#Aerospace Foams Market size

Text

Global Aerospace Foams Market Size, Share - Industry Forecast 2029

According to Precision Business Insights, The size analysis of the aerospace foams market is expected to reach a value of USD 9.6 billion from 2023-29

The global aerospace foams market size was valued at USD 6.2 Billion in 2022 and is poised to grow at a significant CAGR of 8.4% during the forecast period 2023-29. It also includes market size and projection estimations for each of the five major regions from 2023 to 2029. The research report includes historical data, trending features, and market growth estimates for the future. Furthermore, the study includes a global and regional estimation and further split by nations and categories within each region. The research also includes factors and barriers to the aerospace foams market growth, as well as their impact on the market's future growth. The report gives a comprehensive overview of both primary and secondary data.

View the detailed report description here - https://www.precisionbusinessinsights.com/market-reports/global-aerospace-foams-market

The global aerospace foams market segmentation:

1) By Foam Type : Polyurethane, Polyethylene, Ceramic, Metal foam, Others

2) By Application : General Aviation, Commercial Aircraft, Military Aircrafts

3) By Geography : North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa

The primary factors of the aerospace foams market drivers are increasing demand for lightweight and fuel-efficient aircraft. The aerospace foams market report helps to provide the best results for business enhancement and business growth. It further helps to obtain the reactions of consumers to a novel product or service. It becomes possible for business players to take action for changing perceptions. It uncovers and identifies potential issues of the customers. It becomes easy to obtain the reactions of the customers to a novel product or service. It also enlightens further advancement, so it suits its intended market.

The aerospace foams marketresearchreport gives a comprehensive outlook across the region with special emphasis on key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America was the largest region in the aerospace foams market report, accounting for the highest share in 2022. It was followed by Asia Pacific, and then the other regions.

Request sample report at - https://www.precisionbusinessinsights.com/request-sample/?product_id=35263

The important profiles and strategies adopted by aerospace foams market key players are BASF SE, Huntsman Corporation, ARMACELL, Boyd Corporation, Evonik Industries, Rogers Corporation, SABIC Innovative Plastics, General Plastics Manufacturing Company, Zetofoams Plc, ERG Materials, covered here to help them in strengthening their place in the market.

About Precision Business Insights:

We are a market research company that strives to provide the highest quality market research insights. Our diverse market research experts are enthusiastic about market research and therefore produce high-quality research reports. We have over 500 clients with whom we have a good business partnership and capacity to provide in-depth research analysis for more than 30 countries. In addition to deliver more than 150 custom solutions, we already have accounts with the top five medical device manufacturers.

Precision Business Insights offers a variety of cost-effective and customized research services to meet research requirements. We are a leading research service provider because of our extensive database built by our experts and the services we provide.

Contact:

Mr. Satya

Precision Business Insights | Toll Free: +1 866 598 1553

Email: [email protected]

Kemp House, 152 – 160 City Road, London EC1V 2NX

Web: https://precisionbusinessinsights.com/ | D U N S® Number: 852781747

#aerospace foams market size#aerospace foams market share analysis#aerospace foams market growth drivers#aerospace foams market trends#aerospace foams market dynamics

0 notes

Text

The aerospace foams market size is projected to grow from USD 4.4 billion in 2019 to USD 6.5 billion by 2024, at a CAGR of 8.2% from 2019 to 2024. The rising demand for lightweight and fuel-efficient aircraft have led to the extensive use of advanced materials such as PU foams and PE foams, among others, in the aerospace industry. The manufacture of advanced materials as well as new products launched by several prominent players for the aerospace industry is one of the key factors driving the growth of the aerospace foams industry across the globe.

Aerospace foams are advanced materials of various cell sizes, capacities, and properties. The cell sizes of the aerospace foams determine the flexibility or rigidity of the foams and thus, dictates the application areas where they can be used. Aerospace foams are manufactured using various materials, such as PU (polyurethane), PE (polyethylene), melamine, metal, and PMI/polyimide, among others, which meet the flame, smoke, and toxicity (FST) standards in the aerospace industry. These foams are used in various applications in aircrafts such as seating, seals, gaskets, carpet pads, headrests, rotor blades, doors, windshields, cockpit instrument panels, wingtip lens, and several others.

Based on material type, the aerospace foams market has been segmented into PU foams, PE foams, melamine foams, metal foams, PMI/polyimide foams, and others which includes PVDF foams, PPSU foams, silicone foams, ceramic foams, PEI foams, PET foams, PVC foams, and polycarbonate foams. The PU foams segment has the highest market share in terms of both value and volume, among all the material type segments in 2018. It is projected to follow the same trend from 2019 to 2024 in terms of both value and volume. PU foams are used in a variety of applications ranging from seating, airframes, interiors, and packaging in the aerospace industry. The availability in different forms ranging from low to high density with varying rigidity as well as ease-of-use makes them compatible to be used in a multitude of aerospace applications. Some useful properties of PU foams include durability, lightweight, and recyclability. These factors support the rising global demands for lightweight and fuel-efficient aircraft, which is one of the primary drivers of the aerospace foams market.

