#FastenerSolutions

Explore tagged Tumblr posts

Text

Golden Screw Trading LLC

Welcome Golden Screw Trading LLC on TradersFind Golden Screw Trading LLC is a prominent importer, stockist, and supplier of a wide range of bolts, nuts, washers, and other fastener items. With a reputation for excellence, Golden Screw Trading LLC offers a wide range of products meeting your requirements.

Click here to explore their offerings on TradersFind: https://www.tradersfind.com/seller/golden-screw-trading-llc

#goldenscrewtrading#fastenersuae#boltsandnuts#fastenersolutions#uaeimporters#uaestockist#supplieruae#qualityfasteners#industrialfasteners#engineeringsolutions#constructionmaterials#buildingsupplies#uaeengineering#uaeconstruction#hardwaresupplies#mechanicalparts#fastenerexperts#reliablesupplies#topqualityfasteners#fastenerstockist#industrialsupplies#fasteningsolutions#uaeimports#tradersfinduae#b2bmarketplace

2 notes

·

View notes

Text

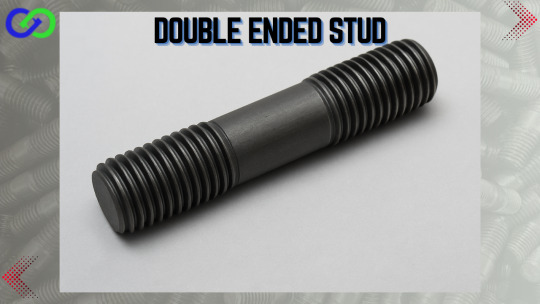

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

How does Royal Hardware support the construction industry's demand for specialized fasteners in Karachi?

Royal Hardware is a leading supplier of specialized fasteners in Karachi, catering to the needs of the construction industry. The company provides a wide range of high-quality fasteners, including bolts, nuts, screws, washers, and anchors, that are crucial for construction projects. By offering a diverse selection of fasteners in different sizes and materials, Royal Hardware ensures that construction companies can find the right components for their specific needs.

Their commitment to quality and reliability is evident through their partnerships with top manufacturers and their focus on sourcing durable, corrosion-resistant fasteners suitable for various environmental conditions. Whether for residential, commercial, or industrial projects, Royal Hardware’s fasteners are designed to meet the stringent demands of construction professionals.

Moreover, Royal Hardware also provides expert guidance and customer support, ensuring that clients make informed choices when selecting fasteners for their projects. With a robust distribution network, they ensure timely delivery of products to construction sites, making them a trusted partner for the construction industry in Karachi.

For more information, visit Royal Hardware.

#RoyalHardware#SpecializedFasteners#ConstructionIndustry#Karachi#BuildingMaterials#ConstructionSupplies#Fasteners#ConstructionProjects#HardwareSupplies#ConstructionSupport#QualityFasteners#IndustrialHardware#FastenerSolutions#KarachiConstruction#BuildingSolutions#HardwareForConstruction

0 notes

Text

How to Choose the Right Washer for Your Application

When selecting the right washer for your application, it’s important to consider factors like material, load distribution, and the operating environment. Here’s a quick guide to help you make the best choice:

1. Know Your Material

Choose a washer material that fits your application needs. For corrosion resistance, stainless steel washers are ideal, while brass washers are great for conductivity. If you need extra durability, consider machined washers that offer precise dimensions for specific applications.

2. Consider the Environment

Think about the operating environment. If you are dealing with high vibrations, wedge lock washers, spring lock washers, or self-locking washers are perfect choices for preventing loosening. For securing fasteners in high-stress conditions, shim washers and fender washers offer added support.

3. Application-Specific Washers

Depending on your needs, you might also opt for Ogee washers, tab washers, conical washers, or sealing washers to provide a more customized solution. External tooth lock washers and hex washers are useful in ensuring tight, secure fastening.

4. Find a Reliable Supplier

Look for trusted shim washer manufacturers or a reputable washer manufacturer to ensure you're getting high-quality products that will perform well in your specific application.

By understanding your material and environmental requirements, you can select the right Industrial washers for optimal performance and reliability.

