Don't wanna be here? Send us removal request.

Text

Hdpe container manufacturer | Regentplast

Regentplast stands as a premier HDPE container manufacturer, dedicated to crafting top-quality packaging solutions that epitomize durability, reliability, and innovation. As a leading player in the industry, Regentplast excels in the design and production of High-Density Polyethylene (HDPE) containers, offering a diverse range of packaging solutions tailored to meet the stringent needs of various industries.

Read More-

#packaging#manufacturing#sustainability#hdpebottles#environment#plastic#recycling#eco friendly#lifestyle

0 notes

Text

Packaging bottle manufacturers | Regentplast

Regentplast, a leading name in the realm of packaging bottle manufacturers, stands out as a premier choice for businesses seeking top-notch packaging solutions. With a commitment to innovation and quality, Regentplast specializes in crafting cutting-edge packaging bottles that cater to diverse industry needs.Regentplast's packaging bottles are not just containers; they are a testament to precision engineering, durability, and aesthetic appeal. The company's diverse range of bottles caters to various sectors, including food and beverages, pharmaceuticals, cosmetics, and more.

Read More-

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#plastic#eco friendly#lifestyle

0 notes

Text

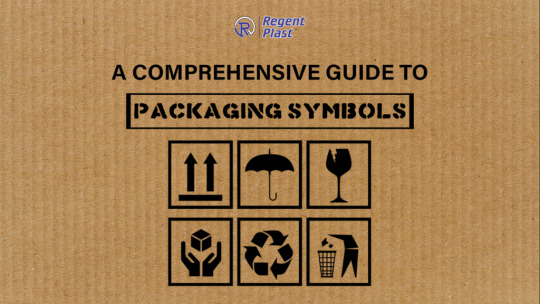

A Comprehensive Guide to Packaging Symbols: Global Standards Every Designer and Exporter Must Know

Introduction: Navigating the Maze of Packaging Symbols

In the global packaging industry, one small symbol can carry immense weight. Whether it’s a mark indicating recyclability, handling instructions, or international compliance, packaging symbols speak a universal language — if you know how to read them. Yet for many packaging designers and import/export professionals, deciphering these icons is a recurring challenge. Misinterpreting even one symbol can lead to customs delays, regulatory penalties, or customer dissatisfaction.

This comprehensive guide by Regent Plast is tailored to help packaging designers, brand teams, and exporters better understand and utilize packaging symbols. With a focus on global standards, we’ll walk you through the most common and critical symbols, their meanings, and how to apply them correctly — so your packaging communicates safety, compliance, and professionalism across borders.

What Are Packaging Symbols and Why Do They Matter?

Packaging symbols are standardised graphical indicators placed on product packaging to convey specific information such as storage conditions, material composition, environmental responsibility, or handling precautions. These symbols transcend language barriers and help streamline international shipping, protect consumers, and ensure proper disposal.

Why they’re important:

Regulatory compliance: Incorrect or missing symbols can result in fines or rejected shipments.

Consumer trust: Recognised symbols communicate quality and safety.

Sustainability transparency: Green symbols convey eco-conscious practices.

Operational efficiency: Handling and safety symbols prevent mishandling during transport.

Categories of Packaging Symbols

To make it easier for professionals to navigate, packaging symbols can be broadly categorised:

1. Handling and Safety Symbols

Used extensively in logistics and warehousing, these symbols instruct how the product should be stored and transported.

Fragile — Handle with Care: A broken glass icon indicating delicate contents.

This Way Up: Arrows showing the correct upright position.

Keep Dry: An umbrella with rain shows moisture-sensitive items.

Do Not Stack: Indicates the box should not have weight placed on top.

These symbols are especially vital for bulk exporters, ensuring that couriers and freight handlers treat packages appropriately, reducing damage and claims.

2. Hazard Symbols

Required on packaging for chemicals, pharmaceuticals, and flammable products.

GHS (Globally Harmonised System) symbols, such as:

Explosive

Flammable

Toxic

Corrosive

Environmental Hazard

These symbols are mandated by international regulatory bodies and are essential for businesses exporting to countries that follow GHS guidelines.

3. Recyclability and Environmental Symbols

In a sustainability-driven market, these symbols have become just as critical as handling icons.

