#Generative AI For Cost-Effective Manufacturing

Explore tagged Tumblr posts

Text

Discover how generative AI solves manufacturing challenges: predictive maintenance, optimized design, quality control, and supply chain efficiency. Innovate your production today!

#AI-Driven Production Enhancements#Generative AI For Process Automation#AI In Manufacturing Intelligence#Generative AI For Manufacturing Improvement#AI In Industrial Efficiency#AI-Enhanced Manufacturing Workflows#Generative AI For Operational Excellence#AI In Production Management#AI-Driven Manufacturing Optimization#Generative AI For Supply Chain Resilience#AI In Process Innovation#AI In Manufacturing Performance#Generative AI For Manufacturing Analytics#AI In Production Quality#AI-Powered Factory Efficiency#Generative AI For Cost-Effective Manufacturing

0 notes

Text

Tariffs, another chaotic venture of the barely four-month-old Trump administration, are set to rollick every sector of the economy and nearly all the goods and services people use across the world. But tariffs could also cause the tech in your phone and other devices you use every day to stagnate as supply chains are hit by the rise in costs and companies scramble to balance the books by cutting vital development research.

Let’s get a couple important caveats out of the way here, starting with the possibility that the US might just come to its senses and back down on tariffs after all. President Trump promises he won't, of course, but he has now enacted a 90-day delay on higher tariffs for all countries except China, which has had its tariffs hiked from 34 to 145 percent.

While the tariff reprieve may ease pressures elsewhere, it is terrible news for Big Tech, which has supply chains that rely heavily on Chinese companies and Chinese-made components. Some companies have already gotten very creative about trying to dodge those additional costs, like Apple, which Reuters reports airlifted about 600 tons of iPhones to India in an effort to avoid Trump’s tariffs.

Whether tech leaders more broadly can yet negotiate special exemptions that allow their products to swerve these costs remains to be seen, but if they don’t, sky-high tariffs are likely to limit what new technologies companies can cram into their devices while keeping costs low.

“There's absolutely a threat to innovation,” says Anshel Sag, a principal analyst at Moor Insights and Strategies. “Companies have to cut back on spending, which generally means cutting back on everything.”

Smartphones in particular are at risk of soaring in price, given that they are the single largest product category that the US imports from China. Moving the wide variety of manufacturing capabilities needed to produce them in the US would cost an amount of money that’s almost impossible to calculate—if the move would even be possible at all.

The trouble tariffs cause smartphone makers will come as they try to battle rising costs while making their products ever more capable. Apple spent nearly $32 billion on research and development costs in 2024. Samsung spent $24 billion on R&D that same year. Phone companies need their devices to dazzle and excite users so they upgrade to the shiny new edition each and every year. But people also need to be able to afford these now near essential products, so striking a balance in the face of exponentially high tariffs creates problems.

“As companies shift their engineering teams to focus on cost reductions rather than creating the next best thing, the newest innovation—does that hurt US manufacturers?” asks Shawn DuBravac, chief economist at the trade association IPC. “Are we creating an environment where foreign manufacturers can out innovate US manufacturers because they are not having to allocate engineering resources to cost reduction?”

If that’s how it goes down, the result will be almost the exact opposite effect of what Trump claims he intended to do by implementing tariffs in the first place. Yet sadly it’s a well-known fact of business that R&D is one of the first budgets to be cut when profits are at risk. If US manufacturers are forced to keep costs low enough to entice customers in this new regime, it’ll more than likely mean innovation falters.

“Rather than focusing on some new AI application, they might want to focus on reengineering this product so that they're able to shave pennies here and pennies there and reduce production cost,” DuBravac says. “What ends up happening is you say, ‘Ah, you know what? We're not going to launch that this year. We're going to wait 12 months. We’re going to wait for the cost to fall.’”

Sag says that a lower demand—likely caused because people will have less money as we potentially careen toward a recession—also leads to a slowdown of the refresh cycle of a product. Less people buying a thing means less need to make more of the thing. Some products may get to the point where there is just no market for them anymore.

He points to product categories such as folding phones, which after six years of adjustment and experimentation at high price points have finally started to come into their own. The prices have come down as well, meaning folding phones are nearly at the phase of being at an attractive price point for more regular buyers.

It has been rumored that Apple has a folding phone close to debuting, but who knows how that plays out in a world where Apple is subject to the same trade tariffs as everyone else with a heavy reliability on China production? A complicated or potentially risky device might be delayed, or be deemed too ambitious, because tariff costs forced budgets elsewhere.

“It definitely affects product cycles and which features get made—and even which configurations of which chips get shipped,” Sag says. “The ones that are more cost optimized will probably get used more.”

8 notes

·

View notes

Text

AGARTHA Aİ - DEVASA+ (4)

In an era where technology and creativity intertwine, AI design is revolutionizing the way we conceptualize and create across various industries. From the runway to retail, 3D fashion design is pushing boundaries, enabling designers to craft intricate garments with unparalleled precision. Likewise, 3D product design is transforming everything from gadgets to furniture, allowing for rapid prototyping and innovation. As we explore these exciting advancements, platforms like Agartha.ai are leading the charge in harnessing artificial intelligence to streamline the design process and inspire new ideas.

AI design

Artificial intelligence (AI) has revolutionized numerous industries, and the realm of design is no exception. By leveraging the power of machine learning and advanced algorithms, AI is transforming the way designers create, innovate, and deliver their products. AI-driven tools enable designers to harness vast amounts of data, allowing for more informed decision-making and streamlined workflows.

In the context of graphic design, AI can assist artists in generating ideas, creating unique visuals, and even automating repetitive tasks. For instance, programs powered by AI design can analyze trends and consumer preferences, producing designs that resonate with target audiences more effectively than traditional methods. This shift not only enhances creativity but also enables designers to focus on strategic thinking and ideation.

Moreover, AI is facilitating personalized design experiences. With the help of algorithms that analyze user behavior, products can be tailored to meet the specific needs and tastes of individuals. This level of customization fosters deeper connections between brands and consumers, ultimately driving customer satisfaction and loyalty in an increasingly competitive market.

3D fashion design

In recent years, 3D fashion design has revolutionized the way we create and visualize clothing. Using advanced software and tools, designers can create lifelike virtual garments that allow for innovative experimentation without the need for physical fabric. This trend has not only streamlined the design process but has also significantly reduced waste in the fashion industry.

Moreover, 3D fashion design enables designers to showcase their creations in a more interactive manner. By utilizing 3D modeling and rendering technologies, designers can present their collections in virtual environments, making it easier for clients and consumers to appreciate the nuances of each piece. This immersive experience also helps in gathering valuable feedback before producing the final product.

Furthermore, the integration of 3D fashion design with augmented reality (AR) and virtual reality (VR) technologies is bringing a fresh perspective to the industry. Consumers can virtually try on clothes from the comfort of their homes, thereby enhancing the shopping experience. As this field continues to evolve, it promises to bridge the gap between creativity and technology, paving the way for a sustainable and forward-thinking fashion future.

3D product design

3D product design has revolutionized the way we conceptualize and create products. With advanced software tools and technologies, designers can now create highly detailed and realistic prototypes that are not only visually appealing but also functional. This process allows for a quicker iteration of ideas, enabling designers to experiment with various styles and functionalities before arriving at the final design.

One of the significant advantages of 3D product design is the ability to visualize products in a virtual environment. Designers can see how their creations would look in real life, which is essential for understanding aesthetics and usability. Additionally, this technology enables manufacturers to identify potential issues in the design phase, reducing costs associated with prototype development and rework.

Moreover, the rise of 3D printing has further enhanced the significance of 3D product design. Designers can swiftly turn their digital models into tangible products, allowing for rapid prototyping and small-batch manufacturing. This agility not only speeds up the time-to-market for new products but also paves the way for more innovative designs that were previously impossible to execute.

