#AI-Driven Factory Processes

Explore tagged Tumblr posts

Text

Generative AI: Transforming manufacturing with predictive maintenance, innovative designs, superior quality control, and efficient supply chains. Drive innovation in your industry!

#AI-Enhanced Manufacturing Solutions#Generative AI For Factory Efficiency#AI In Supply Chain Analytics#AI-Driven Industrial Efficiency#Generative AI For Manufacturing Intelligence#AI In Production Workflows#AI-Powered Manufacturing Transformation#Generative AI For Operational Efficiency#AI In Manufacturing Cost Management#AI-Driven Factory Processes#Generative AI For Industrial Productivity#AI In Production Forecasting#AI-Powered Manufacturing Automation#Generative AI For Quality Manufacturing#AI In Operational Innovation#AI-Driven Manufacturing Analytics

0 notes

Text

News of the Day 6/11/25: AI

Paywall free.

More seriously, from the NY Times:

"For Some Recent Graduates, the A.I. Job Apocalypse May Already Be Here" (Paywall Free)

You can see hints of this in the economic data. Unemployment for recent college graduates has jumped to an unusually high 5.8 percent in recent months, and the Federal Reserve Bank of New York recently warned that the employment situation for these workers had “deteriorated noticeably.” Oxford Economics, a research firm that studies labor markets, found that unemployment for recent graduates was heavily concentrated in technical fields like finance and computer science, where A.I. has made faster gains. [...] Using A.I. to automate white-collar jobs has been a dream among executives for years. (I heard them fantasizing about it in Davos back in 2019.) But until recently, the technology simply wasn’t good enough. You could use A.I. to automate some routine back-office tasks — and many companies did — but when it came to the more complex and technical parts of many jobs, A.I. couldn’t hold a candle to humans. That is starting to change, especially in fields, such as software engineering, where there are clear markers of success and failure. (Such as: Does the code work or not?) In these fields, A.I. systems can be trained using a trial-and-error process known as reinforcement learning to perform complex sequences of actions on their own. Eventually, they can become competent at carrying out tasks that would take human workers hours or days to complete.

I've been hearing my whole life how automation was coming for all our jobs. First it was giant robots replacing big burly men on factory assembly lines. Now it seems to be increasingly sophisticated bits of code coming after paper-movers like me. I'm not sure we're there yet, quite, but the NYT piece does make a compelling argument that we're getting close.

The real question is, why is this a bad thing? And the obvious answer is people need to support themselves, and every job cut is one less person who can do that. But what I really mean is, if we can get the outputs we need to live well with one less person having to put in a day's work to get there, what does it say about us that we haven't worked out a way to make that a good thing?

Put another way, how come we haven't worked out a better way to share resources and get everyone what they need to thrive when we honestly don't need as much labor-hours for them to "earn" it as we once did?

I don't have the solution, but if some enterprising progressive politician wants to get on that, they could do worse. I keep hearing how Democrats need bold new ideas directed to helping the working class.

More on the Coming AI-Job-Pocalypse

I’m a LinkedIn Executive. I See the Bottom Rung of the Career Ladder Breaking. (X)

Paul Krugman: “What Deindustrialization Can Teach Us About The Effects of AI on Workers” (X)

How AI agents are transforming work—and why human talent still matters (X)

AI agents will do programmers' grunt work (X)

At Amazon, Some Coders Say Their Jobs Have Begun to Resemble Warehouse Work (X)

Why Esther Perel is going all in on saving the American workforce in the age of AI

Junior analysts, beware: Your coveted and cushy entry-level Wall Street jobs may soon be eliminated by AI (X)

The biggest barrier to AI adoption in the business world isn’t tech – it’s user confidence (X)

Experts predicted that artificial intelligence would steal radiology jobs. But at the Mayo Clinic, the technology has been more friend than foe. (X)

AI Will Devastate the Future of Work. But Only If We Let It (X)

AI in the workplace is nearly 3 times more likely to take a woman’s job as a man’s, UN report finds (X)

Klarna CEO predicts AI-driven job displacement will cause a recession (X)

& on AI Generally

19th-century Catholic teachings, 21st-century tech: How concerns about AI guided Pope Leo’s choice of name (X)

Will the Humanities Survive Artificial Intelligence? (X)

Two Paths for A.I. (X)

The Danger of Outsourcing Our Brains: Counting on AI to learn for us makes humans boring, awkward, and gullible. (X)

AI Is a Weapon Pointed at America. Our Best Defense Is Education. (X)

The Trump administration has asked artificial intelligence publishers to rebalance what it considers to be 'ideological bias' around actions like protecting minorities and banning hateful content. (X)

What is Google even for anymore? (X)

AI can spontaneously develop human-like communication, study finds

AI Didn’t Invent Desire, But It’s Rewiring Human Sex And Intimacy (X)

Mark Zuckerberg Wants AI to Solve America’s Loneliness Crisis. It Won’t. (X)

The growing environmental impact of AI data centers’ energy demands

Tesla Is Launching Robotaxis in Austin. Safety Advocates Are Concerned (X)

The One Big Beautiful Bill Act would ban states from regulating AI (X)

& on the Job-Pocalypse & Other Labor-Related Shenanigans Generally, Too

What Unions Face With Trump EOs (X)

AI may be exposing jobseekers to discrimination. Here’s how we could better protect them (X)

Jamie Dimon says he’s not against remote workers—but they ‘will not tell JPMorgan what to do’ (X)

Direct-selling schemes are considered fringe businesses, but their values have bled into the national economy. (X)

Are you "functionally unemployed"? Here's what the unemployment rate doesn't show. (X)

Being monitored at work? A new report calls for tougher workplace surveillance controls (X)

Josh Hawley and the Republican Effort to Love Labor (X)

Karl Marx’s American Boom (X)

Hiring slows in U.S. amid uncertainty over Trump’s trade wars

Vanishing immigration is the ‘real story’ for the economy and a bigger supply shock than tariffs, analyst says (X)

3 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Top 10 Pneumatic Actuator Brands In 2025

The pneumatic actuator market continues to thrive in 2025, driven by advancements in automation and industrial efficiency. Based on comprehensive evaluations by CN10/CNPP research departments, which integrate big data analytics, AI-driven insights, and market performance metrics, here are the leading brands shaping the industry.

1. SMC (SMC Corporation)

Performance & Reliability: As a global leader since 1959, SMC delivers over 10,000 pneumatic components, including high-precision cylinders, valves, and F.R.L. units. Its products are renowned for durability, energy efficiency, and adaptability to extreme industrial conditions. Industry Applications: Widely used in automotive manufacturing, semiconductor production, and robotics, SMC’s actuators ensure seamless automation across 80+ countries. Its China-based facilities, established in 1994, serve as a primary global production hub.

