#ASTM threaded rod

Explore tagged Tumblr posts

Text

#LEADING COPPER ROUND ROD C101 SUPPLIER IN INDIA#ASTM B133 COPPER ROUND RODS#WEIGHT OF C12200 FLAT BAR#UNS C10300 HEX BAR STOCKIST#COPPER THREADED ROD MANUFACTURER#COPPER WELDING ROD#C110 BAR SUPPLIER#C10100 COPPER ROUND BAR WEIGHT CHART#ASTM B187 UNS C11000 ROD SUPPLIER IN INDIA.

0 notes

Text

Enhancing Industrial Efficiency with SS 904L Fasteners

In the dynamic landscape of industrial operations, the reliability and durability of fastening solutions play a pivotal role in ensuring seamless functionality and structural integrity. Among the myriad options available, SS 904L fasteners stand out for their exceptional corrosion resistance, high tensile strength, and superior performance even in the most demanding environments. Let’s delve deeper into the realm of SS 904L fasteners and explore how they elevate industrial efficiency and longevity.

Unveiling SS 904L Fasteners:

SS 904L, also known as N08904, is a super-austenitic stainless steel renowned for its robustness in harsh conditions. Its composition, enriched with nickel, chromium, and molybdenum, imparts remarkable resistance to corrosion, particularly in chloride-containing environments. These qualities make SS 904L fasteners an ideal choice for industries such as chemical processing, pharmaceuticals, oil and gas, and marine engineering, where exposure to corrosive elements is inevitable.

Metalloy International: Your Trusted Partner in Quality Fasteners:

At Metalloy International, we take pride in offering a comprehensive range of SS 904L fasteners meticulously crafted to meet the exacting standards of diverse industrial applications. Our commitment to excellence is reflected in the superior quality and performance of our products, ensuring maximum reliability and longevity.

Key Products Offered:

ASTM A 193 SS 904L Bolt

ASTM A 193 SS 904L Threaded Rod

DIN 1.4539 Stud Bolt

UNS N08904 Nut

ASME SA 193 SS 904L Bolt

ASTM A 193 SS 904L Fasteners

UNS N08904 Threaded Rod

ASTM A 193 SS 904L Stud Bolt

Elevating Industrial Efficiency:

The utilization of SS 904L fasteners translates into enhanced operational efficiency and reduced maintenance costs. Their resistance to corrosion minimizes the risk of premature failure, thereby ensuring uninterrupted workflow and prolonged equipment lifespan. Whether it’s securing critical components in offshore platforms or facilitating process equipment assembly in chemical plants, SS 904L fasteners deliver unparalleled performance, thereby optimizing productivity and reliability.

Conclusion:

In a landscape where reliability, durability, and performance are paramount, SS 904L fasteners emerge as the epitome of excellence. At Metalloy International, we combine superior craftsmanship with cutting-edge technology to deliver fastening solutions that exceed expectations. Experience the difference with our premium SS 904L fasteners and elevate your industrial operations to new heights of efficiency and resilience.

For more information and to explore our extensive range of SS 904L fasteners, visit Metalloy International. Unlock the potential of stainless steel excellence today!

#ASTM A 193 SS 904L Threaded Rod#DIN 1.4539 Stud Bolt#UNS N08904 Nut#ASME SA 193 SS 904L Bolt#ASTM A 193 SS 904L Fasteners#UNS N08904 Threaded Rod#ASTM A 193 SS 904L Stud Bolt.#ASTM A 193 SS 904L Bolt

0 notes

Text

Threaded Rod Stud | Threaded Bar | Threaded Stud

In the vast realm of construction and industrial applications, the importance of small yet pivotal components cannot be overstated. Among these unsung heroes is the threaded rod stud—a seemingly simple piece of hardware that plays a crucial role in securing structures, facilitating installations, and ensuring stability in various projects. Let's delve into the intricacies of threaded rod studs, exploring their diverse applications and the role they play in modern engineering.

Understanding Threaded Rod Studs

Threaded rod studs are cylindrical rods with threading along their entire length, allowing nuts and other fittings to be screwed onto them. They come in various diameters, lengths, materials, and thread sizes, offering flexibility to cater to a wide range of applications. These studs are typically made from materials such as stainless steel, carbon steel, or other alloys, selected based on factors like strength requirements, environmental conditions, and corrosion resistance.

Applications Across Industries

The versatility of threaded rod studs lends itself to an array of applications across different industries:

Construction: In construction projects, threaded rod studs are extensively used for anchoring structural elements such as columns, beams, and trusses. They provide a reliable means of securing various building components, ensuring structural integrity and stability.

