#ultrasonic testing equipment

Text

Phased Array Ultrasonic Testing services in India

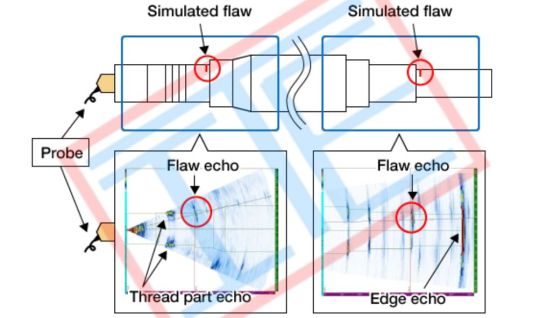

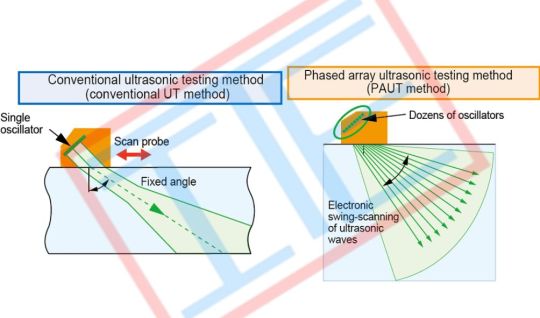

Phased Array Ultrasonic Testing (PAUT) services in India have gained significant popularity in recent years. PAUT is a non-destructive testing technique that uses ultrasonic waves to inspect materials for defects or flaws. It offers several advantages over traditional methods, making it a preferred choice for material testing in various industries.

PAUT inspection involves the use of an array of ultrasonic transducers that can be electronically controlled to emit and receive ultrasonic waves at different angles. This allows for the creation of a detailed and accurate image of the material being tested. The ability to control the angle and focus of the ultrasonic waves makes PAUT testing highly versatile and effective in detecting both surface and subsurface defects.

One of the major benefits of PAUT testing is its speed and efficiency. With traditional ultrasonic testing methods, multiple scans are required to cover the entire area being inspected. However, with PAUT, multiple beams can be emitted simultaneously, covering a larger area in a single scan. This not only reduces the inspection time but also increases productivity and cost-effectiveness.

Another advantage of PAUT inspection is its ability to provide real-time imaging. The data collected from the ultrasonic waves can be displayed as a visual image, allowing for immediate analysis and interpretation. This real-time imaging feature enables faster decision-making and reduces the need for additional testing or re-inspection.

PAUT testing is widely used in various industries such as aerospace, oil and gas, power generation, manufacturing, and infrastructure. In the aerospace industry, PAUT is used for inspecting critical components such as aircraft wings, turbine blades, and engine parts. In the oil and gas industry, it is used for inspecting pipelines, storage tanks, and pressure vessels. In power generation, PAUT is used for inspecting boilers, turbines, and heat exchangers.

India has witnessed a significant growth in the demand for PAUT services due to its numerous advantages and applications. Several testing service providers in India offer PAUT inspection services to cater to the growing needs of industries. These service providers use advanced PAUT equipment and employ trained technicians who are proficient in operating and interpreting the results from PAUT systems.

When selecting a PAUT testing service provider in India, it is important to consider factors such as experience, expertise, and certifications. The service provider should have a proven track record in performing PAUT inspections and should be equipped with state-of-the-art equipment. Additionally, they should have a team of qualified technicians who are trained in conducting PAUT inspections and interpreting the results accurately.

In conclusion, PAUT inspection services in India have gained immense popularity due to their speed, efficiency, and accuracy. The ability to detect both surface and subsurface defects makes PAUT an ideal choice for material testing in various industries. With the growing demand for reliable non-destructive testing methods, PAUT is expected to continue being widely used in India's industrial sectors.

If you are looking for testing service in Delhi/NCR, India worldwide. Look no further now, contact us : +91-9810059715, +91-9953489999 . Our Address is F 22-23, Site C, Surajpur Industrial Area, UPSIDC, Greater Noida, 201306.