2. FESTO (Festo AG & Co. KG)

Performance & Reliability: With nearly a century of expertise, Festo combines innovative engineering with IoT-enabled solutions. Its actuators emphasize precision control, low maintenance, and compatibility with smart factory ecosystems. Industry Applications: Festo dominates sectors like pharmaceuticals, food processing, and renewable energy, offering customized automation systems that enhance productivity and sustainability.

Other Notable Brands In The 2025 Rankings

While SMC and Festo lead the list, the following brands also excel in specific niches:

Brand A: Specializes in compact actuators for medical devices.

Brand B: Focuses on heavy-duty applications in construction machinery.

Brand C: Pioneers eco-friendly designs with reduced carbon footprints.

Key Trends Driving Market Growth

Smart Automation: Integration of AI and real-time monitoring in actuator systems.

Sustainability: Energy-efficient designs aligned with global decarbonization goals.

Customization: Tailored solutions for niche industries like aerospace and biotechnology.

This ranking underscores the critical role of innovation and adaptability in maintaining competitive advantage. Brands that prioritize R&D and cross-industry collaboration are poised to lead the next decade of pneumatic automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

2 notes

·

View notes

Text

AI & IT'S IMPACT

Unleashing the Power: The Impact of AI Across Industries and Future Frontiers

Artificial Intelligence (AI), once confined to the realm of science fiction, has rapidly become a transformative force across diverse industries. Its influence is reshaping the landscape of how businesses operate, innovate, and interact with their stakeholders. As we navigate the current impact of AI and peer into the future, it's evident that the capabilities of this technology are poised to reach unprecedented heights.

1. Healthcare:

In the healthcare sector, AI is a game-changer, revolutionizing diagnostics, treatment plans, and patient care. Machine learning algorithms analyze vast datasets to identify patterns, aiding in early disease detection. AI-driven robotic surgery is enhancing precision, reducing recovery times, and minimizing risks. Personalized medicine, powered by AI, tailors treatments based on an individual's genetic makeup, optimizing therapeutic outcomes.

2. Finance:

AI is reshaping the financial industry by enhancing efficiency, risk management, and customer experiences. Algorithms analyze market trends, enabling quicker and more accurate investment decisions. Chatbots and virtual assistants powered by AI streamline customer interactions, providing real-time assistance. Fraud detection algorithms work tirelessly to identify suspicious activities, bolstering security measures in online transactions.

3. Manufacturing:

In manufacturing, AI is optimizing production processes through predictive maintenance and quality control. Smart factories leverage AI to monitor equipment health, reducing downtime by predicting potential failures. Robots and autonomous systems, guided by AI, enhance precision and efficiency in tasks ranging from assembly lines to logistics. This not only increases productivity but also contributes to safer working environments.

4. Education:

AI is reshaping the educational landscape by personalizing learning experiences. Adaptive learning platforms use AI algorithms to tailor educational content to individual student needs, fostering better comprehension and engagement. AI-driven tools also assist educators in grading, administrative tasks, and provide insights into student performance, allowing for more effective teaching strategies.

5. Retail:

In the retail sector, AI is transforming customer experiences through personalized recommendations and efficient supply chain management. Recommendation engines analyze customer preferences, providing targeted product suggestions. AI-powered chatbots handle customer queries, offering real-time assistance. Inventory management is optimized through predictive analytics, reducing waste and ensuring products are readily available.

6. Future Frontiers:

A. Autonomous Vehicles: The future of transportation lies in AI-driven autonomous vehicles. From self-driving cars to automated drones, AI algorithms navigate and respond to dynamic environments, ensuring safer and more efficient transportation. This technology holds the promise of reducing accidents, alleviating traffic congestion, and redefining mobility.

B. Quantum Computing: As AI algorithms become more complex, the need for advanced computing capabilities grows. Quantucm omputing, with its ability to process vast amounts of data at unprecedented speeds, holds the potential to revolutionize AI. This synergy could unlock new possibilities in solving complex problems, ranging from drug discovery to climate modeling.

C. AI in Creativity: AI is not limited to data-driven tasks; it's also making inroads into the realm of creativity. AI-generated art, music, and content are gaining recognition. Future developments may see AI collaborating with human creators, pushing the boundaries of what is possible in fields traditionally associated with human ingenuity.

In conclusion, the impact of AI across industries is profound and multifaceted. From enhancing efficiency and precision to revolutionizing how we approach complex challenges, AI is at the forefront of innovation. The future capabilities of AI hold the promise of even greater advancements, ushering in an era where the boundaries of what is achievable continue to expand. As businesses and industries continue to embrace and adapt to these transformative technologies, the synergy between human intelligence and artificial intelligence will undoubtedly shape a future defined by unprecedented possibilities.

20 notes

·

View notes

Text

Vehicle Design and Manufacturing Processes

Introduction: Vehicle design and manufacturing processes have evolved dramatically over the years. From manual assembly lines to high-tech automation, the automotive industry has witnessed numerous advancements that enhance vehicle performance, safety, and sustainability. This blog explores the latest trends in vehicle design and the manufacturing processes that are transforming the industry.

Design Considerations: Designing a vehicle is a complex and multi-disciplinary process that involves engineering, aerodynamics, ergonomics, safety, and aesthetics. Engineers must consider factors like fuel efficiency, performance, and environmental impact, all while ensuring the vehicle’s safety for occupants and pedestrians.

For example, modern car designs prioritize aerodynamics to reduce fuel consumption, with sleek shapes and specialized components that minimize air resistance. Additionally, the safety of the vehicle is ensured by incorporating advanced safety systems, such as collision avoidance technologies, airbags, and crumple zones.

Manufacturing Technologies: The rise of automation has revolutionized vehicle manufacturing. Robotic arms, AI, and 3D printing are now integral to automotive production. Robotics allows for faster and more precise assembly, while AI systems help in predicting maintenance needs and optimizing production schedules.

One significant advancement is the use of 3D printing for creating prototype parts and even some vehicle components. This technology enables manufacturers to design and produce intricate parts with reduced material waste and lower costs. Additionally, automation has sped up assembly lines, allowing for mass production while maintaining consistent quality.

Sustainability: As the world becomes more eco-conscious, the automotive industry has shifted toward more sustainable practices. Electric vehicles (EVs) are at the forefront of this revolution, offering a cleaner alternative to traditional gasoline-powered cars. In addition to EVs, car manufacturers are adopting environmentally friendly materials, such as recycled plastics and plant-based composites, to reduce the carbon footprint of their vehicles.

Furthermore, energy-efficient manufacturing practices, such as using renewable energy to power factories and reducing waste, are helping the industry move toward a more sustainable future.

Future Trends: The future of vehicle design and manufacturing is exciting. One of the biggest trends is the development of autonomous vehicles, which use sensors, AI, and machine learning to navigate roads without human intervention. These vehicles promise to increase safety, reduce traffic, and improve transportation efficiency.