#Aerospace Foams Market#PU Foams#PE Foams#Melamine Foams#Metal Foams#PMI Foam#Polyimide Foams#erg metal foam#Global Aerospace Foams Market#COVID 19 impact on Aerospace Foams Market#Aviation foam suppliers#Aircraft structural foam#Aerospace Foams industry#Aerospace Foams Market Share#Aerospace Foams Market size#Demand of Aerospace Foams#Sales of Aerospace Foams#Aerospace Foams Market Manufacturers#Aerospace Foams Market Opportunity#growth of the aerospace foams industry#commercial aircraft Foams#aviation foams#PU aerospace foams

0 notes

Text

Space Tourism Market Strategic Assessment: Market Size, Share, and Growth Projections

The global space tourism market size is expected to reach USD 10.09 billion by 2030, according to a new report by Grand View Research, Inc. It is anticipated to grow at a CAGR of 44.8% from 2024 to 2030. Space tourism is defined as human space travel for recreational, leisure, or business purposes. High-net-worth individuals' growing appetite for transformative experiences is driving demand, with some willing to pay premium prices for the novelty of space travel. Concurrently, private companies like SpaceX, Blue Origin, and Virgin Galactic are significantly investing in R&D, propelling advancements in reusable rockets, spacecraft design, and life support systems, which are gradually reducing costs and enhancing safety. These technological breakthroughs are attracting more players to the market, fostering competition and innovation. In addition, strategic partnerships between aerospace firms, luxury brands, and governments are emerging, creating a supportive ecosystem for space tourism infrastructure, including plans for orbital hotels and lunar excursions.

Space Tourism Market Report Highlights

The suborbital segment is expected to dominate the market and expand at a CAGR of 44.4% from 2023 to 2030. This growth is driven by lower ticket prices compared to orbital flights, shorter training requirements, and a rapidly expanding fleet of suborbital vehicles from companies like Virgin Galactic and Blue Origin, making it the more accessible entry point for space tourists.

The commercial segment is projected to grow at the fastest CAGR over the forecast period. This high CAGR in the commercial space tourism sector is fueled by aggressive private investment, technological advancements reducing launch costs, and a growing ecosystem of companies offering not just flights but also ancillary services like space hotels and in-orbit experiences.

Market analysis indicates that the U.S., followed by Russia, Japan, and China, will be the primary source market for space tourism. Industry players will focus their promotional efforts on the U.S. due to its high concentration of affluent consumers and potential for significant market impact.

In June 2024, Virgin Galactic completed its 12th mission to date, 'Galactic 07,' with one researcher and three private astronauts aboard. The flight served as the seventh research mission. With a focus on advancing space exploration, the mission carried out experiments and demonstrated the company's capabilities, furthering its vision of commercial human spaceflight.

For More Details or Sample Copy please visit link @: Space Tourism Market Report

Space tourism is anticipated to democratize access to space research, enabling individuals to engage more actively in space science. With the high costs associated with space exploration, these flights will provide a more affordable avenue for conducting research. In addition, space tourism is expected to drive innovation and the development of new technologies. Many technological advancements have stemmed from space exploration, with inventions such as running shoes, bulletproof vests, and foam mattresses being byproducts of lunar visits.

Space tourism is bifurcated into suborbital and orbital tourism. Suborbital flights cater to clients seeking a brief but intense exposure to the space environment. These journeys involve reaching the fringes of Earth's atmosphere without entering orbit, with total flight durations generally spanning from a few minutes to approximately two hours. This segment targets customers who prioritize the novelty of experiencing microgravity and viewing Earth from high altitude over extended time in space.

In contrast, the orbital segment offers a more immersive space travel product. Clients in this category remain in Earth's orbit for significantly longer durations, typically ranging from several days to weeks. This extended timeframe allows for a comprehensive experience, potentially including activities such as scientific experiments, extended Earth observation, or stays in orbital habitats. The orbital segment appeals to clients who seek a more profound engagement with the space environment and are willing to invest more time and resources in this comprehensive experience.

Space tourism raises environmental concerns due to the environmental impact of rocket launches. Rocket engines burn fuel, emitting black carbon (soot particles) and harmful gases into the upper atmosphere, leading to ozone depletion. However, some space companies, like Blue Origin's New Shepard, use liquid hydrogen-fueled engines that produce water vapor instead of carbon emissions. Despite this, the potential popularity of space tourism poses a significant environmental threat, as increased rocket launches will result in higher carbon footprints. For example, Virgin Galactic plans to launch 400 flights annually, contributing to the release of black carbon. The cumulative impact of 1,000 space tourism flights could lead to a one-degree Celsius increase in the temperature of Antarctica.

