#MachineVision

Explore tagged Tumblr posts

Text

🎧🎶 Front Line Assembly Announces "Machine Vision" by Bill Leeb! 🎧

Front Line Assembly has just announced “Machine Vision,” the new solo project from mastermind Bill Leeb! Dive into this exciting new release from the iconic electronic music pioneer. Check It Out HERE Deep Dive into the Universe of Bill Leeb and Front Line Assembly: 🎧🎶 Front Line Assembly Official Site – Bill Leeb Bandcamp – Front Line Assembly Facebook – Front Line Assembly Instagram,

#Aggrotech#billleeb#djdarkside#💀#ebm#electroindustrial#ElectronicMusic#evolradio#FrontLineAssembly#IndustrialDance#industrialmusic#MachineVision#MusicRelease#NewMusic#SoloProject

0 notes

Text

Why Flip-Off Cap Inspection Is the Missing Link in Your Pharma Packaging Line

When it comes to injectable packaging, flip-off seals are more than just aluminum caps — they’re your brand’s first line of defense in ensuring sterility, safety, and quality. Unfortunately, they’re also one of the most overlooked areas in quality control.

Enter Optomech’s FOSIS — a next-gen flip-off seal inspection system that combines machine vision, high-speed automation, and regulatory-ready software to eliminate defects before your products leave the line.

🔍 What Can Possibly Go Wrong with a Flip-Off Seal?

You’d be surprised.

During mass production, flip-off caps often suffer from:

Black spots

Short fills on the PP button

Wrinkles or dents on the aluminum shell

Color mismatches

Dust, dirt, or improper crimps

Missing caps or incomplete assemblies

Individually, these might seem minor. But together, they can:

Lead to product recalls

Fail regulatory inspections

Damage brand reputation

Cause delays in batch release

⚙️ How FOSIS Detects These Defects in Real-Time

The Flip-Off Seal Inspection System (FOSIS) uses a combination of:

High-speed vision cameras

Precision lighting and optics

Custom-developed algorithms

21 CFR Part 11 compliant software

Here's how it works:

Seals are fed through a vibratory bowl to a conveyor.

As they pass under the vision station, each cap is captured frame-by-frame.

The system checks for all defined defects in under a second.

Defective caps are immediately rejected without stopping the line.

Data is logged and reports are generated for compliance and traceability.

💼 Where Can FOSIS Be Used?

If you manufacture or package:

Injectables

Sterile vials

Flip-off caps or seals

Pharma glass bottles

…then you’re the perfect use case for FOSIS.

Whether you're a large pharmaceutical company, a contract manufacturing organization (CMO), or a packaging component supplier, FOSIS adds speed, consistency, and reliability to your inspection process.

📊 Built for Pharma Compliance & Performance

Key Features:

Inspects up to 600 caps/min

Handles cap sizes from Dia 15 mm to 36 mm

Detects over 20 defect types including:

Shell deformations

PP button cuts or flashes

Color and shade variations

User-friendly 21” touchscreen with quick product changeovers

Three-level access control: User, Supervisor, Admin

Auto reporting to Excel, with network export and historical data access

📞 Take Control of Your Cap Quality – Don’t Leave It to Chance

With market demands rising and regulatory scrutiny at an all-time high, it’s time to move beyond manual checks and partial sampling.

Optomech’s FOSIS Flip-Off Seal Inspection System gives you:

Faster output

Reduced batch rejections

Higher customer trust

Better compliance audit readiness

🧪 Ready to See It in Action?

Whether you need a demo, pricing, or integration advice, we’ve got you covered.

📧 [email protected] 📞 +91 40 23078371 🌐 www.optomech.in

0 notes

Text

Introducing the FCU3501, our rugged, next-gen embedded computer powered by the Rockchip RK3588 SoC. Designed for industrial AI at the edge, it delivers up to 32 TOPS of AI performance via onboard NPU + Hailo-8 M.2 accelerator.

