#Advanced Process Control (APC) in semiconductors

Explore tagged Tumblr posts

Text

Machine learning applications in semiconductor manufacturing

Machine Learning Applications in Semiconductor Manufacturing: Revolutionizing the Industry

The semiconductor industry is the backbone of modern technology, powering everything from smartphones and computers to autonomous vehicles and IoT devices. As the demand for faster, smaller, and more efficient chips grows, semiconductor manufacturers face increasing challenges in maintaining precision, reducing costs, and improving yields. Enter machine learning (ML)—a transformative technology that is revolutionizing semiconductor manufacturing. By leveraging ML, manufacturers can optimize processes, enhance quality control, and accelerate innovation. In this blog post, we’ll explore the key applications of machine learning in semiconductor manufacturing and how it is shaping the future of the industry.

Predictive Maintenance

Semiconductor manufacturing involves highly complex and expensive equipment, such as lithography machines and etchers. Unplanned downtime due to equipment failure can cost millions of dollars and disrupt production schedules. Machine learning enables predictive maintenance by analyzing sensor data from equipment to predict potential failures before they occur.

How It Works: ML algorithms process real-time data from sensors, such as temperature, vibration, and pressure, to identify patterns indicative of wear and tear. By predicting when a component is likely to fail, manufacturers can schedule maintenance proactively, minimizing downtime.

Impact: Predictive maintenance reduces equipment downtime, extends the lifespan of machinery, and lowers maintenance costs.

Defect Detection and Quality Control

Defects in semiconductor wafers can lead to significant yield losses. Traditional defect detection methods rely on manual inspection or rule-based systems, which are time-consuming and prone to errors. Machine learning, particularly computer vision, is transforming defect detection by automating and enhancing the process.

How It Works: ML models are trained on vast datasets of wafer images to identify defects such as scratches, particles, and pattern irregularities. Deep learning algorithms, such as convolutional neural networks (CNNs), excel at detecting even the smallest defects with high accuracy.

Impact: Automated defect detection improves yield rates, reduces waste, and ensures consistent product quality.

Process Optimization

Semiconductor manufacturing involves hundreds of intricate steps, each requiring precise control of parameters such as temperature, pressure, and chemical concentrations. Machine learning optimizes these processes by identifying the optimal settings for maximum efficiency and yield.

How It Works: ML algorithms analyze historical process data to identify correlations between input parameters and output quality. Techniques like reinforcement learning can dynamically adjust process parameters in real-time to achieve the desired outcomes.

Impact: Process optimization reduces material waste, improves yield, and enhances overall production efficiency.

Yield Prediction and Improvement

Yield—the percentage of functional chips produced from a wafer—is a critical metric in semiconductor manufacturing. Low yields can result from various factors, including process variations, equipment malfunctions, and environmental conditions. Machine learning helps predict and improve yields by analyzing complex datasets.

How It Works: ML models analyze data from multiple sources, including process parameters, equipment performance, and environmental conditions, to predict yield outcomes. By identifying the root causes of yield loss, manufacturers can implement targeted improvements.

Impact: Yield prediction enables proactive interventions, leading to higher productivity and profitability.

Supply Chain Optimization

The semiconductor supply chain is highly complex, involving multiple suppliers, manufacturers, and distributors. Delays or disruptions in the supply chain can have a cascading effect on production schedules. Machine learning optimizes supply chain operations by forecasting demand, managing inventory, and identifying potential bottlenecks.

How It Works: ML algorithms analyze historical sales data, market trends, and external factors (e.g., geopolitical events) to predict demand and optimize inventory levels. Predictive analytics also helps identify risks and mitigate disruptions.

Impact: Supply chain optimization reduces costs, minimizes delays, and ensures timely delivery of materials.

Advanced Process Control (APC)

Advanced Process Control (APC) is critical for maintaining consistency and precision in semiconductor manufacturing. Machine learning enhances APC by enabling real-time monitoring and control of manufacturing processes.

How It Works: ML models analyze real-time data from sensors and equipment to detect deviations from desired process parameters. They can automatically adjust settings to maintain optimal conditions, ensuring consistent product quality.

Impact: APC improves process stability, reduces variability, and enhances overall product quality.

Design Optimization

The design of semiconductor devices is becoming increasingly complex as manufacturers strive to pack more functionality into smaller chips. Machine learning accelerates the design process by optimizing chip layouts and predicting performance outcomes.

How It Works: ML algorithms analyze design data to identify patterns and optimize layouts for performance, power efficiency, and manufacturability. Generative design techniques can even create novel chip architectures that meet specific requirements.

Impact: Design optimization reduces time-to-market, lowers development costs, and enables the creation of more advanced chips.

Fault Diagnosis and Root Cause Analysis

When defects or failures occur, identifying the root cause can be challenging due to the complexity of semiconductor manufacturing processes. Machine learning simplifies fault diagnosis by analyzing vast amounts of data to pinpoint the source of problems.

How It Works: ML models analyze data from multiple stages of the manufacturing process to identify correlations between process parameters and defects. Techniques like decision trees and clustering help isolate the root cause of issues.

Impact: Faster fault diagnosis reduces downtime, improves yield, and enhances process reliability.

Energy Efficiency and Sustainability

Semiconductor manufacturing is energy-intensive, with significant environmental impacts. Machine learning helps reduce energy consumption and improve sustainability by optimizing resource usage.

How It Works: ML algorithms analyze energy consumption data to identify inefficiencies and recommend energy-saving measures. For example, they can optimize the operation of HVAC systems and reduce idle time for equipment.

Impact: Energy optimization lowers operational costs and reduces the environmental footprint of semiconductor manufacturing.

Accelerating Research and Development

The semiconductor industry is driven by continuous innovation, with new materials, processes, and technologies being developed regularly. Machine learning accelerates R&D by analyzing experimental data and predicting outcomes.

How It Works: ML models analyze data from experiments to identify promising materials, processes, or designs. They can also simulate the performance of new technologies, reducing the need for physical prototypes.

Impact: Faster R&D cycles enable manufacturers to bring cutting-edge technologies to market more quickly.

Challenges and Future Directions

While machine learning offers immense potential for semiconductor manufacturing, there are challenges to overcome. These include the need for high-quality data, the complexity of integrating ML into existing workflows, and the shortage of skilled professionals. However, as ML technologies continue to evolve, these challenges are being addressed through advancements in data collection, model interpretability, and workforce training.

Looking ahead, the integration of machine learning with other emerging technologies, such as the Internet of Things (IoT) and digital twins, will further enhance its impact on semiconductor manufacturing. By embracing ML, manufacturers can stay competitive in an increasingly demanding and fast-paced industry.

Conclusion

Machine learning is transforming semiconductor manufacturing by enabling predictive maintenance, defect detection, process optimization, and more. As the industry continues to evolve, ML will play an increasingly critical role in driving innovation, improving efficiency, and ensuring sustainability. By harnessing the power of machine learning, semiconductor manufacturers can overcome challenges, reduce costs, and deliver cutting-edge technologies that power the future.

This blog post provides a comprehensive overview of machine learning applications in semiconductor manufacturing. Let me know if you’d like to expand on any specific section or add more details!