List of major companies in the Space Tourism Market

Blue Origin

Virgin Galactic

SpaceX

Airbus Group SE

Boeing

Zero Gravity Corporation

Axiom Space, Inc.

Rocket Lab USA

#SpaceTourismMarket#AstronomicalTourism#SpaceTravel#CommercialSpaceTourism#ReusableRockets#Aerospace#Spacecraft#OrbitalVehicles#SuborbitalVehicles#AstronomicalFlight

0 notes

Text

Crosslinking Agent Market Share, Size, Future Demand, and Emerging Trends

Market Overview

The crosslinking agent market generated USD 10,207.3 million in 2023, which is projected to increase at a CAGR of 7.4% to attain USD 16,491.4 million by 2030. This is because crosslinking agents perform better, and there is a growing need for a variety of coatings.

The growing emphasis on sustainability and eco-friendly solutions is leading to the development of original cross-linking agents with a lower environmental impact.

Materials with enhanced qualities, such as strength, heat resistance, and durability, are required by industries including electronics, aerospace, and automation. Improved physical qualities are provided by these cross-linking, which are required for long-term heat resistance and durability in applications including medical devices, foam, pipes, cables, wires, and other PE applications.

These crosslinking agents do not produce any pollutants and release very low amounts of volatile organic chemicals. These agents are becoming common in a variety of applications, including wood finishing and automotive coatings.

These agents are used to improve the mechanical strength, chemical resistance, and thermal stability of polymers. In addition, the market's projected expansion is credited to the growing need for water-based crosslinking agents.

The production of bonds by condensation and free-radical polymerization eliminates most issues during usage, which is why the chemical crosslinking technique is mostly opted for.

Key Insights

The amino category held the largest market share, of 40%, in 2023.

This is due to the exceptional crosslinking capabilities and compatibility with a broad range of polymers offered by amino compounds, such as amino resins and amino silanes.

Specialized and advanced crosslinking agents, such as amino-based ones, have been introduced as a result of the ongoing research and development in amino chemistry.

The isocyanate category is expected to show the fastest growth in the market during the expected duration, owing to the growing application of these variants in a range of coating applications, including high-performance, ornamental, appliance, and automotive coatings.

Industrial coating is predicted to show the higher CAGR, of 8%, during the forecast period due to their wide usage in industries such as construction and automotive.

The industrial sector places a high priority on product quality and regulatory compliance, which propels the need for crosslinking agents to adhere to the strict specifications.

These agents increase the mechanical characteristics, chemical resistance, and lifespan of the materials used in various industries.

The decorative category holds the larger market share due to the usage of these coatings in in high volumes in commercial, residential, industrial, and institutional buildings.

The need for crosslinking agents in decorative coatings has increased as a result of the middle class's growing population and disposable income.

The APAC region is expected to grow at the fastest rate in the next few years, with China accounting for the largest share. This is attributed to its expanding economy and the growing automotive, electricals, and manufacturing sectors.

Governments’ encouragement programs for industry, increasing R&D spending, and a growing emphasis on environment-friendly solutions all contribute to the regional market's expansion.

Europe accounted for 20% of the revenue share in 2023 due to the growing construction industry, especially housing.

BASF, which has its headquarters and manufacturing plants in the region, announced in 2023 that it will increase the amount of isocyanate it now produces and increase its manufacturing capacity to approximately 600,000 metric tons annually.

Source: P&S Intelligence

#Crosslinking Agent Market Share#Crosslinking Agent Market Size#Crosslinking Agent Market Growth#Crosslinking Agent Market Applications#Crosslinking Agent Market Trends

1 note

·

View note

Text

Aerospace Foams Market: Size, Trends, and Forecast 2024-2032

The aerospace foams market is set for substantial growth from 2024 to 2032, driven by advancements in technology and increasing demand within the aerospace sector. For an in-depth analysis of the Aerospace Foams Market, let’s explore the key aspects of this evolving industry.

Market Size

Current Growth: The aerospace foams market is witnessing significant expansion due to a surge in aircraft production and technological advancements. This growth is reflected in the increasing demand for specialized foam materials used in various aerospace applications.

Economic Impact: The rise in market size indicates a robust industry trend towards more efficient and high-performance materials. This growth is driven by the need for lightweight components that contribute to fuel efficiency and overall performance.

Trends

Technological Innovations: The development of advanced aerospace foams, such as high-performance composites and eco-friendly materials, is transforming the industry. These innovations enhance the durability, safety, and environmental footprint of aerospace components.

Efficiency Focus: There is a strong emphasis on lightweight materials to improve fuel efficiency. Aerospace foams are crucial in reducing the weight of aircraft, thereby helping manufacturers meet fuel economy and emission reduction targets.

Noise Reduction: Modern aerospace foams are increasingly used for noise reduction in aircraft cabins. This trend is driven by the need to improve passenger comfort and adhere to stricter noise regulations.

