#EngineeringFasteners

Explore tagged Tumblr posts

Text

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

Nut Bolt Supplier with Best Wholesale Prices

✔ Cost Savings – Wholesale pricing helps reduce expenses for large orders. ✔ Wide Product Range – Get all sizes, materials, and types of fasteners. ✔ Bulk Availability – Always have enough stock for construction and industrial needs. ✔ Certified Quality – Ensure durability and reliability for heavy-duty applications. ✔ Fast & On-Time Delivery – Keep your projects running smoothly.

Buying from a wholesale nut bolt supplier ensures you get quality fasteners at the lowest possible cost.

Industries That Need Wholesale Nuts & Bolts

🏗 Construction & Infrastructure – Used in building structures, bridges, and railways. 🏭 Manufacturing & Engineering – Essential for machines, automobiles, and industrial equipment. 🚜 Agriculture – Required in farming equipment and irrigation systems. 🛠 DIY & Hardware Stores – Needed for home improvement and repair projects. ✈ Aerospace & Automotive – Used in aircraft, vehicles, and heavy machinery.

A trusted wholesale supplier ensures that all industries receive strong and reliable fastening solutions.

Types of Nuts & Bolts Available in Wholesale

1. Hex Bolts & Nuts

🔩 Most commonly used in construction, automotive, and machinery. 🔩 Available in mild steel, stainless steel, and high-tensile materials.

2. Carriage Bolts & Nuts

🔩 Ideal for woodworking and metal connections. 🔩 Provides secure and tamper-proof fastening.

3. Anchor Bolts

🔩 Used in concrete and foundation installations. 🔩 Designed for high-strength applications.

4. U-Bolts & Eye Bolts

🔩 Essential for piping, clamps, and support structures. 🔩 Provides strong grip and stability.

5. Flange Bolts & Lock Nuts

🔩 Used for automotive and heavy machinery applications. 🔩 Prevents loosening under vibrations.

Need customized nuts & bolts for your project? Let us know!

Best Wholesale Nut Bolt Suppliers

1. Fastener Manufacturers & Exporters

📍 Location: Available across India. ✅ Best for: Large-scale industrial and export orders.

2. Local Distributors & Stockists

🔩 Affordable options for contractors and resellers. 📍 Available in major industrial cities. ✅ Best for: Hardware stores and bulk buyers.

3. Online Wholesale Suppliers (IndiaMART, TradeIndia, Alibaba)

🛒 Easy ordering with nationwide delivery. 📍 Compare multiple suppliers for the best prices. ✅ Best for: Bulk online purchases.

Would you like supplier details based on your requirements? Let us know!

How to Get the Best Wholesale Prices on Nuts & Bolts?

💡 Compare Multiple Suppliers – Get quotes from different vendors. 💡 Negotiate Bulk Discounts – The bigger the order, the better the price. 💡 Check for Quality Certifications – Ensure ISO, ISI, and ASTM standards. 💡 Inspect Material & Coating – Choose the right material for your industry. 💡 Confirm Stock Availability – Avoid delays in project timelines.

Following these steps helps you get the best deals on nuts and bolts.

Why Buy from a Trusted Wholesale Supplier?

✅ High-Quality Fasteners – Durable, strong, and rust-resistant. ✅ Affordable Bulk Pricing – Cost-effective solutions for all industries. ✅ Wide Range of Products – Get all types of nuts, bolts, and washers. ✅ Reliable Delivery Services – On-time shipping for urgent orders.

Choosing a trusted supplier guarantees top-quality nuts and bolts at the best wholesale rates.

Conclusion

If you're looking for a nut bolt supplier with the best wholesale prices, make sure to compare prices, check quality certifications, and negotiate for bulk discounts. A reliable supplier ensures you get strong, durable, and cost-effective fastening solutions.

For bulk order inquiries, supplier recommendations, or pricing details, explore the top-rated nut bolt wholesalers today!