#ChooseTheRightWasher#WasherSelection#WasherGuide#ApplicationSpecificWashers#RightWasherForTheJob#IndustrialWashers#FastenerSolutions#WasherTypes

0 notes

Text

Searching for reliable molded metal studs? 🛠️ Our premium studs are designed for durability and precision in industrial and commercial applications. Get the strength and performance your projects demand! 💪

0 notes

Text

#HighTensileBolts#BoltSuppliers#ConstructionMaterials#EngineeringEssentials#StructuralIntegrity#BoltStrength#IndustrialSuppliers#BuildingMaterials#FastenerSolutions

0 notes

Text

Upgrade Your Projects with Premium Anchor Fastener Bolts!

Looking for a reliable, durable, and high-performance solution for your construction or DIY projects? Our Anchor Fastener Bolts are here to secure your work like never before!

Heavy-Duty Performance Rust-Resistant & Long-Lasting Easy to Install & Versatile

Whether you're working on concrete, masonry, or heavy structures, our bolts are designed to handle it all. Don’t compromise on safety and quality—choose the best!

Shop now and experience the difference!

#AnchorBolts #FastenerSolutions #ConstructionTools #DIYTools #BuildWithConfidence #HeavyDutyHardware

0 notes

Text

Are you tired of dealing with unreliable conveyor belt clamps that constantly loosen or fail to secure your belts effectively? Look no further! We have the perfect solution to elevate your productivity and streamline your operations - the Conveyor Belt Clamp Fastener.

#ConveyorBeltClamp#FastenerSolutions#IndustrialProductivity#EfficiencyBoost#ConveyorMaintenance#SecureFastening#DurableClamp

0 notes

Text

Top Washer Types to Consider for Your Project

Choosing the right washer for your project is essential for ensuring performance, stability, and longevity. Various types of washers are designed for specific applications, each offering unique benefits. For example, Hex washers are commonly used in machinery and construction to secure fastenings, while Ogee washers are perfect for tension applications, providing flexibility and resilience.

Tab washers are ideal when additional support is needed, particularly in high-vibration environments, and Conical washers offer precise tension and alignment control, making them suitable for pressure distribution. For plumbing or industrial applications that require a watertight seal, Sealing washers are highly effective in preventing leakage. Wedge lock washers prevent loosening under load or vibration, ensuring long-lasting equipment performance. Square washers are designed to distribute large loads evenly, providing enhanced stability, whereas

Spring lock washers are used to prevent loosening from vibrations and thermal expansion. Fender washers are perfect for distributing pressure and protecting softer surfaces, while Countersunk washers are essential for flush fittings that require a smooth, even surface. Additionally, Self-locking washers ensure fasteners remain secure, and External tooth lock washers are excellent for preventing accidental loosening of fasteners.

Understanding the features of these washers helps you choose the best one for your needs. For reliable, high-quality options, consider reaching out to shim washer manufacturers or a trusted washer manufacturer for products like machined washers or industrial washers.

#WasherTypes#ProjectPlanning#IndustrialWashers#FastenerSolutions#EngineeringEssentials#ConstructionMaterials#BuildingProjects#HardwareSolutions

0 notes

Text

The Benefits of Lock Washers: Spring, Tab, and Wedge Types Explained

Lock washers are small but essential components used to secure fasteners in place and prevent loosening due to vibrations or external forces. Whether you’re working with automotive machinery, heavy industrial equipment, or electronics, understanding the different types of lock washers and their benefits is key to making the right choice for your project. In this guide, I’ll explain the unique features of spring lock washers, tab washers, and wedge lock washers, and how they can make a difference in your applications.

Lock washers are designed to prevent the loosening of fasteners such as bolts and nuts over time. In mechanical and industrial assemblies, this function is crucial for ensuring safety and reliability. There are several types of lock washers, each tailored to different needs. The most common types include:

Spring Lock Washers

Tab Washers

Wedge Lock Washers

As an engineer or technician, you may be sourcing these washers from shim washer manufacturers or a washer manufacturer for specific applications. Whether you need machined washers for precise fits or industrial washers for heavy-duty use, understanding each type of lock washer will help you make the best selection.

Benefits of Spring Lock Washers

Spring lock washers are the most commonly used lock washers, and they work by creating a spring action that applies pressure to the fastener and its surface. Here’s why you should consider using them:

Prevents Loosening: Spring lock washers are designed to resist loosening from vibrations, making them ideal for automotive, machinery, and high-vibration environments.