Forecast

Growth Drivers: The aerospace foams market is expected to grow due to technological advancements, increased production rates, and a shift towards more sustainable materials. Investments in new technologies and infrastructure will also play a significant role.

Regional Insights: North America and Europe are expected to remain major markets due to their established aerospace industries. Meanwhile, the Asia-Pacific region is emerging as a key growth area, fueled by rapid industrialization and increased aerospace investments.

0 notes

Text

Innovative Applications in General Aviation Boost Aerospace Metal Foams Market

The global aerospace foams market size is projected to reach USD 6.5 billion by 2024, at a CAGR of 8.2%. The rising demand for lightweight and fuel-efficient aircraft have led to the extensive use of advanced materials such as PU foams and PE foams, among others, in the aerospace industry. The manufacture of advanced materials as well as new products launched by several prominent players for the…

0 notes

Text

Polyfluoroalkyl Substances (PFAS) Waste Management Market Is Valued At US$ 2.9 Bn by the end of 2031

Polyfluoroalkyl substances (PFAS) are a group of man-made chemicals that have been widely used in various industrial and consumer products due to their water and oil-repellent properties. However, their persistence in the environment and potential health risks have raised significant concerns, leading to stringent regulatory measures for their management. The PFAS waste management market encompasses the collection, treatment, and disposal of PFAS-containing waste to mitigate environmental and health impacts.

Governments in several countries regularly update regulations pertaining to PFAS waste management and disposal methods. Stringent implementation of these regulations has created demand for effective treatment and disposal methods in the polyfluoroalkyl substances (PFAS) waste management market. Strict restrictions on PFAS compounds imposed under Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and other regulations are likely to increase demand for PFAS waste management services. The polyfluoroalkyl substances (PFAS) waste management market size stood at US$ 1.8 Bn in 2022 and is projected to reach US$ 2.9 Bn by 2031.

R&D of new technologies to recycle PFAS-containing materials is expected to bolster market development. The study on the polyfluoroalkyl substances (PFAS) waste management industry indicates that the incineration process is a popular method of PFAS management. It has emerged as the best demonstrated available technology (BDAT) for PFAS.

Request for a Sample PDF Report with Latest Industry Insights - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85468

Market Segmentation

By Service Type

Collection and Transportation: This segment includes services related to the gathering and moving of PFAS waste from various sources to treatment facilities.

Treatment: Encompasses methods such as incineration, carbon adsorption, and advanced oxidation for neutralizing or removing PFAS.

Disposal: Involves the final disposal of PFAS waste, including secure landfilling and long-term containment.

By Sourcing Type

Industrial: PFAS waste generated from manufacturing processes, especially in chemical plants and factories.

Municipal: Includes waste from residential areas, often found in water treatment residues.

Commercial: Waste from commercial establishments like airports and firefighting training facilities.

By Application

Water Treatment: Treatment of contaminated water to remove PFAS.

Soil Remediation: Methods to clean up PFAS-contaminated soil.

Industrial Cleaning: Services focused on cleaning PFAS from industrial equipment and sites.

By Industry Vertical

Chemical: Major contributors to PFAS waste, requiring robust management solutions.

Aerospace: Uses PFAS in manufacturing processes.

Defense: Includes military installations where PFAS is used in firefighting foams.

Others: Includes sectors like textiles, electronics, and food packaging.

By Region

North America: Leading market due to stringent regulations and high awareness.

Europe: Significant growth expected with increasing regulatory actions.

Asia-Pacific: Rapid industrialization and urbanization are driving the market.

Rest of the World: Includes emerging markets with growing awareness and regulations.

Regional Analysis

North America

North America holds the largest market share due to stringent regulations by agencies like the EPA and strong public awareness. The U.S. and Canada are major contributors, focusing on advanced PFAS treatment technologies and stringent disposal methods.

Europe

Europe is expected to witness significant growth with increasing regulatory frameworks and initiatives by the European Union to manage and mitigate PFAS contamination. Countries like Germany, the UK, and France are leading the efforts.

Asia-Pacific

The Asia-Pacific region is projected to grow rapidly due to the extensive use of PFAS in industrial applications and the increasing efforts by governments to address environmental concerns. China, Japan, and India are the key markets in this region.

Rest of the World

Regions such as Latin America, the Middle East, and Africa are gradually adopting PFAS waste management practices, driven by international regulations and increasing local awareness.

Market Drivers and Challenges

Drivers

Regulatory Pressure: Stringent regulations on PFAS management and disposal are major market drivers.

Public Awareness: Growing awareness about the health risks associated with PFAS is pushing demand for effective waste management solutions.

Technological Advancements: Development of advanced treatment technologies is facilitating better PFAS management.

Challenges

High Costs: The cost of advanced PFAS treatment technologies can be prohibitive for some stakeholders.

Technical Complexity: Effective treatment and disposal of PFAS require specialized knowledge and infrastructure.