Modular vehicle design is also gaining traction. This approach allows manufacturers to produce customizable vehicles with interchangeable components, which can be tailored to meet different customer needs.

Conclusion: The automotive industry is undergoing a revolution, driven by innovative design principles and advanced manufacturing technologies. As sustainability becomes increasingly important and new technologies such as autonomous driving and electric vehicles take center stage, the future of vehicle design looks promising. By continuing to prioritize safety, efficiency, and environmental responsibility, the industry will continue to transform how we think about transportation.

For comprehensive information and resources on engineering topics, please visit the Engineer's Heaven website.

2 notes

·

View notes

Text

NVIDIA AI Blueprints For Build Visual AI Data In Any Sector

NVIDIA AI Blueprints

Businesses and government agencies worldwide are creating AI agents to improve the skills of workers who depend on visual data from an increasing number of devices, such as cameras, Internet of Things sensors, and automobiles.

Developers in almost any industry will be able to create visual AI agents that analyze image and video information with the help of a new NVIDIA AI Blueprints for video search and summarization. These agents are able to provide summaries, respond to customer inquiries, and activate alerts for particular situations.

The blueprint is a configurable workflow that integrates NVIDIA computer vision and generative AI technologies and is a component of NVIDIA Metropolis, a suite of developer tools for creating vision AI applications.

The NVIDIA AI Blueprints for visual search and summarization is being brought to businesses and cities around the world by global systems integrators and technology solutions providers like Accenture, Dell Technologies, and Lenovo. This is launching the next wave of AI applications that can be used to increase productivity and safety in factories, warehouses, shops, airports, traffic intersections, and more.

The NVIDIA AI Blueprint, which was unveiled prior to the Smart City Expo World Congress, provides visual computing developers with a comprehensive set of optimized tools for creating and implementing generative AI-powered agents that are capable of consuming and comprehending enormous amounts of data archives or live video feeds.

Deploying virtual assistants across sectors and smart city applications is made easier by the fact that users can modify these visual AI agents using natural language prompts rather than strict software code.

NVIDIA AI Blueprint Harnesses Vision Language Models

Vision language models (VLMs), a subclass of generative AI models, enable visual AI agents to perceive the physical world and carry out reasoning tasks by fusing language comprehension and computer vision.

NVIDIA NIM microservices for VLMs like NVIDIA VILA, LLMs like Meta’s Llama 3.1 405B, and AI models for GPU-accelerated question answering and context-aware retrieval-augmented generation may all be used to configure the NVIDIA AI Blueprint for video search and summarization. The NVIDIA NeMo platform makes it simple for developers to modify other VLMs, LLMs, and graph databases to suit their particular use cases and settings.

By using the NVIDIA AI Blueprints, developers may be able to avoid spending months researching and refining generative AI models for use in smart city applications. It can significantly speed up the process of searching through video archives to find important moments when installed on NVIDIA GPUs at the edge, on-site, or in the cloud.

An AI agent developed using this methodology could notify employees in a warehouse setting if safety procedures are broken. An AI bot could detect traffic accidents at busy crossroads and provide reports to support emergency response activities. Additionally, to promote preventative maintenance in the realm of public infrastructure, maintenance personnel could request AI agents to analyze overhead imagery and spot deteriorating roads, train tracks, or bridges.

In addition to smart places, visual AI agents could be used to automatically create video summaries for visually impaired individuals, classify large visual datasets for training other AI models, and summarize videos for those with visual impairments.

The workflow for video search and summarization is part of a set of NVIDIA AI blueprints that facilitate the creation of digital avatars driven by AI, the development of virtual assistants for individualized customer support, and the extraction of enterprise insights from PDF data.

With NVIDIA AI Enterprise, an end-to-end software platform that speeds up data science pipelines and simplifies the development and deployment of generative AI, developers can test and download NVIDIA AI Blueprints for free. These blueprints can then be implemented in production across accelerated data centers and clouds.

AI Agents to Deliver Insights From Warehouses to World Capitals

With the assistance of NVIDIA’s partner ecosystem, enterprise and public sector clients can also utilize the entire library of NVIDIA AI Blueprints.

With its Accenture AI Refinery, which is based on NVIDIA AI Foundry and allows clients to create custom AI models trained on enterprise data, the multinational professional services firm Accenture has integrated NVIDIA AI Blueprints.

For smart city and intelligent transportation applications, global systems integrators in Southeast Asia, such as ITMAX in Malaysia and FPT in Vietnam, are developing AI agents based on the NVIDIA AI Blueprint for video search and summarization.

Using computing, networking, and software from international server manufacturers, developers can also create and implement NVIDIA AI Blueprints on NVIDIA AI systems.

In order to improve current edge AI applications and develop new edge AI-enabled capabilities, Dell will combine VLM and agent techniques with its NativeEdge platform. VLM capabilities in specialized AI workflows for data center, edge, and on-premises multimodal corporate use cases will be supported by the NVIDIA AI Blueprint for video search and summarization and the Dell Reference Designs for the Dell AI Factory with NVIDIA.

Lenovo Hybrid AI solutions powered by NVIDIA also utilize NVIDIA AI blueprints.

The new NVIDIA AI Blueprint will be used by businesses such as K2K, a smart city application supplier in the NVIDIA Metropolis ecosystem, to create AI agents that can evaluate real-time traffic camera data. City officials will be able to inquire about street activities and get suggestions on how to make things better with to this. Additionally, the company is utilizing NIM microservices and NVIDIA AI blueprints to deploy visual AI agents in collaboration with city traffic management in Palermo, Italy.

NVIDIA booth at the Smart Cities Expo World Congress, which is being held in Barcelona until November 7, to learn more about the NVIDIA AI Blueprints for video search and summarization.

Read more on Govindhtech.com

#NVIDIAAI#AIBlueprints#AI#VisualAI#VisualAIData#Blueprints#generativeAI#VisionLanguageModels#AImodels#News#Technews#Technology#Technologynews#Technologytrends#govindhtech

2 notes

·

View notes

Text

Indeed, plumbing has evolved significantly, especially in the commercial industry, thanks to the integration of AI, machine learning, and predictive analytics. These technologies have brought about several advancements and complexities in plumbing systems and operations:

Predictive Maintenance: AI and machine learning can analyze historical data and real-time information from plumbing systems to predict when maintenance or repairs are needed. This predictive approach reduces downtime and costly emergency repairs.

Smart Sensors: IoT (Internet of Things) devices and sensors can be embedded in plumbing systems to monitor various parameters, such as water pressure, temperature, and flow rates. This data can be processed by AI systems to detect leaks or other issues in real-time.

Energy Efficiency: AI-driven systems can optimize water usage and heating in commercial buildings, reducing energy consumption and costs. They can adjust water temperatures and flow rates based on usage patterns and weather conditions.