Agartha.ai

Agartha.ai is a revolutionary platform that merges artificial intelligence with innovative design, creating a new avenue for designers and creators alike. With the rapid advancements in technology, Agartha.ai leverages AI to streamline various design processes, enabling users to produce unique and captivating designs with ease.

The platform provides tools that empower both emerging and established designers to explore the possibilities of AI design. By utilizing intelligent algorithms, Agartha.ai can assist in generating design options, ensuring that creativity is not hindered but enhanced. This results in a more efficient workflow and allows designers to focus on the conceptual aspects of their projects.

One of the standout features of Agartha.ai is its ability to adapt to different design disciplines, such as 3D fashion design and 3D product design. By supporting a broad spectrum of design fields, it positions itself as a versatile tool that meets the evolving needs of today's creative professionals. Whether it's crafting intricate fashion pieces or developing innovative product designs, Agartha.ai is at the forefront of the design revolution.

329 notes

·

View notes

Text

Comprehensive Industrial Solutions by AxisValence: Advancing Productivity, Safety, and Efficiency

In today’s fast-paced manufacturing world, industrial productivity is driven by precision, consistency, safety, and compliance. Whether it’s printing, packaging, converting, textiles, plastics, or pharmaceuticals—modern production lines demand advanced electro-mechanical systems that minimize waste, ensure operational safety, and improve overall efficiency.

AxisValence, a business unit of A.T.E. India, addresses this demand with a complete range of industrial automation and enhancement products. From static elimination to print quality assurance, ink management, and solvent recovery, AxisValence solutions are engineered to optimize each critical point in the production cycle.

This article provides an overview of the key technologies and systems offered by AxisValence across its diverse portfolio:

Electrostatics: Managing Static for Quality and Safety

Electrostatics can compromise product quality, disrupt operations, and pose serious safety hazards, especially in high-speed processes involving films, paper, textiles, or volatile solvents. AxisValence offers a complete suite of static control solutions:

ATEX AC Static Eliminators: Certified for use in explosive or solvent-heavy environments such as rotogravure or flexo printing lines.

AC and DC Static Eliminators: Designed for long-range or close-range static charge neutralization across a range of substrates.

Passive Static Dischargers: Cost-effective, maintenance-free brushes for light-duty static elimination where power isn't available.

Air-based Static Eliminators / Ionisers: Use ionized air streams for dust blow-off and static removal, ideal for hard-to-reach areas.

Static Measurement & Online Monitoring: Includes handheld meters and IoT-enabled monitoring systems for real-time control and diagnostics.

Electrostatic Charging Systems: Generate controlled static charges for bonding or pinning applications in laminating or packaging lines.

Electrostatic Print Assist (ESA): Enhances ink transfer in rotogravure printing by improving ink pickup and registration.

Camera-Based Web Videos for Print Viewing: Real-Time Visual Inspection

High-speed printing applications require instant visibility into print quality. AxisValence’s ViewAXIS systems are high-performance, camera-based web viewing solutions:

ViewAXIS Mega: Entry-level system with high-resolution imaging for real-time visual inspection.

ViewAXIS Giga: Equipped with 14x optical zoom and X-ray vision for deeper inspection of layered prints.

ViewAXIS Tera: Full repeat system with a 55” display, allowing operators to monitor and inspect the complete print layout in real-time.

Camera-Based Web Videos for Print Viewing systems help identify print errors like registration issues, smudging, or color inconsistencies early in the production run—minimizing rework and improving efficiency.

100% Inspection Systems: Intelligent Defect Detection

Modern converters and packaging companies require automated systems that can identify microscopic flaws at high speeds. AxisValence’s DetectAXIS systems use AI-based image processing and line scan cameras for 100% inspection:

DetectAXIS Print: Identifies printing defects such as streaks, misregistration, color deviation, and missing text at speeds up to 750 m/min.

DetectAXIS Surface: Designed for detecting surface anomalies—scratches, gels, holes, fish-eyes—on films, textiles, and nonwovens.

Real-time alerts, digital roll-maps, and adaptive detection improve quality control while reducing material waste and production downtime.

Ink Handling Systems: Consistent Ink Quality and Reduced Waste

Stable ink flow and temperature directly impact print quality and solvent consumption. AxisValence’s Valflow range ensures optimal ink conditioning through:

Ink Filters: Eliminate contaminants like metallic particles, fibers, and dried pigments that can damage cylinders or cause print defects.

Ink Pumps & Tanks: Efficient centrifugal pumps and round stainless-steel tanks designed for continuous ink circulation and minimal ink residue.

Ink Temperature Stabilisers (ITS): Automatically control ink temperature to prevent viscosity drift and reduce solvent evaporation—delivering consistent print shade and odor-free operation.

Valflow Ink handling solutions are ideal for gravure and flexographic printing applications.

Print Register Control Systems: Precision Alignment in Every Print

Maintaining precise print registration control systemis critical in multi-color printing processes. AxisValence offers two specialized systems:

AlygnAXIS: For rotogravure presses, using fiber optic sensors and adaptive algorithms to deliver real-time register accuracy.

UniAXIS: A versatile controller for print-to-mark, coat-to-mark, and cut-to-mark applications—both inline and offline.

These controllers reduce waste, enhance print alignment, and speed up setup during job changes.

Safety and Heat Recovery Systems: Energy Efficiency and Explosion Prevention

Solvent-based processes require strict monitoring of air quality and heat management to meet compliance and reduce operational costs. AxisValence provides:

NIRA Residual Solvent Analyser: Lab-based gas chromatography system for quick analysis of residual solvents in films.

Air-to-Air Heat Exchangers (Lamiflow): Recover and reuse waste heat from drying processes—improving energy efficiency.

LEL Monitoring and Recirculation Systems: Ensure solvent vapor concentrations stay within safe limits in enclosed dryers using flame ionization or infrared detection.

Together, safety and heat recovery systems ensure both environmental safety and process optimization.

Surface Cleaning Systems: Contaminant-Free Production Lines

Particulate contamination can ruin coating, lamination, and printing jobs. AxisValence offers contactless surface cleaning systems that combine airflow and static control:

Non-Contact Web Cleaners: Use air curtains and vacuum to remove dust from moving substrates without physical contact.

Ionising Air Knives: High-velocity ionized air streams neutralize static and clean surfaces entering finishing zones.

Ionising Air Blowers: Cover larger surfaces with ionized air to eliminate static and debris.

Ionising Nozzles & Guns: Handheld or fixed, these tools offer targeted static and dust elimination at workstations.

Waste Solvent Recovery: Sustainable Ink and Solvent Reuse

Reducing solvent consumption and improving environmental compliance is critical for modern converters. AxisValence partners with IRAC (Italy) to offer:

Solvent Distillation Systems: Recover usable solvents from spent ink mixtures, reducing hazardous waste and cutting costs.

Parts Washers: Clean anilox rolls, gravure cylinders, and components through high-pressure, ultrasonic, or brush-based systems.

Waste solvent recovery systems offer a quick ROI and support zero-waste manufacturing goals.

Why Choose AxisValence?

AxisValence combines decades of industrial expertise with innovative product design to deliver reliable, safe, and efficient solutions for manufacturing processes. With a product portfolio spanning:

Electrostatics & Static Control Systems

Web Viewing & Print Inspection Solutions

Ink Handling and Conditioning Equipment

Register Control and Print Automation

Heat Recovery and Air Quality Monitoring

Surface Cleaning Technologies

Waste Solvent Management

…AxisValence serves diverse industries including printing, packaging, plastic and rubber, textile, pharma, and automotive.

From single-device retrofits to complete system integration, AxisValence enables manufacturers to improve output quality, reduce waste, meet safety norms, and gain a competitive edge.

Explore our full product range at www.axisvalence.com or contact our sales network for a customized consultation tailored to your industrial needs.

youtube

2 notes

·

View notes

Text

Air-Insulated vs Gas-Insulated Switchgear: Which One is Right for You?