#paut inspection#paut testing#non destructive testing#ultrasonic testing equipment#material testing#stainless steel welding#steel welding

0 notes

Text

NDT equipment in UAE

Non-Destructive Testing (NDT) equipment is essential in various industries, including oil and gas, aerospace, manufacturing, and construction, to ensure the integrity and reliability of materials and structures without causing any damage. Here’s a comprehensive overview of NDT equipment available in the UAE

https://incorworld.com/products/

0 notes

Text

#non destructive testing#Magnetic Particle Inspection Services#non destructive testing solutions#non destructive testing equipment manufacturers#penetrant inspection near me#non destructive hardness testing#non destructive testing companies near me#non destructive thickness measurement#magnetic particle inspection near me#ndt labs near me#hardness test non destructive#ultrasonic testing gauge#ultrasonic metal thickness tester#ultrasonic gauge thickness tester#material thickness tester#metal thickness testing#ultrasonic level detection#non destructive testing systems#ndt radiography#non destructive testing radiography

0 notes

Text

Ultrasonic NDT Testing Equipment Market Is Estimated To Witness High Growth Owing To Increasing Demand in Aerospace and Automotive Industry

The global Ultrasonic NDT Testing Equipment Market is estimated to be valued at US$ 764.8 Mn in 2022 and is expected to exhibit a CAGR of 7.0% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Ultrasonic non-destructive testing (NDT) is a technique used to evaluate and inspect the integrity and quality of materials or structures using high-frequency sound waves. This method is widely used in various industries such as aerospace, automotive, oil and gas, and power generation, among others. Ultrasonic NDT testing equipment helps in detecting defects, cracks, thickness measurement, and weld inspection, among other applications.

B) Market Dynamics:

The driving factors fueling the growth of the global ultrasonic NDT testing equipment market are the increasing adoption of NDT techniques in the aerospace and automotive industries. With the growing demand for lightweight and fuel-efficient aircraft and automobiles, there is a need for reliable and accurate testing methodologies to ensure the safety and performance of these vehicles. Ultrasonic NDT testing equipment plays a crucial role in fulfilling this requirement by providing accurate and non-destructive inspection results.

Furthermore, rising investments in infrastructure development projects, such as bridges, tunnels, and dams, are also expected to drive the demand for ultrasonic NDT testing equipment. These projects require regular inspection and maintenance to ensure their structural integrity, thus creating a significant demand for NDT testing equipment.

C) Segment Analysis:

The ultrasonic NDT testing equipment market is segmented based on product type, application, and end-use industry. On the basis of product type, the market is categorized into flaw detectors, thickness gauges, imaging systems, and others. Among these, the flaw detectors segment is expected to dominate the market during the forecast period, owing to their wide application in various industries such as aerospace, automotive, and oil and gas.

D) PEST Analysis:

Political: The political environment plays a crucial role in influencing the growth of the ultrasonic NDT testing equipment market. Government regulations and policies regarding worker safety, quality control, and infrastructure development can impact the adoption of NDT techniques.

Economic: The economic stability and growth of a country also affect the demand for ultrasonic NDT testing equipment. Economic growth leads to increased investment in infrastructure and manufacturing sectors, driving the demand for NDT testing equipment.

Social: The growing concerns for safety and quality in industries have led to an increased adoption of NDT techniques, including ultrasonic testing. Additionally, the rising awareness about the advantages of non-destructive testing is expected to drive the market growth.

Technological: Technological advancements, such as the integration of AI and IoT in NDT equipment, are expected to revolutionize the ultrasonic NDT testing equipment market. These advancements will improve the accuracy, efficiency, and ease of operation of these devices.

E) Key Takeaways:

- The global ultrasonic NDT testing equipment market is expected to witness high growth, exhibiting a CAGR of 7.0% over the forecast period, due to increasing demand in the aerospace and automotive industries.

- The Asia Pacific region is expected to be the fastest-growing and dominating region in the global ultrasonic NDT testing equipment market. The region's rapid industrialization, infrastructure development, and adoption of advanced technologies are driving the market growth.

- Key players operating in the global ultrasonic NDT testing equipment market include ROSEN Group, Johnson and Allen Ltd., Advanced NDT Ltd., Olympus Corporation, Intertek Group PLC, Baker Hughes, GE Measurement and Control, and Russell Fraser Sales Pty Ltd., among others.

#Ultrasonic NDT Testing Equipment Market#Ultrasonic NDT Testing Equipment Market Analysis#Ultrasonic NDT Testing Equipment Market Overview#Industrial Automation and Machinery#Coherent Market Insights

0 notes

Text

Athletes Go for the Gold with NASA Spinoffs

NASA technology tends to find its way into the sporting world more often than you’d expect. Fitness is important to the space program because astronauts must undergo the extreme g-forces of getting into space and endure the long-term effects of weightlessness on the human body. The agency’s engineering expertise also means that items like shoes and swimsuits can be improved with NASA know-how.

As the 2024 Olympics are in full swing in Paris, here are some of the many NASA-derived technologies that have helped competitive athletes train for the games and made sure they’re properly equipped to win.

The LZR Racer reduces skin friction drag by covering more skin than traditional swimsuits. Multiple pieces of the water-resistant and extremely lightweight LZR Pulse fabric connect at ultrasonically welded seams and incorporate extremely low-profile zippers to keep viscous drag to a minimum.

