#10000rpm

Photo

#sexy #epic #becauseracecar #eg8 #eg9 #eh9 #eh8 #honda #civic #dashboard #10000rpm #typer #cluster #thankful to those who supported me @zlatkodxb & big thanks to Global Pinoy Auto Repair Workshop Abu Dhabi Mussafah 11 Sam Halabi Performance Garage https://www.instagram.com/p/CliEKdrPZJA/?igshid=NGJjMDIxMWI=

0 notes

Text

.

im supposed to be vacuuming rn but brain said Start A Rachel Piece You Probably Aren't Good Enough For

#does this count as mild gore. idk#thinking about ''eat me / drink me / straight down the rabbit hole''#+ ''love me the way that you'd like / treat me how you want to / i'll let you sacrifice my life''#rotating her in my mindcrowave at 10000rpm#nova scribbles

4 notes

·

View notes

Text

Did some 9000iq things with an angle grinder and hurt myself who woulda guessed

3 notes

·

View notes

Text

okay i wasn't saying anything about it earlier because i was busy rotating aisha laborn at 10000rpm in my head but the "it's the end of the world...AGAIN" thing is so bad. like, first of all, it's inherently hilarious that worm ends in the world ending and then the sequel Also ends in the world ending, and not in a good way. people in the parahumansverse like [snaps fingers] Ah fuck lads. Everything's kersploding again.

but aside from that the reason worm's plot building up to the end of the world Works is that it's synchronized with the life of our traumatized teen protagonist, as a sort of literalizing of how she feels like the world is ending. like it's very explicitly about being a teenager who wants to die, having your world come crashing down around you, & experiencing the visceral, awful catharsis of finally giving into all of the self-rending feelings you've been bottling up as it does--and then realizing that yes, your world ended, but you're somehow still here, and you still have a chance to find out how to live.

the ward protag's life already went straight to shit in the middle of worm--you don't need to throw a second apocalypse at the post-apocalyptic setting, you can literally just write about her Literally living in the ruins of her old life and figuring out how to grow something new there. i'm aware it's very silly to make a wardnalysis post when i have for all intents and purposes not read ward. so take all of this with a grain of salt and/or the whole saltshaker. unless you've read ward and agree with me then feel free to hold the salt

50 notes

·

View notes

Text

High Speed Motor Journal Bearings

product name: High Speed Motor Journal Bearings

Product description:

Bearing bore diameter range:45-250mm

Speed range:5000rpm-32000rpm

Maximum linear speed:120m/s

Average pressure:2.6Mpa

Pads base material:42CrMo or Cu-Cr

Bearing with fix thrust or tilting pad thrust

Pad number:4-pad,5-pad

Pivot offset:0.5,0.55,0.6

Different design style

With RTD,lower temperature rise

Pads with line pivot or spherical pivot

With PTFE for insulation

Babbitt (Tegostar 738) meets Europe REACH requirements

Have made Power/speed at:

200kw-300kw/32000rpm

400kw/20000rpm;500kw/12000rpm;800kw/10000rpm

2500kw/13500rpm;6000kw/8000rpm;10MW/6000rpm

E-mail : [email protected]

0 notes

Text

HPE 2.4 Terabyte, 2.5 inch, 10K, 512e Advanced Format, SAS hard drive with a Data Transfer Rate of 1.2 Gigabytes Per Second and bundled with a SmartDrive Carrier tray. The 881457-B21 is for G9 and G10 HPE ProLiant servers. The Buy HPE 881457-B21 is Encrypted with Digitally Signed Firmware which protects your data from Malicious attacks such as Malware, Harmful Manipulation and Accidental Deletion.

HPE 881457-B21 Overview:

The NEW 881457-B21 HPE 2.4TB SAS Hard Drive is a Small Form Factor (SFF) drive designed to meet the storage needs of HPE ProLiant servers. With a focus on speed, reliability, and efficiency, this hard drive is suitable for various applications and data storage requirements.

