#Label defect detection

Explore tagged Tumblr posts

Text

Revolutionizing Packaging with the LIS-2S Automatic Label Inspection System

In the world of high-speed packaging, precision isn’t optional—it’s critical. Just one poorly applied or misaligned label can cost manufacturers customer trust, regulatory compliance, or even an entire product batch. Enter the LIS-2S automatic label inspection system—a cutting-edge solution designed for the pharma, FMCG, and cosmetics industries that demand nothing less than perfection. Operating seamlessly on high-speed bottling lines, this system brings unmatched accuracy and inspection reliability, ensuring every bottle leaving your facility is 100% label-verified.

Why an Automatic Label Inspection System is a Must-Have Today

Manual label inspection is quickly becoming obsolete. Human eyes can't consistently catch defects at production speeds of 14,000 bottles per hour. Plus, the margin for error grows with fatigue and environmental distractions. That’s why more companies are investing in automated, vision-based solutions. The LIS-2S automatic label inspection system detects: • Label misplacement or skew • Wrinkles or air bubbles • Incorrect label orientation • Missing labels • Overlapping or double-labeled bottles By integrating a robust vision camera setup with intelligent software, LIS-2S offers real-time decision-making—rejecting faulty products before they reach the packaging zone.

High-Speed Performance with Precision Engineering Speed without precision is a recipe for disaster. Fortunately, LIS-2S is engineered to handle both. • Throughput: Up to 14,000 bottles/hour • Inspection Modes: Front label, back label, wrap-around label • Orientation Correction: Capable of verifying label orientation in relation to bottle shape or cap • User Interface: Simple, touchscreen-based GUI for setup and monitoring • Footprint: Compact, easily integrates into existing lines without the need for reconfiguration Whether you’re packaging antibiotics in glass bottles or shampoos in PET containers, the LIS-2S adapts effortlessly, thanks to its custom configurability.

How the Automatic Label Inspection System Ensures Compliance Global compliance standards are tightening. For industries like pharma or cosmetics, even a 0.01% labeling error can result in batch rejection, penalties, or blacklisting by retailers. The automatic label inspection system gives manufacturers a proactive way to stay ahead of audits. Key compliance advantages: • 21 CFR Part 11 ready (for pharma) • Customizable reports & batch logs • Traceability of rejected units • Audit trail with user access control Plus, it helps ensure packaging meets branding standards—logos are correctly placed, labels are level, and branding integrity is never compromised.

Designed for Indian Manufacturing. Built for Global Standards. Optomech’s LIS-2S isn’t just fast and smart—it’s designed with real production environments in mind. Unlike imported systems that are complex to maintain, the LIS-2S offers: • Local tech support & quick servicing • Easy-to-source spares • Customization for Indian bottle formats (HDPE, PET, Glass, etc.) • Affordable total cost of ownership compared to foreign systems This makes LIS-2S a future-ready solution not just for large-scale manufacturers but also for mid-sized companies scaling up their packaging operations.

Key Benefits of Using an Automatic Label Inspection System When you switch to an automated system like LIS-2S, you unlock real, measurable improvements: • Reject rate reduced by up to 95% • Downtime minimized through predictive maintenance • Brand image protected by flawless labeling • Line efficiency improved via real-time rejection alerts • Zero human intervention means zero fatigue-based errors The ROI? Many users recover their investment within 6 to 12 months purely through reduction in wastage and customer complaints.

Where LIS-2S Fits Best This automatic label inspection system is ideal for: • Pharmaceutical packaging lines • FMCG bottling plants • Cosmetic and personal care product lines • Nutraceutical liquid packaging • Agrochemical bottle labeling Whether you're handling 100 ml syrup bottles or 1-liter shampoo containers, LIS-2S adapts to your workflow.

Smart Label Inspection, Smarter Business Investing in the LIS-2S automatic label inspection system is more than just buying a machine—it’s a strategic move. It signals to your customers, partners, and regulatory agencies that your company is committed to zero-defect manufacturing and continuous improvement. It’s not just about catching errors. It’s about preventing brand damage before it happens.

Final Thoughts: Make Every Label Count With the stakes so high in modern packaging, the question isn’t if you need label inspection automation—it’s when. And if you're serious about quality, the LIS-2S automatic label inspection system should be your answer. From regulatory peace of mind to zero-defect shipments, this is one investment your packaging line—and your brand—can’t afford to skip.

#High-speed label inspection machine#Label inspection system#Label defect detection#Automatic label inspection#Inline bottle inspection

0 notes

Text

Dubious roller coaster accident stories are a great example of the media fearmongering about objectively small numbers, bc they all cite the stats that 1,200 people A YEAR are injured at theme parks. Isn't that scary? Omg, 1,200 is so many!

Anyway over 100 million people went to theme parks in the US during that period. 1,200 injuries per 100 million people...is extremely good actually. Like, almost unbelievably safe. And only a little above 100 of those are serious injuries, so most of that number is bruises and scrapes and the like.

I found a Newsweek article when looking up uses of that stat, and it lists "horrifying theme park tragedies". It maps them even. The map goes from mid-2024 to 1980, bc nothing says "widespread phenomenon that happens all the time" like having to go back forty-four years to find enough examples.

The examples of Horrifying Tragedies at these Unsafe Rides include:

Someone jumping a fence and entering a restricted area that was labeled as a restricted area. Actually, it includes five stories of people injured or killed when they entered a fenced-off area clearly labeled as dangerous and off-limits

People stuck on rides. This gets reported a lot as a terrifying malfunction & a sign the ride's not safe, but a ride stopping is a sign that the safety features are *working*, bc that's a failsafe in case something goes wrong. It's like crumple zones on cars: it may look scary, but the alternative is much, much worse

Injuries incurred when a guest's e-cig exploded on a ride

A death from a pre-existing heart condition. Actually, two

Someone who lost their balance on a ride bc of the actions of another guest

Someone who removed their own restraints on a ride and stood up while it was in motion

A few actual accidents caused by error, mostly at obscure parks and/or decades ago, before states had stricter regulations

Masterclass in framing: using several stories about people who were only injured when they knowingly tried breaking all the safety protocols to claim safety protocols don't work. Theme parks can't psychically detect if someone has an undiagnosed heart defect, how can anyone ever go to one again??? Oddly enough it doesn't include the number of people killed or injured driving to and from the parks, even though the number is surely higher, given there's over a million car accident deaths every year

29 notes

·

View notes

Note

I’m having really angsty thoughts about this now. I also have no clue if it’s canon. We are making AUs of our AUs at this point.

—

At first I was trying to think of how/why baby Sunrazor got into the pits and then I remembered that I made it so if any working model is seen as defective then they would be thrown into an arena to get rid of them.

So… Sunrazor is not the only sparkling in the pits.

The twins would know this. They would know that like all of the other sparklings sent in she’s here to die. And if she’s not killed by a gladiator or smth then it’s very possible that whatever’s wrong with her will. And if they figure out that she’s a guardian there’s an additional layer of she’s screwed because Guardians die fast in arenas.

(They can’t turn off their sensors. They can handle crowds when they are working and stuff. But an arena is built to amplify noise, it’s like that to get the gladiators worked up. The crowds in arenas are also typically violent enough that a gladiators threat detection would label them as people to keep an eye on. So if they aren’t overwhelmed upon being shoved out on the arena floor they are already beating expectations.

And then they don’t have stamina like gladiators do. They are stronger than gladiators and can take more of a beating than them. But if they aren’t able to finish the match within the first couple of minutes then they are dead. They were not built for gladiator matches at all.)

It would make sense for the twins to try and get Comet to leave her.

Sideswipe and Sunstreaker would definitely feel like they are in the right. They are protecting Comet from unnecessary pain. Gladiators don’t handle losing attachments well, I mean look at Dropmix. Theremin died and he had like a midlife crisis then proceeded to torture and disfigure people so he could get a shot at revenge.