#semiconductor manufacturing#Machine learning in semiconductor manufacturing#AI in semiconductor industry#Predictive maintenance in chip manufacturing#Defect detection in semiconductor wafers#Semiconductor process optimization#Yield prediction in semiconductor manufacturing#Advanced Process Control (APC) in semiconductors#Semiconductor supply chain optimization#Fault diagnosis in chip manufacturing#Energy efficiency in semiconductor production#Deep learning for semiconductor defects#Computer vision in wafer inspection#Reinforcement learning in semiconductor processes#Semiconductor yield improvement using AI#Smart manufacturing in semiconductors#AI-driven semiconductor design#Root cause analysis in chip manufacturing#Sustainable semiconductor manufacturing#IoT in semiconductor production#Digital twins in semiconductor manufacturing

0 notes

Text

Optimizing Semiconductor Manufacturing with Nav Sooch: Proven Tips for Efficiency

In the highly competitive world of semiconductor manufacturing, optimizing efficiency is paramount for success. One key aspect that plays a crucial role in this endeavor is the streamlined management of the supply chain. A well-organized supply chain ensures that raw materials are readily available, reducing downtime and minimizing production delays.

Nav Sooch highlights that to achieve an efficient supply chain, it's essential to foster strong relationships with suppliers and implement real-time monitoring systems. Utilizing advanced technologies such as IoT sensors and RFID tags allows for precise tracking of inventory levels, enabling manufacturers to make data-driven decisions and maintain optimal stock levels. Additionally, embracing a data-driven approach facilitates predictive maintenance, helping identify potential issues before they disrupt the production process. By adopting these strategies, semiconductor manufacturers can enhance their supply chain management, ultimately boosting overall operational efficiency.

Implementing Advanced Process Control Techniques

Nav Sooch calls attention to the fact that efficient semiconductor manufacturing heavily relies on the implementation of advanced process control (APC) techniques. APC involves utilizing real-time data and analytics to monitor and adjust manufacturing processes, ensuring they operate within specified parameters. This proactive approach minimizes deviations and enhances overall process stability.

One crucial aspect of APC is the integration of machine learning algorithms and artificial intelligence (AI) into the manufacturing processes. These technologies enable the system to learn from historical data and adapt to changing conditions, optimizing performance over time. By continuously refining and adjusting production parameters based on real-time data, semiconductor manufacturers can achieve higher yields, reduce defects, and enhance the overall quality of the final products. The implementation of APC not only improves efficiency but also contributes to cost reduction and increased competitiveness in the semiconductor market.

Investing in Automation for Semiconductor Manufacturing

Nav Sooch brings to light that automation has emerged as a game-changer in semiconductor manufacturing, offering unparalleled efficiency and precision. Investing in advanced robotic systems and automated processes can significantly reduce manual labor requirements, minimize errors, and increase overall production speed.

Incorporating robotics into tasks such as material handling, testing, and packaging can lead to substantial time savings. Furthermore, automation ensures consistency in manufacturing processes, eliminating the variability introduced by human factors. This not only enhances efficiency but also contributes to the production of higher-quality semiconductor products.

Moreover, the integration of automation is not limited to the production floor. Implementing automated data analysis tools and systems for performance monitoring allows for real-time insights, enabling quick decision-making and prompt responses to potential issues. By embracing automation, semiconductor manufacturers can create a more agile and responsive production environment, ultimately optimizing efficiency.

Embracing Sustainable Practices for Environmental and Operational Efficiency

In the contemporary semiconductor industry, optimizing efficiency goes hand in hand with adopting sustainable practices. Beyond meeting regulatory requirements, a commitment to environmental responsibility can enhance both operational efficiency and corporate reputation. One proven approach is to implement energy-efficient technologies and processes throughout the manufacturing facility.

Nav Sooch emphasizes the point that switching to energy-efficient equipment, such as advanced cooling systems and smart lighting, not only reduces environmental impact but also lowers operational costs. Additionally, integrating renewable energy sources, such as solar panels, into the manufacturing facility can contribute to long-term sustainability and decrease dependence on traditional energy grids.

Furthermore, optimizing water usage and waste management practices can have a significant impact on operational efficiency. Implementing closed-loop water recycling systems and waste reduction initiatives not only benefits the environment but also streamlines manufacturing processes. This dual-focus on sustainability and operational efficiency positions semiconductor manufacturers as responsible industry leaders.

Continuous Workforce Training and Development

A highly skilled and knowledgeable workforce is a cornerstone of efficient semiconductor manufacturing. To ensure that employees are well-equipped to handle the latest technologies and processes, continuous training and development programs are essential.

Investing in training programs that focus on the latest advancements in semiconductor manufacturing technology allows employees to stay abreast of industry trends. Cross-training employees in multiple aspects of the production process enhances flexibility, enabling them to adapt to changing production demands seamlessly.

Additionally, fostering a culture of innovation and continuous improvement among the workforce encourages employees to proactively identify and implement efficiency-enhancing measures. Regular skill assessments, workshops, and knowledge-sharing sessions contribute to a dynamic and well-informed workforce, further optimizing semiconductor manufacturing efficiency.

Optimizing efficiency in semiconductor manufacturing is a multifaceted endeavor that demands a comprehensive approach. The strategies outlined above – streamlining supply chain management, implementing advanced process control techniques, investing in automation, embracing sustainable practices, and prioritizing continuous workforce training and development – collectively contribute to a more streamlined and efficient production process.

Nav Sooch gives prominence to the fact that by cultivating strong relationships with suppliers, integrating cutting-edge technologies, and automating various aspects of manufacturing, semiconductor companies can not only enhance their operational efficiency but also stay ahead in a fiercely competitive industry. Sustainable practices not only benefit the environment but also lead to cost savings and heightened corporate responsibility. Furthermore, a skilled and adaptable workforce that undergoes continuous training is an invaluable asset, ensuring that the human element remains at the forefront of innovation and efficiency.

Ultimately, the success of semiconductor manufacturing optimization lies in the integration of these strategies into a cohesive and well-coordinated approach. As the industry continues to evolve, companies that proactively adopt these proven tips will not only achieve higher levels of efficiency but also position themselves as leaders in the ever-changing landscape of semiconductor manufacturing.

0 notes

Text

Automation Market - Forecast (2022-2027)

Automation Market is projected to reach $136.5 billion by 2026 growing at 3.7% CAGR during 2021-2026. Automation is a technology, which involves the usage of automated equipment or machines in various industries to reduce or eliminate human efforts, and increase the efficiency of work in a short period of time. In automation, the manufacturing and industrial sector is growing at a rapid rate and has led to the advancement of technology such as distributed production by factories and services, the implementation of autonomous plants, and the increasing use of remote operations to automate certain operations. Thus, the graph shows the technological, political, and economic development of the automation. Most of the European countries are heading towards innovation and are facing challenges like lack of skilled labor, but the development of automation companies promotes the production efficiency and empowers rapid economic growth. Most countries are seeking ways to enhance their manufacturing industry and most of the automation solution providers for Programmable Logic Controller, Distributed Control System, Supervisory control and data acquisition are seeking to improve the customer experience, which will be based on the new research from Information Services Group (ISG). For example, the implementation of the new policies and regulations such as EU ePrivacy Regulation.

Report Coverage

The report: “Automation Market Report– Forecast (2021-2026)”, byIndustryARCcovers an in-depth analysis of the following segments of the Automation Market

By Instrument Type: Humidity Transmitter, Temperature Transmitter, Pressure Transmitter, Level Transmitter, Control Valves, Analyzers, Communication Hardware and Others.

By Solution: PLC, DCS, MES, SCADA, APS, OTS, Safety Automation and Others.