Water Quality Monitoring: AI and machine learning can continuously monitor water quality and detect contaminants, ensuring that water in commercial facilities is safe for consumption and use.

Leak Detection: AI can identify small leaks and potential problems early, preventing major water damage and reducing water wastage.

Remote Monitoring and Control: Building managers and maintenance personnel can remotely monitor and control plumbing systems through AI-powered interfaces, allowing for quick responses to issues.

Demand Forecasting: Predictive analytics can help businesses anticipate their water and plumbing system usage, allowing for efficient resource allocation and cost savings.

Customized Solutions: AI and machine learning can tailor plumbing systems to specific commercial needs. For instance, restaurants, hotels, and factories may have different plumbing requirements, which AI can adapt to accordingly.

Data-Driven Decision Making: Plumbing systems generate vast amounts of data, which can be used to make informed decisions about maintenance, upgrades, and resource allocation.

Compliance and Regulations: AI can assist in monitoring and ensuring compliance with plumbing and environmental regulations, reducing the risk of fines and penalties.

While these technological advancements have made plumbing systems more efficient, cost-effective, and environmentally friendly, they also require specialized knowledge and expertise to implement and maintain. Additionally, cybersecurity becomes a crucial consideration to protect these systems from potential threats. As a result, the plumbing industry has seen an increased demand for professionals who are well-versed in both traditional plumbing skills and modern technology applications in plumbing systems.

8 notes

·

View notes

Text

"The slowly emerging picture of how Israel’s military is harnessing AI comes against a backdrop of growing concerns about the risks posed to civilians as advanced militaries around the world expand the use of complex and opaque automated systems on the battlefield.

...

‘Mass assassination factory’

Sources familiar with how AI-based systems have been integrated into the IDF’s operations said such tools had significantly sped up the target creation process.

“We prepare the targets automatically and work according to a checklist,” a source who previously worked in the target division told +972/Local Call. “It really is like a factory. We work quickly and there is no time to delve deep into the target. The view is that we are judged according to how many targets we manage to generate.”

A separate source told the publication the Gospel had allowed the IDF to run a “mass assassination factory” in which the “emphasis is on quantity and not on quality”. A human eye, they said, “will go over the targets before each attack, but it need not spend a lot of time on them”.

3 notes

·

View notes

Text

AI in Manufacturing: Real-World Applications and Case Studies

Artificial Intelligence (AI) is revolutionizing the manufacturing industry. What was once associated mainly with robotics and automation is now transforming every stage of the production process—from supply chain optimization to predictive maintenance, and even quality assurance. As manufacturers aim for increased efficiency, reduced costs, and enhanced product quality, AI is emerging as a key enabler of the smart factory era.

In this blog, we’ll explore how AI is applied in real-world manufacturing settings and examine compelling case studies that demonstrate its impact.

The Rise of AI in Manufacturing

AI technologies such as machine learning (ML), computer vision, and natural language processing (NLP) have matured rapidly, and manufacturers are adopting them to address longstanding challenges. Traditional manufacturing systems often struggle with reactive decision-making, lack of real-time insights, and inefficiencies caused by equipment failure or supply chain disruptions.

AI brings a proactive, data-driven approach that empowers decision-makers with predictive insights and automation capabilities.

Real-World Applications of AI in Manufacturing

1. Predictive Maintenance

AI systems analyze data from sensors embedded in machines to predict failures before they occur. By continuously monitoring equipment conditions, manufacturers can schedule maintenance only when needed, reducing downtime and maintenance costs.

Example: General Motors uses AI-powered sensors and machine learning algorithms to monitor factory equipment. This approach helped GM reduce unplanned downtime by up to 50%.

2. Quality Control and Defect Detection

AI, especially computer vision, enables real-time inspection of products on the assembly line. These systems can detect defects at a scale and speed unattainable by human inspectors.

Example: BMW employs AI-based image recognition to identify surface defects on car bodies during the manufacturing process. This has improved quality control precision and reduced rework.

3. Supply Chain Optimization

AI helps manufacturers anticipate demand, optimize inventory, and manage logistics more efficiently. Machine learning algorithms analyze historical sales data, supplier performance, and external factors like weather or geopolitical events.

Example: Siemens uses AI to improve supply chain transparency and optimize inventory levels, resulting in faster production cycles and reduced stockouts.

4. Process Automation and Robotics

AI enhances traditional automation by enabling robots to learn from their environment. Collaborative robots (cobots) can adapt to complex tasks and work alongside humans safely.

Example: Fanuc, a global manufacturer of industrial robots, utilizes deep learning to improve the precision of robotic arms in real-time, allowing them to handle more intricate assembly tasks.

5. Energy Management

AI systems monitor energy consumption patterns and suggest ways to reduce waste. By optimizing usage, manufacturers lower energy costs and minimize their carbon footprint.

Example: Schneider Electric integrates AI into its energy management systems to identify inefficiencies across manufacturing facilities, achieving up to 30% energy savings.

6. Design and Product Development

AI accelerates product development by simulating performance, testing designs, and even generating prototypes based on desired criteria using generative design techniques.

Example: Airbus uses AI-driven generative design to create lighter aircraft components, reducing material costs and improving fuel efficiency.

Case Studies: AI in Action

Case Study 1: Tesla – Smart Factories and Real-Time Analytics

Tesla leverages AI extensively in its Gigafactories. Through data analytics, Tesla predicts equipment failures, optimizes production schedules, and continuously improves its autonomous manufacturing processes. Tesla’s use of AI in robotics and automation has helped it maintain high production rates with limited downtime.

Case Study 2: Bosch – AI-Driven Quality Control

Bosch has implemented AI at scale across its manufacturing operations. By using AI algorithms for anomaly detection in the production of sensors and electronic control units, Bosch has significantly decreased the rate of defective products and improved its overall production yield.

Case Study 3: Foxconn – Smart Factory Transformation

Foxconn, a major electronics contract manufacturer, has invested in AI to improve its operational efficiency. AI is used for predictive maintenance, logistics planning, and even employee safety monitoring. This has enabled Foxconn to enhance production efficiency and reduce operational costs.

The Future Outlook

As AI technologies continue to evolve, their adoption in manufacturing will become more widespread and accessible—even for small and medium enterprises (SMEs). Integration with technologies like IoT (Internet of Things), digital twins, and 5G will further accelerate the shift toward Industry 4.0.

Manufacturers that embrace AI today are not just improving efficiency—they are building resilience, agility, and innovation into their business models.

Conclusion

AI is no longer a futuristic concept AI in manufacturing—it's a present-day reality. From predictive maintenance to quality assurance and energy optimization, AI is delivering measurable results across the industry. By learning from early adopters and understanding the practical applications, manufacturers of all sizes can begin to unlock the value of AI and shape the factories of the future.

0 notes

Text

Discover how generative AI solves manufacturing challenges: predictive maintenance, optimized design, quality control, and supply chain efficiency. Innovate your production today!

