#Advanced Environmental Laboratory Software

Explore tagged Tumblr posts

Text

EPA’s NLLAP Decoded: Achieve Compliance with Advanced Environmental Laboratory Software

Ensuring compliance with the EPA’s National Lead Laboratory Accreditation Program (NLLAP) is essential for laboratories conducting lead analysis in paint, dust, and soil. The EPA has released “Laboratory Quality Standards for Recognition (LQSR 4.0)” under the NLLAP, replacing LQSR 3.0 from 2007. Effective October 23, 2024, labs and accreditation bodies can follow either LQSR 3.0 or 4.0 until December 22, 2025. After that, compliance with LQSR 4.0 is mandatory for NLLAP recognition. Is your lab prepared for the new accreditation requirements?

Our latest blog, “EPA’s NLLAP Decoded: Achieve Compliance with Advanced Environmental Laboratory Software,” explores:

✓ The significance of NLLAP accreditation

✓ Key revisions in the 2024 NLLAP update

✓ Steps involved in NLLAP accreditation

✓ How laboratories can get ahead of NLLAP accreditation

✓ How a LIMS can help with NLLAP compliance

Read the Blog

0 notes

Text

🌟 Life at Sabaragamuwa University of Sri Lanka: A Journey Beyond Academics

🔗 Official Website: https://www.sab.ac.lk/

Nestled in the beautiful hill country of Belihuloya, the Sabaragamuwa University of Sri Lanka (SUSL) is not just an institution for higher education—it’s a complete ecosystem for knowledge, innovation, and personal growth. With a unique blend of nature, academic excellence, cultural diversity, and student engagement, SUSL has established itself as one of the most vibrant universities in Sri Lanka.

Let’s explore what makes this university a truly holistic learning experience.

🎓 Academic Excellence Through Diverse Faculties

SUSL houses several faculties, each tailored to deliver industry-relevant, research-based, and skill-oriented education. Here’s a deeper look:

🧑🌾 Faculty of Agricultural Sciences

Preparing students for climate-resilient and technology-driven agriculture, this faculty integrates practical fieldwork, lab-based research, and modern agritech practices.

Specialized areas: Agribusiness Management, Plantation Management, and Crop Science.

Facilities include a university farm, greenhouses, and plant tissue labs.

💼 Faculty of Management Studies

This faculty is a hub of innovation, leadership, and entrepreneurship.

Offers degrees in Marketing, Accounting, Business Management, and Tourism.

Strong industry links, internship programs, and a business incubation center help bridge theory and practice.

🖥️ Faculty of Computing

A newly established and rapidly growing faculty, offering degrees in cutting-edge areas like:

Software Engineering

Computer Science

Data Science

Information Systems Students benefit from modern computing labs, coding competitions, and project-based learning in collaboration with the tech industry.

⚙️ Faculty of Applied Sciences

Focused on STEM (Science, Technology, Engineering, Mathematics) education and research.

Departments include Physical Sciences, Environmental Sciences, and Biological Sciences.

Advanced laboratory facilities and field studies enhance hands-on learning.

🧪 Faculty of Geomatics

Unique to SUSL, this faculty specializes in geospatial technologies and earth sciences.

Offers degrees in Surveying Sciences and GIS (Geographic Information Systems).

Prepares students for careers in surveying, urban planning, disaster management, and remote sensing.

🌍 Faculty of Social Sciences & Languages

Equipping students to address social, cultural, economic, and political challenges through:

Degrees in Sociology, Political Science, and Languages (English, Sinhala, Tamil).

Cultural awareness programs, language labs, and public speaking forums.

🛠️ Faculty of Technology

Focusing on future-ready technology disciplines, including:

Biosystems Technology

Engineering Technology

Construction Technology

Mechatronics This faculty emphasizes problem-solving, research, and design thinking in all its programs.

🌱 A Campus That Breathes Sustainability

SUSL is set amidst lush greenery, forests, and a reservoir, promoting a deep respect for the environment.

Sustainable practices include rainwater harvesting, waste management, and plastic-free zones.

Nature trails, eco-clubs, and conservation projects give students opportunities to learn from nature while preserving it.

🧑🎓 Student Life: Balance Between Study and Fun

✨ Daily Life

Classes in the morning

Study groups under trees or by the lake

Canteen meals with friends

Sports and clubs in the evening

Quiet study or hostel activities at night

🌐 Cultural Diversity

With students from all over the island, SUSL celebrates:

Sinhala & Tamil New Year festivals

Multilingual debates

Intercultural nights and exhibitions This diversity builds respect, unity, and lifelong friendships.

🏆 Extra-Curricular Excellence

SUSL students shine beyond the classroom. The university supports:

Sports

Cricket, rugby, badminton, athletics, martial arts, and more

Regular inter-faculty competitions and national-level representation

Clubs & Societies

Gavel Club – for public speaking

IEEE & IT Clubs – for coding and tech

Environmental Society – for sustainability

Music, Dance, Drama Societies – for cultural expression

Rotaract & Leo Clubs – for leadership and volunteering

🏛️ Facilities & Campus Life

🏠 Hostels with a peaceful and secure environment

📚 A fully-equipped library with digital and physical resources

🧪 Modern laboratories and research centers

🍛 Affordable and clean canteens

🚌 Campus shuttle and scenic walking paths

🧑⚕️ Health Center with medical and counseling services

📶 Wi-Fi zones and tech support

🔮 Looking Ahead

Sabaragamuwa University is committed to global expansion and academic innovation:

Partnerships with international universities

Smart classrooms and e-learning systems

Plans for new faculties and programs

Research funding and student entrepreneurship support

💬 Final Words

Sabaragamuwa University of Sri Lanka is more than a place to earn a degree—it's a place to grow, lead, and inspire. From nature lovers to tech enthusiasts, from business leaders to language experts, SUSL has something for everyone.

✅ Visit the official website to explore more: https://www.sab.ac.lk/

— Written by Rashmi Tharaka Sewwandi

2 notes

·

View notes

Text

The Complete Guide to Hipot Testing: Standards, Procedures, and Best Practices

When working with electrical devices and components, ensuring safety isn't just recommended—it's absolutely critical. One of the most fundamental tests that every electrical engineer and technician should understand is hipot testing, also known as dielectric strength testing. This comprehensive guide will walk you through everything you need to know about this essential safety procedure.

What is Hipot Testing?

Hipot testing, short for "high potential testing," is a non-destructive test that verifies the electrical insulation in components, devices, and equipment. During this process, a high voltage is applied between a device's current-carrying conductors and its metallic shielding or ground to ensure that the insulation can withstand normal operating voltages without breaking down.

Think of it as a stress test for your electrical insulation. Just like you wouldn't want to discover a bridge's weakness during rush hour traffic, you don't want to find out about insulation failures when equipment is already in use. Hipot testing helps identify potential problems before they become dangerous or costly failures.

Why is Dielectric Strength Testing Critical?

The primary purpose of high voltage testing extends beyond simple compliance—it's about protecting both equipment and human lives. Poor insulation can lead to:

Electric shock hazards for operators and users

Equipment damage and costly downtime

Fire risks in manufacturing facilities

Legal liability issues for manufacturers

Regulatory compliance failures

Modern electrical safety testing has become increasingly sophisticated, with advanced electrical testing equipment capable of detecting even minor insulation weaknesses that might not be apparent during normal operation.