If Comet gets attached and Sunrazor dies he could make stupid decisions and get himself killed. Or the twins killed. They are old enough to understand that now.

Don’t get attached to it. It’s going to die anyway.

So yeah… just some thoughts…. Nothing really important lol

Oh I love all of this!!!

It makes sense, it makes perfect sense. In my head Com just grabs her. Like split second snatches her up. The twins get word and they immediately go into threat mode.

That argument of "Its going to die anyway" is amazing. Them being scared for how it would affect Comet and maybe get them all killed is the direction I was kinda going but your idea definitely cements it.

The details of them getting rid of something defective, that is literally perfect for this how did I not remember. The idea of them just culling younglings, ugh that's horrible. But that would also make sense for poor comet when he gets thrown in. No one cares because things that look like literal children die in the arena all the time. That's why I made Sunny use "it" when talking about Sunrazor, he doesn't want to even acknowledge her as a living thing.

That does make me think of why Sunstreaker would decide to let Comet live, since he has so much blood on his hands already why would he hesitate??

I feel like that would be Comets argument, "I was on the slaughter block, you were my executioner! What makes me any different than them?!" Cue the twins trying to NOT think of Comet suffering before they could protect him.

Maybe their argument would be Comet had already survived and won one match, this kid wouldn't survive her first.

"Why would anyone have to EARN the right to live?!"

"Why do we have to gut and tear out sparks to live Com!?? Why are we monsters??! Life isn't fragging fair that's why."

UGH I love your thoughts, never hesitate to send them to me please.

Thought I may plop this sketch here for how Comet may look in this Au of an Au (I blame the worms for all this) He still looks funny but I thought you may be curious. (his tail is supposed to be sorta like what he had in his Base form, still a rough idea)

#concepts#Baby Sunrazor au#Gladiator Comet#just thoughts#COOL THOUGHTS THO#I love all of this#poor bunch#It does make me wonder about if Sunstreaker and Sideswipe ever had trouble being the executioners after they spared Com#hmmmm#This is so stupid but I kept referring to Comet's full grown design as his#“Im a married man” design#Like that one part of Epic the Musical#Im an idiot ignore me#Cool au name though#Horns and Razors?#meh#maybe

3 notes

·

View notes

Text

Physicists develop method to detect single-atom defects in semiconductors

One of the challenges of cramming smarter and more powerful electronics into ever-shrinking devices is developing the tools and techniques to analyze the materials that make them up with increasingly intimate precision. Physicists at Michigan State University have taken a long-awaited step on that front with an approach that combines high-resolution microscopy with ultrafast lasers. The technique, described in the journal Nature Photonics, enables researchers to spot misfit atoms in semiconductors with unparalleled precision. Semiconductor physics labels these atoms as "defects," which sounds negative, but they're usually added to materials on purpose and are critically important to the performance of semiconductors in today's—and tomorrow's—devices.

Read more.

#Materials Science#Science#Atoms#Semiconductors#Defects#Materials characterization#Microscopy#Lasers#Spectroscopy#Terahertz#Michigan State University

7 notes

·

View notes

Text

Industrial Cabineted X-ray Market Key Growth Drivers Fueling Expansion in the Global Systems Market

Industrial Cabineted X‑Ray Market Drivers

1. Surge in Non‑Destructive Testing (NDT)

One of the primary factors fueling the demand for industrial cabineted X‑ray systems is the escalating need for non‑destructive testing (NDT). Sectors like aerospace, automotive, electronics, and machinery heavily rely on precise inspection tools to ensure structural integrity and detect defects without damaging critical components. Cabineted X‑ray systems deliver high-resolution imaging, enabling the identification of flaws such as voids, inclusions, cracks, or assembly errors—essential for maintaining quality standards in high‑stakes industries.

Regulatory frameworks and industry standards increasingly mandate stringent quality control protocols. The ability of cabineted X‑ray systems to conduct detailed inspections while ensuring compliance with safety regulations makes them indispensable. Regulatory pressure — particularly in aerospace and pharmaceuticals — further amplifies their adoption.

2. Technological Advancements: Digital Imaging & AI Integration

Robust growth in digital radiography (DR) and computed tomography (CT) technologies has revolutionized X‑ray inspection. DR systems, equipped with advanced detectors and imaging software, significantly enhance image quality and operational efficiency. They offer faster acquisition, improved clarity, and decreased radiation exposure—advantages that are increasingly prioritized by industrial manufacturers.

Beyond DR, the advent of artificial intelligence (AI) and machine learning (ML) marks a transformative shift. These systems can automatically detect defects with high precision, reducing manual inspection errors. AI enhances throughput and consistency and can even predict maintenance needs to reduce system downtime.

3. Broadening Applications Across Industries

While traditional industrial sectors—electronics, aerospace, automotive—continue to drive demand, cabineted X‑ray systems are finding new use cases:

Electronics: Miniaturization in semiconductors and surface‑mount technology necessitates high-precision inspection to detect hidden defects in microcomponents.

Pharmaceuticals: X‑ray cabinets ensure tablet integrity, detect contaminants in packaging, and verify labeling accuracy—critical in compliance‑driven environments.

Food & Beverage: Safety concerns demand reliable contaminant detection (e.g., metal shards, glass, stones) in packaged foods; X‑ray systems provide non‑destructive inspection without opening containers.

Security & Logistics: Heightened global security demands have led to widespread use of cabineted X‑ray systems at airports, ports, customs, and government facilities to detect contraband and ensure safe shipments.

4. Safety and Regulatory Mandates

Strong regulatory emphasis on radiation safety is pushing organizations to adopt enclosed cabineted X‑ray solutions. These systems are equipped with shielding to protect personnel and comply with stringent international standards and certifications.

In sectors like pharmaceuticals, aerospace, and defense, thorough inspection is legally required to guarantee safety. Cabineted X‑ray systems offer the reliability and traceability needed to satisfy audits and certification bodies—making the technology a must-have in highly regulated environments.

5. Industry 4.0 & Automation Integration

The shift toward Industry 4.0-driven smart manufacturing favors X‑ray systems that integrate with automated production lines and IoT platforms. Automated conveyor-fed cabineted X‑ray systems provide real-time defect detection and feedback, enabling manufacturers to halt or adjust defective workflows instantly—minimizing waste and improving operational efficiency.

These systems not only detect issues but can also predict maintenance needs through embedded AI and analytics tools, reducing unplanned downtime and extending equipment life.

6. Portable, Compact, and Eco‑Friendly Solutions

Manufacturers are engineering more compact and mobile cabineted X‑ray units, ideal for on-site inspections—particularly in industries like construction, oil & gas, and field service operations.

Moreover, there is a growing emphasis on eco-friendly solutions. Advancements in energy-efficient emitters and green sourcing of components are aligning X‑ray systems with sustainability objectives—an increasing consideration for industrial buyers aiming to reduce carbon footprints.

7. Geographical Market Expansion

North America and Europe remain dominant players due to mature sectors and strict compliance regimes. Meanwhile, Asia‑Pacific—led by China and India—is rapidly catching up thanks to booming industrialization, stronger healthcare infrastructure, and heightened security concerns.

Initiatives like India’s “Make in India” are boosting domestic manufacturing quality standards, driving demand for advanced inspection technologies. Similarly, airport expansions, customs modernization, and healthcare upgrades across the Asia-Pacific region present substantial market opportunities.

Conclusion

The industrial cabineted X‑ray market is experiencing strong, sustained growth, fueled by several interrelated drivers:

A rising need for non‑destructive testing across critical industries

Breakthroughs in digital imaging, AI, and automation

Expanded applications in electronics, healthcare, food safety, and security

Regulatory pressures around quality control and radiation safety

Integration with Industry 4.0 protocols for smart manufacturing

Development of portable, energy‑efficient systems

Rapid industrial expansion in Asia‑Pacific

Together, these factors not only point to increasing adoption—but also signal that cabineted X‑ray technology is becoming integral to quality assurance, safety standards, and operational efficiency in modern manufacturing and inspection landscapes.

