#3D modeling with DLP

Explore tagged Tumblr posts

Text

#digital light processing (DLP)#DLP technology#DLP projectors#DLP vs. LCD#DLP architecture applications#architectural visualization#3D modeling with DLP#benefits of DLP#DLP in presentations#immersive design experiences.

1 note

·

View note

Text

#low qual pics#low quality#small penis size#3d printing#resin#dick pics of the day#mini#bag of dicks#funny#homemade#little penis#micro#3D printer#3D print#mars 4 dlp by elegoo#3d model

1 note

·

View note

Text

I was tagged by @sleightlyoffhand to list 5 topics I can talk on for an hour without preparing any material. You asked for it.

3D printing. This one was too easy. I could talk specifics of FDM machines and materials, or vaguely about other types. These range from SLS to DLP, to more niche high price models I'll never see irl except once. Like anything from Stratasys. Who I used to hecking idolize for having one of the first patents for 3D printing, other than the guy who came up with SLA.

CNC machines. This is probably an extension of 3D printing, as most FDM machines work pretty similar to most CNC mills, engravers etc. The code is the same (gcode). It can be easily written for simple processes like cutting, facing, and drilling. But, just as a slicer program converts 3D models to gcode, there are programs out there for turning 3D information into CNC gcode. It's just a subtractive process instead of an additive one.

The consequences of technology. Especially AI. It may be the best and worst thing to happen to humanity. I could rant about all the wonderful and horrible things that could arise, but it is probably better for both of us if I don't.

Minecraft. Maybe I quit lately, but I could still talk about the history from beta onwards. At least up until whatever update added the chat moderation. I really like pistons (old update) and I really like the bees (is that still considered new?). I love automatic farms, but they are more fun when you have a team that can use them. Don't get me started on redstone, or it will turn into a ramble about electronics and logic gates.

Crash Bandicoot. This place is not a place of honor. No highly esteemed deed is commemorated here. Nothing of value is here. What is here was dangerous and repulsive to us.

Tagging: @wigglerhope @ravenekrops @moth-unit-00

7 notes

·

View notes

Text

3D Projector Market Size to Hit USD 7.71 Billion by 2032

The global 3D projector market size was valued at USD 4.41 billion in 2024 and is projected to grow from USD 4.70 billion in 2025 to USD 7.71 billion by 2032, exhibiting a CAGR of 7.3% during the forecast period. North America led the global market in 2024, capturing a 37.64% market share, driven by demand in education, cinema, gaming, and simulation sectors.

Key Market Highlights:

2024 Global Market Size: USD 4.41 billion

2025 Global Market Size: USD 4.70 billion

2032 Global Market Size: USD 7.71 billion

CAGR (2025–2032): 7.3%

Leading Region (2024): North America (37.64% market share)

Top Players in the Global 3D Projector Market:

Epson

Sony Corporation

Barco NV

BenQ Corporation

Acer Inc.

Panasonic Holdings Corporation

Christie Digital Systems

Optoma Corporation

ViewSonic Corporation

NEC Display Solutions (Sharp Corporation)

LG Electronics

Digital Projection Ltd.

Canon Inc.

Request for Free Sample PDF: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/3d-projector-market-108575

Market Dynamics:

Growth Drivers:

Expanding Demand in Education and Training: Institutions globally are incorporating 3D projectors into classrooms and simulation labs for immersive learning experiences.

Booming Home Entertainment and Gaming Industry: Consumers are increasingly investing in 3D-capable projectors to enhance home theater and gaming setups.

Adoption in Healthcare and Engineering Sectors: Medical training, surgical simulations, and architectural visualizations are driving demand for precision 3D projection.

Evolving Cinema and Event Experiences: Cinemas, exhibitions, museums, and immersive events are deploying advanced 3D projection for interactive storytelling.

Falling Costs and Product Miniaturization: Technology advancements are reducing hardware prices while improving portability and ease of use.

Key Opportunities:

Rise in AR/VR and Mixed-Reality Integration: Hybrid experiences blending 3D projection with augmented content are opening new frontiers in simulation and gaming.

Smart City and Urban Planning Visualization: Government and planning agencies are adopting 3D projection to simulate infrastructure and development scenarios.

Growth in Developing Markets: Emerging economies in Asia Pacific, Latin America, and the Middle East are seeing rapid digital transformation and educational infrastructure upgrades.

3D Projection Mapping: Increasing use in advertising, concerts, and public installations presents a niche but high-growth application area.

Market Trends:

Wireless & Smart Connectivity Integration (e.g., Wi-Fi, Bluetooth, Android OS)

Eco-Friendly Laser Light Sources with longer lifespans

Miniature Projectors for Portability in classrooms and mobile setups

Projection-as-a-Service business models for events and enterprises

Enhanced Color Accuracy and 3D Depth Sensing using AI calibration

Regional Insights:

North America: Dominates with strong adoption in education, film production, and enterprise training. Presence of key market players and institutions supports growth.

Europe: Stronghold in industrial design, museums, and public events using 3D projection mapping.

Asia Pacific: Fastest-growing region, driven by education reforms in China and India and rising tech adoption across Southeast Asia.

Latin America & MEA: Emerging demand for mobile and cost-efficient 3D projectors for learning and events.

Speak to Analyst: https://www.fortunebusinessinsights.com/enquiry/speak-to-analyst/3d-projector-market-108575?utm_medium=pie

Technology Scope & Application Areas:

Projection Technologies:

DLP (Digital Light Processing)

LCD (Liquid Crystal Display)

LCoS (Liquid Crystal on Silicon)

Light Sources:

Laser

LED

Hybrid

Lamp-based

Key Applications:

Education & Training

Home Entertainment

Gaming & Simulation

Events & Exhibitions

Medical & Industrial Visualization

Cinema & Large Venue Projection

Resolutions Supported:

HD (720p)

Full HD (1080p)

4K UHD and beyond

Recent Developments:

March 2024 – Sony unveiled a compact 4K 3D laser projector targeted at simulation and design professionals, featuring HDR10 support and wireless casting.