Versatile: These washers are widely used in industries ranging from automotive to electronics. Their versatility makes them a go-to option in various applications.

Affordable: As one of the most common types of washers, spring lock washers are cost-effective, yet still deliver excellent performance.

Durability: Made from materials like stainless steel or carbon steel, spring lock washers are durable and resistant to corrosion, ensuring a long lifespan in various conditions.

Benefits of Tab Washers

Tab washers are a specialized type of lock washer, often used when extra locking force is needed in a specific direction. Here’s why tab washers could be your best option:

Positive Locking Action: Tab washers feature a tab that fits into a corresponding slot, providing a secure fit and preventing rotational movement.

Used for Heavy Loads: Ideal for applications where the fastener will bear heavy loads or experience extreme forces, such as in industrial machinery and construction.

Prevent Accidental Loosening: Tab washers are effective in applications where accidental loosening can be catastrophic, ensuring the integrity of the fastener in critical systems.

Corrosion-Resistant Materials: Like other lock washers, tab washers can be made from corrosion-resistant materials, ensuring reliability in harsh environments.

Benefits of Wedge Lock Washers

Wedge lock washers are designed to provide the highest level of security by using a wedge-shaped design that locks the fastener in place. Here’s why wedge lock washers might be the best choice for your project:

Superior Vibration Resistance: Wedge lock washers are particularly effective in preventing loosening due to vibrations. Their unique wedge shape ensures that the fastener stays locked even under heavy dynamic loads.

High Load Capacity: These washers are designed for heavy-duty applications, making them perfect for large machinery, structural components, and high-torque fasteners.

Self-Locking Mechanism: Wedge lock washers create a self-locking mechanism by applying pressure on both the fastener and the surface it’s being screwed into, ensuring a secure connection.

Durability and Strength: Wedge lock washers are made from high-quality materials like stainless steel, making them durable, corrosion-resistant, and capable of withstanding extreme conditions.

Conclusion

When choosing the right lock washer for your project, it’s important to understand the benefits of spring lock washers, tab washers, and wedge lock washers. Each type offers unique advantages depending on the specific requirements of your application. Whether you are sourcing these washers from shim washer manufacturers, washer manufacturers, or looking for industrial washers, ensuring you select the right type for your needs will contribute to the safety and longevity of your assembly.

#LockWashers#WasherTypes#SpringWashers#TabWashers#WedgeWashers#FastenerSolutions#IndustrialHardware#MechanicalEngineering

0 notes

Text

The Importance of Choosing Quality Fasteners for Your Industrial Projects

In both industrial and construction projects, the fasteners you choose play a crucial role in the success and longevity of the work. Whether you're using foundation J bolts, foundation bolts, or U bolts, selecting high-quality fasteners is essential to ensuring the stability, safety, and efficiency of your project. Low-quality fasteners can lead to structural failures, higher maintenance costs, and potential safety hazards, which may compromise the integrity of the entire construction. By choosing the right fasteners, you can avoid these issues and achieve long-lasting, secure results.

How to Identify Reliable Fastener Manufacturers

ReputationWhen selecting fasteners, it’s important to choose reputable manufacturers known for their high-quality products. Look for brands or companies with a proven history of producing reliable fasteners, including anchor bolt manufacturers who are trusted for providing sturdy and durable solutions for critical applications.

Material QualityThe material quality plays a vital role in the performance of fasteners. Ensure that your fasteners are made from high-grade materials such as stainless steel or carbon steel. For instance, if you are looking for corrosion-resistant solutions, stainless steel U bolt manufacturers offer fasteners that withstand harsh environments.

CustomizationA reliable fastener manufacturer should be able to provide customized fasteners tailored to your specific project requirements. Whether you need unique sizes or designs, top-tier U clamp manufacturers can provide specialized products that fit your exact needs.

Key Benefits of Choosing High-Quality Fasteners

Enhanced DurabilityHigh-quality fasteners resist corrosion, wear, and breakage. By choosing the right fasteners, such as foundation bolts or stud bolts, you are ensuring that your project remains robust over time. Durable fasteners will help maintain the structural integrity of the project, even under high stress or exposure to the elements.