Mobius Loop (Recycling symbol): Indicates the item is recyclable.

Green Dot: Signifies the manufacturer contributes to a recycling program (popular in Europe).

FSC (Forest Stewardship Council): Used on paper-based packaging to indicate responsible sourcing.

Biodegradable or Compostable Marks: Highlight eco-friendly disposal options.

For manufacturers like Regent Plast, which promote responsible plastic use, using these symbols accurately reflects a commitment to sustainability.

4. Material Identification Codes

To ensure proper recycling, packaging often includes plastic resin codes or other material IDs.

Plastic Codes (#1 to #7): Indicates the type of plastic, such as PET, HDPE, LDPE, PP, etc.

Alu (Aluminum): Common for metal-based packaging.

GL (Glass): Indicates that the product is packaged in glass.

Correct labeling not only helps recyclers but also informs businesses and consumers about the packaging’s environmental impact. For example, Regent Plast is offering HDPE Bottles and Containers with #2 HDPE recycle sign, made of out of Post Consumer Recycled Plastics

5. Legal and Certification Marks

Certain markets require packages to display compliance with standards or certifications.

CE Mark: Required for many products sold within the European Economic Area.

RoHS: Indicates restricted use of hazardous substances in electronics packaging.

UL (Underwriters Laboratories): Used for safety certification in North America.

ISO Marks: Indicate international quality or safety standards.

Failing to include these symbols can prevent products from entering international markets.

READ MORE- https://regentplast.com/a-comprehensive-guide-to-packaging-symbols-global-standards-every-designer-and-exporter-must-know/

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#plastic#eco friendly#lifestyle#Business

0 notes

Text

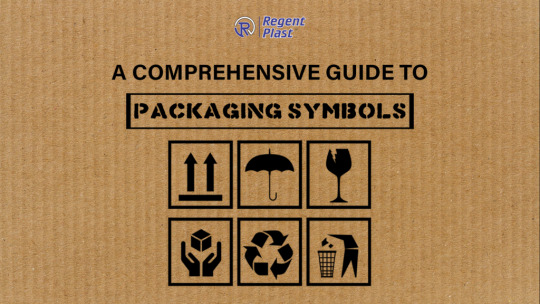

A Comprehensive Guide to Packaging Symbols: Global Standards Every Designer and Exporter Must Know

Introduction: Navigating the Maze of Packaging Symbols

In the global packaging industry, one small symbol can carry immense weight. Whether it’s a mark indicating recyclability, handling instructions, or international compliance, packaging symbols speak a universal language — if you know how to read them. Yet for many packaging designers and import/export professionals, deciphering these icons is a recurring challenge. Misinterpreting even one symbol can lead to customs delays, regulatory penalties, or customer dissatisfaction.

This comprehensive guide by Regent Plast is tailored to help packaging designers, brand teams, and exporters better understand and utilize packaging symbols. With a focus on global standards, we’ll walk you through the most common and critical symbols, their meanings, and how to apply them correctly — so your packaging communicates safety, compliance, and professionalism across borders.

What Are Packaging Symbols and Why Do They Matter?

Packaging symbols are standardised graphical indicators placed on product packaging to convey specific information such as storage conditions, material composition, environmental responsibility, or handling precautions. These symbols transcend language barriers and help streamline international shipping, protect consumers, and ensure proper disposal.

Why they’re important:

Regulatory compliance: Incorrect or missing symbols can result in fines or rejected shipments.

Consumer trust: Recognised symbols communicate quality and safety.

Sustainability transparency: Green symbols convey eco-conscious practices.

Operational efficiency: Handling and safety symbols prevent mishandling during transport.

Categories of Packaging Symbols

To make it easier for professionals to navigate, packaging symbols can be broadly categorised:

1. Handling and Safety Symbols

Used extensively in logistics and warehousing, these symbols instruct how the product should be stored and transported.

Fragile — Handle with Care: A broken glass icon indicating delicate contents.

This Way Up: Arrows showing the correct upright position.

Keep Dry: An umbrella with rain shows moisture-sensitive items.

Do Not Stack: Indicates the box should not have weight placed on top.