HPE 881457-B21 SPECIFICATIONS:

Main Part Number: 881457-B21

Spare Part Number: 881507-001

Manufacturer: HPE

Storage Capacity: 2.4 Terabyte

Spindle Speed: 10000Rpm

Data Transfer Rate: 1.2Gb/s

Bytes Per Sector: 512

Format: Advanced 512e

Form Factor: Small Form Factor

Drive Features: Digitally Signed, 512e Advanced Format

Drive Tray: SmartDrive Carrier Tray

HPE 881457-B21 COMPATIBILITY :

The 881457-B21 is for the following HPE ProLiant Servers:

Gen10 HPE ProLiant:

HPE ProLiant DL385 Gen10

HPE ProLiant DL580 Gen10

HPE ProLiant ML350 Gen10

Gen9 HPE ProLiant:

HPE ProLiant DL20 Gen9

HPE ProLiant DL120 Gen9

HPE ProLiant DL160 Gen9

HPE ProLiant DL180 Gen9

HPE ProLiant ML30 Gen9

HPE ProLiant ML110 Gen9

HPE ProLiant ML150 Gen9

0 notes

Link

Check out this listing I just added to my Poshmark closet: TACKLIFE 3.7V CORDLESS ROTARY TOOL with 32 Pieces Accessories.

0 notes

Text

C-PUMA電動式マイクロモーターシステム

COXO®C-PUMA電動式マイクロモーターシステムは、軽量かつコンパクトなデザインのブラシレスLED付き治療用モーターです。このモーターシステムは、ユニットの4ホールホースに簡単に接続し、ユニットのフットペダルで簡単に制御できます。

このモーターシステムはAC 100~240V 50/60Hzの広い電圧範囲に対応し、最大消費電力はわずか120Wです。回転数は1:1で2000rpmから40000rpm、16:1で125rpmから2500rpm、1:5で10000rpmから200000rpmまで調整可能です。また、LED照度は25000LUX以上で、高精度なトルク出力最大3.5N.cmを提供します。

さらに、COXO®C-PUMAはメモリモード、正転・逆転切替、3つの速度比モード(1:1、16:1、1:5)など、多彩な機能を備えており、歯科医師や歯科技工士にとって非常に便利です。このモーターシステムは高性能と使いやすさを兼ね備え、歯科治療の質を向上させるための理想的な選択肢です。

1 note

·

View note

Text

Tattoo wireless pen

Tattoo wireless pen machine #HM056

Light weight, long-term work will not fatigue, increase work efficiency.

Two-axis adjustment:

Adjust the needle length on the upper wheel

The lower wheel adjusts the hardness of the needle

Stroke: 0-3.5mm

Needle length: 0-4.5mm

Motor: German motor

Speed: 10V 10000rpm

Working voltage 6-12V

Configuration: a pen + four handles (2 aluminum, 2 silicone) + a hook line…

View On WordPress

0 notes

Text

Guide To Centrifugation by Neuation Technologies

Centrifuge is a device that applies centrifugal force to separate mixture in the fluid by putting an object in rotational movement around a fixed axis thereby separating fluids of different densities or liquid from solids.

Centrifuge is a relatively simple instrument but yet tricky to maintain. Most of the centrifuge related blunders are due to user handling error and many machines have been destroyed by the scientists who are in it for simple pelleting. Therefore, it is crucial to understand what we do during centrifugation and avoid damaging the instrument and it’s in for the prolonged stay in the lab

Balance

Centrifugation produces centrifugal force to effectively separate and sediment the sample component based on size and density. Rotors spin very rapidly generating extreme force and therefore it is crucial to properly balance rotors during spin especially when rotors are loaded partially with tubes and plates. Any imbalance in the rotor including placement of the centrifuge on an uneven or slanted work surface can cause abnormal vibration that can in turn damage the rotor. An unbalanced centrifuge is as dangerous as unstable chemical reaction and can start domino effect of catastrophes all the way from instrument failure, to sample breakage, user injury and overall large-scale destruction in the laboratory and can be major safety hazard in the laboratory environment

Precise balancing at high speed becomes more crucial as the centrifugal force generated during centrifugation is directly proportional to sample mass and acceleration. At higher RCF even slight change in sample mass can lead to substantial force imbalance which in turn could be a catastrophe.

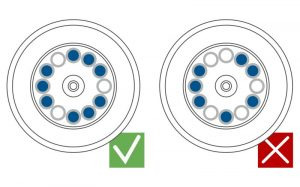

It doesn’t matter if the centrifuge has a fixed angle or swing bucket rotor, two important factors to consider when balancing include sample volume and symmetrical arrangement of tubes. It is important to ensure that the sample volumes are equal in all tubes and the tubes are placed directly opposite each other in the centrifuge. If the solution is not of similar density (eg acetone and water), tubes should be equal mass rather than volume to be correctly balanced. In the case of a swing bucket rotor it is to make sure that all slots contain a rotor bucket appropriate to the machine and are of the same weight.