By Industry Vertical: Process (Oil and Gas, Chemical, Pharmaceutical, Food and Beverage, Metal and Mining, Power, Pulp and Paper, Water and Wastewater and Others), Discrete (Automotive, Aerospace, Medical, Packaging, Industrial Machinery, Semiconductor and Electronics and Others).

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

The use of the advanced software can help in providing flexibility in terms of programming, large memory capacity, better interoperability, and incorporates more features and functions that are suitable for industry applications.

The demand for PLC system is rising owing to its huge applications in complex automation having extensive process control requirements, network connectivity, device interoperability, enterprise data integration, and many more.

The adoption of SCADA in various industries has accelerated owing to its various advantage consisting of updating and upgrading through cloud, easy retrieval of files, and many more.

The use of the MES is observed in many industries such as pharmaceuticals, consumer packaged goods, automotive industry, and many others. The major driving forces for utilizing MES includes development in the production systems, modern logistic concepts, and advanced product development processes.

Automation Market Segment Analysis - By Solution

Programmable logic control is an integration of PC and PLC in a single system to control various processes in industries and is projected to reach $15.9 billion by 2026. This controller comprises of two or more processors, PC-based software applications such as HMI (human machine interface) functions, asset management, historian, advanced process control (APC) and others with PLC capabilities. This system can handle both analog and digital signal as it does not incorporate ladder logic in its programmable interface. This controller is multifunctional, controlling various types of signals, multitasking, controlling, contributing, communicating with various clients, reading and writing to system devices, and many more functions can be performed simultaneously. Multi-domain as the same hardware is opted for data collection, process control, and hybrid manufacturing among others. The new development in PLC is the software can be easily customized according to the requirements. This software incorporates standard communication that assists in transfer of information from various connected systems. This advancement in technology can be beneficial for production and product flexibility in many industries.

Inquiry Before Buying

Automation Market Segment Analysis – By Industry Vertical

In the pharmaceutical industry, automation helps to ensure that a consistency is maintained in each batch of production. It also offers better control of the processes, providing an ability to monitor the processes from remote locations. This increases the demand of automation in the pharma industry. In the pharma industry, the usage of liquid handling robots to improve reproducibility and increase the validity of data in High Throughput Screening (HTS) is one of the developed technology. This is because the automated systems are less likely to have inconsistency in reagent quantities and HTS is a fairly consistent and repetitive process. In Russia, high domestic political motivation for investment and high oil prices ensured fairly good growth rates in most of the industries. Investors are striving to use the favorable situation to the fullest extent and build future-oriented businesses. This is why investments into high-tech industries and industrial automation increased more rapidly. The automation in pharmaceutical market is estimated to grow at a CAGR of 5.9% during the forecast period 2021–2026.

Automation Market Segment Analysis - By Geography

APAC is among the major regions, which has been driving the Automation Market accounting for 36.2% share in 2020. In Europe, the number of rig count is decreasing drastically from year to year. The number of rig count decreased from 117 to 85 between 2015 to 2018. Even though, there was a decrease in rig count, technology development and implementation of automation has been increasing. This combined with the stabilizing of oil and gas industry prior to Covid-19 will spur the market growth especially in APAC region. With automation, oil and gas companies are increasingly able to keep track of their pipes and networks with an extraordinary amount of oversight. Development in technologies such as using autonomous underwater vehicles and unmanned aerial vehicles, onshore and offshore pipelines is being done to protect against terrorist attacks, criminal activities, and even repair damages. Meanwhile, weather monitoring systems can be used to detect changes in seismic activity, as well as ocean and atmospheric levels.

Schedule a Call

Automation Market Drivers

Industry 4.0 Revolution in the Manufacturing Sector

Industry 4.0 revolution creates smart automation in the phase of industrialization. Increasing demand for machines in the manufacturing sector is set to push the Automation Market to new heights. Implementation of automation in industries results in many benefits such as productivity gains, improved team performance, enhanced managerial reporting, error reduction, cost reduction, and higher quality. The growing need to achieve process optimization in lesser time in the industrial operations coupled with various government initiatives to adopt automation is driving the Automation Market. Azerbaijan is planning to invest more in automotive industry which is expected to drive the deployment of automation and controls in this country. Along with the increasing investments in automotive industry it is also observed that the key players in oil and gas and utility sector are planning for the up gradation of the manufacturing units which is expected to drive Automation Market. Rising rate of the population entering the middle and upper classes is increasing the consumption at consumer's end and allowing industries to implement automation to maintain or enhance their production output, thus, enlarging the growth of the market.

Reduction of Operating Costs with the advent of IoT

The main motivation for mechanization of IoT is to suggestively decrease functioning expenditures when automation devices, sensors, transmitters, and actuators are converted to internet enabled devices. The labor cost is highly significant in the total industrial operating cost, making generally 60%–65% of the total cost. In majority of the cases, manual jobs typically consist of two categories, direct staff and indirect staff. Direct staff is responsible for executing the process, while indirect staff is for the backend support for direct staff. In developing nations, there is a constant growth in ageing workforce resulting in issues related to safety, quality control, and productivity. Thus, the automation of industries has become a notable means to tackle the rising wages and workforce age. This has resulted in the industrial operators to rely upon automation to provide a convenient and efficient way of reducing the operational costs, while simultaneously maintaining the productivity at optimum levels.

Buy Now

Automation Market Challenges

High Initial Investment

Automated machines can be one of the most costly operating costs for a company. With automated machines running anywhere between thousands and millions of dollars depending on the type and degree of automation. Apart from the initial costs there might be several unpredictable costs which may surpass the real cost saved by the accomplishing automation in the company. Some of these costs includes research and development costs of automating a process and anticipatory repairs and maintenance costs. In addition to the above mentioned costs, there is a training cost associated with the automated machines and equipment that further restricts the industrial operators’ likeability in developing economies for automating their operating lines.

Automation Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Automation Market. Automation top 10 companies include Honeywell International Inc., Siemens AG, ABB Ltd., Emerson Electric Co., KUKA AG, Schneider Electric, Mitsubishi Electric Corporation, Endress+Hauser AG, Yokogawa Electric Corporation, General Electric among others.

Acquisitions/Product Launches

In March 2020, Yokogawa Electric launched digital manometer. MT300 uses silicon based resonant sensor and is used to monitor pressure in the industrial applications.

In March, 2019, ABB launched “Ability Mine optimize” to its digital portfolio. It is an innovative solution of optimized electrification and automation solutions among others.

For more Electronics related reports, please click here

#Automation Market#Automation Market price#Automation Market share#Automation Market trends#Automation

1 note

·

View note

Text

Embedding analytics and big data in manufacturing

A proliferation of sensors and connected devices, coupled with the emergence of M2M communication, has resulted in an unprecedented number of data points generated from manufacturing industry sensors and connected devices. One can use different types of data, ranging from a simple metric for how long it takes a material to process through a cycle to a more complex measure, such as for measuring materials stresses in the automotive industry.

Manufacturing analytics is one of the most targeted industries by cyber attackers due to the presence of vital information about companies and governments. According to the EEF, nearly half of manufacturers reported a cybersecurity incident.

The manufacturing industry is experiencing increased integration of technology, which has created a significant rise in security concerns.

In general, smart manufacturing focuses on improving manufacturing analytics by integrating physical and cyber capabilities, using advanced information, and increasing flexibility and adaptability. As SM implements big data analytics, it is able to benefit from the massive advances in volume, velocity, variety, accuracy (i.e., data quality), and value (analytics) of data by improving existing analytics capabilities and introducing new ones, such as predictive analytics. Among these advanced process control (APC) capabilities are these improved and new capabilities.

