiency

Automated and advanced techniques like PAUT and AUT significantly reduce inspection times while maintaining high levels of accuracy.

3. Comprehensive Reporting

These methods offer detailed and comprehensive reporting, providing clear images and data that can be used for further analysis and decision-making.

Conclusion

Adopting advanced ultrasonic testing for welding is essential for industries aiming to maintain high quality and safety standards.

Investing in these advanced techniques enhances inspection reliability and ensures compliance with stringent safety regulations. By leveraging the benefits of advanced ultrasonic testing, industries can achieve greater efficiency, accuracy, and overall project success.

9 notes

·

View notes

Text

A Beginner's Guide to Phased Array Ultrasonic Testing (PAUT)

Phased Array Ultrasonic Testing might sound complicated at first, but it’s really just a smart way to "see" inside metal using sound. By combining it with tools like the ultrasonic metal thickness tester and the ultrasonic flaw detector, technicians get a complete picture of a component’s health — without ever taking it apart.

0 notes

Text

Inside the Weld: How Phased Array Ultrasonic Testing Is Redefining NDT

Phased Array Ultrasonic Testing (PAUT) is revolutionizing non-destructive testing with its ability to detect minute flaws deep inside welds. Unlike conventional methods, PAUT inspection provides real-time, high-resolution imaging, ensuring superior accuracy and safety. This advanced PAUT testing technique is ideal for critical industries like oil & gas, aerospace, and power. With the power of phased array ultrasound, technicians can pinpoint defects with unmatched precision, making PAUT a game-changer in structural integrity and asset reliability.

0 notes

Text

Ensure precision, safety, and reliability with Phased Array Ultrasonic Testing (PAUT)! 🔬✅ This cutting-edge NDT method provides detailed imaging, faster inspections, and superior defect detection for various industries, including aerospace, oil & gas, and manufacturing.

✨ Benefits of PAUT: ✅ High-resolution imaging 📸 ✅ Faster & more efficient inspections ⏳ ✅ Detects internal flaws with precision 🎯 ✅ Suitable for complex geometries 🔄

🔗 Learn more: www.bestndtinspection.com

0 notes

Text

Non-destructive Testing Market Innovation and Technological Advancements to 2033

Introduction

Non-destructive testing (NDT) is a critical inspection method used across various industries to evaluate the properties of a material, component, or structure without causing damage. The NDT market has experienced significant growth in recent years due to increasing demand for quality assurance, safety regulations, and advancements in inspection technologies. This article explores the current trends, key drivers, market segmentation, challenges, and future outlook of the NDT market.

Market Overview

The global non-destructive testing market is poised for robust growth, driven by the rising adoption of automated NDT solutions, stringent government regulations, and the growing need for maintenance and inspection in industries such as aerospace, oil & gas, automotive, and construction. According to market research reports, the NDT market size was valued at approximately USD XX billion in 2023 and is expected to grow at a CAGR of over XX% from 2024 to 2030.

Download a Free Sample Report:-https://tinyurl.com/289zdknc

Key Drivers of Market Growth

Stringent Quality and Safety Regulations Governments and regulatory bodies worldwide impose strict safety regulations on industries such as aerospace, automotive, and construction to prevent failures and accidents. NDT techniques ensure compliance with these standards without compromising structural integrity.

Advancements in NDT Technologies The emergence of advanced technologies, such as artificial intelligence (AI), machine learning, and robotics, has enhanced the accuracy and efficiency of NDT methods. Automated ultrasonic testing, eddy current testing, and phased array ultrasonic testing (PAUT) are some of the advanced techniques gaining traction.

Growth in Infrastructure and Manufacturing Sectors Rapid urbanization and industrialization are fueling the need for NDT services in construction and manufacturing. Regular inspections help identify defects early, thereby reducing maintenance costs and increasing the lifespan of structures and equipment.

Aging Infrastructure and Asset Management Many industries, particularly in developed countries, have aging infrastructure that requires continuous monitoring to ensure structural safety and efficiency. NDT plays a crucial role in predictive maintenance strategies.

Increasing Use in Aerospace and Defense The aerospace and defense sectors rely heavily on NDT for inspecting aircraft components, engines, and critical parts. With increasing air travel and defense budgets, the demand for NDT solutions is set to rise.

Market Segmentation

The NDT market is segmented based on testing techniques, end-use industries, and geographic regions.

By Testing Technique

Ultrasonic Testing (UT) – Used extensively in pipeline inspection, aerospace, and automotive sectors.

Radiographic Testing (RT) – Commonly used in detecting internal flaws in castings and welds.

Magnetic Particle Testing (MPT) – Effective in identifying surface and subsurface defects in ferrous materials.

Eddy Current Testing (ECT) – Used in aerospace and power generation for inspecting conductive materials.

Visual Testing (VT) – The most basic yet crucial technique in quality control.

Liquid Penetrant Testing (LPT) – Ideal for detecting surface discontinuities in non-porous materials.

By End-use Industry

Aerospace & Defense – Ensuring safety and reliability of aircraft components.

Oil & Gas – Pipeline and storage tank inspections to prevent leaks and failures.

Automotive – Quality assurance in manufacturing and assembly processes.

Construction & Infrastructure – Structural health monitoring of buildings and bridges.

Power Generation – Inspection of nuclear and renewable energy plants.

By Region

North America – Leading market due to stringent safety regulations and advanced technological adoption.

Europe – Strong presence of aerospace and automotive industries driving demand.

Asia-Pacific – Rapid industrialization and infrastructure development boosting NDT adoption.

Middle East & Africa – Growth fueled by the oil & gas sector.

Challenges in the NDT Market

Despite its growth prospects, the NDT market faces several challenges:

High Initial Investment Costs Advanced NDT equipment and software require substantial upfront investment, limiting adoption among small and medium-sized enterprises.

Shortage of Skilled Workforce The industry faces a shortage of certified and experienced NDT professionals, impacting efficiency and quality of inspections.

Complex Regulatory Compliance Different countries have varying safety and inspection standards, making it difficult for NDT service providers to operate seamlessly across regions.

Limitations in Testing Certain Materials Some NDT techniques have limitations in detecting defects in composite materials and complex geometries.

Future Trends and Opportunities

The future of the NDT market is expected to witness several transformative trends:

Integration of AI and Automation AI-powered NDT systems are improving defect detection capabilities and reducing human error. Automated drones and robots are being deployed for inspections in hazardous environments.

Adoption of IoT and Digital Twins The integration of IoT with NDT enables real-time monitoring and predictive maintenance. Digital twins allow for virtual simulations to detect potential failures before they occur.

3D Imaging and Augmented Reality (AR) Applications 3D imaging technology enhances visualization of defects, while AR assists technicians in performing precise inspections.

Sustainability and Green Energy Inspections The growing focus on renewable energy is increasing the demand for NDT in wind turbines, solar panels, and hydrogen storage systems.

Conclusion

The non-destructive testing market is poised for significant expansion, driven by technological advancements, regulatory compliance, and increasing industrial applications. While challenges such as high costs and skill shortages persist, innovations in AI, automation, and IoT are expected to reshape the industry landscape. As industries continue to prioritize safety and efficiency, the demand for reliable and advanced NDT solutions will remain strong, paving the way for a robust and sustainable market growth in the coming years.Read Full Report:-https://www.uniprismmarketresearch.com/verticals/semiconductor-electronics/non-destructive-testing.html

0 notes

Text

Common Challenges in Ultrasonic Testing and How to Overcome Them

Ultrasonic testing (UT) is a widely used non-destructive testing (NDT) method that leverages high-frequency sound waves to detect flaws, measure material thickness, and assess structural integrity. Its versatility makes it applicable across a variety of industries, from aerospace and automotive to oil and gas and power generation. However, like any testing method, ultrasonic testing comes with its own set of challenges that can affect accuracy, reliability, and efficiency. Understanding these challenges and knowing how to overcome them is key to ensuring successful inspections.

In this article, we will explore some of the most common challenges faced in ultrasonic testing and provide practical solutions to address them.

1. Surface Condition and Coupling Issues

One of the most common challenges in ultrasonic testing is related to the surface condition of the material being inspected. For ultrasonic testing to work effectively, a coupling medium (such as gel, water, or oil) is needed to transmit sound waves between the transducer and the material. If the surface is rough, dirty, corroded, or uneven, it can affect the ability of the coupling medium to maintain proper contact, leading to poor signal transmission.

Solution: Surface Preparation and Advanced Coupling Techniques

To overcome surface-related issues, proper surface preparation is essential. Cleaning the surface, removing rust or debris, and ensuring smoothness can greatly improve the quality of the coupling. Additionally, using specialized couplants that are designed for challenging surfaces or environments, such as high-temperature or underwater applications, can ensure better contact and more reliable results.

In some cases, applying pressure to the transducer or using a delay line can help improve coupling on rough or irregular surfaces.

2. Access to Complex Geometries

Ultrasonic testing works well on flat surfaces and simple geometries, but it can be challenging when inspecting complex shapes, such as curved surfaces, joints, or welded areas. Limited access to certain parts of the structure, such as tight corners or inaccessible regions, can also hinder the ability to perform thorough inspections.