These symbols are especially vital for bulk exporters, ensuring that couriers and freight handlers treat packages appropriately, reducing damage and claims.

2. Hazard Symbols

Required on packaging for chemicals, pharmaceuticals, and flammable products.

GHS (Globally Harmonised System) symbols, such as:

Explosive

Flammable

Toxic

Corrosive

Environmental Hazard

These symbols are mandated by international regulatory bodies and are essential for businesses exporting to countries that follow GHS guidelines.

3. Recyclability and Environmental Symbols

In a sustainability-driven market, these symbols have become just as critical as handling icons.

Mobius Loop (Recycling symbol): Indicates the item is recyclable.

Green Dot: Signifies the manufacturer contributes to a recycling program (popular in Europe).

FSC (Forest Stewardship Council): Used on paper-based packaging to indicate responsible sourcing.

Biodegradable or Compostable Marks: Highlight eco-friendly disposal options.

For manufacturers like Regent Plast, which promote responsible plastic use, using these symbols accurately reflects a commitment to sustainability.

4. Material Identification Codes

To ensure proper recycling, packaging often includes plastic resin codes or other material IDs.

Plastic Codes (#1 to #7): Indicates the type of plastic, such as PET, HDPE, LDPE, PP, etc.

Alu (Aluminum): Common for metal-based packaging.

GL (Glass): Indicates that the product is packaged in glass.

Correct labeling not only helps recyclers but also informs businesses and consumers about the packaging’s environmental impact. For example, Regent Plast is offering HDPE Bottles and Containers with #2 HDPE recycle sign, made of out of Post Consumer Recycled Plastics

5. Legal and Certification Marks

Certain markets require packages to display compliance with standards or certifications.

CE Mark: Required for many products sold within the European Economic Area.

RoHS: Indicates restricted use of hazardous substances in electronics packaging.

UL (Underwriters Laboratories): Used for safety certification in North America.

ISO Marks: Indicate international quality or safety standards.

Failing to include these symbols can prevent products from entering international markets.

READ MORE- https://regentplast.com/a-comprehensive-guide-to-packaging-symbols-global-standards-every-designer-and-exporter-must-know/

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#plastic#eco friendly#lifestyle

0 notes

Text

Plastic Bottle Manufacturer - Regentplast

RegentPlast stands as a premier plastic bottle manufacturer, dedicated to crafting innovative packaging solutions for diverse industries worldwide. With a relentless commitment to quality, sustainability, and customer satisfaction, we specialize in producing a wide range of plastic bottles tailored to meet the unique needs of our clients. From concept to creation, we collaborate closely with our clients to develop custom-designed bottles that perfectly align with their branding, product specifications, and sustainability goals.At RegentPlast, we prioritize environmental responsibility, striving to minimize our ecological footprint at every stage of the manufacturing process.

Read More-

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#plastic#eco friendly#lifestyle

0 notes

Text

Why Regent Plast Can Play a Key Role in Your Sustainability Efforts

In a world increasingly driven by environmental awareness and regulatory pressures, companies are actively seeking sustainable packaging partners who can deliver both performance and compliance. Regent Plast, a leading manufacturer of HDPE bottles and containers, stands at the forefront of this transition with a steadfast commitment to innovation, recycled material integration, and circular economy practices. If your brand is looking to reduce its carbon footprint while maintaining product integrity, Regent Plast can be the key partner in your sustainability journey.

1. Championing Recycled HDPE Packaging

At the heart of Regent Plast’s sustainability drive is its ability to incorporate post-consumer recycled (PCR) HDPE into high-performance packaging. Using advanced multi-layer extrusion blow moulding, Regent Plast manufactures containers with a recycled core and virgin outer layers, ensuring barrier protection, durability, and aesthetic quality. This method allows companies to reduce virgin plastic usage without compromising packaging standards.

Benefits of using recycled HDPE with Regent Plast:

Reduction in carbon emissions

Lower reliance on fossil-fuel-based virgin materials

Compliance with local and international environmental regulations

2. Regulatory Compliance Made Simple

India’s Plastic Waste Management (PWM) Rules and Extended Producer Responsibility (EPR) framework have placed significant responsibility on manufacturers and brands to integrate recycled materials and manage post-consumer waste. Regent Plast actively aligns with these mandates, including the directive requiring 30% recycled plastic usage in specific packaging from 1st of April 2025.