🔧 Key Features:

Dual NPU Architecture – 6 TOPS onboard + 26 TOPS via Hailo‑8

Supports 8K Video Encoding/Decoding – Perfect for smart vision applications

Wide Temp, Fanless Design (–40 °C to +85 °C)

Certified for Industrial Use – CE, FCC, RoHS, EMC-compliant

Modular Storage & Expansion – M.2 SSD, TF card, 4G/5G optional

Rich I/O for Smart Factories, Transportation, Buildings & more

📩 Want a spec sheet or evaluation sample? Contact us: [email protected]

#EdgeAI#RK3588#Hailo8#EmbeddedComputer#IndustrialAutomation#AIAccelerator#SmartFactory#MachineVision#ProductLaunch

0 notes

Text

Capture Every Moment with Precision – 120FPS MIPI Camera Module by Shenzhen Brilliant CMOS Technology Co., Ltd

Looking for ultra-fast image capture with unmatched clarity? Shenzhen Brilliant CMOS Technology Co., Ltd delivers cutting-edge vision technology with its 120FPS MIPI Camera Module. Designed for high-speed applications like industrial automation, robotics, AI vision, and scientific imaging, this monochrome global shutter module ensures crystal-clear images—even in rapid motion environments.

Why choose our camera module? At 120 frames per second, it eliminates motion blur while the MIPI interface guarantees seamless integration with modern processors and systems. The global shutter technology provides superior image quality, ideal for capturing fast-moving objects without distortion—critical for precision-demanding applications.

Engineered for performance, stability, and low power consumption, our camera module is the go-to choice for developers and engineers pushing the limits of machine vision and embedded systems.

Explore more about this powerful module on our official product page: 🔗 https://cbritech.com/product/120fps-mipi-monochrome-global-shutter-camera-module/

✨ Shenzhen Brilliant CMOS Technology – Empowering Vision with Innovation.

#CameraModule#120FPS#GlobalShutter#MIPI#MachineVision#CMOSTechnology#ShenzhenBrilliantCMOS#HighSpeedImaging

1 note

·

View note

Text

Robotic Inspection: The Future of Quality Assurance with Dynalog Inc.

In today’s fast-paced and highly competitive industrial landscape, quality assurance has become more crucial than ever. Whether you're in automotive manufacturing, aerospace, electronics, or any other high-precision industry, ensuring product quality is no longer just a competitive edge—it's a necessity.

Enter Robotic Inspection—an advanced solution reshaping how manufacturers conduct quality control. At the forefront of this innovation is Dynalog Inc., a leading provider of robotic calibration and guidance systems that are helping industries embrace automation with confidence.

What is Robotic Inspection?

Robotic Inspection refers to the use of automated robotic systems equipped with sensors, cameras, and AI-powered software to examine products, parts, or assemblies for defects, dimensional accuracy, or inconsistencies. These systems can detect flaws with incredible speed and accuracy, often surpassing what the human eye or manual inspection tools can achieve.

Instead of relying solely on human inspectors, manufacturers are integrating robotic systems that work tirelessly, consistently, and with precision—day in and day out.

Why Robotic Inspection is Changing the Game

Traditionally, inspection processes have been time-consuming, error-prone, and highly dependent on the skill level of individual inspectors. But with Robotic Inspection systems, companies can benefit from:

Higher Accuracy: Robots don’t get tired or distracted. When paired with advanced vision systems and sensors, they can detect microscopic flaws or misalignments.

Increased Speed: Robotic systems perform inspections in real-time, significantly reducing cycle times and production delays.

Repeatability: Robotic inspection ensures consistent quality across every single part, eliminating variability.

Reduced Labor Costs: While robots do require an initial investment, they can reduce ongoing labor costs and human errors.

Data Collection & Analysis: These systems can be integrated with smart software to collect inspection data, allowing for real-time analysis and continuous improvement.

Dynalog Inc.: Pioneering Robotic Inspection Solutions

Dynalog Inc. has built a reputation as a leader in the field of robotic measurement, calibration, and inspection. For years, Dynalog has supported manufacturers worldwide in their journey toward smarter, more efficient automation. Their Robotic Inspection solutions combine cutting-edge hardware and software to deliver high-performance, plug-and-play systems for industrial environments.

Let’s take a closer look at what sets Dynalog apart:

1. Advanced Robot Calibration Technology

Calibration is key to ensuring a robot performs accurate inspections. Dynalog’s calibration systems ensure that every robotic arm is perfectly aligned with its intended path, reducing positional errors and improving inspection reliability. Their TCP (Tool Center Point) Calibration ensures that the robot knows exactly where the tool is located in 3D space—critical for high-precision inspection tasks.