#AI-Driven Production Enhancements#Generative AI For Process Automation#AI In Manufacturing Intelligence#Generative AI For Manufacturing Improvement#AI In Industrial Efficiency#AI-Enhanced Manufacturing Workflows#Generative AI For Operational Excellence#AI In Production Management#AI-Driven Manufacturing Optimization#Generative AI For Supply Chain Resilience#AI In Process Innovation#AI In Manufacturing Performance#Generative AI For Manufacturing Analytics#AI In Production Quality#AI-Powered Factory Efficiency#Generative AI For Cost-Effective Manufacturing

0 notes

Text

PCBA: The Silent Backbone of Electronic Devices

Printed Circuit Board Assembly (PCBA) serves as the critical foundation for nearly every electronic device in our modern world. From smartphones and laptops to industrial automation systems and aerospace equipment, PCBA ensures that the various electronic components within a device function smoothly and cohesively. Its precision and reliability are not just technical necessities but vital to sustaining innovation in the global tech economy.Get more news about PCBA manufacturer,you can vist our website!

Understanding PCBA

At its core, PCBA refers to the process of soldering electronic components onto a printed circuit board (PCB). While a PCB is simply the board with copper traces that connect components electrically, the assembly process transforms it into a fully functional circuit. This involves mounting integrated circuits (ICs), resistors, capacitors, diodes, and other components using either Surface Mount Technology (SMT), Through-Hole Technology (THT), or a hybrid of both, depending on the design and purpose of the device.

The PCBA Process

The process typically begins with solder paste application, where a stencil is used to apply the paste on predefined areas of the PCB. Automated pick-and-place machines then accurately position the tiny components onto the board. This is followed by reflow soldering, where the board is passed through a controlled oven to melt the solder and secure the components.

For boards requiring through-hole components, manual or wave soldering is used. Once soldered, the board undergoes inspection and testing—ranging from Automated Optical Inspection (AOI) to X-ray analysis and functional testing—to ensure quality and performance. Advanced PCBA plants employ high levels of automation, drastically reducing human error and improving output consistency.

Applications Across Industries

PCBA's influence stretches far beyond consumer electronics. In the automotive sector, it powers systems ranging from infotainment units to electric vehicle battery management. In healthcare, PCBA-based medical devices like ECG machines and portable monitors are critical to patient diagnostics and care. Aerospace and military applications demand high-reliability PCBA to function under extreme environments—an area where rigid quality controls and testing standards become indispensable.

Trends and Innovations

The PCBA landscape continues to evolve rapidly with advances in miniaturization, multi-layer boards, and flexible circuits. With the rise of the Internet of Things (IoT), demand for compact, power-efficient, and wireless-capable assemblies has exploded. Manufacturers are investing in smart factories, using AI-driven inspection and robotics to further optimize production.

Meanwhile, environmental considerations are pushing green manufacturing methods, such as lead-free solder and recyclable board materials. Companies are also embracing design-for-manufacturing (DFM) principles to streamline assembly and minimize waste.

Conclusion

Though rarely visible to end-users, PCBA is the invisible force driving the electronics revolution. Its blend of engineering precision, automation, and innovation enables the digital tools and systems we rely on daily. As global technology continues to push boundaries, PCBA will remain the structural and functional heart of that progress—quietly pulsing behind every screen, circuit, and sensor.

0 notes

Text

Automation and Integration Needs Power Robust Growth in System Integrator Market

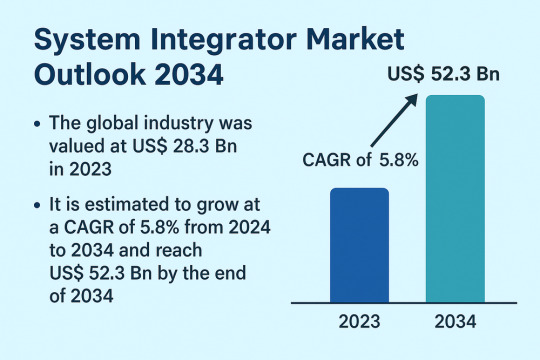

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Factory Automation Market

Factory Automation Market size is forecast to reach $233.5 Billion by 2030, after growing at a CAGR of 3.3% during 2024–2030.

🔗 𝐆𝐞𝐭 𝐑𝐎𝐈-𝐟𝐨𝐜𝐮𝐬𝐞𝐝 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐟𝐨𝐫 𝟐𝟎𝟐𝟓-𝟐𝟎𝟑𝟏 → 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐍𝐨𝐰

Factory Automation Market is a rapidly growing sector driven by the demand for increased productivity, precision, and cost efficiency in manufacturing. It encompasses technologies like robotics, sensors, control systems, AI, and IoT to streamline industrial processes. Automation reduces human intervention, minimizes errors, and enhances operational efficiency.

Key industries adopting automation include automotive, electronics, pharmaceuticals, and food processing. As smart factories and Industry 4.0 trends gain momentum, the market is witnessing significant investments and innovation.

🔑 𝐊𝐞𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 𝐃𝐫𝐢𝐯𝐞𝐫𝐬:

🔸 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝟒.𝟎 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧

Integration of smart technologies like AI, IoT, and big data is transforming factories into intelligent, connected systems.

🔸 𝐑𝐢𝐬𝐢𝐧𝐠 𝐃𝐞𝐦𝐚𝐧𝐝 𝐟𝐨𝐫 𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐜𝐲 & 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐯𝐢𝐭𝐲

Manufacturers seek faster production cycles, reduced downtime, and higher output with fewer errors.

🔸 𝐋𝐚𝐛𝐨𝐫 𝐒𝐡𝐨𝐫𝐭𝐚𝐠𝐞𝐬 & 𝐑𝐢𝐬𝐢𝐧𝐠 𝐋𝐚𝐛𝐨𝐫 𝐂𝐨𝐬𝐭𝐬

Automation helps address skilled labor shortages and reduce long-term labor costs.

🔸 𝐄𝐦𝐩𝐡𝐚𝐬𝐢𝐬 𝐨𝐧 𝐐𝐮𝐚𝐥𝐢𝐭𝐲 & 𝐂𝐨𝐧𝐬𝐢𝐬𝐭𝐞𝐧𝐜𝐲

Automated systems ensure uniform product quality and reduce variability in production.

🔸 𝐆𝐫𝐨𝐰𝐢𝐧𝐠 𝐔𝐬𝐞 𝐨𝐟 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐑𝐨𝐛𝐨𝐭𝐬

Robotics adoption is surging in sectors like automotive, electronics, and logistics for precise and repetitive tasks.