In the world of power distribution, switchgear plays a vital role in ensuring safe, reliable, and efficient control of electrical systems. But when it comes to choosing the right type of switchgear for your application, a common debate arises: Air-Insulated Switchgear (AIS) or Gas-Insulated Switchgear (GIS) — which one is the better fit?

In this blog, we’ll break down the key differences, pros and cons, and application suitability of each, helping you make an informed decision.

What is Switchgear?

Before diving into the comparison, let’s quickly recap what switchgear is. Switchgear is a combination of electrical disconnect switches, fuses or circuit breakers used to control, protect, and isolate electrical equipment. It’s critical for fault detection, power isolation, and system protection in electrical networks.

Switchgear typically falls into two main types based on insulation medium:

Air-Insulated Switchgear (AIS)

Gas-Insulated Switchgear (GIS)

What is Air-Insulated Switchgear (AIS)?

Air-Insulated Switchgear uses air as the primary dielectric medium for insulation between live parts and ground. It’s commonly found in both indoor and outdoor substations.

Pros of AIS:

Lower Initial Cost: Generally less expensive to manufacture and install.

Simple Design: Easier to maintain, inspect, and service.

Ease of Modification: Flexible and scalable for future upgrades or expansions.

Environmentally Safer: No greenhouse gases like SF₆ are used.

Cons of AIS:

Larger Footprint: Requires more physical space, making it unsuitable for compact or urban environments.

Vulnerable to Environmental Factors: Susceptible to dust, humidity, and pollution in outdoor settings.

What is Gas-Insulated Switchgear (GIS)?

Gas-Insulated Switchgear uses sulfur hexafluoride (SF₆) gas as the insulating medium. This technology allows high-voltage switchgear to be extremely compact.

Pros of GIS:

Compact Design: Ideal for space-constrained environments like cities, buildings, and offshore platforms.

High Reliability: Fully enclosed system offers excellent protection against external elements.

Minimal Maintenance: Components are sealed and protected, requiring less frequent servicing.

Longer Lifespan: Designed for durability and consistent performance.

Cons of GIS:

Higher Initial Cost: More expensive in terms of equipment and installation.

SF₆ Gas Concerns: Although SF₆ is effective, it’s a potent greenhouse gas with strict handling requirements.

Complex Repairs: Repairs and servicing can be more specialized and expensive.

AIS vs GIS: Quick Comparison Table

Feature AIS GIS Insulation Medium Air SF₆ Gas Size / Space Needed Larger Very Compact Initial Cost Lower Higher Maintenance Frequent Minimal Environmental Impact Low High (due to SF₆)Installation Complexity Simpler More complex Suitability Rural, open spaces Urban, limited-space settings

Which One Is Right for You?

The decision between AIS and GIS depends on several key factors:

1. Available Space

Choose GIS for space-limited locations like high-rise buildings, tunnels, and offshore platforms.

Choose AIS if you have ample room and want easier access for maintenance.

2. Budget Constraints

If cost is a concern, AIS offers a more economical solution.

If lifetime value and reliability are priorities, GIS might justify the investment.

3. Environmental Considerations

AIS is more eco-friendly due to the absence of SF₆.

GIS requires special handling and monitoring for SF₆, especially in regions with strict environmental regulations.

4. Application Type

AIS is well-suited for:

Power stations

Industrial zones

Rural substations

GIS is ideal for:

Urban substations

Underground systems

Critical infrastructure with limited space

Final Thoughts

Both Air-Insulated and Gas-Insulated Switchgear have their strengths and are engineered to serve specific needs. The right choice ultimately depends on your project requirements, site conditions, budget, and sustainability goals.

As a trusted supplier of high-performance switchgear, we can help you evaluate the best solution tailored to your project — ensuring safety, reliability, and efficiency.

5 notes

·

View notes

Text

AI technique predicts Hall thruster power for spacecraft with high accuracy

A Hall thruster is a high-efficiency propulsion device using plasma that is used for various difficult space missions, such as SpaceX's constellation satellites, Starlink and NASA's asteroid probe, Psyche, and is one of the core space technologies.

KAIST researchers will be verifying the performance of the Hall thruster for CubeSats developed using artificial intelligence techniques by loading it onto the CubeSat K-HERO during the fourth launch of Nuri scheduled for November of this year.

Professor Wonho Choe of the Department of Nuclear and Quantum Engineering developed an artificial intelligence technique that can predict the thrust performance of Hall Effect ion thrusters (i.e., Hall thrusters), which are engines for satellites or space probes, with high accuracy. The study is published in the journal Advanced Intelligent Systems.

Hall thrusters have high fuel efficiency, so they can greatly accelerate satellites or spacecraft using less propellant (fuel), and can generate large thrust relative to the power consumed. Based on these advantages, it is widely used for various missions, such as maintaining formation flight of satellite clusters in space environments where propellant conservation is important, orbital deorbit maneuvers for reducing space debris, and providing propulsion for deep space exploration such as comet or Mars exploration.

Recently, as the space industry has expanded in the era of Newspace, space missions are becoming more diverse and the demand for Hall thrusters is increasing accordingly. In order to quickly develop high-efficiency Hall thrusters optimized for each unique mission, a technique to accurately predict the performance of the thruster from the design stage is essential.

However, existing methods have limitations such as not being able to precisely handle the complex plasma phenomenon occurring in the Hall thruster or being limited to specific conditions, resulting in low performance prediction accuracy.

The research team developed a highly accurate thruster performance prediction technique based on artificial intelligence that drastically reduces the time and cost required for repetitive work of designing, manufacturing, and testing the Hall thruster.

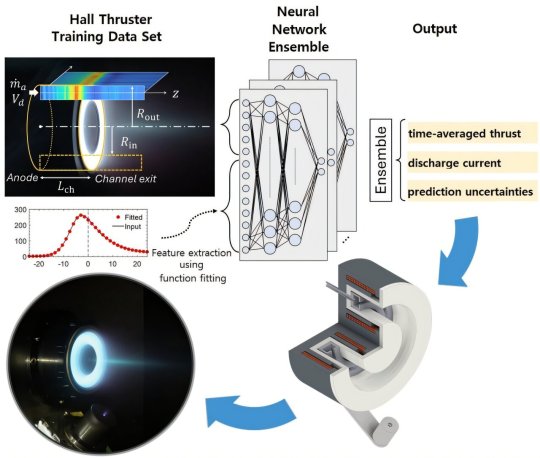

Professor Choe's team, which started the first domestic electric thruster development research in 2003 and has been leading related research and development, introduced an artificial neural network ensemble structure based on 18,000 Hall thruster learning data generated using a self-developed electric thruster computer analysis tool and applied it to predicting thrust performance.

The computer analysis tool developed to secure high-quality learning data models plasma physics and thrust performance. The accuracy of the computer analysis tool was verified to be high, with an average error of less than 10% compared to approximately 100 experimental data performed with 10 Hall thrusters developed for the first time in Korea by the research team.

The artificial neural network ensemble model operates as a digital twin model that can predict thruster performance in a short period of time, within a few seconds, with high accuracy depending on the design variables of the Hall thruster.

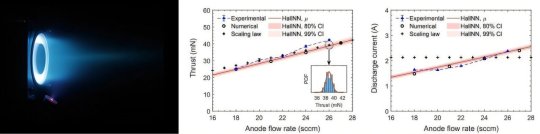

In particular, it can analyze in detail the changes in performance indicators such as thrust and discharge current according to design variables such as fuel flow rate and magnetic field that were difficult to analyze with previously known scaling laws.

The research team showed that the AI neural network model developed this time showed an average error of less than 5% for the 700W and 1kW class Hall thrusters developed in-house, and an average error of less than 9% for the 5kW class high-power Hall thruster developed by the US Air Force Research Laboratory. This study proved that the AI prediction technique developed can be widely applied to Hall thrusters of various power sizes.