What you get with Regent Plast:

Ready-to-deploy packaging compliant with PWM and EPR guidelines

Documentation and reporting support for regulatory submissions

Sustainable product solutions tailored to industry needs

3. Advanced Manufacturing for Eco-Efficient Packaging

Regent Plast partners with recyclers having next-gen recycling technologies, including:

Mechanical recycling: Cleaned and reprocessed HDPE for non-food applications

Chemical recycling: Advanced purification methods that enable food-grade recycled HDPE

We have invested in Multi-layer technology: PCR-rich inner and/or middle layers surrounded by virgin resin for safety and compliance.

The result? Packaging that performs like virgin plastic but supports circular economy goals.

4. Supporting the Circular Economy

Every bottle Regent Plast manufactures with PCR content diverts waste from landfills, reduces greenhouse gas emissions, and extends the lifecycle of plastic materials. By collaborating with certified recycling partners, Regent Plast ensures a traceable, ethical, and reliable PCR supply chain.

Impact at a glance:

Lower environmental footprint

Reduction in plastic waste leakage

Enhanced brand perception with eco-conscious consumers

5. Custom Sustainability Solutions for Every Industry

Whether you’re in pharmaceuticals, personal care, household cleaning, or agrochemicals, Regent Plast offers custom bottle and jar designs that align with your brand identity and sustainability goals. From wide-neck HDPE jars to child-resistant caps and detergent bottles with measuring caps — each product can be optimized for PCR usage and design efficiency.

Applications include:

Pharma-grade containers with tamper-evident seals

Nutraceutical jars have wide mouth openings for easy access, and flip top cap dispensers for tablets.

Liquid detergent bottles with integrated PCR for eco-friendly shelf appeal, and spout dispensers with calibrated measuring cups.

Motor Oil/ Automotive Lubricants/ Engine Oil Bottles from 100 ml to 5 Ltr in volume in a 3-layer structure, restricting PCR/ Recycled plastics in the middle layer. Hence, the external visual appeal/ colour shades of the bottles is preserved and the inner quality of the oil is preserved, as it does not come into direct contact with recycled plastics. Many of our customers, such as Valvoline, HPCL, and Apar Industries, have started the procurement of lubricant bottles and containers with PCR.

READ MORE- https://regentplast.com/why-regent-plast-can-play-a-key-role-in-your-sustainability-efforts/

0 notes

Text

Hdpe 1 litre Plastic Bottle manufacturers | Regentplast

RegentPlast stands out as a premier manufacturer specializing in HDPE 1-liter plastic bottles. With an unwavering commitment to quality and innovation, RegentPlast has established itself as a leader in the industry. Our HDPE 1-liter plastic bottles are crafted with precision and care, reflecting our dedication to delivering products of the highest standard.As a trusted name in the market, RegentPlast's HDPE 1-liter plastic bottles offer durability, reliability, and versatility. These bottles are meticulously manufactured using state-of-the-art technology and premium-grade materials, ensuring a robust and resilient packaging solution for a variety of liquids.

Read More-

0 notes

Text

Why India Is Your Next Best Source After China for Sourcing Custom Plastic Packaging

For decades, China has been the go-to manufacturing hub for global businesses sourcing plastic packaging — from PP Caps, HDPE bottles to industrial jerry cans. Its scale, infrastructure, and low costs made it nearly irreplaceable. But in recent years, a growing number of packaging designers and import-export professionals have been forced to rethink this dependence on the Asian Dragon.

The Cracks in the China-Only Strategy

Ongoing geopolitical instability, rising raw material and labor costs, and sudden supply chain disruptions — from port delays to policy shifts — have exposed the fragility of sourcing solely from China. For companies dealing with high-demand, regulation-sensitive products like liquid chemicals, pharmaceuticals, cosmetics, and nutraceuticals, such disruptions can be costly and reputation-damaging.

In today’s market, brands can’t afford to wait or compromise on delays and/or policy shifts by solely relying on one or more suppliers in a singular geography.