0 notes

Text

Testing and Quality Control in Wire Rope Production

In industries like construction, mining, elevators, shipping, and oil & gas, wire ropes are critical for lifting, pulling, and supporting heavy loads. Their strength and durability directly impact the safety and efficiency of operations. That’s why testing and quality control form the backbone of every reputable wire rope manufacturing process.

A rope that doesn’t meet the required quality standards can lead to serious accidents, equipment damage, and unexpected downtime. To avoid such risks, every step in the production of wire ropes is carefully monitored and tested to ensure the final product performs reliably in demanding environments.

Why Testing and Quality Control Matter in Wire Rope Manufacturing

Wire ropes must withstand constant stress, tension, bending, and twisting during their service life. Even the smallest flaw in manufacturing can cause the rope to fail when it matters most. For this reason, quality checks are built into every stage of wire rope manufacturing to ensure:

Strength and durability under load

Resistance to fatigue from repeated bending

Corrosion protection in harsh environments

Consistent performance across all products

A trusted wire rope manufacturer knows that compromising on these aspects can lead to safety hazards and costly failures in real-world applications.

Key Stages of Quality Control in Wire Rope Production

1. Raw Material Testing

Before any production begins, steel wires are checked for their chemical composition and mechanical properties. The steel used must meet strict standards to ensure the finished rope will be strong, flexible, and corrosion-resistant.

2. Wire Drawing Quality Checks

During wire drawing—the process that reduces steel rods to fine wires—the material is inspected for:

Diameter accuracy

Surface smoothness

Uniform tensile strength

These checks help prevent weaknesses that could develop into serious faults later in the rope's service life.

3. Stranding and Closing Inspections

The next stage involves twisting individual wires into strands and assembling those strands around a core. Throughout this process, the lay length, tension balance, and strand integrity are all carefully monitored.

A professional wire rope manufacturer ensures that these parameters are within specification so that the rope performs reliably without twisting or unraveling during use.

4. Visual and Dimensional Inspection

Finished ropes are inspected for:

Correct diameter and roundness

Surface cleanliness and freedom from defects like nicks or broken wires

These visual inspections catch issues that machines may overlook but can impact real-world performance.

5. Mechanical Performance Testing

Some ropes undergo rigorous mechanical testing to verify:

Breaking load capacity

Bending fatigue resistance

Torsional strength

These destructive tests help confirm that the design and manufacturing processes have produced ropes that meet the required safety and durability standards.

6. Non-Destructive Testing (NDT)

Non-destructive methods like magnetic particle inspection and ultrasonic testing are used to detect internal flaws without damaging the rope. This allows for full inspection of production batches without wasting usable product.

7. Lubrication and Corrosion Resistance Checks

Wire ropes are treated with lubricants during manufacturing to reduce friction and protect against corrosion. Quality control teams check that these coatings are evenly applied and meet environmental protection standards.

8. Packaging and Final Inspection

Before ropes are shipped out, they undergo final checks to ensure proper labeling, documentation, and safe packaging for transport. Any deviation in these final steps can compromise the rope's integrity before it even reaches the customer.

Choosing the Right Wire Rope Manufacturer Matters

All these testing and quality control processes underline one important fact: wire rope manufacturing is as much about precision and safety as it is about production volume. When you select a dependable wire rope manufacturer, you are choosing a partner that prioritizes:

Consistent product quality

Compliance with international standards

Long-lasting performance

Safety for your equipment and workforce

Never compromise when it comes to wire ropes—the right manufacturer will ensure every product meets the highest expectations.

Conclusion

Wire ropes are silent workhorses in countless industries, and their failure is not an option. Testing and quality control in wire rope manufacturing are crucial to guarantee that these essential components can handle the stresses and conditions they will face.

Whether your need is for lifting, pulling, or support, always source products from a reliable wire rope manufacturer committed to thorough testing and uncompromising quality standards. Your project’s safety and success depend on it.

0 notes

Text

Food Testing and Certification Market to Reach USD 28 B by 2034

The Food Testing and Certification Market ensures food safety from farm to table covering chemical, microbiological, allergen, and authenticity testing. As of 2024, this market held an estimated value of USD 11.05 billion and is forecast to reach USD 28.4 billion by 2034 at a CAGR of around 10.4%. Key regional leaders include North America and Asia-Pacific. Blockchain, AI, and certification standards like ISO 22000, FSSC 22000, HACCP, and GLOBALG.A.P are reshaping market dynamics.

To Get Sample Report: https://www.datamintelligence.com/download-sample/food-testing-and-certification-market

Market Drivers & Growth Opportunities

Stringent Regulations & Standards Governments worldwide, including the US FDA, EU bodies, and Japanese regulators, are enforcing tougher food safety regulations and requiring accredited levels of testing and adherence to standards like ISO 22000 and FSSC 22000.

Consumer Confidence & Traceability Consumers increasingly demand transparency on food origin, production methods, allergen safety, and ethical claims (organic, non-GMO, halal). Blockchain-enabled traceability is gaining ground.

Frequent Foodborne Outbreaks High-profile contamination incidents have led to sudden spikes in testing demand, particularly in high-regulation markets like the US and Japan.

Rapid Testing Tech Methods like PCR, immunoassays, and biosensors are gaining traction for faster, on-site results. Japan is investing 5–6% annually in PCR-based and rapid diagnostics.

Digital & AI-Enabled Inspection AI and IoT systems are enhancing real-time monitoring and predictive risk analysis, especially in Japan’s high-tech food industry.

Rise in Certification Types Demand is growing for global and specialty certifications such as ISO 22000, GLOBALG.A.P, FSSC 22000, halal, kosher, and clean-label certifications. ISO 22000 certification is present at over 51,000 global sites.

Regional Market Insights

United States

North America remains the largest market, with strong investment in food safety labs and certification bodies like NSF and AOAC. Recent suspension of milk quality proficiency testing by the FDA has spurred demand for third-party testing and accreditation.

Japan

The food safety testing market in Japan was approximately USD 945 million in 2024, expected to grow at 5.8% to USD 1.61 billion by 2033. Drivers include frequent foodborne incidents, known cases of pesticide and GMO contamination, strict MHLW regulations, and adoption of PCR and immunoassays.

Asia-Pacific

Projected growth at over 8.6% CAGR through 2027. China and India lead volume growth, while Japan emphasizes digital integration, rapid assays, and robust certification infrastructure.

Europe

Driven by strong regulatory alignment with FSSC 22000, HACCP, and GLOBALG.A.P, Europe supports high certification penetration across its food supply chains.

Industry Trends

Digital Traceability Solutions Blockchain integration for end-to-end traceability in supply chains is accelerating adoption, especially in premium and export-driven markets.

AI and IoT Monitoring High-income markets like Japan are investing in AI and IoT-based food quality monitoring and defect detection.

Remote Digital Audits Post-pandemic digital audit capabilities reduce delays and costs in certification processes.

Private-Sector Certification Growth Certification programs from AOAC, NSF, GLOBALG.A.P, and others remain crucial in food safety assurance beyond mandatory regulation.

Challenges

Rising Costs High costs of advanced testing, AI deployment, and ISO accreditation affect small and medium enterprises.

Regulatory Fragmentation Varying standards across regions create complexity in global trade for food exporters.

Skill and Infrastructure Gaps Emerging markets lack access to advanced testing laboratories and qualified personnel, limiting capacity.

Strategic Opportunities

Expand Rapid Testing Platforms Deploy portable and PCR-based kits across emerging and export markets.

Enable Digital Certification Ecosystems Promote blockchain-QC integration in high-value exports (dairy, meat, produce).