Professor Choe said, "The AI-based performance prediction technique developed by the research team has high accuracy and is already being used to analyze the thrust performance of Hall thrusters, which are engines for satellites and spacecraft, and to develop high-efficiency, low-power Hall thrusters. This AI technique can be applied not only to Hall thrusters, but also to the research and development of ion beam sources used in various industries such as semiconductors, surface treatment, and coating."

In addition, Professor Choe explained, "The Hall thruster for the cube satellite developed using AI techniques in collaboration with Cosmo Bee Co., Ltd., an electric propulsion specialist and a laboratory startup of the research team, will be installed on the 3U (30x10x10 cm) cube satellite K-HERO in the 4th launch of Nuri scheduled for November of this year to verify its performance in space."

The results of this study, in which Ph.D. student Jaehong Park of KAIST Department of Nuclear and Quantum Engineering (Space Exploration Engineering Interdisciplinary Major) participated as the first author, were recognized for their innovation by being selected as the journal's front cover paper.

TOP IMAGE: The AI-based technique to predict Hall Effect Ion Source developed by the research team can predict the performance of the thrust according to design variables with high accuracy, rendering it highly useful in the development of high-efficiency Hall thrusters. Credit: Adapted from Advanced Intelligent Systems (2024). DOI: 10.1002/aisy.202400555

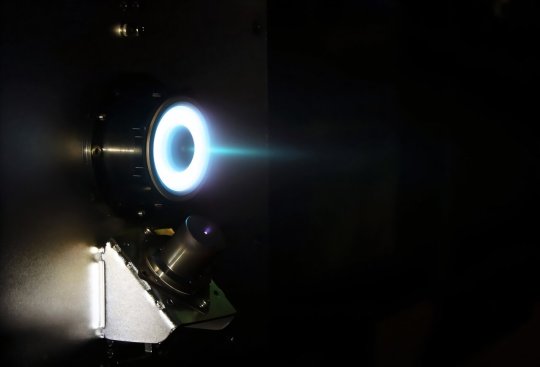

CENTRE IMAGE: The operation of a 150 W-class low-power Hall thruster for (ultra)small satellites that is being developed by the research team of Professor Wonho Choe of KAIST in collaboration with Cosmobee, an electric propulsion specialist company founded by the laboratory. This Hall thruster is scheduled to be installed on the CubeSat, K-HERO, that will be launched into space through the 4th launch of Nuriho in the 4th quarter of 2025 to perform in-orbit verification. Credit: The Korea Advanced Institute of Science and Technology (KAIST)

LOWER IMAGE: The photo on the left shows the Hall thruster in operation in the Electric Propulsion Vacuum Chamber at KAIST, and the graphs to the right show the results of thrust and discharge current according to the anode flow rate. In the graph, the red line represents the results predicted by the AI model, and the blue dots represent the experimental results. Credit: Adapted from Advanced Intelligent Systems (2024). DOI: 10.1002/aisy.202400555

6 notes

·

View notes

Text

AI & Data Centers vs Water + Energy

We all know that AI has issues, including energy and water consumption. But these fields are still young and lots of research is looking into making them more efficient. Remember, most technologies tend to suck when they first come out.

Deploying high-performance, energy-efficient AI

"You give up that kind of amazing general purpose use like when you're using ChatGPT-4 and you can ask it everything from 17th century Italian poetry to quantum mechanics, if you narrow your range, these smaller models can give you equivalent or better kind of capability, but at a tiny fraction of the energy consumption," says Ball."...

"I think liquid cooling is probably one of the most important low hanging fruit opportunities... So if you move a data center to a fully liquid cooled solution, this is an opportunity of around 30% of energy consumption, which is sort of a wow number.... There's more upfront costs, but actually it saves money in the long run... One of the other benefits of liquid cooling is we get out of the business of evaporating water for cooling...

The other opportunity you mentioned was density and bringing higher and higher density of computing has been the trend for decades. That is effectively what Moore's Law has been pushing us forward... [i.e. chips rate of improvement is faster than their energy need growths. This means each year chips are capable of doing more calculations with less energy. - RCS] ... So the energy savings there is substantial, not just because those chips are very, very efficient, but because the amount of networking equipment and ancillary things around those systems is a lot less because you're using those resources more efficiently with those very high dense components"

New tools are available to help reduce the energy that AI models devour

"The trade-off for capping power is increasing task time — GPUs will take about 3 percent longer to complete a task, an increase Gadepally says is "barely noticeable" considering that models are often trained over days or even months... Side benefits have arisen, too. Since putting power constraints in place, the GPUs on LLSC supercomputers have been running about 30 degrees Fahrenheit cooler and at a more consistent temperature, reducing stress on the cooling system. Running the hardware cooler can potentially also increase reliability and service lifetime. They can now consider delaying the purchase of new hardware — reducing the center's "embodied carbon," or the emissions created through the manufacturing of equipment — until the efficiencies gained by using new hardware offset this aspect of the carbon footprint. They're also finding ways to cut down on cooling needs by strategically scheduling jobs to run at night and during the winter months."

AI just got 100-fold more energy efficient

Northwestern University engineers have developed a new nanoelectronic device that can perform accurate machine-learning classification tasks in the most energy-efficient manner yet. Using 100-fold less energy than current technologies...

“Today, most sensors collect data and then send it to the cloud, where the analysis occurs on energy-hungry servers before the results are finally sent back to the user,” said Northwestern’s Mark C. Hersam, the study’s senior author. “This approach is incredibly expensive, consumes significant energy and adds a time delay...

For current silicon-based technologies to categorize data from large sets like ECGs, it takes more than 100 transistors — each requiring its own energy to run. But Northwestern’s nanoelectronic device can perform the same machine-learning classification with just two devices. By reducing the number of devices, the researchers drastically reduced power consumption and developed a much smaller device that can be integrated into a standard wearable gadget."

Researchers develop state-of-the-art device to make artificial intelligence more energy efficient

""This work is the first experimental demonstration of CRAM, where the data can be processed entirely within the memory array without the need to leave the grid where a computer stores information,"...

According to the new paper's authors, a CRAM-based machine learning inference accelerator is estimated to achieve an improvement on the order of 1,000. Another example showed an energy savings of 2,500 and 1,700 times compared to traditional methods"

5 notes

·

View notes

Text

How Indian rice manufacturers are shaping the global market

Indian rice has long held a place of pride in global kitchens, from the aromatic basmati grains that grace royal banquets to the nutritious non-basmati varieties that make up everyday meals worldwide. India is the world’s largest rice exporter, meeting over 40% of global rice demand (Source: FAO). Behind this success is the dedication and innovation of rice manufacturers in India, who are constantly adapting to meet international standards and market needs.

In this blog, we explore how Indian rice manufacturers are shaping the global market, promoting sustainability and securing India’s position as a rice exporting powerhouse.

Key factors driving Indian rice exports

Quality and Variety Rice manufacturers offer a diverse range of rice, from aromatic basmati to versatile non-basmati rice varieties. Each variety caters to different cuisines and preferences, ensuring steady demand in countries such as the United States, the Middle East, and Africa.

Competitive Pricing India's favorable agricultural conditions and cost-effective manufacturing processes enable competitive pricing. Combined with bulk export capabilities, this ensures that India remains a preferred supplier for global buyers.

Government policies and support Supportive government policies such as export incentives and trade agreements have contributed significantly to India's global dominance. For example, the recent removal of export restrictions on certain Indian rice varieties has boosted international trade opportunities.

Technological advances in rice manufacturing

Technology is transforming rice production in India, increasing efficiency and quality while reducing waste.

Modern milling equipment: Automated milling units maintain uniform grain size, texture and polish, which are critical to meeting international quality standards.