Electrical and Mechanical Installations: Threaded rod studs serve as essential components in electrical and mechanical installations. They are used for mounting equipment, supporting conduits, cable trays, and piping systems, offering a sturdy foundation for the installation of fixtures and appliances.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems rely on threaded rod studs for mounting ductwork, supporting HVAC units, and securing components like fans and dampers. These studs play a critical role in ensuring the efficient operation and longevity of HVAC systems.

Industrial Machinery: In manufacturing and industrial settings, threaded rod studs find application in securing heavy machinery, conveyor systems, and equipment frames. Their robust construction and ability to withstand high loads make them indispensable for maintaining operational efficiency and safety in industrial environments.

Suspension Systems: Threaded rod studs are also commonly used in suspension systems for ceilings, lighting fixtures, acoustic panels, and signage. They provide a reliable means of hanging objects securely from overhead structures, offering flexibility in design and installation.

The JFE India Advantage

Among the leading providers of threaded rod studs and related hardware solutions is JFE India. With a commitment to quality, reliability, and innovation, JFE India offers a comprehensive range of products tailored to meet the diverse needs of customers across industries.

JFE India's threaded rod studs are manufactured to the highest standards, ensuring exceptional strength, durability, and performance in demanding applications. Leveraging advanced manufacturing processes and stringent quality control measures, JFE India delivers products that meet or exceed industry specifications, providing peace of mind to customers and end-users alike.

Moreover, JFE India's expertise extends beyond product supply, with a dedicated team of professionals offering technical support, engineering assistance, and customized solutions to address specific project requirements. Whether it's recommending the right materials, assisting with design considerations, or providing on-site support, JFE India goes the extra mile to ensure customer satisfaction and project success.

Conclusion

Threaded rod studs are indispensable components in construction, manufacturing, and industrial applications, providing secure fastening solutions for a wide range of projects. With their versatility, durability, and reliability, threaded rod studs play a vital role in ensuring the structural integrity, functionality, and safety of diverse installations.

#ASTM A193 Stainless steel 304 Threaded Rod Manufacturer#ASTM A193 SS347 Threaded Rod#Stainless Steel ASTM 193 316H Threaded Rod Stud#Stainless Steel ASTM 193 316Ti Threaded Rod Stud#Carbon Steel ASTM 193 B7 Threaded Rod Stud#Hastelloy B3 Threaded Rod Stud#Hastelloy C22 Threaded Rod Stud

0 notes

Text

http://www.jfeindia.com/threaded-rod.html

#ASTM A193 Stainless steel 304 Threaded Rod Manufacturer#ASTM A193 SS347 Threaded Rod#Stainless Steel ASTM 193 316H Threaded Rod Stud#Stainless Steel ASTM 193 316Ti Threaded Rod Stud#Carbon Steel ASTM 193 B7 Threaded Rod Stud#Hastelloy B3 Threaded Rod Stud#Hastelloy C22 Threaded Rod Stud

0 notes

Text

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

Selecting the Right Stud Bolt: Materials, Coatings, and Standards Explained

Delta Fitt Inc is the leading stud bolts manufacturer in India, Choosing the right stud bolt is essential in industries like oil & gas, construction, power, and chemical processing. These threaded fasteners hold critical joints together, often in extreme pressure or temperature environments. When selecting stud bolts, understanding their materials, coatings, and standards is key to ensuring safety, durability, and performance.

This guide will help you make informed decisions when buying from a stud bolts manufacturer in India or a reliable stud bolts supplier in India. We’ll also highlight the importance of the HSFG Bolt Weight Chart and HSFG Nut Weight Chart for heavy-duty applications.

What Are Stud Bolts?

Stud bolts are long threaded rods with threads on both ends. They are used in flange connections and are secured using two heavy hex nuts. These fasteners are ideal for high-load and high-vibration environments due to their strength and stability.

Whether you're building pipelines, pressure vessels, or structural joints, stud bolts are widely trusted for their ability to maintain strong and leak-proof connections.

Common Materials Used in Stud Bolts

Choosing the right material is the foundation of selecting a suitable stud bolt. The material determines the bolt’s mechanical strength, corrosion resistance, and temperature tolerance.

Carbon Steel:

Used in general-purpose industrial applications where corrosion is not a major concern. Affordable and easy to source from any stud bolts manufacturer.

Stainless Steel:

Known for its corrosion resistance and strength. Grades like SS304 and SS316 are perfect for marine, food, and chemical industries.

Alloy Steel:

High tensile strength and excellent performance at elevated temperatures. Frequently used in oil & gas and power generation plants.

Duplex & Super Duplex Steel:

These offer exceptional corrosion resistance, making them ideal for offshore rigs and desalination plants.

A trusted stud bolts manufacturer in India offers all these material grades with quality assurance and third-party inspection certificates.

Protective Coatings for Stud Bolts

To improve the lifespan of stud bolts, manufacturers often apply protective coatings. The type of coating depends on the environmental conditions.