SafetySafety is the primary concern in any industrial or construction project. Reliable fasteners provide the strength and stability needed to secure components, keeping structures safe for workers and occupants. Using quality U bolts manufacturers for securing pipes, rods, or other elements will ensure that the installation is secure and stable, reducing the risk of failure or accidents.

Cost-EffectivenessThough high-quality fasteners may have a higher initial cost, they save money in the long run. By choosing durable fasteners like anchor bolts or foundation J bolts, you reduce the need for repairs or replacements, which can be costly and time-consuming. The longevity and reliability of quality fasteners ultimately lead to cost savings and fewer disruptions during the project.

Conclusion

Selecting the right fasteners is essential for the success of any industrial or construction project. By partnering with trusted anchor bolt manufacturers, stainless steel U bolt manufacturers, and U clamp manufacturers, you ensure that your project is equipped with reliable and durable fasteners. With enhanced durability, safety, and long-term cost savings, investing in quality fasteners not only guarantees the stability of your project but also protects your investment from future problems. Prioritize high-quality fasteners, and ensure the integrity and safety of your industrial projects.

0 notes

Text

How Shim Washers Help in Adjusting Tolerances and Ensuring Proper Fit

If you’ve ever worked on machinery, construction projects, or even DIY tasks, you know how crucial it is to achieve a perfect fit between components. That’s where shim washers come in. These small but powerful components play a vital role in adjusting tolerances, aligning parts, and ensuring everything works as it should.

In this guide, I’ll explain how shim washers work, their benefits, and how you can use them to improve precision and functionality in your projects.

What Are Shim Washers?

Shim washers are thin, flat pieces of material designed to fill small gaps between components. They are commonly used to adjust spacing, align parts, or reduce wear and vibration in various applications.

They are available in various materials, such as:

Stainless steel shims

Brass shim sheets

Plastic or composite materials

You can find them in a range of sizes and thicknesses, including precut shims for easy installation.

How Shim Washers Adjust Tolerances

When components in machinery or structures don’t fit perfectly, shim washers step in to bridge the gap. Here’s how they help:

Fine-Tuning Alignment: Shim washers allow you to make precise adjustments to align parts correctly.

Compensating for Irregularities: They fill gaps caused by uneven surfaces or manufacturing defects.

Ensuring Even Load Distribution: Properly placed shim washers distribute pressure evenly, preventing damage or wear.

Reducing Noise and Vibration: By eliminating loose fits, shim washers reduce operational noise and vibrations.

Applications of Shim Washers

You’ll find shim washers in a variety of industries and tasks, such as:

Machinery Maintenance: Adjust tolerances in gears, bearings, and moving parts.

Construction Projects: Ensure alignment for bolts like foundation bolts and stud bolts.

Automotive and Aerospace: Achieve precision in engines and structural components.

DIY Repairs: Fix loose parts in furniture, appliances, or small machines.

Benefits of Using Shim Washers

Here’s why I recommend shim washers for your projects:

1. Precision Adjustments

Shim washers make it easy to achieve exact tolerances, ensuring a perfect fit every time.

2. Versatility

From heavy-duty industrial applications to everyday repairs, shim washers are incredibly versatile.

3. Durability

High-quality materials like stainless steel shims or brass shim sheets ensure long-lasting performance.

4. Cost-Effectiveness

Using shim washers to adjust tolerances is more affordable than replacing misaligned parts.

5. Ease of Use

Precut shims and custom sizes make installation quick and hassle-free.

Tips for Choosing the Right Shim Washers

Here’s how you can select the best shim washers for your needs:

1. Material Selection

Choose the material based on your application. For example:

Use stainless steel shims for corrosion resistance.

Opt for brass shim sheets for electrical conductivity or aesthetic finishes.

2. Thickness and Size

Ensure the shim washer matches the required gap size and fits the dimensions of your components.

3. Consider Precut Shims

Precut shims save time and effort compared to cutting your own from shim sheet metal.

4. Check for Customization Options

Many shim washer manufacturers offer custom sizes and shapes to meet specific requirements.

5. Buy from Reputable Suppliers

Work with trusted shim manufacturers in India or international providers to ensure quality and reliability.

Conclusion

Whether you’re fine-tuning machinery, securing a structure, or fixing a misalignment, shim washers are indispensable. They provide the precision, stability, and reliability you need to get the job done right.