Support SME Accreditation Offer scalable, cost-effective ISO 22000 and ISO 17025 lab programs for small processors.

Target Specialty Certifications Capitalize on certifications like halal, non-GMO, and allergen-free in niche consumer markets.

Leverage Tech Partnerships Collaborate with AI and IoT vendors to develop real-time compliance tools.

Outlook & Conclusion

The food testing and certification market is forecast to nearly triple to USD 28.4 billion by 2034, driven by stringent regulations, rising consumer expectations, and digital technology adoption. The United States leads due to advanced infrastructure, while Japan and Asia-Pacific showcase rapid growth fueled by testing investments and traceability enforcement. Market leaders who pivot toward digital innovation, scalable certifications, and emerging-market solutions will gain a competitive edge in ensuring global food safety and consumer confidence.

0 notes

Text

Necessary Guide to Phlebotomy Tubes: Types, Uses, and Tips for Safe Blood Collection

essential Guide to Phlebotomy Tubes: Types,Uses,and Tips for Safe Blood Collection

if you’re involved in healthcare,laboratory testing,or training in phlebotomy,understanding the different types of blood collection tubes is essential. Phlebotomy tubes are specialized devices designed to safely and efficiently collect blood samples for diagnostic testing. This comprehensive guide delves into the various types of phlebotomy tubes, their specific uses, best practices for safe blood collection, and practical tips to ensure accurate results and patient safety.

Introduction to Phlebotomy Tubes

Blood collection tubes are pivotal in diagnostic laboratories worldwide. They maintain sample integrity from collection through transportation and analysis. The right tube choice depends on the tests required, sample stability, and safety considerations. This article aims to equip healthcare professionals, students, and laboratory staff with in-depth knowledge about the different types of phlebotomy tubes, their uses, and safety protocols.

Types of Phlebotomy Tubes

1. Serum Tubes

Serum tubes are used to collect blood samples for tests requiring serum, such as hormone counts, serology, and blood chemistry. These tubes typically have a clot activator to facilitate clotting and may contain a rubber stopper or screw cap.

2. Plasma Tubes

Plasma tubes are designed to preserve plasma, the liquid component of blood minus the cells. They contain anticoagulants such as EDTA,citrate,or heparin to prevent clotting.plasma is used for tests like coagulation profiles and blood gases.

3. EDTA Tubes

These tubes contain Ethylenediaminetetraacetic acid (EDTA) as the anticoagulant. They are commonly used in hematology testing, such as complete blood counts (CBC) and blood smears.

4. Citrate Tubes

Citrate tubes contain sodium citrate, which binds calcium to prevent clotting. They’re primarily used in coagulation tests like prothrombin time (PT) and activated partial thromboplastin time (aPTT).

5. heparin Tubes

Heparin tubes include lithium or sodium heparin and are used when plasma is required for chemistry and blood gas analysis.

6. Special Purpose Tubes

Glucose Tubes: Contain additives to prevent glycolysis, preserving glucose levels.

Blood Culture Bottles: Designed for microbiological tests to detect infections.

SPS Tubes: Contains sodium polyanethol sulfonate for blood culture and DNA testing.

Uses of Phlebotomy Tubes

Tube Type

Common Uses

Serum Tubes

Serology, chemistry panels, immunology tests

Plasma Tubes

Coagulation testing, blood gases

EDTA Tubes

Hematology, blood smears

Citrate Tubes

Clotting factor analysis

heparin Tubes

Electrolyte panel, blood gases

Special Purpose Tubes

Diagnostic microbiology, glucose testing

Safety Tips for Blood Collection

1. Proper Patient Identification

Always verify patient identity against request forms to prevent sample mix-up. Use two identifiers such as name and date of birth.

2. Use Appropriate PPE

Wear gloves, masks, and protective eyewear to protect against blood-borne pathogens and prevent contamination.

3. Correct Tube Handling

gently invert the tube instantly after collection to mix additives thoroughly.

Do not force the stopper open; use proper puncture techniques.

Check tubes for cracks or defects prior to use.

4. Safe Disposal

Dispose of sharps in puncture-proof containers immediately after use. follow local protocols for biohazard waste disposal.

5. Labeling and Documentation

Label samples accurately with patient details, date, and time of collection before leaving the bedside or drawing area.

Practical Tips for Effective Blood Collection

ensure the patient is well-positioned and relaxed to facilitate easier blood flow.

Use a tourniquet judiciously-no longer than a minute to prevent hemoconcentration.

Select the appropriate vein-preferably the median cubital vein for minimal discomfort.

Choose the correct tube based on the test requirements and additive compatibility.

Allow tubes to clot or anticoagulate appropriately before processing.

benefits of Using Correctly Selected Phlebotomy Tubes

Sample integrity: Ensures accurate test results.

Patient safety: Minimizes risk of hemolysis, contamination, or injury.

Efficiency: Reduces repeat draws and delays.

Case Study: Improving Blood Collection Safety in a Busy Clinic

At a major outpatient clinic, implementing standardized phlebotomy protocols and staff training on tube selection and safety measures resulted in a 30% reduction in sample rejections and improved patient satisfaction. Proper use of specific blood collection tubes and adherence to safety tips played a crucial role in achieving these results.

First-Hand Experience: My Journey in Blood Collection

During my training as a phlebotomist, I learned firsthand the importance of matching the right tube to the test, maintaining strict safety standards, and handling samples with care. These practices not only improve test accuracy but also build trust with patients, making the blood collection process smoother and safer.

Conclusion

Choosing the right phlebotomy tubes, understanding their specific uses, and following safety protocols are vital components of accomplished blood collection. Whether you’re a seasoned healthcare professional or a student in training, mastering these essentials ensures reliable test results and optimal patient care.Remember, safety and accuracy go hand-in-hand in phlebotomy, and the right tools are your best allies in delivering high-quality healthcare services.

https://phlebotomytrainingcenter.net/necessary-guide-to-phlebotomy-tubes-types-uses-and-tips-for-safe-blood-collection/

0 notes

Text

Your Partner in Protection: Choosing the Right Fire Safety Equipment Company in Singapore

In Singapore, where safety standards for building are some of the highest in the world, fire hydrant pressure testing is fundamental to being fire ready. Not only is it good business to ensure your fire hydrants are operating properly—it is the law. So where do you begin? That is where a respectable fire safety equipment company in Singapore can help.

In this guide, we’ll explore the when, why, and how of hydrant pressure testing, and how choosing the right fire safety equipment company in Singapore can make all the difference. Why Fire Hydrant Pressure Testing Matters It can appear good on the surface, but it is not a guarantee that it will be functional when required. A Singapore fire equipment company realizes that there can be built-in faults, low pressure, or stuck valves which would have catastrophic effects in case of an emergency.

Testing serves the following purposes: 1.Ensures SCDF compliance: SCDF requires periodic testing of fire protective equipment such as hydrants. 2.Saves lives and assets: Working hydrants may serve as the initial defense in extinguishing a fire before it starts to spread. 3.Averts insurance problems: Claims will be disapproved if, after an accident, a defective fire system is discovered. 4.Saves long-term expenses: Fault detection at an early stage avoids costly repairs in the future.

That is why property owners and facility managers usually require a fire safety equipment company in Singapore to perform yearly pressure testing and maintain systems at optimum working conditions.

When to Perform Fire Hydrant Pressure Testing A reliable fire safety equipment company in Singapore normally suggests the following schedule:

Yearly (Minimum SCDF requirement) Upon new installation or extensive repairs Pre-SCDF inspection When water supply systems are upgraded or altered

By engaging with an experienced provider like Drako Fire, you’ll receive timely reminders and scheduled maintenance to stay compliant year-round. How Is Fire Hydrant Pressure Testing Carried Out? While it may seem like a simple task, hydrant pressure testing requires specialized equipment and trained personnel. A certified fire safety equipment company in Singapore will follow a strict testing procedure to ensure all components are functioning optimally.