Swimsuits That Don’t Drag

When the swimsuit manufacturer Speedo wanted its LZR Racer suit to have as little drag as possible, the company turned to the experts at Langley Research Center to test its materials and design. The end result was that the new suit reduced drag by 24 percent compared to the prior generation of Speedo racing suit and broke 13 world records in 2008. While the original LZR Racer is no longer used in competition due to the advantage it gave wearers, its legacy lives on in derivatives still produced to this day.

Trilion Quality Systems worked with NASA’s Glenn Research Center to adapt existing stereo photogrammetry software to work with high-speed cameras. Now the company sells the package widely, and it is used to analyze stress and strain in everything from knee implants to running shoes and more.

High-Speed Cameras for High-Speed Shoes

After space shuttle Columbia, investigators needed to see how materials reacted during recreation tests with high-speed cameras, which involved working with industry to create a system that could analyze footage filmed at 30,000 frames per second. Engineers at Adidas used this system to analyze the behavior of Olympic marathoners' feet as they hit the ground and adjusted the design of the company’s high-performance footwear based on these observations.

Martial artist Barry French holds an Impax Body Shield while former European middle-weight kickboxing champion Daryl Tyler delivers an explosive jump side kick; the force of the impact is registered precisely and shown on the display panel of the electronic box French is wearing on his belt.

One-Thousandth-of-an-Inch Punch

In the 1980s, Olympic martial artists needed a way to measure the impact of their strikes to improve training for competition. Impulse Technology reached out to Glenn Research Center to create the Impax sensor, an ultra-thin film sensor which creates a small amount of voltage when struck. The more force applied, the more voltage it generates, enabling a computerized display to show how powerful a punch or kick was.

Astronaut Sunita Williams poses while using the Interim Resistive Exercise Device on the ISS. The cylinders at the base of each side house the SpiraFlex FlexPacks that inventor Paul Francis honed under NASA contracts. They would go on to power the Bowflex Revolution and other commercial exercise equipment.

Weight Training Without the Weight

Astronauts spending long periods of time in space needed a way to maintain muscle mass without the effect of gravity, but lifting free weights doesn’t work when you’re practically weightless. An exercise machine that uses elastic resistance to provide the same benefits as weightlifting went to the space station in the year 2000. That resistance technology was commercialized into the Bowflex Revolution home exercise equipment shortly afterwards.

Want to learn more about technologies made for space and used on Earth? Check out NASA Spinoff to find products and services that wouldn’t exist without space exploration.

Make sure to follow us on Tumblr for your regular dose of space!

2K notes

·

View notes

Text

Introduction to Ultrasonic Thickness Gauges

You are here:

Home

Informative

Introduction to Ultrasonic Thickness Gauges

May42022

Like an ultrasonic flaw detector, an ultrasonic Thickness Gauge is also non-destructive testing equipment used to measure a component’s thickness. This testing device can assess the thickness of a workpiece by calculating the time sound waves take to move from the transducer through the material and its reflection time back to the transducer. Then the gauge estimates the thickness of the material on the basis of sound waves’ velocity. This equipment can monitor corrosion, evaluate wall thickness, and mould thickness testing.

Quality control professionals use ultrasonic flaw detectors to detect flaws in industrial structures and ultrasonic thickness gauges to assess the thickness of different products utilised in multiple industries for decades. Over the years, the world has witnessed tremendous growth in hardware development and so the ultrasonic thickness gauge has become a potent yet user-friendly tool. Wondering how it works? We have explained it in the simplest way possible.

What Are The Usages of Ultrasonic Thickness Gauge?

However, ultrasonic thickness gauges are commonly used to measure a material’s thickness when a quality inspection professional can’t access both sides of the component. Apart from that, it has multiple significant usages to determine the wellness or integrity of workpieces that are likely to have erosion or corrosion such as ship hulls, boilers, pipelines, tankers, and pressure vessels. Be it TM210 Plus or Edison 10, every advanced ultrasonic thickness measuring device has different usages. Some of the common usages of ultrasonic thickness gauges are mentioned below.

1. To Measure The Thickness Of Tube Wall Or Metal Pipe

The ultrasonic thickness gauge is extensively used to examine the wall thickness of a pipe or tube, and it helps determine inevitable circumstances in an industrial unit. A non-destructive thickness assessment through a gauge isn’t limited to the accessible ends of pipes or tubes. It can measure the concentration of pipes or tubes automatically without shutting down the process or cutting the pipes. The ultrasonic thickness gauge measures thickness over the whole length of tubes or pipes when the process is on the go.