Time, Speed and centrifugation

The choice of centrifugation speed depends on the size of the particle in the sample, smaller the particle size higher centrifugation speed for example bacterial cells are pelleted at higher speeds (2000-10000 g) than mammalian cells. Relative centrifugal force (RCF) generated by a spinning rotor is expressed relative to earth's gravitational force and therefore is also known as G-force . The G force acting on a particle is exponential to the speed of rotation due to this square dependence of RCF in RPM, centrifugation speed of 10000RPM for 5 minutes and 500 RPM for 10 minutes are not interchangeable. The former produces a much larger RCF than the latter. RCF is proportional to the radius of the rotor and to the square of RPM

RPM and RCF are not the same

RPM (Revolution per minutes) and RCF (Relative centrifugal force or g-force) are commonly used to describe centrifugal speed. RCF refers to the acceleration applied to your sample for example 10,000 g means 10,000 times earth’s gravitational force. RPM is not a useful unit because the force varies with radius of the machine (Bigger the radius, the more acceleration is applied to your sample for the same RPM) therefore RPM speed setting needs to be converted to RCF to ensure that the correct centrifugal force is applied.

Centrifugation and the temperature

Centrifugation generates heat because of the movement of molecules and friction with air which in turn can increase the temperature within a centrifuge which can affect stability of the sample. Temperature inside the centrifuge is primarily influenced by three factors: Rotor material, Rotor shape and speed of rotation.

Rotor materials such as steel and aluminium have a high density and high thermal conductivity which means it can transfer heat efficiently and get chilled quickly. Material like polymer and carbon fibre are low density material (Heat Insulator) and helps in maintaining constant temperature.

Rotor Shape determines the airflow within a centrifuge. Optimizing the airflow within a centrifuge through rotor shape is essential to maintaining the temperature.

Speed of Centrifuge, Centrifugation is proportional to the rise in temperature – at higher speed, more heat is generated. The degree of warming is very much depending on the maximum speed and shape of the rotor. It is important to understand the maximum speed of the centrifuge and the range of speed that maintains the temperature range that will not change the outcome of the experiment. This information is supplied by the manufacturer to help users understand the limitation and work around it.

Acceleration and Deceleration

Many Centrifuge offers the option to control deceleration setting (brakes) to bring it to stop faster and what is the effect on sample outcome.

Braking can be particularly useful during centrifugation involving Nucleic acid extraction or bacterial cell pelleting which are not affected by sudden stopping. Experiments that are more sensitive to abrupt deceleration such as isolation of peripheral blood mononuclear cells and gradient centrifugation, braking can cause separated layers to remix.

The Interphase separation of peripheral blood mononuclear cells (PBMC) is very sensitive to vibration and too fast acceleration or deceleration would disturb the gradient and lead to a milky/Non-existent interphase, making it difficult to extract PBMC. To prevent remixing the protocol requires acceleration/deceleration be shut off completely so that the centrifuge accelerates slowly and high forces cannot disturb the gradient and accumulate in the appropriate phase according to their density. When the brake is shut off, the centrifuge simply runs down until the rotor stops by itself.

Thus, centrifuge with different Acceleration/Deceleration ramps offers users the option of adjusting acceleration and deceleration speed and optimizing their protocols quite easily

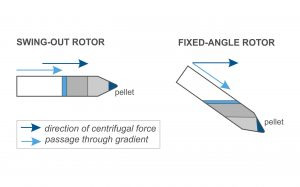

Know where your pellet is?

One of the applications of centrifuge is to pellet down bacterial cells, mammalian cells or nucleic acid. Angle of rotor determines the position of pellet. To Ensure and know where your pellet is, a good lab practice is to always spin the tube with lid hinges placed in the same orientation (for example lid hinges facing outward). In the case of a swing rotor, the pellets are formed at the bottom of the tube.

Hope this article will help you in choosing the right centrifuge product which custom fits your application.

Original Source: https://neuation.com/guide-to-centrifugation/

0 notes

Text

5 Best CNC Machines for Gun Manufacturing

When it comes to manufacturing firearms, there is no one-size-fits-all answer. Different manufacturers will have different needs, depending on the type of firearms they produce. That said, there are a few general things to consider when choosing a CNC machine for gun manufacturing. In this blog post, we will discuss the best CNC machines for gun manufacturing and outline the factors you need to consider when making your decision.