November 2023 – BenQ launched its education-focused 3D projectors across Southeast Asia, integrating cloud-based whiteboard functionality and Google Classroom compatibility.

August 2023 – Epson partnered with a VR startup to explore hybrid projection-AR applications for automotive training in the U.S. and Germany.

Conclusion:

The global 3D projector market is set for steady expansion as immersive content becomes central to modern education, training, and entertainment. With affordable hardware, expanding use cases, and increasing accessibility across regions, 3D projection is moving from niche to necessity.

#3D Projector Market Share#3D Projector Market Size#3D Projector Market Industry#3D Projector Market Analysis#3D Projector Market Driver#3D Projector Market Research#3D Projector Market Growth

0 notes

Text

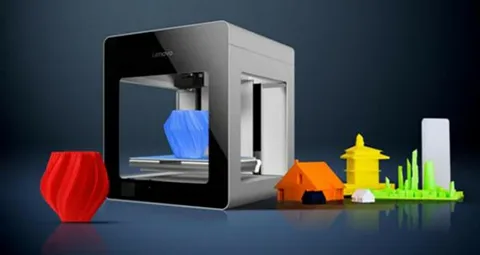

Exxjet Systems LLP

About Exxjet Systems:

Exxjet Systems is a premier provider of advanced additive manufacturing and 3D scanning solutions, renowned for transforming innovative ideas into reality. Specializing in industries such as automotive, aerospace, education, manufacturing, and healthcare, Exxjet combines cutting-edge technology with industry expertise to deliver superior products and services. By integrating high-precision 3D scanners, sophisticated CAD modeling, and advanced 3D printers technologies, Exxjet excels in reverse engineering and end-to-end production workflows, ensuring accurate digital modelling and the creation of exact physical replicas or improved designs.

Exxjet’s comprehensive approach ensures the successful deployment and onboarding of solutions at customer sites. They provide tailored support from initial consultation and design through production and installation, including training and ongoing support to integrate new capabilities into existing processes. This enhances productivity and innovation across various industries. With a focus

Offering Portfolio:

Zortrax M300 Dual: With dual-extrusion technology, this printer can handle complex designs with ease, especially those requiring water-soluble supports. It excels in printing intricate models, offering enhanced possibilities for multi-material prints.

Zortrax M200 Plus/ Zortrax M300 Plus: This printer offers high-speed printing capabilities, making it suitable for batch production and rapid prototyping. Its reliability and precision make it a popular choice for professionals looking to streamline their workflow.

Phrozen Sonic Mega 8K V2: Phrozen Sonic Mega 8K V2 boasts ultra-high-resolution printing capabilities, perfect for crafting intricate models and prototypes with exceptional detail. Its precision and clarity ensure faithful reproduction of even the most complex designs, making it a top choice for professionals seeking unparalleled printing quality.

EinScan HX: As a hybrid 3D scanner, the EinScan HX combines blue LED light and laser technology, resulting in enhanced compatibility with a wide range of materials and surfaces. Its high precision and resolution make it well-suited for industrial applications where accuracy is crucial.

EinScan H2: The EinScan H2 is an advanced handheld 3D scanner that incorporates hybrid technology for improved scanning versatility and efficiency. Its ability to adapt to various scanning scenarios makes it a valuable tool for professionals in industries ranging from manufacturing to healthcare.

Einscan Einstar: This handheld 3D scanner stands out for its high color accuracy, thanks to its RGB color camera. It captures true-to-life colors during the scanning process, making it ideal for applications where color fidelity is important, such as art restoration or product design.

3D Digitization Services

Under the banner of our 3D Digitization services, we offer both fused and individualized solutions tailored to meet specific industry requirements. Seamlessly blending cutting-edge 3D printing and scanning capabilities, we harness a comprehensive array of technologies including FDM, Resin, LCD, Polyjet, and DLP. Whether clients seek integrated solutions for streamlined processes or individual services to address particular needs, our expertise spans from prototyping and reverse engineering to post-processing and batch production. Explore the transformative potential of our 3D Digitization services across industries and applications, unlocking new possibilities in design, manufacturing, and beyond.

3D Printing Services

In the realm of manufacturing and prototyping services, with deep domain expertise we specialize in 3D printing services with comprehensive range of solutions utilizing cutting-edge technologies like FDM, Resin, LCD, Polyjet, and DLP. These technologies enable the production of high-quality parts using a variety of materials, from thermoplastics to photopolymers, catering to diverse application needs with precision and versatility.

FDM technology excels in producing robust, functional prototypes and end-use parts using thermoplastic filaments, making it ideal for engineering applications requiring strength and durability. On the other hand, Resin-based printing methods such as SLA and DLP provide exceptional surface finish and detail, perfect for creating intricate models, jewelry, and dental prosthetics. LCD and Polyjet technologies expand the possibilities further, allowing for the creation of multi-material, multi-color parts with high-resolution detail and smooth surface finishes. These capabilities are invaluable in industries such as consumer electronics, automotive, and medical devices where aesthetics and functional complexity are crucial.

Additionally, we offer a comprehensive range of post-processing options such as lacquering, painting, sanding, and surface finishing to further enhance the appearance and functionality of 3D printed parts. Moreover, for batch production requirements can engage in add-on services like vacuum casting, enabling the replication of high-quality parts in various materials with consistency and efficiency. This holistic approach ensures that clients receive end-to-end solutions tailored to their specific needs, from initial design to final production, all under one roof.

3D Scanning services

Our 3D scanning service offers comprehensive capabilities, accommodating objects ranging from micro to macro scale. From intricate small mechanical parts to imposing sculptures, vehicles, buildings, and boats, we cover a wide spectrum of items. Our scanning solutions serve various purposes, including reverse engineering objects into parametric 3D models, conducting deviation analyses, and providing a foundation for prototyping and 3D printing. These services find application across diverse fields such as industry, architecture, archaeology, art, and research.