Regulatory Variability: Different regulations across regions can complicate compliance and management strategies.

Market Trends

Innovation in Treatment Technologies: Development of more efficient and cost-effective PFAS treatment methods, such as plasma technology and bioremediation.

Sustainable Practices: Increasing focus on sustainable and environmentally friendly PFAS management practices.

Collaborations and Partnerships: Growing trend of partnerships between government agencies, private companies, and research institutions to tackle PFAS issues.

Future Outlook

The PFAS waste management market is expected to continue its growth trajectory, driven by regulatory frameworks, technological advancements, and increasing environmental awareness. Innovations in treatment and disposal methods, along with the implementation of more stringent regulations, will be crucial in shaping the market's future.

Key Market Study Points

Market Size and Forecast: Analysis of current market size and projections for future growth.

Competitive Landscape: Identification of key players and their market strategies.

Regulatory Impact: Examination of how regulations are shaping market dynamics.

Technological Innovations: Insights into new technologies and their market potential.

Competitive Landscape

The competitive landscape of the PFAS waste management market includes a mix of established players and emerging companies focusing on innovative solutions. Key players in the market include:

Veolia Environment: Leading provider of environmental solutions with a strong focus on PFAS waste management.

Clean Harbors, Inc.: Specializes in hazardous waste management, including PFAS treatment and disposal.

Evoqua Water Technologies LLC: Offers advanced water treatment solutions for PFAS removal.

Chemours Company: Engages in PFAS treatment and management services.

Recent Developments

Partnerships and Collaborations: Increasing partnerships between industry players and research institutions to develop new PFAS treatment technologies.

Regulatory Updates: Implementation of new regulations in various regions to control PFAS contamination and enforce strict waste management practices.

Technological Innovations: Introduction of advanced technologies such as granular activated carbon (GAC) and ion exchange resins for more efficient PFAS removal.

Buy this Premium Research Report | Immediate Delivery Available - https://www.transparencymarketresearch.com/checkout.php?rep_id=85468<ype=S

The PFAS waste management market is set to evolve significantly over the next decade, driven by regulatory imperatives and technological advancements. Stakeholders must stay abreast of market trends and innovations to effectively address the challenges and leverage growth opportunities in this critical environmental sector.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Aerospace Foams Market Overview, Top Key Players, Growth Analysis by Forecast to 2031

The Insight Partners stands out as a reliable ally in the syndicated market research and consultation through its steadfast commitment to the market research industry. With extensive experience and proven dedication, we have been delivering outstanding outcomes. With a team of researchers catering to distinct business requirements, we can emerge as a trusted research partner in the past decade.

By prioritizing precision and trust ahead, we are proud to announce the addition of the latest offering titled “Aerospace Foams Market Growth Outlook to 2031”. This report ensures spotless coverage of recent updates and a range of business environment factors impacting the Aerospace Foams market growth. The meticulous approach opted by our researchers can assist companies in transforming business space into the Aerospace Foams market.

Aerospace Foams market report offers a comprehensive analysis of regional and global scenarios. The scope of the market report extends to the competitive landscape, cost analysis, key players, specific market regions, profit margin, and market situation. A glance at wide-ranging factors restricting Aerospace Foams market growth is deliberately included in this study.

Objectives of Aerospace Foams Market Report

To deliver a detailed market overview by integrating quantitative and qualitative analysis

To unveil growth strategies by evaluating the competitive landscape and examining key companies against their position and strategic advantage

To offer estimates on sales volume, market share, size, and CAGR for the projected period.

To offer segment wise insights

This detailed report on Aerospace Foams market size is heavily based on verified information and authoritative sources. The study intended to offer market players an overview of market opportunities in the coming period. This report helps clients as a first-hand source of knowledge on the market while providing a full-fledged analysis of each segment.

The study contains details on frontrunners in the market along with their recent collaborations, segments, revenues, product launches, and Aerospace Foams market trends. It projects the competition in the Aerospace Foams market for an estimated duration. This research further looks at industry channels and the performance of key market players to help businesses stay ahead in the market.

Our Report Sample May Brief On:

Scope of Aerospace Foams market report

Brief introduction of Aerospace Foams market and Industry Overview

Table of Contents

Top market players covered in this report

Report Structure

Research Methodologies by The Insight Partners

Regional Insights:

This section includes insights on different regions and key players present in the region. This section attempts to analyze the growth of a specific regional market based on economic, technological, and environmental factors. Readers may expect revenue-based data and sales insights gathered by our team after comprehensive research. This informative chapter remains an absolute perk for investors, as it will help them to understand potential investment value and expected returns in specific regions.

Report Attributes

Details

Segmental Coverage

Material

PU Foams

PE Foams

Melamine Foams

Others)

End Use

Commercial Aircraft

Military Aircraft

Others)

Application

Aircraft Seats

Aircraft Floor Carpets

Flight Deck Pads

Overhead Stowage Bins

Others)

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Armacell International S.A.