Key Standards Governing Hipot Testing

Several international standards govern hipot testing procedures, each designed for specific applications and industries:

IEC Standards

The International Electrotechnical Commission (IEC) provides comprehensive guidelines through various standards:

IEC 61010: Covers safety requirements for electrical equipment used for measurement, control, and laboratory use

IEC 60950: Focuses on information technology equipment safety

IEC 61000: Addresses electromagnetic compatibility requirements

UL Standards

Underwriters Laboratories (UL) standards are particularly important for North American markets:

UL 1998: Standard for software in medical devices

UL 2089: Covers health/wellness devices and systems

UL 991: Addresses environmental safety requirements

Other Important Standards

ANSI/AAMI ES60601: Medical electrical equipment standards

GB Standards: Chinese national standards for electrical safety

BS Standards: British standards for electrical testing procedures

Essential Equipment for Effective Testing

Selecting the right laboratory testing equipment is crucial for accurate and reliable results. A proper electrical safety tester should include:

Core Components

Variable AC/DC power supply: Capable of delivering test voltages from 100V to 5000V or higher

Current monitoring system: To detect breakdown conditions instantly

Timer function: For controlling test duration accurately

Ground fault detection: Essential safety feature for operator protection

Advanced Features

Modern electrical testing equipment often includes:

Programmable test sequences for consistency

Data logging capabilities for quality records

Remote control options for hazardous testing environments

Automatic discharge circuits for safety

Step-by-Step Testing Procedures

Proper hipot testing requires careful attention to detail and strict adherence to safety protocols. Here's a comprehensive procedure:

Pre-Test Preparation

Equipment inspection: Verify that all electrical safety testing equipment is calibrated and functioning correctly

Environmental check: Ensure testing area is clean, dry, and free from conductive materials

Documentation review: Confirm test specifications, voltage levels, and duration requirements

Safety verification: Check that all safety systems are operational

Test Execution

Initial setup: Connect the device under test to the electrical safety tester using appropriate fixtures

Voltage ramping: Gradually increase voltage to the specified test level (typically over 10-30 seconds)

Hold period: Maintain test voltage for the required duration (usually 1-60 seconds)

Current monitoring: Continuously monitor leakage current throughout the test

Voltage reduction: Slowly decrease voltage to zero before disconnecting

Post-Test Analysis

Record all test results including voltage levels, current readings, and test duration

Document any anomalies or failures observed during testing

Update equipment maintenance logs and calibration records

Common Challenges and Solutions

Even experienced technicians encounter challenges during dielectric strength testing. Here are some frequent issues and their solutions:

False Failures

Sometimes good products fail tests due to:

Moisture contamination: Ensure proper storage and handling of test samples

Surface contamination: Clean all surfaces before testing

Incorrect test parameters: Verify voltage levels and timing specifications

Inconsistent Results

When results vary between identical units:

Check electrical testing equipment calibration

Verify test fixture condition and connections

Review environmental conditions (temperature, humidity)

Ensure consistent handling procedures

Safety Concerns

High voltage testing inherently involves risks:

Always use proper safety equipment and procedures

Implement lockout/tagout procedures

Provide adequate training for all personnel

Maintain emergency response protocols

Best Practices for Reliable Results

Achieving consistent, reliable results requires attention to several key factors:

Equipment Maintenance

Regular maintenance of your laboratory testing equipment ensures accuracy and longevity:

Perform daily visual inspections

Conduct weekly calibration checks

Schedule annual comprehensive calibrations

Keep detailed maintenance records

Environmental Control

Testing conditions significantly impact results:

Maintain stable temperature (typically 23°C ± 2°C)

Control humidity levels (45-75% RH)

Minimize electromagnetic interference

Ensure adequate ventilation

Personnel Training

Proper training is essential for both safety and accuracy:

Provide comprehensive safety training

Ensure understanding of relevant standards

Regular refresher courses on procedures

Certification in electrical safety testing methods

Future Trends in Electrical Safety Testing

The field of electrical safety testing continues to evolve with technological advances:

Automation Integration

Modern facilities increasingly integrate automated testing systems that can:

Reduce human error in repetitive testing

Improve data collection and analysis

Enhance throughput in high-volume applications

Provide better traceability and documentation

Advanced Diagnostics

Newer electrical testing equipment incorporates sophisticated diagnostic capabilities:

Partial discharge detection for early fault identification

Frequency domain analysis for comprehensive insulation assessment

AI-powered result interpretation and trending

Conclusion

Hipot testing remains a cornerstone of electrical safety testing, protecting both products and people from the dangers of electrical failure. By understanding the proper procedures, selecting appropriate electrical safety tester equipment, and following established best practices, you can ensure reliable, accurate results that meet the highest safety standards.

Whether you're setting up a new testing laboratory or improving existing procedures, remember that investment in quality laboratory testing equipment and proper training pays dividends in safety, reliability, and regulatory compliance. The key to successful dielectric strength testing lies not just in following procedures, but in understanding the underlying principles and maintaining a commitment to continuous improvement.

As electrical devices become more complex and safety requirements more stringent, the importance of proper high voltage testing will only continue to grow. Stay current with evolving standards, invest in quality equipment, and never compromise on safety—your products, your customers, and your reputation depend on it.

#electrical safety testing#electrical testing#electrical testing equipment#laboratory testing equipment

0 notes

Text

Exploring the World of Online Engineering Courses

The field of engineering has long been a cornerstone of technological and societal advancement. As the demand for skilled engineers grows, so does the need for accessible and flexible learning platforms. Enter the realm of online engineering courses, which provide aspiring engineers the opportunity to achieve their academic and professional goals from the comfort of their homes. Whether you're looking to earn an online engineering degree or enroll in an online engineering program, there’s never been a better time to explore the possibilities.

The Evolution of Engineering Education

Traditionally, engineering education was confined to physical classrooms and laboratories. However, with the advent of technology, this dynamic has changed. Institutions like University Vidya have embraced digital platforms to offer comprehensive engineering bachelors online programs. These programs cater to individuals who seek flexibility without compromising on quality education.

Benefits of Online Engineering Programs

Flexibility and Convenience One of the most significant advantages of enrolling in an online engineering program is the flexibility it offers. Students can learn at their own pace, balancing studies with personal and professional commitments.

Diverse Learning Opportunities Online platforms host a variety of courses ranging from mechanical to civil and electrical engineering. With programs such as distance learning engineering, students have the freedom to choose from a wide range of specializations.

Accessible to All Geography is no longer a barrier to quality education. Whether you reside in a metropolitan city or a remote village, platforms like University Vidya ensure that you can pursue your dreams of earning an online engineering degree.

Choosing the Best Online Engineering Course

When selecting the right program, several factors should be considered:

Accreditation: Ensure that the program is accredited and recognized globally.

Curriculum: Look for courses that cover a broad spectrum of bachelor of engineering subjects.

Faculty Expertise: Opt for programs led by experienced educators.

University Vidya stands out as a reliable choice, offering some of the best engineering courses that are both innovative and industry-relevant.

Key Features of University Vidya’s Online Engineering Programs

Comprehensive Curriculum The programs include detailed engineering course details, covering theoretical knowledge and practical applications. Subjects range from advanced mathematics to cutting-edge technologies.

Interactive Learning Modules The courses integrate interactive tools such as video lectures, live sessions, and simulation software to enhance learning.

Global Networking Opportunities Students enrolled in distance engineering programs can connect with peers and professionals worldwide, broadening their horizons and expanding their professional networks.

Understanding the Structure of an Online Engineering Degree

An engineering bachelors online program typically spans three to four years, depending on the specialization. Core components include:

Foundational Subjects: Mathematics, physics, and chemistry.

Specialized Engineering Courses: Mechanical, civil, computer science, electrical, and more.

Project Work: Students undertake projects to apply theoretical knowledge in practical scenarios.

Internships: Although online, many programs facilitate virtual or on-site internships.

Popular Specializations in Online Engineering

Mechanical Engineering Focuses on designing and manufacturing machinery.

Civil Engineering Covers construction, infrastructure, and urban development.

Computer Engineering Combines software development with hardware integration.

Electrical Engineering Explores power systems, electronics, and telecommunications.

Environmental Engineering Aims to develop sustainable solutions to environmental challenges.