2. Vision-Integrated Inspection Systems

Dynalog offers systems that incorporate advanced vision technologies—both 2D and 3D—to allow robots to “see” and evaluate parts in real-time. Whether it’s detecting cosmetic flaws, measuring part dimensions, or verifying part presence, these systems operate with remarkable speed and precision.

3. Seamless Integration

One of Dynalog’s strengths is the flexibility of their solutions. Their Robotic Inspection systems are compatible with major robot brands and can be integrated into existing production lines with minimal disruption.

4. Real-Time Error Correction

Through dynamic feedback and compensation mechanisms, Dynalog’s solutions allow robots to self-correct and adapt during inspections. This ensures minimal downtime and improved overall productivity.

Industries Benefiting from Robotic Inspection

While almost every industry can benefit from robotic inspection, some sectors are leading the adoption curve:

Automotive: Ensuring fit, finish, and safety-critical components are defect-free.

Aerospace: Verifying the dimensional accuracy of complex components where failure is not an option.

Electronics: Detecting micro-defects and component misplacements.

Medical Devices: Maintaining ultra-high precision standards for life-saving equipment.

Looking Ahead: The Future of Inspection is Robotic

With the growing demand for smart factories and Industry 4.0 initiatives, Robotic Inspection is poised to become a standard part of modern manufacturing. As technologies like AI, machine learning, and IoT continue to evolve, robotic systems will become even smarter, more intuitive, and capable of making real-time decisions on the factory floor.

Dynalog Inc. is committed to staying ahead of the curve, constantly innovating to meet the demands of tomorrow’s manufacturers.

Ready to Upgrade Your Quality Assurance?

If you're looking to improve your quality inspection processes, reduce costs, and stay competitive, it’s time to explore what Dynalog’s Robotic Inspection Systems can do for your business.

#RoboticInspection#Dynalog#IndustrialAutomation#RobotCalibration#QualityControl#SmartManufacturing#FactoryAutomation#MachineVision#InspectionAutomation#TCPcalibration#RoboticQualityAssurance#Industry40#AutomatedInspection#VisionSystems#ManufacturingInnovation

0 notes

Text

#MachineVision#Automation#IndustrialImaging#SmartManufacturing#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Optical Visual Inspection#OpticalVisualInspection#MachineVision#QualityControl#NonDestructiveTesting (NDT)#PatternRecognition

#Optical Visual Inspection#OpticalVisualInspection#MachineVision#QualityControl#NonDestructiveTesting (NDT)#PatternRecognition

1 note

·

View note

Text

AI consulting Company

Did you know that machine vision is transforming the logistics industry?

0 notes

Text

🌐 Week Eight: Digital Citizenship and Software Literacy - Instagram Filters 📸✨

In today’s post, we’re diving into the world of Instagram filters and their role in shaping digital citizenship and software literacy. Filters are more than just fun effects - they influence how we see ourselves and others, sometimes altering perceptions in profound ways. With their growing popularity, understanding the implications of filters can help us navigate social media more responsibly.

🌈 The Allure and Impact of Instagram Filters

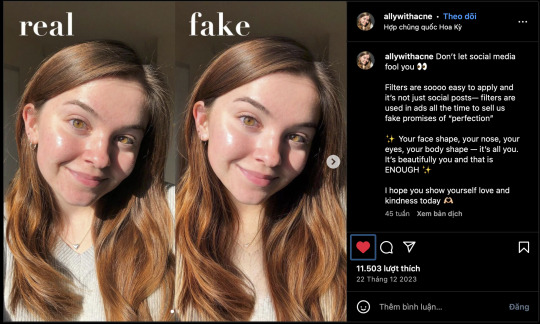

Instagram filters are a staple of visual social media, allowing users to modify their photos with the tap of a screen. While these filters can be creative and entertaining, they also present a version of reality that isn’t entirely authentic. Filters act as cultural tools that shape our perceptions, subtly reinforcing beauty ideals by smoothing skin, brightening eyes, or changing skin tones (Rettberg 2014). Filters, in this way, aren’t just decorative - they influence what we see as desirable and even “normal.”