AI-powered sorting: Advanced sorting systems powered by artificial intelligence help eliminate impurities, ensuring that premium-grade rice reaches global markets.

Packaging innovations: Innovative vacuum-sealing and biodegradable packaging materials have made Indian rice more attractive to environmentally conscious buyers.

Rice manufacturers in India are adopting these advancements to maintain their competitive edge while meeting global priorities.

Sustainability initiatives by Indian manufacturers

As environmental concerns grow, rice exporters in India are adopting sustainable practices to meet global expectations.

Water-efficient farming: Techniques such as alternate wetting and drying (AWD) reduce water consumption, which is crucial for regions facing water scarcity.

Low carbon footprint: Adoption of renewable energy in processing units and adoption of eco-friendly logistics have reduced emissions in the rice supply chain.

Waste Utilization: By-products such as rice husk are being reused for bioenergy and building materials, thereby reducing waste and generating additional revenue streams.

These initiatives not only enhance India’s reputation but also align with the sustainability goals of global buyers.

Conclusion: The future of Indian rice on the global stage

The success of rice manufacturers in India is not just about meeting current demands, but also about shaping the future of the global rice trade. By prioritizing quality, leveraging technology, and adopting sustainable practices, Indian manufacturers have solidified their position as reliable partners in the global food supply chain.

As international markets evolve, India’s ability to adapt and innovate will continue to drive its leadership in the rice export industry, ensuring that Indian rice remains a staple in households around the world.

2 notes

·

View notes

Text

www.carmesine.com

3D Design: More Than Just Flashy Visuals

In a world where speed and precision are critical, 3D design is transforming fashion from concept to creation. It’s not just about eye catching renders; it’s the secret to streamlining the entire process.

Bridging Concepts, to design in 3D

In today’s fast-paced fashion world, 3D design isn’t just a visual upgrade, it’s the key to streamlining the entire process, from initial concepts to final products. Our studio integrates DPC workflows at every stage, ensuring that creativity, production, and marketing all work in harmony, resulting in faster, more efficient results. This means to design in 3D.

Smart Ideation

AI generated sketches and converting 2D drawings into photorealistic images, are useful for quickly exploring concepts, fantastic as ideation tools. Combining both classic design skills and DPC is essential to bring those ideas to life in a way that truly translates into manufacturable designs. This fusion gives brands the agility to innovate while ensuring that ideas remain viable in the real world.

Facing Frustrations

Adopting new digital tools can be overwhelming in some contexts. Many teams struggle with the leap from traditional methods to full digital integration. Decision makers may hesitate, viewing DPC as just another layer of complexity. However, those who embrace DPC as a core part of their process see not only streamlined operations but also significant cost savings and faster time to market. True integration is key.

Freelance Collaboration: A Flexible Solution

As brands struggle to scale DPC internally, our expertise in both capsule and full-line design offers a flexible, cost-effective solution. Carmesine Studio’s freelance services provide the external expertise needed to fully leverage DPC, without the overhead of building inhouse teams. We help brands transition beyond pilot programs, integrating DPC workflows seamlessly to design entire collections or focused capsule projects, maximizing the potential of digital assets while maintaining creativity and efficiency.

Elevate Your Brand's Design with DPC Excellence!

At Carmesine Studiolab, we specialise in crafting innovative designs for your brand using the latest Digital Product Creation techniques. Contact us today to discover how we can collaborate and enhance your design process with cutting-edge DPC solutions!

2 notes

·

View notes

Text

The Future of ERP Software in India: Trends to Watch in 2024

As India continues to solidify its position as a global economic powerhouse, the demand for sophisticated Enterprise Resource Planning (ERP) solutions has never been higher. ERP software companies in India are at the forefront of this transformation, driving innovation and efficiency across various industries. As we look ahead to 2024, several key trends are shaping the future of ERP software in India. This blog delves into these trends, offering insights into how ERP software providers in India are gearing up to meet the evolving needs of businesses.

1. Increased Adoption of Cloud-Based ERP Solutions

One of the most significant trends in the ERP landscape is the shift towards cloud-based solutions. ERP software companies in India are increasingly offering cloud-based ERP systems to meet the growing demand for flexibility, scalability, and cost-efficiency. Cloud ERP solutions eliminate the need for extensive on-premises infrastructure, allowing businesses to reduce capital expenditure and streamline operations.

Cloud-based ERP systems also facilitate real-time data access and collaboration, enabling businesses to make informed decisions quickly. This trend is particularly beneficial for small and medium-sized enterprises (SMEs) that require affordable and scalable ERP solutions to compete effectively in the market.

2. Integration of Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing the ERP landscape. ERP software providers in India are integrating AI and ML technologies to enhance the capabilities of their solutions. These technologies enable predictive analytics, automate routine tasks, and provide intelligent insights, helping businesses to optimize their operations.

For instance, AI-powered ERP systems can forecast demand, manage inventory levels, and predict maintenance needs, significantly improving efficiency and reducing costs. As AI and ML technologies continue to evolve, their integration into ERP systems will become more sophisticated, offering even greater value to businesses.

3. Focus on Industry-Specific ERP Solutions

ERP software companies in India are increasingly developing industry-specific ERP solutions to cater to the unique needs of different sectors. Whether it is manufacturing, retail, healthcare, or finance, each industry has distinct requirements that generic ERP systems might not fully address. Industry-specific ERP solutions offer tailored functionalities and workflows, ensuring better alignment with business processes.

For example, a manufacturing ERP system might include features for production planning, quality control, and supply chain management, while a retail ERP system could focus on inventory management, point of sale (POS) integration, and customer relationship management (CRM). This trend towards specialization ensures that businesses can leverage ERP systems that truly support their operational needs.

4. Enhanced Mobile Accessibility

With the proliferation of smartphones and mobile devices, the need for mobile-friendly ERP solutions is growing. ERP software providers in India are developing mobile applications that allow users to access critical business information on the go. Mobile ERP solutions enable employees to perform tasks such as inventory checks, sales order processing, and expense reporting from their smartphones or tablets.

This trend not only improves accessibility but also enhances productivity by enabling employees to work remotely and make decisions in real-time. As mobile technology continues to advance, the functionality and user experience of mobile ERP applications will improve, making them an indispensable tool for modern businesses.

5. Increased Emphasis on Data Security and Compliance

As businesses become more reliant on digital technologies, data security and compliance have become paramount. ERP software providers in India are prioritizing data protection by incorporating advanced security features into their solutions. This includes encryption, multi-factor authentication, and regular security audits to safeguard sensitive business information.

Moreover, with the implementation of regulations such as the General Data Protection Regulation (GDPR) and India’s Personal Data Protection Bill, compliance is a critical concern for businesses. ERP software providers are ensuring that their systems comply with these regulations, helping businesses avoid legal penalties and build trust with their customers.

6. Rise of Hybrid ERP Solutions

While cloud-based ERP systems offer numerous advantages, some businesses prefer on-premises solutions due to specific regulatory or operational requirements. To cater to these diverse needs, ERP software companies in India are offering hybrid ERP solutions that combine the benefits of both cloud and on-premises systems.

Hybrid ERP solutions provide the flexibility of cloud-based systems while allowing businesses to maintain critical applications on-premises. This approach offers a balanced solution, enabling businesses to optimize their IT infrastructure based on their unique needs and preferences.

7. Adoption of Advanced Analytics and Business Intelligence

Data is the new currency in today’s business environment, and the ability to harness and analyze data is a key competitive advantage. ERP software providers in India are integrating advanced analytics and business intelligence (BI) tools into their systems. These tools enable businesses to gain deep insights into their operations, identify trends, and make data-driven decisions.

Advanced analytics and BI tools can analyze large volumes of data from various sources, providing comprehensive reports and dashboards. This helps businesses to monitor performance, identify inefficiencies, and uncover new opportunities for growth.

