#0.05mm

Text

if i have to see someone complain about the skid blocks being deemed illegal "only" by 0,05mm again aaargh

1 note

·

View note

Text

LETS BEGINNNNNN DUN DUN DUN DUN ....~~~~~~

"Turn the TV ONNNNNNN!!!"

WIP of the VOX Figure were making heuheuehueheuheuhe but his Now available for Pre-Order : https://www.kaizenminis.com/product-page/vox-scale-figure-6-7-inches-tall

OR if u just want the FILE ITS FREE if u use our

COUPON CODE " VOXKM8"

#hazbin angel dust#hazbin alastor#hazbin hotel fanart#alastor hazbin hotel#hazbin hotel#hazbin art#hazbin charlie#hellaverse#hazbin vox#hazbin hotel vox#vox

102 notes

·

View notes

Note

do koltin and kilton fit in your extended demonology lorebuilding? interested what youd classify em as

THEY SURE DO, ANON, THANKS FOR ASKING!

Right so like, BotW/TotK is so incredibly far from the events of my AU, but I have definitely overthought about how the Demon Tribe stuff would fit Kilton and Koltin in.

Firstly though, some Boko Tribe stuff reminders

1) Their advantage is having very plastic physical adaptability <- to account for their wide variety of body types in the different games, encompass all the various subtypes (Moblin, Bokoblin, Miniblin, etc), and explain why they're the only demon tribe that has persisted in any noticeable numbers through the ages. They're just really pro at adapting to new things.

2) They're easily affected/warped by Magicka <- to account for the game's evil Bokos. In this way, they're a result of Malice being overused to control and resurrect them, rather than evil behavior being their norm. Basically they are on the same level of sentience as humans, but exposure to uncontrolled Malice degrades their minds much faster than it would others. It's essentially the flipside to the above plasticity advantage. They're malleable in ways that are both good and bad.

Man, what does this have to do with Kilton and Koltin, Shea?

✨They have mixed Hylian/Boko heritage ✨

(I always thought the silhouettes here were really similar and wondered if it was intentional, but anyways)

So the headcanon here is that Kilton and Koltin's parents are a non-corrupted blue Boko and a particularly adventurous Hylian. I imagine they're a very sweet couple!!!! Here they are when they were younger.

I never thought of names for them, they just exist somewhere and probably don't hang out much in towns. (We love a power couple, but this sort of thing is likely to freak out the Hylian locals.)

I like to draw the two brothers with tiny little horn nubs as a nod to this. They don't have full horns and never will, but they probably were very excited for their lil skull bumps to grow like 0.05mm over the years.

The family would very much be aware of the whole Malice corruption thing. That's why Kilton is so passionate about "monster education" - he knows the corrupt Bokos were once normal people and often just mind their own business in the wilderness, but also knows that it's dangerous for humans to try and approach. So his ventures with his traveling stall and presentations in Tarrey Town are his way of trying to bridge that gap safely.

Additionally, I imagine Kilton and Koltin can travel pretty easily amongst corrupted Bokos, but not bands of Lizal or Lynel. Kilton would have attempted creating masks because of this issue, then afterwards added the various Boko masks for humans to use. (The Magicka is extremely rudimentary, like, barely a Glamour if you're familiar with my magic systems, which is why they fail frequently). And sidenote for monster extract, I think it would be funny if it's just like, a normal ingredient his mom uses and he just puts purple food coloring in it for the Exotic Flair. Like it's just vanilla extract or something lmao.

That was the rambliest possible answer, but tldr they're half-Bokoblin teehee

#thank you for the ask i couldnt sleep so i decided i should doodle things#answered ask#demon tribes au#zelda headcanons#botw#totk#bokoblin#boko kana#my art#im back at it again with giving backstories to silly side characters#koltin is just reverse batreaux send tweet#kilton#koltin

157 notes

·

View notes

Text

LJ78ランクルプラド-10

ストレートエッジの終わり

ヘッドの周りもバラして、リビルド品がくるのを待つばかりとなりました。ですがシリンダーブロックの上面もみないといけません。かなりがんばってくれている測定器のストレートエッジを使います。

