#commercial aircraft Foams

Text

I know we've been manifesting S8 Air Ops since that photo of a hangar was posted by a member of the scouting team. And I know the other side has been mocking us for being delusional when other bts photos of an aircraft came out. So here I am, taking my shipper's goggles off, and diving into the aviation side of things. I have to admit, it left me with more questions than answers.

They already have a hangar for Air Ops in S7, they don't need another one

No. The 911!Air Ops we see in S7 is the Helinet hangar at Van Nuys Airport. Helinet is a company that rents and operates helicopters for news stations, film crews, medivac service or regular charter flights. You can compare images from 7x02 and 7x03 with Google Street Views of the Helinet Hangar.

You can also see N67TV and N29HD here.

Helinet is where ABC usually rents its news helicopters from, so it's cheaper and more convenient to film a couple scenes there when helicopters are needed. It can't be used for regular filming though, because Helinet has a business to run, and when a helicopter takes off, it's so noisy that you can't even hear each other talking, let alone shooting a scene. (I recommend watching the whole video, if you're interested in accuracy when it comes to writing fics.)

It's a plane related emergency so it must be related to Tommy

Also no. Again, I've written a piece about how Tommy was not the air tanker pilot in 2x14 before, and if he was not qualified for that, he's not qualified to fly an airliner either. It's not impossible that he flies a small turboprop aircraft like a Cessna 172, but he would never have the time to get certified as a commercial airliner pilot while working as an active firefighter since 2005.

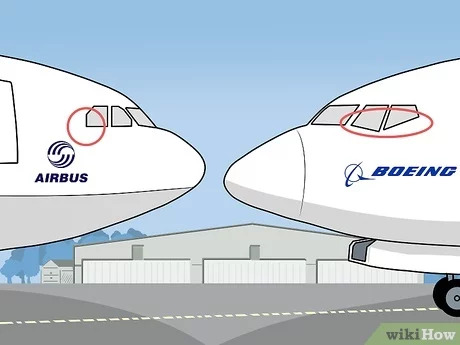

And this is a prop for an Airbus airliner.

It's actually pretty easy to tell an Airbus aircraft from a Boeing one, as the shape of the rear cockpit windows is pretty different between the two. It's just a matter of which Airbus model it is. I believe it's a narrow body single aisle aircraft from the A320 family.

Wide body Airbus aircrafts, like this A300, have their side cockpit windows more tapered to the top. It also applies to other Airbus twin aisle aircrafts, like the A330 and the A340.

On the A320 though, the side windows are flat on the top.

So it's a pretty safe bet that the aircraft we see in that bts photo is one from the A320 family. I can't pinpoint which one it exactly is, because again, I can just see a tiny section of the cockpit, not the rest of the aircraft.

So the hangar must be for the airplane then?

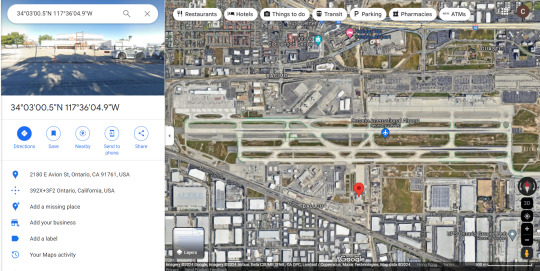

The hangar itself is a former Air National Guard maintenance hangar at Ontario International Airport (ONT/KONT). It's especially used for filming. There are bigger hangars at the same airport for filming, but this one looks the best on camera.

They don't need a hangar for scenes inside of the plane, they have cockpit and cabin mock-ups at the studio for them.

You can clearly see the cabin door right here from recent bts footage. It looks just like a training facility for flight attendants.

They only film on location if they want shots of the entire aircraft from the outside. Like in 1x04, the scenes of Athena responding to an alleged unruly passenger were filmed in a set. The plane crash rescue parts of the episode though, were filmed in an actual retired 757 in a tub of water.

youtube

(Lone Star worked with this exact company for 3x08. Though, that plane was a 737 I believe.)

I can't think of any disastrous scenario happening in a maintenance hangar, where the aircraft is powered off with only maintenance staff present, no passengers or crew. Well, there have been cases of planes crashing into a hangar, but even then I don't see the need for the 118 to be there. Every major airport has at least one fire station on site with dedicated foam and crash units. In fact, there is a fire station right next to this hangar IRL.

Another problem, although I'm not sure because I don't have the actual measurements, is that the celling of the hangar looks quite low. (Refer to page 44 of this document) It was originally built in 1955 to house fighter jets. The F-102, the type of aircraft operated there in the 60s and 70s, has a total height of 6.5 meters. The tail of an A320 on the other hand can reach 11.76 m from the ground. (The shortest variant of the A320 family is actually even taller, 12.51 m.) So there could be some tail bumping action if you try to tow an A320 into this hangar.

So Air Ops is still a possibility?

Yes. This hangar is quite a bit larger than the Helinet hangar, but still not as big as the actual Air Ops facility. A helicopter is obviously much smaller than a passenger airliner that can seat over 180, you can easily fit multiple helicopters in there with plenty of space left for other set props. But the problem is, they don't have enough helicopters.

They have that one replica of N211FN that they used to film the search and rescue in 7x03, that's it. All the other helicopters you see on screen, including the real N211FN that actually flies, belong to Helinet. Sure, they can get some more fake helicopters that are empty inside just for looks, but I don't see the need to spend so much extra money just to show Tommy's place of work unless it's related to some major plot points. For now, I don't see how that would fit into the story.