The standard process includes: 1.Site Preparation Clearing the operating space surrounding the hydrant. Community stakeholders are alerted to prevent interference. 2.Pressure and Flow Measurement A calibrated pressure gauge and flow meter are fitted by technicians. Static pressure, residual pressure, and flow rate in liters per minute are noted. 3.Functional Testing Valves, nozzles, and hoses are tested for leakage, corrosion, or clogging. The hydrant is fully tested to identify any mechanical malfunction. 4.Reporting and Documentation They provide a complete report, highlighting pressure levels, flow rates, and any maintenance that needs to be done. That is for SCDF audits.

I you have them done by a certified fire safety equipment company in Singapore, you also have the bonus of certified reports and being sure that all is fine.

Common Issues That Are Often Found During Testing Trained professionals of a fire safety equipment firm in Singapore typically detect problems like:

Aging pipes with weak water pressure Damaged or rusted valves Clogged outlets Truncated or illegible hydrant labels Unauthorized obstructions

Early detection prevents emergency breakdowns and full system operability. Why Hire a Fire Safety Equipment Firm in Singapore? Many building owners and business firms would wonder: "Can't our maintenance crew simply inspect the hydrants?" The answer is no—not adequately. It is only a certified fire protection equipment firm in Singapore that possesses the tools, expertise, and training to inspect hydrants completely and to SCDF standards.

Firms such as Drako Fire provide turnkey services, from testing and reporting to repair and equipment enhancement. Having specialists on call not just guarantees safety but also makes compliance easier, which is worrying without professional assistance.

Such a reputable fire safety equipment company in Singapore would also advise the replacement of aged hydrants when replacement is due or suggest upgrades for improved performance, particularly in older buildings. Conclusion Hydrant pressure testing is not only a technical necessity—it's a matter of safety. With Singapore's cities as densely populated as they are and its stringent fire codes, you have zero margin for error.

With the professional services of a well-established fire safety equipment company in Singapore, your fire hydrant system is always on standby and ready. From year-round maintenance to SCDF inspection preparation, companies like Drako Fire can do it all for you so you have one less thing on your plate.

In need of hydrant pressure testing support? Call Drako Fire—your go-to Singapore fire safety equipment expert—for expert service and complete compliance.

0 notes

Text

Customizing Blister Pack Inspection Systems for Niche Pharmaceutical Applications

In today’s pharmaceutical landscape, manufacturing is no longer a one-size-fits-all operation. The growing complexity of drug formulations, delivery methods, and regulatory expectations has given rise to specialized or niche pharmaceutical products. These include personalized medicine, biologics, orphan drugs, pediatric formulations, and high-potency medications. Each of these categories presents unique packaging and quality control challenges, especially when it comes to inspection. As a result, the need for customizing blister pack inspection systems to meet these niche requirements is more critical than ever.

Understanding the Diversity of Niche Pharmaceutical Applications

Niche pharmaceutical products differ significantly from conventional drug formats in terms of:

Dosage forms and sizes (e.g., mini tablets, soft gels, powders)

Blister pack geometries (e.g., irregular cavities, non-standard layouts)

Special handling needs (e.g., temperature-sensitive or light-sensitive compounds)

Small batch production for personalized or low-volume drugs

These variations make standard inspection systems less effective, and sometimes incompatible. A customized approach is necessary to maintain both product quality and regulatory compliance.

Key Customization Requirements for Blister Pack Inspection Systems

1. Adaptability to Unique Blister Formats

Standard blister pack inspection systems are calibrated for common cavity sizes and layouts. However, niche applications may use unusual pack configurations to accommodate:

Multi-compartment designs (e.g., drug + diluent)

Circular, oval, or irregular cavity shapes

Custom perforation lines and peelable seals

Customizing the vision system’s field of view, lighting angles, and software mapping tools ensures accurate detection of defects across all cavity types and orientations.

2. Inspection of Unconventional Dosage Forms

In personalized and pediatric medicines, manufacturers often use mini tablets, micro-tablets, granules, or films. These forms differ significantly in appearance and behavior from standard pills or capsules. Customized blister pack inspection systems must be trained to detect subtle variances in:

Color and texture

Uniformity and fill level

Shape and size tolerances

Advanced vision algorithms powered by AI can be tailored to recognize the acceptable range of variation for these niche forms, reducing false positives.

3. Low Volume, High-Mix Production Compatibility

Niche pharmaceuticals often involve short production runs and frequent product changeovers. An inspection system must be flexible enough to:

Reconfigure quickly between different blister formats

Store multiple product profiles in the software interface

Allow operators to make swift adjustments without technical intervention

Custom user interfaces, recipe libraries, and modular hardware design enable the system to support agile, small-batch operations.

4. Support for Sensitive or Hazardous Materials

Certain medications require stringent containment due to their potency or sensitivity. These include cytotoxic drugs, vaccines, and biologics. A customized blister pack inspection system should:

Operate in cleanroom or isolator environments

Incorporate non-intrusive inspection techniques (e.g., contactless vision, sealed camera housings)

Use materials and enclosures compatible with decontamination procedures

Tailoring these aspects ensures the system does not interfere with containment protocols or product integrity.

5. Multilingual and Region-Specific Label Verification

Some niche pharmaceuticals are distributed in multiple regions with unique regulatory labeling standards. Blister pack lidding often contains localized languages, artwork, or compliance marks. Customized OCR (optical character recognition) and pattern-matching capabilities allow inspection systems to:

Validate language-specific batch info and expiry dates

Verify localized regulatory logos and codes

Detect incorrect or missing country-specific labeling

This ensures regulatory alignment and prevents costly recalls due to labeling errors.

The Role of Advanced Technologies in Customization

Artificial Intelligence and Machine Learning

AI-powered inspection systems can be trained on a dataset of acceptable and defective samples, even for rare or novel drug forms. They continually improve accuracy over time, making them ideal for low-volume, high-complexity production.

3D and Hyperspectral Imaging

For inspecting depth variations, fill volumes, and material properties in complex blister formats, 3D vision and hyperspectral imaging offer additional layers of analysis. These can detect inconsistencies not visible to traditional 2D vision.

Cloud Integration and Remote Monitoring

For companies managing niche drug production across multiple facilities or CMOs (Contract Manufacturing Organizations), customized systems can include:

Cloud-based inspection data storage

Real-time monitoring dashboards

Remote troubleshooting capabilities

This ensures centralized quality oversight across decentralized production environments.

Benefits of Customizing Blister Pack Inspection Systems

Increased accuracy and lower false rejection rates

Compliance with niche product regulations (e.g., FDA, EMA, PMDA)

Reduced downtime during changeovers

Enhanced operator usability and training

Improved patient safety and brand reputation

Ultimately, customized systems reduce operational risks and improve ROI by aligning quality control with the unique requirements of specialized pharmaceutical lines.

Collaborating with the Right Inspection Partner

When customizing a blister pack inspection system, manufacturers should seek partners with:

Experience in niche pharmaceutical applications

Engineering flexibility to adapt hardware and software

In-depth understanding of industry-specific compliance

Strong after-sales support for maintenance and upgrades

Close collaboration between the packaging line team, quality assurance, and system providers ensures that the final solution meets operational, regulatory, and technical needs.

Conclusion

As the pharmaceutical industry continues to diversify, the demand for tailored quality assurance solutions grows in parallel. Customizing a blister pack inspection system for niche pharmaceutical applications is no longer optional—it is essential to maintaining integrity, compliance, and competitive edge in a specialized market.

With the right technology and a partner-focused approach, manufacturers can deploy inspection systems that are as specialized as the products they protect, ensuring every blister pack meets the highest standards of safety and accuracy.