First and foremost, you need to consider the type of firearms you will be manufacturing. Different types of firearms require different types of machining, so it is important to choose a CNC machine that is capable of handling the specific machining requirements of your products. For example, if you are manufacturing handguns, you will need a CNC machine that can handle small-scale machining. On the other hand, if you are manufacturing rifles, you will need a CNC machine that can handle large-scale machining.

Another important factor to consider is the volume of production. If you are only producing a few firearms per month, then a smaller CNC machine may suffice. However, if you are producing hundreds or even thousands of firearms per month, then you will need a larger CNC machine that can handle the increased production volume.

Finally, you need to consider the cost of the CNC machine. There are a wide range of prices for CNC machines, so it is important to find one that fits within your budget. Keep in mind that the price of the machine is not always indicative of its quality; there are many high-quality CNC machines available at competitive prices.

5 Best CNC Machines for Gun Smithing

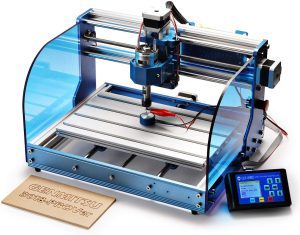

SainSmart Genmitsu 3018-PROVer CNC Router Machine

If you're in the business of gun manufacturing, you know that having a reliable and high-quality CNC machine is essential. There are a lot of options on the market, but not all machines are created equal. When it comes to finding the best CNC machine for gun manufacturing, the SainSmart Genmitsu 3018-PROVer is a great option.

This machine is built with precision and power in mind, and it's perfect for creating accurate and intricate parts. It's also easy to use, making it a great choice for businesses of all sizes. Whether you're just starting out or you've been in the business for years, the SainSmart Genmitsu 3018-PROVer is a great option for you.

So, if you're in the market for a new CNC machine, be sure to check out the SainSmart Genmitsu 3018-PROVer. It's a great choice for businesses of all sizes and it's sure to help you take your gun manufacturing business to the next level.

For user reviews and to buy online for best pricing and fast delivery - Click Here

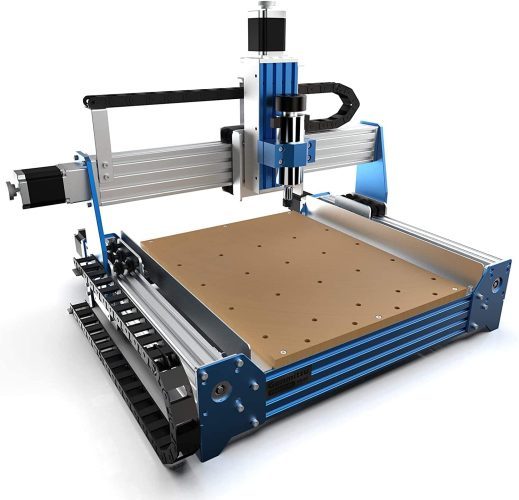

Genmitsu PROVerXL CNC Router Machine

The Genmitsu PROVerXL CNC Router Machine is a powerful and precise machine that can be used for a variety of applications. It features a sturdy aluminum frame, linear guide rails, and a spindle speed of up to 10000rpm. With its precision and versatility, the Genmitsu PROVerXL is perfect for both hobbyists and professionals alike.

For user reviews and to buy online for best pricing and fast delivery - Click Here

FoxAlien 4040-XE CNC Router Machine

The FoxAlien 4040-XE is a powerful and precise CNC router machine that is perfect for a wide range of applications. With its robust construction and high-quality components, it can handle even the most demanding projects with ease. It also features a user-friendly control panel that makes it easy to operate, even for beginners. Whether you're looking to create detailed woodworking projects or simply want to add a personal touch to your home décor, the FoxAlien 4040-XE is the perfect machine for the job.

For user reviews and to buy online for best pricing and fast delivery - Click Here

Axiom Precision Iconic CNC Router Machine

Axiom Precision Iconic is a highly accurate and precise measuring instrument that is perfect for use in a wide range of industries. From engineering and manufacturing to quality control and research, the Axiom Precision Iconic is an essential tool for ensuring precise measurements. With its advanced features and easy-to-use interface, the Axiom Precision Iconic is the perfect choice for any application where accuracy and precision are paramount.