今まで自分が使ってたものは今回なんか変😕 ブロックの上面に立てて使いますが、シックネスゲージを入れる向きを変えるとゲージが通ったり通らなかったり😩 これはもしや… と思い、知り合いから別のヤツを借りてきて試すことにしました。

ちゃんとしたところのものなので状態はたぶんOK。今回の2L-TEエンジンのブロック上面はこれで測定しました。結果は何とかいけそうなレベルだったのでブロックはそのまま掃除だけして使うことにします。

ですが、かなり長い😅 直列6気筒エンジンも測れる長さです。

いろんなエンジンでよく使う0.05mmのシックネスゲージを刺してみると… これはアウトです😫 入らないとこ…

View On WordPress

14 notes

·

View notes

Text

Eyyo, it's WIP Wednesday and I actually have something in the works I would like to share!

More so to see if I can actually do it but also to get practice with my nice new ink brush thing I bought the other day. There is a, hurdle, in obtaining the good Legends Arceus cards, as some of them in particular are uhhhhh... unfortunately VERY pricey for even most folks to consider buying one card a good idea coughcough SneaslerV alt art, pearl clan with ingo card, Iridas full art coughcough Or even just a card for a character doesn't exist yet!!

So I decided if I want something badly enough, I'll just, make my own unique cards!

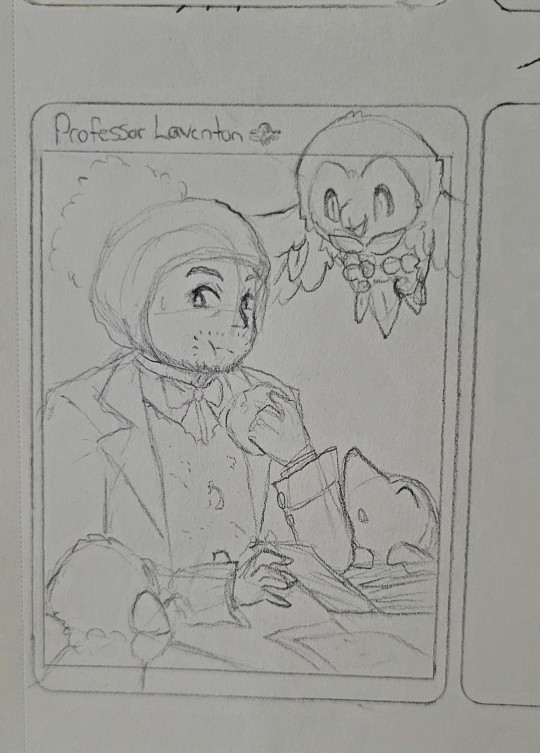

So far the VERY rough prep and idea work on normal paper for 2 folks who DESPERATELY deserve their own full art cards.

Laventon has his own normal looking trainer card, but thats it for him. He doesnt even get new art for it either it's just the one from his release! If he had a full art card it would very much have to include the three P's. His Pokemon, Pokedex, and Potato Mochi!

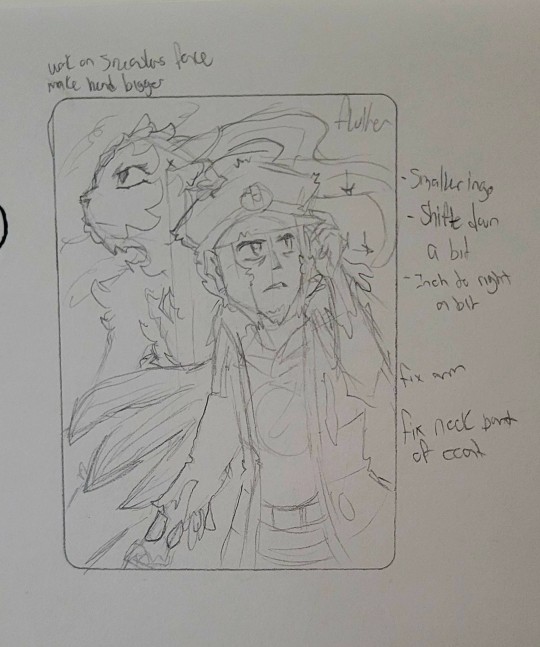

Then the one I really wanted to do from the start when I had this idea a while ago, good ol' Warden Ingo, well before his appearance in V Star Universe with the Pearl Clan was shown. He may not be doing his signature pose, but he's with his Lady Sneasler doing Warden things.