2. To Inspect The Wellness Of A Ship Hull

This is one of the most critical uses of the ultrasonic thickness gauge. As it is difficult to inspect the wholeness of a ship’s hull through eyes because a protective coating is applied on the hull’s outer surface to extend its life. The protective layer makes it difficult to evaluate the wellness of the ship hull. But, the thickness gauge assesses the metal thickness and detects the corrosion spot instantly without removing the protective coating. The tool figures the metal density by measuring the delay in the echo.

The ultrasound thickness gauge transmits multiple echoes to get a precise image. It measures and determines the thickness of the protective coating by the first echo. The device automatically logs the determinations, overlooking the material delay of the protective coating for the next two echoes. The hull inspectors use these figures to determine the ship’s wellness allowing them to make an informed decision related to the ship’s maintenance.

3. To Examine Weathering Steel Structures

Weathering steels encounter continuous decay due to extended corrosion. Therefore, industrial units use thicker steel and closely monitor corrosion. The ultrasonic thickness gauge measures the leftover steel through the rust layer. In this testing technique, transducers are not required to travel the sound waves through the steel. The device not only measures the thickness of the remaining steel but the thickness of the rust layer as well.

Different Materials That Can Be Measured With An Ultrasonic Thickness Gauge?

However, other techniques and methods have limitations as they can be used to measure the thickness of certain materials, an ultrasonic thickness gauge has varied applications for different materials for numerous purposes. Some of them are mentioned below:

1. Erosion

The ultrasonic thickness measuring device assesses the thickness of a coated material that is applied to a component due to erosion. Different parts of industrial structures, nuclear reactors, jet engines, water turbines, and boilers are prone to erosion.

2. Corrosion

When metals are exposed to natural factors such as atmospheric moisture, they frequently corrode. An ultrasonic thickness gauge, on the other hand, is a precise non-destructive inspection instrument that can determine the level of corrosion in concealed interior metal parts through a single checkpoint.

3. Metals

Ultrasonic thickness gauges are frequently used to gauge duplicate, machined, wadded, cast, or extruded metal components with thicknesses ranging from 0.2mm to 500mm, depending on grain formation.

4. Ceramic

The ultrasonic thickness gauge is used to inspect the integrity of all structural and electronic ceramics including ceramic pipes and valves, coatings, containers, and turbine blades. Apart from that, the tool is used to calculate the absolute value of elasticity through sound velocity measurement.

5. Other Materials

Because of their ability to measure general metals and plastics, ultrasonic gauges are utilized to measure an extensive range of different materials such as elastic polymers, porcelain, crystal soft contact lenses, wax patterns, and biological specimens including soft tissues.

Type Of Ultrasonic Thickness Gauges

The ultrasonic thickness gauges come in different types on the basis of their usages and transducers. Though, the most extensively used gauges are –

1. Corrosion Gauges

These are application-based gauges that are used to measure the corrosion in metals through the travel time gap of sound waves between the two sides of the material’s wall. Also, they are widely used to determine the time between two consecutive sound waves.

2. Precision Gauges

Apart from metals, precision ultrasonic thickness gauges are frequently used for materials such as plastics, porcelain, ceramics, crystals, and other materials utilized in industrial units. The term comes from the fact that these gauges can accurately and precisely measure a broad range of wall thicknesses ranging from 0.2mm to 500mm.

Conclusion

Ultrasonic thickness gauge manufacturers offer different ultrasonic testing equipment including ultrasonic flaw detectors, ultrasonic thickness gauges, probes, Edison 10, and calibration blocks. If you need these devices for industrial uses, Modsonic can be your trustworthy partner. It is one of India’s leading and trusted ultrasonic thickness gauge manufacturers which is known for its range of ultrasonic testing equipment.

Read to learn more about Ultrasonic Thickness Gauges. Modsonic also offers ultrasonic equipment.

https://www.modsonic.com/introduction-to-ultrasonic-thickness-gauges/

#ultrasonic testing#ultrasonic thickness gauges#ultrasound#ultrasonic flaw detectors#ultrasonic flaw detector#ultrasonic#ultrasonic testing device#ultrasonic transducers#ultrascans#ultrasonic equipment

0 notes

Text

Sure, the newspaper calls them “eco-terrorists,” but that’s a bit of a self-interested position coming from something that is printed on trees. If anything, they should be thanking the weird gang of environmentalist guerrillas who come down every spring thaw from the mountains. They don’t really do violence, either, except against industrial equipment (that I later harvest the turbos from at the junkyard.) In fact, most of what they do is plant trees. Lots, and lots, and lots of trees.

You might not think that planting trees is very intimidating, and you’d be right. As the members explained to me one night at the bar, it’s all about where you plant them. A tree is impressive up top, sure, but if you pick the right breed of them, you’ll find that the roots are made of some truly boffo shit. Thick enough roots will split open the foundation and basement of, say, the offices of an oil and gas disinformation trust, and lead them to spend a bunch of their money on sump pumps and concrete pours instead of giving air cover to billionaires.

Normally, it takes decades, even centuries, for a tree to get big enough to cause this kind of damage. Turns out that up in those mountains, they’ve got themselves some kind of fucked-up bioengineering lab, making angrier, fiercer varieties of local trees. Ones that have a voracious appetite to spread and spread and spread, and which will eventually, if left unchecked, destroy all of human civilization. So naturally I was interested in making friends with them, in case they had any leftover vibratory tumblers, or ultrasonic cleaners, or two-stroke lawn equipment at this lab.

Unfortunately, the classic downfall of activism has struck me. Despite the fact that all of my vehicles are made up of recycled garbage, they produce enough smog, backfires, tire particles, and unburned gasoline clouds to qualify as a miniature Exxon Valdez. Once again, an unnecessarily rigorous purity test has denied this activist group a valuable ally. For instance, I could break down in front of the newspaper offices again, blocking their delivery trucks, which are diesels. And then I could steal the turbochargers out of those trucks.

621 notes

·

View notes

Text

right, so, i have until jan 2 to empty out my lab and put everything back differently. but now that i’m home, i’m really feeling like laying in bed for the next few days. what will i do

here’s the lab currently ish:

here’s the new plan:

clockwise from bottom: drill press/bench grinder/ultrasonic/router/etc., 3d printer, work computer setup, microscope and soldering station, personal computer setup, ee test equipment & assembly (in front of the window)

i’ve realized that i need the computer (personal) to be closer to the test equipment for logic analyzers and stuff, and if it’s closer to the soldering setup, i can use the microscope camera more easily too. many benefits to doing the reorg, but the drawback is getting out of bed and probably cleaning other parts of the apartment to have space for shuffling things around.

#poll#polls#lab#soldering#girlrotting#i wonder if i’ll need a more powerful fan for the fume extractor#any girlies in the seattle area wanna come help

6 notes

·

View notes

Text

Are you looking for a reliable Tool and Die Steel Supplier in Bangalore, Karnataka?

Consider connecting with Virat Special Steels Pvt. Limited. Here’s why they stand out!

About Bangalore:

Bangalore or Bangaluru, the bustling capital city of Karnataka, is not only a hub for IT and biotechnology but also a thriving center for industrial development. The city's history of industrial growth dates back to its early days when it was under the rule of various dynasties and colonial powers. Today, Bangalore stands as a testament to India's rapid urbanization and industrialization.

For businesses looking to source high-quality tool and die steel in Bangalore, Virat Special Steels Pvt. Limited represents a blend of tradition and modernity, offering products that are at the forefront of industrial excellence. Their presence in the city adds to Bangalore's reputation as a destination for industrial prowess and technological innovation.

Virat Special Steels Pvt. Limited:

Offerings: Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel.

Services: They provide value-added services such as material machining, cut pieces, and tailor-made solutions.

Quality Assurance: Virat Special Steels has a fully equipped quality assurance facility, including chemical tests, spectrometry, ultrasonic examinations, and hardness testing.

Available Grades:

Die Steel (HH 370 – 410 BHN): Grades like DB6, DIN-1.2714, and AISI L6.

Hot Work Steels: Encompasses DIN 2343, 2344, AISI H11, and H13.

Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

Cold Work Steels (HCHCr): Comprising DIN 2379, 2080, AISI D2, and D3.

Alloy Steels, EN-Series, and More.

Make In INDIA: They also offer competitive prices, great quality, and prompt service, positioning themselves as a reliable “Make In INDIA” choice.

Consultation:

For further assistance, consult their #Gurugram office. Learn more

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-bangalore/

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#steel#iso9001#bangalore#karnataka#db6 steel#h13diesteel#h13steel#h11steel#p20steels#din 2714#din2344

2 notes

·

View notes

Text

Denning DRV-1 by Denning Mobile Robotics (1982), Woburn, MA. The Denning Research Vehicle is a drum shaped robot with three-wheel synchro steering and a sturdy chassis capable of carrying heavy payloads. It looks like the Denning ‘Sentry’ but without the rotating turret. The top photo shows Georgia Tech’s DRV-1, known as ‘George’, flanked by Ren (right) & Stimpy (left), the lab's MRV-2s. “The Laboratory for Mobile Robotics provides the facilities for the development and testing of new concepts and models in autonomous mobile robots. … The Laboratory’s mobile robot, George, is a Denning research vehicle equipped with 24 ultrasonic sensors, shaft encoders, and a single CCD camera for computer vision.” – Ronald Arkin and Robin Murphy, Autonomous Navigation in a Manufacturing Environment (1990).

25 notes

·

View notes

Text

Different? Better?

The adventure with the 1990s high end tube amp goes on.

There is good, and there is bad. Clearing away the bad issue is it will cost money to keep this beastie running. The good is it has the seductive sound of the vacuum to tempt and to tease me. Such a tease.

Last night I played 4 albums. The result was interesting.

The first one was my original copy of "I Robot" Alan Parson's Project. It sounded really good. AP was a recording engineer of great talent and is responsible for Dark Side of the Moon among many others. If you are familiar with that you can appreciate that the mixes are complex and deep and leave much to be untangled. If you are a detail geek as I am it is required listening. Lots of fun.

Next up was a "special" I found in my densely packed hoard of LPs. It is on the Wilson Audiophile label titled Center Stage.

It has an amazing back story and provenance. It was commissioned by Absolute Sound Magazine and the recording engineers, and mastering gurus are a who's who of the high end. Everything custom and tweaked. They even note the tape preservative used. Yes tape and pure analog full on. Should be great right?

I know TAS used it to evaluate equipment and crown the winners of that month's SOTA awards.

I may have mentioned that you can have great music recorded well or poorly. You can have great recordings of good or poor music. Bad recordings of bad music stay in the bin where they belong. Some things are doomed to be test records and this is one of those.

In the full golden ear style of reviewing I will note my equipment. The Phase Linear 8000 series 2 tangential tracking TT with an AT7V cartridge front end. Preamp is the ARC SP-14 with 50 pf load on the phono, and the Amp is the ARC Classic 60. Speakers are my own "invisible speakers" bass reflex in lovely birch plywood cabinets.

The music was movie and Broadway tunes played by horns and woodwinds with percussion. Basically a symphony orchestra without any strings. There was good space and I am a full on fan of how drums are portrayed. They are big deep and with amazing texture. Horns let you show off lots of audiophile type tricks. But the music was BORING. After two cuts I could not help but think if I hear another John Williams tune I will throw up. No FN imagination just quotes of everyone from Brahms to Stravinsky.

This is big loud music, and I was falling asleep droogs. I played both sides and yes the technical production is full on high end, but this goes back in the heap for a long time. Just not fun.

Since I was bored I decided to pull up "Year of the Cat" Mofi which I have talked about before. Wonderful recording of the most boring singer in history. Now this was interesting.

With the Franken-Amp this is broad and front row and deep with really really good clear sound. With the tuber it was almost muffled. Mr Stewart was pushed back a few yards and there was fog or smoke around him. ( not literally just an audible fuzziness thing ) I could still hear it clearly and all the parts were sharp and good. The guitar was very nice and metallic. The treble was really good. This is a Mofi after all. But the perspective of the mix was far different. I was in full on WTF mode. I bet it was mixed in a studio with all Solid State gear.

Very different, but not better.

OK one more then I have to shut it down. Emmylou Harris "Quarter moon...." I just got a Mofi used record from a cool shop a 5 hour drive away. There was some groove noise like dirt, they said they had ultrasonically cleaned it. Under the noise the recording was very nice. Actually a bit of discwasher brushing cleaned it up noticeably. I suppose the mix is simpler and cleaner so the sound was as I recall it before no big changes.

One thing and I will come back to it again. There is a background singer with a really cool tone to her voice. She is there, but not as easy to separate out as I recall. That may be the mix as Mofi does fiddle it's masters, or it may be the tuber. I have the original vanilla disk right in the milk crate there. I will check it.

[ Update: I did check it next day. The original disc was much clearer and the other singer was very easy to distinguish and understand. So did Mofi remix it and mess it up a bit? Interesting that the old copy sounded just as good as the mofi. Old master tape copy perhaps?]

In a related thing I ordered a set of the driver tubes. (EHX Russian). Far cheaper than a full set of 6550s and likely 30 years old. I want to pull the covers for a peak and will throw those in. It is a lot of bother to do so. I need some things to do in there aside from look. I will also check the bias of the output tubes. I will also scope some capacitors on the PC board that can go funny. There are 4 electrolytics there that are not power supply related and are known to be vulnerable. Just to risk my life you know. I gave up motorcycles decades ago.

The Amp does help warm the room and there was frost on the car this morning.

Cheers to all.

2 notes

·

View notes

Text

In the early 1970s, a zoologist out hunting for the haunts of Britain’s last small colonies of horseshoe bats, happened to pass one such group of standing stones on his way home in a spring dawn, and noticed something peculiar. He was equipped with an ultrasonic detector to monitor the high frequency sounds of bat navigation, and was startled to find a strong signal coming from the ancient site. It was a rapid and regular pulse unlike anything he had ever recorded before. He searched the area for signs of life, but found nothing and left just as the sun came up, with the slightly uncomfortable feeling that he had been eavesdropping on some megalithic conversation amongst the stones themselves.