By understanding their applications and choosing the right washers, you’ll not only save time and money but also ensure long-lasting performance for your projects. So, next time you’re faced with a tolerance issue, reach for a shim washer—it’s a small investment with big returns.

#ShimWashers#AdjustingTolerances#ProperFit#PrecisionEngineering#IndustrialWashers#FastenerSolutions#ManufacturingExcellence

0 notes

Text

How Tab Washers Enhance Bolt Security and Prevent Loosening | Ultimate Guide

This article helps in understanding tab washer is a type of locking washer designed to prevent bolts and nuts from loosening under vibration, movement, or other external forces. Unlike standard flat washers, tab washers have one or more tabs that engage with the surface of the surrounding material or the nut, locking it in place.

These Shim washers are simple yet highly effective in maintaining the tightness of bolts, even in the harshest environments. The tab works by physically engaging with a slot or hole in the component it's securing, effectively locking the bolt in place and preventing it from turning or loosening.

While tab washer are excellent for preventing bolt loosening, there are other fastening solutions available. Here's a quick comparison:

1. Lock Nuts

Lock nuts are another solution to prevent bolt loosening, but they tend to be more expensive and can sometimes damage the threads.

2. Loctite Adhesives

Loctite adhesives are often used to secure bolts, but they can be difficult to remove if servicing is required. In contrast, tab washers are reusable and easy to work with.

3. Spring Washers

Spring washers provide tension to prevent loosening but don’t have the locking mechanism of tab washers, which makes tab washers a more secure option in many cases.

4. Locking Bolts

Locking bolts offer security similar to tab washers but are more complex to install and typically more expensive.

This article also helps as, tab washer are used in a wide range of industries and applications. Here are some examples of where they excel:

1. Automotive Industry

In vehicles, where high vibrations are common, tab washers prevent critical fasteners from loosening and ensure the safety and functionality of the vehicle.

2. Industrial Equipment

Tab washers are commonly used in machinery to prevent bolts from loosening under heavy usage.

3. Aerospace

In aerospace applications, where safety is paramount, tab washers are often used to secure fasteners in components like engines and structural parts.

4. Construction

For large construction projects, tab washers are essential in ensuring bolts in steel structures and heavy equipment stay securely in place.

Conclusion

Tab washers are an essential component in ensuring the security of Foundation bolts and preventing loosening over time. Whether you're working on an automotive, industrial, or aerospace project, tab washers offer a simple, cost-effective solution to keep your fasteners secure and your operations running smoothly. With various types available and numerous benefits, they’re an excellent choice for anyone looking to enhance the longevity and durability of their mechanical assemblies.

So, the next time you're considering securing a foundation bolt in a high-vibration or high-stress environment, consider using tab washers to provide that extra level of bolt security.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

How Tab Washers Enhance Bolt Security and Prevent Loosening | Ultimate Guide

#TabWashers#BoltSecurity#FastenerSolutions#PreventLoosening#EngineeringEssentials#SecureFastening#DIYTips#MechanicalStability#WasherGuide#UltimateGuide

0 notes

Text

Where Are Tab Washers Used? Key Applications and Benefits

This article helps in understanding tab washer as a type of locking washer that’s designed to prevent bolts or nuts from loosening. It consists of a flat washer with one or more tabs that can be bent to lock the washer in place. These tabs engage with the surface to hold the fastener securely, creating a robust connection that resists vibrations and movement. Tab washers are usually made of steel, stainless steel, or brass, depending on the environment and application.

Unlike traditional flat washers, which provide only a surface for even pressure distribution, tab washers provide additional security by locking the bolt in place. They are often used in situations where other forms of locking mechanisms (like lock washers) might not be sufficient.

Tab washers work by using their tabs to engage with the fastener or the surface where the fastener is mounted. Once the washer is placed beneath the bolt or nut and tightened, the tabs are bent over the edges of the fastener, locking it into place. This locking action prevents the fastener from loosening due to external forces like:

Vibrations: In applications involving high-speed machinery or transportation (like in vehicles), constant vibrations can cause bolts to loosen over time. Tab washers are designed to resist such forces and keep everything in place.