With University Vidya, students can choose from these top engineering courses and many more, tailoring their education to align with their career goals.

The Role of Distance Learning in Engineering Education

Engineering distance education has revolutionized how technical knowledge is imparted. Platforms offering distance learning engineering courses focus on providing hands-on experience through virtual labs and simulations.

University Vidya ensures that students pursuing distance engineering programs gain practical skills comparable to traditional classroom setups. This approach bridges the gap between theory and practice, preparing graduates for real-world challenges.

Success Stories: Alumni from University Vidya

Many graduates from University Vidya have shared their inspiring journeys of transitioning from students to successful professionals. The institution’s commitment to providing high-quality online engineering programs has been instrumental in shaping their careers.

One such success story is that of Ramesh Kumar, who completed his online engineering degree in computer engineering. Today, he works with a leading tech company, attributing his success to the strong foundation laid by University Vidya.

Advancing Your Career with an Online Engineering Degree

Earning an engineering bachelors online opens up numerous career opportunities. Graduates can work in:

Research and development

Design and manufacturing

Construction and infrastructure projects

IT and software development

Renewable energy and sustainability sectors

Moreover, employers now recognize the credibility of online engineering courses, understanding that these programs equip students with both technical and soft skills.

Why Choose University Vidya?

University Vidya has established itself as a pioneer in engineering distance education. Its programs are designed to meet industry standards, ensuring that graduates are job-ready. With a focus on innovation and quality, the institution has become synonymous with excellence in online engineering courses.

The journey to becoming an engineer has never been more accessible, thanks to online engineering programs. Whether you’re a working professional, a student in a remote area, or someone looking to switch careers, platforms like University Vidya offer a plethora of opportunities to help you achieve your goals. With courses covering extensive engineering course details and an emphasis on practical learning, the possibilities are limitless.

Embark on your journey today. Enroll in an online engineering course with University Vidya and take the first step toward a fulfilling and dynamic career in engineering.

0 notes

Text

Exploring Growth in the Global Sample Preparation Market

Meticulous Research®—a leading global market research company, published a research report titled ‘Sample Preparation Market Size, Share, Forecast & Trends Analysis by Product (Workstation, Pipette, Washer, Centrifuge, Grinder, Filters, Plates, Kits) Technique (Solid Phase Extraction, Purification), Application, End User – Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the sample preparation market is projected to reach $12.77 billion by 2031, at a CAGR of 6.4% during the forecast period. The growth of this market is driven by technological advances in sample preparation procedures, increasing process automation in laboratories, the development of bio clusters for supporting research activities, increasing R&D investments in the pharmaceutical and biotechnology industries, and active research in genomics and proteomics. Additionally, the widening applications of sample preparation in emerging economies and the increasing focus on personalized medicines are expected to offer significant market growth opportunities.

However, the high purchasing costs of automated sample preparation systems restrain the growth of this market. Additionally, the high costs of maintaining sample preparation systems pose a significant challenge to the market's growth.

Key Players

The key players operating in the sample preparation market are Agilent Technologies, Inc. (U.S.), Bio-Rad Laboratories, Inc. (U.S.), Danaher Corporation (U.S.), Illumina, Inc. (U.S.), Merck KGaA (Germany), Hamilton Company (U.S.), PerkinElmer, Inc. (U.S.), QIAGEN N.V. (Netherlands), F. Hoffmann-La Roche Ltd (Switzerland), Thermo Fisher Scientific Inc. (U.S.), Tecan Group Ltd. (Switzerland), Promega Corporation (U.S.), and Norgen Biotek Corp. (Canada).

Sample Preparation Reagents Market: Future Outlook

The sample preparation market is segmented based on product (Consumables [Sample preparation Kits & Reagents {Isolation Kits & Reagents (DNA Isolation Kits & Reagents, RNA Isolation Kits & Reagents, Protein Isolation Kits & Reagents), Extraction Kits & Reagents (DNA Extraction Kits & Reagents, RNA Extraction Kits & Reagents, Protein Extraction Kits & Reagents), Purification Kits & Reagents (DNA Purification Kits & Reagents, RNA Purification Kits & Reagents, Protein Purification Kits & Reagents), Other Reagents}, Filters, Tubes, Plates, Other Consumables], Instruments [Liquid Handling Systems {Automated Liquid Handling Robots/Systems, Manual Pipettes, Reagent Dispensers, Microplate Washers, Other Liquid Handling Systems}, Centrifuges, Filtration Systems, Extraction Systems, Purification Systems, Other Sample Preparations Systems], Workstations, Software), Technique (Solid Phase Extraction (SPE), Liquid Phase Extraction (LPE), Filtration, Dilution, Precipitation, Other Sample Preparation Techniques), Application (Drug Discovery, Diagnostics, Genomic Studies, Proteomic Studies, Analytical Testing, Other Applications), End User (Pharmaceutical & Biotechnology Companies, Contract Research Organizations (CRO), Academic & Research Institutes, Hospital & Diagnostics Laboratories, Food & Beverage Companies, Environmental Testing Laboratories, Other End Users), and geography. The study also evaluates industry competitors and analyzes the regional and country-level markets.

Based on the product, the sample preparation market is segmented into consumables, instruments, workstations, and software. In 2024, the consumables segment is expected to account for the largest share of the sample preparation market. Consumables include sample preparation kits & reagents, filters, plates, and others. Sample preparation kits, & reagents will help improve the quality of purification, isolations, and extractions, increasing the lab’s efficiency and decreasing sample variability. Hence, there will be an increase in the adoption of these kits while extracting or isolating the proteins or nucleic acids from the sample. Also, the new product launches will further contribute to the segment’s growth.

Based on the technique, the sample preparation market is segmented into Solid Phase Extraction (SPE), Liquid Phase Extraction (LPE), filtration, dilution, precipitation, and other sample preparation techniques. In 2024, the Solid Phase Extraction (SPE) segment is expected to account for the largest share of the sample preparation market. Solid phase extraction technique is widely used due to its rapid and selective sample preparation process. Due to its advantages, this technique has been adopted for various applications, including pharmaceutical compounds, drugs of abuse, environmental pollutants, pesticides, agriculture compounds, fractionation of lipids, desalting of proteins and peptides, and water, which contributes to the segment’s largest share.

Based on the applications, the sample preparation market is segmented into drug discovery, diagnostics, genomic studies, proteomic studies, analytical testing, and other applications. In 2024, the drug discovery segment is expected to account for the largest share of the sample preparation market. Higher demand for pharmaceutical and biopharmaceutical products, accelerated research in biopharmaceuticals, and high prevalence of infectious diseases and non-infectious diseases driving the need for innovative therapies is why there was a rise in the adoption of sample preparation products.

Based on the end user, the sample preparation market is segmented into Pharmaceutical & Biotechnology Companies, Contract Research Organizations (CROs), Academic & Research Institutes, Hospital & Diagnostics Laboratories, Food & Beverage Companies, Environmental Testing Laboratories, and Other End Users. In 2024, the pharmaceutical & biotechnology companies’ segment is expected to account for the largest share of the sample preparation market. The large market share of this segment is attributed to the increased adoption of sample preparation systems by pharmaceutical and biotechnology companies for various applications, including drug discovery, toxicology testing, and vaccine research. Furthermore, high spending on pharmaceutical R&D and a burden on pharmaceutical companies to introduce novel therapies to the market are driving the demand for sample preparation systems.

This research report analyzes major geographies and provides a comprehensive analysis of North America (U.S. and Canada), Europe (Germany, France, U.K., Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, India, and Rest of Asia-Pacific), Latin America, and the Middle East & Africa. In 2024, North America is expected to account for the largest share of the sample preparation market, followed by Europe and Asia-Pacific. Furthermore, in 2024, the U.S. is expected to be the largest market shareholder in North America. North America’s major market share is attributed to the highly developed healthcare infrastructure and the presence of major market players such as Thermo Fisher Scientific (U.S.), Danaher Corporation (U.S.), and Agilent Technologies, Inc. (U.S.).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5527

Key questions answered in the report:

Which are the high-growth market segments in terms of product, technique, application, end user, and region/country?