0 notes

Text

Colour Detection Sensor Market Drivers: Key Factors Shaping Future Industry Growth and Adoption

The colour detection sensor market is witnessing significant growth due to a combination of technological advancements and increasing demand across various industries. These sensors, designed to detect and measure the intensity and wavelength of colours in an environment, play a critical role in enhancing automation, quality control, and user experience. Understanding the key market drivers helps stakeholders, manufacturers, and investors gauge the future trajectory and capitalize on emerging opportunities.

Rising Demand from Consumer Electronics Industry

One of the primary drivers propelling the colour detection sensor market is the booming consumer electronics sector. Smartphones, tablets, cameras, and wearable devices increasingly integrate colour detection sensors to improve display calibration, image capturing quality, and ambient light detection. These sensors enable devices to automatically adjust screen brightness and colour tone for optimal visual experience. Additionally, their use in digital cameras and photo printers ensures colour accuracy, appealing to photography enthusiasts and professionals alike. As consumer preferences evolve towards smarter and more intuitive devices, the reliance on colour sensors continues to grow substantially.

Expansion in Automotive Applications

The automotive industry is another significant contributor to the rising adoption of colour detection sensors. Modern vehicles utilize these sensors for various functions, including driver assistance systems, environmental sensing, and interior lighting control. For example, sensors can detect traffic signal colours or lane markings to support autonomous driving features and safety mechanisms. Furthermore, colour sensors in automotive interiors can adjust ambient lighting to enhance driver comfort and aesthetics. With the push towards electric and autonomous vehicles, demand for advanced sensor technologies like colour detection sensors is expected to escalate, boosting market growth.

Increasing Automation in Manufacturing and Quality Control

Manufacturing industries are increasingly automating their processes to improve efficiency, reduce errors, and maintain consistent product quality. Colour detection sensors play a vital role in automated inspection and sorting systems by accurately identifying product colours, detecting defects, and ensuring correct assembly. For example, in packaging lines, these sensors verify the presence and correct positioning of labels and barcodes based on colour differentiation. Similarly, in textile and food industries, they help in sorting products by colour shades, ensuring quality and compliance with standards. The rising adoption of Industry 4.0 and smart factory concepts further drives demand for such sensors in automated quality control systems.

Growing Healthcare and Medical Applications

Healthcare is an emerging sector witnessing increasing integration of colour detection sensors. These sensors aid in medical diagnostics, monitoring, and research by detecting colour changes in biological samples or test strips. For instance, in blood analysis and urine testing, sensors help in identifying abnormalities by measuring colour variations, allowing rapid and non-invasive diagnosis. Additionally, colour sensors are used in wearable health devices to monitor vital signs such as oxygen saturation through skin colour detection. As the healthcare industry focuses on improving diagnostic accuracy and patient monitoring, the demand for colour detection sensors is poised to grow.

Advancements in Sensor Technology

Technological innovation is a key driver enhancing the capabilities and reducing the costs of colour detection sensors. Improvements in sensor accuracy, sensitivity, and miniaturization enable integration into compact and portable devices. The development of multi-spectral and RGB sensors capable of detecting a broad range of wavelengths expands their application scope. Furthermore, integration with IoT and AI technologies allows real-time data processing and predictive analytics, making colour sensors smarter and more versatile. Continuous R&D efforts ensure better performance, lower power consumption, and enhanced durability, attracting various industries to adopt these sensors.

Increasing Adoption in Environmental Monitoring

Environmental monitoring and smart agriculture sectors increasingly rely on colour detection sensors for monitoring soil health, water quality, and crop conditions. By detecting colour changes in leaves or water samples, these sensors help identify nutrient deficiencies, pest infestations, or contamination. This information supports precision farming techniques that optimize resource usage and improve yield. Additionally, colour sensors contribute to air quality monitoring systems by detecting pollutants or particulate matter colours. Growing global awareness of environmental sustainability and demand for smart solutions in agriculture fuel the adoption of colour detection technologies.

Government Regulations and Standards

Government initiatives focused on enhancing product safety, environmental protection, and smart infrastructure development also drive the colour detection sensor market. Regulatory mandates for quality control in manufacturing, automotive safety standards, and healthcare device approvals encourage the use of accurate and reliable sensor systems. Incentives and funding for technology innovation further support market growth by enabling manufacturers to develop advanced colour detection solutions. Compliance requirements often necessitate sophisticated sensor integration, prompting industries to adopt these technologies to meet global standards.

Increasing Focus on Energy Efficiency and Cost Reduction

The pressure to reduce operational costs and enhance energy efficiency motivates industries to adopt colour detection sensors. Automated detection and sorting reduce manual labour, minimize waste, and improve resource management. Colour sensors help optimize lighting systems in smart buildings and vehicles by adjusting brightness and colour temperature based on ambient conditions, leading to energy savings. Additionally, their use in industrial processes ensures minimal material wastage and higher productivity. These economic benefits drive companies to invest in advanced sensor solutions, propelling the market forward.

Conclusion

The colour detection sensor market is propelled by multiple drivers, including the expanding consumer electronics and automotive industries, growing automation in manufacturing, and rising applications in healthcare and environmental monitoring. Advances in sensor technology, government regulations, and a focus on energy efficiency further accelerate growth. As industries continue to embrace smart technologies and automation, the demand for precise and efficient colour detection sensors will remain robust, shaping the future of this dynamic market.

0 notes

Text

The Hidden Risks of Ignoring Flip-Off Cap Inspection in Pharma Packaging

In pharmaceutical manufacturing, every detail counts — from sterile filling to labeling. But one component often overlooked is the flip-off cap that seals injectable vials. It’s small, yes — but the consequences of not inspecting it are anything but.

Let’s talk about why ignoring flip-off seal inspection is a risk no modern pharma brand should take, and how Optomech’s FOSIS system brings precision, automation, and peace of mind to the process.

🧨 The Problem: Small Defects, Big Consequences

You may think a cap is just a cap. But even minor defects in flip-off seals can cause:

Regulatory failures during batch audits

Sterility breaches in transit or storage

Patient safety risks due to contaminated vials

Brand reputation damage from recalls or customer complaints

Typical issues include:

Black spots

Short filling of the PP button

Cut or dented aluminum shells

Color mismatches

Improper or missing plastic caps

Now imagine these defects slipping through manual or random inspections. That’s a compliance risk pharma companies can no longer afford.

✅ The Solution: Meet FOSIS – Flip-Off Seal Inspection System

FOSIS is Optomech’s high-speed, camera-based vision inspection system — purpose-built to scan, detect, and reject defective flip-off caps with unmatched accuracy.

🎯 Key Features at a Glance:

Speed: Inspects up to 600 caps/min

Vision Accuracy: Detects 20+ types of defects

Automation: No manual checking, no guesswork

Rejection System: Faulty caps are auto-ejected instantly

Compliance: Fully 21 CFR Part 11 compliant

🧠 How It Works:

Caps are fed into the system via a vibratory bowl.

High-speed cameras capture images from multiple angles.

Advanced algorithms compare each cap to a defect-free reference.

Defective caps are rejected, and logs are generated.

Reports can be exported via Excel/network sharing.

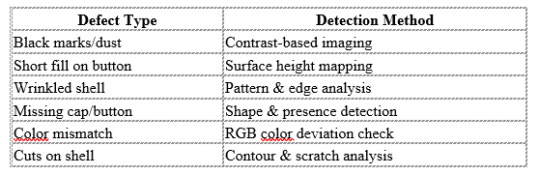

📊 Defects Detected by FOSIS:

🏭 Who Needs FOSIS?

FOSIS is ideal for:

Pharmaceutical manufacturers of injectable drugs

CMOs (Contract Manufacturing Organizations)

Flip-off cap producers

Companies targeting zero-defect packaging

Whether you're building a new packaging line or upgrading your existing setup, FOSIS integrates seamlessly and boosts inspection reliability from day one.