As users, we should be aware of how filters affect our self-image and interactions with others. Filters can reinforce narrow beauty standards that leave little room for diversity. For example, beauty filters can often alter facial features to align with Eurocentric ideals, which can be damaging to self-esteem and cultural identity (Baker 2020). This isn’t just a minor issue; it’s a form of digital literacy we must cultivate to critically engage with the content we create and consume.

You can easily find a series of "HOW TO LOOK LIKE AN INSTGRAM FILTER IN REAL LIFE" on Google.

👁️ Biometric Influence: Filters and Machine Vision

Instagram filters don’t just modify images; they also teach us how to interact with machine vision. Filters work by using augmented reality (AR) to superimpose changes onto our faces in real-time, effectively turning our selfies into data for machine learning (Rettberg, 2017). This process can affect our self-perception, as we adapt our images to match the “ideal” encoded within the filters. According to Rettberg (2017), our engagement with these filters is part of a broader trend toward biometric citizenship, where our faces become data points in algorithmic systems (Rettberg, 2017).

The implications of this are significant. As we grow accustomed to using filters, we might be subtly shifting our ideas of beauty and self-worth to align with machine-driven standards. It’s essential to develop software literacy so we can understand the influence these tools have on us and use them more mindfully.

🔍 Navigating the Ethics of Filter Use

Understanding software literacy means recognizing both the benefits and drawbacks of filters. While filters can be fun and allow for creative expression, they can also lead to digital deskilling, as we rely on pre-made effects rather than creating original content. Filters encourage us to present polished versions of ourselves, which might not always reflect reality. By questioning our use of filters, we engage in digital citizenship, making informed choices about how we want to be perceived online (Barker, 2020).

In light of this, digital citizens can make a conscious effort to either reject or use filters in ways that support genuine self-expression and inclusivity. It’s also helpful to encourage conversations about the impact of filters on body image and self-esteem. As Rettberg (2014) reminds us, filters are both cultural and technological tools that shape our experiences—so let’s make sure we’re shaping them with intention.

References

Barker, J 2020, Making-up on mobile: The pretty filters and ugly implications of Snapchat, Fashion, Style & Popular Culture, vol. 7, no. 2 & 3, pp. 207-221, DOI: 10.1386/fspc_00015_1.

Rettberg, JW 2014, Seeing Ourselves Through Technology: How We Use Selfies, Blogs and Wearable Devices to See and Shape Ourselves, Palgrave Macmillan, Basingstoke, DOI: 10.1057/9781137476661.0004.

Rettberg, JW 2017, ‘Biometric Citizens: Adapting Our Selfies to Machine Vision’, in Selfie Citizenship, ed. Kuntsman, A., Springer, Cham, DOI: 10.1007/978-3-319-45270-8_10.

0 notes

Text

Color Detection Sensors Market - Forecast(2024 - 2030)

Sample Request :

The color detection sensor market is crucial for the success of industry automation on a global scale. This market has been witnessing tremendous growth due to increasing industries and new technological advancements. Advanced Economies also maintain a stable growth mainly due to reimbursements offered for specific equipment and health policies of government and private entities. Portability, customization, ease of use, and automation are the key factors that Color Detection sensors market players use to differentiate their products and services.

The working principle of color detection sensors typically involves shining a light source (often an LED) onto the target object and capturing the reflected light with photodetectors. The sensor then processes this information to determine the color by comparing the detected wavelengths to known color standards.

Applications of color detection sensors include:

Quality Control: Ensuring products meet specific color standards in manufacturing.

Robotics: Allowing robots to identify objects based on color for sorting or assembly tasks.

Agriculture: Assessing crop health based on color changes.

Consumer Electronics: Enhancing user experience through color recognition in devices like smart cameras.

Inquiry Before Buying:

The global color detection sensor market is projected to reach $3.01 billion by 2021; the market will show a single digit growth in the forecast period. Europe was the largest market for color detection sensors in 2015; APAC will replace Europe and emerge out as the largest market in the forecast period. APAC derives its growth from newly establishing industries and technological advancements.