There is also the possibility that the hangar has nothing to do with anything aviation related. I mean, they've filmed countless ads, music videos and movies, including Ford vs Ferrari there. Your guess is as good as mine. Maybe that's why that crew member eventually got the green light to confirm the hangar is indeed for 9-1-1, it tells us absolutely nothing.

51 notes

·

View notes

Note

I have no idea if you answered it yet but,

As an avid plane and aerospace fan, I gotta know what Pat's fav plane according to your standards. And I don't mean like commercial plane, no that's too boring. I want to see what's the most fucked up army or dismissed plane projects he'd absolutely foam about. Like the X-29. Or really niche unconventional plane.

GOD i don't wanna seem like a dork in front of people who are actually into aircrafts but like. Just by doing a quick research on unconventional aircrafts I've been finding so many silly looking ones he'd totally be into like .

Why do they have a snoot. They're so silly

10 notes

·

View notes

Text

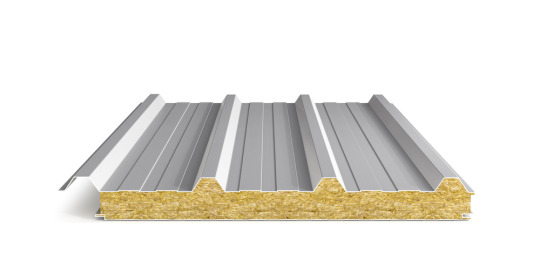

The Practical Benefits of PUF Panels for Commercial Construction: A Comprehensive Guide

Few places is this more apparent than in the world of industrial/commercial construction, where making the right material choices can have a marked effect on how long a project lasts, as well as its capacity for energy efficiency and overall cost-effectiveness. Construction Quality PUF Panels are getting widely promoted for their property of thermal insulation value, energy conservation and structural strength and that is why it is more considered to be the first choice for industries those who strive for efficiency and long-lasting durability.

In this post, we delve into the fundamental, concrete advantages of incorporating PUF Sandwich Panels in commercial ventures and elucidate why they are the preferred choice for heavy industries across India.

Quick and Easy Installation: As compared to conventional building methods, PUF Panels are light-weight on account of flexibility which makes the panel quicker to install that means faster construction. They are also more easily managed, reducing labor, and construction time. Nowhere is this more important than in commercial sectors such as warehouses, industrial sheds and cold storage units — where swift of project timelines remain critical without loss of quality, all to enhance levels of competitiveness. Less labor is needed which means these panels are one of the most cost-effective on the market.

Enhanced Thermal Insulation and Energy Savings: The principal attribute of PUF Panels for Construction, is its excellent thermal insulation. The panels come with a layer of polyurethane foam for insulation and protection against the external temperature. It makes it possible for companies to preserve a constant interior environment year-round, such as in cold storage or clean room. The result? Significant energy savings. Reports suggest that the usage of PUF Insulated Sandwich Panels in buildings can reduce energy consumption by as much as 50%, translating into large savings on heating and cooling expenses.

Long Lifetime and Durable: PUF panels are extremely durable, has high resistance against all weather conditions throughout its life, in case of extreme heat or cold. Because of this, PUF Roofing Panels are a long-term solution for industries like aircraft hangars, metro stations and industrial enclosures where the structure has to endure environmental stress while continuing its operations. Consequently, PUF Sandwich Panels possess an economical and sturdy solution against the corrosion as well pests & fungi affording a long endurance with negligible maintenance costs.

4. Versatility Across Applications: One of the main benefits of Sandwich PUF panels is their versatility across applications. These panels are widely used as wall panelling, roofing and factory buildings and multistored car parking etc. Because of their modularity, they can be easily dismantled and reassembled on another site if needed, so they are useful for industries which frequent relocate. Being useful for projects like hospital buildings, school buildings, foot over bridges and similar business can take benefit of the versatile PUF panels.

5. Low Maintenance After installation: PUF Panels hardly need any maintenance. Termites, rust and environmental damage — internet cables are immune to all of these common problems. As a result, globally they prove to be an energy-saving solution for commercial structures such as auditoriums, exhibition halls and metro/bus/railway stations, where the maintenance costs are typically high.

6. Flexibility: This is a common belief that these panels are purely to cater the need and do not have much aesthetic value, but PUF Sandwich Panels provide for high degree of customization. These panels are available in different thickness, colors and textures that can be customized according to the design as well as the aesthetic of a building. These make them ideal for architectural and specific applications the other than an industrial shed like office buildings, shopping complex & stadiums.

India-Specific Data Points:

How PUF Panels Can Boost Energy Efficiency Here in India, energy efficiency has been a major concern for enterprises across various sectors that include warehousing and industrial construction. Buildings contribute to almost 30% of the total energy consumption in India, as per Bureau of Energy Efficiency When companies make use of PUF Panels for Construction, they can save a lot of money each year on electricity. These panels provide thermal protection and hence lower the use of artificial heating or cooling that is very advantageous in places like Gujarat, Rajasthan – where temperatures can touch extreme highs and hence energy consumption will be uncontrollable.

The other aspect that also supports the insulation space is the requirement of PUF Insulated Sandwich Panels in India given its massive growth enhances with which our cold chain industry is growing. With a CAGR growth of 14% estimated by the National Centre for Cold-chain Development (NCCD) by 2025, India stands tall to expand its cold chain sector.