Moreover, our expertise extends beyond mere data acquisition; we offer comprehensive post-processing services to refine and enhance scanned data, ensuring optimal compatibility with downstream applications such as CAD modelling and simulation. Explore the diverse range of customer stories showcasing the transformative impact of our 3D scanning solutions across various industries and applications.

Exxjet Expertise:

With 8 years of industry experience, our 3D printing services cater to a diverse range of sectors, offering advanced solutions for rapid prototyping, high-precision manufacturing, and custom medical device production. Leveraging cutting-edge technologies, we ensure detailed, realistic prototypes, durable end-use components, and streamlined workflows tailored to the specific needs of automotive, aerospace, education, manufacturing, and healthcare industries.

Automotive: Rapid prototyping and production of both full-color and functional custom parts, ensuring detailed and realistic prototypes as well as durable, end-use components.

Aerospace: High-precision components for complex assemblies, ensuring durability and performance through advanced 3D printing technologies.

Education: Advanced tools for teaching and research, including full-color models for enhanced learning experiences and visualization.

Manufacturing: Streamlined workflows for efficient production, utilizing high-resolution 3D printing to create detailed and functional parts.

Healthcare: Custom medical devices and anatomical models for pre-surgery analysis, improving patient outcomes with precise and accurate 3D-printed models.

#3d printers#types of 3d printers#best 3d printers#3d printers india#3d printers near me#3d printers in india#3d printers in bangalore#industrial 3d printers#different types of 3d printers#3d printers for sale#best 3d printers in india#what are 3d printers#3d printers cost#3d printers bangalore#3d scanners#types of 3d scanners#handheld 3d scanners#3d scanners for 3d printers#artec 3d scanners#top 3d scanners#3d scanners for reverse engineering#industrial 3d scanners#how do 3d scanners work#cheap 3d scanners#3d scanners for 3d printing#best 3d scanners#3d printers and scanners#3d scanners near me#3d scanners in india

1 note

·

View note

Text

How fast is 3D printing?

How fast can 3D printing be? In what scenarios can it really bring the dual advantages of speed and cost? This article will compare mainstream 3D printing technologies (such as FDM, SLA, SLS, MJF) with traditional processes (such as CNC, injection molding, casting), combined with typical production scenarios, to dismantle the technical core and commercial significance of "3D printing speed" for you.

I believe that after reading this article, you will have a clearer answer to "when to use 3D printing and why it is so fast and meaningful".

Fast 3D Printing vs. Traditional Crafts: Which is Faster?

Before we compare specific technologies, let's clarify a basic issue: FDM (fused deposition modeling), SLA (stereolithography), MJF (multi-jet fusion), these names are all different molding principles of 3D printing. They each have their own unique printing methods, material adaptability and speed performance, so they have their own advantages in efficiency. In sharp contrast to them, traditional manufacturing processes such as CNC, injection molding, and casting also have completely different production capacity structures and response rhythms. Let's disassemble them one by one to see whether 3D printing technology can catch up in terms of speed.

FDM vs. CNC

When you need to make a small tool sample urgently (for example, wThe advantage of this technology lies not only in its speed, but also in its flexibility. In particular, after adjusting the nozzle diameter (such as above 0.6mm), the nozzle speed can reach 150 mm/s, and a medium-complex part with a height of 100mm can be printed within 1 hour. FDM has obvious advantages in printing speed, which can significantly improve molding efficiency and is suitable for rapid prototyping and testing of medium-complexity prototypes.hen the design is completed at 3 pm and the installation verification is required in the evening), FDM (fused deposition modeling) technology will be the best solution.

But if it is changed to CNC, the delivery time is often measured in days due to the preparation of process documents, debugging of tool fixtures, and cutting process.

SLA/DLP vs. Injection Molding

SLA (stereolithography) is known for its high precision, with a layer thickness of 0.025–0.1 mm, an accuracy of up to ±25μm, and a molding speed of about 10–30 mm/h. The advantage of SLA printing speed is not its high speed, but its ability to output stably while maintaining surface quality, which is suitable for scenes with high requirements for process consistency.

DLP (digital light processing) is more efficient in printing. It increases the printing speed to 50-100 mm per hour by exposing the entire layer of the image at the same time, which is particularly efficient in the production of small-sized and large-quantity parts. The advantage of DLP printing speed is that it can quickly respond to batch requirements. It keeps a certain degree of accuracy while minimizing the unit molding time.

In contrast, although injection molding is very fast in single-piece molding speed, its overall delivery cycle is often extended by the pre-process of "mold development", which usually takes several days or even weeks and is accompanied by high costs. If the product design is frequently adjusted, the trial and error cost of repeated mold changes will also be very high.

SLM vs. Metal Casting

The biggest feature of SLM is that it can print complex structures in one go - for example, parts with through holes, buckles, and grids, without any support. Since SLM does not require mold opening and prefabrication processes, it can significantly speed up the overall delivery speed in the early stages of product development.

In contrast, although metal casting has cost advantages in mass production, the preparation process is long - mold design, casting cooling, and deburring often take several days or even a week. If you encounter a business scenario that requires rapid iteration, metal casting technology is basically unsolvable.

How fast 3D printing wins in three major scenarios with speed

In addition to the differences in the technology itself, the advantages of 3D printing speed also vary in different practical scenarios. From R&D proofing to mass production, we take a panoramic look at its actual performance at the application level.

Rapid prototyping

In the early stages of hardware product development, whether or not samples can be produced within a day often determines the efficiency of project iteration. Compared with traditional manufacturing that requires production scheduling, mold making, and debugging, 3D printing can achieve same-day design and same-day delivery. FDM printing is suitable for structural verification and preliminary testing, while SLA can achieve high-quality appearance models with a resolution of ±25μm. No mold is required, and samples can be produced directly, which is the biggest speed advantage of 3D printing in the prototype stage.

3D printing technology understands that prototype verification is not a one-time delivery, but a cycle mode of rapid trial and error-instant correction to promote continuous product evolution. Making trial and error fast and low-cost is the key force that 3D printing technology gives to the rhythm of product development.

