eInnoSys specializes in SECS/GEM solutions, offering efficient communication protocols to optimize semiconductor factory automation and data management.

Don't wanna be here? Send us removal request.

Text

Is Your OEM-Provided SECS/GEM System Falling Short in Terms of Performance or Reliability?

In the fast-paced world of semiconductor manufacturing, seamless communication between equipment and control systems is vital for achieving high operational efficiency. SECS/GEM—the Semiconductor Equipment Communication Standard and Generic Equipment Model—is the cornerstone protocol enabling this level of communication. However, many Original Equipment Manufacturer (OEM)-provided SECS/GEM systems fail to deliver the performance and reliability manufacturers demand. If your current SECS/GEM system isn’t meeting expectations, it may be time to reevaluate your approach.

The Critical Role of SECS/GEM Systems

SECS/GEM serves as the backbone of equipment-to-host communication, ensuring that machines interact effectively with Manufacturing Execution Systems (MES). From automating routine processes to monitoring equipment health, SECS/GEM protocols are integral to semiconductor operations. A robust SECS/GEM

communication protocol should provide:

Real-time data exchange for actionable insights.

Seamless GEM300 compliance for advanced automation.

Reliable and efficient equipment monitoring and control.

However, many OEM-provided SECS/GEM solutions are generic by design, which can lead to limitations in customization, scalability, and performance. These limitations often manifest as delayed responses, unreliable data transfers, and restricted flexibility in adapting to specific operational needs.

Common Shortcomings of OEM SECS/GEM Systems

Limited Customization: Most OEM SECS/GEM systems are designed for general use rather than tailored for your specific manufacturing environment. This lack of customization can result in a mismatch between the system’s capabilities and your operational requirements.

Performance Issues: Generic SECS/GEM software often struggles with handling large data loads or maintaining consistent communication during peak operations. These issues can lead to unexpected downtime or operational inefficiencies.

Integration Challenges: OEM systems may lack the flexibility required for seamless SECS/GEM integration with your existing MES. This can hinder the flow of information across your manufacturing ecosystem, reducing overall productivity.

Lack of Advanced Features: Features such as predictive maintenance and comprehensive analytics—increasingly important in modern semiconductor manufacturing—are often absent or underdeveloped in OEM-provided SECS/GEM communication protocols.

Overcoming SECS/GEM System Limitations

To address these shortcomings, manufacturers can explore third-party SECS/GEM interface solutions that are specifically designed to enhance communication and operational efficiency. These systems are built with flexibility, scalability, and reliability in mind, providing an edge over standard OEM options.

Key Advantages of Upgrading Your SECS/GEM System:

Enhanced Performance: Custom SECS/GEM software solutions can handle higher data loads and deliver faster response times, ensuring reliable communication even under demanding conditions.

Greater Flexibility: Advanced SECS/GEM communication systems allow for greater customization to suit specific manufacturing needs.

Seamless GEM300 Compliance: Upgraded systems ensure adherence to GEM300 standards, facilitating advanced process automation and interoperability.

Improved Integration: Robust SECS/GEM integration capabilities simplify the connection between equipment and MES, enabling smoother operations.

Advanced Analytics: Modern SECS/GEM communication protocols often come with built-in tools for real-time data analysis and predictive maintenance, offering deeper insights into equipment performance.

Real-World Example: Transforming Operations with Upgraded SECS/GEM Systems

Consider a semiconductor manufacturer struggling with frequent communication breakdowns and operational delays due to an underperforming OEM-provided SECS/GEM system.

By deploying a custom third-party SECS/GEM communication protocol, they were able to:

Reduce downtime by 40% through reliable real-time data exchange.

Achieve seamless SECS/GEM integration with their MES, streamlining workflows.

Leverage predictive maintenance to prevent equipment failures, improving uptime.

Ensure GEM300 compliance for advanced automation capabilities.

The result? Higher operational efficiency, lower maintenance costs, and improved production yields.

If your OEM-provided SECS/GEM system is falling short in terms of performance or reliability, it’s time to explore advanced solutions. Investing in a robust SECS/GEM communication protocol tailored to your needs can significantly enhance your manufacturing capabilities. From seamless SECS/GEM integration and GEM300 compliance to predictive maintenance and real-time analytics, modern SECS/GEM systems are designed to meet the demands of today’s semiconductor industry.

Don’t let an outdated system hold you back. Upgrade your SECS/GEM interface today and unlock new levels of productivity and efficiency in your operations.

For more information on advanced SECS/GEM solutions, contact our team of experts. Let us help you achieve unparalleled performance and reliability in your manufacturing processes.

#SECS GEM#SECS GEM protocol#SECS GEM Communication Protocol#GEM300#SECS/GEM Software#SECS/GEM Interface#SECS/GEM Communication#SECS/GEM Integration#SECS/GEM integration

0 notes

Text

eInnoSys SECS/GEM Solutions for Semiconductor Manufacturing turned 6 today!

0 notes

Text

Machine learning applications in semiconductor manufacturing

Machine Learning Applications in Semiconductor Manufacturing: Revolutionizing the Industry

The semiconductor industry is the backbone of modern technology, powering everything from smartphones and computers to autonomous vehicles and IoT devices. As the demand for faster, smaller, and more efficient chips grows, semiconductor manufacturers face increasing challenges in maintaining precision, reducing costs, and improving yields. Enter machine learning (ML)—a transformative technology that is revolutionizing semiconductor manufacturing. By leveraging ML, manufacturers can optimize processes, enhance quality control, and accelerate innovation. In this blog post, we’ll explore the key applications of machine learning in semiconductor manufacturing and how it is shaping the future of the industry.