This will guarantee both the levels of energy loss and the maintenance of optimal temperatures for whatever goods being stored in a given warehouse while minimising utility bills as much as possible.

Why EPACK Prefab?

One of the most trusted PUF Panel Suppliers in India, EPACK Prefab is known for its high quality custom solutions suitable for various industries. EPACK has years of experience in prefabricated and pre-engineered building systems, which have enabled us to successfully satisfy numerous clients from across the country. PUF Insulation Panels are designed with the best of thermal performance, long life and also ease of installation. Our panels can used in many of applications ranging from the cold storage units to control rooms and GIS buildings.

Our core competencies lies in the turnkey solution where we deliver PUF Panels also coupled with whole range of other components of prefab and pre engineered building structures. Industry: Warehousing, Airport Terminal Buildings or any other large-scale Commercial Project, so that your building materials are best in class and optimum cost & energy efficient.

youtube

Conclusion:

PUF Panels for Construction — More than just Thermal Insulation and Energy Saving With their fast installation, durability and flexibility they suit a wide spectrum of commercial applications from industrial sheds to factory buildings & school buildings to stadiums. In light of India's recent push toward energy efficiency and sustainable construction, PUF Sandwich Panels are poised to drive a new age of architecture in the nation. We, the EPACK Prefab are specialized in delivering avant-grade PUF Panels to cater different industrial needs all over India.

Count on us if you have a cold storage plant to build, an airport terminal to construct or that office building.

Read More: PUF Panels – Reliable and Energy Efficient

#PUFPanels#ConstructionMaterials#ThermalInsulation#EnergyEfficiency#PUFInsulatedPanels#PrefabConstruction#IndustrialSheds#ColdStorageSolutions#WarehouseConstruction#CommercialBuildings#PrefabricatedBuildings#PUFPanelsForConstruction#SandwichPUFPanels#EnergySavings#EPACKPrefab#BuildingSolutions#SustainableConstruction#IndustrialConstruction#FactoryBuildings#InsulationPanels#Youtube

0 notes

Text

Aerospace Foam Market: Dominance of North America in Driving Innovations and Market Growth

Introduction

The aerospace foam market is a critical component of the aerospace industry, providing essential materials that enhance the performance, safety, and efficiency of aircraft. These foams are used in various applications, including seating, insulation, packaging, and structural components.

As the aerospace industry continues to evolve, the demand for high-performance materials such as aerospace foams is on the rise. North America, in particular, stands out as the dominant region in this market, driven by technological advancements, a robust aerospace sector, and significant investments in research and development.

Download Free Sample: https://www.nextmsc.com/aerospace-foam-market/request-sample

Key Drivers of the Aerospace Foam Market in North America

Technological Advancements

North America is home to some of the world's leading aerospace companies and research institutions, which are at the forefront of technological advancements.

The region's focus on innovation has led to the development of advanced aerospace foams with enhanced properties such as improved thermal insulation, fire resistance, and lightweight characteristics. These advancements are crucial for meeting the stringent safety and performance standards of modern aircraft.

Robust Aerospace Sector

The aerospace sector in North America, particularly in the United States, is one of the largest and most advanced in the world. This sector encompasses a wide range of activities, including commercial aviation, defense, and space exploration.

The presence of major aircraft manufacturers, such as Boeing and Lockheed Martin, drives the demand for high-quality aerospace foams. Additionally, the defense sector's need for advanced materials for military aircraft and spacecraft further fuels market growth.

Investments in Research and Development

Significant investments in research and development (R&D) are a hallmark of the North American aerospace industry. Both government and private sectors allocate substantial funds to R&D projects aimed at developing new materials and improving existing ones.

This emphasis on R&D has resulted in continuous innovation in aerospace foams, making them more efficient, durable, and environmentally friendly. Government initiatives and collaborations between industry players and research institutions play a pivotal role in fostering these advancements.

Inquire Before Buying: https://www.nextmsc.com/aerospace-foam-market/inquire-before-buying

Key Applications of Aerospace Foams in North America

Seating and Interior Components

One of the primary applications of aerospace foams is in aircraft seating and interior components. Lightweight foams are used to manufacture comfortable and durable seats that contribute to the overall weight reduction of the aircraft. This weight reduction is essential for improving fuel efficiency and reducing emissions.

Additionally, aerospace foams are utilized in interior panels, overhead compartments, and other cabin components to enhance passenger safety and comfort.

Insulation and Noise Reduction

Aerospace foams are extensively used for insulation and noise reduction purposes. These foams provide excellent thermal insulation, helping to maintain a stable internal temperature in the aircraft.

Moreover, they play a crucial role in reducing noise levels within the cabin, ensuring a more pleasant flying experience for passengers. The ability of aerospace foams to dampen vibrations and minimize noise is especially important in the development of quieter and more efficient aircraft.

Structural Components and Packaging

In addition to seating and insulation, aerospace foams are used in various structural components and packaging applications. High-strength foams are employed in the construction of lightweight yet robust structures, such as wings, fuselage panels, and control surfaces.

These foams provide the necessary strength and rigidity while minimizing the overall weight of the aircraft. Furthermore, aerospace foams are utilized in packaging to protect delicate components and equipment during transportation and storage.

Market Trends and Opportunities

Growing Demand for Lightweight Materials

The aerospace industry is continuously striving to develop lighter and more fuel-efficient aircraft. This trend is driving the demand for lightweight materials, including advanced aerospace foams.