Zinc Plating:

Good for indoor applications or dry conditions. Provides basic corrosion resistance.

Hot-Dip Galvanizing:

A popular choice for outdoor use. It creates a thick protective layer that withstands rust and abrasion.

PTFE (Teflon) Coating:

Highly chemical-resistant. Used in acidic or highly corrosive environments.

Black Oxide:

Improves appearance and offers mild corrosion protection. Ideal for automotive or machinery parts.

Always check with your stud bolts supplier in India for coating options and compliance with your industry requirements.

Key Standards to Follow

When choosing stud bolts, compliance with international standards ensures performance and safety. These standards define mechanical strength, dimensions, and material properties.

ASTM A193 – Covers alloy and stainless steel stud bolts for high-temperature services.

ASME B16.5 – Standards for flanges and flange fasteners.

DIN & ISO – European and international norms for bolt sizes and threads.

Working with a certified stud bolts manufacturer guarantees full compliance with these standards, including test reports and traceability.

Importance of HSFG Bolt & Nut Weight Charts

For structural applications like bridges or high-rise buildings, High Strength Friction Grip (HSFG) bolts are used. These bolts are tightened to apply a clamping force that resists slip between connected components.

HSFG Bolt Weight Chart

Shows the weight of bolts based on size and length. This is essential for transport planning, inventory management, and structural load calculations.

HSFG Nut Weight Chart

Helps match nuts precisely with corresponding bolts, ensuring torque values are correct and performance is consistent.

Make sure to request the HSFG Bolt Weight Chart and HSFG Nut Weight Chart from your supplier for accurate engineering and procurement planning.

Why Buy from a Stud Bolts Manufacturer in India

India is known for producing high-quality industrial fasteners at competitive prices. A reputed stud bolts manufacturer in India offers:

Wide material range and custom specifications

Fast production and on-time delivery

Global standards (ASTM, ASME, DIN)

Cost-effective pricing

Reliable stud bolts suppliers in India can also provide full documentation, test reports, and MTCs (Material Test Certificates) for quality assurance.

Conclusion

Selecting the right stud bolt involves more than choosing the correct size. Consider the material, coating, and international standards. Also, always refer to HSFG Bolt Weight Chart and HSFG Nut Weight Chart for precision in design and planning.

When you choose a trusted stud bolts manufacturer or stud bolts supplier in India, you ensure quality, performance, and long-term reliability in every joint. Whether your project is small or industrial-scale, the right fastener makes all the difference.

0 notes

Text

Weld Neck Flanges are engineered for high-pressure and high-temperature applications, offering unmatched strength and durability.

Reliable Strength, Seamless Performance.

Key Benefits:

Superior Strength: Evenly Distributes Stress for Tough Applications. Leak Proof: Minimizes Leak Risks with Smooth Transition. Versatile: Available in Various Sizes, Materials & Pressure Ratings. Easy Installation: Simple Welding for a Secure, Permanent Joints.

For Bulk Enquiries Mail us or Contact us for more information! 📞 +91 89800 30979 📩 [email protected]

#stainlesssteel #Alloysteel #Carbonsteel #Bend #Reducer #caps #Tee #Crosstee #Stubends #nipple #Elbow #Flanges #Fittings #Slipon #Weldneck #spectacleblind #paddlespacer #socketweld #Threaded #Outlets #Olets #Pipes #Rods #sheets #Plates #Coils #seamlesspipe #erwpipe #weldedpies #Fasteners #manufacturer #factory #Buttweld #Suppliers #ASTM #A105 #316L #304L #Forging #piping #alloy #Forging #Rawmaterial #vocalforlocal #bigsizeflanges #Pipes #Flanges #Fittings #Slipon #Weldneck #spectacleblind #paddlespacer #socketweld #Threaded #Tee #Outlets #Olets #Pipes #Rods #sheets #Plates #Coils #seamlesspipe #erwpipe #Fasteners #SliponFlange #BlindFlange #weldneckflange

0 notes

Text

Foundation Bolts Manufacturer in India – Precision. Strength. Eshaji.

When it comes to the integrity of structural foundations, the importance of strong and precisely engineered foundation bolts cannot be overstated. These critical components are the unseen strength behind every stable structure, whether it's a factory, bridge, tower, or machine base. If you're searching for a trusted foundation bolts manufacturer in India, Eshaji is your go-to partner for quality, reliability, and engineering excellence.

What Are Foundation Bolts?

Foundation bolts are used to anchor structures and machinery to concrete foundations. They are essential in ensuring that vibrations, loads, and environmental stressors are evenly distributed and effectively managed. Commonly used in construction, power generation, oil & gas, and industrial installations, foundation bolts come in a variety of types:

L-Type Foundation Bolts

J-Type Bolts

U-Bolts

Straight Rods with Nuts & Washers

Sleeve & Expansion Bolts

Eshaji offers standard and custom fabrication based on IS, ASTM, and DIN specifications, making us a preferred foundation bolts manufacturer in India.