BASF SE

Boyd Corporation

Evonik Industries AG

ERG Materials and Aircraft Corp.

FoamPartner

Rogers Corporation

SABIC

UFP Technologies, Inc.

Zotefoams PLC.

Other key companies

Why The Insight Partners?

Proven Expertise: The Insight Partners comprises expert market research analysts who have extensive industry-specific knowledge. Through this report, our team is bringing years of experience to the table while safeguarding the accuracy of insights.

Actionable Insights: TIP relies on a combination of primary and secondary research methodologies that drive tangible results. We are committed to keeping our offerings clear, accessible, and concise to guide businesses in the decision-making process.

Integration of Technology: We embrace technology in all its forms as the core of our research tactics. We use various tools and platforms to analyze and interpret the data. This allows timely results.

Summary:

Current and Future Market Estimates- Aerospace Foams Market Share, and Size | 2031

Market Dynamics – Drivers, Challenges, Regional Trends, and Market Opportunities

Market Segmentation – Product, Application, End-use Industries, and Regional Growth Prospects.

Competition Matrix – Key Market Players and Strategies

Recent Developments and Innovation contributing Market Growth

Author’s Bio:

Shashikant Ligade

Senior Analyst The Insight Partners

0 notes

Text

Aerospace Foams Market Size, Share, Trends, Forecast 2030

0 notes

Text

The Aluminum Slug Market: Trends, Drivers, and Future Prospects

The aluminum slug market plays a pivotal role in the broader aluminum industry, supplying critical components for a diverse array of end-use applications. These small, cylindrical pieces of aluminum are essential in the manufacturing of various products, ranging from aerosol cans to automotive components. This article delves into the current trends, key drivers, challenges, and future prospects of the aluminum slug market.

Sample Report: https://www.econmarketresearch.com/request-sample/EMR0075/

Market Overview

Aluminum slugs are intermediate products in the aluminum processing chain, produced primarily through the extrusion process. They are further processed into end products by means of impact extrusion, a technique that involves forcing the slug into a mold at high pressure to create hollow shapes. This method is particularly valued for its ability to produce lightweight, durable, and corrosion-resistant items.

Key Applications

The aluminum slug market caters to several significant sectors:

Packaging Industry: One of the largest consumers of aluminum slugs is the packaging industry, especially for producing aerosol cans and beverage containers. The demand for convenient, lightweight, and recyclable packaging solutions has driven the growth in this sector.

Automotive Industry: Aluminum slugs are used to manufacture various automotive components such as shock absorber tubes, airbag inflators, and engine parts. The automotive industry's shift towards lightweight materials to enhance fuel efficiency and reduce emissions has bolstered the demand for aluminum slugs.

Pharmaceutical and Cosmetic Industries: The demand for aluminum tubes in the pharmaceutical and cosmetic industries has been robust, as these sectors require packaging that ensures product safety, hygiene, and extended shelf life.

Electrical and Electronics Industry: Aluminum’s excellent conductivity and lightweight properties make slugs valuable for producing electrical components and housings for electronic devices.

Gate Full Information: https://www.econmarketresearch.com/industry-report/aluminum-slug-market/

Other Reports:

SOC Containers Market Growth

HVAC Chillers Market Size

Aluminum Slug Market

Digital Brain Health Market Analysis

Cognitive Robotics Market Trends

Industrial IoT Display Market Share

Edible Offal Market Application

Potato and Yam Derivatives Market

Surgical Booms Market Overview

Marine Application Market Opportunities

Wind Power Parks Market Revenue

Fuel Cells In Aerospace And Defense Market

Floor Adhesive Market Sales

Pet Fitness Care Market Technology

Axial Flux Motor Market Drivers

Audio and Video Equipment Market Types

Self Stabilizing Spoon Market Challenges

Solar Backsheet Films Market Outlook

Marine Sensors Market Analysis

Dry Shipping Container Market Segmentation

Blood Stream Infection Testing Market Size

Ethyl Vanillin Market Growth

Prebiotic Fiber Market Future

Solar Watch Market Trends

Industrial and Commercial Floor Scrubbers Market Analysis

Electro-Mechanical Brake Market Share

Fiber-Reinforced Plastics Recycling Market Segmentation

Closed Cell Foam Market Drivers

Perfume Ingredient Chemicals Market Technology

Bucket Wheel Excavator Market Revenue

Female Fragrance Market Sales

Yard Crane Market Outlook

0 notes

Text

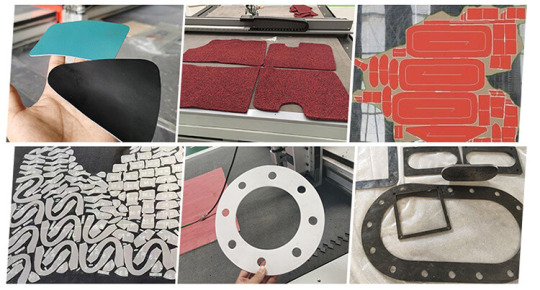

CNC Knife Cutter Machine for PE and EVA Foams

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

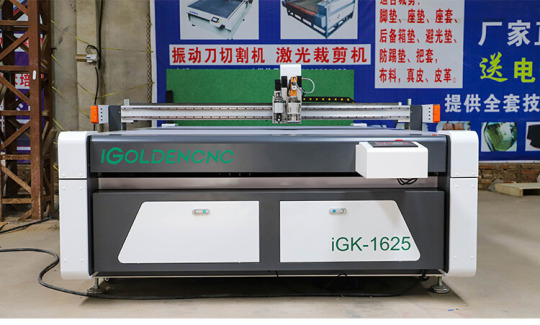

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

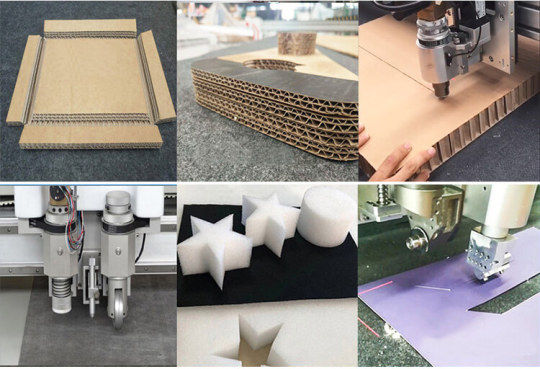

CNC Knife Cutter Machine Processing advantages

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

0 notes

Text

The global aerospace foams market estimated to be valued US$ 4.8 billion in 2020 and poised to grow at significant CAGR of over 8.4% during 2021 to 2027 to reach USD 8.3 billion by 2027. Growing need for economical carrier airlines has augmented the demand for aerospace foam in viable aircrafts, on the account of its insulating properties and excellent lightweight. Moreover, industrial development has boosted the demand for aerospace foam in the aircraft manufacturing. Government initiatives undertaken by government to provide financial assistance in military aircrafts is projected to lift the aerospace market. Furthermore, the rising use age of polyurethane foam products in interior cabins and aircraft flight decks has improved, due to their cushioning formulations and outstanding absorption. However, high cost associated with the use of these products dampens the growth of market. Request Sample : https://www.precisionbusinessinsights.com/request-sample/?product_id=35263

#aerospace foams market size#aerospace foams market share analysis#aerospace foams market growth drivers#aerospace foams market trends#aerospace foams market dynamics

0 notes

Text

The aerospace foams market size is projected to grow from USD 4.4 billion in 2019 to USD 6.5 billion by 2024, at a CAGR of 8.2% from 2019 to 2024. The rising demand for lightweight and fuel-efficient aircraft have led to the extensive use of advanced materials such as PU foams and PE foams, among others, in the aerospace industry. The manufacture of advanced materials as well as new products launched by several prominent players for the aerospace industry is one of the key factors driving the growth of the aerospace foams industry across the globe.

Aerospace foams are advanced materials of various cell sizes, capacities, and properties. The cell sizes of the aerospace foams determine the flexibility or rigidity of the foams and thus, dictates the application areas where they can be used. Aerospace foams are manufactured using various materials, such as PU (polyurethane), PE (polyethylene), melamine, metal, and PMI/polyimide, among others, which meet the flame, smoke, and toxicity (FST) standards in the aerospace industry. These foams are used in various applications in aircrafts such as seating, seals, gaskets, carpet pads, headrests, rotor blades, doors, windshields, cockpit instrument panels, wingtip lens, and several others.

Based on material type, the aerospace foams market has been segmented into PU foams, PE foams, melamine foams, metal foams, PMI/polyimide foams, and others which includes PVDF foams, PPSU foams, silicone foams, ceramic foams, PEI foams, PET foams, PVC foams, and polycarbonate foams. The PU foams segment has the highest market share in terms of both value and volume, among all the material type segments in 2018. It is projected to follow the same trend from 2019 to 2024 in terms of both value and volume. PU foams are used in a variety of applications ranging from seating, airframes, interiors, and packaging in the aerospace industry. The availability in different forms ranging from low to high density with varying rigidity as well as ease-of-use makes them compatible to be used in a multitude of aerospace applications. Some useful properties of PU foams include durability, lightweight, and recyclability. These factors support the rising global demands for lightweight and fuel-efficient aircraft, which is one of the primary drivers of the aerospace foams market.