8. Greater Focus on User Experience and Interface Design

The user experience (UX) and interface design of ERP systems are critical to their adoption and effectiveness. ERP software companies in India are placing a greater emphasis on developing intuitive and user-friendly interfaces. This trend is driven by the need to ensure that ERP systems are accessible and easy to use for all employees, regardless of their technical expertise.

Modern ERP systems feature clean, responsive interfaces with customizable dashboards and navigation options. This focus on UX design helps to improve user satisfaction, reduce training time, and increase overall productivity.

9. Integration with the Internet of Things (IoT)

The Internet of Things (IoT) is transforming the way businesses operate by enabling real-time monitoring and data collection from connected devices. ERP software providers in India are integrating IoT capabilities into their systems to enhance operational efficiency and decision-making.

IoT-enabled ERP systems can monitor equipment performance, track inventory levels, and optimize supply chain operations. For example, sensors placed on manufacturing equipment can detect anomalies and trigger maintenance requests before a breakdown occurs. This integration of IoT with ERP systems allows businesses to leverage real-time data for proactive management and improved efficiency.

10. Sustainable and Green ERP Solutions

Sustainability is becoming a key consideration for businesses across industries. ERP software companies in India are developing solutions that support sustainable practices and environmental responsibility. Green ERP solutions help businesses to monitor and reduce their environmental impact by tracking energy consumption, waste management, and resource utilization.

By integrating sustainability metrics into their ERP systems, businesses can set and achieve environmental goals, comply with regulations, and enhance their corporate social responsibility (CSR) initiatives. This trend towards sustainable ERP solutions reflects the growing importance of environmental stewardship in today’s business landscape.

Conclusion

The future of ERP software in India is marked by innovation, adaptability, and a deep understanding of the unique needs of businesses. ERP software providers in India are leading the charge, offering solutions that are not only technologically advanced but also aligned with the evolving demands of the market. As we move into 2024, the trends highlighted in this blog will play a crucial role in shaping the ERP landscape, driving efficiency, and fostering growth across industries.

ERP software providers in India are well-positioned to support businesses in their digital transformation journeys, providing the tools and insights needed to thrive in a competitive environment. By staying ahead of these trends, businesses can leverage ERP solutions to achieve operational excellence and sustainable growth.

#ERP software Companies in India#ERP software providers in India#ERP software company in India#ERP software in India#ERP solution provider#ERP software#ERP system#cloud ERP#ERP solutions

4 notes

·

View notes

Text

A Look Into The Future: What Will The Adsreel Industry Look Like In 10 Years?

youtube

Introduction: In the present electronic age, video advertising and marketing happens to be a crucial tool for organizations to reach their target audience effectively. Even so, developing partaking video clip adverts is often time-consuming and complicated, specifically for Individuals without technological abilities. That's exactly where AdsReel is Click here for more available in. This State-of-the-art software package System utilizes artificial intelligence (AI) to simplify the procedure, enabling companies to produce fascinating online video adverts in only a subject of minutes. In this article, we will check out how AdsReel revolutionizes how firms generate video adverts, empowering them to reinforce their advertising and marketing approaches and Strengthen consumer engagement.

Making use of AI for Seamless Video clip Advertisement Generation: AdsReel leverages the strength of AI technological know-how to streamline the online video creation process. With only a few clicks, end users can generate Expert-top quality online video adverts without the will need for in depth video clip enhancing abilities. The program gathers crucial business enterprise particulars from the Net, guaranteeing the advertisements are tailored into the target audience. By automating these time-consuming jobs, AdsReel enables enterprises to avoid wasting useful time and methods, allowing them to deal with other facets of their advertising and marketing approaches.

A Myriad of Customization Possibilities: AdsReel will not just quit at automating online video generation; What's more, it supplies customers with a big range of customization selections to help make their adverts stick out. The platform presents different predefined designs, for example inspirational, impressive, and even more, making it possible for corporations to select the right tone for his or her advertising and marketing campaign. In addition, customers can certainly include their particular manufacturer components, which include logos, slogans, and shade schemes, making sure model consistency and recognition through their movie adverts. This degree of customization boosts the overall appeal and reinforces manufacturer id, capturing the eye of viewers and rising engagement costs.

Effortless Distribution and Optimization: When the video adverts are created, AdsReel can take it a step further by offering effortless distribution and optimization alternatives. Users can seamlessly upload their videos to well-liked social networking platforms such as Facebook, Instagram, and YouTube straight from the software program interface. By tapping in to the large opportunity of those platforms, corporations can correctly get to a broader viewers and travel conversions. Also, AdsReel presents insightful analytics to aid end users keep an eye on the overall performance in their movie adverts. These analytics offer you beneficial data on views, engagement rates, and conversions, allowing for organizations to improve their strategies in true-time for maximum affect.

The many benefits of AdsReel for Enterprises: By leveraging AdsReel's Superior attributes, corporations can encounter a multitude of advantages, including:

Time and value Efficiency: AdsReel eliminates the need for costly video manufacturing services and comprehensive modifying program, enabling corporations to avoid wasting both time and cash.

Greater Engagement: Captivating movie adverts designed with AdsReel can drastically improve client engagement, resulting in higher simply click-by charges, sales, and manufacturer recognition.

Seamless Integration: The computer software is usually seamlessly built-in into current advertising methods, complementing other promotion channels and strategies.

Increased Get to: With the ability to distribute online video adverts throughout popular social media platforms, AdsReel enables businesses to faucet into bigger audiences and grow their shopper foundation.

Summary: Within an era exactly where online video advertising and marketing dominates the advertising landscape, companies require a aggressive edge to jump out. AdsReel delivers a powerful Alternative by employing AI to simplify and accelerate the process of building charming online video adverts. With its substantial customization solutions, simple distribution, and optimization abilities, this Sophisticated software program empowers companies to create many hundreds of engaging video adverts in only minutes. By leveraging AdsReel, enterprises can boost their marketing strategies, boost customer engagement, and eventually drive expansion inside their respective industries.

2 notes

·

View notes

Text

Electronics manufacturing trends to pay attention to in years to come

Despite the pandemic-induced economic slowdown, technological advancements played a significant role in the growth of the electronics manufacturing sector. Smarter manufacturing practices have been the biggest driver of this growth. We intend to explore five trendsetting developments in this article today.

Internet of Things The electronics manufacturing industry can leverage the Internet of Things (IoT) for unprecedented growth opportunities. The IoT allows electronic manufacturing units to be digitally connected while storing and processing information without external support. The IoT can improve efficiency, security, cost-effectiveness, and product innovation. Cloud computing, smaller censors, and the growth of the Internet have prompted IoT’s lead in the race of emerging technologies. With everything in place, you can have real-time data at your fingertips to make informed business decisions.

Automation While complete automation in the electronics manufacturing sector is still a distant dream, various automation technologies have made production trouble and error-free. These technological advancements in automation includes smart factories, manufacturing robots, and the smart supply chain management system. These automation systems in conjunction with IoT devices create an efficient manufacturing operation. Innovative supply chain As businesses strive for better products and spend less while doing so, the best way forward is to innovate supply chain management. This trend aims at improving the logistics to revamp the supply chain, which, in turn, can significantly reduce costs in several key areas. This allows electronics manufacturers to be more agile in their operations and thus be more open to fluctuating market demands.

Predictive maintenance Any manufacturing company’s smooth operation is entirely dependent on its types of equipment. Because if they break down the entire operation comes to a halt and so will your revenue generation. However, using AI and IoT data collection, you can accurately identify problem areas before they happen. This helps electronic manufacturers avoid downtime and plan maintenance at a convenient time. Identify a cost-effective manner to conduct repairs and include the same in your budget. A trend like predictive maintenance removes any scope of surprise downtime, thus improving the efficiency of your manufacturing operations.