Your Trusted Source for Foundation Bolts in Chennai

If you're looking for foundation bolts in Chennai, Eshaji provides quick, dependable supply across Tamil Nadu and South India. We have a wide product range with ready stock and the ability to manufacture bolts based on your designs and requirements.

Our Chennai-based supply chain is supported by:

⚙️ High-precision CNC machines

🔧 In-house threading, cutting, and forging

🧱 Rust-resistant finishes (Hot-Dip Galvanized, Zinc Plated, etc.)

✅ Inspection & testing certificates for quality assurance

We work with clients across infrastructure, industrial EPCs, civil contractors, and machinery manufacturers to provide the best anchoring solutions available.

Why Eshaji for Foundation Bolts?

✔️ ISO-certified quality standards ✔️ Custom solutions for any size or specification ✔️ Bulk supply capabilities with consistent lead times ✔️ Competitive pricing for projects big and small ✔️ Decades of experience in industrial fastener manufacturing

Our products are designed to perform under the toughest conditions, providing long-term strength and stability.

📞 Call Now for Foundation Bolts in Chennai & Across India

0 notes

Text

COPPER ROD

Copper has been a cornerstone in human advancement for thousands of years, and today, its applications are more critical than ever. Among the many forms that copper takes, the copper rod stands out as a versatile and indispensable component in various industrial sectors. Nexus Copper Pvt. Ltd, a leader in the copper industry, exemplifies excellence in the production and supply of high-quality copper rods. This article delves into the importance of copper rods, their manufacturing process, applications, and how Nexus Copper Pvt. Ltd is setting new standards in the industry.

Understanding Copper Rods

Copper rods are long, cylindrical bars of copper that are used in a wide range of applications due to their superior electrical conductivity, thermal conductivity, corrosion resistance, and malleability. These rods are typically produced through a process known as continuous casting and rolling, which ensures uniformity and high-quality standards.

The Manufacturing Process

The production of copper rods involves several steps:

Melting: Copper scrap or raw copper is melted in a furnace at temperatures exceeding 1,000 degrees Celsius.

Casting: The molten copper is then poured into a casting machine to create billets or large ingots.

Rolling: These billets are heated again and rolled into long rods of specific diameters.

Drawing: The rods are then drawn through dies to achieve the precise dimensions required.

Finishing: Finally, the rods are cooled, cut to the desired lengths, and subjected to quality checks.

Nexus Copper Pvt. Ltd employs state-of-the-art technology in each of these stages, ensuring that every copper rod meets stringent quality standards.

Applications of Copper Rods

Copper rods play a vital role in numerous industries, including:

Electrical Industry: Copper rods are essential in the production of electrical cables and wires due to their excellent conductivity.

Construction: Used in plumbing, roofing, and industrial machinery, copper rods offer durability and resistance to corrosion.

Automotive Industry: Copper rods are used in the manufacturing of various electrical components and in cooling systems.

Telecommunications: The superior conductivity and durability of copper rods make them ideal for use in telecommunications cables.

Renewable Energy: Copper rods are pivotal in the construction of wind turbines and solar panel systems.

Nexus Copper Pvt. Ltd: A Leader in the Industry

Nexus Copper Pvt. Ltd stands at the forefront of the copper industry, renowned for its commitment to quality and innovation. The company's advanced manufacturing facilities and rigorous quality control processes ensure that their copper rods consistently meet the highest standards. Nexus Copper Pvt. Ltd has established a reputation for reliability, with products that are trusted by clients worldwide.

Commitment to Sustainability

In addition to producing top-quality copper rods, Nexus Copper Pvt. Ltd is dedicated to sustainable practices. The company invests in eco-friendly technologies and recycling processes to minimize its environmental impact. This commitment to sustainability not only benefits the planet but also enhances the company's reputation as a responsible and forward-thinking industry leader.

Conclusion

Copper rods are fundamental to modern industry, enabling advancements in technology, construction, and energy. Nexus Copper Pvt. Ltd has distinguished itself as a premier producer of these essential components, combining cutting-edge technology with a commitment to quality and sustainability. As the demand for copper continues to grow, Nexus Copper Pvt. Ltd is well-positioned to meet the needs of a rapidly evolving market, ensuring that copper remains a key driver of progress and innovation.

#LEADING COPPER ROUND ROD C101 SUPPLIER IN INDIA#ASTM B133 COPPER ROUND RODS#WEIGHT OF C12200 FLAT BAR#UNS C10300 HEX BAR STOCKIST#COPPER THREADED ROD MANUFACTURER#COPPER WELDING ROD#C110 BAR SUPPLIER#C10100 COPPER ROUND BAR WEIGHT CHART#ASTM B187 UNS C11000 ROD SUPPLIER IN INDIA.