What was the historical market size for sample preparation across the globe?

What are the market forecasts and estimates for 2024–2031?

What are the major drivers, restraints, and opportunities in the global sample preparation market?

Who are the major players in the global sample preparation market?

What is the competitive landscape like, and who are the market leaders in the global sample preparation market?

What are the recent developments in the sample preparation market?

What strategies are adopted by the major players in the sample preparation market?

What are the geographical trends and high-growth regions/countries?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#SamplePreparationMarket#LabAutomation#LifeSciences#PharmaceuticalResearch#DiagnosticsMarket#SampleProcessing#HealthcareInnovation#Biotechnology#AnalyticalInstruments#MeticulousResearch

0 notes

Text

Global Metagenomic Sequencing Market is driven by Technological Advances

Metagenomic sequencing platforms enable comprehensive analysis of genetic material directly from environmental or clinical samples, bypassing the need for traditional culturing methods. These products include high-throughput DNA sequencers, library preparation kits, and bioinformatics software tailored for microbiome profiling, pathogen detection, and biodiversity assessment. Advantages such as unbiased community profiling, rapid turnaround times, and scalable workflows make metagenomic sequencing indispensable for research institutions, pharmaceutical developers, and diagnostic laboratories. The ability to detect novel organisms and antimicrobial resistance genes directly influences drug discovery, public health surveillance, and agricultural biosecurity initiatives. Growing concerns over emerging infectious diseases and the quest for precision medicine have intensified the need for Global Metagenomic Sequencing Market, driving investments in improved sample prep and cloud-based analytics. Ongoing market research into enhanced read lengths and error correction methods further bolsters confidence in metagenomic data for regulatory submissions. As sequencing costs decline and data interpretation tools mature, adoption is expanding across clinical and environmental applications, reshaping the industry’s market dynamics and enabling businesses to capture greater market share. Global metagenomic sequencing market size is expected to reach US$ 6.16 Bn by 2032, from US$ 1.96 Bn in 2025, exhibiting a compound annual growth rate (CAGR) of 17.8% during the forecast period.Key Takeaways Key players operating in the Global Metagenomic Sequencing Market are: -Illumina-QIAGEN-Thermo Fisher Scientific-Oxford Nanopore Technologies-BGI GroupThese market players leverage robust R&D pipelines to introduce next-generation sequencing instruments, advanced sample prep solutions, and AI-driven analysis software. Illumina’s NovaSeq series, QIAGEN’s QIAseq kits, Thermo Fisher’s Ion Torrent systems, Oxford Nanopore’s MinION platform, and BGI Group’s DNBSEQ instruments exemplify the competitive landscape. Through strategic collaborations, acquisitions, and co-development agreements, these companies aim to extend their product portfolios and strengthen service offerings. Their efforts are guided by comprehensive market research and detailed market reports, ensuring that portfolio expansions align with evolving customer demands and regulatory requirements. Continuous innovation in sequencing chemistries and data compression algorithms supports sustained revenue growth and reinforces their leading positions in the global industry.Rising awareness of the human microbiome’s role in health and disease is driving strong demand for metagenomic sequencing services. Healthcare providers and researchers seek detailed microbial profiles to inform personalized treatment plans, monitor therapeutic interventions, and detect pathogens in real time. Similarly, agricultural and environmental sectors adopt metagenomic workflows to optimize crop yields, assess soil health, and track pollutant-degrading bacteria. The convergence of big data analytics with advanced sample processing has unlocked new market opportunities across pharmaceuticals, diagnostics, and ecology. Growing investments in microbiome-based therapeutics and probiotic formulations further ignite demand.

‣ Get More Insights On: Global Metagenomic Sequencing Market

‣ Get this Report in Japanese Language: 世界のメタゲノムシーケンシング市場

‣ Get this Report in Korean Language: 글로벌메타게놈시퀀싱시장

‣ Resources- Global Metagenomic Sequencing: Unlocking the Secrets of Microbial Communities

0 notes

Text

Best Civil Engineering Colleges in Jaipur – Why SGVU Stands Out

When it comes to building a successful career in civil engineering, choosing the right college is the first and most crucial step. Jaipur, the capital city of Rajasthan, is not only known for its architectural heritage but also for its top engineering institutions. Among the many options available, Suresh Gyan Vihar University (SGVU) is widely recognized as one of the best civil engineering colleges in Jaipur, offering a blend of academic excellence, practical exposure, and industry-oriented learning.

Why Choose Civil Engineering in Jaipur?

Jaipur is rapidly developing with modern infrastructure, smart city projects, and expanding urban landscapes. This makes it an ideal hub for civil engineering students to learn and explore real-time projects. Civil engineering colleges in Jaipur are known for their advanced curriculum, experienced faculty, and excellent placement records. But one institution that consistently tops the list is SGVU.

Top Reasons Why SGVU is the Best Civil Engineering College in Jaipur

1. NAAC ‘A’ Grade Accredited University

SGVU is among the few private universities in Rajasthan to be awarded an 'A' grade by NAAC, ensuring high academic standards, world-class infrastructure, and innovative teaching methodologies.

2. Industry-Oriented Curriculum

The civil engineering program at SGVU is designed to bridge the gap between theoretical concepts and industry requirements. The university integrates project-based learning, internships, and industrial visits as part of the curriculum to enhance practical knowledge.

3. State-of-the-Art Laboratories and Infrastructure

SGVU boasts well-equipped laboratories for Structural Engineering, Geotechnical Engineering, Fluid Mechanics, and Environmental Engineering. Students have access to modern software tools like AutoCAD, STAAD Pro, and Primavera for design and analysis.

4. Highly Qualified Faculty

The Department of Civil Engineering at SGVU comprises experienced professors, researchers, and industry professionals who guide students with cutting-edge knowledge and real-world insights.

5. Strong Placement Support

SGVU has a dedicated Training & Placement Cell that connects students with top recruiters in construction, infrastructure, and consultancy firms. Renowned companies like L&T, Tata Projects, Shapoorji Pallonji, and Adani Group frequently recruit from SGVU.

6. Live Projects & Internships

SGVU encourages students to participate in live construction projects, government tenders, and smart city initiatives. These real-world experiences help students build strong portfolios and industry connections even before graduation.

7. Focus on Innovation & Research

With multiple MoUs signed with global universities and R&D centers, SGVU promotes research in sustainable construction, green buildings, and new materials, giving students an edge in emerging civil engineering domains.

Other Top Civil Engineering Colleges in Jaipur

While SGVU leads the way, here are a few other notable colleges offering civil engineering in Jaipur:

Malaviya National Institute of Technology (MNIT)

Poornima College of Engineering

JECRC University

Manipal University Jaipur

Rajasthan Technical University (RTU) affiliated colleges

Each of these has its merits, but SGVU stands out due to its holistic approach to civil engineering education and its commitment to shaping future-ready engineers.

Final Thoughts

If you are looking for the best civil engineering college in Jaipur that offers top-tier education, practical training, and great placement opportunities, Suresh Gyan Vihar University (SGVU) should be your top choice. With its modern infrastructure, experienced faculty, and focus on innovation, SGVU prepares students not just to succeed, but to lead in the civil engineering industry.

0 notes

Text

Top PET Preform Manufacturers India Leaders in Packaging Innovation

India has emerged as a global powerhouse in PET preform manufacturing, with top manufacturers leading the way in packaging innovation and sustainability. These industry leaders are known for their cutting-edge technology, precision engineering, and commitment to quality, catering to diverse sectors such as beverages, pharmaceuticals, cosmetics, and household products. By offering customized, eco-friendly, and cost-effective solutions, India’s PET preform manufacturers are setting new benchmarks in the global packaging industry. This blog explores the top PET preform manufacturers in India, highlighting their capabilities, production standards, and contributions to transforming the future of packaging with efficiency, reliability, and environmental responsibility at the core.

India’s PET Preform Industry A Rapidly Growing Sector

The pet preform manufacturers india industry in India has seen remarkable growth over the last decade, fueled by rising demand in beverage, pharma, and FMCG sectors. Indian manufacturers have scaled their operations using world-class machinery, automation, and R&D to deliver preforms that meet international standards. This growth is not only driven by domestic needs but also by increasing exports to Asia, Africa, and the Middle East. The Indian government’s support for manufacturing and sustainability further enhances the sector’s competitiveness. With a focus on innovation, Indian PET preform producers are now seen as reliable global partners for premium-quality packaging solutions.

Technology-Driven Manufacturing for Precision and Consistency

Top PET preform manufacturers in India leverage state-of-the-art injection molding machines, robotics, and advanced quality control systems to ensure consistency in weight, clarity, and dimensional accuracy. Automation plays a significant role in reducing human error and enhancing productivity. These technological investments allow for faster turnaround times and flexible production lines capable of handling custom specifications. From high-speed manufacturing units to integrated software monitoring, India’s leading manufacturers are setting a new standard for precision. This technical edge not only ensures product reliability but also improves efficiency across supply chains, benefiting both domestic clients and international buyers.

Customization Capabilities to Serve Diverse Industries

One of the defining strengths of Indian PET preform manufacturers is their ability to offer tailor-made solutions. Whether it’s neck size, weight variation, or specific color and resin requirements, manufacturers provide complete customization to meet client specifications. This versatility caters to a wide range of applications, including water, carbonated beverages, edible oils, cosmetics, and pharmaceuticals. The flexibility to create preforms suitable for unique bottle shapes or specialized storage conditions gives Indian manufacturers a competitive advantage. This adaptability ensures that businesses can maintain brand consistency, improve product protection, and respond swiftly to changing market trends.

Strict Quality Control and Global Certifications

India’s top PET preform manufacturers adhere to rigorous quality control standards and hold international certifications such as ISO 9001, FSSC 22000, and GMP. These manufacturers conduct in-depth testing at every stage of production—from raw material assessment to final product inspection. Parameters such as color uniformity, acetaldehyde content, and dimensional precision are meticulously checked to ensure flawless output. With dedicated in-house laboratories and real-time monitoring systems, Indian producers guarantee high-quality and safe packaging materials. Their commitment to quality has earned them long-standing trust among global brands, especially those in the food and pharmaceutical sectors where compliance is non-negotiable.

Eco-Friendly Practices and Sustainable Production

Sustainability is becoming a core priority for PET preform manufacturers in India. Many top companies are adopting green practices such as energy-efficient machinery, waste recycling systems, and the use of recycled PET materials. Lightweighting initiatives help reduce plastic usage without compromising performance. These sustainable innovations not only lower environmental impact but also reduce production costs for clients. Additionally, manufacturers focus on eco-friendly packaging designs that support recycling and reduce landfill waste. By integrating environmental responsibility into their operations, India’s PET preform leaders are playing a vital role in shaping the future of sustainable packaging worldwide.

Cost-Effectiveness and Competitive Advantage

One of the key reasons global buyers are turning to India for PET preform solutions is cost-effectiveness. Indian manufacturers offer high-quality preforms at competitive prices, thanks to efficient production systems, affordable labor, and access to raw materials. Bulk manufacturing capabilities and strategic supply chain management further drive down operational costs. Despite lower pricing, these companies maintain strict quality standards and fast turnaround times, making them highly attractive for both small-scale and large-scale packaging needs. This value-for-money proposition allows Indian PET preform suppliers to compete successfully in both domestic and international markets without compromising on excellence.

Export Excellence and Global Market Reach

India’s leading PET preform manufacturers have significantly expanded their international footprint, supplying to over 50 countries across the globe. Backed by strong logistics networks, adherence to international regulations, and superior product quality, they serve clients in Europe, the Middle East, Africa, and Southeast Asia. Export-driven growth is also supported by government incentives and trade agreements that encourage Indian companies to explore new markets. By participating in global packaging expos and forging strategic partnerships, these manufacturers continuously boost their brand visibility. Their global presence affirms India’s rising status as a trusted, innovative, and scalable PET preform production hub.

Conclusion

The top PET preform manufacturers in India are redefining the standards of packaging through innovation, quality, and sustainability. With state-of-the-art technology, strict quality control, and a customer-centric approach, these industry leaders cater to a wide range of sectors both locally and globally. Their ability to offer customized, cost-effective, and eco-friendly solutions positions India as a key player in the global packaging market. As demand for reliable and sustainable packaging continues to grow, India’s PET preform manufacturers stand ready to meet future challenges and opportunities, delivering excellence at every stage of the production and supply chain.

0 notes

Text

The laboratory analytical equipment market is at the heart of scientific innovation and critical decision-making across various industries. From pharmaceutical drug development and food safety to environmental monitoring and forensic investigations, these instruments enable accurate measurement, detection, and characterization of materials at the molecular level. As global industries embrace precision-driven operations, the reliance on sophisticated analytical tools is intensifying. The market is projected to grow steadily from 2025 to 2035, fueled by increased investments in R&D, evolving healthcare diagnostics, and a push toward automation and digital transformation in laboratories.

Market Overview

The laboratory analytical equipment market encompasses a broad array of instruments used to analyze chemical, biological, and physical properties of substances. These include chromatographs, spectrometers, microscopes, titrators, and thermal analyzers, among others. The market is witnessing robust growth, underpinned by expanding applications in clinical diagnostics, pharmaceuticals, biotechnology, environmental science, materials testing, and food quality control. Moreover, advancements in miniaturization, real-time analysis, and integrated software systems are transforming how labs conduct testing and generate data.

As laboratories modernize and automation becomes more accessible, there is a significant shift toward instruments that offer high throughput, improved accuracy, and reduced human error. This transformation is especially evident in the pharmaceutical and biotech sectors, where fast and precise results are essential to meet stringent regulatory requirements and competitive timelines.

Key Market Drivers

1. Rising Demand from the Healthcare and Pharmaceutical Sectors

The global focus on health and wellness, particularly in the aftermath of COVID-19, has intensified investments in clinical research and diagnostics. Laboratory analytical equipment plays a crucial role in drug development, biomarker analysis, genetic screening, and disease diagnostics. The rise of personalized medicine, which requires highly accurate molecular-level analysis, has further boosted demand for next-generation instruments.

2. Technological Advancements

Modern analytical instruments are being integrated with AI, machine learning, and cloud-based data management to facilitate smarter laboratories. These technologies enhance data interpretation, speed up workflows, and enable predictive analytics. Instruments such as automated mass spectrometers, high-resolution microscopes, and real-time PCR systems are examples of how technology is reshaping laboratory operations.

3. Regulatory and Quality Assurance Requirements

Industries such as pharmaceuticals, food and beverage, and chemicals are bound by strict quality assurance and compliance standards. Regulatory frameworks including GMP (Good Manufacturing Practices), ISO certifications, and FDA requirements demand precise and reproducible testing protocols. This has led to increased procurement of high-performance analytical tools to ensure product safety and regulatory compliance.

4. Growing Focus on Environmental Monitoring

With increasing global awareness around environmental pollution and climate change, demand for analytical tools in water, air, and soil testing has surged. Instruments like atomic absorption spectrometers and gas chromatographs are essential for detecting contaminants and ensuring adherence to environmental standards. Government agencies, academic institutions, and private organizations are expanding their monitoring efforts, contributing to market growth.