Manufacturers are focusing on developing foams with superior strength-to-weight ratios to meet the industry's evolving requirements.

The adoption of lightweight materials not only enhances fuel efficiency but also contributes to the reduction of greenhouse gas emissions, aligning with the industry's sustainability goals.

Increasing Use of Bio-Based Foams

Environmental sustainability is a significant concern in the aerospace industry. As a result, there is a growing interest in bio-based aerospace foams derived from renewable resources.

These foams offer similar or even superior performance characteristics compared to traditional petroleum-based foams while reducing the environmental footprint. The development and adoption of bio-based foams represent a promising opportunity for the aerospace foam market in North America.

Advancements in Manufacturing Techniques

Advancements in manufacturing techniques, such as additive manufacturing (3D printing), are revolutionizing the aerospace foam market. Additive manufacturing enables the production of complex foam structures with precise control over material properties.

This technology allows for the creation of customized aerospace foams tailored to specific applications, improving performance and efficiency. The integration of additive manufacturing into the aerospace foam production process is expected to drive market growth and open new avenues for innovation.

Focus on Fire-Resistant Materials

Safety is paramount in the aerospace industry, and the development of fire-resistant materials is a top priority. Aerospace foams with enhanced fire resistance properties are in high demand to ensure passenger safety and comply with stringent regulatory standards.

Ongoing research and development efforts are focused on improving the fire-resistant characteristics of aerospace foams without compromising their other performance attributes. This emphasis on safety is expected to drive the adoption of advanced fire-resistant foams in the market.

Conclusion

North America remains the dominant region in the aerospace foam market, driven by technological advancements, a robust aerospace sector, and significant investments in research and development. The region's focus on innovation and sustainability is propelling the market forward, with growing demand for lightweight, bio-based, and fire-resistant foams.

As the aerospace industry continues to evolve, the North American aerospace foam market is poised for sustained growth, contributing to the development of safer, more efficient, and environmentally friendly aircraft.

#aerospace foam#aerospace and defense industry#aviation#market research'#industry trends#industry analysis#business insights

0 notes

Text

Thermoplastic Elastomer Market Size, Share and Growth Report, 2031

Global thermoplastic elastomers market is projected to witness a CAGR of 3.9% during the forecast period 2024-2031, growing from 6.25 million tons in 2023 to 8.49 million tons in 2031. The flourishing footwear industry is augmenting the demand for thermoplastic elastomers market growth. This growth is attributed to footwear sales through e-commerce sites and increasing sports events. The increasing deployment of thermoplastic elastomers in transport parts bolstered market growth. For instance, according to the Alliance for Automotive Manufacturers, in 2022, investments in automotive parts manufacturing reached USD 43 billion.

The robust growth of the transportation sector is ascribed to various factors, including the production expansion of aircraft, multiple government initiatives to develop electric vehicle manufacturing hubs, and the ongoing manufacturing activities associated with the new marine vessels. The increasing consumer demand for a new range of footwear, shifting consumer preferences, and advancements in manufacturing technologies are some of the prime attributes influencing the growth of the footwear industry at the global level. Thus, the robust growth of the transportation and footwear sectors at the global level is boosting the demand for thermoplastic elastomers to ensure superior chemical resistance, which, in turn, is supplementing the market growth.

In addition, the recent opening of new facilities for thermoplastic elastomer development will boost the supply of products in the global market, thereby creating a lucrative opportunity for market growth in the long run. For instance, in October 2022, Audia Elastomers launched a new manufacturing plant in Changshu, China. The new manufacturing facility of Audia Elastomers is manufacturing a range of elastomers, including thermoplastic elastomers (TPEs). However, thermoplastic elastomers have several performance limitations, restraining the market’s growth.

The Booming Transportation Industry at the Global Level is Augmenting the Market Traction

In the transportation industry, deploying thermoplastic elastomers is vital as the material ensures superior benefits, such as being lightweight, cost-effective, and highly durable, as opposed to thermoset materials in the total system cost, thereby making it increasingly desirable for transport product manufacturers. Thermoplastic elastomers are employed in transportation products such as commercial aircraft, passenger vehicles, cruise ships, and others. The development of new transport manufacturing facilities, rising commercial flight activities, increasing aircraft production, and surging innovations in the upgraded transport vehicle models are some of the prominent variables fostering the transportation sector’s growth at the global level.

For instance, according to Airbus, a global aircraft manufacturer, the production of A330 aircraft reached 3 per month in 2022. Moreover, Airbus is focusing on increasing the production of A330 aircraft by 4 in 2024. Furthermore, Airbus delivered 611 commercial aircraft units, and in 2022, it was 661 units, an annual growth rate of 8%. Hence, the booming transportation industry is fueling the adoption of thermoplastic elastomers for manufacturing bumpers, air ducts, and high & low-pressure pipes, which forms a major aspect accelerating the market growth.

Download free Sample Report- https://www.marketsandata.com/industry-reports/thermoplastic-elastomers-market/sample-request

The Bolstering Footwear Sector is Supplementing the Growth of the Market

Thermoplastic elastomers are ideal for manufacturing footwear midsoles as TPEs serve significantly higher levels of flexibility than traditional materials such as ethylene-vinyl acetate (EVA) foams. Additionally, thermoplastic elastomers can be molded into complex shapes for enhanced cushioning, shock absorbency, and support. The footwear sector is experiencing significant demand growth due to several key factors, including the growing sales facilitated by e-commerce, extensive spending on advertising by footwear brands, rising demand for athletic, trendy, and comfortable footwear, and rapid urbanization.