Nothing exceedingly extravagant, but more so to see if I can go through and complete my ideas. These 2 will be on normal paper for now as practice with using my brush to line tiny details, and once done I'll pencil crayon them in with the colours I plan to use for my tried and true cards in the end, which will be watercoloured! That way I have a better visual for what I want the watercolours to be like!

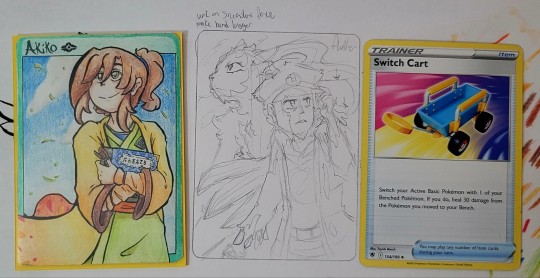

So far my lining has been rather consistent in my first solid testing!

I decided to do my Legends OC Akiko as my first prototype card with the inking! The only thing I didn't use my brush pen for was the writing for the pokedex and the framing of the inside portion of the box, which I used a 0.05mm pen for, but literally everything else was with one tool! Along with Akikos card, I'm gonna do this tealish colour for the border of the others cards, since I used the similar colour to the "Legends" text on the title card for Legends arceus. Along with the border, im also making my own special backing of the cards im doing!

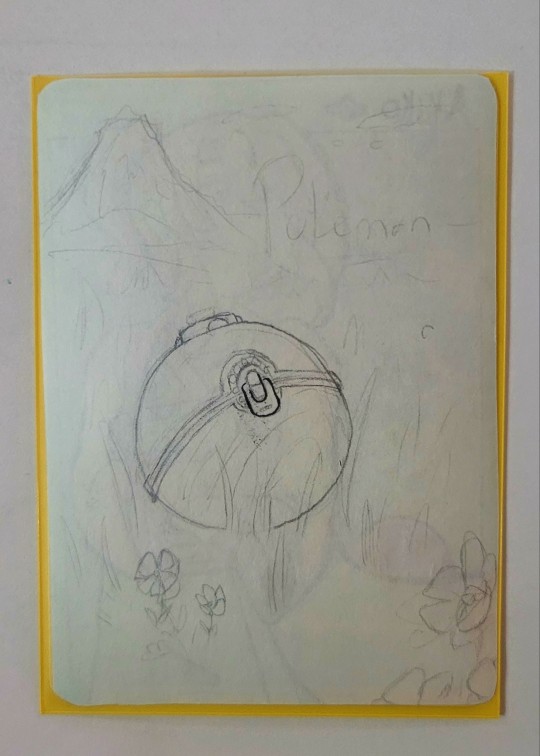

Instead of the good ol' swooshy blue backing with the cracked open pokeball we see in every card since the dawn of the TCG, these are gonna a have a Hisuian pokeball, calmly sitting in the grass with Mount Coronet in the distance! With a stylized "Pokemon" to go with it! And each back will inevitably be hand drawn!

To get an idea of why I want so much prep and practice done beforehand to the main watercoloured cards, I'm doing them to scale

They are all going to be made to be the size of the real cards themselves. Practice ones too! I gotta get good with a steady hand!! So many tiny details, so many thin lines, SO MANY WAYS TO MESS UP AND WORRY!!!