0 notes

Text

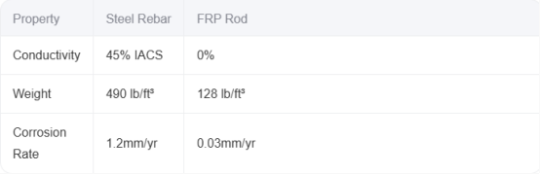

FRP Rod Systems: Reinventing Structural Integrity from Seafloor to Skyline

Let's get real about corroded steel rebar in bridges. You've seen those rusted skeletons poking through concrete, the black bar phenomenon eating through structures like termites in chloride-rich environments. That's where Fiberglass Reinforced Polymer Rods come in, flipping the script on traditional reinforcement with non-conductive tendons and spider-web filament patterns.

Take the fictional 2022 Baltic Sea wind farm project. Hongwo's seismic-grade Composite Rebar rods, ranging from 3/8" to 2.5" diameters, survived twin 8.2M quakes during installation. The secret sauce? Their patented alkaline-resistant fibers that laugh at saltwater corrosion. Contractors saved $2.5M in lifecycle costs compared to steel – numbers that'll make any project manager's eyes light up.

Here's the kicker: FRP Rods aren't just lightweight superstars. With tensile strength from 250,000-620,000 psi and operational temps from -80°F to 300°F, they're basically the Swiss Army knife of construction materials. Installation's a breeze too, just remember – pre-tension loads should never exceed manufacturer specs, and always use those #6 threaded couplers.

Hongwo's big breakthrough? A spider-web filament winding process that eliminated delamination risks. UC Berkeley's 7.8 magnitude shake table tests proved it – their rods flexed like Olympic gymnasts while steel rebar snapped like dry spaghetti. The 2023 NREL study backs this up, showing 19% cost savings over steel when you factor in reduced maintenance.

FRP Rod systems aren't some sci-fi fantasy. They're here, they're weirdly durable, and they play nice with ASTM D7205 standards. Whether you're battling arctic cold or desert heat, these Composite Reinforcing Bars keep structures standing when steel would tap out. Download Hongwo's FRP spec sheets today – your next bridge project will thank you when it's still standing in 2123.

Fiberglass Reinforced Polymer Rods aren’t a futuristic fantasy—they’re battle-tested in the harshest environments. With Hongwo’s spider-web filament technology and compliance with ASTM D7206, these Composite Reinforcing Bars redefine durability.

Grab Hongwo’s FRP load tables → to see how 2.5" diameter rods handle 620k psi loads while laughing at -80°F Arctic cold. Your next project doesn’t need last century’s steel—it needs tomorrow’s FRP.

0 notes

Text

Threaded Rod Stud | Threaded Bar | Threaded Stud

High quality of Threaded Rod we provide at best Price . All Threaded Rod ASTM A193 Stainless Steel 304, 316Ti, 316H Threaded Rod Manufacturer, Threaded Bar, Acme Threaded Rod, 8mm Threaded Rod

0 notes

Text

Duplex Fasteners Manufacturer, Supplier & Exporter in India Introduction

In challenging environments where both strength and corrosion resistance are crucial, duplex fasteners offer a superior solution. Manufactured from duplex stainless steel, these fasteners combine the qualities of austenitic and ferritic steels making them highly durable, cost-effective, and reliable.

These fasteners are manufactured using duplex stainless steel, which is a microstructure consisting of approximately equal parts of austenite and ferrite. This unique composition offers the benefits of both microstructures, making duplex fasteners a preferred choice in industries such as oil & gas, petrochemical, marine, construction, and more.

Ananka Fasteners is a trusted manufacturer of premium Duplex Fasteners in India, providing an extensive range of high-strength, corrosion-resistant fasteners in various grades, dimensions, and specifications for demanding industrial applications.

What are Duplex Fasteners?

Duplex fasteners include bolts, nuts, washers, studs, threaded rods, and screws made from duplex stainless steel. These fasteners offer:

High mechanical strength (almost double that of standard austenitic stainless steel)

Good weldability and formability

High fatigue strength and toughness

Grades of Duplex Stainless Steel Used

Ananka Fasteners manufactures duplex fasteners using the following popular grades:

Types of Duplex Fasteners We Manufacture

1. Duplex Bolts

Hex Head Bolts

Heavy Hex Bolts

Flange Bolts

U Bolts

Carriage Bolts

Stud Bolts

2. Duplex Nuts

Hex Nuts

Heavy Hex Nuts

Lock Nuts

Dome Nuts

Coupling Nuts

3. Duplex Washers

Plain Washers

Spring Washers

Lock Washers

Flat Washers

4. Duplex Screws

Machine Screws

Self-tapping Screws

Socket Head Cap Screws

Wood Screws

5. Duplex Threaded Rods & Studs

Fully Threaded Rods

Double-end Studs

Tap-end Studs

Duplex Fasteners Specifications & Standards

We manufacture duplex fasteners according to the following international standards:

ASTM A276 / A479 – Stainless steel bars and rods

ASTM A193 / A194 – Bolting Materials for High Temperature or Pressure Service

ASME B18.2.1, B18.2.2, B18.3 – Dimensional Standards

DIN, ISO, JIS, BS – Global Fastening Standards

Applications of Duplex Fasteners

Offshore Oil & Gas Rigs

Chemical Processing Equipment

Desalination Plants

Marine and Shipbuilding

Heat Exchangers and Condensers

Power Generation and Energy Sectors

Structural Components in Buildings & Bridges

Why Choose Ananka Fasteners for Duplex Fasteners?

In-House Manufacturing Facility

We operate a state-of-the-art manufacturing plant in Vasai, Maharashtra, equipped with modern machinery and quality control labs.

Strict Quality Control

Every fastener is tested for tensile strength, hardness, corrosion resistance, and dimensional accuracy before dispatch.

Custom Solutions

From non-standard sizes to specialized coatings (PTFE, Zinc, Hot Dip Galvanized), we offer tailor-made solutions for your project needs.

Global Export Network

We supply duplex fasteners to countries across Europe, the Middle East, Asia, Africa, and the Americas, ensuring timely delivery and complete documentation support.

Packaging & Delivery

Packaging: Wooden boxes, HDPE bags, bubble wraps, or as per customer request.

Delivery: Domestic and international shipping with clear markings, heat numbers, and traceability.

Conclusion

If you're looking for a reliable Duplex Fasteners Manufacturer, Ananka Fasteners is your trusted partner. Our premium quality, commitment to precision engineering, and vast export experience make us the first choice for businesses worldwide. Whether it's a complex offshore application or a structural requirement, our duplex fasteners are engineered to perform flawlessly in harsh environments.

FAQs – Duplex Fasteners

Q1. What’s the difference between Duplex and Super Duplex Fasteners?

Super Duplex fasteners contain elevated levels of chromium, molybdenum, and nitrogen, delivering superior strength and enhanced corrosion resistance compared to standard duplex grades.

Q2. Are duplex fasteners magnetic?

Yes, duplex stainless steels have a ferritic structure that makes them slightly magnetic, unlike austenitic stainless steels.

Q3. Can duplex fasteners withstand seawater?

Yes, especially Super Duplex grades like S32750 and S32760 are highly resistant to seawater corrosion.

Q4. Do you provide test certificates for duplex fasteners?

Absolutely. We provide EN 10204 3.1 / 3.2 certification, third-party inspection reports, and all relevant material test reports.

Q5. What coatings are available for duplex fasteners?

We offer coatings like PTFE, Xylan, Zinc, Hot Dip Galvanized, and custom finishes on request.

#Duplex#DuplexFasteners#Duplex2205Bolts#SuperDuplexFasteners#DuplexFastenersManufacturer#OffshoreFasteners#MarineFasteners#OilAndGasBolts#AnankaFasteners#IndiaManufacturer#GlobalExporter#Blog#Articles#tumblr blog#blogs#tumblr

0 notes

Text

Stud Bolts What They Are and Why Every Industry Needs

Akbarali Enterprises is the Best Stud Bolt Manufacturer in India, In the fast-paced world of industrial construction and engineering, precision and reliability are everything. Whether it's the oil & gas sector, power generation, petrochemical plants, or large-scale infrastructure projects, one small component plays a big role in ensuring everything holds together the stud bolt.

While often overlooked, stud bolts are the backbone of industrial fastening systems. Their unique design and unmatched strength make them a go-to solution across sectors where safety, durability, and efficiency are non-negotiable.

Let’s break down what stud bolts are, why they matter, and why every industry relies on them.

What is a Stud Bolt?

A stud bolt is a type of threaded fastener without a traditional bolt head. Instead, it's a rod that is fully or partially threaded on both ends and is typically used with two nuts on either side to create a strong, stable connection.

Stud bolts are primarily used to fasten flanges, valves, and other components in piping systems, heavy machinery, and structural applications. They are often preferred over conventional bolts in high-pressure and high-temperature environments due to their superior strength and stability.

A trusted Stud Bolt Manufacturer In India will often supply a wide variety of stud bolts, including:

Flange Stud Bolt

Tap end stud bolts

Double end stud bolts

Reduced Shank Studs

Why Every Industry Needs Stud Bolts

1. Unmatched Strength for Critical Applications

In industries where safety is paramount, there's no room for weak links. Stud bolts offer exceptional tensile strength and load-bearing capacity, making them ideal for high-stress environments. Whether you're joining pipeline flanges in an offshore rig or assembling pressure vessels in a chemical plant, stud bolts provide the reliable hold you need.

That's why top engineers and procurement teams source from a certified Stud Bolt Manufacturer who ensures every product meets international standards such as ASTM, ASME, or DIN.

2. Corrosion Resistance for Longevity

Many stud bolts are manufactured from corrosion-resistant materials like stainless steel, Inconel, or other alloys. This allows them to withstand exposure to moisture, chemicals, saltwater, and extreme weather conditions without degrading.

A reputable Stud Bolt Supplier In India will offer a range of materials and coatings, including hot-dip galvanized, PTFE-coated, or zinc-plated finishes, to match your specific application.

3. Essential for Flange Connections in Piping Systems

Stud bolts are especially vital in flange joints, where maintaining a leak-proof seal is critical. Their design ensures uniform tension across the flange face, providing consistent clamping force and reducing the risk of leakage in high-pressure systems.

4. Wide Range of Industrial Applications

Stud bolts are used across industries such as:

Oil & Gas

Petrochemicals

Power Plants

Water Treatment

Marine & Shipbuilding

Automotive

Construction

This versatility makes stud bolts one of the most commonly used fasteners worldwide. Reliable Stud Bolt Suppliers cater to diverse sectors, offering fast turnaround and customizable solutions.

5. Ease of Maintenance and Replacement

Unlike conventional bolts, stud bolts allow for easier maintenance. You can remove nuts on either side without removing the entire fastener, which is a huge benefit in confined spaces or during system inspections.

This feature helps reduce downtime and speeds up repairs—critical in industries where time is money.

Conclusion

Stud bolts may be small in size, but their impact on structural integrity and operational safety is massive. They’re engineered to withstand the toughest conditions and deliver uncompromising performance across industries.

Whether you’re building a refinery, installing a pipeline, or working on a mega construction project, don’t underestimate the importance of quality fasteners. Partner with a trusted Stud Bolt Manufacturer In India and ensure your infrastructure stands the test of time.

0 notes

Text

What Makes SS Hex Bolts Manufacturers in India the Most Preferred Choice

The modern industrial industry demands dependable strong fasteners at a faster pace. SS hex bolts serve numerous industries such as construction and machinery production plus automobile manufacturing. They become famous because of extensive strength and their ability to resist rust while lasting for many years. The global market selects SS Hex Bolts Manufacturers in India because they deliver top-notch products on time at competitive prices. This post shows how SS hex bolt manufacturers became reliable partners for international buyers.

High Quality with International Standards

Manufacturers achieve wide success because of their superior products. SS Hex Bolt manufacturers in India manufacture their products according to ASTM DIN and ISO international requirements. The manufacturing process makes sure every bolt can handle tough environments because of its strength and longevity.

They apply best quality raw materials through advanced production methods. These Indian companies maintain product quality standards by working as SS Fasteners manufacturers in India.

Advanced Manufacturing and Forging Technology

Technology-driven facilities enable Indian companies to make hex bolts in all sizes and quality options. Numerous companies apply hot forging to produce stronger and more precise bolt parts. The production tools create products that stay reliable for extended periods with precise results.

Certain companies operate as producers and suppliers of hot forged fasteners to strong industry sectors. They test every bolt at their testing facilities using certified inspectors before sending the shipment.

Wide Range and Custom Sizes

International buyers select Indian suppliers because the companies provide many product choices. They offer every bolt size type including custom orders at a single provider location. They serve as a single source by providing threads rods and other bolts such as SS Threaded Rod Manufacturers in India, SS Stud Bolts Manufacturers in India, and SS Eye Bolts Manufacturers in India.

The service helps customers complete large projects faster and with less effort. They provide a broad range of products through their supply of Duplex steel hex bolts and high-performance alloy fasteners.

Export Expertise and Material Traceability

The majority of SS Hex Bolt factories in India have exported products for many years. They understand all standards for international shipping documents. They provide documentation tests together with package preparation solutions and third-party inspection services.

These companies provide special fastener metals through Titanium fastener producers and Nickel alloy fastener producers alongside Available from Inconel fastener manufacturers. Customers gain extensive material tracking when they purchase Inconel 625, Inconel 718, and Hastelloy C276 fasteners from our top-quality range.

Conclusion

When you select SS Hex Bolts Manufacturers in India you access world-class strength and excellent quality services from a single location. These manufacturers stand out due to their advanced manufacturing tools plus tested and broad product range. We supply stainless steel and alloy custom fasteners to serve all industry requirements at Hilton Steel. Our production line provides customers durable performance-driven materials such as Inconel 625 rounds and Hastelloy C276 rounds.

0 notes

Text

How to Source High-Quality Metric Threaded Rods for Your Business

Whether you're in construction, manufacturing, or mechanical design, sourcing high-quality metric threaded rods is crucial for structural integrity, durability, and safety. These rods serve as essential fasteners in everything from framework assemblies to securing equipment. But with so many suppliers and material options available, how do you ensure you're choosing the best for your business? Here's a practical guide to help you make an informed decision.

Understand Your Application Requirements

Before approaching suppliers, clearly define what you need the threaded rods for. Consider:

Load requirements (light, medium, or heavy-duty)

Temperature conditions

Thread pitch and rod length

Understanding these variables helps you determine the right material, coating, and thread specifications for the job.

Choose the Right Material

Metric threaded rods come in a variety of materials:

Carbon Steel – Cost-effective and ideal for general-purpose applications.

Stainless Steel – Corrosion-resistant and perfect for outdoor or chemical environments.

Brass or Aluminum – Used for specialized electrical or lightweight applications.

High-Tensile Steel – Best for heavy-duty construction and high-stress environments.

Select a material that balances strength, corrosion resistance, and cost depending on the job.

Check for Standards Compliance

Ensure the threaded rods comply with international standards such as:

ISO (International Organization for Standardization)

ASTM (American Society for Testing and Materials)

Standards ensure product quality, compatibility, and interchangeability with other components.

Vet Your Suppliers

Not all suppliers are created equal. Look for:

Industry reputation – Check reviews, testimonials, and years of operation.

Certifications – Look for ISO 9001, quality management systems, and material traceability documentation.

Technical support – Reliable suppliers can guide you on material selection and custom requirements.

Sample availability – A good supplier will offer samples for testing before you place bulk orders.

Building a long-term relationship with a reputable supplier ensures consistent quality and smoother project timelines.

Request Material Test Reports (MTRs)

A Material Test Report verifies the chemical composition, tensile strength, and other critical data of the rod. MTRs are especially important in industrial or high-performance applications where compliance and safety are essential.

Compare Pricing Without Compromising Quality

It’s tempting to go with the cheapest option, but in the world of fasteners, low cost can mean low quality. Instead, look for value durability, service, on-time delivery, and material consistency all contribute to long-term cost savings.

Final Thoughts

Sourcing high-quality metric threaded rods doesn’t have to be complicated. Start with a clear understanding of your application needs, choose the appropriate material, verify standards, and work with reputable suppliers. Investing in quality upfront can save you time, reduce failures, and strengthen your business reputation in the long run.

0 notes

Text

Top Anchor Bolts Manufacturer & Supplier in Chennai – Eshaji Engineering Excellence

In the world of construction and industrial installations, anchor bolts are critical to ensuring structural stability and safety. Whether you're anchoring a steel column, mounting heavy machinery, or erecting a transmission tower, you need fasteners that are engineered to last. That’s where Eshaji, one of the top anchor bolts manufacturers in Chennai, comes in.

What Are Anchor Bolts?

Anchor bolts are heavy-duty fasteners used to connect structural and non-structural elements to concrete. These include everything from foundation plates and equipment bases to beams and industrial supports. At Eshaji, we manufacture a full range of anchor bolts including:

L-type and J-type bolts

Sleeve and expansion bolts

U-bolts, eye bolts, and custom-formed anchor rods

Heavy hex head and threaded rods with nuts & washers

Each bolt is designed for strength, precision, and corrosion resistance—ideal for India's diverse climate and industrial conditions.

Anchor Bolts Manufacturers in India – Why Eshaji?

As one of the most trusted anchor bolts manufacturers in India, Eshaji has built its reputation on:

✅ Custom fabrication to match any specification ✅ High-grade raw materials – including MS, SS, EN8, and high-tensile alloys ✅ Protective coatings like hot-dip galvanizing, electroplating, or epoxy ✅ Strict quality control as per IS, ASTM, and DIN standards ✅ Bulk manufacturing & on-time nationwide delivery

Whether you're managing a metro rail project or building a thermal plant, we provide anchor bolts engineered to meet your structural requirements.

Anchor Bolts Supplier in Chennai – Local Service, National Reach

As a leading anchor bolts supplier in Chennai, Eshaji is strategically positioned to serve clients across Tamil Nadu and South India. Our in-house manufacturing facility allows us to respond quickly to urgent project needs, custom orders, and bulk quantities without compromising quality.

From builders and OEMs to EPC contractors and infrastructure developers, clients choose Eshaji for precision, reliability, and local support.

Applications of Our Anchor Bolts

Construction & Civil Engineering

Power Plants & Substations

Steel Structures & PEB Buildings

Oil & Gas Refineries

Renewable Energy Foundations

Machine Mountings & Foundations

📞 Call Now – Your Reliable Anchor Bolts Partner in Chennai

0 notes