Market Segmentation

By Product Type:

Chromatography Systems: Widely used in pharmaceuticals and food testing for separating and identifying components of complex mixtures.

Spectroscopy Instruments: Include UV-Vis, NMR, and Mass Spectrometry; vital for quantitative and structural analysis.

Microscopes: Optical, electron, and atomic force microscopes enable visualization of micro and nano-scale structures.

Titrators and Electrochemical Analyzers: Used in chemical and petrochemical labs for quality control.

Thermal Analyzers: Employed in material science to study properties like melting point and heat capacity.

Others: Includes particle size analyzers, rheometers, and pH meters.

Among these, chromatography and spectroscopy dominate the market due to their extensive use in analytical laboratories and their ability to deliver comprehensive chemical profiles.

By End-user:

Pharmaceutical & Biotechnology Companies: The largest end-user segment, driven by the need for consistent product testing, formulation research, and regulatory validation.

Academic & Research Institutions: These entities drive innovation through basic and applied research across disciplines.

Environmental Testing Laboratories: Utilize analytical instruments for pollution monitoring, resource management, and sustainability studies.

Food & Beverage Industry: Instruments are employed to verify ingredient authenticity, detect adulteration, and comply with food safety regulations.

Chemical & Petrochemical Industry: Analytical tools are essential for monitoring process chemistry, ensuring product specifications, and improving production efficiency.

Clinical Diagnostics Laboratories: Use instruments for routine tests, infectious disease detection, and personalized diagnostics.

By Region:

North America: Leading the market due to strong R&D infrastructure, high healthcare expenditure, and early adoption of automation.

Europe: Driven by stringent quality regulations and a strong academic research base.

Asia Pacific: Fastest-growing region, supported by expanding pharmaceutical manufacturing, increased government investments in R&D, and growing academic initiatives in countries like China, India, and South Korea.

Latin America and MEA: Emerging regions showing growth due to improvements in healthcare access and environmental monitoring initiatives.

Emerging Trends

1. Automation and Smart Labs

Laboratories are increasingly embracing automation to improve efficiency and data accuracy. Robotic sample handlers, smart sensors, and automated titration systems are being integrated with software platforms to streamline workflows and reduce human error. Fully integrated labs capable of remote operation are becoming a reality.

2. Portable and Miniaturized Instruments

There is a growing demand for handheld or portable analytical devices in industries such as agriculture, environmental testing, and food safety. These instruments offer real-time results at the point of use, significantly speeding up decision-making processes.

3. Cloud Connectivity and Remote Monitoring

Instruments with cloud-based data storage and real-time monitoring features are revolutionizing laboratory data management. Scientists can now access, share, and analyze data remotely, improving collaboration and workflow continuity.

4. Green Laboratory Practices

Sustainability is gaining importance in laboratory operations. Equipment that reduces chemical usage, energy consumption, and waste generation is increasingly preferred. Manufacturers are also focusing on developing eco-friendly instruments and consumables.

Competitive Landscape

The market is moderately consolidated, with leading players focused on continuous innovation, global expansion, and strategic partnerships. Major players include:

Thermo Fisher Scientific Inc.

Agilent Technologies Inc.

Shimadzu Corporation

PerkinElmer Inc.

Waters Corporation

Bruker Corporation

Danaher Corporation (including Beckman Coulter and Sciex)

Metrohm AG

Horiba Ltd.

Hitachi High-Tech Corporation

These companies offer comprehensive product portfolios and frequently invest in R&D to improve instrument sensitivity, portability, and automation. Strategic acquisitions and collaborations are also common as companies seek to enter new markets or expand their technological capabilities.

Market Forecast and Outlook (2025–2035)

The global laboratory analytical equipment market is poised for strong, sustained growth over the next decade. As more industries integrate data-driven and evidence-based decision-making processes, the need for robust analytical infrastructure will only intensify. While developed markets will continue to invest in high-end instruments and digital integration, emerging economies will witness increased adoption due to improved funding and awareness.

By 2035, the market is expected to benefit from:

Widespread adoption of AI and big data tools in labs

Growing importance of regulatory compliance

Rapid technological innovation in sample preparation and real-time analysis

Expansion of testing applications in non-traditional fields such as nutraceuticals, cosmetics, and agriculture

Conclusion

The laboratory analytical equipment market is undergoing a profound evolution shaped by technological advancements, changing regulatory landscapes, and shifting scientific priorities. As laboratories worldwide seek faster, smarter, and greener solutions, the demand for next-generation analytical tools will continue to accelerate. The period between 2025 and 2035 will be pivotal in defining the market's future—marked by greater automation, decentralized testing, and cross-sector innovation.

0 notes

Text

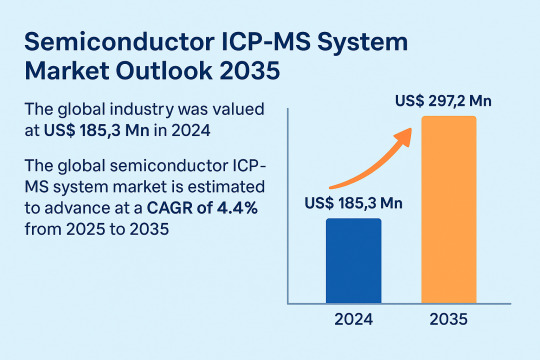

Semiconductor Industry Drives Growth in ICP-MS Systems Market

The semiconductor industry is entering a new era of complexity with shrinking device nodes, multilayered architectures, and growing sensitivity to material purity. In this evolving environment, Inductively Coupled Plasma Mass Spectrometry (ICP-MS) systems have become essential for semiconductor manufacturers. These systems provide high-resolution, multi-element analysis at ultra-trace levels, enabling manufacturers to detect and eliminate even minute contaminants during production.

Valued at US$ 185.3 Mn in 2024, the global semiconductor ICP-MS system market is projected to reach US$ 297.2 Mn by 2035, showcasing a robust CAGR of 4.4%. This growth is largely attributed to rising demand for advanced semiconductor manufacturing technologies, yield improvement measures, and regional investments in R&D.

Market Drivers & Trends

Increasing Focus on Yield Improvement and Defect Reduction As semiconductor devices become more complex and miniaturized, even the slightest impurity can result in performance degradation or device failure. ICP-MS systems enable trace-level detection of contaminants in raw materials, wafers, and finished chips. This precise analysis helps in reducing defects and improving overall production yields, which is crucial for applications in sectors such as automotive electronics, aerospace, and medical devices.

Rising Demand for Advanced Manufacturing Processes The global surge in 5G deployment, AI integration, electric vehicles, and consumer electronics demands highly efficient and pure semiconductor components. As a result, semiconductor fabs are investing in advanced analytical instrumentation like ICP-MS to support next-generation chip fabrication.

Regulatory Pressure & Environmental Monitoring With increasing global focus on environmental protection, the semiconductor industry is required to comply with stringent material safety and emission standards. ICP-MS systems are pivotal in this context, offering compliance assurance through accurate trace element detection.

Latest Market Trends

Shift Toward High-Resolution Systems: In 2024, High Resolution ICP-MS accounted for 54.1% of the market share and is expected to grow at a CAGR of 4.8%. These systems are highly valued for their enhanced sensitivity and ability to detect ultratrace elements critical to semiconductor reliability.

Process Automation and Smart Integration: Recent systems are being designed with enhanced software, automation, and remote monitoring features. This aligns with the semiconductor industry's push toward Industry 4.0 adoption and process optimization.

Triple Quadrupole ICP-MS Gaining Momentum: For applications involving complex matrices, Triple Quadrupole ICP-MS is emerging as a preferred solution due to its accuracy, lower detection limits, and interference removal capabilities.

Key Players and Industry Leaders

Key companies shaping the semiconductor ICP-MS system landscape include:

Agilent Technologies Inc.

