#3DPrintingInnovations

Explore tagged Tumblr posts

Text

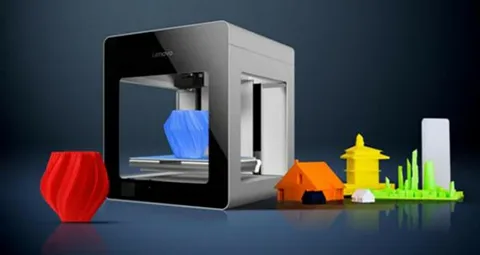

Desktop 3D Printer Market Growth Drivers Transforming Additive Manufacturing Industry Globally

The desktop 3D printer market has witnessed remarkable growth over recent years, revolutionizing how products are designed, prototyped, and even manufactured. As additive manufacturing technology continues to advance, the demand for desktop-sized 3D printers has surged among hobbyists, educators, small businesses, and professionals. Understanding the primary drivers behind this market growth is essential for stakeholders aiming to capitalize on the expanding opportunities. This article delves into the key factors propelling the desktop 3D printer market forward.

1. Technological Advancements and Innovation

One of the most significant drivers behind the desktop 3D printer market is ongoing technological innovation. Improvements in printer hardware, including better precision, faster print speeds, and enhanced reliability, have made desktop 3D printers more accessible and capable. The evolution from basic fused deposition modeling (FDM) to more sophisticated technologies such as stereolithography (SLA) and digital light processing (DLP) has broadened application possibilities, encouraging more users to adopt desktop 3D printing.

Moreover, advances in printing materials—from plastics to composites and even metal-infused filaments—have expanded the functional range of desktop 3D printers. These improvements enable users to create durable, high-quality prototypes and end-use parts, making desktop 3D printing a viable option across many industries.

2. Decreasing Costs and Increasing Affordability

Cost reduction is another powerful driver for the desktop 3D printer market. Early 3D printers were prohibitively expensive for individual users and small businesses. However, economies of scale, increased competition among manufacturers, and technological maturity have drastically lowered prices. Today, entry-level desktop 3D printers are available at affordable prices, opening the market to hobbyists, students, and startups.

Alongside hardware costs, the decreasing price of printing materials and software solutions further contributes to affordability. This overall reduction in total cost of ownership encourages wider adoption and frequent usage of desktop 3D printers.

3. Growing Demand for Rapid Prototyping and Customization

Industries increasingly demand rapid prototyping to accelerate product development cycles. Desktop 3D printers allow designers and engineers to quickly iterate designs without relying on costly third-party manufacturing. This on-demand prototyping significantly reduces lead times, lowers development costs, and enables faster time-to-market.

Additionally, the rise of mass customization in sectors like healthcare, fashion, and consumer goods boosts the need for flexible manufacturing solutions. Desktop 3D printers empower small-scale production of customized items tailored to individual specifications, meeting customer demands for uniqueness and personalization.

4. Expansion of Educational and DIY Markets

Educational institutions and maker communities play an influential role in expanding the desktop 3D printer market. Schools and universities integrate 3D printing into STEM curricula to provide students hands-on experience with emerging technologies. This exposure cultivates future professionals familiar with additive manufacturing, thereby sustaining market growth.

The DIY and maker movement thrives on accessible, affordable desktop 3D printers, enabling enthusiasts to create prototypes, replacement parts, and artistic projects. Online communities sharing designs and knowledge stimulate further interest and innovation, broadening the user base.

5. Enhanced Software and User-Friendly Interfaces

User experience improvements drive the market by making 3D printing less intimidating for new users. Advanced software with intuitive interfaces, pre-configured print profiles, and automated calibration simplify the printing process. Cloud-based platforms and mobile apps offer seamless remote management, design sharing, and collaboration.

Such user-friendly solutions lower the entry barriers and increase productivity, encouraging adoption by non-technical users and businesses alike.

6. Increasing Adoption in Healthcare and Other Key Industries

The healthcare industry’s adoption of desktop 3D printing significantly influences market growth. Customized implants, surgical guides, prosthetics, and anatomical models are increasingly produced using desktop printers for personalized patient care. This sector’s expanding use cases highlight the practical benefits of desktop 3D printing technology.

Similarly, industries like automotive, aerospace, consumer electronics, and architecture are leveraging desktop 3D printers for prototyping, tooling, and small-batch production, driving broader market demand.