There is a trinity of challenges shaping the emergence and evolution of equipment- and process-based analytics in semiconductor manufacturing. Manufacturing semiconductors presents a wide range of challenges, most of which are not unique to SM. In fact, they have been around for decades.

When processing big data, it's necessary to rewrite algorithms in many cases to use parallel computations so that data can be processed in a timely manner. As well, new algorithms will likely be developed that are more suitable for big data.

0 notes

Text

Advanced Process Control Market Size Worth $24.9 Billion By 2025 | Global and Regional Forecast | Grand View Research, Inc.

The global advanced process control market size is expected to reach USD 24.9 billion by 2025, registering a CAGR of 9.2% over the forecast period, according to a new report by Grand View Research, Inc. The market is expected to witness considerable growth across the globe owing to the growing emphasis of several end use industries on the improvement and optimization of the production process. Advanced process control solutions enable organizations to significantly improve the accuracy of product testing, enhance quality, and reduce error.

As companies seek ways of improving the quality of their products and reduce the cost of operations to be able to maintain their competitive edge, the demand for advanced process control systems is likely to continue to rise in the near future. Furthermore, the increasing adoption of advanced process control systems across industries such as nuclear power, chemical, and semiconductor is encouraging APC companies to invest in research and development activities to develop systems with enhanced capabilities. These factors are anticipated to further propel the growth of the global market over the forecast period.

APC is a software-based closed-loop feedback-based process control system that helps increase productivity, minimize waste, and improve quality assurance under real-world operating conditions. By enabling the easy deployment of technologies such as model predictive control and advanced computing systems in the processing and manufacturing sectors, the use of APCs has enabled companies to increase the affordability of products. Moreover, APC systems also aid in lead time reduction to decrease the operational cost associated with it.

Additionally, APCs have a significant demand in the oil and gas sector and are used for optimization and control of a variety of processes. The steady expansion of the chemical industry is also anticipated to drive the adoption of APCs over the forecast period to stabilize industrial operations and optimize plant performance by minimizing the fluctuations of key process variables. Increasing competition has compelled process industries to adopt advanced process control systems to bring about an improvement in economic performance to maintain their competitive edge. However, the need for high initial investments could restrain the growth of the APC market to a certain extent over the forecast period.

Browse Full Report (Tables & Figures) @ https://www.grandviewresearch.com/industry-analysis/advanced-process-control-apc-market

Contact Us:

Grand View Research, Inc. 201 Spear Street 1100, San Francisco, CA 94105 United States

Phone: 1-415-349-0058 Toll Free: 1-888-202-9519 Email: [email protected]

0 notes

Text

Advanced Process Control Market Statistics, Size, Share, Future Trend, Global Demand and Current Scenario by Forecast to 2027

Market Highlights

According to Market Research Future (MRFR), the global advanced process control market would register 12.09% CAGR throughout the forecast period (2017-2023), witnessing exponential accruals.

Advanced Process Control (APC) is a comprehensive model predictive control software that enhances process profitability by improving quality, increasing throughput while reducing energy usages. This state-of-the-art technology provides automatic control systems that are capable of releasing process potential across the industries including Food & Beverages, Refining, Petrochemical, and Mining.

Leverage to the economic environment, today, manufacturers are confronted by the need to curtail the capital budgets due to the rising overheads, manufacturing cost, energy costs, and struggle to stay at the front of the market competition.

Advanced process control helps manufacturers to address such complex challenges with various solutions that can extract maximum value from the manufacturing processes. APC also improves production yield, quality, and reduce energy consumption, optimizing manufacturing operations.

Resultantly, advanced process control solutions are garnering a colossal market prominence, getting quickly absorbed in various industries for optimized operational techniques. The APC market is witnessing rising deployments of these solutions. Moreover, increasing mandates to save energy are acting as significant tailwinds escalating the market on the global platform.

Additional factors influencing the growth of the market include the introduction of new labor safety norms, increasing requirement for energy-efficient process control solutions, and the integration of APC with the traditional business process.

The demand for high efficiency and a low-cost model and the success achieved in easing business processes are major driving forces supporting the growth of the market. Conversely, high costs of implementation and the reduced potential APC for knowledge-based business processes are some of the factors challenging the growth of APC market.

Get a Free Sample @ https://www.marketresearchfuture.com/sample_request/4805

Regional Analysis:

The North American region leads the global advanced process control market holding the largest market share. Factors fueling the growth of the regional market include substantial investments transpired into the field of technological development and the presence of the fervent market players that can offer cutting-edge technologies. Simultaneously, the increasing adoption of these tools in some of the burgeoning sectors such as healthcare, media & entertainment, BFSI, and IT & telecommunication are impacting the market growth, positively.

Besides the availability of well-established infrastructure that allows faster implementation of advanced technologies provides impetus to the market growth. The U.S. and Canada heading with the increasing technological advancements and the uptake of APC solutions are leading the North American market. Continuing with the same growth trends, North America is expected to retain its dominance over the global APC market creating a larger revenue pocket.

The European APC market, led by the demand from the various sectors accounts for the second-largest market, globally. Also, the augmented uptake of these solutions fuels the increase in the regional market. The resurging economy is playing a major role in contributing to the market growth in the region, significantly.

Asia Pacific region, on the other hand, is emerging as a profitable market for the advanced process control and is expected to witness a healthy growth over the review period. Factors such as increasing urbanization alongside the growing healthcare and entertainment industry which is driven by the improving economy in the region foster the market growth.

Segmentation:

The report is segmented into four key market dynamics to widen the scope of understanding,

By Type: Multivariable Model Predictive Control, Advanced Regulatory Control, Inferential Control, Compressor Control, and Sequential Control, among others.

By Revenue Source: Software and Services, among others.

By Application: Pharmaceuticals, Oil & Gas, Power, Food & Beverages, Chemicals, Petrochemicals, and Semiconductors among others.

By Region: Europe, North America, Asia Pacific, and the Rest-of-the-World.

Competitive Dashboard:

Highly competitive, the advanced process control market appears to be diversified due to the presence of several large and small-scale small players. To gain an edge over their competitors in the market, matured players adopt strategies such as acquisition and merger, expansion, collaboration, and technology launch.

These players also invest increasingly in R&D to develop a cost-competitive product portfolio and to acquire small yet promising companies in the emerging markets. They strive to address the critical market needs with a wide range of solutions and effective & complete workflow.

Major Players:

Players leading the global APC market are Aspen Technology, Inc., Emerson Electric Co., ABB Ltd., Honeywell International, Inc., Rockwell Automation, Inc., General Electric Co., Schneider Electric SE, Yokogawa Corporation, Rudolph Technologies, Inc., and Siemens AG, among others.

Industry/ Innovation /Related News:

June 24, 2019 --- Nanometrics Incorporated (the US), a leading provider of advanced process control metrology and software analytics, and Rudolph Technologies, Inc. (the US), a leading provider of semiconductor process control systems, announced the signing of a merger to create a premier semiconductor process control company.

Combining an all-stock merger of equal transactions, the merged company will be a premier company, providing end-to-end process control software, metrology, inspection, and lithography equipment to the semiconductor industry and other advanced markets. Considering the fact that customers are to continue to invest in more advanced process control (APC) solutions, the combined technology portfolio and established channels to these markets are estimated to accelerate the ability to serve both front-end and back-end markets.