Predictive Maintenance

Semiconductor manufacturing involves highly complex and expensive equipment, such as lithography machines and etchers. Unplanned downtime due to equipment failure can cost millions of dollars and disrupt production schedules. Machine learning enables predictive maintenance by analyzing sensor data from equipment to predict potential failures before they occur.

How It Works: ML algorithms process real-time data from sensors, such as temperature, vibration, and pressure, to identify patterns indicative of wear and tear. By predicting when a component is likely to fail, manufacturers can schedule maintenance proactively, minimizing downtime.

Impact: Predictive maintenance reduces equipment downtime, extends the lifespan of machinery, and lowers maintenance costs.

Defect Detection and Quality Control

Defects in semiconductor wafers can lead to significant yield losses. Traditional defect detection methods rely on manual inspection or rule-based systems, which are time-consuming and prone to errors. Machine learning, particularly computer vision, is transforming defect detection by automating and enhancing the process.

How It Works: ML models are trained on vast datasets of wafer images to identify defects such as scratches, particles, and pattern irregularities. Deep learning algorithms, such as convolutional neural networks (CNNs), excel at detecting even the smallest defects with high accuracy.

Impact: Automated defect detection improves yield rates, reduces waste, and ensures consistent product quality.

Process Optimization

Semiconductor manufacturing involves hundreds of intricate steps, each requiring precise control of parameters such as temperature, pressure, and chemical concentrations. Machine learning optimizes these processes by identifying the optimal settings for maximum efficiency and yield.

How It Works: ML algorithms analyze historical process data to identify correlations between input parameters and output quality. Techniques like reinforcement learning can dynamically adjust process parameters in real-time to achieve the desired outcomes.

Impact: Process optimization reduces material waste, improves yield, and enhances overall production efficiency.

Yield Prediction and Improvement

Yield—the percentage of functional chips produced from a wafer—is a critical metric in semiconductor manufacturing. Low yields can result from various factors, including process variations, equipment malfunctions, and environmental conditions. Machine learning helps predict and improve yields by analyzing complex datasets.

How It Works: ML models analyze data from multiple sources, including process parameters, equipment performance, and environmental conditions, to predict yield outcomes. By identifying the root causes of yield loss, manufacturers can implement targeted improvements.

Impact: Yield prediction enables proactive interventions, leading to higher productivity and profitability.

Supply Chain Optimization

The semiconductor supply chain is highly complex, involving multiple suppliers, manufacturers, and distributors. Delays or disruptions in the supply chain can have a cascading effect on production schedules. Machine learning optimizes supply chain operations by forecasting demand, managing inventory, and identifying potential bottlenecks.

How It Works: ML algorithms analyze historical sales data, market trends, and external factors (e.g., geopolitical events) to predict demand and optimize inventory levels. Predictive analytics also helps identify risks and mitigate disruptions.

Impact: Supply chain optimization reduces costs, minimizes delays, and ensures timely delivery of materials.

Advanced Process Control (APC)

Advanced Process Control (APC) is critical for maintaining consistency and precision in semiconductor manufacturing. Machine learning enhances APC by enabling real-time monitoring and control of manufacturing processes.

How It Works: ML models analyze real-time data from sensors and equipment to detect deviations from desired process parameters. They can automatically adjust settings to maintain optimal conditions, ensuring consistent product quality.

Impact: APC improves process stability, reduces variability, and enhances overall product quality.

Design Optimization

The design of semiconductor devices is becoming increasingly complex as manufacturers strive to pack more functionality into smaller chips. Machine learning accelerates the design process by optimizing chip layouts and predicting performance outcomes.

How It Works: ML algorithms analyze design data to identify patterns and optimize layouts for performance, power efficiency, and manufacturability. Generative design techniques can even create novel chip architectures that meet specific requirements.

Impact: Design optimization reduces time-to-market, lowers development costs, and enables the creation of more advanced chips.

Fault Diagnosis and Root Cause Analysis

When defects or failures occur, identifying the root cause can be challenging due to the complexity of semiconductor manufacturing processes. Machine learning simplifies fault diagnosis by analyzing vast amounts of data to pinpoint the source of problems.

How It Works: ML models analyze data from multiple stages of the manufacturing process to identify correlations between process parameters and defects. Techniques like decision trees and clustering help isolate the root cause of issues.

Impact: Faster fault diagnosis reduces downtime, improves yield, and enhances process reliability.

Energy Efficiency and Sustainability

Semiconductor manufacturing is energy-intensive, with significant environmental impacts. Machine learning helps reduce energy consumption and improve sustainability by optimizing resource usage.

How It Works: ML algorithms analyze energy consumption data to identify inefficiencies and recommend energy-saving measures. For example, they can optimize the operation of HVAC systems and reduce idle time for equipment.

Impact: Energy optimization lowers operational costs and reduces the environmental footprint of semiconductor manufacturing.