7. Government Initiatives and Investments

Government policies and initiatives promoting innovation and advanced manufacturing also act as growth drivers. Funding for research, subsidies for equipment acquisition, and support for technological education encourage adoption of desktop 3D printing. Such measures foster an ecosystem conducive to market expansion.

Conclusion

The desktop 3D printer market is propelled by a combination of technological innovations, cost reductions, and growing demand for rapid prototyping and customization. Expanding applications in education, healthcare, and industry further amplify growth prospects. As software becomes more user-friendly and governments support advanced manufacturing initiatives, the desktop 3D printer market is set to continue its dynamic growth trajectory, reshaping traditional manufacturing paradigms and enabling creativity across sectors.

0 notes

Text

Top 10 3D Printing Services Companies in 2025: Leading the Future of Additive Manufacturing

In the fast-evolving world of digital manufacturing, 3D printing has revolutionized the way businesses approach design, prototyping, and production. Whether you’re a startup or an established enterprise, selecting from the best 3D printing service providers is key to ensuring quality, precision, and innovation. Below is a curated list of the top 10 3D printing services companies, with a special spotlight on Vee Technologies.1. Vee TechnologiesVee Technologies leads the industry as one of the most reliable 3D printing services companies with a global presence. Known for delivering 3D printing services in India and globally, Vee Technologies uses state-of-the-art equipment to produce high-quality prototypes and components across industries like healthcare, automotive, aerospace, and consumer goods. Their emphasis on quality, timely delivery, and client collaboration makes them a preferred partner for businesses of all sizes.2. Think3DThink3D is a top-tier 3D printing service company in India offering end-to-end solutions for rapid prototyping and additive manufacturing. It serves industries such as medical, architecture, and automotive with excellent service and turnaround times.3. ShapewaysBased in the USA, Shapeways is a leading 3D printing services company known for its vast material options and advanced technology. It allows businesses and individuals to bring complex designs to life through a user-friendly online platform.4. 3D SystemsAs one of the pioneers in the 3D printing space, 3D Systems provides industrial-grade solutions and software tools to support high-volume production and prototyping.5. ImaginariumHeadquartered in India, Imaginarium provides advanced 3D printing services in India with applications across jewelry, engineering, and medical sectors. Their rapid innovation and material variety stand out.ConclusionAs demand grows for on-demand production and prototyping, choosing the best 3D printing service provider can significantly impact product development timelines and costs. Whether you’re launching a new product or optimizing an existing one, these top 10 3D printing services companies are paving the way for a smarter, more efficient manufacturing future

#3DPrinting2025#AdditiveManufacturing#Top3DPrintingCompanies#DigitalManufacturing#3DPrintingInnovation#AdvancedManufacturing#3DPrintingServices#AMLeaders#FutureOfManufacturing

0 notes

Text

Shape the Future of Model Making with Us!

Discover innovation with our advanced 3D printers, seamlessly merging technology and artistry. Let's collaborate on your ideas—whether it's architectural models or unique creation models, we're here to bring your visions to life!

Contact us for more: +91-966-488-3746

Email : [email protected]

Website : https://maadhucreatives.com/3d-printing/

0 notes

Text

Recyclable 3D Printing Filament: The Green Future of Printing—Market Growing from $1.2B to $3.8B by 2034

Recyclable 3D printing filament market is projected to grow from $1.2 billion in 2024 to $3.8 billion by 2034, achieving a robust CAGR of 11.6%. This market is centered on eco-friendly filaments crafted from recycled materials, addressing the demand for sustainable manufacturing. These filaments, including PLA and PETG, are derived from post-consumer and post-industrial waste, enabling reduced environmental impact while supporting industries like prototyping, consumer goods, and education.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS11069 &utm_source=SnehaPatil&utm_medium=Article

The growth of this market is fueled by increasing environmental awareness and advancements in 3D printing technologies. PLA (Polylactic Acid) leads the segment, thanks to its biodegradability and user-friendly nature, appealing to both professionals and hobbyists. PETG (Polyethylene Terephthalate Glycol) follows closely due to its strength, durability, and recyclability.

Regionally, North America dominates the market, driven by its innovative ecosystem and adoption of sustainable practices. Europe is a strong contender, with nations like Germany and the Netherlands emphasizing circular economy initiatives. Meanwhile, the Asia-Pacific region is witnessing rapid growth, led by industrialization and investments in sustainable technologies in countries such as China and Japan.

In 2023, the market volume reached 250 million metric tons and is forecasted to double by 2033. The PLA segment held a commanding 45% share, followed by PETG at 30% and ABS at 25%. Companies like Filamentive, 3D Printlife, and ColorFabb are at the forefront, driving innovation and enhancing the recyclability of filament products.