Solution: Use of Flexible Probes and Phased Array Technology

To address the challenge of complex geometries, flexible or curved transducers can be used to better conform to the surface shape of the material. These transducers allow for better sound wave transmission and more accurate readings on irregular surfaces.

For even greater versatility, Phased Array Ultrasonic Testing (PAUT) can be employed. Phased array technology uses multiple elements in the transducer to focus and steer the sound beam electronically, allowing for more precise inspection of complex geometries. It also provides detailed imaging of internal structures, making it easier to detect flaws in hard-to-reach areas.

3. Signal Interference and Noise

Interference or "noise" in ultrasonic signals is a common challenge, especially in environments with high levels of vibration or electromagnetic activity. This noise can distort the signals, making it difficult to differentiate between real flaws and false indications. In addition, certain materials, like coarse-grained metals, can cause scattering of sound waves, resulting in poor signal clarity.

Solution: Frequency Tuning and Advanced Filtering

To minimize signal interference, using the correct frequency for the material and application is crucial. Lower frequencies tend to penetrate deeper into the material, making them suitable for coarse-grained metals or thick materials. However, higher frequencies provide greater resolution and are ideal for detecting small defects in fine-grained materials.

In addition, modern ultrasonic testing equipment often includes advanced signal filtering options that can help distinguish between genuine flaws and background noise. Employing these filters, along with techniques like Time-of-Flight Diffraction (TOFD), can significantly improve signal clarity and accuracy.

4. Operator Skill and Experience

Ultrasonic testing requires a skilled operator to interpret the signals accurately. Without proper training and experience, even the best equipment can yield inaccurate results. Misinterpretation of signals can lead to missed defects or false positives, both of which can have serious consequences in industries where safety and reliability are paramount.

Solution: Comprehensive Training and Certification Programs

To address the challenge of operator skill, investing in comprehensive training programs is essential. Operators must be trained not only in the proper use of equipment but also in interpreting the results. Certification programs, such as those provided by organizations like the American Society for Nondestructive Testing (ASNT), offer standardized training at various levels of expertise.

In addition to formal training, continuous practice and real-world experience are critical for improving an operator's ability to detect and interpret flaws accurately.

5. Material Properties Affecting Signal Penetration

Different materials exhibit varying levels of acoustic impedance, which affects the way sound waves travel through them. For example, certain materials, like composites or highly attenuating metals, can absorb or reflect sound waves more readily, making it difficult to achieve deep penetration or accurate flaw detection.

Solution: Material-Specific Adjustments and Equipment Selection

To overcome this challenge, it is important to select the appropriate equipment and settings for the material being tested. Using transducers with different frequencies or wave modes (e.g., longitudinal or shear waves) can help achieve better penetration and resolution for specific materials. In some cases, adjusting the gain or sensitivity on the ultrasonic testing equipment can help improve signal detection in challenging materials.

Furthermore, advanced techniques like Immersion Ultrasonic Testing (where the component is submerged in water to improve sound transmission) can be effective for inspecting materials with poor acoustic properties.

Conclusion

Ultrasonic testing is a powerful and versatile method for non-destructive testing, but it is not without its challenges. From surface preparation and signal interference to complex geometries and material properties, each challenge requires careful consideration and appropriate solutions. By adopting advanced technologies, using material-specific equipment, and investing in operator training, the accuracy and reliability of ultrasonic testing can be significantly enhanced. These improvements are essential to ensuring the safety, integrity, and performance of critical components across various industries.

0 notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

SAIL-BSP inaugurates Phased Array Ultrasonic Testing (PAUT) facility

Phased Array Ultrasonic Testing (PAUT) Team News Riveting Bhilai, August 19 Phased Array Ultrasonic Testing (PAUT) of weld joints was inaugurated at Universal Rail Mill, Bhilai Steel Plant in the presence of Director In Charge, BSP, Anirban Dasgupta on 16th Aug’2024. The long pending requirement of Indian Railways to start PAUT on weld joints has been fulfilled with the commissioning of this…

0 notes

Text

How Phased Array Ultrasonic Testing is Transforming the UK Manufacturing Industry?

Production and safety are the priorities for the UK manufacturing industry, which is highly competitive. One technology that is making a breakthrough in this field is Phased Array Ultrasonic Testing (PAUT). Non-destructive testing in this advanced form makes a huge difference to manufacturers nationwide.

What is Phased Array Ultrasonic Testing?

PAUT is an advanced ultrasonic testing technique that uses multiple ultrasonic elements and electronic time delays to create beams that can be steered, scanned, and focused electronically. This imaging method provides much more data and is more accurate than the old ultrasonic testing method.