𝐓𝐨𝐩 𝐊𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬:

BizLink Factory Automation & Machinery | Mitsubishi Electric Ireland Factory Automation | Mitsubishi Electric Factory Automation Benelux | Festo USA | ABB | Avago Technologies | Banner Engineering | FANUC America Corporation | Invio Automation | MISUMI USA | Hai Robotics | Afag | Discrete Automation | OTC Industrial Technologies

#FactoryAutomation #SmartManufacturing #IndustrialAutomation #ManufacturingInnovation #AutomationSolutions #AutomatedManufacturing #SmartFactory #DigitalManufacturing #Industry40 #IoTInManufacturing

0 notes

Text

5G IoT Chip Market: Technology Trends and Future Outlook 2025–2032

MARKET INSIGHTS

The global 5G IoT Chip market size was valued at US$ 4.87 billion in 2024 and is projected to reach US$ 12.43 billion by 2032, at a CAGR of 14.6% during the forecast period 2025-2032.

5G IoT chips are specialized semiconductor components that integrate 5G connectivity with IoT device functionalities. These system-on-chips (SoCs) combine radio frequency (RF) transceivers, baseband processors, and application processors in compact form factors, enabling high-speed, low-latency wireless communication for smart devices. Leading manufacturers are focusing on chips manufactured at 7nm, 10nm, and 12nm process nodes to balance performance and power efficiency.

The market expansion is driven by several factors, including the rollout of 5G infrastructure globally, increasing demand for industrial automation, and the proliferation of smart city applications. While the semiconductor industry overall grows at 6% CAGR, 5G IoT chips represent one of the fastest-growing segments due to their critical role in enabling next-generation applications. Key players like Qualcomm, MediaTek, and Intel are investing heavily in R&D to develop energy-efficient chips capable of supporting massive machine-type communications (mMTC) and ultra-reliable low-latency communications (URLLC) – two fundamental 5G IoT use cases.

MARKET DYNAMICS

MARKET DRIVERS

Proliferation of 5G Network Infrastructure Accelerating IoT Chip Adoption

The global rollout of 5G networks is creating unprecedented demand for compatible IoT chipsets. With over 290 commercial 5G networks deployed worldwide as of early 2024, telecom operators are investing heavily in infrastructure that requires low-latency, high-bandwidth connectivity solutions. The enhanced capabilities of 5G—including speeds up to 100 times faster than 4G and latency under 5 milliseconds—enable mission-critical IoT applications that were previously impractical. This technological leap is driving adoption across industries from manufacturing to healthcare, where real-time data processing is becoming essential for operational efficiency. Recent enhancements in network slicing capabilities further allow customized connectivity solutions for diverse IoT use cases.

Industrial Automation Revolution Driving Demand for Robust Connectivity Solutions

Industry 4.0 transformation across manufacturing sectors is creating substantial demand for 5G IoT chips capable of supporting advanced automation. Smart factories require thousands of connected sensors, actuators and control systems that demand reliable, low-latency communication. Predictive maintenance applications alone are projected to save manufacturers billions annually through reduced downtime. Autonomous mobile robots (AMRs) in warehouse operations increasingly rely on 5G’s ultra-reliable low-latency communication (URLLC) capabilities, creating new requirements for industrial-grade IoT chipsets. The growing integration of AI at the edge further intensifies processing demands, prompting chipmakers to develop solutions that combine 5G connectivity with neural processing capabilities.

Government Initiatives for Smart City Development Stimulating Market Growth

National smart city programs globally are accelerating deployment of 5G-powered IoT solutions for urban infrastructure management. Many governments have designated 5G as critical infrastructure, with billions allocated for digital transformation projects. Smart utilities, intelligent transportation systems, and public safety applications collectively require millions of connected devices. Smart meter deployments alone are projected to exceed 1.5 billion units globally by 2027, with advanced models incorporating 5G connectivity for real-time grid monitoring. These large-scale public sector IoT implementations create sustained demand for ruggedized, energy-efficient 5G chips designed for long-term outdoor deployment.

MARKET RESTRAINTS

High Power Consumption of 5G Modems Constraining Mass IoT Adoption

While 5G offers superior bandwidth and latency characteristics, the technology’s power requirements present significant challenges for battery-operated IoT devices. Current 5G modem implementations consume substantially more power than LTE-M or NB-IoT alternatives, limiting practicality for deployments requiring years of battery life. This power inefficiency affects adoption in asset tracking, agricultural monitoring, and other remote sensing applications where long intervals between maintenance are critical. Though chipmakers are developing low-power modes and advanced power management architectures, achieving parity with LTE power profiles while maintaining 5G performance remains an ongoing engineering challenge restricting certain market segments.

Complex Regulatory Compliance Increasing Time-to-Market for New Chip Designs

The global regulatory environment for 5G spectrum usage creates substantial barriers to IoT chipset development. Unlike previous cellular generations, 5G operates across numerous frequency bands (sub-6GHz and mmWave) with varying regional allocations and certification requirements. A single chipset intended for worldwide deployment must comply with dozens of different technical regulations regarding radio emissions, frequency use, and security protocols. This regulatory complexity extends development timelines and increases testing costs, particularly for smaller semiconductor firms without established compliance infrastructure. Recent geopolitical tensions have further fragmented the regulatory landscape, requiring manufacturers to develop region-specific variants of their products.

MARKET CHALLENGES

Semiconductor Supply Chain Vulnerabilities Disrupting Production Timelines

The 5G IoT chip market faces ongoing challenges from global semiconductor supply chain instability. Advanced nodes required for 5G modem integration (particularly 7nm and below) remain capacity-constrained at leading foundries, creating allocation challenges for fabless chip designers. The industry’s heavy reliance on a limited number of advanced packaging facilities further compounds supply risks. Recent geopolitical developments have introduced additional uncertainty regarding access to critical semiconductor manufacturing equipment and materials. These supply chain limitations create unpredictable lead times that complicate product roadmaps and constrain manufacturers’ ability to respond to sudden demand surges in key vertical markets.

Security Vulnerabilities in Heterogeneous IoT Ecosystems Creating Deployment Concerns

The distributed nature of 5G IoT implementations introduces significant cybersecurity challenges that chipmakers must address. Unlike traditional IT systems, IoT deployments incorporate numerous edge devices with varying security capabilities connected through potentially vulnerable networks. Recent analyses indicate that over 40% of IoT devices contain critical security flaws that could compromise entire networks. While 5G standards include enhanced security protocols compared to previous generations, their effective implementation relies on robust hardware-level security in endpoint chips. The semiconductor industry faces increasing pressure to incorporate hardware roots of trust, secure boot mechanisms, and hardware-based encryption accelerators—features that add complexity and cost to chip designs.