For user reviews and to buy online for best pricing and fast delivery - Click Here

FoxAlien Masuter 4040 CNC Router Machine

The FoxAlien Masuter 4040 CNC Router Machine is a powerful and versatile tool that can be used for a variety of applications. With its high-speed spindle and large working area, it is perfect for precision machining and routing. The machine comes with a comprehensive set of features that makes it easy to use and operate. It is also very user-friendly and has a wide range of safety features.

For user reviews and to buy online for best pricing and fast delivery - Click Here

Is it Illegal to Make Guns with CNC Machines?

There is no definitive answer to this question as laws vary from country to country. In the United States, for example, it is generally legal to make your own firearms for personal use, but there are some restrictions on manufacturing guns for sale or distribution. In other countries, such as Australia, it is illegal to manufacture firearms without a license. So, it is important to research the laws in your own country, before attempting to build a gun with a CNC machine.

Where to find CNC Gun Plans

There are a few places where you can find CNC gun plans. One is to look on the search engines, and you will find websites that focus on DIY gun smithing projects. For example, you can easily find websites with free CNC gun manufacturing plans, such as this one, here. You can also check out forums devoted to gun enthusiasts, as they may have links to downloadable plans. Finally, you can try contacting companies that sell CNC machines; some of them may be willing to sell you plans for making guns. Whatever route you take, make sure you do your research so that you end up with high-quality plans that will result in a functional firearm.

How to use and operate a CNC machine safely and effectively

Assuming you have a working knowledge of how to use a CNC machine, the following tips will help you operate it safely and effectively:

- Make sure that all safety guards are in place and in good condition before starting the machine.

- Keep your hands clear of moving parts while the machine is in operation.

- Be careful when removing finished workpieces from the machine, as they may be sharp.

- Always wear appropriate personal protective equipment (PPE) when operating a CNC machine. This includes safety goggles, gloves, ear protection, etc.

- Follow all safety procedures and signs posted in the area around the machine.

- Never attempt to reach into or touch any part of the machine while it is in operation.

- If you need to adjust anything on the machine, make sure to first turn it off and unplug it from its power source.

- If you are not familiar with how to operate a CNC machine, do not attempt to do so without proper training and supervision.

When it comes to choosing the best CNC machine for gun manufacturing, there is no easy answer. However, by considering the factors outlined above, you can narrow down your options and choose the best machine for your specific needs.

Read the full article

1 note

·

View note

Text

Cryocooler Market - Forecast (2022 - 2027)

Cryocooler Market Size is forecast to reach $18.4 billion by 2026, at a CAGR of 8.5% during 2021-2026. Cryocoolers are standalone devices utilized for providing cooling temperatures at different cryogenic levels. There are different types of cryocoolers available based upon the operating thermodynamic cycles. These cycles assist cryocoolers to attain different levels of cryogenic temperatures that are applicable to specific set of applications in plethora of industry verticals. Cryocooler is a mechanical refrigerator designed to cool an application down to cryogenics temperatures. Cryocoolers are significantly used for applications in the transportation/storage of gases at extremely low temperatures as well as cooling of products, particularly infrared products in various applications. Cryocooling solutions have been witnessing a wide popularity across the major end-use verticals including medical, mining, power plants and are subjected to repeated as well as continuous usage, the need for regular maintenance or repair, fixing customer queries in times of malfunctioning, replacing spare parts with new ones and so on becomes highly essential. These services help the end-use customers to continue production activities without causing time delays, operation failures and hampering business productivity.

Report Coverage

The report: “Cryocooler Market Report– Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Cryocooler market

By Rotor Type: Inner Rotor, Outer Rotor.

By Type: Single Phase, Three Phase.

By Efficiency Class: IE1, IE2, IE3, IE4.

By Output Power: Upto 350W, 350-700W, 700-1000W, 1-2KW, 2-5KW, 5KW and Above.

By Speed: Upto 500RPM, 500-1000RPM, 1000-2000RPM, 2000-5000RPM, 5000-10000RPM, 10000RPM and Above.

By Voltage: Upto 1KV, 1-6.6 KV, Above 6.6KV.

By Vertical: Industrial, Commercial, Residential, Agriculture, Automotive and Others.

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

Technical Support services help the users or customers to select best cryocooling components or spare parts according to their industrial requirements, offering details about on-service contracts, or discounted service packages, diagnosis or repairing faults, troubleshooting technical issues along with a proper guidance on servicing intervals. With the help of technical support services, various end-use customers have been able to maximize their productivity with a cost-efficient approach.