As procurement strategies evolve, a critical question arises: Where else can you find scalable, customizable, and globally compliant plastic packaging solutions without the volatility?

India: The Emerging Alternative You Can Trust

India is fast becoming the next best source for custom plastic packaging. A blend of competitive manufacturing costs, improving infrastructure, and a skilled workforce makes India well-positioned to step into the gap.

But beyond just cost, India offers something even more strategic — dependability with customisation.

Whether it’s:

5-litre HDPE jerry cans designed for liquid chemicals

Shampoo bottles and cream jars with sleek designs and export-ready standards

Engine oil and coolant containers built for industrial robustness

Pharmaceutical-grade HDPE bottles and tablet jars with US DMF certification

Nutraceutical jars, ink bottles, flip-top caps and closures built to spec

India is now delivering packaging solutions that meet — and often exceed — global benchmarks.

READ MORE- https://regentplast.com/why-india-is-your-next-best-source-after-china-for-sourcing-custom-plastic-packaging/

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#plastic#eco friendly#lifestyle

0 notes

Text

Reagent Bottle exporter - Regentplast

Regentplast stands as a distinguished Reagent Bottle exporter, delivering unparalleled quality and precision to meet the diverse needs of laboratories and scientific institutions worldwide. As a trusted supplier, Regentplast ensures that each Reagent Bottle embodies excellence, combining cutting-edge technology with superior materials to guarantee optimal performance and reliability.Our Reagent Bottle export range is crafted with meticulous attention to detail, adhering to the highest industry standards.

Read More-

0 notes

Text

Hdpe wide neck jar manufacturer - Regentplast

Regentplast, a leading manufacturer, specializes in the production of high-quality HDPE wide neck jars. Renowned for its commitment to excellence, Regentplast excels in crafting durable and versatile containers that meet the highest industry standards. As a trusted HDPE wide neck jar manufacturer, the company leverages cutting-edge technology and a meticulous manufacturing process to ensure precision and consistency in every product.

#packaging#sustainability#manufacturing#hdpebottles#environment#recycling#plastic#eco friendly#lifestyle

0 notes

Text

Detergent containers manufacturer - Regentplast

RegentPlast, a leading player in the industry, stands out as a premier detergent containers manufacturer, dedicated to delivering top-notch packaging solutions. With an unwavering commitment to quality and innovation,we produce a diverse range of detergent containers that meet the highest industry standards.As a trusted manufacturer, RegentPlast employs cutting-edge technology and advanced production processes to create durable and functional detergent containers.

Read More-

0 notes

Text

Sustainable Packaging Explained: Benefits & Solutions by Regent Plast

Packaging plays a vital role in protecting products and delivering them efficiently to consumers. However, the same packaging, especially when made from conventional plastics, has become a leading contributor to global pollution. Landfills are filling up. Oceans are choking on waste. And consumers are becoming increasingly aware of the environmental impact of their purchasing decisions.

Yet amidst this challenge, there’s a growing demand for change. Businesses are searching for smarter packaging solutions that are not only functional but environmentally responsible. This is where sustainable packaging comes into the spotlight — and companies like Regent Plast are leading the way in redefining what’s possible.

What is Sustainable Packaging?

Sustainable packaging refers to packaging solutions that have a minimal environmental footprint across their lifecycle — from sourcing and production to use and disposal. It typically involves:

Using recyclable or biodegradable materials

Reducing energy and water consumption in manufacturing

Designing for reuse or minimal waste

Supporting circular economy principles

For manufacturers, it’s not just about “going green” — it’s about creating efficient, cost-effective solutions that meet consumer expectations and comply with emerging global regulations.

Why HDPE is Part of the Solution

High-Density Polyethylene (HDPE) is one of the most widely used plastics in the packaging world. It’s lightweight, strong, and — importantly — recyclable. When managed responsibly, HDPE can be part of a sustainable packaging ecosystem, especially when combined with forward-thinking manufacturing practices.

Regent Plast: Pioneering Sustainability in HDPE Packaging

As a trusted HDPE plastic manufacturing company, Regent Plast is not only producing high-quality packaging solutions but also taking concrete steps toward sustainability. Here’s how:

1. Incorporating Recycled HDPE into Production

Regent Plast has invested in technology and processes to integrate recycled HDPE (rHDPE) into its product lines. This helps reduce the demand for virgin plastic while supporting the circular use of materials — turning yesterday’s waste into tomorrow’s packaging.