Accelerating Research and Development

The semiconductor industry is driven by continuous innovation, with new materials, processes, and technologies being developed regularly. Machine learning accelerates R&D by analyzing experimental data and predicting outcomes.

How It Works: ML models analyze data from experiments to identify promising materials, processes, or designs. They can also simulate the performance of new technologies, reducing the need for physical prototypes.

Impact: Faster R&D cycles enable manufacturers to bring cutting-edge technologies to market more quickly.

Challenges and Future Directions

While machine learning offers immense potential for semiconductor manufacturing, there are challenges to overcome. These include the need for high-quality data, the complexity of integrating ML into existing workflows, and the shortage of skilled professionals. However, as ML technologies continue to evolve, these challenges are being addressed through advancements in data collection, model interpretability, and workforce training.

Looking ahead, the integration of machine learning with other emerging technologies, such as the Internet of Things (IoT) and digital twins, will further enhance its impact on semiconductor manufacturing. By embracing ML, manufacturers can stay competitive in an increasingly demanding and fast-paced industry.

Conclusion

Machine learning is transforming semiconductor manufacturing by enabling predictive maintenance, defect detection, process optimization, and more. As the industry continues to evolve, ML will play an increasingly critical role in driving innovation, improving efficiency, and ensuring sustainability. By harnessing the power of machine learning, semiconductor manufacturers can overcome challenges, reduce costs, and deliver cutting-edge technologies that power the future.

This blog post provides a comprehensive overview of machine learning applications in semiconductor manufacturing. Let me know if you’d like to expand on any specific section or add more details!

#semiconductor manufacturing#Machine learning in semiconductor manufacturing#AI in semiconductor industry#Predictive maintenance in chip manufacturing#Defect detection in semiconductor wafers#Semiconductor process optimization#Yield prediction in semiconductor manufacturing#Advanced Process Control (APC) in semiconductors#Semiconductor supply chain optimization#Fault diagnosis in chip manufacturing#Energy efficiency in semiconductor production#Deep learning for semiconductor defects#Computer vision in wafer inspection#Reinforcement learning in semiconductor processes#Semiconductor yield improvement using AI#Smart manufacturing in semiconductors#AI-driven semiconductor design#Root cause analysis in chip manufacturing#Sustainable semiconductor manufacturing#IoT in semiconductor production#Digital twins in semiconductor manufacturing

0 notes

Text

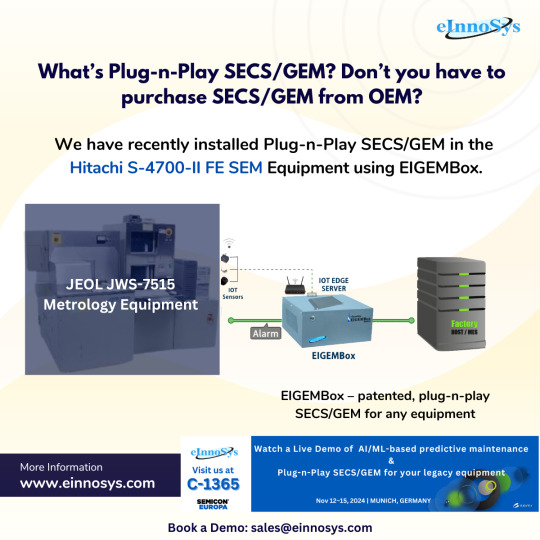

SECS/GEM on JEOL JWS-7515 Metrology Equipment: Enhancing Efficiency with EIGEMBox

In the fast-paced world of semiconductor manufacturing, precision and efficiency are paramount. One key aspect of this process is the metrology equipment used to ensure that every component meets stringent quality standards. The JEOL JWS-7515 is a leading tool in this field, particularly when combined with the EIGEMBox, which facilitates the SECS/GEM protocol. In this blog, we’ll explore the significance of SECS/GEM, the features of the JEOL JWS-7515, and how the EIGEMBox enhances metrology processes.