According to the recent statistics published by the World Footwear Yearbook 2023, 2022 global footwear production was 23.9 billion pairs, representing a year-on-year growth rate of 7.6%. Likewise, according to the Sports & Fitness Industry Association (SFIA), the sporting goods industry experienced record-breaking sales in 2021, with a 15.8% increase in revenue from 2020 and a 16.4% increase since 2019 pre-pandemic numbers. Henceforth, the bolstering footwear sector is spurring the demand for thermoplastic elastomers to ensure superior damping properties, propelling the market growth.

Superior Technical Properties of Thermoplastic Elastomers are Amplifying the Market Growth

The thermoplastic elastomers are equipped with beneficial technical properties such as specific gravity at 0.89-1.0, shore hardness of 60A-75D, low-temperature limit at -60°C, high-temperature limit at 120°C, compression set resistance at 100 °C, and resistance to hydrocarbon fluids. Thus, due to the above technical properties, thermoplastic elastomers are often deployed in various applications such as transport parts, construction extruded seals, and electrical and electronic components.

For instance, according to the recent data published by Invest India, in 2022, the production of electronic components in India was valued at USD 11 billion and is projected to reach USD 18 billion by 2026. Therefore, the superior technical properties associated with thermoplastic elastomers augment the adoption of TPEs across various applications, thereby proliferating the market growth.

Asia-Pacific Held a Significant Share in the Thermoplastic Elastomers Market

The regional economic growth of the Asia-Pacific is driven by the expansion of the various end-use industries such as medical equipment, transportation, building & construction, and industrial. Prominent variables, such as increasing spending power of people, flexible trade regulations, easy availability of raw materials, and ease of import-export policies, are some of the favorable aspects fostering the growth of the transportation sector in the Asia Pacific region.

According to the recent report published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2022, the Asia Pacific region held the highest manufacturing share in the global automotive share, which was 58.8% of the global automotive share. Moreover, in 2021, the production of automobiles in the Asia-Pacific region was 46,768,800 units, whereas in 2022, it was 50,020,793, representing a year-on-year growth rate of 7%. Thus, the booming transportation sector in the Asia-Pacific region is boosting the adoption of thermoplastic elastomers to ensure superior durability, thereby supplementing the market growth in the region.

Impact of COVID-19

The COVID-19 pandemic in 2020 restrained the supply of raw materials, labor movement, and halt in the production of non-essential industrial products. As a result, the demand for thermoplastic elastomers declined. Furthermore, the demand revenue losses incurred by various end-use industries, such as transportation, industrial, and building and construction, resulted in the decline in the growth of the thermoplastic elastomers industry.

For instance, according to the statistics published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2019, the global production of automotive was 92,175,805 units and in 2020, it was 77,621,582, a decline of 15.8%. However, the sudden surge in the need for medical equipment boosted the demand for thermoplastic elastomers. Additionally, favorable government measures across various countries efficiently promoted the resurgence of various end-use industries, including thermoplastic elastomers, thereby accelerating the market growth in the years 2021 and 2022.

Impact of Russia Ukraine War

The Russia and Ukraine war had a strong impact on respective economies. Since Russia is among the major trade partners of Europe, the supply chain disruption strongly impacted the production activities in the region. As a result, there was a shortage of automotive components in the European countries during 2022, ultimately resulting in a decline in automotive production in the region.

For instance, according to the recent data published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2021, the automotive production in Netherlands was 107,021 units and in 2022, it was 101,670 units, an annual decline of 5% as compared to 2021. However, the procurement of materials from local sources and other prominent markets such as China and India aided the growth of the thermoplastic elastomers market despite the impact of the Russia-Ukraine war in the first half of 2022.

Report Scope

“Thermoplastic Elastomers Market Assessment, Opportunities and Forecast, 2017-2031F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of the global thermoplastic elastomers market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities, and forecast between 2024 and 2031. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/thermoplastic-elastomers-market

Contact

Mr. Vivek Gupta

5741 Cleveland street,

Suite 120, VA beach, VA, USA 23462

Tel: +1 (757) 343–3258

Email: [email protected]

Website: https://www.marketsandata.com

#Thermoplastic Elastomer Market#Thermoplastic Elastomer Market Size#Thermoplastic Elastomer Market Share

0 notes

Text

What is firefighting pipes ? and where is uses and benefits...

Firefighting pipes, also known as fire protection pipes or fire sprinkler pipes, are specialized piping systems designed to transport water or other fire suppression agents to extinguish fires. These pipes are a critical component of fire protection systems in buildings and industrial facilities.

Uses of Firefighting Pipes:

Fire Sprinkler Systems:

Used to distribute water to fire sprinkler heads installed in ceilings or walls of buildings. When a fire is detected, the sprinkler heads release water to suppress or extinguish the fire.

Fire Hydrant Systems:

Connected to fire hydrants, allowing firefighters to access a reliable water supply for firefighting.

Standpipe Systems:

Vertical pipes installed in multi-story buildings, providing firefighters with easy access to water on each floor.

Deluge Systems:

Designed to quickly deliver large volumes of water over a specific area, typically used in high-hazard areas like chemical plants or aircraft hangars.

Foam Systems:

Used in facilities where water alone might not be effective, such as oil refineries or chemical storage areas. These systems mix foam concentrate with water to create a foam solution that can suppress flammable liquid fires.