BUT

Like I said, if I want a card badly enough, I'll just make it myself! XD

Hopefully you'll all like the end results of my agonies, our boys need cards of their own, even if they're just gonna be for me XD

#pokemon legends arceus#arceus#ingo#warden ingo#professor laventon#legends arceus#lady sneasler#GOD THE APP ON MY PHONE FROZE BEFORE I COULD SAVE THIS AS A DRAFT AND IT CLOSED OUT#thankfully it somehow retained my work and i got everything back so yaaaaay#my discovery about the hisuian pokedex being worned down with time was because i was looking it up for Akikos Pokedex in her hands!#the more ya know!#pokemon#legends of arceus#pla#cyndaquil#rowlet#oshawott#potato mochi#pokemon tcg#akiko#handmade card#smish pokemon#smashwolfen#i gotta say its surreal seeing something you made actually be made#like having my own OC as a physical card i made tucked away in a sleeve like the real deal is insane like i cant believe i MADE that#bonkers man#wip wednesday

58 notes

·

View notes

Text

Hello. Just sharing another little drawing of mine 🫣👀

This one I did with Steadtler Fineliner 0.05mm. Took me about 4 hours.

And this time with some details.

#my art#im just drawing whatever I like#but I do enjoy various kind of techniques 😬#I don’t really have an art style soooo#enjoy?#artists on tumblr#fineliner art

14 notes

·

View notes

Text

Gemini ✨

0.05mm Unipin Fineliner

#babylonian#twins#illustration#pen drawing#ink drawing#ink#sketchbook#stick and poke#pen and ink#pen#original art#portrait#pointillism#dotwork#custom tattoo#fine line#irish art#irish artist#tattoo flash#support the artist#buy me a coffee#big cartel#pinned post#small artist

3 notes

·

View notes

Text

maturing is realizing that i dont think tech is hard to draw. its realizing that i was just a fucking coward and i wasnt raised to be a little bitch. so. my sketchbook is slowly getting overtaken with sketches n practice drawings of tech and industrial designs. and so is my camera roll. idk i think its fun. is it complicated? kinda. but it can be solved w just using a 0.05mm pen for the extra tiny details. so. yknow.

2 notes

·

View notes

Photo

Itty-bitty Tunisian crochet. 0.05mm nylon thread and a 2mm hook. I definitely need my glasses for this 😁 #tunisiancrochet #crochet #nuttybeads (at Adelaide, South Australia) https://www.instagram.com/p/CmS3TPkP1Pk/?igshid=NGJjMDIxMWI=

11 notes

·

View notes

Text

What is the tolerance of CNC machining?

Tolerance is the amount of variation allowed in size. It is the allowable deviation range of size specified by the designer on the design drawing based on the product's use requirements and the feasibility of the manufacturing process. Tolerances are divided into dimensional tolerance, shape tolerance and position tolerance.

Dimensional tolerance refers to the amount of variation allowed in size. For example, if the diameter design size of a shaft is 50mm and the tolerance is ±0.05mm, then the actual diameter of the shaft is qualified between 49.95mm and 50.05mm. In the manufacture of industrial equipment and packaging machinery, reasonable determination of dimensional tolerance can improve production efficiency and reduce costs while ensuring product quality.

Shape tolerance refers to the total amount of variation allowed in the shape of a single actual element. Such as flatness, roundness, cylindricity, etc. In CNC machining, the control of shape tolerance is crucial to ensuring the function and assembly accuracy of parts.

Position tolerance refers to the total amount of variation allowed in the position of the associated actual element to the reference. Such as parallelism, verticality, coaxiality, etc. In the assembly of industrial equipment and packaging machinery, the control of position tolerance directly affects the performance and reliability of the equipment.

In the manufacturing of industrial equipment, reasonable tolerance design can reduce production costs and improve production efficiency. If the tolerance design is too strict, it will increase the difficulty of processing and increase the cost; if the tolerance design is too loose, it may affect the performance and quality of the equipment.