Small batch custom production

When products pursue personalization and frequent iterations, the mold development and assembly processes of traditional manufacturing often cannot keep up with the pace. 3D printing technologies such as MJF and SLM do not require mold opening and can directly print finished parts. Taking MJF as an example, the industrial model has an hourly output of more than 3,000 cm⊃3;, which is suitable for typical scenarios such as orthopedic brackets and customized shells.

The key to small-batch customization is not the unit cost, but the response speed of delivery and the freedom of design. 3D printing provides a new generation of flexible manufacturing path.

Large-scale standardized production

Although injection molding and CNC still dominate in mass manufacturing, 3D printing is becoming an accelerator for early verification. In the stages of new product trial sales and regional testing, 3D printing can deliver hundreds of samples within a few days, seize the market time window, and reduce the risk of repeated mold modifications.

In mass manufacturing, 3D printing is not a substitute, but an accelerator. It helps companies quickly try and fail in uncertainty and make more informed judgments before formal mass production.

In an era where manufacturing efficiency has become a competitive threshold, the speed dividend of 3D printing has moved from prototypes to mass production, from innovation to profits. It can not only fill the response window of traditional processes, but also provide a decision buffer in uncertainty. The question is not whether 3D printing can be used, but when it is most cost-effective to use it. The following table summarizes the performance of various manufacturing methods in terms of speed, flexibility and cost under different production goals, helping you to judge at a glance:

3D printing is not the opposite of traditional manufacturing, but a powerful complement to it. From rapid prototyping, flexible trial production to product verification, it allows companies to conduct trial and error quickly and at low cost, speeding up the pace of every idea to implementation. This is exactly the key point mentioned at the beginning of the article: the real manufacturing advantage does not lie in how fast the machine runs, but in whether you can use "speed" on the blade of innovation at the right time.

Want to learn more about which 3D printing solution is best for your product design or production line? Contact us for a free consultation.

1 note

·

View note

Text

Durable and Accurate Prints with High-Quality 3D Printing Resin

Achieve flawless surfaces and fine detail with cutting-edge 3D Resin. Preferred across industries for its precision and consistent performance.

Modern manufacturing demands precision, durability, and innovation. Engineers, designers, and developers across the globe are constantly searching for the right material to bring digital designs into the physical world without compromising on quality. For industries looking to take their additive manufacturing capabilities to the next level, advanced 3D Printing resin has become an essential material. This resin offers the ideal combination of strength, flexibility, and resolution—making it indispensable for professional-grade 3D printing tasks.

At the core of this innovation lies Jyoticeramic , a brand known for engineering materials with exceptional performance in mind. The JYOCURE resin range is specifically developed for high-resolution stereolithography (SLA) and digital light processing (DLP) printers. This resin meets the needs of professionals who prioritize smooth finishes, detailed accuracy, and reliable outcomes in every print.

Resin printing has outpaced traditional methods in many sectors because of its ability to replicate even the smallest design elements. From functional parts to intricate concept models, 3D printing has revolutionized rapid prototyping. What sets apart high-grade resins is their post-cure durability and low warping properties—factors that are fully addressed in this modern printing material.

JYOCURE by jyoticeramic : Performance You Can Trust Engineered for industrial-grade performance, JYOCURE resin meets the demands of high-resolution 3D printing applications. It is designed to reduce shrinkage and eliminate layer misalignment during both the printing and curing processes. This resin adapts seamlessly across various sectors such as automotive, aerospace, dental, and consumer electronics, offering reliability and efficiency for professionals working in diverse printing environments.

Key Benefits of the Resin:

Excellent tensile strength ensures structural integrity

High-definition output on intricate geometries

Smooth, matte finish suitable for direct use

Reduced post-processing shrinkage

UV resistance and extended shelf life

Its robust formulation supports a wide range of printing systems, providing flexibility and consistent results.

Industrial Applications Driving Change The adaptability of this has made it a popular choice beyond conventional prototyping. Professionals use it to craft functional master molds, precise mechanical parts, and visually accurate mockups. Its role in medical modeling provides realistic anatomical structures beneficial for educational and surgical use.

With clear visual output and high thermal endurance, the resin is suitable for translucent enclosures and parts exposed to environmental stress. Its reliable mechanical properties make it ideal for rigorous product testing, both functional and aesthetic.

Professionals High-Performance Resin Automotive researchers benefit from this resin's ability to replicate detailed curves and fine textures directly from CAD models. This reduces development time and enhances prototype accuracy. Automotive parts printed with this material are visually polished and capable of fit and function testing, which improves team collaboration and speeds up design validation.

Engineers value this resin for consistent performance without requiring frequent recalibration. It enables complex design execution while maintaining fast iteration speeds. From mechanical assemblies to presentation-ready models, the resin supports innovation and efficiency in every stage of product development.

Design Studios Using 3D Resin for Client Mockups Design and marketing agencies rely on presentation-quality outputs. This resin accurately replicates engraved text, fine edges, and layered detail, helping creators deliver samples that match the original concept. It elevates customer interaction and supports faster decision-making.

Architects and consumer brands use this material to create scaled models that are not only visually compelling but also durable enough for handling. The tactile feedback enhances client satisfaction and makes concept validation smoother.

Educational Use and Innovation Hubs Academic institutions and tech labs are leveraging this advanced resin to support hands-on learning. It is widely used in fields ranging from biology to electronics. From visual teaching aids to circuit housing prototypes, the resin facilitates affordable and accessible digital fabrication.

Its compatibility with standard SLA systems makes it ideal for institutions aiming to improve their technical infrastructure without significant investments.

Applications Include:

Prototyping for automotive and aerospace industries

Dental and anatomical modeling

Jewelry and precision mold casting

Engineering and industrial design mockups

Educational and research-based fabrication

This versatile material transforms ideas into high-quality physical prototypes effortlessly.