Browse Complete Report @ https://www.marketresearchfuture.com/reports/advanced-process-control-market-4805

0 notes

Text

Panasonic to Team up with IBM Japan in Improving Semiconductor Manufacturing Processes

Panasonic PSX307 Plasma Cleaner

IBM Japan, Ltd. and Panasonic Corporation’s subsidiary, Panasonic Smart Factory Solutions Co., Ltd. (hereafter “Panasonic”), revealed today that the business have actually concurred to work together to establish and market a brand-new high-value-added system to enhance the general devices efficiency (OEE) of clients’ semiconductor manufacturing processes and to recognize premium manufacturing.

As part of its circuit development procedure service, Panasonic presently establishes and markets edge gadgets and manufacturing techniques that contribute to improving semiconductor manufacturing of innovative product packaging. These brand-new gadgets and techniques consist of dry engraving devices, plasma dicers to produce premium wafers, plasma cleaners that increase metal and resin adhesion and high-accuracy bonding gadgets. This know-how will be integrated with strategies and technology that IBM Japan has actually established for semiconductor manufacturing to aid Panasonic develop clever factory technology. These consist of an information analysis systems consisting of innovative procedure control (APC) and fault detection and category (FDC), in addition to an upper-layer manufacturing execution system (MES) — therefore improving quality and automating production management in semiconductor manufacturing processes.

In current years, IoT and 5G gadgets are ending up being quicker, smaller sized, and more multi-functional. This has actually provided increase to manufacturing that is based upon innovative product packaging technology, in which a middle-end procedure (that integrates the wafer procedure from the front-end procedure and the product packaging technology from the back-end procedure) has actually been included in between the front-end and back-end processes in semiconductor manufacturing.

Through the cooperation revealed today, IBM Japan and Panasonic will collectively establish an information analysis system that will be included into Panasonic’s edge gadgets. The goal of this high-value-added system is to substantially minimize the variety of engineering processes needed, to support item quality, and to enhance the operating rates of manufacturing centers. Particularly, the business mean to establish an automated dish generation system for plasma dicers, which is a brand-new innovative product packaging production technique that is drawing increased attention in the semiconductor manufacturing field, and a procedure control system that integrates an FDC system in plasma cleaners — devices that has actually shown excellent outcomes in the back-end procedure. Moving forward, the brand-new system and IBM Japan’s MES will be linked to enhance OEE factory-wide and to recognize premium manufacturing.

The 2 business mean to establish the brand-new system for the back-end procedure initially, then check out a growth of the scope to the front-end procedure in the future.

Features of the brand-new high-value-added system

1. Advancing plasma dicers through automated dish generation

The computing algorithm collectively established by the 2 business makes it possible for clients to enter their wanted dicing shape (engraving shape), which differs from item to item, and instantly produce devices criteria including numerous hundred mixes. This function is anticipated to substantially minimize item launch times and engineering expenses. It can likewise be used to the APC system, which instantly changes devices criteria according to differing processing quality from front- and back-end processes; which will keep processed shapes steady, resulting in a premium dicing procedure.

2. Advancing plasma cleaners through FDC

FDC constantly collects functional information from running manufacturing devices, identifies failures through its own information analysis technique, and makes it possible for the condition of devices to be analyzed instantly. This function creates devices upkeep target locations and frequency requirements, projections and avoids failures, enhances upkeep scheduling, lowers devices downtime, and enhances operating rates.

IBM has actually been a leader in the IT market for more than 100 years and a leader in the semiconductor field in R&D of innovative miniaturization processing technology — providing strong service outcomes at 300 mm-semiconductor factory throughout the world. In addition, as an options service provider of production operation systems which allow non-stop complete automation at factories, IBM has actually been contributing to the semiconductor manufacturing field for several years. As semiconductors play an essential function in emerging innovations such as IoT and edge-computing, there are growing requirements for higher elegance and miniaturization of semiconductors. Working beyond standard limits, IBM objectives to promote the awareness of clever factories through co-creation with Panasonic, therefore offering brand-new worth to society.

Under its “Gemba Process Innovation” vision, Panasonic is broadening its B2B options service. The gemba, or physical website for frontline operations, refers to all locations where items are made, moved or offered — the locations where worth is produced and issues need to be challenged. By using the business‘s 100-years of experience and know-how got in the manufacturing market with its noticing innovations and edge gadgets, Panasonic objectives to co-create with its clients and partners to resolve issues at the gemba. Panasonic is advancing the Gemba Process Innovation vision, intending to end up being an overall options integrator with offerings to the 3 primary locations of manufacturing, logistics, and retail.

Aims of the cooperation

Expanded usage of innovative product packaging technology

Panasonic APX300 Plasma Dicer (DM alternative)

Panasonic PSX307 Plasma Cleaner

About IBM Japan

For more details on IBM Japan, see https://www.ibm.com/ibm/jp/en/

About Panasonic

Panasonic Corporation is an around the world leader in the advancement of varied electronic devices innovations and options for clients in the customer electronic devices, real estate, vehicle, and B2B organisations. The business, which commemorated its 100th anniversary in 2018, has actually broadened worldwide and now runs 582 subsidiaries and 87 associated business worldwide, taping combined net sales of 8.003 trillion yen for the year ended March 31, 2019. Dedicated to pursuing brand-new worth through development throughout divisional lines, the business utilizes its innovations to develop a much better life and a much better world for its clients. To read more about Panasonic: https://www.panasonic.com/global.

New post published on: https://livescience.tech/2019/10/17/panasonic-to-team-up-with-ibm-japan-in-improving-semiconductor-manufacturing-processes/

0 notes

Text

Global piezoelectric actuator market

Global piezoelectric actuator market

size was US$ XX Bn in 2019 and is expected to reach US$ XX Bn by 2027, at a CAGR of ~4% during the forecast period.

The report study has analyzed the revenue impact of COVID -19 pandemic on the sales revenue of market leaders, market followers, and market disrupters in the report, and the same is reflected in our analysis.

Market Definition

Piezoelectric actuators are devices that are used to convert electrical signals into linear motion or mechanical displacement with unlimited resolution, high force, and speed. They are widely used in the high precision positioning mechanism as it provides benefits such as ease of use, stable displacement, and large generated force.

Market Dynamics

A surge in the adoption of piezoelectric actuators in various advanced high-tech sectors such as semiconductor inspection & test, bio-nanotechnology, aerospace and astronomy technology and in super-resolution microscopy field is major driving factor behind the growth of the market. A growing adoption of piezoelectric actuators in precision motion control applications, rising significance in high-frequency switches and industrial automation, increasing demand of piezoelectric actuators in aerospace applications and growing technological advancements in piezoelectric effect are expected to improve growth of the market during the forecast period.However, high initial cost required for the integration of piezoelectric actuators into the industrial machines is the major restraining factor that could hamper the growth of the market.

Global Piezoelectric Actuator Market: Segmentation Analysis

By industry, medical segment dominated the market in 2019 and is projected to witness fast growth at a CAGR of XX% during the forecast period. A surge in the adoption of piezoelectric actuators in variety of medical devices such as in surgical devices, laser beam steering devices, micro dose dispensers, micro-liter and nano-liter pumps, ultrasonic emitters and in 3D scanners is accredited to the growth of the market. In addition, rising significance of piezoelectric actuators in applications such as MRI-compatible robotics, drug delivery and material handling applications are expected to expand growth of the market in medical industry.