MARKET OPPORTUNITIES

Emergence of AI-Enabled Edge Computing Creating Demand for Intelligent 5G IoT Chips

The convergence of 5G connectivity with edge AI processing represents a transformative opportunity for the IoT chip market. Next-generation applications require localized decision-making capabilities to reduce latency and bandwidth requirements. Smart cameras for industrial quality control, autonomous vehicles, and augmented reality devices increasingly integrate AI acceleration alongside 5G modems. This trend is driving demand for heterogeneous chips that combine neural processing units (NPUs) with cellular connectivity in power-efficient packages. Leading chipmakers are responding with architectures that enable on-device machine learning while maintaining always-connected 5G capabilities, opening new markets at the intersection of connectivity and intelligence.

Enterprise Digital Transformation Initiatives Fueling Private 5G Network Deployments

The growing adoption of private 5G networks by industrial enterprises presents significant opportunities for specialized IoT chip solutions. Unlike public networks, private 5G implementations require tailored connectivity solutions that prioritize reliability, security, and deterministic performance. Manufacturing plants, ports, and mining operations are increasingly deploying private networks to support mission-critical IoT applications. This emerging market segment demands industrial-grade chipsets with support for network slicing, ultra-reliable low-latency communication (URLLC), and precise timing synchronization. Semiconductor vendors able to address these specialized requirements while meeting industrial certifications stand to gain substantial market share in this high-value segment.

5G IoT CHIP MARKET TRENDS

5G Network Expansion Fuels Demand for Advanced IoT Chips

The global expansion of 5G networks is revolutionizing the IoT chip market, with 5G IoT chip shipments expected to grow at a CAGR of over 35% between 2024 and 2030. The superior bandwidth, ultra-low latency, and massive device connectivity offered by 5G technology have created unprecedented opportunities for IoT applications across industries. Manufacturers are increasingly focusing on developing 7nm and 10nm process chips that offer optimal performance while maintaining energy efficiency for IoT edge devices. Recent innovations include integrated AI capabilities directly on IoT chips, enabling faster localized decision-making in smart applications from industrial automation to connected healthcare.

Other Trends

Industrial IoT Adoption Accelerates

Industries are rapidly deploying 5G-enabled IoT solutions for predictive maintenance, asset tracking, and process optimization. The industrial segment now accounts for nearly 30% of all 5G IoT chip demand. Factories implementing Industry 4.0 solutions particularly favor chips supporting URLLC (Ultra-Reliable Low-Latency Communications), which enables real-time control of machinery with latencies below 10ms. Meanwhile, the renewable energy sector is leveraging 5G IoT for smart grid management, with chipmakers developing specialized solutions that can withstand harsh environmental conditions.

Smart Cities Drive Heterogeneous Chip Demand

Urban digital transformation initiatives worldwide are creating diverse requirements for 5G IoT chips. While smart meters typically use economical 28nm chips, more advanced applications like autonomous traffic management systems require high-performance 7nm processors with integrated AI accelerators. The Asia-Pacific region leads in smart city deployments, accounting for nearly 50% of global smart city 5G IoT chip consumption. Chip manufacturers are responding with flexible system-on-chip (SoC) designs that can be customized for various municipal applications, from environmental monitoring to public safety systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Semiconductor Giants Compete for Dominance in 5G IoT Chip Innovation

The global 5G IoT chip market exhibits a dynamic competitive landscape, dominated by established semiconductor manufacturers and emerging fabless players. This arena is characterized by rapid technological evolution, strategic partnerships, and intense R&D investments as companies vie for market share in this high-growth sector.

Qualcomm Technologies Inc. currently leads the market with approximately 35% revenue share in 2024, demonstrating technological prowess with its Snapdragon X series chipsets designed specifically for IoT applications. The company’s success stems from its early-mover advantage in 5G modems and strong relationships with smartphone manufacturers expanding into IoT solutions.

MediaTek and Hisilicon collectively hold about 28% market share, capitalizing on cost-competitive solutions for mid-range IoT devices. MediaTek’s recent Helio i series chips gained significant traction in smart home and industrial automation segments, while Hisilicon’s Balong chips power numerous connected devices in China’s expanding IoT ecosystem.

Smaller specialized players demonstrate remarkable agility in niche applications. Sequans Communications secured design wins with several European smart meter manufacturers, while Eigencomm made breakthroughs in antenna integration technologies for compact IoT devices. These innovators threaten incumbents by addressing specific pain points neglected by larger competitors.

The competitive intensity is escalating as traditional computing giants enter the fray. Intel leveraged its process technology advantage to launch 10nm IoT-focused SoCs, targeting industrial and automotive applications where its x86 architecture maintains influence. Meanwhile, UNISOC and ASR Microelectronics continue gaining ground in emerging markets through aggressive pricing strategies and customized solutions.

List of Key 5G IoT Chip Manufacturers Profiled

Qualcomm Incorporated (U.S.)

MediaTek Inc. (Taiwan)

Hisilicon (China)

Intel Corporation (U.S.)

UNISOC (China)

ASR Microelectronics Co., Ltd. (China)

Eigencomm (China)

Sequans Communications (France)

Segment Analysis:

By Type

7 nm Segment Dominates Due to High Performance and Energy Efficiency in 5G Connectivity

The market is segmented based on type into:

7 nm

10 nm

12 nm

Others

By Application

Industrial Applications Lead as 5G Chips Drive Smart Manufacturing and Automation

The market is segmented based on application into:

PC

Router/CPE

POS

Smart Meters

Industrial Application

Other

By End User

Telecom Sector Emerges as Key Adopter for 5G Network Infrastructure Deployment

The market is segmented based on end user into:

Telecommunication

Automotive

Healthcare

Consumer Electronics

Others

Regional Analysis: 5G IoT Chip Market

North America The North American 5G IoT chip market is driven by rapid advancements in connectivity infrastructure and strong investments from major tech firms. The U.S. remains a key player, accounting for over 60% of regional market share, primarily due to high 5G deployment rates and innovations from companies like Qualcomm and Intel. Industries such as smart manufacturing, automotive, and healthcare are accelerating demand for low-latency, high-speed IoT connectivity. However, regulatory complexities around spectrum allocation and security concerns pose challenges for large-scale IoT adoption. The rise of private 5G networks for industrial automation is expected to further fuel growth, supported by government initiatives like the National Spectrum Strategy.

Europe Europe’s 5G IoT chip market is characterized by strict data privacy regulations (e.g., GDPR) and a strong push for industrial digitization under initiatives like Industry 4.0. Germany and the U.K. lead in adoption, particularly in smart city and automotive applications. The EU’s focus on semiconductor sovereignty, including the Chips Act, is increasing local production capabilities to reduce dependency on imports. While sustainability and energy-efficient chips are prioritized, slower 5G rollouts in certain countries—due to bureaucratic hurdles—impede faster market expansion. Nonetheless, the demand for ultra-reliable IoT solutions in logistics and healthcare continues to grow, creating long-term opportunities.