0 notes

Text

Retractable Eyebrow Definer Pencil with Spoolie, Dark Brown, Waterproof Long Lasting Brow Pencil, Soft Textured, Angled Tip Applicator for Natural-Looking Brows, Eyebrow Filler Pen Makeup for Women-01

Price: (as of – Details)

Offer 4 different bade sculpting eyebrow pencil colors, features a 0.05mm slim blade nib that outlines and fills brows with precision, smooth and non-clumping, waterproof & sweat-proof & smudge-proof, easy to use, rotate and push out to use no need to sharpen pen, suitable for all.Description: Net Content: 270mgColor: 4 color Package Include: 1Pc x eyebrow pencil…

0 notes

Text

Looks like the 3rd time really is a charm. The 1st time (bottom right), as a prototype, was printed upside down, where the support lattice was interfacing the visible side. Once I started printing a few more I noticed how clean the ironed side was, so I figured I would need to try again (top right). Because I was having a hard time with getting a clean bed layer, I tried with the support structure basically "touching" it with a 0.05mm separation. So while the top layer was good, it was essentially impossible to get the support lattice off and a clean enough outer ring that would fit to its adjacent neighbor. But after at least 4 or 5 attempts, I gave up on this one and went to printing other rings that still needed to be done.

After a bit of a break, I came back to try again and to finally figure how can I preserve the small details without the lift and peel. Slower is basically always better as a rule of thumb, and I slowed the initial layers to a snails crawl pace of 5mm/s. This particular series of black can't stand a lot of sheer force, where normally even 10mm/s is slow by most colors.

Like in life, it doesn't hurt to slow down, reevaluate, and try again to get it right, because there isn't a need to give up on something you know will turn out great once you figure out how.

As a test fitment these are all the layers except the last 2 because of their size. All fit well together with the exception of two of them that are a bit on the loose side. The whole assembly will be super glued in place once the body is complete.

The violet is a bit too purply, but it was a better option than the 'army purple' which looked almost black. Trying to create a 'glow' with no lighting and only reflective surfaces can be a challenge, but it turned out well even with a color misprint on the #5 ring which it turns out I liked better anyway.

0 notes

Text

Laser Cutting

https://mydprecision.com/laser-cutting/

High precision: High processing accuracy, for example, the dimensional accuracy of the cut parts can reach ±0.05mm, the laser cutting incision is narrow, the two sides of the cut are parallel and perpendicular to the surface.

Fast and efficient: Laser cutting is fast, which improves production efficiency and shortens product development cycle.

Flexibility: The laser beam is easy to control and can cut any complex shape and size without being limited by traditional molds or tool shapes.

Wide material adaptability: Applicable to a variety of materials, including carbon steel, stainless steel and non-metallic materials, almost all materials can be processed except for metals with high reflectivity (such as gold, silver, and copper).

Low heat affected zone: The heat affected zone of laser cutting is small, reducing the risk of material deformation.

Non-contact processing: Laser cutting is a non-contact processing that does not cause mechanical stress or damage to the surface of the material.

0 notes

Text

360° No-dead-angle And No-bubble Labeling Solution

The core of the visual labeling machine lies in its highly integrated visual recognition system and advanced laminating technology. At present, many factories are manually laminating and manually positioning the auxiliary materials, but there are still bubbles and large laminating accuracy errors. In order to solve this industry pain point, the bubble-free laminating technology ensures the seamless connection between the label and the product surface, improving the overall aesthetics and market competitiveness of the product. The laminating accuracy is as high as ±0.05mm to ±0.15mm, which provides higher efficiency for labeling operations. Gosunm has developed a high-precision visual positioning auxiliary material laminating machine.

Featureds

360° no-dead-angle lamination

gosunm visual labeling machine can handle products of various complex shapes, and can achieve precise lamination no matter which part of the product needs to be labeled.

Bubble-free lamination

By precisely controlling the labeling process, ensure that the label is tightly attached to the product surface without bubbles or wrinkles, thus ensuring the labeling quality

Non-standard customization

In response to the special needs of different customers, gosunm visual labeling machine provides non-standard customization services to meet various specific production needs,

High-precision lamination

The lamination accuracy is as high as ±0.05mm to ±0.15mm, ensuring the high precision of labeling operations and meeting the industry standards with strict requirements on product quality.

Multiple advantages of visual labeling machine

◆Perfect combination of efficiency and precision

The Hardson visual labeling machine greatly improves production efficiency through automated processes. At the same time, its high-precision visual system ensures the accuracy of labeling position, meeting the dual needs of modern production for speed and quality.