The Advantages of PAUT in Manufacturing

1. Enhanced Detection Capabilities

Apart from non-destructive testing methods like the PAUT, you can also use it to scan the part to detect flaws and defects that other methods might have missed. And this way, they ensure the product's quality is top; nonetheless, it's a solid alloy.

These state-of-the-art advanced ultrasonic testing techniques perform flaw detection in the impossibility of other ultrasonic testing methods. Its capability to examine irregular shapes and thick materials is a more important aspect of industries, especially automotive and aerospace manufacturing.

2. Increased Efficiency

The quick scanning process and inspection time reduction are the main features of Phased Array Ultrasonic Testing (PAUT). With the most improvements in speed, this scanner is serving not only in higher productivity but also bringing the cost to the manufacturer all the way down.

3. Improved Data Visualisation

PAUT gives tangible images/clearer, easy-to-understand images of the things tried out. This visual data helps technicians and engineers make more precise product safety and quality decisions.

4. Versatility

PAUT, an advanced ultrasonic technique, can be used on various materials and components of different types, from ridges and pipelines to composite materials, also known as modern materials used in manufacturing.

PAUT vs Traditional Non-Destructive Testing

While traditional non-destructive testing methods like radiography and dye penetrant testing are suitable on their own, PAUT is particularly good for several reasons:

Some methods, such as Gamma(γ) radiation or Welded plates, will not produce the same effect when the same materials are inspected with Radiography.

Ability to inspect thicker materials than conventional ultrasonic testing

Rechecking the defects, depending on the severity of the defect, can prevent catastrophic failures.

Unlike traditional ultrasonic testing, the lower number of individual angle probes may be in the distant future.

The Future of PAUT in UK Manufacturing

Given the commitment of UK manufacturers to technological advancements, the availing of advanced ultrasonic testing techniques such as PAUT will only get spat. This equation has a dual side: the safety of vital elements is ensured while the other one is that the overall product quality is increased. The role of Phased Array Ultrasonic Testing in the latter case of product inspection is the answer to the problem of low-quality parts.

Frequently Asked Questions

Can Phased Array Ultrasonic Testing (PAUT) be automated? PAUT can be automated for consistent, high-speed inspections in manufacturing environments.

How does PAUT enhance safety in manufacturing? PAUT is a great technology that increases security. This is done by identifying hidden defects on any surface, minimising the chance of a defective product being produced. The potential use of PAUT will empower UK manufacturers to achieve the best quality control level and thus be competitive in the fast global market.

#ManufacturingInnovation#PhasedArrayUltrasonicTesting#NonDestructiveTesting#UKManufacturing#AdvancedTechnology#ManufacturingSafety#AerospaceTechnology

0 notes

Text

Ultrasonic Testing Market Valuation and Overview – 2024-2030

The Ultrasonic Testing Market is projected to experience significant growth from 2024 to 2030, driven by the escalating demand for non-destructive testing (NDT) techniques across various industries such as oil & gas, aerospace, automotive, and construction. Valued for its accuracy, safety, and efficiency in detecting material flaws and structural integrity issues, ultrasonic testing is increasingly being adopted to ensure compliance with stringent safety and quality standards.

Technological advancements, including the development of phased array ultrasonic testing (PAUT) and automated ultrasonic testing (AUT) systems, are expected to enhance inspection capabilities and drive market expansion. The rising focus on infrastructure maintenance, coupled with the need for extending the lifespan of aging assets, is further propelling market growth.

The global ultrasonic testing market size is projected to reach USD 4.2 billion by 2026, at a compound annual growth rate (CAGR) of 7.1% during the forecast period.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=131229239

The ultrasonic technique (UT) is likely to be the largest contributor in the market during the forecast period The market for the UT (ultrasonic testing) technique is projected to largest contributor in Market. It is presently the most popular NDT technique due to its ability to identify defects and accurately determine their severity. Some advanced techniques such as ultrasonic immersion testing and guided-wave ultrasonic testing can be used for critical applications in the oil & gas and aerospace industries, among many others.

Inspection services to account for the largest market size by 2021 Ultrasonic testing and inspection services are likely to account for the largest share of the market in 2021. Ultrasonic testing techniques' primary purpose is to inspect objects, materials, machinery, and structures for defects so that they can be rectified in a timely and cost-effective manner. After inspection services, training services are likely to continue to gain the second-largest market share in the coming years since training NDT technicians to keep them updated with new technological trends and make them aware of the customers' changing demands is equally essential.