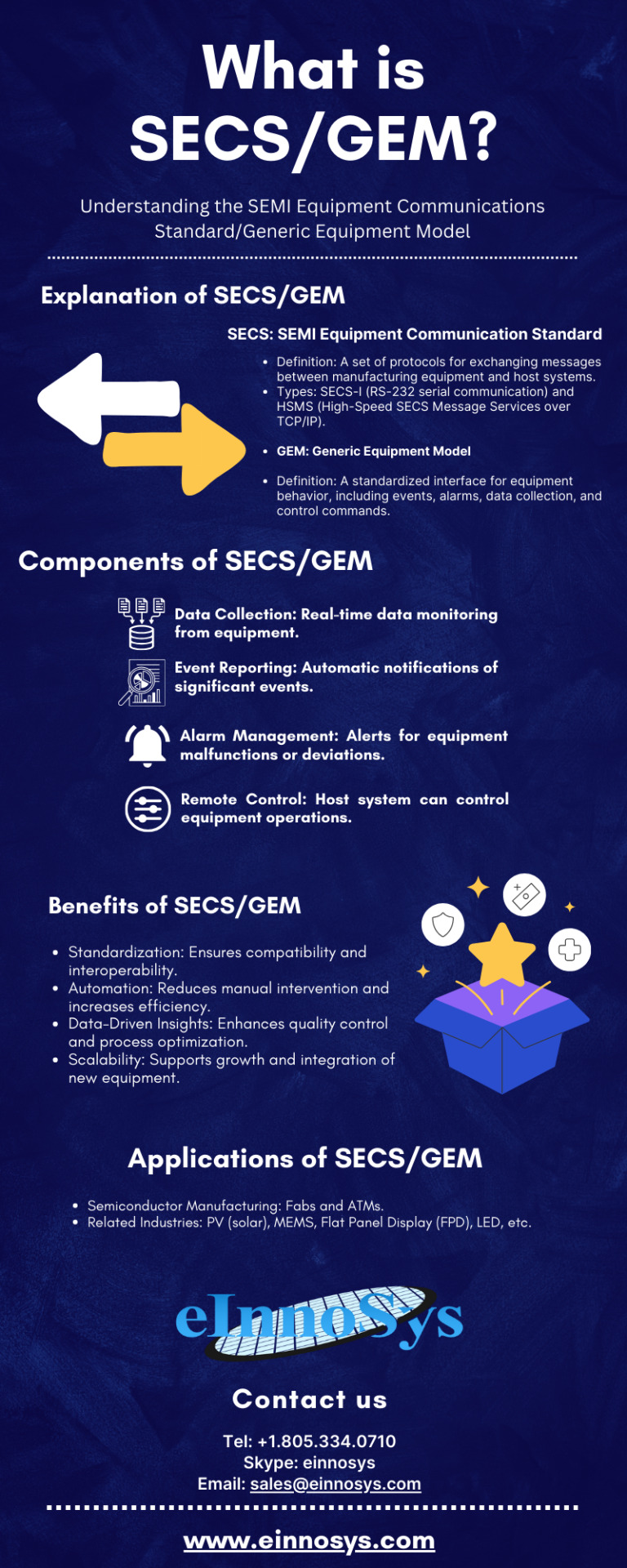

What is SECS/GEM?

SECS/GEM stands for SEMI Equipment Communication Standard/Generic Equipment Model. It is a widely adopted communication protocol in the semiconductor manufacturing industry that allows for seamless data exchange between manufacturing equipment and host systems. This standard is critical for achieving automation and real-time data acquisition, which helps improve production efficiency and reduce errors.

Why SECS/GEM Matters

Standardization: By providing a uniform communication protocol, SECS/GEM simplifies the integration of various equipment and systems, leading to smoother operations.

Real-time Monitoring: With SECS/GEM, manufacturers can monitor equipment performance in real-time, allowing for quick adjustments and better decision-making.

Data Collection: The protocol facilitates extensive data collection, which is essential for analysis, reporting, and continuous improvement initiatives.

Overview of JEOL JWS-7515

The JEOL JWS-7515 is an advanced metrology tool designed for high-resolution imaging and analysis of semiconductor wafers. Here are some of its standout features:

High-Resolution Imaging

The JWS-7515 utilizes cutting-edge electron beam technology to achieve high-resolution imaging. This capability allows for detailed inspections of wafer surfaces, crucial for identifying defects that could compromise performance.

Versatility

This equipment is versatile enough to handle various materials and applications, making it an invaluable asset in a semiconductor fab. Its ability to analyze different substrates and feature sizes helps manufacturers maintain high standards across diverse product lines.

Automated Functionality

Automation is a key feature of the JWS-7515, which enhances throughput and minimizes human error. The system’s ability to integrate with software tools and other equipment makes it a central hub for metrology operations.

The Role of EIGEMBox

The EIGEMBox is a powerful tool that enhances the capabilities of the JEOL JWS-7515 by facilitating SECS/GEM communication. Here’s how it works:

Seamless Integration

The EIGEMBox acts as a bridge between the JEOL JWS-7515 and the host system, enabling seamless data transfer. This integration is crucial for manufacturers who require real-time insights into their metrology processes.

Enhanced Data Management

With the EIGEMBox, data collected by the JWS-7515 can be efficiently managed and analyzed. The ability to centralize data from multiple sources helps manufacturers streamline operations and improve decision-making.

Flexibility and Scalability

The EIGEMBox is designed to be flexible, accommodating a variety of equipment and systems. As manufacturing needs evolve, the EIGEMBox can be scaled to meet increased demands without significant infrastructure changes.

Benefits of Using SECS/GEM with JEOL JWS-7515 and EIGEMBox

Improved Efficiency

By automating data exchange and analysis, the combination of SECS/GEM, the JEOL JWS-7515, and the EIGEMBox significantly improves operational efficiency. Manufacturers can reduce downtime and optimize workflow, leading to faster production cycles.

Enhanced Quality Control

The ability to conduct real-time monitoring and analysis of wafer conditions ensures that quality control measures are always in place. This capability minimizes the risk of defects reaching the production stage, ultimately enhancing product reliability.

Data-Driven Decision Making

Access to comprehensive, real-time data allows manufacturers to make informed decisions quickly. This responsiveness is critical in a competitive landscape where even minor delays can have significant consequences.

Implementation Considerations

While the benefits of integrating SECS/GEM with the JEOL JWS-7515 and EIGEMBox are clear, several implementation considerations should be taken into account:

Training and Support

To fully leverage the capabilities of these technologies, manufacturers should invest in training for their staff. Understanding how to use the equipment and interpret data is essential for maximizing the benefits.

System Compatibility

Ensuring that the EIGEMBox is compatible with existing systems is crucial for a successful integration. Manufacturers should conduct thorough assessments before implementation to identify any potential challenges.

Ongoing Maintenance

Regular maintenance of both the JWS-7515 and the EIGEMBox is essential to maintain optimal performance. A proactive maintenance schedule can help prevent equipment failures and ensure long-term reliability.

Conclusion: Elevate Your Metrology Operations Today

The integration of SECS/GEM with the JEOL JWS-7515 metrology equipment, enhanced by the EIGEMBox, represents a significant advancement in semiconductor manufacturing. By improving efficiency, enhancing quality control, and enabling data-driven decision-making, this combination positions manufacturers for success in a highly competitive market.

If you're looking to elevate your metrology operations and embrace the future of semiconductor manufacturing, now is the time to act! Contact us today to learn more about how SECS/GEM, JEOL JWS-7515, and EIGEMBox can transform your processes. Don’t miss out on the opportunity to enhance your operational efficiency and product quality!

#secs/gem#fab automation#equipment software#secs/gem software#eigembox#secs/gem protocol#semiconductor#secs gem software#JEOL JWS-7515#Metrology Equipment

1 note

·

View note

Text

Revolutionizing the Semiconductor Industry with AI: EinnoSys Insights

Welcome to EinnoSys, where innovation meets intelligence! Today, we’re diving into the transformative impact of artificial intelligence (AI) on the semiconductor manufacturing landscape.

The AI-Driven Revolution As the demand for faster and more efficient semiconductors skyrockets, AI technologies are stepping in to streamline manufacturing processes. By leveraging machine learning algorithms, companies can optimize production schedules, predict equipment failures, and reduce waste, leading to significant cost savings.

Smart Manufacturing AI enhances real-time data analysis during the manufacturing process. With advanced analytics, we can identify anomalies in production lines, ensuring high-quality standards and minimizing defects. This not only improves yield but also accelerates time-to-market for new chips.

Design Optimization AI isn’t just for manufacturing; it’s also revolutionizing chip design. Machine learning models can simulate various design parameters, helping engineers create more efficient architectures that push the limits of performance. This synergy between AI and design leads to breakthroughs in semiconductor technology.

AI-Powered Supply Chains The semiconductor supply chain is complex and often unpredictable. AI algorithms can forecast demand trends and manage inventory more effectively, helping companies respond to market fluctuations and avoid shortages.

Looking Ahead The future of AI in the semiconductor industry is bright. As we continue to explore these technologies at EinnoSys, we’re excited to contribute to a more efficient, sustainable, and innovative semiconductor ecosystem.

Join us as we navigate this fascinating intersection of AI and semiconductors! Follow us for more insights, updates, and industry trends.

#artificial intelligence semiconductors#machine learning semiconductor#AI in Semiconductor Industry#semiconductors ai#semiconductors for ai

0 notes

Text

What is SECS/GEM? Understanding the SEMI Equipment Communications Standard/Generic Equipment Model

#secs/gem#secs/gem software#semiconductor#equipment software#secs gem software#secs/gem protocol#fab automation

0 notes

Text

SECS/GEM on Canon MPA 600 Super Aligner Through the EIGEMBox

In the dynamic world of semiconductor manufacturing, ensuring that legacy equipment can keep up with modern communication standards is essential for maintaining productivity and efficiency. The Canon MPA 600 Super Aligner, a widely used piece of equipment in semiconductor fabs, often lacks the native SECS/GEM capabilities required for seamless integration into contemporary manufacturing systems. Enter EIGEMBox, a patented, plug-and-play solution that brings SECS/GEM compliance to legacy equipment without the need for extensive hardware or software installations.

In this blog, we will explore the benefits of using EIGEMBox to enable SECS/GEM on the Canon MPA 600 Super Aligner and how this can revolutionize your manufacturing process.

What is SECS/GEM?

SECS/GEM (SEMI Equipment Communications Standard/Generic Equipment Model) is a set of protocols developed by SEMI (Semiconductor Equipment and Materials International) to standardize communication between semiconductor manufacturing equipment and host systems. These protocols are critical for enabling automation, real-time data collection, and equipment control, which are essential for the efficiency and productivity of modern semiconductor fabs.

The Importance of SECS/GEM Compliance SECS/GEM compliance offers several significant benefits for semiconductor manufacturing: Automation: SECS/GEM protocols enable the automation of equipment operations, reducing the need for manual intervention and minimizing the risk of human error. This leads to higher throughput and more consistent production quality.

Data Collection and Analysis: SECS/GEM allows for real-time data collection from equipment, which can be analyzed to monitor performance, optimize processes, and predict maintenance needs. This data-driven approach helps in making informed decisions that improve overall efficiency.

Equipment Control: With SECS/GEM, equipment can be controlled remotely by the host system, allowing for better coordination and scheduling of manufacturing tasks. This ensures optimal utilization of resources and reduces downtime.

Interoperability: SECS/GEM provides a standardized communication framework, ensuring that equipment from different vendors can work together seamlessly. This interoperability is crucial for maintaining a cohesive and efficient manufacturing environment.

Challenges with Legacy Equipment

While SECS/GEM offers numerous advantages, many legacy equipment like the Canon MPA 600 Super Aligner lack native SECS/GEM capabilities. Upgrading these machines to meet modern standards can be a complex and costly process, often requiring significant hardware and software modifications. This is where EIGEMBox comes into play.