Thermo Fisher Scientific Inc.

PerkinElmer Inc.

Shimadzu Corporation

Analytik Jena GmbH

Applied Spectra

Teledyne CETAC Technologies

Eurofins Scientific

Intertek Group, Inc.

Nu Instruments

Skyray Instruments USA, Inc.

These players are actively investing in product innovation, strategic collaborations, and R&D initiatives to strengthen their market presence.

Recent Developments

In October 2024, Thermo Fisher Scientific launched the iCAP MX Series ICP-MS, which includes single and triple quadrupole systems. Designed for environmental and industrial laboratories, these instruments improve trace element detection capabilities across various materials, supporting high-stakes applications including semiconductor fabrication.

Agilent Technologies continues to expand its modular platforms with enhanced software and data analytics tools to aid real-time quality monitoring in semiconductor manufacturing lines.

Gain a preview of important insights from our Report in this sample –

Market Opportunities

Emerging Applications in AI and EVs: As AI chips and EV power modules become mainstream, the need for ultra-clean, high-performance semiconductors will increase. ICP-MS systems are vital in ensuring the required material standards.

Integration with Smart Fab Technology: Growing interest in automated, sensor-driven semiconductor fabs presents opportunities for integrating ICP-MS systems into digital twins and predictive maintenance platforms.

Growth in Outsourced Semiconductor Manufacturing: The rise of fabless companies and semiconductor foundries is creating new demand for analytical instrumentation that supports cross-vendor process validation.

Future Outlook

Looking ahead, the semiconductor ICP-MS system market is expected to evolve in tandem with semiconductor technology advancements. Miniaturization trends, increasing need for zero-defect manufacturing, and regulatory compliance will drive long-term growth. Additionally, increased R&D activity in material science and nanotechnology will fuel innovation in ICP-MS instrumentation and applications.

Market Segmentation

The global market is segmented by:

Offering: Hardware (detector, pump, torch, cones), Software, and Services

Technology: Quadrupole Based ICP-MS, Multicollector ICP-MS, High Resolution ICP-MS, Single/Triple Quadrupole ICP-MS

Deployment: Benchtop, Floor-standing

Installation: Laboratory, Process

Application: Wafer, Slurry, Process Chemicals, Organic & Metal Analysis

End-use: Integrated Device Manufacturers (IDM), Foundries

Regional Insights

Asia Pacific leads the global market, accounting for 52.4% share in 2024, and is expected to maintain its dominance with a CAGR of 4.8%. Major semiconductor powerhouses such as Taiwan, South Korea, China, and Japan are driving this leadership through extensive production infrastructure and R&D investments.

North America: The presence of key industry players and innovation hubs makes it a significant contributor.

Europe: Countries like Germany and France are investing in local semiconductor production and analytical instrumentation.

Rest of World: Markets in ASEAN and India are emerging, driven by electronics demand and investment-friendly policies.

Why Buy This Report?

In-depth analysis of the global semiconductor ICP-MS system market dynamics, trends, and forecasts through 2035

Comprehensive company profiles and recent strategic developments

Regional and country-level market breakdowns

Technological segmentation and future outlook by deployment, application, and end-use

Insights into competitive landscape and market share by key players

Cross-segment and value chain analysis for informed decision-making

Frequently Asked Questions (FAQs)

Q1. What is the market size of the semiconductor ICP-MS system market in 2024? A1. The market was valued at US$ 185.3 Mn in 2024.

Q2. What is the projected market value by 2035? A2. It is expected to reach US$ 297.2 Mn by 2035.

Q3. What is the CAGR for the forecast period 2025–2035? A3. The market is projected to grow at a CAGR of 4.4%.

Q4. Who are the leading players in this market? A4. Major companies include Agilent Technologies, Thermo Fisher Scientific, PerkinElmer, and Shimadzu Corporation, among others.

Q5. Which region dominates the market? A5. Asia Pacific is the leading region, driven by strong semiconductor manufacturing activity.

Q6. What trends are shaping the market? A6. Trends include rising demand for high-resolution systems, smart fab integration, and increasing regulatory compliance needs.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Sabaragamuwa University

Sabaragamuwa University of Sri Lanka: A Beacon of Knowledge Amidst Nature Nestled in the serene landscapes of Belihuloya, the Sabaragamuwa University of Sri Lanka (SUSL) stands as a testament to academic excellence intertwined with natural beauty. Established in 1995, SUSL has evolved into a premier institution, fostering innovation, research, and holistic education.

A Glimpse into History SUSL's journey began in 1991 as the Sabaragamuwa Affiliated University College. By 1995, it achieved full university status, marking the inception of a new era in Sri Lankan higher education. Over the years, SUSL has expanded its academic horizons, embracing diverse disciplines and fostering a culture of research and community engagement.

Diverse Faculties Shaping Futures SUSL boasts a range of faculties, each dedicated to cultivating expertise and fostering innovation:

Faculty of Agricultural Sciences: Offers programs focusing on sustainable agriculture, agribusiness, and environmental management. Faculty of Applied Sciences: Provides courses in biological sciences, physical sciences, and computing, emphasizing practical applications. Faculty of Geomatics: Specializes in surveying sciences, GIS, and remote sensing, producing professionals adept in spatial data analysis. Faculty of Management Studies: Focuses on business management, marketing, finance, and tourism, preparing students for dynamic corporate environments. Faculty of Social Sciences and Languages: Explores disciplines like sociology, economics, and languages, promoting cultural understanding and social research. Faculty of Technology: Offers programs in biosystems and engineering technology, integrating modern technological advancements. Faculty of Computing: Established in 2022, this faculty addresses the growing demand for IT professionals, offering courses in software engineering and information systems. Faculty of Medicine: The latest addition, focusing on producing competent medical professionals through rigorous academic and clinical training. Campus Life: Learning Amidst Nature The SUSL campus is a harmonious blend of modern infrastructure and natural beauty. Surrounded by lush greenery and rolling hills, the environment fosters tranquility and inspiration. Students benefit from state-of-the-art facilities, including advanced laboratories, libraries, and recreational centers, all designed to enhance the learning experience.

Commitment to Research and Innovation SUSL is dedicated to advancing knowledge through research. The university encourages interdisciplinary studies, leading to innovations that address real-world challenges. Collaborations with national and international institutions further amplify its research impact, contributing significantly to various fields.

Vibrant Student Life Beyond academics, SUSL offers a vibrant student life. Numerous clubs, societies, and events provide platforms for students to explore interests, develop soft skills, and build lasting friendships. From cultural festivals to sports tournaments, the campus buzzes with activities that enrich the university experience.

Connect with SUSL Location: Sabaragamuwa University of Sri Lanka, P.O. Box 02, Belihuloya, 70140, Sri Lanka. Website: www.sab.ac.lk Contact: [email protected] Embark on a transformative educational journey at the Sabaragamuwa University of Sri Lanka, where knowledge meets nature, and dreams take flight.

1 note

·

View note

Text

✨Sabaragamuwa University of Sri Lanka:

A Beacon of Knowledge Amidst Nature

Nestled in the serene landscapes of Belihuloya, the Sabaragamuwa University of Sri Lanka (SUSL) stands as a testament to academic excellence intertwined with natural beauty. Established in 1995, SUSL has evolved into a premier institution, fostering innovation, research, and holistic education.

🕰️ A Glimpse into History

SUSL's journey began in 1991 as the Sabaragamuwa Affiliated University College. By 1995, it achieved full university status, marking the inception of a new era in Sri Lankan higher education. Over the years, SUSL has expanded its academic horizons, embracing diverse disciplines and fostering a culture of research and community engagement.

🎓 Diverse Faculties Shaping Futures

SUSL boasts a range of faculties, each dedicated to cultivating expertise and fostering innovation:

Faculty of Agricultural Sciences: Offers programs focusing on sustainable agriculture, agribusiness, and environmental management.