🔒 Why Flip-Off Cap Inspection Can’t Be Optional Anymore

In today’s regulated pharma landscape:

Quality audits are stricter

Sterility concerns are growing

Brand protection is non-negotiable

FOSIS isn't just a machine — it's your frontline quality gate. It helps you catch defects before regulators or customers do.

🏁 Final Takeaway: Inspection Is No Longer Optional — It's Strategic

Flip-off seal inspection may be a “last step” in the process, but with FOSIS, it becomes a first-class safeguard for your production integrity. Speed, accuracy, compliance — all in one automated system.

📞 Want to see FOSIS in action or schedule a demo? 📧 [email protected] 🌐 www.optomech.in/flipoff-inspection-system-2

#flipoffsealinspection#pharmapackaging#capdefectdetection#machinevisionqc#21cfrcompliant#injectablepackaging#optomechinspection#capinspectionmachine#visualinspectionpharma#zeroDefectPackaging

0 notes

Text

Machine Vision for Defect Detection in Production Lines

In today’s competitive manufacturing landscape, ensuring product quality is paramount. Defects on production lines not only reduce efficiency but also damage brand reputation and increase costs. This is where Machine vision technology steps in as a game-changer, offering automated, precise, and real-time defect detection.

What is Machine Vision?

Machine vision refers to the use of cameras, sensors, and software to automate visual inspection tasks that traditionally relied on human inspection. Unlike human eyes, machine vision systems provide consistent accuracy, speed, and the ability to work in harsh industrial environments without fatigue. These systems analyze images captured from production lines to detect anomalies and defects effectively.

The Role of Machine Vision in Defect Detection

Defect detection on production lines is critical for maintaining high standards and minimizing waste. Machine vision systems capture detailed images of products as they move along the production line. These images are then processed through advanced algorithms designed to identify defects such as scratches, cracks, missing parts, discolorations, and misalignments.

By integrating machine vision, manufacturers can detect defects early in the production process, reducing the cost and time associated with manual inspections or rework. This proactive approach helps to maintain consistent product quality and enhances overall operational efficiency.

Benefits of Using Machine Vision for Defect Detection

Implementing machine vision in defect detection offers several advantages:

Accuracy: Machine vision systems provide highly accurate defect detection, reducing false positives and negatives.

Speed: Unlike human inspectors, machine vision can analyze products at high speeds, matching the pace of modern production lines.

Consistency: The system performs consistently without being affected by fatigue or distractions, ensuring reliable quality control.

Cost Efficiency:��Early defect detection prevents costly recalls and reduces scrap and rework.

Data Collection: Machine vision systems collect valuable data on defect patterns, which can be used for process improvement.

Key Technologies Behind Machine Vision

Several technologies power effective machine vision systems for defect detection:

High-Resolution Cameras: Capture detailed images to identify minute defects.

Lighting Systems: Proper lighting enhances image quality and highlights defects.

Image Processing Software: Uses algorithms like edge detection, pattern recognition, and artificial intelligence to analyze images.

3D Vision: Some advanced systems use 3D imaging to detect surface defects and dimensional inaccuracies.

Deep Learning: Modern machine vision increasingly incorporates AI and deep learning to improve defect recognition accuracy over time.

Applications of Machine Vision in Production Lines

Across industries, machine vision is transforming defect detection processes:

Electronics Manufacturing: Detecting soldering defects, missing components, and surface scratches.

Automotive Industry: Inspecting parts and assemblies for cracks, dents, or alignment issues.

Food and Beverage: Ensuring packaging integrity, label accuracy, and product consistency.

Pharmaceuticals: Verifying packaging and labeling for safety and compliance.

Textile Production: Identifying weaving errors, color variations, and fabric defects.

Challenges and Future Trends in Machine Vision

While machine vision is highly effective, challenges such as varying lighting conditions, reflective surfaces, and complex defect patterns remain. However, advances in AI, better sensors, and improved lighting techniques continue to enhance the reliability and adaptability of machine vision systems.

Looking ahead, the integration of machine vision with IoT (Internet of Things) and Industry 4.0 frameworks will allow smarter production lines with predictive maintenance and real-time quality analytics. This evolution will empower manufacturers to achieve near-zero defect rates, maximizing productivity and quality.

Why Choose Sciotex for Your Machine Vision Needs?

At Sciotex, we specialize in cutting-edge machine vision solutions tailored for defect detection in production lines. Our expertise ensures seamless integration of the latest technologies to meet your specific manufacturing challenges. Whether you need high-speed inspection or complex defect analysis, our machine vision systems deliver precision, reliability, and scalability.

0 notes

Text

AI Vision System for Smarter, Safer Supply Chain Management

Supply chains today face unprecedented challenges: tighter delivery windows, increased demand for transparency, and rising labor costs. In this high-pressure environment, visibility is key—and that’s precisely what an AI Vision System delivers.

What Is an AI Vision System?

An AI vision system uses computer vision and machine learning to interpret real-time visual data. In supply chain management, this means tracking inventory, monitoring warehouse activity, and optimizing workflows using intelligent camera systems.

Unlike traditional surveillance, Vision AI actively understands what it sees—identifying inefficiencies, risks, or bottlenecks before they impact your bottom line.

Applications of Vision AI Solutions in the Supply Chain

🔹 Smart Inventory Management Vision AI tracks product movement throughout warehouses, reducing errors and ensuring real-time inventory updates. This means fewer stockouts and better order accuracy.

🔹 Automated Package Verification Ensure that every package is labeled, sealed, and shipped correctly. Vision AI systems scan for barcode errors, incorrect weights, or missing items without slowing down fulfillment.

🔹 Loading Dock Efficiency AI monitors loading zones to improve truck turnaround time, prevent accidents, and detect potential workflow delays—enhancing overall productivity.

🔹 Worker Safety & Compliance Cameras equipped with AI can detect if workers are wearing proper safety gear, entering restricted areas, or operating machinery unsafely. Alerts are triggered in real time to prevent workplace accidents.

Why Supply Chains Are Turning to Vision AI

Traditional supply chains depend heavily on human oversight. But human error and fatigue can cause costly disruptions. By deploying Vision AI Solutions, businesses can:

✅ Increase transparency and accuracy ✅ Automate repetitive quality checks ✅ Reduce loss, theft, and damage ✅ Improve workforce safety and compliance

In a world where speed and precision are critical, Vision AI becomes your 24/7 digital operations partner.

Vision AI Solutions for Manufacturing and Logistics

While supply chains are a major application, the same AI-driven vision technology powers Vision AI Solutions for Manufacturing—ensuring consistent product quality and safety from production to packaging.

This end-to-end visibility creates a seamless data ecosystem where all departments—from manufacturing to delivery—operate in sync.

The InovarTech Advantage

At InovarTech, we provide customized AI vision systems for logistics, warehousing, and manufacturing. Our scalable solutions integrate with your existing infrastructure and grow with your business.

We assist you in maintaining operational excellence, from defect detection to smart logistics automation.

Final Thoughts

In an increasingly complex supply chain environment, the need for intelligent, real-time monitoring is no longer optional—it’s essential. Vision AI Solutions give you the eyes and intelligence to operate faster, safer, and smarter.

Let’s connect and discuss how Vision AI can optimize your supply chain today.

0 notes

Text

The Role of Apparel Testing Labs in Boosting Ajman’s Textile Exports | +971 554747210

Ajman, one of the fastest-growing industrial hubs in the UAE, has witnessed significant growth in its textile and garment manufacturing sector over the past decade. As global demand for quality apparel increases, local manufacturers and exporters must meet stringent international standards to remain competitive. This is where the role of an Apparel Testing Lab becomes indispensable.

Apparel testing labs in Ajman play a critical role in maintaining quality, ensuring compliance, and enhancing the global reputation of the region’s textile industry. From verifying fabric durability to testing for harmful substances, these labs are essential for the success of Ajman’s textile exports.