Organic electronics Organic electronics has become a market rage in recent times owing to its efficiency, low cost, flexibility, lightweight, indissoluble nature, and optical transparency. Additionally, the demand for environmentally friendly production and sustainable development is growing, prompting electronic manufacturers to choose organic electronics. One of the most significant trends in electronics production is the creation of gadgets using biodegradable and recyclable materials or designing circuits with microbial components. The use of organic materials in producing electronic devices also permits the use of safer and readily accessible raw materials. As a result, it gives organizations new business opportunities, while being environmentally responsible.

The electronic manufacturing trends discussed in this article pave a path for smarter, efficient, and cost-effective practices. The use of advanced technology and materials can help you achieve this. Apart from the five trends discussed here, we'd also like to mention printed electronics, Artificial Intelligence, immersive technology, and 3D printing. These evolving technologies only point to a brighter future. For more information on the electronics manufacturing process, get in touch with the experts at Radiant Appliances & Electronics.

#manufacturing#led tv manufacturing#smart tv#led tv manufacturers in india#Home appliances manufacturers in India#TV Manufacturing Company#Radiant Appliances & Electronics#Televisions We Manufacture#Smart LED Televisions

2 notes

·

View notes

Text

This really resonates with my stance on the call for artists to be more civil when people feel entitled to make demands of artists whose work displeases them.

We also don't owe people civility when the thing they're defending is openly antagonistic to our community, our rights, and our professional environment as part of its core function.

The current physical environmental costs of AI are also valid and imminently destructive so, it's just another a delaying tactic to say, it's not a bad as some things and on par with other things.

I do not care.

I'm no more required to argue on the terms of the person perpetuating or justifying the offense than I am to be gentle about it. If something's on fire, waiting to see if it was maliciously set before putting it out only serves the fire or the person who started it. It's destructive, it's dangerous, and it's already spread too far for comfort.

AI isn't like providing packaged food to people who can't cook. It's like food designed by creatures who just have one orifice for eating and secretion, and only recognize food as a thing you extract resources from. It doesn't matter what it tastes like or where it came from as long as it fills a hole and it's not the user's hole they actually care about filing.

Is something like that also nice for people who can't cook but still want food? Yes. However, treating that hole-filling slop like a revolution in expanded human capabilities in order to allow literally any business that makes food to fire their cooks and prep staff and replace them with cut-rate temps who will babysit The Machine to make sure it doesn't give the customer a salad of ethnic slurs, is shitty, disingenuous, and fundamentally antagonistic to the majority of essential workers in the food service industry. It makes thoughtful, healthy nutritionally relevant food too expensive for competitors to produce. It will drive the price of traditional food up for all consumers who don't want to eat bespoke forgery slop. If it looks exactly like what you, as a chef or line cook make but it costs 80% less, and you can get it on every corner worldwide, it's going to devalue your entire profession even if every bite actually tastes like candied styrofoam. It's fast food done worse, with more exploration, for higher profits for the manufacturer, bosses, the executives, and the shareholders but no one else.

Its fast, cheap, slop that you can have now, and you get to pretend it's yours because you told The Machine how many tits the burger should have, and don't know the people who now have to work two extra jobs because you think they were greedy snobs.

AI is a deeply self-interested, exploitative enterprise that converts stolen media into profit, and generates simulated expression as a byproduct. Exacerbating existing power disparity in creative fields is a bonus. They argue that it isn't theft because their training data was scraped from public sites but that's effectively the Stolen Land model of procurement. The original inhabitants may not have been exploiting its full spectrum of usefulness but the fact that you are and have been doing so without being stopped doesn't change the fact that all of your profits ultimately stem from theft and displacement.

I think approaching this exclusively from a copyright angle is also a bit of misdirection because copyright law is kind of a "masters tools" situation to protect the value of their investments from depreciation. That said, the harm of dilution in this context is also a very real harm and one recognized in courts. Courts that aren't packed with crooked shameless puppets, anyway.

Recognition is one of the most valuable and powerful assets an artist has. Giving everyone free run of the Counterfeit Media Machine blows a massive bleeding hole in that. People can do this by hand as well but it harder and we have pretty clear-cut remedies for the artist if the imitator tries to pass off fakes as genuine, or profits from creating visually indistinguishable material that negatively impacts the artists. AI can scrape an artists entire portfolio and create images the artist never would've agreed to, doesn't know about, and can cause irreparable damage their reputation on a heretofore unimaginable scale.

This is why so much of the Disruption Economy effectively boils down to scams. They profit from undercutting skilled labor, established businesses, and industry standards, relying on less, novelty, hype, and speculative investment to deliver a product that bleeds off just enough profit to tank a competitors ability to sustain operation. It doesn't even matter if the disruptor's system is itself unsustainable, as long as it outlasts the competition. The disruptor is now free in our Capitalist food chain to assume the niche of the predecessor, increase prices, reduce service, quality, and support, or demand to be bailed out if they find themselves in the red because they're the sole surviving provider now and failure means a vacuum. This is how monopolies defend themselves in the wild.

That last part is why they need to convince consumers that the purpose of their product is how consumers use it, and not what it does for their shareholders. By promising to level the playing field, democratize niches of privilege, empower the disenfranchised, and create opportunities for YOU, they recruit volunteers to hype up the brand for free (I fuckin SEE you over there Tesla).

They're always preaching the gospel of the future, where their sky pie has freed us from ossified elitism because it's easy to point out inefficiencies with established systems and win people over by pretending that identifying problems and fixing them are the same thing. This is why so many billionaires are pathologically long-termist. Their bread and butter is fantasy and it only has to work long enough for our money to land in their pockets. They use that money to defend the gravy train through lobbying, industry capture, and continuing to manufacture support by beating our favorite drum full of shit: marketing. It's an ouroboros of screwing people who used to make money before the next disruptor gets their turn running the exploitation factory.

We're fooling ourselves is we think they're above screwing the average user. Not just by charging for premium services, but by purposely cultivating an environment where you can't actually make a living using the tool they made for you. AI still sucks compared to professional creative labor. Its output just isn't consistent, controllable, or good enough on its own without skilled artists to fix it. Fun fact: they won't pay you artist rates if they class you as "quality control" instead. CEOs, owners, and studio executives want to replace their stubborn, inconvenient creative staff with programs that they have more direct control over. They need people to believe the tech raises them up to professional-quality work so they'll have huge pools of eager, replaceable staff with very little professional experience. AI needs you to swallow that hook too because these companies want to push paywalled premium features and railroad users into subscription access (we fuckin SEE you overthere, Adobe, Sony, Apple, Tesla again, Microsoft, Amazon, Twitter, Netflix, YouTube...).

It's the short-handled hoe of creative labor. It turns a cheap tool they bought into 3 cheaper ones they rent out. It lets you do what they need, but you have to stoop to use it, and they can take it from you whenever they want without much of a fight because you can't wield it against them in a way that really matters.

I say all that to drive home why we absolutely do not owe AI and it's biggest cheerleaders polite debate. Its purpose is what it does. Presently, what it's doing is placing even more power in the hands of management to be the ultimate decider of labor's value. It's equipping a pool of intentionally unskilled labor with nontransferrable skills to push out more competent and qualified skilled labor, and those tailor-made prompt jockeys will have even less right to ownership or fair compensation than the artists whose work was stolen to make the whole thing viable in the first place.

If someone independently decides to mark up our work, post it back to us and says, "Look, I just made your work better without you. You should have made this instead. I could do your job." That's disrespectful. It begs credit for a minimum of unwanted effort. It doesn't automatically merit a polite response.

The nicest I'd probably offer is, "Don't do that."

They're not my editor, my collaborator, my partner, my boss, or my friend. They may not even be my audience! People are free to consume things that weren't made with them in mind but demanding editorial privileges is ridiculous. Consuming hasn't bought them a creative stake in the game. Some may think the changes improved the work but art isn't a matter of public committee. They can't just declare what they've done must be OK unless it's universally denounced. That's what AI is doing while they lobby for regulation that validates their platform, secures their rights, and further insulates them from people they've already stolen from.