Thermal Expansion: In environments with fluctuating temperatures, materials expand and contract, which could lead to loosening fasteners. Tab washers ensure that these changes don’t affect the integrity of the connection.

General Wear and Tear: Over time, standard washers can wear out, but tab washers are designed to stay secure and maintain their locking function even after prolonged use.

While tab washers are durable, regular maintenance ensures their longevity and performance:

Inspection: Regularly inspect the washers for wear, especially in high-stress environments like machinery and automotive applications.

Replace When Necessary: If a tab washer becomes worn out or the tabs break off, replace it immediately to maintain the security of the fastener.

Clean Periodically: Keep the washers free of debris and rust by cleaning them regularly, especially in outdoor or marine environments.

Tab washers are a simple but effective solution for securing bolts, nuts, and fasteners across a wide range of industries. Whether you're working with automotive parts, construction equipment, or marine applications, tab washers offer unparalleled benefits, including vibration resistance, durability, and cost-effectiveness.

By understanding where tab washer are used and how to select, install, and maintain them properly, you can ensure your fasteners remain secure and your equipment operates efficiently for years to come.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

Where Are Tab Washers Used? Key Applications and Benefits

#TabWashers#IndustrialWashers#BoltSecurity#FastenerSolutions#WasherApplications#EngineeringTools#ConstructionMaterials#MachineryMaintenance#FastenerSafety#IndustrialEquipment

0 notes

Text

What is the Function of Spring Washer? | Understanding Its Role

This article helps in undertsanding spring washer as,it is a type of washer that features a curved design, allowing it to provide a spring effect when compressed. Often made from materials like stainless steel or carbon steel, these washers are primarily used in mechanical assemblies to prevent loosening due to vibrations or movements.

Understanding the role of spring washers is crucial for anyone involved in engineering, manufacturing, or assembly processes. They may seem small, but their impact on the performance of mechanical systems is significant.

This aritcle also helps in understanding the primary functions of spring washers:

Preventing Loosening: The primary function of a spring washer is to prevent loosening of nuts and bolts due to vibration. This is especially important in machinery and automotive applications where movements can be substantial.

Absorbing Shock and Vibration: By providing a cushioning effect, spring washers absorb shock and vibration, reducing the risk of damage to components and extending their lifespan.

Maintaining Clamping Force: The preload created by a spring washer ensures that the clamping force remains consistent, which is vital for maintaining the integrity of mechanical assemblies.

Compensating for Tolerance Gaps: In cases where there are slight misalignments or tolerance gaps, spring washers can help maintain a secure fit by compensating for these discrepancies.

Choosing the right spring washer is essential for achieving optimal performance. Here are some factors to consider:

Material: Select a washer made from a material that suits your application’s environment. Stainless steel is excellent for corrosion resistance, while carbon steel is strong and cost-effective.

Size: Ensure the spring washer fits the diameter of the bolt or fastener you are using. A proper fit is crucial for effective function.

Load Rating: Consider the load that the spring washer will need to support. Always choose a washer with a sufficient load rating for your application.

Type of Spring Washer: Depending on your assembly requirements, you might need a specific type, such as a conical washer or a locking washer.

If you're unsure, consult with a trusted washer manufacturer or supplier who can help guide you based on your specific needs. Additionally, look into reputable shim washer manufacturers if your assembly requires complementary components.

Spring washers are crucial components in mechanical assemblies that serve multiple functions, including preventing loosening, absorbing shocks, and maintaining clamping force. Their versatility makes them applicable across a wide range of industries, from automotive to aerospace and beyond.

Understanding the importance of spring washers will help you make informed decisions about their use in your projects. By selecting the right type and size, you can enhance the reliability and safety of your mechanical assemblies.

Whether you are a professional in the field or a DIY enthusiast, don't underestimate the power of a simple spring washer. Investing in quality washers can make all the difference in achieving optimal performance in your assemblies.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

What is the Function of Spring Washer? | Understanding Its Role

#SpringWasherFunction#MechanicalEngineering#WasherUses#EngineeringBasics#SpringWasherRole#FastenerSolutions#UnderstandingWashers#SpringWasherPurpose#HardwareEssentials#EngineeringComponents#DIYMechanics#WasherApplications#BoltingSolutions#MechanicalParts#FasteningBasics

0 notes