Alternatively, aerospace and defence segment is projected to witness fast growth at a CAGR of XX% during the forecast period. A growing adoption of piezoelectric devices such as actuators, sensor and motors in aerospace and defence applications is attributed to the growth of the market. An increasing use of piezoelectric actuators in various parts of aircraft to damp unwanted vibrations, rising significance of this actuators is in wind turbines, planes, motors, laboratory tables and machine tools and rising production of commercial and military aircrafts are likely to impel growth of the market during the forecast period.

Global Piezoelectric Actuator Market: Regional Analysis

Region wise, Asia pacific held the largest market share in 2019 and is expected to maintain its dominance at CAGR of XX% during the forecast period. The developing economies such as China, Japan, South Korea, and India are the major key contributors behind the growth of the market. The growth is attributed to the high adoption of piezoelectric actuators in industries such as automotive, aerospace and defense and medical industry across the globe.

Growing technological advancements in micro electromechanical (MEMS), materials, manufacturing and biotechnology field, rapid growth in industrial automation technology and rising adoption of piezoelectric actuators in semiconductor processing equipments are driving the growth of the market in APAC region.

The objective of the report is to present a comprehensive analysis of the Global Piezoelectric Actuator Market including all the stakeholders of the industry. The past and current status of the industry with forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. The report covers all the aspects of the industry with a dedicated study of key players that includes market leaders, followers and new entrants. PORTER, SVOR, PESTEL analysis with the potential impact of micro-economic factors of the market have been presented in the report. External as well as internal factors that are supposed to affect the business positively or negatively have been analyzed, which will give a clear futuristic view of the industry to the decision-makers. The report also helps in understanding Global Piezoelectric Actuator Market dynamics, structure by analyzing the market segments and projects the Global Piezoelectric Actuator Market. Clear representation of competitive analysis of key players by Application, price, financial position, Product portfolio, growth strategies, and regional presence in the Global Piezoelectric Actuator Market make the report investor’s guide.

For More Information Visit :

https://www.maximizemarketresearch.com/market-report/global-piezoelectric-actuator-market/78990/

Scope of Global Piezoelectric Actuator Market

Global Piezoelectric Actuator Market, By Type

• Multilayer Actuators• Multilayer Chip Actuators• Bulk Stacked Actuators• Shear Actuators• Amplified Actuators• BendersGlobal Piezoelectric Actuator Market, By Application

• Valves• Printed Heads• Positioners• Optical Instruments• Scientific Instruments• OthersGlobal Piezoelectric Actuator Market, By Industry

• Automotive• Medical• Consumer Electronics• Aerospace & Defence• Manufacturing & Processing• OthersGlobal Piezoelectric Actuator Market, By Region

• North America US Canada• Europe UK France Germany Italy Spain Norway Russia• Asia Pacific China India Japan South Korea Australia Malaysia Indonesia• South America Brazil Mexico Argentina• Middle East and AfricaGlobal Piezoelectric Actuator Market, Key Players

• APC International Ltd.• Cedrat Technologies• CeramTec GmbH• CTS Corporation• TDK Corporation• Johnson Matthey• Kinetic Ceramics• Murata Manufacturing Co. Ltd.• Tokin Corporation• NGK Insulators• PCB Motor Ltd.• Physik Instrumente (PI) GmbH & Co. KG.• Piezomechanik GmbH• Steminc (STEINER & MARTINS, INC.)• Thorlabs Inc.• Ningbo Best Group Co., Ltd.• Hanse-john Electronics Co., Ltd• Piezo Hannas (Wuhan) Tech Co Ltd.• Sinocera Piezotronics, INC• XX

• XX

This Report Is Submitted By : Maximize Market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Lumawant Godage

Organization Address: MAXIMIZE MARKET RESEARCH PVT. LTD.

Email: [email protected]

Address : Pune, Maharashtra 411051, India.

Contact: +919607195908

0 notes

Text

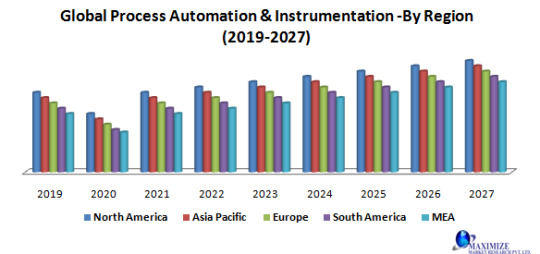

Global Process Automation & Instrumentation Market – Industry Analysis and Forecast (2019-2027)

Global Process Automation & Instrumentation Market size was US$ 71.4 Bn in 2019 and is expected to reach US$ XX Bn by 2027, at a CAGR of 6% during the forecast period.

Global Process Automation & Instrumentation Market

The report study has analyzed the revenue impact of COVID -19 pandemic on the sales revenue of market leaders, market followers, and market disrupters in the report, and the same is reflected in our analysis.

Market Definition

Process automation is a system using digital technology to execute a process or processes to complete a function or workflow in a certain industry. Process instrumentation is a systemthat allows real-time measuring, analyzing, and controlling physical quantities such as levels, pressure, flow, pH, humidity, and temperature.

Market Dynamics

Growing adoption of process automation and instrumentation system in various industries such as in food & beverage, mining, oil and gas, semiconductor manufacturing, marine, and others is a major driving factor behind the growth of the market.The increasing importance of optimum utilization of resources and industrial automation, rising demand of cost-efficient and energy-efficient automation and instrumentation processes, growing requirement for multi variable pressure transmitter, high adoption of safety automation systems, a surge in the adoption of IoT technology in various industrial applications and increasing stringent regulations and compliance in process industries are expected to improve the growth of the market during the forecast period.

Process automation and instrumentation system provide some benefits such as reduced labour costs, improved quality, safety,and consistency, which are ultimately propelling the growth of the market.

However, the high initial investment for execution and considerable maintenance cost for process instrumentation and automation solutions are major restraining factors that could hamper the growth of the market. Lack of technically skilled workforce and concerns regarding increasing cyber-attacks could hinder the growth of the market.

Global Process Automation & Instrumentation Market: Segmentation Analysis

By instrument, the field instrument segment dominated the market in 2019 and is expected to maintain its dominance at CAGR of XX% during the forecast period. Growing adoption of field instruments in various industries to measure and control various automation processes is driving the growth of the market.Field instrumentconsists of actuators, sensors, robust communication, and intelligent signal processing tools and it can be operated inharsh environments.

Field instruments provide some benefits such as increased safety and security, advanced sensing capability, safety through diagnostics, and highly accurate measurement, which lead to the increasing demand of field instruments in various industries for process automation.

Alternatively, the control valves segment is projected to witness high growth at CAGR of XX% during the forecast period. Increasing adoption of control valves in industries to ensure accurate flow control, to reduce wastage and resources, and to enable automatic operations is propelling the growth of the market.

By solution, the MES segment is projected to witness high growth at CAGR of XX% during the forecast period.MES stands fora manufacturing execution system (MES). It is an information system that is used to connect, control, and monitor complex manufacturing systems and to understand the real-time conditions on the plant floor. MES provides some benefits such as more accurate capture of cost-information, improved fault finding, reduced downtime, and increased uptime, reduced waste, and reduced inventory, which are ultimately impelling the growth of the market.

Global Process Automation & Instrumentation Market: Regional Analysis

Region-wise, North America held the largest market share in 2019 and is expected to witness high growth at CAGR of XX% during the forecast period. The US and Canada are major key contributors behind the growth of the market. The growth is attributed to growing technological advancements and the presence of well-established various manufacturing industries.