2. Designing for Reusability and Recycling

From flip-top caps to shampoo bottles and chemical containers, Regent Plast designs products that are easy to clean, reuse, and recycle. Their packaging solutions are compatible with existing recycling systems, helping end users dispose of them responsibly.

3. Optimizing Material Use

Through intelligent product design and lightweighting techniques, Regent Plast reduces the amount of raw material needed without compromising strength or durability. This cuts down carbon emissions during manufacturing and shipping.

4. Energy-Efficient Manufacturing

By upgrading to energy-efficient machinery and optimizing operational workflows, Regent Plast has significantly reduced its energy consumption by executing a captive roof top solar plant in its Umbergaon facility. This contributes to lower greenhouse gas emissions and aligns with global sustainability targets.

5. Compliance with Environmental Standards

Regent Plast adheres to national and international environmental standards, ensuring that its processes are environmentally sound and safe. This commitment strengthens its credibility as a responsible manufacturer in the plastic packaging industry. We are already working with our esteemed customers such as Apar Industries, Valvoline Cummins and Hindustan Petroleum Corp Ltd (HPCL) to supply Engine Oil bottles with 30% PCR as per Indian Plastic Waste Management Act Rules wef the 1st of April 2025.

Discover Our Sustainable Products

At Regent Plast, sustainability is built into every product we manufacture. Explore our diverse and eco-conscious range:

HDPE Bottles and Jerry Cans — Durable and 100% recyclable, ideal for industrial and household applications

1 Ltr Bottles & 5 Liter Jerry Cans for Chemicals & Agro-chemicals/ Pesticides — Designed for safe transport and storage of liquid chemicals

Specialized Containers for Liquid Chemicals — Engineered for performance and environmental responsibility

Shampoo Bottles and Cream Jars — Sleek, sustainable, and customizable to your brand’s needs

Engine Oil Containers and Coolant Bottles — Tough, leak-proof, and recyclable

Pharmaceutical Bottles, Tablet Jars, Caps and Closures — US DMF Certified packaging for sensitive applications

Nutraceutical Jars — Clean, secure packaging that meets health industry standards

Flip Top Caps — Reusable and recyclable dispensing solutions

Ink Bottles — Lightweight and eco-friendly for high-volume commercial use

Liquid Detergent Bottles — Easy to pour bottles either in 100% PCR or with 30% to 50% PCR (Post Consumer Recycled) HDPE Content

Whether you’re in personal care, pharmaceuticals, industrial chemicals, or nutraceuticals, we offer packaging solutions that combine sustainability, safety, and style.

READ MORE- https://regentplast.com/sustainable-packaging-explained-benefits-solutions-by-regent-plast/

#ecofriendly#environment#lifestyle#sustainability#packaging#sustainable packaging#sustainable living#Hdpe bottles

0 notes

Text

Why is India’s Cosmetic Packaging Market Growing?

1. India’s Expanding Consumer Base

India’s population surpassing 1.4 billion, with a rapidly growing middle-class segment, is a major driver of the cosmetic industry’s expansion. Urbanization and increasing disposable incomes have significantly altered consumer behaviour, leading to heightened demand for https://regentplast.com/cosmetics-beauty/.

Consumers now seek premium, sustainable, and aesthetically appealing packaging, making it crucial for brands to invest in high-quality cosmetic containers that align with their brand ethos. This shift has fueled the demand for innovative packaging solutions such as Regent Plast’s premium shampoo bottles and cream jars.

Explore Our Shampoo Bottles — Designed for durability and style, our shampoo bottles are available in various sizes, shapes, and closure options, ensuring a perfect fit for different haircare products.

Discover Our Cream Jars — Crafted for skincare formulations, our cream jars provide secure, airtight storage while offering an elegant look for premium cosmetic brands.

2. Influence of Beauty and Personal Care Trends

The beauty and personal care industry in India has undergone a significant transformation, with an increasing emphasis on skincare, organic beauty, and gender-neutral products. The men’s grooming segment has also witnessed exponential growth, with an increasing number of brands catering to male skincare and haircare needs.