At best, when individuals do this they're just being critics, another job that can't exist without someone else putting in the time and labor to make something first. Generative AI lays claim to the sum of available media as research, pretends it's doing humanitarian R&D, then accumulates wealth and power by eroding the barrier of "people expect to be paid for their work". It's not science though. It's not research. It's not philanthropy. It's a product that's inherently hostile to labor within the industries it claims to serve. It does this on purpose and we know this because the people who built it said so it in messages they didn't expect anyone else to see.

People with power don't want other people to have more of it. They want the power others have to flow from them. If you then ask, "Isn't that what artists are doing? Then you are not actually familiar with how art works as a profession. It's a thing you can live on with enough of a devoted following but that following comes from your skill, your reputation, and your ability to market yourself. AI kills that. It's a predator that kills skill, wears its skin, walks around pretending to be the next evolution of human creative expression, and stuffs the saggy spots in its disguise with cash from people who believe that creative labor needs to shut up and be grateful for the exposure.

Shouldn't we be proud that people love our work so much that they want to make it perfect in their eyes?

No. Why exactly should I?

Why do the people who rip on us get a say in what should be validating to us? I'm proud to know I connected to someone though what I've made. Or when they see themselves in my expression. I'm proud if people want me to make their thing so much that they believe I'm worth the cost, or at least worth negotiating with. I'm proud if people see my work and respect me enough not to steal it, fuck it up, or show me its reassembled corpse as evidence that I did it wrong.

I don't have a ton of followers, influence, or much of a reputation myself, but my friends do. I would love to be able to support myself as working artist, but AI is going to close off avenues of opportunity for countless new and established artists. It's a cost cutting tool first and foremost. It does that by manufacturing its own evidence that, "actually this is really super easy lol." Any benefit to you as a user is secondary.

I see it like like a humidifier that achieves perfect ambient humidity but does so by converting tap water to tritium mist, which your landlord, in conjunction with the manufacturer, recover and sell. You get a few nice benefits from perfect humidity but you're filling your home with radioactive poison, contaminating it for future occupants, and generating value for people who will only reap benefits so hard that they can afford to buy their way of most foreseeable consequences.

Workers asking for fair compensation didn't make corporations act like they do. Corporations exist to insulate their shareholders from risk and they're increasingly seeing livable wages as an intolerable threat to being comfortable-bunker-rich as the world they've built starts to catch up with them again. They deserve something but civility ain't it.

AI people: we're just as much artists as you are, you gotta be so observant and go through so many correcting phases for the picture to look good uwu also AI people:

77K notes

·

View notes

Text

Powering Safety and Precision: Discover DOLD Automation Products at Aeliya Marine Tech

In the industrial automation world where seconds matter and each failure accrues expense, there is one name that continues to rise to the challenges of reliability, safety, and innovation: DOLD. Established in Germany with a history spanning close to a century, DOLD has become an institution in the development and production of high-performance safety relays, control equipment, and automation components.

Today, marine, manufacturing, energy, and automation companies count on DOLD products to achieve strict international regulations and maintain systems in top working condition. And now, with Aeliya Marine Tech, you can find a complete range of DOLD components — from traditional timer relays to sophisticated safety modules — all online with worldwide shipping, reliable sourcing, and technical assistance.

Why DOLD Is a Global Leader in Industrial Automation

DOLD is not only another automation brand; it’s a name that signifies German engineering excellence. With precision-engineered products certified to industry-leading safety directives like ISO 13849, IEC/EN 61508, and EN 60204–1, DOLD components are not only designed for function but also for compliance and peace of mind.

Some of the major reasons why industrial buyers and engineers prefer DOLD are:

Uncompromising Safety Standards

Excellent Durability and Build Quality

Modular, Space-Saving Designs

Support for Functional Safety Applications

Broad Compatibility with New Generation Control Systems

From factories to offshore ships, DOLD relays, timers, and safety controllers are designed to maximize automation reliability while guaranteeing the safety of people.

Aeliya Marine Tech: Your Reliable Supplier of DOLD Components

When buying industrial automation components, authenticity and support are just as important as product choice. Aeliya Marine Tech has established a niche in the automation industry as a genuine, tested, and ready-to-ship parts supplier to world industries.

Their DOLD collection includes both new and pre-owned units, meticulously inspected and documented to ensure operational integrity. Whether you’re outfitting a new automation cabinet or replacing a legacy system, Aeliya Marine provides cost-effective access to DOLD’s full range.

You’ll find:

Emergency stop safety relays (e.g., BN5930.48)

Monitoring relays for voltage, current, and temperature

Multi-function timer relays (e.g., AI series)

Interface modules and switching relays

Complete product documentation and support

Every product listing contains technical details, actual images, weights, model numbers, and unambiguous part identification for easy identification.

Explore the DOLD Collection Now →

DOLD Popular Products in Stock at Aeliya Marine — A Spotlight Now let us review a few popular DOLD products available in the Aeliya Marine collection and where they are applied in actual systems.

DOLD BN5930.48 : Emergency Stop Safety Relay

A standard in machine safety circuits, the BN5930.48 watches over emergency stop circuits and provides quick shutdown under hazardous situations. The relay is widely applied in press controls, robotic arms, and assembly line equipment where safety does not come second. The relay is dual-channel input with cross-fault detection and can initiate redundant contactors or actuators.

DOLD AI Series Timer Relays

Timing is critical in automation, whether you’re sequencing motor operations or delaying control signals. The AI series from DOLD offers multifunction timing modes such as ON-delay, OFF-delay, pulse generation, and interval timing. These units are plug-and-play and ideal for retrofitting older panels with more intelligent timing logic.

DOLD SL Series Monitoring Relays

DOLD’s SL series allows for real-time monitoring of operating parameters such as overvoltage, undervoltage, phase sequence, and phase failure. The relays are essential in pump protection, motor control, and fault detection for energy management systems. Their LED status displays offer instant diagnostics, minimizing downtime while troubleshooting.

DOLD Interface Modules

Applying in signal switching and isolation, these modules interconnect actuators, PLCs, and sensors in a system without the possibility of interference or overload. They provide secure signal transmission and make complex wiring structures in large control panels easier.

Applications : Where DOLD Products Make a Difference

DOLD products are applied in nearly every significant industry that prioritizes automation and safety. Some of the most important application areas include:

Marine Automation

On ships and offshore platforms, DOLD relays are applied in engine rooms, cargo handling systems, and power management to deliver safety-critical functionality in extreme environments.

Manufacturing and Robotics

Safety relays protect operators against high-speed machinery and collaborative robots (cobots), while timer relays coordinate operations on conveyors, presses, and packaging systems.

Energy and Power Distribution

Monitoring relays monitor transformers, motors, and switchgear, avoiding failures due to voltage irregularities or phase imbalance.

HVAC and Building Management

Timer relays and monitoring modules control fans, lighting, and climate systems automatically according to demand and timing cycles.

Water and Waste Treatment

Pump control systems utilize DOLD products to control pressure, sequence motor runs, and offer safe lockout in maintenance procedures.

Advantages of Purchasing DOLD from Aeliya Marine Tech

In addition to product selection, purchasing from Aeliya Marine Tech guarantees a number of distinct benefits:

Tested and Verified Inventory

Every item is tested (where possible) and photographed, so you can be certain of what you’re purchasing — no surprises.

Fast Global Shipping

With customers in Europe, Asia, the Middle East, and the Americas, Aeliya Marine Tech can ship fast and securely to you.

Expert Support from Automation Specialists

Their personnel is not order-taking; they know the products and are able to help you choose alternatives, double-check compatibility, or supply documentation.

Cost-Effective Alternatives

Both new and used versions are available. Used parts are subjected to a comprehensive inspection process and provide substantial cost savings.

One-Stop Automation Shop