Choose a trusted 3D Printing Resin for creating reliable prototypes and end-use parts. It empowers innovation through accuracy, speed, and material strength.

Visit: https://www.jyoticeramic.com/jyocure.php

Contact: +91 253 6918111

0 notes

Text

Desktop 3D Printer Market Growth Drivers Transforming Additive Manufacturing Industry Globally

The desktop 3D printer market has witnessed remarkable growth over recent years, revolutionizing how products are designed, prototyped, and even manufactured. As additive manufacturing technology continues to advance, the demand for desktop-sized 3D printers has surged among hobbyists, educators, small businesses, and professionals. Understanding the primary drivers behind this market growth is essential for stakeholders aiming to capitalize on the expanding opportunities. This article delves into the key factors propelling the desktop 3D printer market forward.

1. Technological Advancements and Innovation

One of the most significant drivers behind the desktop 3D printer market is ongoing technological innovation. Improvements in printer hardware, including better precision, faster print speeds, and enhanced reliability, have made desktop 3D printers more accessible and capable. The evolution from basic fused deposition modeling (FDM) to more sophisticated technologies such as stereolithography (SLA) and digital light processing (DLP) has broadened application possibilities, encouraging more users to adopt desktop 3D printing.

Moreover, advances in printing materials—from plastics to composites and even metal-infused filaments—have expanded the functional range of desktop 3D printers. These improvements enable users to create durable, high-quality prototypes and end-use parts, making desktop 3D printing a viable option across many industries.

2. Decreasing Costs and Increasing Affordability

Cost reduction is another powerful driver for the desktop 3D printer market. Early 3D printers were prohibitively expensive for individual users and small businesses. However, economies of scale, increased competition among manufacturers, and technological maturity have drastically lowered prices. Today, entry-level desktop 3D printers are available at affordable prices, opening the market to hobbyists, students, and startups.

Alongside hardware costs, the decreasing price of printing materials and software solutions further contributes to affordability. This overall reduction in total cost of ownership encourages wider adoption and frequent usage of desktop 3D printers.

3. Growing Demand for Rapid Prototyping and Customization

Industries increasingly demand rapid prototyping to accelerate product development cycles. Desktop 3D printers allow designers and engineers to quickly iterate designs without relying on costly third-party manufacturing. This on-demand prototyping significantly reduces lead times, lowers development costs, and enables faster time-to-market.

Additionally, the rise of mass customization in sectors like healthcare, fashion, and consumer goods boosts the need for flexible manufacturing solutions. Desktop 3D printers empower small-scale production of customized items tailored to individual specifications, meeting customer demands for uniqueness and personalization.

4. Expansion of Educational and DIY Markets

Educational institutions and maker communities play an influential role in expanding the desktop 3D printer market. Schools and universities integrate 3D printing into STEM curricula to provide students hands-on experience with emerging technologies. This exposure cultivates future professionals familiar with additive manufacturing, thereby sustaining market growth.

The DIY and maker movement thrives on accessible, affordable desktop 3D printers, enabling enthusiasts to create prototypes, replacement parts, and artistic projects. Online communities sharing designs and knowledge stimulate further interest and innovation, broadening the user base.

5. Enhanced Software and User-Friendly Interfaces

User experience improvements drive the market by making 3D printing less intimidating for new users. Advanced software with intuitive interfaces, pre-configured print profiles, and automated calibration simplify the printing process. Cloud-based platforms and mobile apps offer seamless remote management, design sharing, and collaboration.

Such user-friendly solutions lower the entry barriers and increase productivity, encouraging adoption by non-technical users and businesses alike.

6. Increasing Adoption in Healthcare and Other Key Industries

The healthcare industry’s adoption of desktop 3D printing significantly influences market growth. Customized implants, surgical guides, prosthetics, and anatomical models are increasingly produced using desktop printers for personalized patient care. This sector’s expanding use cases highlight the practical benefits of desktop 3D printing technology.

Similarly, industries like automotive, aerospace, consumer electronics, and architecture are leveraging desktop 3D printers for prototyping, tooling, and small-batch production, driving broader market demand.

7. Government Initiatives and Investments

Government policies and initiatives promoting innovation and advanced manufacturing also act as growth drivers. Funding for research, subsidies for equipment acquisition, and support for technological education encourage adoption of desktop 3D printing. Such measures foster an ecosystem conducive to market expansion.

Conclusion

The desktop 3D printer market is propelled by a combination of technological innovations, cost reductions, and growing demand for rapid prototyping and customization. Expanding applications in education, healthcare, and industry further amplify growth prospects. As software becomes more user-friendly and governments support advanced manufacturing initiatives, the desktop 3D printer market is set to continue its dynamic growth trajectory, reshaping traditional manufacturing paradigms and enabling creativity across sectors.

0 notes

Text

Exploring 3D Printer Printing Materials: A Comprehensive Guide

3D printing has revolutionized the way we create objects, from prototypes and tools to finished products. Central to the success of any 3d printer printing material, also known as filament or resin, depending on the type of printer. With a wide variety of options available today, choosing the right material can significantly impact the strength, flexibility, cost, and visual appeal of the final print.

1. PLA (Polylactic Acid)

PLA is one of the most popular and beginner-friendly 3D printing materials. Made from renewable resources like corn starch, it is biodegradable and easy to print with due to its low printing temperature (around 180-220°C). PLA does not require a heated bed, making it ideal for hobbyists and entry-level 3D printers.

Pros:

Environmentally friendly

Low warping

Available in various colors and finishes

Cons:

Brittle compared to other plastics

Not suitable for high-temperature environments

2. ABS (Acrylonitrile Butadiene Styrene)

ABS is another widely used material, especially in industrial and engineering applications. It’s tougher and more durable than PLA, making it suitable for parts that need to withstand wear and tear. However, it requires a heated bed and emits fumes during printing, so proper ventilation is essential.