Faculty of Applied Sciences: Provides courses in biological sciences, physical sciences, and computing, emphasizing practical applications.

Faculty of Geomatics: Specializes in surveying sciences, GIS, and remote sensing, producing professionals adept in spatial data analysis.

Faculty of Management Studies: Focuses on business management, marketing, finance, and tourism, preparing students for dynamic corporate environments.

Faculty of Social Sciences and Languages: Explores disciplines like sociology, economics, and languages, promoting cultural understanding and social research.

Faculty of Technology: Offers programs in biosystems and engineering technology, integrating modern technological advancements.

Faculty of Computing: Established in 2022, this faculty addresses the growing demand for IT professionals, offering courses in software engineering and information systems.

Faculty of Medicine: The latest addition, focusing on producing competent medical professionals through rigorous academic and clinical training.

🌳 Campus Life: Learning Amidst Nature

The SUSL campus is a harmonious blend of modern infrastructure and natural beauty. Surrounded by lush greenery and rolling hills, the environment fosters tranquility and inspiration. Students benefit from state-of-the-art facilities, including advanced laboratories, libraries, and recreational centers, all designed to enhance the learning experience.

🔬 Commitment to Research and Innovation

SUSL is dedicated to advancing knowledge through research. The university encourages interdisciplinary studies, leading to innovations that address real-world challenges. Collaborations with national and international institutions further amplify its research impact, contributing significantly to various fields.

🏅 Vibrant Student Life

Beyond academics, SUSL offers a vibrant student life. Numerous clubs, societies, and events provide platforms for students to explore interests, develop soft skills, and build lasting friendships. From cultural festivals to sports tournaments, the campus buzzes with activities that enrich the university experience.

🌟 Connect with SUSL

Location: Belihuloya, Sri Lanka

Website: www.sab.ac.lk

Contact: [email protected]

Embark on a transformative educational journey at the Sabaragamuwa University of Sri Lanka, where knowledge meets nature, and dreams take flight.

1 note

·

View note

Text

Innovative ERP Software Tailored for Chemical Manufacturers in the UK

In the UK, the chemical manufacturing industry stands at a critical junction where innovation, regulatory compliance, and operational efficiency must work in harmony. Amid strict environmental regulations, complex formulations, and a volatile global supply chain, manufacturers need a standard digital software to attain their desired goal.

A tailored ERP Software can be considered a smart software choice to overcome supply chain challenges, ensure compliance, meet safety, and optimize inventory.

This blog will delve into how modern ERP systems are transforming the way chemical manufacturers in the UK manage everything from formulations and batch production to regulatory compliance and sustainability reporting.

The UK Speciality Chemicals Landscape: Evolving, Complex, Crucial

The chemical manufacturers in the current era must navigate:

Stricter sustainability targets under the UK’s net-zero roadmap.

Global supply chain volatility and geopolitical risks.

Stringent regulatory environments (such as GHS, REACH, Chemical Act, GLP Directive) need effective documentation and traceability.

Demand for innovation in developing and launching new, greener chemical formulations quickly and safely.

These factors contribute to an increasingly complex environment where traditional, non-specialized ERP systems can not fit in.

Why Doesn’t a Generic ERP Fit in?

Generic ERP systems can cover basic functions like basic inventory management and more. Still, an ERP software specific to the chemical industry functions and requirements can fulfil peculiar needs and solve unique challenges promptly. Some of these challenges are:

Formulation Control

The ability to manage and revise multiple versions of chemical recipes while tracking chemical properties, density, viscosity, etc.

Lot Traceability

Full visibility of raw materials and intermediates throughout the production cycle is critical for quality assurance and compliance.

Laboratory Integration

Without direct integration with lab instruments and QC workflows, efforts toward innovation, sustainability, and quality remain fragmented, leading to inefficiencies, increased risk of errors, and missed opportunities for continuous improvement.

Features of an Industry-specific ERP Software for Chemical

An industry-specific ERP software for chemical manufacturing efficiency provides features like:

Advanced Formulation Management

Maintain version control for multiple formula revisions

Perform built-in checks for regulatory compliance and allergens

Support for formula-specific parameters such as potency, density, pH, and more

Ensure formula security to protect intellectual property rights Comprehensive Lot Traceability

End-to-end tracking of raw materials, intermediates, co-products, and by-products

Full audit trail and lot genealogy for rapid recall management and regulatory audits

Supports bi-directional lot tracking across the supply chain and production Real-Time Costing

Monitor & analyse actual versus standard costs throughout the production cycle

Perform cost breakdowns by material, labour, overheads, and packaging

Drive continuous improvement through actionable insights Built-in Compliance & Safety Management

Automated creation and management of Safety Data Sheets (SDS) and GHS labels

Supports UK and EU chemical regulations, including REACH, Chemicals Act, and other standards

Features for HAZMAT handling, SARA compliance, and transport labelling Sustainability Tracking

Track carbon footprint at the batch level

Record and analyse waste output Quality Control

Pre-process, in-process, post-process and Inventory QC

User defined as well as Double sampling and testing, pass/fail/alphanumeric/numeric test types Mobile Access & Remote Monitoring

Access dashboards and KPIs on the go via mobile devices

Real-time alerts for production deviations and quality incidents

Role-based interfaces tailored to production, QA, and compliance teams

Why Now is the Time to Act!

For UK-based chemical manufacturers, digital transformation is no longer optional, it’s a strategic imperative. Implementing a specialised Chemical Manufacturing ERP software like BatchMaster ERP enables manufacturers to stay competitive and resilient in a rapidly evolving industry. BatchMaster ERP delivers robust capabilities in formulation management, ensures compliance with UK and international regulatory standards, and offers real-time insights into both production and financial performance. Whether you are a mid-sized operation or a growing enterprise, BatchMaster ERP lays a strong digital foundation to drive innovation, enhance operational efficiency, and support sustainable long-term growth.

To explore the advantages of ERP for speciality chemicals, read our blog: Software Solutions for Speciality Chemical

0 notes

Text

Latin America NGS Market Demand and Forecast Analysis

Meticulous Research®—a leading global market research company, published a research report titled, "Latin America NGS Market by Offering (Kits [Library Prep, QC, DNA Extraction], System) Type (Genome, Exome, Targeted) Application (Reproductive, Oncology, Infectious, Drug Discovery) Technology (SBS, Nanopore, Nanoball, SMRT Seq, DNB) - Forecast to 2032."

According to this latest publication from Meticulous Research®, the Latin America NGS market is expected to reach $765.2 million by 2032, at a CAGR of 13.9% from 2025 to 2032. The growth of the Latin America NGS market can be attributed to various factors, including the increasing initiatives by governments and organizations for genomic sequencing projects, advancements in sequencing procedures, decreasing costs of genome sequencing, a rise in cancer prevalence, and the expanding application of NGS in cancer treatment and research. However, the high costs of NGS systems and consumables and the availability of alternative technologies restrain the market's growth.

The rising adoption of bioinformatics and genomic data management solutions, as well as collaborations and partnerships to support next-generation sequencing, are expected to create market growth opportunities. However, the lack of skilled professionals and ethical and legal issues related to NGS-based diagnosis pose a significant challenge to the market's growth.

Key Players

The key players profiled in the Latin America NGS market report are Thermo Fisher Scientific Inc. (U.S.), Illumina, Inc. (U.S.), Qiagen N.V. (Netherlands), F. Hoffmann-La Roche Ltd (Switzerland), PerkinElmer, Inc. (U.S.), Agilent Technologies, Inc. (U.S.), Danaher Corporation (U.S.), Bio-Rad Laboratories, Inc. (U.S.), Oxford Nanopore Technologies Plc. (U.K.), and 10X Genomics, Inc. 2(U.S.).

Latin America NGS Market: Future Outlook