◆Strong adaptability and high flexibility

Whether it is regular or irregular product shape, the Hardson visual labeling machine can quickly adapt to different labeling needs through software adjustment, greatly improving the flexibility and adaptability of production.

◆Reduce labor costs and improve safety

Automated visual labeling machines reduce the physical and mental requirements of operators, which not only reduces long-term labor costs, but also reduces errors and safety hazards that may be caused by manual operation.

Application fields and industry impact

Visual labeling machines are widely used in many fields, including but not limited to:

Consumer electronicsMainly used for labeling of structural shell accessories such as mobile phones, laptops, and tablets

Electronic componentsSuitable for laminating operations of electronic components such as cooling fans and foot pads

Emerging fieldsSuch as FPC wireless charging laminating operations, Hardson visual labeling machines meet the strict requirements of emerging technologies for labeling operations with their high precision and high efficiency

As a key component of intelligent manufacturing, the visual labeling machine has promoted the process of industrial automation. It not only significantly improves production efficiency, but also ensures the consistency and accuracy of product labeling, becoming an indispensable "precision eye" in modern manufacturing. With the continuous advancement of technology, we have every reason to believe that CCD visual labeling machines will play a more important role in intelligent production.

#visual labeling machine#gosunm#CCD visual labeling machines#visual positioning auxiliary material laminating machine#Automated visual labeling machine#visual inspection

0 notes

Text

Some well-known laser engraver suppliers

Here are some well-known laser engraver suppliers:

Laserpecker - Known for its intuitive, compact, and highly portable laser engravers, especially the LaserPecker 2, which offers rapid 600mm/s engraving with an extremely precise compressed spot of 0.05mm x 0.05mm.

xTool - A relatively new brand specializing in affordable desktop machines, with the D1 Pro being its most popular product, widely regarded as one of the finest hobbyist laser engravers.

Atomstack - Renowned for its budget machines that typically retail for less than other popular hobbyist brands.

Ortur - Popular for its Laser Master series of laser engravers, especially the Laser Master 3, which offers super-fast 20,000mm/min cutting speed.

Glowforge - Known for its user-friendly laser machines that resemble printers in their sleek enclosures, offering Basic, Plus, and Pro models.

OMTech Laser - A U.S. company established in 2018, offering over 30 products including CO2 and fiber lasers.

Trotec - An Austrian brand with a global presence, selling over 15 models across five different series of laser machines.

Triumph Laser - Focuses on providing industrial-grade laser cutters for businesses, known for its fiber laser brands.

DXTech - A Chinese brand specializing in various types of laser machines using CO2 lasers as the primary laser source.

Style CNC - A Chinese brand known for its budget machinery, focusing on manufacturing a variety of CNC and laser equipment.

Linxuan Laser - With over 18 years of experience in the laser industry, it is a top industrial laser marking/engraving machine manufacturer in China, offering customized laser marking and engraving solutions.

These laser engraver suppliers cater to laser engravers for hobbyists to professional and industrial use, meeting the needs of various users.

0 notes

Text

Injection Mold Checklist

Excellence in manufacturing depends on injection frisbee quality. Our injection Mold Checklist simplifies this procedure, walking you through the necessary stages to uphold high standards. This checklist is an essential tool for any injection molding expert, as it includes all the necessary steps to optimize injection molding solutions, reduce errors, and increase productivity from original design to final inspection.

Mold appearance and dimension

Is the kind of water connector correct? Is there sufficient clearance in the hole for the water connector? The hole's outside border must be consistent and chamfered.

Indicate the water lines with "IN," "OUT," and neatly and legibly number them. For instance, INT1, OUT1.

Pneumatic or oil connection numbers must begin with the prefix "O" or "G," for example, G IN1, O IN1.

The gas, oil, and water plugs' screw threads all match the Tooling datasheet.

Are the KO pattern and size up to par?

The Locating ring's diameter and fastening type comply with the Tooling specification.

The tooling datasheet's sprue bushing sphere radius must be met.

The total size of the mold must satisfy the customer's press (tie bar space), and the clamping technique must satisfy the customer's demand.