Increasing adoption of industrial automation, factory automation systems, and increasing investments by the US governments in the petrochemical & chemical industry is driving the growth of the market in the region.

The objective of the report is to present a comprehensive analysis of the Global Process Automation & Instrumentation Market including all the stakeholders of the industry. The past and current status of the industry with forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. The report covers all the aspects of the industry with a dedicated study of key players that includes market leaders, followers, and new entrants.

PORTER, SVOR, PESTEL analysis with the potential impact of micro-economic factors of the market have been presented in the report. External as well as internal factors that are supposed to affect the business positively or negatively have been analyzed, which will give a clear futuristic view of the industry to the decision-makers. The report also helps in understanding Global Process Automation & Instrumentation Market dynamics, structure by analyzing the market segments and projects the Global Process Automation & Instrumentation Market. Clear representation of competitive analysis of key players by Application, price, financial position, Product portfolio, growth strategies, and regional presence in the Global Process Automation & Instrumentation Market make the report investor’s guide. The Scope of Global Process Automation & Instrumentation Market

Global Process Automation & Instrumentation Market, By Instrument

• Field Instrument • Control Valve • Analytical Instrument Global Process Automation & Instrumentation Market, By Solution

• PLC • DCS • SCADA • HMI • Safety Automation • APC • MES Global Process Automation & Instrumentation Market, By Industry

• Food & Beverages • Pharmaceuticals • Chemicals • Energy & Power • Oil & Gas • Metals & Mining • Water & Wastewater • Pulp & Paper • Others Global Process Automation & Instrumentation Market, By Region

• North America • Europe • Asia Pacific • South America • Middle East & Africa Global Process Automation & Instrumentation Market, Key Players

• ABB • Siemens • Emerson Electric • Schneider Electric • Honeywell International • General Electric • Mitsubishi Electric • Rockwell Automation • Endress+Hauser • Yokogawa Electric • HollySys

<p><b>About Us:</p></b> Maximize Market Research provides B2B and B2C market research on 20,000 high growth emerging technologies & opportunities in Chemical, Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.</p>

<p><b>Contact info:</p></b> Name: Vikas Godage Organization: MAXIMIZE MARKET RESEARCH PVT. LTD. Email: [email protected] Website:www.maximizemarketresearch.com

0 notes

Text

Manufacturing analytics and big data

In the manufacturing industry, data points generated from sensors and connected devices has increased dramatically as a result of the proliferation of sensors and connected devices and the emergence of M2M communications. Various types of data can be used, ranging from a simple metric detailing how long a material takes to process through one a cycle to one that is more complex, such as the measurement of material stress in the automotive industry.

Due to the presence of vital information about companies and governments, manufacturing analytics is one of the most targeted industries by cyber attackers. A cybersecurity incident has been reported by over 45% of manufacturers, according to the EEF.

The manufacturing industry is experiencing increased integration of technology, which has created a significant rise in security concerns.

The term smart manufacturing (SM) generally refers to an increase in manufacturing analytics that integrate physical and cyber capabilities, and use advanced information for increased flexibility and adaptability. Big data analytics enable SM to leverage the tremendous advances in volume, velocity, variety, veracity (i.e., data quality), and value (analytics) of data, often referred to as "big data," by improving existing analysis capabilities and introducing new ones, such as predictive analytics. APC is a family of advanced process control (APC) capabilities that include these new and improved capabilities, summarized in figure 1.

A trio of challenges has shaped the emergence and evolution of equipment- and process analytics in semiconductor manufacturing. There are many challenges facing semiconductor manufacturers, but they are not unique to SM. Instead, they have existed for decades.

Big data solutions require rewriting the algorithms in many cases in order to use parallel computations to process the data in a timely manner. In addition, new algorithms that are better suited to big data may be developed.

0 notes

Text

PAC Programming Software | Schneider Electric, Opto 22, AutomationDirect

Global PAC Programming Software Market Insights, Forecast to 2025 offers built-in trends, share, and analysis to the people intending to have it. The report functions crucial inspection facets such as PAC Programming Software drivers, restraints, challenges, and patterns, openings, limits, and methods framing the global PAC Programming Software market development. A team of experts, research workers, and analysts have obtained extra efforts in applying global PAC Programming Software market information together side tools and practices to examine analysis and research about analysis information successfully.

Summary of the report: It begins with PAC Programming Software market review and goes on to growth prospects. International PAC Programming Software industry 2019 is an extensive, professional report bringing research data which will be relevant for new market entrants and recognized players.

Request Sample Report at: http://www.marketresearchglobe.com/request-sample/1011219

This report covers the market size of leading companies, and also their profiles key players covered in the report are:Dominance by Key Players:

Schneider Electric, Opto 22, AutomationDirect, Mitsubishi Electric Corporation, Siemens AG, KINGSTAR, ABB Ltd., Panasonic Electric Works Europe AG, Lamonde Automation Ltd., Phoenix Contact (I) Pvt. Ltd.

Based on product types, Split-by:

HMI (Human Machine Interface) Software

Advanced Process Control (APC)

OPC Server

Database Connectivity

Asset Management

Integrated Development Environment (IDE)

Others

On the Grounds of their end-users/applications, such as:

Discreet Manufacturing

Process Manufacturing

Automotive

Semiconductor

Energy & Utilities

Chemical

Others

Get Exclusive Discounts at: http://www.marketresearchglobe.com/check-discount/1011219

The report assesses the global PAC Programming Software industry requirement. Significant countries covered in this report comprises regional analysis:

North America, China, Rest of Asia-Pacific, UK, Europe, Central & South America, Middle East & Africa

Important Facets Included within this Report:

The PAC Programming Software report provides players fundamental data, product classification, price, and gross advantage (2014-2019);

Market stocks PAC Programming Software drivers, imperatives, openings, threats, and challenges;

Information regarding top PAC Programming Software regions, end-users together with the market quantity;

Valuing methods, geological propagate, crucial PAC Programming Software methodologies, growth patterns, and also distinct financials systems;

Various happenings in the market along with previous data and PAC Programming Software innovative prediction are analyzed in the report;

Cost evaluation, value chain evaluation, business strategies, and usage examination

Reliant ability and manufacturing information, supply, the current R&D advancements;

Company profiling with comprehensive PAC Programming Software plans, financials, and present advancements;

Dominant tendencies developing increased chances;

The substantial application and potential businesses regions;

Enquire More about the report at: http://www.marketresearchglobe.com/send-an-enquiry/1011219

Customization of this Report:

This report can be customized to satisfy up with the customer's requirements. Please contact our sales team ([email protected]), who will assist you in acquiring which works for your needs.

0 notes

Text

Global Advanced Process Control Market: Industry Analysis and Forecast (2019-2026)

Global Advanced Process Control Market was valued US$ XX Bn in 2018 and is expected to reach US$ 27.10 Bn by 2026, at a CAGR of around XX % during a forecast period.

Global Advanced Process Control Market

Process manufacturers have been using advanced process control (APC) for several decades. Advances are being made on the business front, increasing manufacturers’ needs to simplify systems on open computing platforms, and robust representation of the plant or plants. As such, one of their most pressing challenges lies in the efficient deployment and sustainment of assets with minimum human resources so that plants can effectively respond to new opportunities with-out compromising quality and profitability.

Increasing adoption of advanced process control in development industries in demand to reduce productions and to increase operational flexibility is expected to drive the market during the forecast period. However, to address specific economic improvement and data accuracy and faster implementation of software provides necessary growth opportunities in process control. Hence, the high implementation costs of advanced process control are likely to restrict the market growth.