Wet and Dry Systems:

Wet systems maintain water in the pipes at all times, while dry systems keep the pipes empty until a fire is detected, at which point the pipes are filled with water.

Benefits of Firefighting Pipes:

Enhanced Safety:

Provides a reliable means of quickly delivering water or other fire suppression agents to control or extinguish fires, thereby protecting lives and property.

Compliance with Regulations:

Essential for meeting building codes and fire safety regulations, ensuring that structures are legally compliant and safe for occupancy.

Rapid Response:

Allows for an immediate response to fires, significantly reducing the potential for damage and the spread of fire.

Versatility:

Can be used in a variety of environments, including residential, commercial, industrial, and public buildings.

Durability:

Made from materials that can withstand high pressure and temperature, ensuring long-lasting performance even in emergency situations.

Low Maintenance:

Designed to require minimal maintenance, with regular inspections ensuring that the system remains operational and ready to use.

Firefighter Support:

Provides firefighters with a reliable water supply, enhancing their ability to combat fires effectively and safely.

Insurance Benefits:

Buildings equipped with proper fire protection systems may benefit from lower insurance premiums due to the reduced risk of fire damage.

Peace of Mind:

Knowing that an effective fire protection system is in place can provide peace of mind to building occupants, owners, and managers.

Types of Materials Used in Firefighting Pipes:

Galvanized Steel:

Commonly used due to its strength and corrosion resistance.

Stainless Steel:

Preferred in environments where corrosion resistance is paramount, such as in chemical plants or coastal areas.

Copper:

Used in certain applications due to its durability and resistance to corrosion.

CPVC (Chlorinated Polyvinyl Chloride):

A type of plastic pipe that is lightweight, easy to install, and resistant to corrosion and scale buildup.

Ductile Iron:

Used in some high-pressure applications due to its strength and durability.

Firefighting pipes are a crucial element of fire protection systems, offering a reliable means to deliver fire suppression agents and enhance the safety of buildings and their occupants. Their ability to quickly respond to fires and their durability make them indispensable in modern fire safety infrastructure.

More Read: Best Firefighting Pipes

0 notes

Text

Molded Foam Component Market 2024: Emerging Trends, Major Driving Factors, Business Growth Opportunities

Molded Foam Component Market provides in-depth analysis of the market state of Molded Foam Component manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Molded Foam Component in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Molded Foam Component Market Report:

The report offers a comprehensive and broad perspective on the global Molded Foam Component Market.

The market statistics represented in different Molded Foam Component segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Molded Foam Component are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Molded Foam Component.

Major stakeholders, key companies Molded Foam Component, investment feasibility and new market entrants study is offered.

Development scope of Molded Foam Component in each market segment is covered in this report. The macro and micro-economic factors affecting the Molded Foam Component Market

Advancement is elaborated in this report. The upstream and downstream components of Molded Foam Component and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/molded-foam-component-market-101483

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Molded Foam Component Market

Narrowband IoT (NB-IoT) Chipset Market Growth

Global Hydrogen Production Equipment by Electrolysis of Water Market Growth

Global UVC LED Market Size

Global Truffle Oil Market Share

Flow Switches Market Forecast

Hand Dryers Market Size

Smart Meter Market Growth Rate

Earmuffs Market Analysis

Blockchain in Telecom Market Share

Ultrasonic Level Sensors Market Growth

Roof Insulation Market

Global Student Information System Market Size

Global Lithium-Sulfur Battery Market Growth

Thermoplastic Polyurethane (TPU) Market Forecast

Global Distributed Natural Gas-Fueled Generation Market Share

AI (Artificial Intelligence) Image Recognition Market Growth Rate

Circular Push Pull Connectors Market Size

Fleece Knitting Yarn Market Share

Apheresis Machines Market Analysis

Underwater ROV Market

Metal Seals Market Growth

Global Automotive Remote Diagnostics Market Growth

Global Portable Engine Driven Pumps Market Size

Global Strapping Market Share

Isolator Gloves Market Forecast

Ion Exchange Resins Market Size

Sterilization Equipment and Disinfectants Market Growth Rate

Commercial Aircraft Battery Management System (BMS) Market Analysis

Burn Treatment Anti-Infectives Products Market Share

Cloud Infrastructure Services Market Growth

Security Screening Market

Global Breast Imaging Equipment Market Size

Global Food Grade Phosphates Market Growth

Agarose Market Forecast

Global Industrial Door Sensing Devices Market Share

Intelligent Hearing Protection Device Market Growth Rate

Air Quality Apps Market Size

Commercial Clothes Dryer Market Share

Digital Impression Standalone Scanners Market Analysis

#Molded Foam Component Market Size#Molded Foam Component Market Share#Molded Foam Component Market Trends#Molded Foam Component Market Industry#Molded Foam Component Market Growth

0 notes

Text

Couplings Fire Hoses: Ensuring Reliable Fire Protection in Every Crisis

In the face of a fire emergency, every second counts. Reliable firefighting equipment is not just a necessity but a lifeline that can make the difference between containment and catastrophe. Among the crucial components of firefighting arsenal are couplings fire hoses, designed to deliver water swiftly and efficiently to the heart of the blaze. In this blog, we explore the vital role of couplings fire hoses in fire suppression, their key features, and how they contribute to saving lives and protecting property during emergencies.

The Importance of Couplings Fire Hoses

Couplings fire hoses are essential tools in the firefighting toolkit, serving as the conduit through which water is delivered from a pressurized water source to the fire site. These hoses are specifically designed to withstand the extreme conditions encountered during firefighting operations, including high temperatures, abrasion, and exposure to chemicals and debris. Couplings, typically made of durable materials such as aluminum or brass, provide secure connections between lengths of hose, ensuring uninterrupted water flow under pressure.

Key Features and Specifications

Couplings fire hoses come in a variety of sizes, materials, and configurations to meet the diverse needs of firefighting professionals. Standard hose diameters range from 1 inch to 6 inches, with larger diameters capable of delivering higher volumes of water for more significant fires. The choice of hose material depends on factors such as durability, flexibility, and resistance to heat and abrasion. Common materials include synthetic rubber, thermoplastic, and woven fabric reinforced with polyester or nylon.

Furthermore, couplings fire hoses are often equipped with additional features to enhance performance and usability. These may include lightweight construction for easy handling, kink resistance to prevent hose blockages, and compatibility with various nozzle types for versatile firefighting applications. Additionally, some hoses are designed to withstand harsh environmental conditions, such as extreme temperatures or exposure to UV radiation, ensuring long-term durability and reliability.

Applications in Fire Suppression

Couplings fire hoses play a critical role in fire suppression efforts across a wide range of settings, including residential, commercial, industrial, and wildland environments. In urban firefighting scenarios, firefighters rely on hydrant systems and municipal water supplies to deliver water to the fire scene through a network of hoses and couplings. In rural or remote areas, where access to pressurized water sources may be limited, portable pumps and tanker trucks are used to supply water to firefighting crews on the ground.

Moreover, couplings fire hoses are indispensable tools in specialized firefighting operations, such as aircraft rescue and firefighting (ARFF), hazardous materials (HAZMAT) response, and wildfire suppression. In these contexts, hoses are often deployed in conjunction with foam proportioning systems, water cannons, or aerial firefighting aircraft to deliver targeted suppression agents to the fire front.

Conclusion: Ensuring Firefighter Safety and Effectiveness

In conclusion, couplings fire hoses are integral components of firefighting operations, providing firefighters with the means to deliver water swiftly and effectively to extinguish fires and protect lives and property. With their robust construction, versatile configurations, and advanced features, these hoses enable firefighters to confront a wide range of fire emergencies with confidence and efficiency. By investing in high-quality couplings fire hoses and ensuring regular maintenance and training, firefighting agencies can enhance their readiness and effectiveness in responding to crises and safeguarding communities against the ravages of fire. For more details visit our website: www.simsinter.com

#Fire Fighting Equipment#Blasting & Painting Equipment#Special Trucks Equipment#Couplings Fire Hoses#Couplings Anti Corrosion#Power & Hand Tools Kits#Paint Spraying Equipment#Airless Electric Guns#Topcoats Equipment Near Me#Hydraulic Equipment Near Me#Coupling Equipment#Hydraulic Equipment Manufacturers#Hydraulic Tools And Equipment#Hydraulic Equipment Suppliers#Hydraulic Lifting Tools#Hydraulic Pump Manufacturers in Cameroon

0 notes

Text

Aerospace Foams Market Overview, Top Key Players, Growth Analysis by Forecast to 2031

The Insight Partners stands out as a reliable ally in the syndicated market research and consultation through its steadfast commitment to the market research industry. With extensive experience and proven dedication, we have been delivering outstanding outcomes. With a team of researchers catering to distinct business requirements, we can emerge as a trusted research partner in the past decade.

By prioritizing precision and trust ahead, we are proud to announce the addition of the latest offering titled “Aerospace Foams Market Growth Outlook to 2031”. This report ensures spotless coverage of recent updates and a range of business environment factors impacting the Aerospace Foams market growth. The meticulous approach opted by our researchers can assist companies in transforming business space into the Aerospace Foams market.

Aerospace Foams market report offers a comprehensive analysis of regional and global scenarios. The scope of the market report extends to the competitive landscape, cost analysis, key players, specific market regions, profit margin, and market situation. A glance at wide-ranging factors restricting Aerospace Foams market growth is deliberately included in this study.

Objectives of Aerospace Foams Market Report

To deliver a detailed market overview by integrating quantitative and qualitative analysis

To unveil growth strategies by evaluating the competitive landscape and examining key companies against their position and strategic advantage

To offer estimates on sales volume, market share, size, and CAGR for the projected period.

To offer segment wise insights

This detailed report on Aerospace Foams market size is heavily based on verified information and authoritative sources. The study intended to offer market players an overview of market opportunities in the coming period. This report helps clients as a first-hand source of knowledge on the market while providing a full-fledged analysis of each segment.

The study contains details on frontrunners in the market along with their recent collaborations, segments, revenues, product launches, and Aerospace Foams market trends. It projects the competition in the Aerospace Foams market for an estimated duration. This research further looks at industry channels and the performance of key market players to help businesses stay ahead in the market.

Our Report Sample May Brief On:

Scope of Aerospace Foams market report

Brief introduction of Aerospace Foams market and Industry Overview

Table of Contents

Top market players covered in this report

Report Structure

Research Methodologies by The Insight Partners

Regional Insights:

This section includes insights on different regions and key players present in the region. This section attempts to analyze the growth of a specific regional market based on economic, technological, and environmental factors. Readers may expect revenue-based data and sales insights gathered by our team after comprehensive research. This informative chapter remains an absolute perk for investors, as it will help them to understand potential investment value and expected returns in specific regions.