Scheduled maintenance had been gaining a wide popularity within the cryocooler market owing to various service providers offering maintenance contracts, emergency support, warranty offers and so on. These services have proved to be a beneficial factor as the cryogenic components including compressors, cold heads and so on helps in early detection of defects or damages, which can ultimately benefit the end-use customers to schedule or pre-book repair or refurbishment services, within lesser costs and efforts.

Applications including cooling in MRI systems, superconducting magnets, low temperature sensors, storage of biological cells or specimens, cyropumps for semiconductor fabrication, cryosurgery and so on are considered as some of the major factors impacting the growth of various cyrogenic hardware over the years.

Cryocooler Market Segment Analysis - By Temperature Range

50K-100K temperature range type hold the highest market share accounting for $649.3 M in 2020 and $906.0 Million by 2026 with a CAGR of 6.3% over 2021-2026. Cryocoolers which can provide cooling within range of 50K-100K are used for applications including liquefaction of nitrogen & mixed gases and cooling the gas temperature ranges from 60-80 K. Cryocoolers that can supply cooling up to the range of 100K are used in Cooling of satellite typically in the milliwatt range at 60-80K. On January 2020, NASA developed a 20 Watt 20 Kelvin cryocooler is a critical step in enabling zero boil-off of liquid hydrogen. Active thermal control of cryogenic propellants is made possible by integrating a cryocooler to intercept and collect heat from the cryogenic tank support structure and/or a broad area cooled shield. 10K-50K temperature range cryocooler type is witnessing fast growth rate with a CAGR of 7.63% during the forecast period 2021 – 2026 owing to the wide range of applications employed in liquefaction of Solid Hydrogen in the temperature range of 10-14K and liquefaction of hydrogen in the temperature range of 18-30 K.

Inquiry Before Buying

Cryocooler Market Segment Analysis - By Vertical

In Power and Energy vertical, applications of cryocooler includes LNG for peak shaving, Infrared sensors for thermal loss measurements, SC magnetic energy storage for peak shaving and power conditioning, SC power applications (motors, transformers etc.). The superconductor industry is closely linked to the cryogenic industry due to operating temperatures required for superconductivity being below 130K. Such cooling comes from cryocoolers. The use of a superconductor and the fact that superconductors currently need a cryogenic temperature to operate means SMES is part of the superconductivity and cryogenics industry. Thus, cryocooler play an important role in creating cryogenic temperatures required for superconductivity. In SMES energy is stored in a magnetic field created by the flow of direct current (DC) in a superconducting coil, which has been cryogenically cooled below its critical temperature. Energy storage is a rapidly growing market with a number of trends. The increase in decentralized renewable energy, the advent of smart grids, smart micro-grids and smart houses, the electrification of transport, the increasing demand on the ageing electricity infrastructure and climate change targets are all helping to drive the energy storage market. Thus, with the increase in energy storage devices such as SMES the market growth for cyrocoolers will increase as it used for direct cooling of superconducting magnets.

Cryocooler Market Segment Analysis - By Geography

Geographically, Asia-Pacific hold major share 33.2% of Cryocooler Market share in 2020 terms of revenue owing to increasing applications in Defense sector, Healthcare and Space sector. For instance, On May 2019, China unveiled the prototype for its sleek new magnetic levitation (maglev) train. Developed by the state-owned China Railway Rolling Stock Corporation (CRRC), the world's largest supplier of rail transit equipment announced that the new train is capable of travelling at a speed of 600km/h. Moreover, India’s Defense Research and Development Organization (DRDO) announced that their Anti-Tank Guided Missile (NAG) is set to be exported to global market and India further look to expand its production units. This will propel the application of cryocooler in large scale further enhancing its market growth. South America region is anticipated to witness the significant market growth during the forecast period 2021-2026 with a CAGR of 7.7%. The market growth in this region is mainly due to rising applications of cryocooler such as to offer high speed imaging and sensing infrared detectors across a variety of different sectors, including space, defense and commercial. With Brazil ramping up domestic space satellite, rocket programs the cryocooler market will grow significantly.