Introducing EIGEMBox

EIGEMBox is an innovative, patented solution designed to bring SECS/GEM capabilities to legacy equipment without the need for additional hardware or software installations. This plug-and-play device makes it easy to upgrade older machines, ensuring they can communicate effectively with modern control systems and integrate seamlessly into automated manufacturing environments.

Key Features of EIGEMBox

Plug-and-Play Convenience: EIGEMBox is designed for easy installation and operation. Simply connect the device to your legacy equipment, and it starts working immediately, without the need for extensive configuration or setup.

No Hardware or Software Installation Required: Unlike traditional SECS/GEM integration solutions that often require complex hardware and software installations, EIGEMBox eliminates these hassles. This makes it a cost-effective and time-saving solution for upgrading your equipment.

Patented Technology: EIGEMBox utilizes patented technology to ensure reliable and efficient communication between your legacy equipment and modern control systems. This guarantees seamless integration and improved operational efficiency.

Enhanced Data Exchange: With EIGEMBox, your legacy equipment can exchange data in real-time with control systems, enabling better monitoring, analysis, and optimization of manufacturing processes.

Benefits of Using EIGEMBox with Canon MPA 600 Super Aligner

Upgrading the Canon MPA 600 Super Aligner with EIGEMBox offers several significant benefits:

Extended Equipment Life: By enabling SECS/GEM compliance, EIGEMBox extends the operational life of the Canon MPA 600 Super Aligner, allowing you to maximize your investment in this equipment.

Improved Efficiency: Enhanced communication and control capabilities lead to better coordination of manufacturing tasks, increased throughput, and reduced downtime. This results in the overall improved efficiency of your manufacturing process.

Cost Savings: EIGEMBox eliminates the need for costly hardware and software upgrades, providing a more affordable solution for integrating SECS/GEM protocols into your manufacturing processes.

Seamless Integration: EIGEMBox ensures that your Canon MPA 600 Super Aligner can communicate effectively with modern control systems, enabling a smoother and more efficient manufacturing operation.

Case Study: Successful Integration of EIGEMBox with Canon MPA 600 Super Aligner

One of our clients, a leading semiconductor manufacturer, faced challenges in integrating SECS/GEM protocols into their Canon MPA 600 Super Aligner. After implementing EIGEMBox, they experienced a significant improvement in production efficiency. The plug-and-play nature of EIGEMBox allowed for a quick and hassle-free integration process, resulting in a 20% increase in equipment utilization and a 15% reduction in downtime. The client was able to extend the life of their existing equipment while achieving substantial cost savings. How to Get Started with EIGEMBox Ready to revolutionize your semiconductor manufacturing processes with EIGEMBox? Here’s how you can get started:

Contact Us: Reach out to our team for a consultation. We’ll assess your current equipment and provide tailored recommendations for integrating EIGEMBox into your manufacturing environment.

Easy Installation: Once you’ve decided to move forward, our team will guide you through the simple installation process. No need for extensive configuration or setup – just plug it in and start reaping the benefits.

Ongoing Support: Our commitment to your success doesn’t end with installation. We offer comprehensive support to ensure that your EIGEMBox operates seamlessly and delivers the desired improvements in efficiency and productivity.

Contact Us Today! Don’t let outdated equipment hold back your semiconductor manufacturing operations. With EIGEMBox, you can achieve modern communication and control capabilities without the need for costly hardware or software installations. Contact us today to learn more about how EIGEMBox can transform your Canon MPA 600 Super Aligner and drive your manufacturing processes forward.

#SECS/GEM integration#Canon MPA 600 Super Aligner#EIGEMBox#semiconductor manufacturing#legacy equipment upgrade#plug-and-play SECS/GEM#SECS/GEM compliance#semiconductor automation#factory automation#SECS/GEM protocol#SECS/GEM communication#equipment control systems#real-time data collection#manufacturing process optimization#cost-effective SECS/GEM solution#improve production efficiency#legacy equipment SECS/GEM#EIGEMBox installation#semiconductor industry standards#SECS/GEM host simulation#reduce equipment downtime

0 notes

Text

Revolutionizing Industrial Efficiency: AI/ML-Based Pump & Motor Health Monitoring and Predictive Maintenance

In today’s fast-paced industrial landscape, minimizing downtime and optimizing operational efficiency are crucial for maintaining a competitive edge. Pumps and motors are essential components in numerous industries, and their failure can lead to significant operational disruptions and financial losses. Traditional maintenance approaches, often based on reactive or scheduled maintenance, are no longer sufficient. The solution lies in leveraging advanced technologies: AI and Machine Learning (ML) for predictive maintenance. The Power of Predictive Maintenance

Predictive maintenance uses AI and ML algorithms to analyze data from pumps and motors, predicting potential failures weeks in advance. This proactive approach allows maintenance teams to address issues before they escalate into costly downtime or catastrophic failures.

Key Benefits of AI/ML-Based Health Monitoring

AI/ML algorithms can detect anomalies in pump and motor performance far earlier than human operators or traditional monitoring systems. By identifying subtle changes in vibration, temperature, or sound patterns, these systems can predict failures weeks before they occur, providing ample time for corrective action.