Although challenges such as high production costs and limited consumer awareness persist, the market holds immense promise. Stringent EU regulations on plastic waste management and increasing R&D investments are paving the way for advancements. With AI-driven design optimization and sustainable manufacturing practices, the future of recyclable 3D printing filaments looks brighter than ever.

#3DPrinting #SustainableManufacturing #RecyclableFilament #EcoFriendlySolutions #PLA3DPrinting #PETGMaterials #CircularEconomy #AdditiveManufacturing #GreenTechnology #3DPrintingInnovation #PrototypingSolutions #BiodegradableMaterials #3DPrintingSustainability #EcoInnovation #RecycledFilaments #Industrial3DPrinting #FutureOf3DPrinting #SustainabilityGoals #3DPrintingForGood #PlasticWasteReduction #AdvancedMaterials #TechForSustainability #RethinkPlastics #AIIn3DPrinting #GreenManufacturing

0 notes

Link

Full Episode 109 - Getting Into 3D Printing Retrospective #FutureOf3DPrinting, #3DPrinting,#3DPrintersUnleashed, #3DPrintingInnovation, #Tech

0 notes

Photo

#3dprinting #3dmodeling #3Ddesign #AI #futuristictech #innovation #3Dtech #3Dprintingtech #3Drendering #3Dvisualization #3Dsoftware #3Dprintingindustry #3Dprintingsolutions #3Dprintingrevolution #3Dprintinginnovations #3Dprintingworld #3Dprintingtechnology #3Dprintinginnovation #3Dprintingforbeginners Ai 3d printing is a revolutionary technology that uses artificial intelligence (AI) algorithms to generate 3D models that can be printed. It offers a wide range of possibilities to 3D printing, from producing unique designs to automating the entire workflow. This technology has the potential to revolutionize the 3D printing industry and make it accessible to everyone. https://www.instagram.com/p/CosC1EJKquN/?igshid=NGJjMDIxMWI=

#3dprinting#3dmodeling#3ddesign#ai#futuristictech#innovation#3dtech#3dprintingtech#3drendering#3dvisualization#3dsoftware#3dprintingindustry#3dprintingsolutions#3dprintingrevolution#3dprintinginnovations#3dprintingworld#3dprintingtechnology#3dprintinginnovation#3dprintingforbeginners

0 notes

Text

How 3D Printing Is Changing the World - 3D-printing innovations in recent years have brought a change in the fabrication of everything from automobile parts to human bio-tissues - Learn More...

0 notes

Photo

These tires for the OpenRC F1 car by @danielnoree are printed in the brand new varioShore TPU by @colorfabb_official on the Original Prusa i3 MK3 by @josefprusa. This material is great for jobs like these. It has variable shorehardness because of it's active foam technology which means that higher print temperatures give you reduced weight and density so creating soft, medium and hard tires is a piece of cake. #3dprinting #3dprintinginnovation #3dp #colorfabb #varioshore #colorfabbbetatesting #expandingtpu #tpufilament #filament #technology #innovation #prusa3d #prusaprinters #prusaresearch #prusai3mk3 #makermovement #openrcf1 #de3dprintman https://www.instagram.com/p/B3ZhGfLjlV5/?igshid=okvkjsn9k6d4

#3dprinting#3dprintinginnovation#3dp#colorfabb#varioshore#colorfabbbetatesting#expandingtpu#tpufilament#filament#technology#innovation#prusa3d#prusaprinters#prusaresearch#prusai3mk3#makermovement#openrcf1#de3dprintman

1 note

·

View note

Text

Sports 3D Printing Services Market :Driven by Customization, Performance, and Advanced Material Innovations

The Sports 3D Printing Services Market is experiencing robust growth due to a range of dynamic drivers, including increasing demand for personalization, enhanced performance optimization, cost efficiency, and technological advancements. As the sports industry becomes more competitive and innovation-driven, 3D printing is transforming how equipment is designed, prototyped, and manufactured. Below are the key factors propelling the growth of this market.

Personalization and Customization

One of the most significant drivers of the Sports 3D Printing Services Market is the growing demand for customized sports gear. Athletes, both professional and amateur, increasingly seek equipment tailored to their body type, playing style, and preferences. 3D printing allows for precise customization of items such as insoles, helmets, protective gear, and footwear. For instance, footwear companies are now able to 3D print midsoles based on biometric data, offering enhanced comfort and performance. This level of personalization was not economically viable with traditional manufacturing methods but has become feasible and scalable through additive manufacturing.