Schedule a Call :

Color provides relevant information for object recognition; this information can be filtered and used for various purposes. The ability to differentiate objects by their colors with incredible accuracy and consistency has significantly driven the growth of color detection sensors. The color detection sensors detect the color of the object by analyzing the light reflected from the surface of the object. Color detection sensors are used in various industries including food and beverage, automotive and manufacturing. These sensors are widely used in consumer electronics for backlight control and display calibration.

Sample Companies Profiled in this Report are:

SICK AG,

Banner Engineering Corp.,

Rockwell Automation Inc.,

Hamamatsu photonics K.K.,

Pepperl + Fuchs GmbH,

10+.

The data for color detection sensors is gathered from different primary and secondary sources. Quantitative and qualitative data is collected by analyzing latest developments and trends for the global market. Bottom-up approach was followed for revenue estimates. The end use application of color sensors was used to calculate shipments and average selling prices were collected from various primary and secondary sources. Optical sensors market and photoelectric sensors market was also analyzed to validate the end result.

Buy Now :

Color detection sensors are devices designed to identify and differentiate colors based on the light they reflect. These sensors use various technologies, such as photodiodes, color filters, and digital signal processing, to analyze the wavelengths of light that an object reflects. Commonly used in industries such as manufacturing, robotics, and quality control, these sensors help automate processes by providing real-time feedback on color consistency, which is crucial for tasks like sorting materials, quality assurance, and even art restoration.

Key Market Players:

The Top 5 companies in the Color Detection Sensors Market are:

Sick AG

EMX Industries Inc.

Wenglor Sensoric GmbH

Rockwell Automation Inc.

Panasonic Corporation

For More about Color Detection Sensors Market Report click here

0 notes

Text

Learn the fundamentals of machine vision, its core components, and practical applications in industries to streamline operations and improve accuracy.

0 notes

Text

MSI MS-C906: Tiny Ultra low power Fanless Edge AI IPC

Edge AI Applications

MSI Introduces the MS-C906, a Compact, Ultra-Low-Power Fanless Box IPC for Edge AI.

The debut of the MS-C906, a small box PC with an Intel 13th Gen Raptor Lake-P U Series processor, is proudly announced by MSI, a leader in AI and advanced computing solutions worldwide. Built for ultra-low power fanless operation, the MS-C906 delivers unmatched performance and dependability, making it the perfect choice for edge AI applications.

Principal Elements

High Performance

Allows for up to 32GB of DDR5 5200 MHz RAM and has four separate HDMI screens, making it ideal for a variety of commercial and industrial settings where visual output is needed.

Strong Network Connectivity

This device has four Intel 2.5GbE LAN ports, which makes for strong network connectivity. SATA and M.2 ports offer a wide range of storage choices.

AI Integration

This feature speeds up the implementation of AI solutions, especially in image processing and machine vision applications, by integrating with the Intel OpenVINO AI development tools. Suitable for additional AIoT applications, smart cities, and smart manufacturing.

Durability

The wide operating temperature range of -20°C to 70°C and the wide voltage DC-IN of 12~24V allow the MS-C906 to function dependably in challenging industrial situations. The gadget is protected against electrical abnormalities and ensures reliable and secure operation with its features of Over Current Protection (OCP) and Over Voltage Protection (OVP).

The MS-C906 is a strong option for a range of industrial applications because of these precautions, which also increase its longevity and durability. Its IEC 61373-compliant anti-vibration and shockproof construction further guarantees that the gadget can resist shocks and vibrations in industrial environments.

Numerous Serial Connections

Four COM ports (RS-232/422/485) allow you to connect a wide range of industrial devices, including controllers, sensors, and legacy equipment. This improves overall operational efficiency in settings like smart factories, retail stores, and healthcare facilities.

Fanless Design

Because fanless design ensures silent operation and lowers maintenance, it’s perfect for places like retail stores and healthcare facilities where dust and noise are issues.

Security

The enhanced security of TPM 2.0 (Trusted Platform Module) makes it appropriate for applications including financial services, healthcare, and government that demand safe data management and protection.

Rich Interface for I/O:

4 HDMI Ports

Four HDMI ports are perfect for multi-display configurations, digital signage, and high-definition video output.

Four USB ports

Four USB 3.2 Gen2 ports allow accessories like external storage, cameras, and other USB devices to transport data quickly.