#NutBoltSupplier#WholesaleFasteners#IndustrialFasteners#ConstructionSupplies#BulkOrders#AffordableFasteners#ReliableSupplier#Manufacturing#DIYProjects#EngineeringFasteners

1 note

·

View note

Text

Guide on Bolts: Manufacturing Process, Grades, Specifications, and Materials

Designed to securely join two or more components, bolts offer high tensile strength, durability, and reliability under varying loads and environmental conditions. Unlike simple nails or screws, bolts typically work in combination with nuts and washers, providing a strong clamping force that maintains structural integrity even under vibration, stress, and extreme temperatures.

From massive infrastructure projects like bridges and skyscrapers to critical machinery in aerospace, automotive, marine, oil & gas, and manufacturing industries, bolts ensure safety and performance across countless applications. They are available in a wide range of sizes, materials, grades, and specifications to meet the unique requirements of each industry. Understanding the different types of bolts, their manufacturing process, material grades, and specifications is crucial for selecting the right fastener for any application.

Bolt Manufacturing Process: Step-by-Step Overview

The bolt manufacturing process involves multiple stages, ensuring high-quality fasteners for diverse applications:

Raw Material Selection: The process begins by selecting raw materials like carbon steel, stainless steel, alloy steel, brass, titanium, Inconel, and Monel based on application needs.

Cutting: The raw material is cut into precise lengths (blanks) which are then processed into bolts.

Heading: Undergoes cold or hot forging to form the bolt head.

Thread Rolling: Threads are formed through thread rolling, enhancing the bolt's strength and precision without removing material.

Heat Treatment: Bolts are heat-treated to achieve desired mechanical properties like tensile strength, hardness, and durability.

Surface Treatment: Coatings such as zinc plating, galvanization, black oxide, or anodizing are applied for corrosion resistance.

Inspection and Testing: Each bolt undergoes strict quality checks for dimensional accuracy, strength, and surface finish.

Packaging and Dispatch: Bolts are packaged and shipped to clients worldwide.

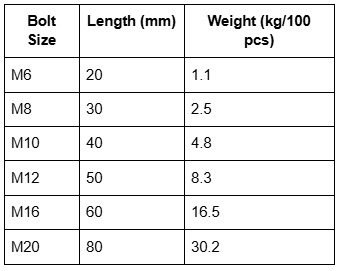

Bolt Weight Chart: Quick Reference

A bolt weight chart helps determine the weight based on dimensions and material type, crucial for logistics and structural calculations.

Note: Weight varies depending on material density.

High-Temperature Bolt Materials: Top Choices

For high-temperature applications, selecting the correct bolt material is crucial to ensure both safety and optimal performance.

Inconel Alloys (600, 625, 718): Superior strength and oxidation resistance.

Hastelloy: Outstanding corrosion and high-temperature resistance.

Stainless Steel (310, 321, 347): Designed to withstand high-temperature oxidation and minimize creep deformation.

Nickel Alloys: Deliver exceptional stability against thermal expansion and corrosion across a wide temperature range.

Titanium Alloys: Lightweight with excellent strength and heat resistance.

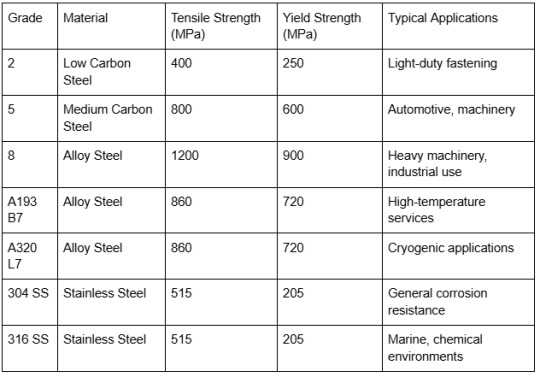

Bolt Grades: Classification and Applications

Understanding bolt grades is crucial for ensuring structural integrity and achieving optimal performance in various applications:

Grade 5: Produced from medium carbon steel and subjected to heat treatment, widely used in automotive, machinery, and equipment manufacturing due to its improved strength and durability.

Grade 8: Constructed from alloy steel and heat-treated, designed for heavy-duty industrial and high-stress environments.

ASTM A193 B7: An alloy steel grade engineered for high-temperature service, ideal for use in pressure vessels and piping systems.

ASTM A320 L7: Alloy steel designed for low-temperature services.

Stainless Steel Grades (304, 316, 410, 17-4PH): Superior corrosion resistance for marine and chemical industries.

Bolt Specifications: Industry Standards

Bolt specifications detail the size, material type, mechanical properties, and protective coatings needed for specific applications. Leading international standards include:

ASTM Standards: A193, A307, A325, A490.

ISO Standards: ISO 898-1.

DIN Standards: DIN 931, DIN 933.

SAE Standards: SAE J429.

Specifications generally cover:

Bolt dimensions (diameter, length, thread pitch)

Material and grade

Mechanical properties (tensile strength, yield strength, hardness)

Coating and surface finish

Bolt Grades Chart: Complete Data Table

Bolt Material Grades: Selection Criteria

Selecting the correct bolt material grade ensures performance, safety, and longevity. Consider:

Environmental factors (corrosion, temperature)

Load-bearing requirements (tensile/yield strength)

Compliance with industry standards

Cost-effectiveness

Common Bolt Material Grades:

Carbon Steel: Cost-effective for general applications.

Stainless Steel (304, 316, 410): Provides outstanding corrosion resistance, with 316 offering enhanced performance in chloride-rich environments.

Alloy Steel: Superior strength and durability.

Exotic Alloys (Inconel, Hastelloy, Monel): For extreme environments and specialty industries.

Bolts Manufacturing Industry Overview

The global bolts manufacturing industry serves numerous sectors, including construction, automotive, oil & gas, aerospace, and infrastructure development. Key growth drivers include:

Rising demand for high-performance, corrosion-resistant fasteners.

Technological advancements in CNC machining, forging, and additive manufacturing.

Expanding infrastructure projects in emerging economies.

Strict adherence to ISO, ASTM, and ASME standards ensures consistent quality, safety, and compatibility across applications.

Leading manufacturers invest significantly in R&D to develop innovative, high-strength, corrosion-resistant, and lightweight bolt solutions.

Conclusion

Bolts are indispensable fasteners that come in a variety of grades, materials, and specifications. Understanding the bolt manufacturing process, bolt weight chart, high-temperature bolt materials, bolt grades, bolt specifications, and bolt material grades ensures that engineers and procurement managers make informed choices for maximum safety, performance, and cost efficiency. The bolts manufacturing industry continues to evolve with technological advancements, offering cutting-edge solutions for every industrial need.

FAQs

Q1. What are the most commonly used bolt materials?

A1. Due to their combination of affordability, strength, and durability, carbon steel and stainless steel are the most widely used materials for bolt manufacturing.

Q2. Which materials are ideal for high-temperature bolts?

A2. Inconel, Hastelloy, certain stainless steel grades (310, 321), and titanium alloys are best suited for high-temperature environments.

Q3. What does bolt grade signify?

A3. Bolt grade indicates the mechanical characteristics like tensile strength, yield strength, and hardness, helping to select the right fastener for specific applications.

Q4. How can I calculate bolt weight?

A4. Bolt weight is calculated based on its dimensions and material density. Bolt weight charts provide quick reference values.

Q5. Why is heat treatment crucial in bolt manufacturing?

A5. Heat treatment enhances bolt strength, hardness, and durability, making them suitable for demanding industrial applications.

#Bolts#Fasteners#BoltManufacturing#BoltGrades#BoltSpecifications#BoltMaterials#HighTemperatureBolts#IndustrialFasteners#EngineeringFasteners#Ananka#Anankafasteners#Linkedin#manufacturer#supplier

0 notes