Pros:

High strength and durability

Better heat resistance than PLA

Cons:

Warps easily without proper bed temperature

Emits strong fumes when printing

3. PETG (Polyethylene Terephthalate Glycol)

PETG is a hybrid of PLA and ABS, offering the best of both worlds. It is durable, slightly flexible, and has excellent chemical resistance. PETG is ideal for printing mechanical parts, water bottles, and enclosures.

Pros:

Strong and impact-resistant

Water and chemical resistant

Easy to print with minimal warping

Cons:

Slightly more difficult to print than PLA

Can be stringy during extrusion

4. TPU (Thermoplastic Polyurethane)

TPU is a flexible filament that’s great for applications requiring elasticity, such as phone cases, gaskets, and wearable items. While it can be tricky to print, especially for beginners, the results are rewarding for functional prototypes and end-use parts.

Pros:

Flexible and elastic

Durable under stress

Resistant to abrasion

Cons:

Requires slow printing speeds

Not compatible with all extruders

5. Nylon

Nylon is a high-performance synthetic polymer known for its strength, flexibility, and abrasion resistance. It’s widely used in industrial-grade 3D printing for gears, hinges, and mechanical parts. Nylon is hygroscopic, meaning it absorbs moisture from the air, which can affect print quality.

Pros:

Excellent mechanical properties

Good impact and chemical resistance

Cons:

Requires high printing temperatures

Must be stored in a dry environment

6. Resin (for SLA/DLP printers)

Unlike the filaments used in FDM printers, SLA and DLP 3D printers use liquid resin. There are different types of resins available, including standard, tough, flexible, and biocompatible. Resin printing offers unmatched detail and surface finish, making it popular for miniatures, dental models, and jewelry prototypes.

Pros:

Extremely high resolution

Smooth surface finish

Cons:

Requires post-processing (cleaning and curing)

Resin is toxic and needs careful handling

Choosing the Right 3D Printing Material

The ideal material depends on your specific needs—whether it’s strength, flexibility, aesthetic appeal, or environmental sustainability. Beginners may prefer starting with PLA due to its ease of use, while more advanced users might explore ABS, PETG, or Nylon for functional parts. For high-detail models, resin is the preferred choice.

Conclusion

The world of 3D printer printing materials is vast and continually evolving. Whether you’re printing prototypes, tools, or finished products, understanding the properties and applications of each material ensures better results. As technology advances, new materials are emerging that combine strength, flexibility, and environmental friendliness, making 3D printing more versatile than ever before.

0 notes

Link

This Full HD 120 Inch Smart laser projection TV, part of the new EpiqVision Ultra range, comes with Android TV and sound by YAMAHA. Open up the possibilities to bigger and more exciting home entertainment while keeping your home stylish, without a black screen permanently on the wall. Epson's Full HD ultra-short-throw laser projection TV is sleek in design with Android TV and sound by YAMAHA, and is designed for projecting up to 120 Inch with 3LCD technology, a high contrast ratio and sharp images. THE BIG SCREEN EXPERIENCE Feel immersed in everything you watch or play with this stylish and affordable Full HD projector which can produce up to a 120 Inch image. Smart home entertainment Android TV offers thousands of movies, shows, and games from Google Play, You Tube and other favourite apps. Enjoy dynamic audio and 3D surround sound with sound by YAMAHA, which can be used with or without a visual display by simply selecting the the visual display to mute and can also connect to a smart device with Bluetooth audio. LONG-LASTING SOLUTION Looking for a long-term, hassle-free and affordable solution to replace your TV? With this model's long-lasting lamp light source, you'll be able to enjoy entertainment for up to 10 years. SUPERIOR PICTURE QUALITY With a high brightness of 3,600 lumens and contrast ratio of 2,500,000:1, this projector delivers lifelike content and defined shadow detail. Epson's 3LCD technology means its projectors have up to three times brighter colours, than comparable 1-chip DLP projectors. Full HD Smart laser projection TV - supersize your favourite films, games and sporting events at home Smart entertainment - part of the EpiqVision Ultra range with Android TV and sound by YAMAHA Long-lasting solution - enjoy entertainment for up to 10 years Affordable, high-tech equipment - display close to projected image, up to 120" Impressive, bright display - equally high White and Colour Light Output of 3,600 lumens

0 notes

Text

Advancements in Composite Materials for 3D Printing

Exploring the Dynamic World of 3D Printing Materials Market

The world of 3D Printing Materials Market has come a long way since its inception, evolving from a niche technology to a mainstream manufacturing process. At the heart of this transformation is the ever-expanding universe of 3D printing materials. These materials are not just a means to an end; they are pivotal in defining what can be created, how it can be produced, and what industries can benefit from this cutting-edge technology. In this blog, we will delve into the key aspects of the 3D printing materials market, exploring the types, applications, and future trends shaping this exciting field.

Sample copy report:

https://wemarketresearch.com/reports/request-free-sample-pdf/3d-printing-materials-market/1338

Types of 3D Printing Materials

Thermoplastics: Thermoplastics are among the most widely used materials in 3D printing. They are known for their ease of use, affordability, and versatility. Popular thermoplastics include:

PLA (Polylactic Acid): Known for its eco-friendly nature and ease of printing, PLA is a favorite among hobbyists and beginners.

ABS (Acrylonitrile Butadiene Styrene): This material offers greater strength and durability, making it ideal for functional prototypes and end-use parts.

PETG (Polyethylene Terephthalate Glycol): Combining the ease of printing with durability, PETG is commonly used in applications requiring resistance to impact and moisture.

Resins: Resins are liquid materials that solidify under UV light and are used primarily in SLA (Stereolithography) and DLP (Digital Light Processing) printers. They offer high resolution and detail, making them suitable for applications such as jewelry and dental products. Key types include:

Standard Resins: Ideal for detailed models and prototypes.

Tough Resins: Engineered for increased durability and impact resistance.

Flexible Resins: Designed to produce parts with rubber-like properties.

Metals: Metal 3D printing is used for high-performance applications in industries such as aerospace, automotive, and medical. Metal powders, such as titanium, aluminum, and stainless steel, are used in processes like SLM (Selective Laser Melting) and EBM (Electron Beam Melting). Metal 3D printing offers:

High Strength-to-Weight Ratio: Essential for aerospace and automotive components.