4 LAN Ports

With four 2.5 GbE LAN ports, this network is well-suited for applications including data centres and surveillance systems that demand fast internet and network access. since of its sophisticated network capabilities, the MS-C906 is more suitable for a wider range of industrial and commercial situations since it offers dependable and fast connectivity.

4 COM Ports

Four COM ports (RS-232/422/485) are necessary to link industrial devices, such as sensors, controllers, and legacy equipment. This feature makes the port appropriate for automation systems and smart factories.

DIO (Digital Input/Output)

SMBus connections for better multimedia and system administration; audio and amplifier; and digital input/output (DIO) for a variety of control and monitoring applications.

Power Input

DC power input ranging from 12 to 24 volts provides a range of power choices suitable for various settings.

Utilizations

Smart Factories

By utilising the MSI MS-C906 for data analysis, equipment monitoring, and machine vision inspection, production efficiency and product quality can be improved. Smart factories will find the Intel 13th Gen Raptor Lake-P U Series Processor, quadruple HDMI a monitors, and four Intel 2.5GbE LAN connections ideal. Its broad operating temperature range of -20°C to 70°C, anti-vibration and shockproof construction, combined with its integration with the Intel OpenVINO AI framework for sophisticated image processing and machine vision, guarantee dependable performance in demanding industrial environments.

Retail and Commercial

The MS-C906 can be utilized to improve customer service and operational efficiency in the retail and commercial sectors through customer flow analysis, smart vending machines, and digital signage (both indoor and outdoor). Perfect for dynamic digital signage and client involvement, its quadruple HDMI 2.0 independent displays feature the EDID Lock display capability.

The M.2 and SATA interfaces offer versatile storage options, while the four Intel 2.5GbE LAN ports guarantee dependable network access. The ability to analyze consumer traffic and operate smart vending machines is improved by the integration with the Intel OpenVINO AI toolset.

Healthcare

By using MS-C906 for telemedicine, patient monitoring, and medical image processing, healthcare services can be provided more effectively and at a higher quality. Clear and detailed medical imaging is made possible by its quadruple HDMI screens, which are essential for precise diagnosis and patient care.

For seamless telemedicine consultations and real-time patient monitoring, the four Intel 2.5GbE LAN ports provide dependable and quick network connectivity. Advanced diagnosis and treatment planning are made possible by the integration with the Intel OpenVINO AI toolbox, which improves medical imaging processing capabilities.

With cutting-edge solutions that satisfy its clients’ changing needs, MSI is at the forefront of the industry. Purchases of the MS-C906 can now be made via authorised distributors and MSI’s official channels.

Read more on govindhtech.com

#MSIMSC906#EdgeAIIPC#EdgeAIApplications#AIapplications#msi#HDMIscreens#AIsolutions#IntelOpenVINO#healthcare#machinevision#intel13thGen#monitor#LakePUSeriesProcessor#cuttingedgesolutions#intel#hdmi#ai#ms#technology#technews#news#govindhtech

0 notes

Text

OPTO 1200 Quick Measuring Machine — Precision Screw Inspection in Just Seconds

Opto1200- Optomech engineers pvt ltd

Revolutionize Your Quality Control with Instant, Accurate, and Hands-Free Measurement

Intoday’s era of micro-precision and mass production, quality inspection is no longer just about checking dimensions — it’s about doing it faster, smarter, and without compromise. Whether you’re manufacturing automotive components, aerospace fasteners, or industrial-grade tools, ensuring that every screw meets exact specifications is non-negotiable.

Enter the OPTO 1200 Quick Measuring Machine — a powerful, camera-based dimensional inspection system that allows users to measure 2D parts like screws instantly with incredible accuracy, without operator intervention. No complex setup. No manual handling. Just place the part, press a button, and let the system do the rest.

Why Choose OPTO 1200 for Screw Inspection?

Screws, though seemingly simple, are geometrically complex. They include multiple critical parameters like:

Thread pitch

Head diameter

Shaft length

Chamfer angle

Root diameter

Any deviation can result in poor fit, torque failure, or total product rejection.

Traditional methods like calipers, micrometers, or profile projectors are time-consuming and subject to human error. With OPTO 1200, you can measure every screw in seconds, store the results, and even generate reports — all with minimal training.