The report covers in-depth analysis of driving factors, opportunities, restraints, and challenges for gaining the key insight of the market. The report emphasizes on all the key trends that play a significant role in the enlargement of the market from 2019 to 2026.

The multivariable model predictive control segment is expected to dominate the XX% market share during the forecast period. The multivariable model predictive control segment is a current technology, generally planned on a management control computer that categorizes important dependent process dynamic relationships between them, and optimization algorithms to control multiple variables simultaneously. Some constraint of multivariable model predictive control is that the representations must be linear across the operating range of the control.

By applications, the oil and gas segment is held to dominate the XX% market share during the forecast period. The oil and gas industry needs to attain a low margin of fault to maintain an innocent working atmosphere, requiring the use of advanced process controls. Moreover, changing the controlling structure of the industry makes the implementation of advanced process control systems essential.

Regionally, North America is expected to account for the largest share of the advanced process control market during the forecast period, Owing to the establishment of different power plants, the occurrence of primary semiconductor manufacturing industries, and demand for industrial automation is expected to augment the North American advanced process control systems. Furthermore, technological advancements in drilling fracturing of shale formations have led to a rise in oil and gas production. As advanced process control systems improve atomic power plant reliability, they are observing a significant increase in their demand in the region.

The report covers the recent development in the advanced process control market like in April 2018, Yokogawa announced their plant resource management software tools implements for managing and observing a large size of data that provides statistical data to identify the complete status of the procedures in the manufacturing industry.

The objective of the report is to present a complete calculation of the Global Advanced Process Control Market and contains thoughtful insights, historical data, facts, industry-validated market data and plans with a suitable set of assumptions and methodology. The report also helps in the Global Advanced Process Control Market is a dynamic structure by identifying and analyzing the market segments and project the global market size. The additional, report also focuses on the competitive analysis of key player’s by-product, financial position, price, product portfolio, growth strategies, and regional presence. The report also provides PEST analysis, PORTER’s analysis, and SWOT analysis to address the question of shareholders to prioritizing the efforts and investment shortly to the emerging segment in the Global Advanced Process Control Market. Scope of the Global Advanced Process Control Market

Global Advanced Process Control Market, By Product Type

• Hardware o Control Systems o Interface and Display o Computing Systems o Others • Software Global Advanced Process Control Market, By Control Type

• Advanced regulatory control • Multivariable model predictive control • Inferential control • Sequential control • Compressor control Global Advanced Process Control Market, By Applications

• Oil & Gas • Petrochemicals • Chemicals • Power • Pharmaceuticals • Food & Beverages • Automobiles • Others Global Advanced Process Control Market, By Region

• North America • Europe • Asia Pacific • Middle East & Africa • South America Key players operating in the Global Advanced Process Control Market

• ABB Ltd • Aspen Technology Inc. • Emerson Electric Co. • General Electric Co. • Honeywell International Inc. • Rockwell Automation Inc. • Rudolph Technologies Inc. • Schneider Electric SE • Siemens AG • Panasonic Corporation • Maverick Technologies • Yokogawa Electric Corp.

Maximize Market Research provides B2B and B2C market research on 20,000 high growth emerging technologies & opportunities in Chemical, Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Vikas Godage Organization: MAXIMIZE MARKET RESEARCH PVT. LTD. Email: [email protected] Website:www.maximizemarketresearch.com

0 notes

Text

Advanced Process Control Market Growth, Size, Share, Global Forecasts Analysis, Company Profiles, Competitive Landscape and Key Regions, Research Report Forecast to 2023 | Corona-Virus Impact

Market Highlights

According to Market Research Future (MRFR), the global advanced process control market would register 12.09% CAGR throughout the forecast period (2017-2023), witnessing exponential accruals.

Advanced Process Control (APC) enhances process profitability by improving quality, increasing throughput while reducing energy usages. The state-of-the-art APC technologies are capable of releasing process potential across the industries, including food & beverages, refining, petrochemical, and mining.

Leverage to the economic environment, today, manufacturers are confronted by the need to curtail the capital budgets due to the rising overheads, manufacturing cost, energy costs, and struggle to stay at the front of the market competition.

Advanced process control helps manufacturers to address such complex challenges with various solutions that can extract maximum value from the manufacturing processes. APC also improves production yield, quality, and reduce energy consumption, optimizing manufacturing operations.

Resultantly, advanced process control solutions are garnering a colossal market prominence, getting quickly absorbed in various industries for optimized operational techniques. The APC market is witnessing rising deployments of these solutions. Moreover, increasing mandates to save energy are acting as significant tailwinds escalating the market on the global platform.

Additional factors influencing the growth of the market include the introduction of new labor safety norms, increasing requirement for energy-efficient process control solutions, and the integration of APC with the traditional business process.

The demand for high efficiency and a low-cost model and the success achieved in easing business processes are major driving forces supporting the growth of the market. Conversely, high costs of implementation and the reduced potential APC for knowledge-based business processes are some of the factors challenging the growth of APC market.

Competitive Dashboard:

Highly competitive, the advanced process control market analysis appears to be diversified due to the presence of several large and small-scale small players. To gain an edge over their competitors in the market, matured players adopt strategies such as acquisition and merger, expansion, collaboration, and technology launch.

Major Players:

Players leading the global APC market are Aspen Technology, Inc., Emerson Electric Co., ABB Ltd., Honeywell International, Inc., Rockwell Automation, Inc., General Electric Co., Schneider Electric SE, Yokogawa Corporation, Rudolph Technologies, Inc., and Siemens AG, among others.

Regional Analysis:

North America would retain its leading position in the global advanced process control market. Factors fueling the regional market growth include substantial investments made into the development of technologies and the presence of major manufacturers that can offer cutting-edge technologies. Also, the increasing adoption of these solutions in some of the burgeoning sectors, including healthcare, O&G, and Power, is influencing the growth of the market in the region.

Besides, the well-established infrastructure in the region provides impetus to the regional market growth, allowing faster development and implementation of advanced technologies. The US and Canada lead the North American APC market, heading with the increasing technological advancements and the uptake of these solutions.

The advanced process control market in the European region accounts for the second-largest market, globally. The demand from the various sectors and the augmented uptake of these solutions lead the market growth, predominantly. The resurging economy in the region s playing a significant role in the growth of the market.

The advanced process control market in the Asia Pacific region is emerging as a profitable market, globally. The improving economy that drives the urbanization and healthcare and entertainment industry in the region fosters market growth. The market is estimated to witness healthy growth over the review period.

These players also invest increasingly in R&D to develop a cost-competitive product portfolio and to acquire small yet promising companies in the emerging markets. They strive to address the critical market needs with a wide range of solutions and effective & complete workflow.

Segmentation:

The report is segmented into four key market dynamics to widen the scope of understanding,

By Type: Multivariable Model Predictive Control, Advanced Regulatory Control, Inferential Control, Compressor Control, and Sequential Control, among others.

By Revenue Source: Software and Services, among others.

By Application: Pharmaceuticals, Oil & Gas, Power, Food & Beverages, Chemicals, Petrochemicals, and Semiconductors among others.

By Region: Europe, North America, Asia Pacific, and the Rest-of-the-World.

Industry/ Innovation /Related News:

June 24, 2019 --- Nanometrics Incorporated (the US), a leading provider of advanced process control metrology and software analytics, and Rudolph Technologies, Inc. (the US), a leading provider of semiconductor process control systems, announced the signing of a merger to create a premier semiconductor process control company.