Schedule a Call

Cryocooler Market Drivers

Growing Applications in Military and Defense

The extensive deployment of cryocoolers for defense and military applications such as cooling of infrared focal planes and infrared sensors is likely to be the major driving factor for the growth of global cryocoolers market. Cryocooler are often used for tactical military applications such as airborne, ground mounted and shipboard IR sensors that are associated with cryocoolers for cooling needs. Indium antimonide (InSb), Mercury-cadmium-telluride (HgTeCd) and other prominent detector materials used in these applications are required to be cooled to cryogenic temperatures to ensure proper operation of sensor device by reducing the random transition of electrons between energy bands. Moreover, improving power, size and weight constraints of space qualified cryocoolers boosted the utilization of these devices in large military satellite electro optical infrared missions.

Growing Adoption of Night Vision Cameras

Most of the advanced security cameras are featured with night vision to provide footages of the location even in dark and night conditions. These cameras rely on infrared light and capture footages by lighting the field of view with infrared light source. Night vision cameras installed in military applications such as video surveillance for enemy detection uses cryocoolers. These devices use high efficiency compact pulse tube cryocoolers as cooling element for IR sensing materials to enhance the picture clarity and colour discrimination. The growing demand or night vision cameras in typical commercial applications owing to theft and other anti-social activities is propelling the cryocoolers market.

Buy Now

Cryocooler Market Challenges

Low Efficiency in Closed Cycle Mode and High Internal Losses

The internal losses associated with most of the regenerative and recuperative cryocoolers pose a very significant effect on the overall efficiency of the system and this is the major factor hindering the growth of cryocoolers market. The irreversible gas compression mechanism in cryocoolers results in regenerator inefficiency of the system. Other internal losses such as pressure drop loss and clearance seal loss also impact the performance of the system negatively. The losses experienced by Pulse tube type cryocoolers within pulse tube itself include heat transfer between tube wall and gas, circulation of gas within the pulse tube due to oscillating pressures and mixing of warm and cold gas segments.

Cryocooler Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Cryocooler market. Cryocooler top 10 companies include Sumitomo, Chart Industries, Sunpower, Air Liquide, Janis Research, Ricor, Cryomech and Brooks Automation.

Acquisitions/Product Launches

In September 2020, Air Liquide S.A. acquired Cryoconcept which enabled Air Liquide to strengthen its expertise in the field of extreme, or close to absolute zero, cryogenics.

In July 2019, Atlas Copco acquired Brooks Semiconductor Cryogenics through which it will develop a worldwide sales and service network of cryo pumps operations.

For more Electronics related reports, please click here

#cryocoolers market#spectrometers cryocoolers market price#cryocoolers market report#cryocoolers market research#cryocoolers market size#cryocoolers market shape#cryocoolers market analysis#cryocoolers market forecast#thermodynamic cycles#helium gas

1 note

·

View note

Note

top 5 undersiders :3

in retrospect asking for top 5 asks was a questionable decision because i'm like "oh god...but there are at least 3 different frameworks under which i could rank them...what do i do..."

here, we'll do a subjective "which ones make my brain spin in circles the fastest" ranking:

5. lisa (i would Like to understand her better, am occasionally really compelled by her, and still workshopping some more solid opinions on her. she's SO breeds there a man by isaac asimov core)

4. brian (i like him. he's my special guy. i wanna take him out for ice cream he deserves a nice treat. he would try to pay but i wouldn't let him. the version of him in my head cobbled together from various WoGs and worm details is very interesting to me and all my brianposts get mad notes so apparently you guys agree)

3. taylor (i would unironically rank her as one of The Best Book Characters, Ever, and whenever i remember this fact my brain starts spinning at 7000rpm)

2. aisha (10000rpm)

1. alec (no, i don't get it either)

no, rachel is not on the 'makes my brain do circles' list. i have genuinely no fucking idea why because literally everything about her should be incredibly catered to me--she's a massive dyke no matter what wildbow says, she's got dogbrain autism, she's a cert. violent problem child and this is narratively portrayed as genuinely nuanced + sympathetic + a result of systematic mistreatment, she kills and maims, she's incredibly funny and fun and interesting to read about, she's Just Plain Cool--And Yet. for reasons entirely indiscernible to me. i literally just do not think about her that much. 10/10 dish of my favorite food that i am bewilderingly uninterested in. i'm sorry bitch :(

now if we do a less subjective ranking. taylor scores first place and the other slots are all also taylor as well