Why Apparel Testing is Essential for Export Success

When exporting garments to international markets such as Europe, the USA, and Asia, compliance with various standards is non-negotiable. Buyers expect garments to be safe, durable, and manufactured with ethical practices. Apparel testing ensures that each product aligns with these expectations.

Here’s how a reliable Apparel Testing Lab supports exporters in Ajman:

1. Compliance with International Standards

Markets like the EU and the US have strict regulations concerning apparel imports. These include:

REACH Regulation (EU): Restricts the use of harmful chemicals

OEKO-TEX® Certification: Verifies textiles are free from harmful substances

ASTM & ISO Standards: Cover everything from fabric strength to colorfastness

Ajman-based Apparel Testing Labs ensure garments are tested according to these standards before they are shipped abroad, reducing the risk of rejection or recalls.

2. Ensuring Product Quality and Durability

International buyers and retailers prioritize quality. A single defective batch can harm a brand's reputation and lead to costly returns. Apparel testing labs assess:

Shrinkage and dimensional stability

Colorfastness to washing, light, and rubbing

Tensile and tear strength

Seam slippage and stitching quality

By identifying potential issues early, manufacturers can rectify problems before mass production or export, protecting their reputation in global markets.

3. Chemical Safety and Consumer Health

Apparel that comes into direct contact with skin must be free from harmful chemicals such as:

Formaldehyde

Azo dyes

Heavy metals (lead, mercury, cadmium)

Flame retardants

An Apparel Testing Lab in Ajman can detect these substances and certify garments as safe for consumer use, an essential requirement for exports to countries with strict chemical safety laws.

4. Support for Eco-Friendly and Sustainable Exports

Sustainability is a growing priority among global consumers and retailers. Many buyers demand certifications like GOTS (Global Organic Textile Standard) or OEKO-TEX®. Testing labs assist exporters by:

Verifying eco-friendly dyes and materials

Testing biodegradable or recycled fabrics

Supporting compliance with sustainable production standards

By meeting these standards, Ajman’s textile exporters can appeal to environmentally conscious markets.

Key Services Offered by Apparel Testing Labs in Ajman

Ajman’s apparel testing facilities are equipped to perform a wide range of assessments, including:

Physical testing: Tensile strength, abrasion resistance, pilling

Colorfastness testing: To washing, perspiration, light, and rubbing

Chemical testing: pH level, presence of heavy metals, formaldehyde

Flammability testing: Especially for children’s clothing and workwear

Label and packaging compliance: Ensuring correct labeling for export destinations

These services ensure each shipment aligns with the technical and legal requirements of the importing country.

Building Global Trust with Reliable Test Reports

One of the biggest challenges for exporters is building trust with international buyers. A verified third-party test report from a certified Apparel Testing Lab acts as a mark of reliability. Labs that are ISO/IEC 17025 accredited ensure that test results are:

Accurate and reproducible

Conducted under standardized conditions

Recognized internationally

This documentation becomes a critical asset during quality audits or customs inspections in the importing country.

Economic Impact on Ajman’s Textile Sector

The growth of Apparel Testing Labs in Ajman has had a direct impact on the region’s textile industry. Here’s how:

Increased Export Volumes: With better compliance, Ajman’s garment exporters face fewer rejections at borders, leading to higher successful shipments.

Market Expansion: Certified garments can be sold in more countries, opening up opportunities in high-value markets.

Investor Confidence: International buyers are more likely to partner with manufacturers who follow stringent quality assurance protocols supported by testing labs.

Job Creation and Innovation: Labs drive the adoption of new fabric technologies and sustainable practices, creating jobs in quality control, testing, and compliance.

Choosing the Right Apparel Testing Lab in Ajman

Not all testing labs offer the same level of service. When selecting a lab, exporters should consider:

Accreditation: Look for ISO/IEC 17025 certified labs

Service Portfolio: Ensure they provide both physical and chemical testing

Turnaround Time: Fast reporting is critical for tight production schedules

Expertise: Labs with textile engineers and experienced chemists deliver better insights

Customer Support: A dedicated support team helps interpret test results and ensure compliance

Ajman is home to several reputable testing labs that cater to the needs of small, medium, and large-scale garment exporters. Partnering with the right lab can be a game-changer in maintaining quality and achieving global market access.

Future Outlook: Testing Labs as Innovation Hubs

The role of Apparel Testing Labs in Ajman is evolving. They are not just quality control centers—they are becoming innovation partners. Many are now helping manufacturers:

Develop new, high-performance fabrics

Test smart textiles and wearable tech

Explore sustainable dyeing and finishing processes

Comply with emerging global standards such as circularity and carbon neutrality

By aligning with these innovation trends, Ajman’s textile sector is well-positioned to remain competitive and forward-thinking.

Final Thoughts

As Ajman positions itself as a leading textile exporter in the region, the importance of Apparel Testing Labs cannot be overstated. These labs ensure that garments are not only compliant and safe but also meet the high expectations of global consumers.

From facilitating compliance and improving product quality to enhancing brand reputation and market access, apparel testing labs are the backbone of Ajman’s textile export success. By investing in reliable testing services, manufacturers can future-proof their businesses and confidently explore new opportunities on the global stage.

0 notes

Text

Automatic Filling Line: A Game-Changer for High-Precision Manufacturing

Introduction

An automatic filling line is a cutting-edge manufacturing solution, designed to streamline packaging operations, enhance accuracy, and improve production efficiency. By automating filling, sealing, and labeling processes, businesses can boost output, minimize waste, and maintain high-quality standards. Used across industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals, automatic filling lines ensure cost-effective, reliable, and scalable production.

Why Manufacturers Choose Automatic Filling Line Systems

The integration of an automatic filling line in production facilities offers significant benefits:

High-Speed Operation – Increases product throughput while ensuring precise filling measurements.

Enhanced Accuracy & Consistency – Reduces variation and human error for uniform product quality.

Versatile Product Handling – Suitable for liquids, powders, gels, granules, and pastes.

Labor Cost Reduction – Minimizes manual intervention, optimizing efficiency and cost savings.

Compliance with Hygiene Standards – Maintains strict sanitary conditions, essential for food and pharmaceutical manufacturing.

Key Features to Consider in an Automatic Filling Line

1. Advanced Filling Technology

Opt for systems with volumetric, piston, or gravity-based filling mechanisms to achieve optimal precision.

2. Customizable Packaging Solutions

Choose equipment that supports multiple container sizes, materials, and shapes, ensuring flexibility for different product types.

3. Integrated Quality Control Measures

Ensure the system includes automated sensors and inspection capabilities for defect detection.

4. Multi-Product Compatibility

Select machinery capable of handling viscous, granular, liquid, or powdered substances, meeting diverse industry requirements.

5. Regulatory Compliance

Partner with suppliers that adhere to global industrial safety and hygiene standards, ensuring certified production quality.

Industries & Applications for Automatic Filling Lines

Food & Beverage Processing – Efficient bottling, canning, and pouch-filling for juices, dairy, condiments, and sauces.

Pharmaceutical & Healthcare Manufacturing – Ensures accurate dosage control for medicines, syrups, and medical formulations.

Cosmetic & Personal Care Industry – Automates packaging for shampoos, lotions, skincare, and beauty products.

Chemical & Industrial Production – Facilitates precise filling of lubricants, adhesives, and cleaning solutions.

Why Investing in an Automatic Filling Line is Crucial for Business Growth

As demand rises for efficient, high-speed, and precision-based manufacturing, integrating an automatic filling line ensures optimized output, reduced overhead costs, and long-term scalability.

Conclusion

An automatic filling line is an essential asset for modern manufacturers, offering speed, accuracy, and efficiency. Whether applied in food processing, pharmaceuticals, cosmetics, or industrial packaging, automatic filling lines enable seamless production, improved consistency, and increased profitability.

0 notes