The zoologist mentioned his odd experience later to the writer Paul Devereaux, who in turn passed it on to the Institute of Archaeology at Oxford where it reached the ears of a research chemist. Don Robins is one of a small group of scientists – physicists, geologists and electronic engineers – who call themselves the Dragon Project, after the active energy currents which are said to illuminate a landscape in Chinese geomancy. The group are interested in the factors which led those who built stone circles to such tremendous efforts, which clearly stretched the “macro-chip” technology of their day to its limits. The Project members wondered, when they first got together, whether there was anything special about the sites, some physical factor which could be measured. An anomaly, perhaps, in Earth’s electromagnetic field which produced unusual interactions with cosmic and solar radiation.

The problem they faced was which end of the spectrum to begin their explorations, and the zoologist’s story was just the hint they needed. A sensitive wide-band ultrasonic detector was constructed and field-tested for the first time in 1978 on the Rollright Stones in Oxfordshire.

Rollright is not a major megalithic site like Stonehenge or Avebury, but it is little visited and much revered. It has a circle of approximately seventy-three stones called the King’s Men – rumour has it that they keep moving and can’t be accurately counted; traces of several other circles; the Kingstone – an isolated menhir; and a collapsed dolmen known as the Whispering Knights, whose capstone was once dragged down the hill to be used as a bridge across the stream, until, it is said, it too kept moving and had to be returned.

Robins arrived at Rollright before dawn on a foggy morning in late October that year. “I walked around the site,” he said, “clutching the detector rather self-consciously, fully prepared to pretend that it was a transistor radio should I encounter a stray visitor. The detector showed a flickering, minimal background, but in the vicinity of the Kingstone I observed a rapid regular pulsing. This ultrasound effect was noticeable for some yards around the Kingstone … and faded soon after dawn.”

Encouraged by this finding, the group built an even more sensitive detector designed to exclude all possibility of radio interference and stray signals from local energy sources or geological faults. And they put it into action all year round. On streets and bridges, in gardens and woods nearby, there was never anything more than weak and random background noise. But at Rollright there was a consistent pulsing which could be measured near dawn on any day, regardless of weather conditions, and which rose to an ultrasonic screech lasting for several hours on those mornings in March and October which coincide with the feasts of equinox. And there are records of equinoctial rites being held at Rollright even in historic times.

[...]

At other times, the stones seemed almost to be creating an ultrasonic barrier. “This was the weirdest thing,” says Robins:

You always have a background of ultrasound in the country – the movement of grasses, leaves rustling, even your own clothing. It all registers. But one morning, as we moved in and out of the circle monitoring the levels, suddenly we found that there was complete ultrasonic silence inside the circle. Our first thoughts were that it was an instrument malfunction. Then we walked through a gap in the stones and there was sound. Inside, silence – outside, normal background levels.

-- Lyall Watson, Beyond Supernature

13 notes

·

View notes

Text

#heat treatment#hardness testing#industrial radiography#radiography#material test & lab equipment#magnetic practicle testing#ultrasonic testing#ndt equipment in uae#uv light#visual & welding inspection equipment#general equipment#incor technical#uae

0 notes

Text

#ndt radiography#non destructive testing radiography#non destructive testing equipment manufacturers#penetrant inspection near me#non destructive hardness testing#non destructive testing companies near me#non destructive thickness measurement#magnetic particle inspection near me#ndt labs near me#non destructive testing solutions#hardness test non destructive#ultrasonic testing gauge

0 notes

Text

Nickel 200 Wires Exporters in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a Wires provider and exporter of Nickel 200 wires. We Manufacture them open in custom nuances, plans, lengths, thickness, widths, and that is only a brief gander at something more prominent. We are known Exporters in the general market of ferrous and nonferrous things. Our clients can intercessors for nickel wires as shown by their application necessities.

Nickel 200 Wires are made with the assistance of the different Amalgam affiliations like carbon, manganese, silicon, copper, sulfur, chromium, iron, nickel, nitrogen, etc. too. These nickel wires ought to have physical and mechanical properties like thickness, loosening up point, flexibility, yield strength, astonishing rigid nature, broadening, warm conductivity, electrical conductivity, and modulus of extension. These wires are made with different decisions like broadness, shape, size, length, width, thickness, types, structures, condition, surface, application, standard, finish, obstacles, etc. as well. These wires are accessible in many sorts, for example, reshape wire, made never-ending wire.

Nickel 200 Wires are material in various organizations, for instance, offshore oil entering undertakings, petrochemicals industry, power age plant, drug industry, substance gear, seawater equipment, drug equipment, special engineered industry, paper industry, pound industry, heat exchanger, and condenser. These wires are also significant in many general purposes like valves, shaft, shipbuilding, structure advancement, transportation equipment, range improvement, radiator parts, and various temperature-safe things.

Nickel 200 Wires are made with the best material and incredible mechanical and real properties. These wires are a good blend of formability, usefulness, welding, and resistance from the high temperatures. These wires are outrageous, hard, and made with the protected material to work at high temperatures. These wires are furthermore protected against the entire expansive disintegration like gap utilization, stress breaking, pitting block, and impact disintegration. These wires are protected in the oxidizing, decreasing and unprejudiced circumstances. These wires have the low electrical and warm conductivity that helps the wires with contradicting the electric.

Nickel 200 Wires need to go through many tests after the creation from the business, for example, erupting test, straightening test, large scale test, miniature test, hydrostatic test, ultrasonic test, pitting test, radiography test, hardness test, synthetic test, mechanical test, PMI test, etc too.

For more information :

Visit our website : https://www.merakimetals.ae/

Contact us : +971-523973687, +971-48801107, +971-48240333

Email : [email protected]

#Nickel 200 Wires Manufacturers in UAE#Nickel 200 Wires Suppliers in UAE#Nickel 200 Wires Stcokists in UAE#Nickel 200 Wires Exporters in UAE

3 notes

·

View notes

Text

5 Latest Manufacturing Process of Heavy Wall Thickness CS Seamless Pipes

Heavy wall thickness CS seamless pipes are used in various applications, from oil and gas to construction and infrastructure. These pipes are known for their high strength, durability, and resistance to corrosion, making them an ideal choice for harsh environments.

The manufacturing process for heavy wall thickness CS seamless pipes involves several steps, each critical to the final product's quality.

Raw Material Selection: The first step in the manufacturing process is the selection of high-quality raw materials. Heavy wall thickness CS seamless pipes are typically made from carbon steel, which is known for its strength and durability. The steel is selected based on its chemical composition, mechanical properties, and other factors to meet the required specifications.

Billet Production: The next step is the production of billets and cylindrical steel pieces that serve as the starting point for the pipe-making process. The steel is heated to a high temperature and then rolled into a cylindrical shape. The resulting billet is cut to the desired length using a saw or other tool.

Piercing and Rolling: Once the billets have been cut to the desired length, they are ready for piercing and rolling. The billets are heated to a high temperature and then pierced with a mandrel, which creates a hollow tube. The tube is then rolled using a series of rollers to reduce its diameter and increase its length.

Heat Treatment and Finishing: After the piercing and rolling process, the tube is heat treated to improve its mechanical properties. The tube is heated to a high temperature and then quenched in water or oil to harden the steel. This process helps to improve the pipe's strength and durability. Once the heat treatment process is complete, the pipe undergoes finishing. This involves cutting the pipe to the desired length and removing excess material or burrs. The pipe is then inspected for quality control to ensure it meets the required specifications.

Testing and Certification: Before the heavy wall thickness CS seamless pipes are shipped to the customer, they undergo testing and certification. The pipes are subjected to various tests, including hydrostatic testing, ultrasonic testing, and visual inspection, to ensure they meet the required quality standards. Once the pipes have passed all required tests, they are certified and shipped to the customer.

In addition to the steps mentioned above, several other important factors must be considered in manufacturing heavy wall-thickness CS seamless pipes.

One of the key considerations is the quality of the equipment used in the production process. Modern equipment and technology, such as advanced rolling mills and heat treatment furnaces, can significantly improve the efficiency and quality of the process.

Another important consideration is the quality control measures throughout the manufacturing process. Strict quality control measures ensure that the pipes meet the required strength, durability, and corrosion resistance standards.

These measures can include regular inspections and testing throughout the production process and comprehensive final testing and Certification.

It is also worth noting that the manufacturing process for heavy wall thickness CS seamless pipes can vary depending on the specific application and customer requirements.

For example, some applications may require additional steps, such as surface treatment or coating, to enhance the pipe's corrosion resistance.

Overall, the manufacturing process for heavy wall thickness CS seamless pipes requires careful attention to detail and a commitment to quality at every step. By selecting high-quality raw materials, using modern equipment and technology, and implementing strict quality control measures, manufacturers can produce pipes that meet the most stringent requirements for strength, durability, and corrosion resistance.

For more such stories, kindly follow Tumblr.

#metal industrial#construction#stainless steel#architecture#alloy#buildings#carbon steel pipe#seamless pipe#heavy wall pipe#CS Seamless Pipes#Carbon Steel#SEAMLESS CARBON STEEL HEAVY WALL THICKNESS PIPES#ASTM A53 Heavy Wall Thickness Seamless Pipes#ASTM A106 Gr B Steel A53 Heavy Wall Thickness CS Seamless Pipe

2 notes

·

View notes