Additionally, the influence of beauty influencers, social media, and online product reviews has further propelled the demand for attractive and functional cosmetic packaging. A product’s packaging design, finish, and tactile experience now play a crucial role in shaping consumer perceptions and purchasing decisions.

Regent Plast offers soft-touch HDPE bottles, which provide a luxurious, velvety feel that enhances user experience while maintaining durability.

Read Our Blog on Soft-Touch HDPE Bottles — Learn how this premium finish is revolutionizing the personal care industry.

3. Shift Towards Sustainable and Premium Packaging

With increasing environmental awareness, eco-friendly packaging solutions are now a top priority for both brands and consumers. Companies are seeking packaging that aligns with sustainability goals while maintaining a premium appeal.

Regent Plast’s diamond-finish and soft-touch packaging solutions are designed to offer a sleek, high-end look and a luxurious user experience. These finishes cater to brands looking to differentiate themselves in the competitive beauty and personal care market.

Explore Our Diamond-Finish Packaging — Perfect for brands looking for a luxury-feel, ultra-premium packaging solution.

4. E-commerce and Retail Boom in India

The rise of online beauty shopping has further increased the importance of secure and visually appealing packaging. Unlike traditional retail, where consumers can physically examine products, online shoppers rely heavily on product images and packaging design.

In this scenario, packaging needs to be: Leak-proof and durable — to withstand shipping Visually appealing — to attract online buyers User-friendly and functional

Regent Plast’s liquid detergent bottles are designed for both e-commerce and retail environments, ensuring convenience and efficiency in dispensing liquids.

Check Out Our Liquid Detergent Bottles — Built for easy handling, these bottles offer spill-proof caps and ergonomic designs for a seamless user experience.In 2025, we are introducing pourer spout with measuring cup and induction seal wad to arrest leakage in transit and e-commerce channels.

READ MORE- https://regentplast.com/why-is-indias-cosmetic-packaging-market-growing/

#packaging#manufacturing#sustainability#Beauty#Lifestyle#Makeup#Packaging#Cosmetic packaging#Skincare

0 notes

Text

Projected Growth of the Indian Packaging Industry and Its Implications for HDPE Manufacturers

The Indian packaging industry is experiencing remarkable growth, driven by rapid urbanization, evolving consumer preferences, and a booming e-commerce sector. As the industry expands, the demand for high-quality, durable, and sustainable packaging solutions is at an all-time high.

Regent Plast, a leading manufacturer of HDPE plastic bottles and containers, is at the forefront of this transformation. With a legacy of innovation and excellence, Regent Plast provides customized packaging solutions for industries including pharmaceuticals, chemicals, personal care, and food & beverages. The company’s commitment to superior quality, sustainable production, and cutting-edge technology has made it one of the most trusted names in the industry. By adhering to stringent international quality standards and continually innovating its product line, Regent Plast ensures that businesses receive the best packaging solutions tailored to their needs.

With the Indian packaging industry poised for exponential growth, it is essential to understand the market dynamics and how companies like Regent Plast can leverage this opportunity to drive success.

Current Market Size and Growth Projections

The Indian packaging market is currently valued at USD 71.90 billion and is expected to reach USD 130 billion by 2028, reflecting an impressive Compound Annual Growth Rate (CAGR) of 12.60% from 2023 to 2028. This robust expansion highlights the increasing importance of packaging across industries and its role in ensuring product safety, enhancing brand appeal, and meeting regulatory standards.

This substantial growth presents significant opportunities for packaging manufacturers, particularly those specializing in high-quality and sustainable materials like HDPE. As consumer preferences shift towards recyclable and eco-friendly packaging, manufacturers must adapt to meet the growing demand while maintaining cost-effectiveness and efficiency.

Factors Driving Growth in the Packaging Industry

Several factors contribute to the rapid expansion of the Indian packaging industry. Understanding these drivers can help businesses align their strategies to capitalize on emerging opportunities.

1. Economic Expansion

India’s economic growth fuels the increasing demand for packaging. With a projected GDP growth rate of 6.2% between FY 2023 and FY 2028, industries such as pharmaceuticals, personal care, and food & beverage will see a surge in packaging requirements.