Asia-Pacific Asia-Pacific dominates the global 5G IoT chip market, with China, Japan, and South Korea collectively contributing over 50% of worldwide shipments. China’s aggressive 5G rollout and government-backed IoT projects, such as smart city deployments, drive massive demand for cost-effective chips. Meanwhile, India’s expanding telecom infrastructure (e.g., BharatNet) and rising investments in edge computing present new growth avenues. While regional players like Huawei’s Hisilicon and MediaTek lead innovation, geopolitical tensions and supply chain dependencies on Western technology remain key challenges. The shift toward AI-enabled IoT chips for industrial automation and consumer electronics further strengthens the region’s market position.

South America South America’s 5G IoT chip market is nascent but growing, fueled by gradual 5G deployments in Brazil and Argentina. Limited telecom infrastructure and economic instability slow adoption compared to other regions, but sectors like agricultural IoT and smart energy management show promise. Local chip production is almost nonexistent, leaving the region reliant on imports, which inflates costs and delays implementation. However, partnerships with global semiconductor firms and pilot projects in urban centers indicate potential for mid-term growth, particularly as government policies begin prioritizing digital transformation.

Middle East & Africa The Middle East & Africa region is witnessing sporadic but strategic 5G IoT adoption, led by the UAE, Saudi Arabia, and South Africa. Telecom operators are investing heavily in smart city projects (e.g., NEOM in Saudi Arabia), creating demand for high-capacity IoT chips. Conversely, Africa’s market growth is constrained by underdeveloped 5G infrastructure and affordability barriers. Despite challenges, sectors like oil & gas digitization and remote monitoring in mining are driving niche demand. The lack of local semiconductor manufacturing increases reliance on imports, but regional collaborations and foreign investments signal gradual market maturation.

Report Scope

This market research report provides a comprehensive analysis of the global and regional 5G IoT Chip markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The Global 5G IoT Chip market was valued at USD 1.2 billion in 2024 and is projected to reach USD 3.8 billion by 2032, growing at a CAGR of 15.6%.

Segmentation Analysis: Detailed breakdown by product type (7nm, 10nm, 12nm), application (PC, Router/CPE, Industrial IoT), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific currently holds 48% market share.

Competitive Landscape: Profiles of leading market participants including Qualcomm, MediaTek, Intel, and Hisilicon, covering their product portfolios and strategic initiatives.

Technology Trends & Innovation: Assessment of emerging 5G NR standards, AI integration in chipsets, and advanced fabrication techniques below 10nm.

Market Drivers & Restraints: Evaluation of 5G infrastructure rollout, IoT adoption, and challenges like supply chain constraints and geopolitical factors.

Stakeholder Analysis: Strategic insights for semiconductor manufacturers, IoT device makers, telecom operators, and investors.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/fieldbus-distributors-market-size-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/consumer-electronics-printed-circuit.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/metal-alloy-current-sensing-resistor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/modular-hall-effect-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/integrated-optic-chip-for-gyroscope.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/industrial-pulsed-fiber-laser-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/unipolar-transistor-market-strategic.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/zener-barrier-market-industry-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/led-shunt-surge-protection-device.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/type-tested-assembly-tta-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/traffic-automatic-identification.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/one-time-fuse-market-how-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pbga-substrate-market-size-share-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nfc-tag-chip-market-growth-potential-of.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silver-nanosheets-market-objectives-and.html

0 notes

Text

How Data Science is Helping Fight Climate Change

Climate change is no longer a distant threat—it’s a reality affecting ecosystems, economies, and everyday lives. From rising sea levels to extreme weather events, the impact is global. But there’s a powerful tool helping scientists, policymakers, and activists respond more effectively: Data Science.

With the explosion of big data, sensors, satellites, and machine learning algorithms, data science is becoming a central force in the fight against climate change. Let’s explore how.

1. Predicting Climate Patterns with Machine Learning

One of the most powerful applications of data science is in climate modeling and forecasting. Traditional models were limited in processing power and granularity. Now, with advanced machine learning techniques and high-performance computing, scientists can:

Simulate climate changes decades into the future

Predict weather patterns more accurately

Model extreme events like hurricanes, floods, or droughts

For example, DeepMind’s AI model, trained on vast datasets of radar data, can now predict rainfall with higher precision than traditional methods. These forecasts help communities prepare for disasters and reduce damage.

2. Satellite Imagery and Earth Observation

Satellites continuously gather images and climate data from space. These images are rich with information—about deforestation, glacier melting, ocean temperatures, and more.

Data scientists use image recognition and geospatial analytics to:

Monitor forest cover loss in the Amazon

Track ice sheet melting in Antarctica

Identify urban heat islands in growing cities

Measure carbon emissions from industrial zones

Organizations like NASA, ESA, and Google Earth Engine are publishing petabytes of open climate data for researchers to build models, apps, and solutions.

3. Carbon Footprint Analysis

Governments and companies are under increasing pressure to reduce their carbon footprints. But first, they need to measure them accurately.

Data science enables:

Carbon accounting across supply chains

IoT integration in factories for real-time emission tracking

Predictive models to simulate the impact of green policies

For instance, companies like Microsoft and Apple are using advanced analytics to reduce their net carbon emissions and optimize energy use across data centers.

4. Climate-Smart Agriculture

Agriculture is both a victim and a contributor to climate change. Data science is helping farmers adapt through climate-smart agriculture practices:

Yield prediction using historical and weather data

Soil health monitoring through sensors and analytics

Pest and disease detection using AI-driven image classification

Precision irrigation to reduce water usage

Platforms like IBM’s Watson Decision Platform for Agriculture use AI to give farmers insights that boost productivity while reducing environmental impact.

5. Greener Cities with Smart Data

Urban areas contribute heavily to CO₂ emissions. With smart data collected from sensors, traffic cams, GPS, and public utilities, data scientists help cities become more sustainable:

Optimizing public transport to reduce fuel consumption

Monitoring air quality in real-time

Planning green spaces using heat maps

Managing waste and recycling more efficiently

Cities like Singapore, Amsterdam, and San Francisco are already leading the way in becoming “smart cities,” using data science to reduce emissions and improve quality of life.

6. Renewable Energy Optimization

The shift to solar, wind, and hydro power brings new challenges: fluctuating outputs, grid integration, and energy storage. Here’s where data science steps in:

Forecasting sunlight and wind speeds to predict energy generation

Optimizing battery storage and distribution

Balancing supply and demand across the smart grid

AI models from companies like Google DeepMind have already improved the output prediction of wind farms by up to 20%.

7. Climate Research and Citizen Science

Open-source projects and platforms allow anyone to contribute to climate research. Data scientists use crowd-sourced data to:

Map plastic waste in oceans

Collect wildlife migration data

Record local temperature anomalies

Tools like Zooniverse, Kaggle, and Climate Central invite data scientists and enthusiasts to work on real-world climate datasets and challenges.

8. Policy and Decision-Making Support

Data science doesn't just help collect and analyze data—it also helps governments make better decisions.

Predictive models simulate the outcome of climate policies