22 notes

·

View notes

Text

Icopy kingston

#ICOPY KINGSTON HOW TO#

#ICOPY KINGSTON SOFTWARE#

#ICOPY KINGSTON PROFESSIONAL#

Right now, I will have to replace 0402003 (my old prefix) to 0511063 (my new prefix).1100+ times!Īnyway, I have got some renaming to do. But when you 50+ subfolders like I do, you wished there was a "Yes to All" option.ģ) When it comes to renaming the File Name, I could realy use a "Replace String Function", or a "Add Prefix Function". If you have 2 sub-folders it will only require 2 clicks (2x "Yes"). How nice would it be to filter-out those two things, so only items are being shown which belong in the Workspace.Ģ) If you change the File Location, Inventor will ask if any sub-folders should be created. I am only copying the files from my Workspace, all my Content Center files and other library files will not be copied. I could really use a Filter on the File Location. I still need to rename ALL references from the main project (800+ unique files) one-by-one, which will take.like forever.or so.ġ) Filters. I have now changed all the FileLocations from my Workspace to the target location, and I have added and renamed all the associated IDW's. (We are not using Vault and we don't have any other PDM system yet (we are looking into AM Meridian), so no "Copy Design" function for us).Īs you might have guessed, trying to copy and rename 1100+ references is a PITA. I am posting this as I am trying to copy a complete design (450 MB of parts, assemblies and IDW's) with the DA. Once (and DA will mark all the "instances" of that Skeleton Part asĪs for the "pure BS".You said that "The DA will not be even able to openĪn assembly to deal with" That's not true, not true at all. (or even more), but you will only have to rename/replace that Skeleton Part A Skeleton Part will be listed like 100 times But because you are using the Skeleton Modeling Technique you will Will traverse all the links (references), thus you will get a huge list ofįiles. Yes, you do have to wait a long time before DA reads all the references.

#ICOPY KINGSTON PROFESSIONAL#

Operating System: Windows XP professional edition SP2 Monitor: Samsung 913N 19” 8ms response LCD panel Power Supply: Thermal Take 420watt true power PSU Network: 2X onboard Gigabit LAN and 1X 54MB wireless Video Card: ATI FIRE GL V7100 256MB PCI express workstation

#ICOPY KINGSTON SOFTWARE#

Optical Drive: Pioneer 109 DVDRW with nero software System HDD: 2X Western Digital 36GB Raptor (10000rpm sata) HDD’s RAM: 2GB Kingston Hyper X Gold 2.2.2.5 timing ram Just inĬase if you (or anyone who reads this post) is interested in my computer Have to rename one part at a time, open up an assembly and resolve the link.Īnd it is by far the fastest option. "The DA will not be even able to open an assembly to deal with". Open an assembly in DA it took 40 minutes and then the bloody thing justĬrushed. I appreciate the help, I am sure there is a way please point me in the right direction, thanks.Īnd how long is a long time? Let me tell you, that last time I was trying to

#ICOPY KINGSTON HOW TO#

If I load a Drawing into the DA, how do I update those parts in OTHER drawings at the same time with the new names? If I load an assembly and rename and copy parts, how do I update all the drawings at the same time? If I have ONE master drawing of the assembly and 10 drawings with parts on them, how can I make sure all of these drawings are updating when I am copying and moving and renaming files? I have been trying to copy a project with about 10 drawings and have been struggling with how to rename parts as I copy them so everything stays together in the new folder, drawings and all. With Inventor, I can't find anywhere to take lets say 10 drawings with all their files and then relocate and then also rename the files using Find Replace, such as C1A to C1B, etc. It’s very simple to take an entire project, drawings and all, rename anything and set it somewhere else with no conflicts on where the files went or if they are pointing to the right location. I am a CSWP (SolidWorks) and can copy, with move and rename, of files in SW in a few minutes using the Save As Copy and Reference buttons, along with Find & Replace. Forgive me I am a beginner here with Inventor.

1 note

·

View note

Text

KROST Metal Electric Chainsaw Stand Bracket Set for Angle Grinder Machine. (11.5" Chainsaw Stand + Grinder + Wheels)

KROST Metal Electric Chainsaw Stand Bracket Set for Angle Grinder Machine. (11.5″ Chainsaw Stand + Grinder + Wheels)

Price: (as of – Details)

Heavy duty 850w angle grinder machine,,, wheel size: 100mm voltage/frequency : 230v/50hz input power : 850w no load speed : 10000rpm. Power: 850 watt, cutting wheel size: 100 mm (4-inch), speed: 11,000 rpm, spindle size: M10, cable: 2 m 850 watts powerful motor makes grinding and cutting operations run smoothly runs at 11000 rpm making all grinding operations easy and…

View On WordPress

0 notes