Performance Optimization

The use of 3D printing in sports equipment enables the production of complex geometries and lightweight structures that are not possible with traditional manufacturing methods. These properties directly contribute to enhanced athletic performance. For example, cycling helmets and aerodynamic gear made via 3D printing can reduce drag and improve speed. Similarly, racket and bat designs can be fine-tuned for optimal weight distribution and grip. As competition becomes more intense, the need for performance-enhancing innovations has become a major driver.

Rapid Prototyping and Reduced Time-to-Market

3D printing significantly reduces the time required for prototyping new products. In traditional manufacturing, creating molds and tooling is time-consuming and costly, particularly when multiple iterations are needed. Additive manufacturing allows for quick changes and immediate production of new prototypes. This rapid prototyping capability enables sports companies to experiment more freely, bringing innovative products to market faster. The ability to respond to market trends and consumer feedback in near real-time is a strong competitive advantage.

Cost Efficiency for Small Batch Production

While traditional manufacturing is efficient for large-scale production, it becomes prohibitively expensive for small batches due to tooling costs. 3D printing eliminates the need for tooling, making it cost-effective for producing limited-edition sports products or catering to niche sports markets. This is particularly valuable for startups and smaller sports brands that cannot afford high-volume production runs. Moreover, waste material is significantly reduced in additive manufacturing, leading to lower raw material costs.

Technological Advancements in Materials

Another critical driver is the advancement in 3D printing materials. Modern 3D printing can now utilize a wide variety of polymers, metals, and composite materials, which offer strength, flexibility, and durability suitable for rigorous sports applications. Materials such as carbon-fiber-reinforced nylon and thermoplastic polyurethane (TPU) have opened new avenues for producing high-performance sports gear. These developments ensure that 3D-printed products can meet or exceed the quality standards of traditionally manufactured equipment.

Sustainability and Eco-Friendly Manufacturing

Sustainability is an increasing priority in the sports industry. 3D printing supports eco-friendly practices through on-demand production, local manufacturing, and significant reductions in material waste. Additionally, recycled and bio-based printing materials are being explored and adopted, aligning with the growing demand for sustainable sports products. The ability to produce equipment locally also reduces the carbon footprint associated with global supply chains.

Expanding Application Areas

Initially used mainly for prototyping, 3D printing in the sports industry is now being applied across a wide range of products and disciplines. From personalized golf clubs and ski boots to custom-molded mouthguards and training aids, the applications are diverse. As knowledge and experience with the technology grow, sports organizations and manufacturers are discovering new ways to integrate 3D printing into both consumer and professional sports products.

Supportive Ecosystem and Collaborations

The growing ecosystem of service providers, technology vendors, and research institutions is another growth driver. Many sports brands are forming partnerships with 3D printing companies and academic institutions to leverage cutting-edge research and manufacturing capabilities. These collaborations help accelerate the development of next-generation products and further integrate 3D printing into mainstream sports manufacturing.

Enhanced Athlete Safety and Injury Prevention

Customized protective gear enabled by 3D printing has contributed to increased athlete safety. Products such as custom-fit helmets, shin guards, and orthopedic insoles help reduce the risk of injury by offering better fit and shock absorption. This driver is particularly relevant in contact sports like football, hockey, and rugby, where player protection is a top priority.

Growing Adoption Across All Levels of Sport

Finally, the democratization of 3D printing services has made the technology accessible not only to elite athletes but also to amateur sports enthusiasts. As desktop 3D printers and service bureaus become more widespread, the technology is no longer confined to high-end professional use, leading to broader adoption across recreational and youth sports markets.

In conclusion, the Sports 3D Printing Services Market is being propelled by a confluence of technological, economic, and social factors. As additive manufacturing continues to mature, its role in reshaping the sports equipment landscape is set to expand significantly in the years ahead.

0 notes

Link

Full Episode 108 - Evolution of 3D Printers, #EvolutionOf3D, #FutureOf3DPrinting, #3DPrinting,#3DPrintersUnleashed, #PrintTheFuture, #AdditiveManufacturingEvolved, #3DPrintingInnovation, #Tech

0 notes

Link

Full Episode 107 - Unconventional 3D Printers #3DPrintingInnovations #3DPrintTech #FutureOf3DPrinting #Innovate3D #3DPrintingUnleashed #3DInnovationLab #Creative3DPrinting #NextGen3DPrinting

0 notes