#Aerospace Foams Market#PU Foams#PE Foams#Melamine Foams#Metal Foams#PMI Foam#Polyimide Foams#erg metal foam#Global Aerospace Foams Market#COVID 19 impact on Aerospace Foams Market#Aviation foam suppliers#Aircraft structural foam#Aerospace Foams industry#Aerospace Foams Market Share#Aerospace Foams Market size#Demand of Aerospace Foams#Sales of Aerospace Foams#Aerospace Foams Market Manufacturers#Aerospace Foams Market Opportunity#growth of the aerospace foams industry#commercial aircraft Foams#aviation foams#PU aerospace foams

0 notes

Text

0 notes

Text

Coating Additives Market Industry Analysis| 2031

The Insight Partners introduces its new market research as “Coating Additives Market Industry Analysis| 2031”. The company specializes in syndicated market research and consultation services. Through this research company is offering both qualitative and quantitative data assisting Coating Additives market investors.

Key Chapters Under This Research

Current Market Scenario and Estimates to 2031

Market Drivers, Opportunities, and Trends

Market Competition Analysis

This chapter offers insights on established and new entrant Coating Additives market players. Understanding competition helps companies understand their position in the market. Through this chapter, the report offers insights on threats and opportunities ahead of Coating Additives market players. Comparing pricing strategies and organic growth strategies used by key market participants provides opportunities for growth in the Coating Additives market.

Report Attributes

Details

Segmental Coverage

Type

Acrylic

Metallic

Fluoropolymer

Urethane

Others

Formulation

Water-Borne

Solvent-Borne

Powder-Based

Function

Anti-Foaming

Wetting and Dispersion

Biocides

Rheology Modification

Others

Application

Automotive

Architectural

Industrial

Wood and Furniture

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

AkzoNobelN.V.

ArkemaGroup

AshlandInc.

BASFSE

BYK-ChemieGmbH

EastmanChemicalCompany

Elementisplc

EvonikIndustriesAG

MomentivePerformanceMaterialsInc.

TheDowChemicalCompany

Other key companies

Research Methodology

This Coating Additives market report includes findings based on scrutiny of different factors impacting on business environment. Both primary and secondary methods of research are used to generate insights. Details on Coating Additives market share, key players, micro-financial pointers, and other demographic factors.

Key market players are analyzed for their market share and overall growth in the industry. Based on forecast duration, these key market players are evaluated for their incomes. This market research brings local, regional, and national level information on the market

Go-To-Market Framework:

Development trends, competitive landscape analysis, supply-side analysis, demand-side analysis, year-on-year growth, competitive benchmarking, vendor identification, CMI quadrant, and other significant analysis, as well as development status.

Customized regional/country reports as per request and country-level analysis.

Potential & niche segments and regions exhibiting promising Coating Additives market growth are covered.

Analysis of Coating Additives Market Size (historical and forecast), Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM), Market Growth, Technological Trends, Market Share, Market Dynamics, Competitive Landscape, and Major Players (Innovators, Start-ups, Laggard, and Pioneer).

Key Benefits for Buyers

Strategic Insights to increase per-customer revenue and overall consumer experience.

Assistance and strategic roadmap to device marketing tactics

Details-oriented approach, authorized information, and new optimal business solutions

Preferred target demographic, regions, and market channels

Customized Insights and Consultation services.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

Eco-friendly Innovations Propel Industrial Foam Market Toward Sustainable Growth on Global Scale by 2033

Overview and Scope

Industrial foam is an expanded plastic and rubber created by forcing gas bubbles into a polymer material. Industrial foam is highly-efficient for insulation against water, air, chemical substances, and adhesives. Industrial foam is used as padding for several consumer and business products, such as mattresses, furniture, car interiors, carpet underlay, and packaging.

Sizing and Forecast

The industrial foam market size has grown strongly in recent years. It will grow from $63.14 billion in 2023 to $68.05 billion in 2024 at a compound annual growth rate (CAGR) of 7.8%.

The industrial foam market size is expected to see strong growth in the next few years. It will grow to $91.5 billion in 2028 at a compound annual growth rate (CAGR) of 7.7%.

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/industrial-foam-global-market-report

Segmentation & Regional Insights

The industrial foam market covered in this report is segmented –

1) By Foam Type: Flexible, Rigid

2) By Resin Type: Polyurethane, Polystyrene, Polyolefin, Phenolic, PET, Other Resin Types

3) By End-Use: Building And Construction, HVAC, Industrial Pipe Insulation, Marine, Aerospace, Industrial Cold Storage, Others End-Uses

Asia-Pacific was the largest region in the industrial foam market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the industrial foam market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8209&type=smp

Major Driver Impacting Market Growth

Growing demand for energy-efficient and lightweight materials is expected to propel the industrial foam market. Lightweight materials are manufactured using lightweight raw materials that directly reduce the weight of the material while maintaining its performance. Industrial foam is a type of lightweight material made up of tiny cells filled with gas or air and used in applications such as insulation, packaging, and construction.

Key Industry Players

Major companies operating in the industrial foam market report are Covestro AG, BASF SE, Dow Inc., Huntsman Corporation, Sekisui Chemical Co. Ltd., Saint-Gobain S.A., Chemtura Corporation, Recticel N.V, Rogers Corporation

The industrial foam market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes