#Advanced Non Destructive Testing Service

Explore tagged Tumblr posts

Text

Top Advanced Non Destructive Testing Service in India

What is Non-Destructive Testing (NDT)?

Advanced Non-Destructive Testing refers to a range of techniques used to evaluate the properties of materials, components, and structures without causing any harm. The primary goal of NDT is to detect and evaluate defects, flaws, or irregularities that could compromise safety and performance. Unlike traditional methods that might require the destruction of the test sample, NDT allows for ongoing monitoring and inspection without affecting the item being tested.

Why Choose Advanced NDT Services?

While conventional NDT methods are valuable, advanced techniques offer enhanced capabilities, greater accuracy, and broader applications. At ITE, we specialize in advanced NDT services that leverage the latest technology to provide comprehensive and reliable inspections. Here’s why our advanced NDT services stand out:

1. Enhanced Accuracy

Advanced NDT methods utilize sophisticated equipment and algorithms to detect even the most subtle defects. Our state-of-the-art tools ensure precise measurements and detailed insights, minimizing the risk of missed anomalies.

2. Greater Sensitivity

Our advanced techniques are designed to identify smaller and more complex defects that traditional methods might overlook. This sensitivity is crucial for industries where safety and reliability are non-negotiable.

3. Real-Time Results

Many of our advanced NDT services provide real-time data, allowing for immediate analysis and decision-making. This capability is particularly valuable in critical situations where time is of the essence.

4. Broader Applications

From aerospace and automotive to construction and energy, our advanced NDT services are applicable across a wide range of industries. We tailor our approach to meet the specific needs of each sector, ensuring relevant and actionable results.

Our Advanced NDT Services

At ITE, we offer a comprehensive suite of advanced NDT services, each designed to address different inspection needs:

1. Ultrasonic Testing (UT)

Ultrasonic Testing uses high-frequency sound waves to detect internal flaws in materials. Our advanced UT systems provide precise measurements and can detect various types of defects, including cracks, voids, and weld quality issues.

2. Radiographic Testing (RT)

Radiographic Testing involves the use of X-rays or gamma rays to inspect the internal structure of materials. Our advanced RT services offer high-resolution imaging, allowing for the detection of intricate defects within thick materials.

3. Eddy Current Testing (ECT)

Eddy Current Testing is a technique that uses electromagnetic induction to detect surface and near-surface defects. Our advanced ECT systems provide rapid and accurate results, making them ideal for inspecting conductive materials.

4. Magnetic Particle Testing (MPT)

Magnetic Particle Testing involves the application of magnetic fields and iron particles to detect surface and near-surface discontinuities. Our advanced MPT methods enhance sensitivity and reliability, ensuring thorough inspections.

5. Acoustic Emission Testing (AET)

Acoustic Emission Testing monitors the release of energy from materials under stress. This method is highly effective for assessing the condition of structures under load and identifying potential failure points.

Why ITE?

Choosing ITE means partnering with a team of experts dedicated to delivering exceptional NDT services. Here’s why we are the preferred choice:

Expertise: Our team comprises highly skilled professionals with extensive experience in advanced NDT methods.

Technology: We invest in the latest technology to ensure the highest standards of accuracy and reliability.

Tailored Solutions: We understand that each industry and project has unique requirements. Our services are customized to meet your specific needs.

Commitment to Safety: We prioritize safety and quality in every inspection, ensuring that our findings contribute to the overall reliability and safety of your operations.

Conclusion

In the world of industrial inspection and maintenance, advanced Non-Destructive Testing is a game-changer, offering unparalleled accuracy and reliability. At ITE, we are committed to providing top-notch advanced NDT services across India, helping industries maintain the highest standards of safety and performance. Whether you’re in aerospace, automotive, construction, or any other sector, our advanced NDT solutions are designed to meet your unique needs and exceed your expectations.

For more information on how ITE can enhance your inspection processes with advanced NDT services, contact us today. Let us help you unlock the power of precision and ensure the integrity of your materials and structures.

For more details, please visit :-

Website :- https://www.itenoida.com/

Contact No. :- +91–9891174696, +91–9810059715

Email :- [email protected], [email protected]

1 note

·

View note

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

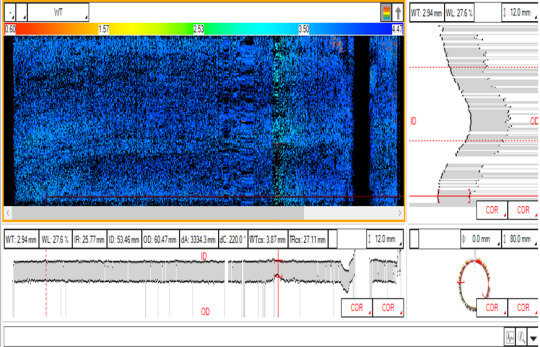

Inspection of Boiler Bank Tubes | Internal Rotary Inspection System (IRIS)

Are you unable to carry out the Inspection of Boiler Bank tubes?

Are you regularly carrying out Capital Investment by purchasing tubes rather than finding only the defective Bank Tubes?

Here is the solution for inspection of Boiler Bank Tubes –

In case of Boiler Bank Tubes, only the Front Column of Tubes are available for Inspection for Thickness Testing externally there is no other way to check the rest of the Tubes. Thus, we have only 5 % of the Tubes available while we miss out on an inspection of the rest of the 95% of the tubes.

RFET was done previously to ascertain the condition of the rest of the 95% of the tubes but due to the limitation of the technique it is also not a right testing method. Then we tried IRIS on these tubes and got amazing results.

HOW IT WORKS –

Because IRIS is an ultrasonic technique, it requires a couplant. In this case, water. Tubes under test must therefore first be flooded to use this technique. IRIS relies on a transducer to generate an ultrasonic pulse parallel to the axis of the tube under test. It also relies on a rotating mirror that directs the ultrasonic wave into the tube wall.

The mirror is driven by a small turbine powered by the pressure of water pumped into the tube. Part of the ultrasonic wave is reflected by the inner diameter (ID) wall, while the rest is reflected by the outer diameter (OD) wall of the tube. Because the ultrasonic velocity of the tube’s material is known, it is possible to assess the thickness of the wall by calculating the difference in times of flight between the two diameters. As the probe is pulled, the spinning motion of the mirror results in a helical scan path.

A critical aspect of IRIS is ensuring that the mirror is at the centre of the tube. An off-centre ultrasonic pulse yields a distorted scan image because of the different ID and OD wall sound paths. That’s why our IRIS kits are equipped with centring devices helping operators keep the system centred.

About IRC Engineering Pvt. Ltd.

IRC is one of the fastest growing Testing and Inspection company in India. We at IRC provide Liquid Penetrant Testing, Non-Destructive Testing, Destructive Testing, Advanced NDT, Third Party Inspection, Condenser Testing, Electrical Testing, Residual Life Assessment of Power Plant, O&M Services, Fitness For Service, Civil Testing and Training services.

Our website - https://ircengg.com/

2 notes

·

View notes

Text

Avoid Costly Delays: How Scanning Utility Locating Saves You Time and Money

In today's fast-paced construction and infrastructure development landscape, time is money. Any unforeseen delays can significantly inflate costs and disrupt project timelines. One of the most effective ways to mitigate these risks is by employing advanced scanning utility locating techniques. Safe Scanners, a leader in this field, offers state-of-the-art GPR Services, GPR Scanning, Ground Penetrating Radar, and Concrete Scanning Services. These services ensure that projects proceed smoothly, without the costly interruptions caused by unforeseen utility line strikes or structural issues.

The Importance of Utility Locating Services

Before any excavation, drilling, or construction work begins, it's crucial to know what lies beneath the surface. Utility locating services help identify the presence of underground utilities such as water pipes, gas lines, electrical cables, and telecommunications infrastructure. Unintended strikes on these utilities can cause severe delays, legal liabilities, safety hazards, and increased costs.

Safe Scanners' Utility Locating Services use advanced technology to provide accurate and reliable subsurface information. This proactive approach not only prevents damage but also enhances project planning and efficiency.

How Ground Penetrating Radar (GPR) Works

Ground Penetrating Radar (GPR) is a non-destructive method that uses radar pulses to image the subsurface. GPR Scanning involves transmitting high-frequency radio waves into the ground. When these waves encounter a buried object or a boundary between different materials, they reflect back to the surface, where they are detected by a receiver. The time it takes for the radar waves to return is used to create a detailed image of the subsurface.

GPR Services provided by Safe Scanners are invaluable in detecting utilities, voids, rebar, and other structural components. This technology is highly effective in a variety of materials, including soil, rock, concrete, and asphalt, making it versatile for different construction needs.

Benefits of GPR Scanning and Concrete Scanning Services

Accuracy and Precision: GPR Scanning delivers highly accurate results, allowing construction teams to pinpoint the exact location and depth of utilities and other subsurface features. This precision reduces the risk of damaging existing infrastructure and ensures compliance with safety regulations.

Cost Savings: By identifying and avoiding utilities and other subsurface hazards, Safe Scanners' GPR Services prevent costly repairs, project delays, and potential legal issues. The upfront investment in scanning services can save significant amounts of money in the long run.

Safety Enhancement: Excavating without proper knowledge of underground utilities can lead to dangerous situations, including gas leaks, electrical hazards, and water main breaks. Using Ground Penetrating Radar and Concrete Scanning Services minimizes these risks, protecting workers and the public.

Non-Destructive Testing: GPR is a non-invasive method that does not disturb the surveyed area. This means that the site remains intact, avoiding the mess and potential damage associated with exploratory digging.

Versatility: GPR Scanning can be used in various environments and for multiple applications, from large-scale construction projects to smaller residential renovations. Safe Scanners' expertise ensures that each project benefits from tailored solutions.

Case Studies: Real-World Applications of GPR

Case Study 1: Urban Infrastructure Development

In a major city development project, Safe Scanners was enlisted to perform GPR Scanning before the installation of new utilities. The dense urban environment posed a challenge due to the existing network of underground utilities. Using advanced Ground Penetrating Radar, Safe Scanners successfully mapped out the complex subsurface layout, allowing the construction team to proceed without incident. This avoided potential delays and saved the city significant costs in rerouting and repairs.

Case Study 2: Historic Building Renovation

A historic building undergoing renovation required Concrete Scanning Services to locate rebar and voids within its foundation. Safe Scanners deployed its GPR technology to scan the concrete structure, providing detailed imagery of the rebar patterns and any hidden voids. This information was crucial in planning the renovation work, ensuring structural integrity and preserving the building's historical value. The project was completed on time and within budget, thanks to the accurate data provided by Safe Scanners.

Future Trends in Utility Locating and GPR Technology

As technology advances, the capabilities of GPR and utility locating services continue to expand. Innovations such as 3D GPR imaging and real-time data processing are enhancing the accuracy and speed of subsurface investigations. Safe Scanners is at the forefront of adopting these new technologies, ensuring that clients benefit from the latest advancements in the field.

Moreover, the integration of GPR data with Geographic Information Systems (GIS) allows for more comprehensive and accessible mapping of subsurface utilities. This integration provides a holistic view of the project site, further reducing risks and improving planning efficiency.

In the realm of construction and infrastructure development, avoiding costly delays is paramount. Safe Scanners' GPR Services, including GPR Scanning, Ground Penetrating Radar, and Concrete Scanning Services, offer a reliable and effective solution to this challenge. By accurately locating subsurface utilities and other features, these services save time, reduce costs, and enhance safety on job sites.

Investing in advanced utility locating services is a proactive step that pays off in both the short and long term. With Safe Scanners' expertise and cutting-edge technology, you can ensure your projects proceed without unexpected interruptions, keeping your timelines and budgets intact.

For more information on how Safe Scanners can assist with your next project, visit our website or contact us directly. Together, we can build a safer, more efficient future.

2 notes

·

View notes

Text

Get Maximum Value for Your Gold – Sell to Amruta Gold Buyers in Hyderabad

The Growing Demand for Reliable Gold Buyers in Hyderabad

With the value of gold steadily increasing, more individuals in the city are turning to gold as a dependable financial backup. Whether it’s for medical emergencies, education, weddings, or business needs, selling gold has become a common and practical solution. However, choosing the right buyer is crucial. That’s where Amruta Gold, the most Trusted Gold Buyers in Hyderabad, comes in—delivering honest, transparent, and efficient service to everyone who walks through our doors.

✅ Sell your gold with confidence by visiting Amruta Gold Official Website – where transparency meets top value.

What Makes Amruta Gold Stand Out

As one of the most Trusted Gold Buyers in Hyderabad, we stand apart through our customer-first policies and value-driven services:

Live Gold Rate Access: We provide real-time pricing so you always get the true value of your gold.

No Hidden Charges: Every transaction is transparent, with no surprise deductions.

Certified Practices: All testing and weighing procedures follow BIS and ISO norms.

Customer Service: Our staff is trained to assist you with professionalism, empathy, and accuracy.

🔗 Get an instant quote now by clicking here to visit Amruta Gold

Safe and Instant Gold Selling Experience

We understand that selling your gold is often tied to urgent needs or emotional value. At Amruta Gold, your safety and peace of mind are our priority. Our showrooms in Hyderabad are equipped with:

24x7 CCTV Surveillance

Private Evaluation Cabins

Hygienic and Secure Environments

As one of the most Trusted Gold Buyers in Hyderabad, we ensure that each customer’s valuables are handled with utmost integrity. The entire process, from evaluation to payment, is completed in less than 30 minutes.