Complex Geometries: Allows for the creation of intricate designs that are difficult to achieve with traditional manufacturing methods.

Composites: Composite materials combine thermoplastics with reinforcing fibers, such as carbon fiber or glass fiber, to enhance strength and rigidity. These materials are used in applications where lightweight and high strength are critical, including in the automotive and sports equipment industries.

Innovations Driving the 3D Printing Materials Market

The 3D printing materials market is experiencing rapid innovation, driven by advancements in technology and changing industry needs. Here’s a closer look at some of the latest innovations that are transforming the landscape of 3D printing materials:

Nanomaterials: Nanotechnology is making waves in the 3D printing industry by enabling the creation of materials with enhanced properties at the nanoscale. Nanomaterials can improve strength, durability, and thermal resistance, making them ideal for high-performance applications. For example, incorporating nanoparticles into polymers can enhance their mechanical properties, leading to more robust and reliable printed parts.

Bio-inks and Bioprinting: Bioprinting is revolutionizing the medical and research fields by enabling the creation of living tissues and organs. Bio-inks, which are made from natural and synthetic biopolymers, are used in this process to print cellular structures. These materials can be tailored to support cell growth and tissue development, opening up new possibilities for regenerative medicine and personalized healthcare.

Applications of 3D Printing Materials Market

The versatility of 3D printing materials market has led to their adoption across various sectors:

Aerospace: Lightweight and durable materials are used to manufacture complex parts and components, reducing overall weight and fuel consumption.

Healthcare: Custom prosthetics, implants, and dental products are tailored to individual patients using biocompatible materials.

Automotive: 3D printing enables rapid prototyping and production of lightweight parts, enhancing vehicle performance and reducing time-to-market.

Consumer Goods: Customized products, from eyewear to home decor, benefit from the flexibility and personalization offered by 3D printing.

Future Trends in 3D Printing Materials Market

As the 3D printing industry continues to evolve, several trends are likely to shape the future of 3D printing materials:

Biodegradable and Sustainable Materials: There is a growing focus on developing eco-friendly materials that reduce environmental impact. Innovations in biodegradable plastics and recycling processes are set to make 3D printing more sustainable.

Advanced Metal Alloys: The development of new metal alloys with enhanced properties will open up new possibilities for high-performance applications in industries such as aerospace and defense.

Multi-Material Printing: Advances in multi-material printing technologies will allow for the creation of complex objects with varying properties in a single print, expanding the range of applications and functionalities.

Smart Materials: The integration of materials that respond to environmental changes (such as temperature or pressure) will lead to the development of "smart" products with adaptive capabilities.

Related Reports:

Global Nanocomposites Market

Green Solvent Market

Aliphatic Polyester Polyols Market

Self-Healing Coatings Market

Benefits of 3D Printing Materials Market Report:

Analyst Support: Get your query resolved by our expert analysts before and after purchasing the report.

Customer Satisfaction: Our expert team will assist with all your research needs and customize the report.

Inimitable Expertise: Analysts will provide deep insights into the reports.

Assured Quality: We focus on the quality and accuracy of the report.

Conclusion

The 3D printing materials market is a dynamic and rapidly evolving field, driven by continuous innovation and technological advancements. From thermoplastics and resins to metals and composites, the variety of materials available today provides limitless possibilities for creators and manufacturers alike. As we look to the future, emerging trends and new material developments promise to further revolutionize the industry, offering exciting opportunities for growth and transformation across various sectors. Whether you're a hobbyist, a designer, or an industry professional, staying informed about these advancements will be key to leveraging the full potential of 3D printing technology.

#3D Printing Materials Market#3D Printing Materials Market Scope#3D Printing Materials Market Growth#3D Printing Materials Market Overview#3D Printing Materials Market Size#3D Printing Materials Market Insight#3D Printing Materials Market Trends#3D Printing Materials Market Share#3D Printing Materials Market Industry Analysis

0 notes

Text

Visualizing the Future: DLP in Architectural Design

This article examines how DLP technology is visualizing the future of architectural design. Discover its role in creating immersive experiences and facilitating design reviews. We'll explore case studies where DLP has enhanced collaboration and innovation. Learn about its integration with virtual reality for more engaging presentations. See how DLP is paving the way for the next generation of architectural visualization. Click the link and visit website for the more information!

#digital light processing (DLP)#DLP technology#DLP projectors#DLP vs. LCD#DLP architecture applications#architectural visualization#3D modeling with DLP#benefits of DLP#DLP in presentations#immersive design experiences

1 note

·

View note

Text

Looking for the Best Resin for Dental 3D Printing? Protosculpt offers high-precision dental resins designed for superior accuracy, durability, and biocompatibility. Ideal for crowns, bridges, aligners, models, and prosthetics, our 3D printing dental resins deliver exceptional detail and strength.

At Protosculpt, we ensure that our resins meet industry standards for safety, precision, and wear resistance. Whether you are a dental lab, orthodontist, or prosthodontist, our high-performance resin guarantees smooth surface finishes and excellent dimensional stability for every print.

Compatible with DLP, SLA, and LCD 3D printers, our dental resin ensures minimal shrinkage, high detail reproduction, and long-lasting results. Choose Protosculpt for reliable, biocompatible, and professional-grade dental 3D printing resins.

https://3dpresin.com/product/dental-model-plus-resin/

0 notes

Text

From Imagination to Reality: The Power of Professional 3D Printing Services

In the digital age, innovation is at the forefront of every industry. One of the most transformative technologies making waves across multiple sectors is professional 3D printing services. From rapid prototyping to full-scale production, 3D printing has revolutionized how we bring ideas to life. But what makes professional 3D printing so powerful? Let’s explore its capabilities, advantages, and how it is shaping the future of design and manufacturing.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering material based on a digital design. Unlike traditional manufacturing, which often requires cutting or molding materials, 3D printing builds objects layer by layer, making it highly efficient and customizable.