Real-World Application: Measuring a Precision Screw

Let’s walk through how a screw is measured using the OPTO 1200 system:

Step 1: Template Creation

Using Opto Precision V1 software, a template is created by simply drawing around the screw’s edge.

The software auto-detects contours and generates geometric elements like lines, circles, and arcs.

Nominal dimensions and tolerances are input by the quality team.

Step 2: Place and Measure

The operator places the screw on the OPTO 1200 stage.

On clicking the “Measure” button, the system:

Captures the image

Matches it with the template

Automatically measures:

Head diameter

Thread pitch

Shank length

Chamfer angles

Concentricity

Provides instant PASS/FAIL validation

Step 3: Reporting

The results are stored in a secure database.

A statistical report including Min, Max, Mean, Std Dev, CPK is generated.

Reports can be exported or printed as per requirement.

This is true plug-and-play metrology, making it a must-have tool for modern precision workshops.

What Makes OPTO 1200 Unique for Screw and Small Part Inspection?

1. Speed

Inspects each screw in under 5 seconds

Measures multiple screws at once on a single stage

2. Accuracy

Accuracy: ±10 μm

Repeatability: ±5 μm

Resolution: 1 μm

3. Simplicity

Just place the screw and press a button

No specialized operator skills needed

4. Reporting & Traceability

Every measurement logged

Reports generated automatically

Compliant with industrial audit requirements

Key Features at a Glance

Feature

Specification

Field of View

120 mm x 95 mm

Camera

20 MP Monochrome CMOS

Lens

Double Telecentric Optics

Software

Opto Precision V1

Display

21.5” Full HD Touchscreen

Illumination

Collimated Green LED

Accuracy

±10 μm

Repeatability

±5 μm

Report Generation

Real-time with summary stats

Industries That Benefit from OPTO 1200

If your industry relies on tight tolerance parts like screws, bolts, pins, and fasteners, the OPTO 1200 is for you:

Aerospace & Aviation

Automotive

Medical Device Manufacturing

Electronics & PCB Assemblers

Tool & Die Making

Defense & Heavy Engineering

From prototype analysis to full production QA, this machine fits right into your digital workflow.

FAQs — Quick Insights for Buyers and Operators

Q1: Can OPTO 1200 measure different types of screws?

A: Yes. You can create and save multiple templates for each screw type and recall them instantly.

Q2: How does it ensure accuracy for threads?

A: The double telecentric lens and edge-detection software ensure consistent and distortion-free thread measurements.

Q3: Can I use it for batch inspection?

A: Absolutely. You can place multiple screws and measure them all in one click.

Q4: Is it difficult to operate?

A: Not at all. It’s user-friendly with an intuitive interface — no metrology experience required.

Q5: Does it store past reports and results?

A: Yes. Every measurement and inspection report is saved and can be retrieved anytime.

Conclusion: Make Screw Inspection Smarter, Faster, and Reliable with OPTO 1200

In a manufacturing world driven by precision and productivity, the OPTO 1200 is your edge. It empowers your team to inspect complex parts like screws with unparalleled accuracy, zero human error, and faster cycle times.

Whether you’re inspecting 10 parts a day or 1,000, the OPTO 1200 guarantees performance, repeatability, and ease — all packed into one powerful machine.

Measure better. Deliver faster. Trust OPTO 1200.

0 notes

Text

Machine vision integration solution by Intsoft Tech

#deep learning#machine learning#ai vision#machinevision#industrial defect detection#intsoft tech#machine vision integration

1 note

·

View note

Text

Forlinx FET3588-C CPU Board: Empowering Intelligent Manufacturing and Creating High-end 8K Panoramic Cameras

Exciting news for the Machine Vision Industry! Introducing the Forlinx FET3588-C CPU Board, powering high-end 8K panoramic cameras in intelligent manufacturing.

With multi-camera support, 8K decoding, and a built-in NPU, this cutting-edge technology is revolutionizing machine vision.

Read More: 👇 👇👇

0 notes

Video

youtube

Vision China 2023, the largest Vision Exhibitions in China. What are the excellent products at LR-LINK booth?

1 note

·

View note