The Ultrasonic testing market in APAC to grow at the highest CAGR during the forecast period Asia Pacific is likely to be the fastest-growing region in the ultrasonic testing market due to the rapid infrastructural development and automation adoption in manufacturing industries in countries such as India and China. Countries in Asia Pacific are involved in the manufacturing of defense aircraft, which is expected to increase ultrasonic testing equipment and services in the defense & aerospace industry. Many infrastructural development projects are under construction and scheduled to be constructed in the region during the forecast period. The demand for automobiles is estimated to grow substantially by 2026.

The market was dominated by ultrasonic testing companies such as Baker Hughes(US), Olympus Corporation (Japan), MISTRAS Group (US), Intertek (UK), Sonatest (UK), Zetec, Inc. (US), T.D. Williamson Inc. (US), Bosello High Technology srl (Italy), Eddyfi (Canada), and Magnaflux (US), Fischer Technology Inc. (US), Cygnus Instruments Ltd. (UK), NDT Global GmbH (Germany), Acuren (US), and LynX Inspection (Canada).

0 notes

Text

Integrated NDE Solution in Pune: Leading the Way in Ultrasonic Testing and NDT Services

In the realm of industrial quality assurance, ensuring the structural integrity and reliability of materials and components is paramount. Integrated NDE Solutions in Pune stands at the forefront of this crucial sector, offering state-of-the-art Non-Destructive Testing (NDT) services, with a particular emphasis on Ultrasonic Testing. This article delves into the intricacies of Ultrasonic Testing, explores the comprehensive range of NDT services provided by Integrated NDE Solution in Pune, and underscores the pivotal role they play in various industries.

What is Ultrasonic Testing?

Ultrasonic Testing (UT) is a highly advanced and versatile NDT method used to detect internal flaws, measure material thickness, and evaluate the properties of materials without causing any damage. This technique employs high-frequency sound waves that penetrate the material and reflect back, providing detailed insights into the material's integrity.

How Ultrasonic Testing Works

The process involves transmitting ultrasonic pulses into the material using a transducer. When these pulses encounter a boundary, such as a flaw or the back wall of the material, they reflect back to the transducer. The time it takes for the echoes to return is measured and analyzed to determine the presence, location, and size of any defects.

Benefits of Ultrasonic Testing

Accuracy: UT offers precise measurements and can detect very small flaws.

Depth Penetration: It is capable of inspecting thick materials.

Versatility: Suitable for a wide range of materials, including metals, plastics, and composites.

Safety: Non-hazardous and safe for operators.

Real-Time Results: Immediate feedback allows for on-the-spot decision-making.

Integrated NDE Solution in Pune: Your Partner in Quality Assurance

Integrated NDE Solution in Pune is a premier provider of NDT services, renowned for its expertise, cutting-edge technology, and commitment to quality. Their Ultrasonic Testing services are second to none, ensuring that clients receive the most reliable and accurate results.

Comprehensive NDT Services Offered

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Magnetic Particle Testing (MPT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Visual Inspection (VI)

Industries Served

Integrated NDE Solution in Pune caters to a broad spectrum of industries, including:

Aerospace: Ensuring the safety and reliability of aircraft components.

Automotive: Inspecting parts to prevent failures and ensure quality.

Construction: Verifying the integrity of structures and materials.

Oil and Gas: Inspecting pipelines and equipment to prevent leaks and failures.

Power Generation: Ensuring the reliability of critical infrastructure.

Advancements in Ultrasonic Testing Technology

Integrated NDE Solution in Pune continuously invests in the latest ultrasonic testing technology to enhance their service offerings. Some of the cutting-edge advancements include:

Phased Array Ultrasonic Testing (PAUT): This technology uses multiple transducers to create a detailed image of the material's interior, allowing for more accurate flaw detection.

Time of Flight Diffraction (TOFD): TOFD is a highly accurate method for measuring the size and location of flaws, particularly in welds.

Automated Ultrasonic Testing (AUT): Automation increases inspection speed and consistency, making it ideal for large-scale inspections.

The Importance of Certified Technicians

The accuracy and reliability of Ultrasonic Testing heavily depend on the skill and expertise of the technicians performing the inspections. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their expertise ensures that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune places a strong emphasis on quality and safety. Their adherence to international standards and best practices ensures that all inspections are performed with the utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is paramount. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it's a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In an industry where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in Ultrasonic Testing and NDT services. Their dedication to quality, use of advanced technology, and customer-centric approach makes them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to pave the way for innovation and excellence in Non-Destructive Testing. Their Ultrasonic Testing services not only detect flaws and defects but also provide invaluable insights that drive improvements in quality and safety. For businesses seeking the highest standards of NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results.

1 note

·

View note