Reduced Downtime and Maintenance Costs

By predicting and preventing failures, companies can significantly reduce unplanned downtime and the associated costs. Maintenance can be scheduled at optimal times, avoiding the need for emergency repairs and minimizing production disruptions.

Extended Equipment Lifespan

Regular, condition-based maintenance helps keep pumps and motors running at peak efficiency, extending their operational lifespan. This reduces the frequency of equipment replacements and lowers capital expenditure.

Improved Safety and Reliability

Predictive maintenance ensures that equipment is always in good working condition, enhancing the overall safety of operations. Reliable equipment also means fewer interruptions and more consistent production output.

How AI/ML-Based Systems Work

AI/ML-based health monitoring systems use a combination of sensors, data analytics, and machine learning models to continuously monitor the condition of pumps and motors.

Data Collection

Sensors attached to pumps and motors collect real-time data on various parameters, including vibration, temperature, pressure, and electrical currents.

Data Processing and Analysis

The collected data is processed and analyzed using advanced ML algorithms. These algorithms learn the normal operating conditions and identify patterns that indicate potential issues.

Anomaly Detection

When the system detects anomalies that deviate from the learned normal patterns, it flags them for further analysis. These anomalies can indicate early signs of wear and tear, misalignment, or other potential failures.

Predictive Modeling

Based on historical data and identified anomalies, predictive models forecast the remaining useful life of the equipment and predict the likelihood of future failures. This allows maintenance teams to prioritize and schedule interventions proactively.

Actionable Insights

The system provides actionable insights and recommendations to maintenance teams, enabling them to address issues before they lead to failure. This could include instructions for specific repairs, adjustments, or replacements.

Applications Across Industries

AI/ML-based health monitoring and predictive maintenance systems are versatile and can be applied across various industries, including:

Manufacturing

Ensuring continuous operation of critical machinery, reducing production downtime, and optimizing maintenance schedules.

Oil and Gas

Monitoring pumps and motors in harsh environments, predicting failures, and preventing costly shutdowns.

Water and Wastewater Management

Ensuring the reliability of pumps and motors in treatment plants, preventing service interruptions, and reducing maintenance costs.

HVAC Systems

Monitoring the health of motors and pumps in heating, ventilation, and air conditioning systems, improving efficiency and reducing energy consumption.

The Future of Industrial Maintenance

As AI and ML technologies continue to evolve, the capabilities of predictive maintenance systems will only improve. Future advancements may include more sophisticated anomaly detection algorithms, better integration with other industrial systems, and enhanced user interfaces that provide more intuitive insights and recommendations.

Call to Action

Implementing an AI/ML-based health monitoring and predictive maintenance system is not just a technological upgrade; it's a strategic investment in your business's future. By adopting these advanced solutions, you can ensure the longevity and reliability of your pumps and motors, reduce maintenance costs, and maintain continuous, efficient operations.

Don't wait for unexpected failures to disrupt your operations. Embrace the future of maintenance today and see the difference predictive maintenance can make for your business. Contact us to learn more about how our AI/ML-based pump and motor health monitoring systems can transform your maintenance strategy and drive your business towards greater efficiency and reliability.

#AI/ML-Based Health Monitoring#predictive maintenance system#Predictive Maintenance#Motor Health Monitoring#predictive modeling#Manufacturing#Industrial Maintenance#motor health monitoring systems#AI/ML-based pump and motor health monitoring systems

0 notes

Text

Introduction to SECS/GEM: Revolutionizing Semiconductor Manufacturing

What is SECS/GEM?

SECS/GEM (SEMI Equipment Communications Standard/Generic Equipment Model) is a set of standards developed by SEMI (Semiconductor Equipment and Materials International) to facilitate communication and control in semiconductor manufacturing. It allows equipment and factory systems to interact seamlessly, enabling automated processes, real-time data collection, and precise control over manufacturing operations.

History and Evolution of SECS/GEM

The SECS/GEM standards emerged in the 1980s to address the growing complexity and automation needs in semiconductor manufacturing. Initially, SECS-I (SEMI Equipment Communications Standard 1) used RS-232 serial communication. As technology advanced, the need for faster communication led to the development of HSMS (High-Speed SECS Message Services), which utilizes TCP/IP for quicker and more reliable data transmission.

Importance of SECS/GEM in the Semiconductor Industry In the semiconductor industry, precision and efficiency are crucial. SECS/GEM ensures that equipment from different manufacturers can communicate using a standardized protocol, reducing integration time and costs. This standardization enhances productivity, minimizes downtime, and improves yield by enabling precise monitoring and control of manufacturing processes.

How SECS/GEM Enhances Equipment Communication and Control

Detailed Overview of SECS/GEM Protocols

SECS/GEM consists of two main protocols:

SECS-I (SEMI Equipment Communications Standard 1):

Uses RS-232 for serial communication.

Suitable for environments where high-speed communication is not critical.

HSMS (High-Speed SECS Message Services):

Uses TCP/IP for faster communication.

Ideal for modern manufacturing environments requiring high-speed data exchange.

GEM provides a standardized model for equipment behavior, including status reporting, data collection, and control commands, making it easier to manage and integrate various equipment. Benefits of Using SECS/GEM for Equipment Communication Standardization: Facilitates seamless integration of equipment from different vendors.