2. Urbanization and Lifestyle Changes

As more people migrate to urban areas, there is an increasing preference for packaged and convenience products. Ready-to-eat foods, personal care products, and pharmaceuticals all require advanced packaging solutions to cater to this growing demand.

3. E-commerce Boom

With the expansion of online shopping, packaging plays a crucial role in product protection and customer satisfaction. E-commerce platforms require durable, tamper-proof, and aesthetically appealing packaging to enhance the consumer experience and reduce damage during transit.

Segment-Specific Insights

The Indian packaging industry comprises several sub-segments, each witnessing substantial growth.

Flexible Packaging

Market value in FY 2023: INR 823.92 billion

Expected to reach INR 1,726.18 billion by FY 2028

Driven by rising demand in food, beverages, and pharmaceuticals

Food Packaging

Estimated at INR 2,515.84 billion in 2022

Projected to reach INR 5,225.76 billion by 2028

Growing consumer preference for packaged food products propels this expansion

Sustainable Packaging

Expected to grow from 5.46 million metric tonnes in 2022 to 8.22 million metric tonnes by 2028

Increasing demand for eco-friendly and biodegradable materials encourages manufacturers to shift towards sustainable packaging solutions

Implications for HDPE Plastic Manufacturers

The projected growth in the Indian packaging industry offers significant opportunities for HDPE plastic manufacturers. Here’s how companies like Regent Plast can leverage these trends:

1. Increased Demand for HDPE Packaging

With the expansion of industries such as food & beverages, pharmaceuticals, and personal care, the need for high-quality HDPE bottles and containers is rising. HDPE’s durability, lightweight nature, and recyclability make it a preferred choice for packaging solutions.

2. Sustainability and Eco-Friendly Initiatives

As regulatory policies and consumer preferences lean towards sustainable packaging, manufacturers must innovate to produce recyclable and reusable HDPE solutions. Regent Plast, with its expertise in sustainable plastic manufacturing, is well-positioned to cater to this evolving demand.

3. Advanced Manufacturing Technologies

To stay competitive, HDPE manufacturers need to adopt advanced manufacturing techniques such as:

Blow Molding Technology: Ensures consistency and precision in bottle production.

Recycled HDPE Usage: Supports environmental sustainability and reduces carbon footprint.

Customization Capabilities: Enables businesses to create unique packaging designs that enhance brand identity.

READ MORE- https://regentplast.com/projected-growth-of-the-indian-packaging-industry-and-its-implications-for-hdpe-manufacturers/

0 notes

Text

Serum Bottle Manufacturers - Regentplast

RegentPlast stands out as a premier choice among serum bottle manufacturers, showcasing an unparalleled commitment to quality and precision in the production of pharmaceutical packaging solutions. As a leading player in the industry, RegentPlast specializes in the manufacturing of cutting-edge serum bottles designed to meet the stringent standards of the healthcare sector.These bottles are meticulously engineered to ensure the safe and secure storage of sensitive medical substances, maintaining the integrity of the contents throughout their shelf life.

Read More-

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#eco friendly#lifestyle#zero waste

0 notes

Text

Fliptop Caps Exporter - Regentplast

RegentPlast stands as a premier Fliptop Caps Exporter, dedicated to delivering top-notch packaging solutions globally. Specializing in the production and export of high-quality fliptop caps, RegentPlast has earned a stellar reputation for its commitment to excellence and innovation in the packaging industry.RegentPlast's Fliptop Caps are designed to enhance user convenience while ensuring the integrity and freshness of the packaged contents.

Read More-

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#eco friendly#lifestyle#hdpe bottles

0 notes

Text

Liquid Detergent Bottles Exporter - Regentplast

RegentPlast emerges as a leading player in the realm of liquid detergent bottles export, setting the industry standard with its high-quality packaging solutions. As a dedicated liquid detergent bottles exporter, RegentPlast combines precision engineering, innovative design, and top-notch manufacturing processes to deliver packaging solutions that meet the diverse needs of global clients.

Read More-

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#eco friendly#lifestyle#Hdpe Bottles#Zero waste

0 notes