When installing a mold that requires installation instruction, the cavity or core plate should be etched with an arrow that reads "UP."

Each part must have a unique number. Moreover, the standard mold datum needs to be etched.

It is not permitted to make any of the components within the home.

Using the right steel is important, and the molding injection company must submit the steel certification.

All connection screw threads, including K.O. and eyebolt holes, must be precise.

Wear plates should employ oil grooves whose designs adhere to client specifications.

The shut-off pieces must fulfill customer requirements and have a disparity in hardness.

Does Slide Gib require a dowel pin?

Are side locks properly purchased and installed?

Cycle Installing a counter as per the mold design sketch.

Make a vent opening for the guide bush.

Is a dustproof sheet required?

Are the slides assembled and properly fit the molding injection company?

The PL vent needs to be planned and cut. Is it directly cut to the part location and appropriate for parting?

Clearance space should be designed and created in the region beyond the portion wall. There is no need to invest in a grinding machine.

Sprue bushing should be OK and should not break.

Ejection, Return, Pull system and Removing

Smoothly ejecting, No unique sound, no get stick.

Lifter surfaces must be polished, lubricant slots must be made, and heat or nitride treatment must be applied (depending on the client's needs).

A & B plate guide pins, guide bushings, and ejector plate guide pins must satisfy client requirements.

Uneven ejector pins need to be placed in the molding injection company.

The ejecting plate ought to fully retract.

A flat-surfaced space block must be utilized for the ejecting stroke.

A return spring must be a normal part; it cannot be split or polished.

Does the material for the lifter, wedge block, and gib match the requirements of the customer? It must be heat-treated or nitride-treated.

Install a restricted switch on a hydraulic cylinder or slide.

The lifter stroke or slide must be sufficient to satisfy the requirements.

Both the ejector pin and the ejector plate must have the ejector number stamped on them.

Return pin top surfaces must be level and free of welding; bottom surfaces cannot have pillows or welding. The required hole clearance is 0.07 mm.

Unless otherwise noted, there should be 0.05mm of space between the B plate and the ejector guide pin (Conform to the molding injection company design specification).

With a sufficient stroke, the runner stripper plate moves smoothly.

The steel dimensions must be examined, and a steel check report must be submitted.

Cooling System

Water line seals must be leak-free, and utilize Teflon sealing tape.

Is the flow appropriate for cooling? To determine this, a flow metre must be used and the flow value recorded.

Cooling manifold installation must be done accurately and by client specifications.

The water baffle needs to fit the molding injection company specifications

Cold Runner System

Sprue bushing inside surface must be polished to design specifications.

It is necessary to polish the runner channel to the drawing standard.

For multi-molding injection company, the short-shot has to be tesmolding injection company.

Hot Runner System

Specifying the desired kind and size of sockets and installing safety settings is necessary.

Is there mold protection equipment placed on the outside of the connection box? The wiring must match the shop's given design.

To prevent breakage, wires must be bundled and covered with a plate.

When both connector sizes are the same, they must be carefully marked to prevent incorrect assembly.

Wires that are visible outside of the mold surface are prohibited.

The transition slot that allows the wire to pass through the plate and manifold must be rounded to prevent damage.

Does a mold-insulating plate exist? If not, has the consumer given their approval?

Mold Packing

The steel type, certification, and heat treatment must satisfy the client's needs.

Safety locks (at least two pieces) ought to fulfill the design specification, and a rest hole must be created.

The CD's files are full?

Are there any particular requirements for the outside surface of mold?

Are all the spare components filled up? And it must be supplied with a thorough list.

Mold must be wrapped in a plastic membrane.

After marking the positioning direction, spread mold # with lacquer.

Everything on the packing list must be packed.

Conclusion

In conclusion, obtaining consistent quality and operational efficiency requires the use of an injection mold checklist. You may drastically lower mistakes, raise the caliber of your output, and increase productivity by using this thorough guidance. By putting this checklist into practice, you can revolutionize your cheap injection molding process and make sure every project surpasses customer expectations and industry standards.

#plastic injection mold design#injection molding solutions#best injection molding company#injection frisbee#injection molding maker

0 notes