Real-Time Data Collection: Enables continuous monitoring of equipment performance and process parameters.

Enhanced Automation: Reduces manual intervention, leading to higher efficiency and productivity.

Improved Yield: Precise control and monitoring help identify and rectify issues promptly, enhancing overall yield.

Examples of SECS/GEM in Action

Wafer Fabrication: SECS/GEM is used to monitor and control processes such as etching, doping, and deposition.

Assembly and Test: Ensures that testing equipment communicates effectively with the MES (Manufacturing Execution System) to provide real-time results and feedback. Implementing SECS/GEM in Your Manufacturing Process

Steps to Integrate SECS/GEM with Existing Equipment

Assessment: Evaluate your current equipment and determine SECS/GEM compatibility.

Selection: Choose appropriate SECS/GEM software and hardware solutions.

Integration: Install and configure the SECS/GEM interfaces with your equipment and factory systems.

Testing: Conduct thorough testing to ensure proper communication and control.

Training: Provide training for staff on the new system and its functionalities.

Challenges and Solutions in SECS/GEM Implementation

Compatibility Issues: Ensure that both old and new equipment can communicate using SECS/GEM standards.

Technical Expertise: Invest in training and, if necessary, consult with experts to facilitate smooth integration.

Cost: While initial implementation might be costly, the long-term benefits in efficiency and yield outweigh these expenses.

1 note

·

View note

Text

Introduction to SECS/GEM: Communication Interface Protocols for Semiconductor Equipment

#secs/gem#gem300#secs/gem software#fab automation#equipment software#semiconductor#secs gem software

0 notes

Text

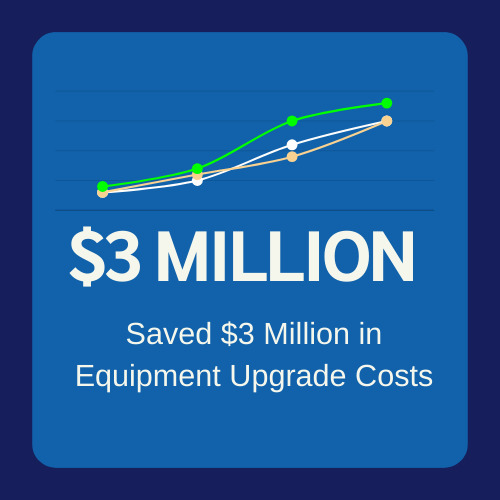

In the fast-paced world of semiconductor manufacturing, staying ahead of technology while managing costs is a constant challenge. Einnosys, a company dedicated to innovative industrial solutions, introduced EIGEMbox—a simple yet powerful device that can transform existing semiconductor equipment by adding modern automation capabilities. This case study explores how EIGEMbox helped semiconductor fabs save a massive $3 million in equipment upgrade costs and enhance their operational efficiency.

#EIGEMBox#SECS/GEM#secs gem software#gem300#secs/gem software#fab automation#predictive maintenance for pumps

0 notes

Text

XPump is a cutting-edge, AI/ML-based solution designed for real-time monitoring and predictive maintenance of pumps. It continuously tracks critical parameters like vibration, temperature, and voltage, providing early warnings to prevent failures and optimize performance. XPump integrates seamlessly with your existing systems, enhancing operational efficiency and reducing downtime and maintenance costs.

#Real Time Pump Monitoring System#predictive maintenance software#predictive maintenance for pumps#best predictive maintenance software#predictive maintenance systems#predictive maintenance applications#predictive maintenance pumps#predictive maintenance software cost

0 notes

Text

Introducing EI-AOI, the cutting-edge solution for automated visual inspection that sets a new standard in precision and efficiency. Our revolutionary software, powered by advanced industrial cameras, transforms the monitoring of various meters, including gas flow meters, chemical meters, and all types of analog meters, across industrial sectors.

#AIO#Automated Visual Inspection#Automated Visual Inspection Solutions#Valve Manifold Panels and Boxes#Valve Manifold Boxes

0 notes

Text

🛠️🔮 Discover the power of predictive maintenance in factory settings! In today's competitive manufacturing landscape, minimizing downtime and maximizing efficiency are crucial. Learn how predictive maintenance can revolutionize your operations, saving costs and improving efficiency.

#Implementing Predictive Maintenance#predictive maintenance#Predictive Maintenance Action#predictive maintenance for rotary devices#predictive maintenance for vacuum pumps#Predictive Maintenance in Factory#predictive maintenance semiconductor industry

0 notes

Text

#Healthcare#Pharmaceutical#Pharmaceutical Software#Pharmaceutical Software Development#Healthcare Software#pharmaceutical industries Software#Healthcare and Pharmaceutical Software Development Services

0 notes

Text

Explore the power of predictive maintenance with AI/ML for vacuum pumps, motors, and more. Enhance reliability and reduce downtime. Learn more!

#Predictive Maintenance Vacuum Pumps#Vacuum Pump Reliability#Vacuum Pump Failure Prevention#Predictive Maintenance Motors#Predictive Maintenance Furnaces#Predictive Maintenance Rotary Devices#Predictive Maintenance AI/ML Bases#AI/ML for Equipment Maintenance#Machine Learning in Maintenance#Predictive Analytics for Maintenance#ML Algorithms for Maintenance

0 notes

Link

0 notes