Use Cases – Why People Sell Gold

Gold is more than jewelry—it’s a safety net. Here are a few reasons why our customers choose to unlock its value:

Medical Emergencies

Hospital bills can be unexpected and overwhelming. We ensure fast-track services to help customers get immediate cash in such crucial times.

Education and Weddings

Whether funding higher studies or planning a dream wedding, many clients trust us to convert idle gold into meaningful investments.

Business or Home Needs

From home renovations to small business funding, Amruta Gold is the go-to choice for those looking for quick liquidity without compromise.

💬 Speak to our experts today at Amruta Gold – Hyderabad’s Gold Experts

Our Purity Testing Standards (XRF Machines)

We use advanced XRF Technology (X-ray Fluorescence) for testing the purity of gold—ensuring accurate and damage-free assessment. This cutting-edge technology allows:

Non-destructive Testing

Immediate Results with 99.99% Accuracy

Full Transparency with Live Screen Display

As one of the leading and Trusted Gold Buyers in Hyderabad, we believe our customers should never be left guessing. Every step is explained, and every reading is visible in real-time.

Quick Process – From Gold Check to Payment

Here's how the streamlined process at Amruta Gold works:

Walk-In: Bring your gold along with a valid government ID.

Purity Check: Our staff performs free, instant testing in front of you.

Weighing and Valuation: Based on current live rates, we calculate the value.

Instant Payment: You receive money immediately via cash, NEFT, IMPS, or UPI.

Receipt and Documentation: Full invoice with every transaction.

With Amruta Gold, the entire experience is fast, fair, and stress-free.

🚶♀️ Visit your nearest branch or book an appointment now via AmrutaGold.com

Connect with Amruta Gold – Call or Visit Today

Thousands of satisfied customers have made Amruta Gold their first choice when it comes to selling gold. With multiple locations across the city and an unwavering reputation as the most Trusted Gold Buyers in Hyderabad, we continue to serve with honesty and professionalism.

Amruta Gold Locations

Amruta Gold – Gold Buyers in Dilsukhnagar, Hyderabad

📍 9-16, 1st Floor, Vijeta Complex, Lalitha Nagar, Dilsukhnagar, Hyderabad, Telangana 500060

Amruta Gold – Gold Buyers in Hyderabad, Miyapur

📍 1-120, 1st Floor, SSR Complex, Opp Axis Bank, Allwyn Colony Cross Roads, Hyderabad, Telangana 500049

#amrutagold#1 gold buyers#best place to sell gold in vijayawada#gold buyers hyderabad#best gold buyers hyderabad#best gold buyers vijayawada#gold buyers vijayawada#gold buyers bhimavaram#gold buyers in vijayawada

0 notes

Text

Enhancing Industrial Safety: Top ECT Tube Inspection Services Company in India

Ensuring industrial safety begins with precise evaluation, and that's where a trusted ECT Tube Inspection Services Company in India plays a vital role. Using advanced eddy current testing (ECT), this non-destructive testing (NDT) technique detects flaws like cracks, corrosion, and pitting in heat exchangers and condenser tubes without damaging the material. As a leader in NDT testing, we deliver fast, accurate, and reliable results that help prevent failures, reduce downtime, and optimize performance. Choose expert eddy current solutions for uncompromised safety and operational excellence.

#NDTTesting#NonDestructiveTesting#EddyCurrentTesting#EddyCurrent#ECTTubeInspectionServicesCompanyInIndia

0 notes

Text

Premium Manganese Castings from India – Akjay International LLC

In the world of heavy machinery and industrial wear parts, manganese casting plays a vital role in enhancing durability, performance, and cost-efficiency. Today, manganese castings from India are highly sought after due to their superior quality, affordability, and reliability. One of the industry’s leading names in this space is Akjay International LLC, a global exporter of top-grade manganese casting components.

Understanding Manganese Casting

Manganese casting involves using manganese steel—an alloy with exceptional impact strength and resistance to abrasion—to manufacture components such as crusher jaws, hammers, liners, and rail components. These castings are essential in industries like:

Mining & Quarrying

Construction & Earthmoving

Cement & Steel Plants

Railways & Infrastructure

Power Generation

The unique property of manganese steel is its ability to harden when subjected to impact and stress. This self-hardening capability ensures longer service life and reduced replacement frequency, making manganese casting a cost-effective solution in high-wear environments.

Why Choose Manganese Castings from India?

India has become a global hub for manganese castings due to its blend of modern manufacturing capabilities, skilled labor, and cost competitiveness. Companies around the world trust Indian manufacturers for the following reasons:

Advanced Foundries: Equipped with modern furnaces, sand casting systems, and quality testing labs.

Customization Capabilities: Castings are produced to match specific engineering drawings and material specifications.

Competitive Pricing: Lower production costs without compromising quality.

Global Logistics Network: Seamless delivery to North America, Europe, the Middle East, and Asia.

Akjay International LLC – Your Reliable Partner

Among the top providers of manganese castings from India, Akjay International LLC has earned a strong reputation for precision, quality, and customer service. Serving industries worldwide, the company specializes in manufacturing and exporting high-performance manganese steel castings built to endure extreme wear conditions.

Key Features of Akjay’s Manganese Casting Solutions:

1. High-Quality Materials: Akjay uses premium-grade manganese steel (12-14% Mn content) that offers a perfect balance of hardness and ductility.

2. Wide Range of Components: The company supplies a broad range of products, including cone crusher liners, jaw plates, impact bars, excavator teeth, and more—each engineered for performance and longevity.

3. Tailored to Specifications: Need a custom shape or dimension? Akjay International LLC delivers manganese castings that meet your precise technical and operational requirements.

4. Strict Quality Assurance: Each casting undergoes rigorous inspections and testing, including hardness checks, dimensional accuracy, and non-destructive testing (NDT).

5. Reliable Export Services: With extensive experience in international shipping, Akjay ensures timely delivery with proper documentation and safe packaging.

Applications of Manganese Castings

Mining Crushers – Jaw plates and cone liners

Construction Machinery – Bucket teeth and wear plates

Railway Infrastructure – Crossing frogs and switch parts

Steel Plants – Chutes, hoppers, and liners

Cement Plants – Blow bars and hammer heads

These components are used in the harshest industrial environments, and their performance directly impacts operational efficiency and safety.

Why Akjay International LLC?

Choosing Akjay International LLC means partnering with a company committed to quality, innovation, and customer satisfaction. With a strong presence in exporting manganese castings from India, Akjay bridges the gap between Indian manufacturing excellence and global demand.

Their dedication to continuous improvement, competitive pricing, and on-time delivery makes them a preferred supplier for businesses seeking durable and efficient manganese casting solutions.

1 note

·

View note

Text

What We Recycle: Accepted Electronics and E-Waste at 3R Technology

At 3R Technology, we don’t just recycle devices; we provide a responsible, secure, and scalable solution for managing electronic waste. Our facility is equipped to handle a broad spectrum of electronics and peripheral equipment, from individual consumer devices to enterprise-level infrastructure. If it has a circuit board or a wire, chances are we can recycle it. Materials accepted include a wide range of electronic components and devices, ensuring comprehensive e-waste management.

Our goal is simple: recover usable materials, protect sensitive data, and divert e-waste from landfills through environmentally sound practices.

Electronics We Accept

We accept a wide range of electronics, including but not limited to:

Computers & Laptops: Whether outdated, broken, or surplus, desktops and laptops are among the most common items we process.

Servers, Networking, & Data Centre Equipment: We handle enterprise-grade hardware such as servers, switches, routers, firewalls, and related gear.

Monitors & Displays: We recycle LCD, LED, and flat-panel monitors. CRTs are accepted with restrictions. Contact us in advance.

Devices: Smartphones, tablets, and other portable electronics are accepted, regardless of age or condition.

Printers, Scanners & Peripherals: Workplace devices, from multi-function printers to external hard drives and keyboards, are recyclable through our facility's services.

Cabling & Wiring: Power cords, data cables, and electrical wiring are all accepted, as copper and metals can be recovered during processing.

Speciality & Industrial Electronics

In addition to standard electronics, we also process equipment used in specialised or industrial environments:

Medical Electronics: Monitors, imaging equipment, and diagnostics systems (non-hazardous) can be evaluated for responsible recycling.

Laboratory Instruments: Items used in research or testing settings, including analysers, oscilloscopes, and measuring devices.

Point-of-Sale Systems: Barcode scanners, card readers, registers, and related accessories.

Manufacturing Controls: PLCs, automation hardware, and embedded systems often contain valuable recoverable components.

If you’re unsure whether your item qualifies, we are here to review it.

What We Don’t Accept

While our facility can handle a wide range of materials, there are a few exceptions due to safety and compliance regulations:

Household appliances (e.g., refrigerators, microwaves)

Hazardous materials (e.g., items with chemical, biological, or radioactive exposure)

CRT monitors with damaged tubes (accepted on a case-by-case basis)

Light bulbs, batteries, and loose toner cartridges (unless part of a larger electronics load)

If you're managing a large project or facility decommission, we encourage you to contact us for a tailored solution. Based on volume and overall condition, we may accept items not listed here.

Why Choose 3R Technology

We’re not just a drop-off point, but a full-service electronics lifecycle partner. We adhere to R2v3 and ISO 14001 standards for responsible recycling and data security. Every item is processed to maximize recovery while minimizing environmental impact.

Our team also provides certified data destruction services, both on-site and off-site. Whether it’s a single device or a thousand, we ensure data-bearing devices are sanitised to NIST and DoD standards.

We work with businesses, schools, healthcare providers, government agencies, and individual residents across the Pacific Northwest. Our services scale to meet the needs of small offices or multi-site corporations.

Contact us to schedule a pickup or drop-off.

3R Technology, a CTL Company

8002 S 208th St Suite E105 Kent, WA 98032

(206) 582-7100

0 notes

Text

How to Select the Best Material Testing Lab in Abu Dhabi? | +971 554747210

When undertaking any construction, manufacturing, or infrastructure project in Abu Dhabi, one key factor that can determine your success is the quality and reliability of your material testing. Whether you are verifying concrete strength, assessing soil composition, or checking the durability of metals, choosing the right Material Testing Lab in Abu Dhabi is critical.

With many labs offering similar services, selecting the best one can be overwhelming. This blog provides a detailed guide on how to select the best material testing lab in Abu Dhabi — ensuring accuracy, compliance, and peace of mind for your project.

Why Choosing the Right Material Testing Lab Matters

Material testing labs play a pivotal role in verifying the safety, durability, and compliance of construction and industrial materials. The quality of the testing lab directly impacts:

Accuracy of Results: Reliable data helps engineers make informed decisions.

Regulatory Compliance: Accredited labs ensure tests meet local and international standards.

Project Timelines: Fast turnaround times avoid costly delays.

Risk Management: Identifying defects early prevents structural failures and financial losses.

Selecting the wrong lab can lead to inaccurate reports, regulatory issues, and even safety hazards. Therefore, making an informed choice is essential.

Key Factors to Consider When Selecting a Material Testing Lab in Abu Dhabi

1. Accreditation and Certification

The most important factor is accreditation. Look for labs accredited by reputable bodies such as the Emirates International Accreditation Centre (EIAC), which follows international standards like ISO/IEC 17025. Accreditation guarantees the lab meets strict quality and competence requirements.

An accredited lab provides:

Valid and internationally recognized test results.

Compliance with Abu Dhabi Quality and Conformity Council (QCC) regulations.

Consistency and reliability in testing methods.

Always ask to see the lab’s accreditation certificate and verify its scope.

2. Range of Testing Services Offered

Choose a lab that offers a comprehensive range of testing services to suit your specific needs. Typical material testing services include:

Concrete and cement testing

Soil and geotechnical testing

Metals and alloys testing

Aggregate testing

Non-destructive testing (NDT)

Chemical and environmental testing

A full-service lab reduces the need for multiple vendors, streamlining your workflow and ensuring consistent quality.

3. Experience and Expertise

Evaluate the lab’s technical expertise and experience, especially in projects similar to yours. Experienced labs:

Understand local material conditions and project requirements.

Have skilled technicians and engineers who can interpret complex data.

Provide consultation and support beyond testing, helping with problem-solving and compliance.

Request case studies or client references to gauge the lab’s track record.

4. Testing Equipment and Technology

Modern, well-maintained equipment is essential for accurate and efficient testing. The best labs invest in:

Advanced testing instruments that meet international standards.

Regular calibration and maintenance schedules.

Automated and digital data management systems for faster reporting.

Outdated or poorly maintained equipment can lead to inaccurate results and delays.

5. Turnaround Time and Reporting

Time is often a critical factor in construction and manufacturing projects. Select a lab that offers:

Prompt sample testing and fast turnaround times.

Clear, detailed, and easy-to-understand test reports.

Digital delivery options for convenience.

Efficient reporting keeps your project on schedule and helps you make timely decisions.

6. Location and Accessibility

Choosing a lab located conveniently in Abu Dhabi can:

Reduce sample transportation time and costs.

Enable easier communication and on-site visits if needed.

Provide faster response times for urgent testing requirements.

7. Cost and Value for Money

While cost is important, don’t compromise quality for low prices. Compare quotes from multiple labs, but also consider:

The lab’s reputation and quality of services.

Additional benefits such as technical support, consultancy, and flexibility.

Hidden costs like sample handling or re-testing fees.

Aim for the best value — high-quality testing at a reasonable price.

8. Customer Support and Communication

Effective communication is key to smooth collaboration. The best labs provide:

Responsive customer service to answer queries.

Technical guidance on test selection and interpretation.

Regular updates on sample status and report delivery.

Good support minimizes misunderstandings and improves project coordination.

Questions to Ask Before Selecting a Material Testing Lab

To ensure you choose the best lab, consider asking:

Is your lab accredited? Can I see the certificate?

What is your experience with projects in Abu Dhabi’s environment?

Which testing standards and methods do you follow?

What is your average turnaround time?

Can you provide client references or case studies?

How do you ensure data accuracy and quality control?

What are your pricing and payment terms?

Do you offer technical support and consultancy?

The Role of Accredited Material Testing Labs in Abu Dhabi’s Growth

Abu Dhabi’s vision to develop world-class infrastructure and sustainable cities depends heavily on quality assurance throughout the construction process. Accredited material testing labs support this vision by:

Ensuring all materials meet safety, durability, and environmental standards.

Helping builders and manufacturers comply with evolving regulations.

Providing data to optimize design and reduce construction risks.

Supporting innovation through advanced testing techniques.

Choosing the right lab aligns your project with Abu Dhabi’s commitment to excellence.

Conclusion

Selecting the best Material Testing Lab in Abu Dhabi is a crucial step toward ensuring construction quality, regulatory compliance, and project success. By focusing on accreditation, range of services, expertise, equipment, turnaround times, and customer support, you can find a reliable partner that meets your specific needs.

Don’t rush this decision — take the time to evaluate labs carefully and choose the one that offers trustworthy testing, timely reports, and valuable technical guidance. This choice will pay off in safer structures, smoother project delivery, and enhanced credibility for your business.

#material testing lab in abu dhabi#material testing lab#material testing#testing lab near me#testing lab uae

0 notes

Text

High-Quality Investment Casting Solutions by Aleader Machinery

Investment Casting stands as one of the most precise and refined processes in the manufacturing world, delivering complex parts with exceptional accuracy and integrity. At Aleader Machinery, we pride ourselves on offering Investment Casting solutions that meet the highest industry standards, made possible by our excellent casting capabilities and commitment to quality. Our company is dedicated to providing customers with high-quality casting products tailored to a wide range of applications, ensuring every requirement is met to the greatest extent.

Understanding Investment Casting and Its Superior Advantages

Investment casting, also known as lost-wax casting, is an intricate manufacturing method that allows the creation of metal parts with fine detail and smooth finishes. It involves creating a wax pattern, coating it with ceramic material, and then melting the wax away to form a mold. Molten metal is poured into this mold to produce parts with unparalleled accuracy. The precision and versatility of investment casting makes it indispensable for industries demanding components with complex geometries.

One of the key reasons customers choose Aleader Machinery’s investment casting services is because of our ability to produce parts that require minimal post-processing, reducing overall manufacturing costs and speeding up delivery times. Our advanced technology and skilled team ensure that every product aligns perfectly with customer specifications.

Our Extensive Casting Capabilities

Aleader Machinery’s casting capabilities are backed by state-of-the-art equipment and a highly trained workforce dedicated to excellence in investment casting. We specialize in a broad spectrum of metals and alloys including stainless steel, carbon steel, aluminum, and special alloys, providing flexibility to our clients to choose the best materials for their applications.

Our casting process supports the production of parts of varying sizes—ranging from small precision components to larger, more robust industrial equipment parts. Thanks to our efficient production workflows, we are able to provide both prototype and mass production runs, offering cost-effective solutions without compromising quality.

Meeting Diverse Application Requirements

Investment casting products from Aleader Machinery find utility across multiple industries. From aerospace to medical devices, automotive to industrial machinery, our casting solutions cater to the unique demands of each sector. The ability to manufacture parts with intricate details, thin walls, and complex shapes make our casting services indispensable for high-performance applications.

Our customers benefit from components that are not only durable but also offer high dimensional accuracy and reproducibility. We work closely with clients to understand their application requirements and customize our processes accordingly to deliver castings that contribute to their product’s success and longevity.

Commitment to Quality and Compliance

At Aleader Machinery, quality is not just a goal but a fundamental principle. Our investment casting operations undergo rigorous quality control inspections throughout every stage of production. We employ precise measurement techniques and non-destructive testing methods to ensure that every casting meets or exceeds industry standards.

Our quality assurance team also ensures compliance with relevant certifications and regulations, providing clients with peace of mind that their casting products hold up under stringent audits and performance criteria. This dedication to quality establishes Aleader Machinery as a trusted partner for superior investment casting solutions.

Technology and Innovation Driving Excellence

In today’s competitive manufacturing market, staying ahead requires continuous innovation. Aleader Machinery invests heavily in modern casting technology and research. Our facilities are equipped with advanced molding systems, computer-controlled casting processes, and automation that improve precision and reduce human error.

We also leverage cutting-edge software for simulation and process optimization, allowing us to predict potential defects and optimize weight distributions before actual production begins. This technological edge ensures that our investment casting products consistently exceed client expectations.

Environmental Responsibility in Casting

Aleader Machinery recognizes the importance of environmental stewardship in manufacturing. Our investment casting processes are designed to minimize waste and energy consumption. We recycle materials where possible, utilize eco-friendly binders, and comply with strict environmental regulations to reduce our carbon footprint.

Choosing Aleader Machinery means partnering with a company committed not only to quality but also to sustainable manufacturing practices.

Customized Solutions for Customer Satisfaction

Every client has unique casting needs, and Aleader Machinery thrives on delivering tailored investment casting solutions. Whether it’s a small batch prototype or a large-scale production order, we adapt our workflows and materials selection to fit the exact demands of your project.

Our dedicated customer service team works alongside production engineers to ensure clear communication and timely updates throughout the casting lifecycle. This collaborative approach ensures client satisfaction and long-term partnership success.

Industry-Leading Turnaround Times and Reliability

Timely delivery is crucial in manufacturing supply chains, and Aleader Machinery excels in providing reliable lead times for all our investment casting projects. By optimizing each step, from pattern production to final finishing, we ensure fast turnaround without compromising quality.

Our flexibility to scale production according to demand means clients can depend on us for both expedited jobs and consistent volume orders.

Highly Skilled Workforce Empowering Precision

The excellence of Aleader Machinery’s investment casting solutions begins with our talented team. Our technicians and engineers are experts in metallurgy, pattern making, and casting operations, trained to bring out the best in every project.

This expertise allows us to overcome complex casting challenges and consistently produce flawless parts meeting customer requirements to the fullest.

Applications of Aleader Machinery’s Investment Castings

Our investment casting components serve critical functions in aerospace engines, medical implants, automotive drivetrain parts, and power generation equipment. The ability to produce components with optimal strength and finish makes us a preferred supplier to demanding sectors.

We also cater to industrial machinery requiring wear-resistant parts, ensuring longevity and superior performance through our casting processes.

Why Choose Aleader Machinery for Your Investment Casting Needs?

Choosing Aleader Machinery means accessing a partner committed to excellence in investment casting. Our combination of advanced technology, skilled workforce, and customer-centric approach ensures best-in-class casting products tailored to your exact needs.

We stand behind the quality and durability of every casting we deliver, backed by rigorous testing and quality control for your peace of mind.

Global Reach with Localized Service

Aleader Machinery serves clients across markets worldwide while maintaining an attentive and localized service model. Our global distribution network ensures reliable shipping and logistics, while our customer service teams provide personalized support.

This balance allows us to respond swiftly to inquiries and resolve challenges effectively, no matter where our clients are located.

Exploring the Future of Investment Casting with Aleader Machinery

The future of manufacturing lies in innovation and adaptability. Aleader Machinery continuously expands its investment casting capabilities by integrating new materials, refining processes, and exploring emerging technologies such as additive manufacturing integration and digital twins.

This forward-thinking approach ensures our customers receive the most advanced casting solutions available today and tomorrow.

Partnering for Success in Complex Manufacturing Environments

Complex manufacturing demands partners who can deliver not only products but also strategic value. Aleader Machinery collaborates closely with customers to optimize casting designs, materials, and processes, creating value beyond simple production.

Our expertise in investment casting enables us to contribute to product innovation, cost savings, and enhanced manufacturing workflows.

A Legacy of Reliability and Trust

With years of experience in investment casting, Aleader Machinery has built a reputation for reliability and integrity. Our customers trust us to handle sensitive projects and deliver superior castings consistently.

This legacy inspires continuous improvement in every aspect of our operations.

Customer Testimonials Reflecting Excellence

Clients consistently praise Aleader Machinery for attention to detail, superior casting quality, and exceptional customer service. Their success stories inspire our team to maintain high standards in investment casting and customer collaboration.

We are proud to play a pivotal role in their manufacturing achievements.

Comprehensive Support from Design to Delivery

Our investment casting services cover the entire production spectrum starting from design consultation, tooling, prototype development, to full-scale manufacturing and delivery. We provide value-added services such as secondary machining and finishing to deliver ready-to-use components.

This comprehensive approach reduces complexity for clients and streamlines supply chain management.

Ensuring Long-Term Client Success

Aleader Machinery is more than just a casting provider; we strive to be a strategic partner for our clients’ long-term growth. Our adaptive manufacturing solutions and commitment to innovation support the evolving needs of our customer base across industries.

With Aleader Machinery, customers gain a partner invested in their success throughout the product lifecycle.

Contact Aleader Machinery for Unmatched Investment Casting Solutions

If you are looking for top-tier investment casting capabilities that combine precision, quality, and customer focus, Aleader Machinery welcomes your inquiry. Our team is ready to discuss your requirements and deliver casting solutions tailored specifically to meet your needs.

Experience the difference of working with a reliable, innovative casting partner committed to excellence in investment casting.

1 note

·

View note

Text

Best Preform Testing Instruments in Uttarakhand

Source of Info: https://www.perfectgroupindia.co.in/blog/best-preform-testing-instruments-in-uttarakhand

Introduction

The quality and strength of PET preforms are verified before their final processing into bottles or containers by using Preform Testing Instruments in Uttarakhand. These tools confirm similar standards of manufacturing by testing factors such as stress distribution, top load strength, wall thickness and transparency. They are commonly used in the packaging, beverage and pharmaceutical industries to help save waste, increase product reliability and reduce errors. Perfect Group India provides a wide variety of these high quality equipment that have been created for satisfying the quality control requirements of manufacturers in Uttarakhand's increasing manufacturing industries.

The Role of Preform Testing Equipments in Modern Manufacturing

Preform Testing Instruments in Uttarakhand are designed to analyze multiple PET preform properties including thickness, transparency, stress distribution and dimensional accuracy. These tools help manufacturers to identify differences early in the production process, reducing waste while avoiding recalls and guaranteeing an excellent final item. In Uttarakhand's competitive economic growth where industries are continually modernizing, access to accurate tools is no longer a luxury but it is a need. Perfect Group India has adjusted to this demand by providing a wide variety of testing solutions customized for modern industry requirements.

Why Uttarakhand Needs Advanced Preform Testing Solutions

Uttarakhand has evolved as a manufacturing powerhouse because of its advantageous rules and industrial zones, including Pantnagar, Haridwar and Dehradun. As the region continues to attract more investment in the plastics and packaging industries the need for Preform Testing Instruments in Uttarakhand has increased greatly. Perfect Group India understands this need and dedicates itself to providing high performance equipment suitable for the needs of the region's small, medium and large scale companies. By delivering locally available and globally competitive testing equipment we support Uttarakhand businesses in maintaining their quality control advantage.

What Makes Perfect Group India the Preferred Choice?

When it comes to Preform Testing Instruments in Uttarakhand not all manufacturers are similar. Perfect Group India provides a wide variety of machinery which includes:

Top load testers: To measure the vertical load bearing capacity of preforms and bottles.

Preform thickness gauges: For accurate and non destructive measurement of wall thickness.

Polarization testers: To analyze stress distribution.

Torque testers: To ensure cap and neck compatibility.

Perfect Group India manufactures each instrument with accuracy by using modern technology and provides great service after the sale. Our own research and development and quality assurance teams make sure every product meets the highest levels of dependability and performance.

Local Support and Global Standards

One of the main benefits of working together with Perfect Group India is our local presence in Uttarakhand. We understand the unique issues that manufacturers face in this area which range from transportation logistics to environmental conditions and customize our solutions to meet their needs. When you choose Preform Testing Instruments in Uttarakhand from us you are not just investing in a machine but you are also gaining an adviser who is dedicated to your success. We provide on site installation, training and testing services to ensure a smooth and efficient recruitment experience.

Industry Applications of Our Instruments

Our instruments serve a wide range of industries, including:

Beverage and Bottled Water

Pharmaceutical Packaging

Personal Care and Cosmetics

Household Chemicals

Whatever your industry, Perfect Group India offers customized options that match with your production goals. Companies that use our Preform Testing Instruments in Uttarakhand can reduce downtime, increase productivity and get better quality assurance results.

Stay Ahead with Technological Innovation

In the current economic climate staying ahead requires more than just low prices. It requires technical innovation. That is why Perfect Group India is always updating its product line to include smart features such as digital readouts, software inclusion and data recording. Our Uttarakhand clients benefit from simple equipment that are not only quick to operate but also compatible with modern data management systems. This simplifies and improves fulfilling legal requirements and tests.

Environmental and Economic Impact

Using correct Preform Testing Instruments in Uttarakhand supports durability. Early defect detection allows businesses to reduce raw material waste, energy use and carbon impact. At Perfect Group India we believe in delivering solutions that help achieve both economic and environmental goals. We also provide guidance on best practices for maximizing equipment use and maintaining long term operations. Whether you are opening a new facility or upgrading your current line we can help you with choosing and executing the process.

Conclusion

Investing in the correct equipment is not an option for any manufacturer who values quality but it is a requirement. Preform Testing Instruments in Uttarakhand provide unparalleled dependability, performance and support. With an in-depth understanding of local industry demands and a dedication to innovation we are happy to be a trustworthy partner in the region's industrial development. If you want to update your quality control systems or develop new manufacturing standards contact Perfect Group India now. Allow us to help you in establishing the standard for manufacturing excellence.

0 notes

Text

Advanced Non Destructive Testing Services in India

Inspection & Testing Engineers (ITE) offers comprehensive Advanced Non-Destructive Testing (NDT) services in India, ensuring the highest standards of safety and quality. Utilizing cutting-edge technologies, ITE provides a range of NDT methods including ultrasonic testing, radiographic testing, magnetic particle testing, and eddy current testing. These techniques are essential for detecting flaws and irregularities in materials and structures without causing any damage, thereby ensuring reliability and longevity. ITE's skilled professionals are trained to handle intricate inspections in various industries such as aerospace, automotive, oil and gas, and construction. By leveraging advanced NDT methods, ITE helps clients maintain compliance with stringent regulatory standards, improve operational efficiency, and reduce downtime. With a commitment to excellence and innovation, ITE stands as a trusted partner for all non-destructive testing needs in India.

For more Information:-

Call:- +91-9891174696, +91-9810059715

Email:- [email protected], [email protected]

Address:- F 22-23, Site C, Surajpur Industrial Area UPSIDC, Surajpur, Greater Noida, 201306

0 notes

Text

Best Preform Testing Instruments in Uttarakhand

Source of Info: https://www.perfectgroupindia.co.in/blog/best-preform-testing-instruments-in-uttarakhand

Introduction The quality and strength of PET preforms are verified before their final processing into bottles or containers by using Preform Testing Instruments in Uttarakhand. These tools confirm similar standards of manufacturing by testing factors such as stress distribution, top load strength, wall thickness and transparency. They are commonly used in the packaging, beverage and pharmaceutical industries to help save waste, increase product reliability and reduce errors. Perfect Group India provides a wide variety of these high quality equipment that have been created for satisfying the quality control requirements of manufacturers in Uttarakhand's increasing manufacturing industries.

The Role of Preform Testing Equipments in Modern Manufacturing Preform Testing Instruments in Uttarakhand are designed to analyze multiple PET preform properties including thickness, transparency, stress distribution and dimensional accuracy. These tools help manufacturers to identify differences early in the production process, reducing waste while avoiding recalls and guaranteeing an excellent final item. In Uttarakhand's competitive economic growth where industries are continually modernizing, access to accurate tools is no longer a luxury but it is a need. Perfect Group India has adjusted to this demand by providing a wide variety of testing solutions customized for modern industry requirements.

Why Uttarakhand Needs Advanced Preform Testing Solutions Uttarakhand has evolved as a manufacturing powerhouse because of its advantageous rules and industrial zones, including Pantnagar, Haridwar and Dehradun. As the region continues to attract more investment in the plastics and packaging industries the need for Preform Testing Instruments in Uttarakhand has increased greatly. Perfect Group India understands this need and dedicates itself to providing high performance equipment suitable for the needs of the region's small, medium and large scale companies. By delivering locally available and globally competitive testing equipment we support Uttarakhand businesses in maintaining their quality control advantage.

What Makes Perfect Group India the Preferred Choice? When it comes to Preform Testing Instruments in Uttarakhand not all manufacturers are similar. Perfect Group India provides a wide variety of machinery which includes:

Top load testers: To measure the vertical load bearing capacity of preforms and bottles.

Preform thickness gauges: For accurate and non destructive measurement of wall thickness.

Polarization testers: To analyze stress distribution.

Torque testers: To ensure cap and neck compatibility.

Perfect Group India manufactures each instrument with accuracy by using modern technology and provides great service after the sale. Our own research and development and quality assurance teams make sure every product meets the highest levels of dependability and performance.

Local Support and Global Standards One of the main benefits of working together with Perfect Group India is our local presence in Uttarakhand. We understand the unique issues that manufacturers face in this area which range from transportation logistics to environmental conditions and customize our solutions to meet their needs. When you choose Preform Testing Instruments in Uttarakhand from us you are not just investing in a machine but you are also gaining an adviser who is dedicated to your success. We provide on site installation, training and testing services to ensure a smooth and efficient recruitment experience.

Industry Applications of Our Instruments Our instruments serve a wide range of industries, including:

Beverage and Bottled Water

Pharmaceutical Packaging

Personal Care and Cosmetics

Household Chemicals

Whatever your industry, Perfect Group India offers customized options that match with your production goals. Companies that use our Preform Testing Instruments in Uttarakhand can reduce downtime, increase productivity and get better quality assurance results.

Stay Ahead with Technological Innovation In the current economic climate staying ahead requires more than just low prices. It requires technical innovation. That is why Perfect Group India is always updating its product line to include smart features such as digital readouts, software inclusion and data recording. Our Uttarakhand clients benefit from simple equipment that are not only quick to operate but also compatible with modern data management systems. This simplifies and improves fulfilling legal requirements and tests.

Environmental and Economic Impact Using correct Preform Testing Instruments in Uttarakhand supports durability. Early defect detection allows businesses to reduce raw material waste, energy use and carbon impact. At Perfect Group India we believe in delivering solutions that help achieve both economic and environmental goals. We also provide guidance on best practices for maximizing equipment use and maintaining long term operations. Whether you are opening a new facility or upgrading your current line we can help you with choosing and executing the process.

Conclusion Investing in the correct equipment is not an option for any manufacturer who values quality but it is a requirement. Preform Testing Instruments in Uttarakhand provide unparalleled dependability, performance and support. With an in-depth understanding of local industry demands and a dedication to innovation we are happy to be a trustworthy partner in the region's industrial development. If you want to update your quality control systems or develop new manufacturing standards contact Perfect Group India now. Allow us to help you in establishing the standard for manufacturing excellence.

#industrial#equipments#perfectgroupindia#perfectinstruments#technology#droptester#business#boxcampressiontester#toploadertester#prefectgroupindia

0 notes

Text

Plate Load Testing chennai - Falcon Industrial Testing Laboratory

When it comes to construction materials testing in Chennai, the plate load testing chennai is a crucial geotechnical investigation method used to determine the bearing capacity of soil. At FITPL, we provide reliable plate load testing services in Chennai to ensure the stability and safety of your construction projects.

What is a Plate Load Test?

Before building pavements, foundations, or other structures, the plate load test is a field test used to determine the soil's ability to support loads.This test helps engineers understand how much load the soil can withstand without excessive settlement.

Why is Plate Load Testing Important?

Ensures safe foundation design

Prevents uneven settlement of structures

Helps in optimizing construction costs

Complies with geotechnical investigation standards

Plate Load Test Procedure

Site Preparation – The test area is cleared and leveled.

Plate Placement – A steel plate (usually 300mm to 750mm in diameter) is placed on the ground.

Load Application – Incremental loads are applied using a hydraulic jack, and settlement is measured.

Data Recording – Load vs. settlement data is recorded until the soil reaches its failure point.

Analysis: Settlement parameters and bearing capacity are ascertained.

Applications of Plate Load Testing in Chennai

Plate load testing is widely used in:

Building construction – To assess foundation stability

Road and pavement construction – To check subgrade strength

Industrial projects – For heavy machinery foundations

Bridge construction – To ensure safe load distribution

Other Testing Services in Chennai

At FITPL, we offer a wide range of construction materials testing and geotechnical investigation services, including:

1. Soil Testing in Chennai

Standard Penetration Test (SPT) in Chennai – Measures soil density and strength

Earth Resistivity Test in Chennai – Assesses soil’s electrical resistance for earthing systems

2. Building Materials Testing in Chennai

Steel Testing in Chennai – Ensures quality and strength of reinforcement bars

Non-Destructive Testing (NDT) in Chennai – Evaluates concrete strength without damage

3. Environmental Testing in Chennai

Water Testing in Chennai – Checks purity and contamination levels

Air Testing in Chennai – Monitors indoor and outdoor air quality

Pollution Testing in Chennai – Assesses environmental impact

Wastewater Testing in Chennai – Ensures compliance with disposal standards

4. Food Quality Testing in Chennai

Ensures food safety and regulatory compliance

Why Choose FITPL for Plate Load Testing in Chennai?

Experienced geotechnical engineers

Advanced testing equipment

Accurate and reliable results

Fast turnaround time

Compliance with IS standards

The plate load test is an essential part of geotechnical investigation in Chennai, ensuring the safety and durability of construction projects. In order to satisfy industry standards, FITPL offers thorough soil, building material, and environmental testing services.

For plate load testing and other construction material testing services in Chennai, contact FITPL today!

Ensure your project’s stability with professional plate load testing in Chennai!

Contact us

Phone number : +918056159517

Website: https://fitpl.in/load-test-pile-integrity-testing-in-chennai.php

0 notes

Text

Europe Flooring Market Global Trends, Statistics, Size, Share, Regional Analysis by Key Players (2022-2028)

The Europe flooring market is expected to grow from US$ 75.48 million in 2022 to US$ 108.52 million by 2028; it is estimated to grow at a CAGR of 6.2% from 2022 to 2028.

Europe Flooring Market Introduction

Expect significant expansion in the European flooring market, driven by two key factors: the growing popularity of loose lay flooring and the integration of aqua+ technology in laminate options. Top manufacturers like Aqua Flooring, Kronotex, Senhong, and Egger are supplying laminate flooring, adhesives, and plasticizers that feature advanced waterproofing. This makes their products an excellent choice for environments susceptible to moisture, including kitchens, bathrooms, hallways, and commercial properties. These firms have also developed a patented waterproof acoustic flooring adhesive that sets a new industry benchmark for moisture resistance. Moreover, the market will be buoyed by the increasing adoption of flooring solutions with interlocking mechanisms for easy installation and self-adhesive applications, offering convenient do-it-yourself solutions. These innovations are poised to attract new customers and enable vendors to extend their reach into burgeoning markets, thereby strongly fueling the Europe flooring market's growth throughout the forecast period.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/BMIRE00025823

Europe Flooring Strategic Insights

Strategic insights for the Europe Flooring market offer a comprehensive, data-driven analysis of the industry landscape. This includes a close examination of current trends, key players, and important regional specificities. These insights provide practical recommendations, enabling readers to distinguish themselves from competitors by identifying unexplored market segments or crafting unique value propositions. Through data analytics, these insights assist industry participants—be they investors, manufacturers, or other stakeholders—in anticipating future market shifts. A forward-looking perspective is crucial, helping stakeholders foresee market changes and prepare for sustained success in this evolving region. Ultimately, sound strategic insights empower readers to make well-informed decisions that lead to profitability and help them achieve their business goals within the market.

Europe Flooring Regional Insights

The geographic scope of the Europe Flooring market outlines the specific areas where a company conducts its operations and competes. Grasping local distinctions—like varied consumer preferences (e.g., demand for certain plug types or battery backup durations), diverse economic landscapes, and differing regulatory frameworks—is crucial for adapting strategies to individual markets. Businesses can expand their reach by identifying regions with unmet needs or by customizing their product offerings to cater to local demands. A focused market approach allows for more efficient resource allocation, targeted marketing efforts, and better positioning against local competitors, ultimately fostering growth in those specific areas.

Europe Flooring Market Segmentation

Europe Flooring Market

By Product Type

Polymer Matrix

Ceramic Matrix

Metal Matrix

Europe Flooring Market

By Testing Method

Destructive

Non-Destructive

Europe Flooring Market

By Application

Aerospace and Defense

Transportation

Wind Energy

Building and Construction

Electrical and Electronics

Europe Flooring Market

Regions and Countries Covered

Europe

UK

Germany

France

Russia

Italy

Rest of Europe

Europe Flooring Market

Market leaders and key company profiles

Mohawk Flooring

Shaw Industries Group, Inc.

Tarkett

Forbo International SA

Gerflor

Interface, Inc.

Beaulieu International Group

Toil Corporation

Milliken

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

0 notes

Text

Beyond Basics: Exploring the Future of Advanced NDT Services

Advanced NDT services are transforming industrial inspection with smarter, faster, and more accurate techniques. From phased array ultrasonic testing to cutting-edge NDT inspection, these non-destructive testing services ensure asset reliability without compromising safety. As industries demand higher precision, NDT technologies evolve to deliver deeper insights and data-driven decisions. Embrace the future with advanced NDT services designed for complex challenges and critical operations.

0 notes