Types of 3D Printing Technologies

There are several types of 3D printing technologies, each catering to different applications. Here are the most popular ones:

1. Fused Deposition Modeling (FDM)

The most common type of 3D printing.

Uses thermoplastic filaments to build objects layer by layer.

Ideal for prototypes and consumer products.

2. Stereolithography (SLA)

Uses ultraviolet (UV) lasers to harden liquid resin into solid objects.

Provides high detail and smooth finishes.

Best for detailed models and intricate parts.

3. Selective Laser Sintering (SLS)

Uses a laser to fuse powdered materials, typically nylon or metal.

Excellent for functional prototypes and durable parts.

4. Digital Light Processing (DLP)

Similar to SLA but uses a digital light projector instead of a laser.

Faster than SLA with high accuracy.

5. Multi Jet Fusion (MJF)

Uses fusing and detailing agents along with a heat source to create precise and durable objects.

Often used in industrial applications.

Industries Benefiting from Professional 3D Printing

The adoption of 3D printing services is growing across industries, providing efficiency, cost savings, and limitless creativity.

1. Healthcare and Medical

Custom prosthetics and implants.

3D-printed surgical models for better pre-surgical planning.

Bioprinting for tissue engineering.

2. Aerospace and Automotive

Lightweight yet durable parts.

Rapid prototyping for faster innovation.

Reduction in material waste.

3. Architecture and Construction

Intricate architectural models.

3D-printed homes and structures.

Enhanced visualization for clients.

4. Consumer Goods and Retail

Custom jewelry and fashion accessories.

Personalized products tailored to individual needs.

Rapid production cycles for trendy products.

5. Education and Research

Hands-on learning with 3D-printed models.

Research in material science and engineering.

Educational tools for various disciplines.

Benefits of Professional 3D Printing Services

1. Cost-Effective Production

Traditional manufacturing often involves high setup costs, but 3D printing minimizes waste and reduces material expenses.

2. Rapid Prototyping

Businesses can develop and test prototypes faster, allowing for quicker iterations and improvements.

3. High Customization

Unlike mass production, 3D printing allows for unique, custom designs tailored to specific needs.

4. Reduced Waste and Sustainability

Since material is used only where needed, there’s less environmental impact compared to traditional manufacturing.

5. Complex Geometries and Enhanced Design Freedom

Objects with intricate details and complex shapes can be produced with ease, pushing the boundaries of creativity.

Choosing the Right 3D Printing Service Provider

Selecting a professional 3D printing service ensures quality, reliability, and efficiency. Here’s what to consider:

1. Expertise and Experience

Look for providers with a proven track record in your industry.

2. Range of Technologies and Materials

Ensure they offer a variety of 3D printing options and materials suited to your project.

3. Quality Assurance and Precision

A reliable provider should offer high-resolution prints with strict quality control.

4. Turnaround Time and Scalability

Choose a service that can meet deadlines and scale production as needed.

5. Customer Support and Consultation

A good service provider offers guidance and support throughout the process.

The Future of 3D Printing

As 3D printing technology advances, we can expect:

More sustainable materials and biodegradable printing options.

Integration with AI for enhanced design optimization.

Faster and larger-scale printing for industries like construction and aerospace.

Advancements in bioprinting, potentially leading to 3D-printed organs.

Conclusion

From concept to creation, professional 3D printing services offer unmatched possibilities for businesses and individuals alike. Whether you’re looking to innovate in healthcare, architecture, or product design, the right 3D printing partner can turn your vision into reality. With cutting-edge technology and expertise, Wintech Digital ensures precision, efficiency, and superior quality for all your 3D printing needs.

0 notes

Text

Automotive 3D Printing Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive 3D Printing Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive 3D Printing Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive 3D Printing Market is experiencing robust growth driven by the expanding globally. The Automotive 3D Printing Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive 3D Printing Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive 3D Printing Market Size, Share & Industry Analysis, By Technology Type (Electronic Beam Melting (EBM), Selective Laser Sintering (SLS), Digital Light Processing (DLP), Fused Disposition Modelling (FDP)), By Material Type (Ceramic, Metal, Polymer), By Application Type (Production, Innovation and R&D, Prototyping) and Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/103613

Key Strategies

Key strategies in the Automotive 3D Printing Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive 3D Printing Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive 3D Printing Market.

Major Automotive 3D Printing Market Manufacturers covered in the market report include:

The major companies in the global 3D printing market include 3D Systems Corporation, Stratasys Ltd., Arcam AB, EnvisionTEC, Ponoko Limited, The ExOne Company, Autodesk Inc., Hoganas AB, Optomec, Inc., Voxeljet AG among others.

Globally, the rise in urbanization, high standard of living, and increased demand of customers are leading to an increase in the automotive industry. Furthermore, the adoption of advanced technology, less time required to manufacture intricate designs, low cost of raw materials, innovation in printing methods an also investment of government to develop new technology is driving the growth of the market. However, the lack of skilled laborers and high printing costs may hamper the growth of the market.

Trends Analysis

The Automotive 3D Printing Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive 3D Printing Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive 3D Printing Market Solutions.

Regions Included in this Automotive 3D Printing Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive 3D Printing Market.

- Changing the Automotive 3D Printing Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive 3D Printing Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive 3D Printing Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive 3D Printing Market?

► Who are the prominent players in the Global Automotive 3D Printing Market?

► What is the consumer perspective in the Global Automotive 3D Printing Market?

► What are the key demand-side and supply-side trends in the Global Automotive 3D Printing Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive 3D Printing Market?

Table Of Contents:

1 Market Overview

1.1 Automotive 3D Printing Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Automotive 3D Printing Market#Automotive 3D Printing Market Share#Automotive 3D Printing Market Size#Automotive 3D Printing Market Trends#Automotive 3D Printing Market Growth#Automotive 3D Printing Market Insights#Automotive 3D Printing Tech

0 notes