Report Attributes

Details

Segmental Coverage

Material

PU Foams

PE Foams

Melamine Foams

Others)

End Use

Commercial Aircraft

Military Aircraft

Others)

Application

Aircraft Seats

Aircraft Floor Carpets

Flight Deck Pads

Overhead Stowage Bins

Others)

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Armacell International S.A.

BASF SE

Boyd Corporation

Evonik Industries AG

ERG Materials and Aircraft Corp.

FoamPartner

Rogers Corporation

SABIC

UFP Technologies, Inc.

Zotefoams PLC.

Other key companies

Why The Insight Partners?

Proven Expertise: The Insight Partners comprises expert market research analysts who have extensive industry-specific knowledge. Through this report, our team is bringing years of experience to the table while safeguarding the accuracy of insights.

Actionable Insights: TIP relies on a combination of primary and secondary research methodologies that drive tangible results. We are committed to keeping our offerings clear, accessible, and concise to guide businesses in the decision-making process.

Integration of Technology: We embrace technology in all its forms as the core of our research tactics. We use various tools and platforms to analyze and interpret the data. This allows timely results.

Summary:

Current and Future Market Estimates- Aerospace Foams Market Share, and Size | 2031

Market Dynamics – Drivers, Challenges, Regional Trends, and Market Opportunities

Market Segmentation – Product, Application, End-use Industries, and Regional Growth Prospects.

Competition Matrix – Key Market Players and Strategies

Recent Developments and Innovation contributing Market Growth

Author’s Bio:

Shashikant Ligade

Senior Analyst The Insight Partners

0 notes

Text

PUF Panels and Sandwich Panels: Applications Across Industries

Efficiency, durability, and versatility are essential in the realms of construction and industrial design. One innovation that has revolutionized these aspects is the introduction of Polyurethane Foam (PUF) panels and sandwich panels. These composite materials, consisting of a core sandwiched between two outer layers, offer numerous advantages and are widely used across various industries. In this text, we will explore the different areas where PUF panels and sandwich panels are commonly applied.

Cold Storage and Refrigeration: PUF panels excel in thermal insulation properties, making them ideal for cold storage facilities and refrigeration units. These panels create an efficient barrier against temperature fluctuations, helping to maintain the desired temperature inside the storage area. From food processing plants to pharmaceutical storage facilities, PUF panels ensure the integrity and freshness of perishable goods.

Commercial and Industrial Buildings: The versatility of PUF panels and sandwich panels extends to the realm of commercial and prefab construction. These panels are widely used for roofing, wall cladding, and partitioning in warehouse manufacturers, factories, workshops, and offices. Their lightweight nature facilitates quick installation, reducing construction time and costs. Moreover, their excellent insulation properties contribute to energy efficiency, leading to reduced heating and cooling expenses.

Modular Construction: The modular construction industry heavily relies on PUF panels and sandwich panels for their prefabricated structures. Whether it's modular homes, portable cabins, or temporary shelters, these panels offer a convenient solution for rapid assembly and disassembly. The modular nature of PUF panels allows for easy customization, enabling architects and designers to create versatile spaces tailored to specific needs.

Transportation Sector: PUF panels play a vital role in the transportation sector, particularly in the construction of refrigerated trucks, vans, and containers. These panels help to create insulated compartments that safeguard perishable goods during transit. Additionally, sandwich panels find applications in the aerospace industry for aircraft interiors, providing lightweight yet robust solutions for cabin walls and partitions.

Clean Rooms and Laboratories: Precision-controlled environments such as clean rooms and laboratories require stringent temperature and contamination control. PUF panels offer an ideal solution due to their ability to create airtight enclosures with superior insulation properties. These panels help maintain stable environmental conditions necessary for sensitive manufacturing processes, research, and testing activities.

Agricultural Sector: In agriculture, PUF panels are utilized for constructing storage facilities, cold rooms, and greenhouses. These panels help farmers and growers extend the shelf life of their produce by providing an insulated environment conducive to preservation. Additionally, sandwich panels are employed in livestock housing, offering comfortable and hygienic shelters for animals.

Conclusion: PUF panels and sandwich panels have emerged as indispensable materials across a myriad of industries, thanks to their exceptional thermal insulation, structural strength, and versatility. From cold storage facilities to commercial buildings, from transportation to clean room environments, the applications of these panels are diverse and far-reaching. As technology continues to advance, we can expect further innovations in the design and utilization of PUF panels, driving efficiency, sustainability, and performance across various sectors.

1 note

·

View note

Text

What are the key features and properties of PET foam board?

Title: The Versatility and Benefits of PET Foam Board in Modern Applications

In the realm of manufacturing and construction, the quest for lightweight yet durable materials has led to the development of innovative solutions. Among these, PET foam board has emerged as a versatile option revolutionizing various industries with its exceptional properties and wide-ranging applications.

Understanding PET Foam Board

PET foam board, also known as polyethylene terephthalate foam board, is a lightweight and rigid material derived from recycled PET plastic. It is composed of closed-cell foam structures that offer excellent strength-to-weight ratio, insulation properties, and dimensional stability. PET foam board is widely used in construction, transportation, packaging, and other industries where lightweight yet robust materials are required.

Exploring the Advantages of PET Foam Board

PET foam board offers several key advantages that make it a preferred choice for manufacturers, engineers, and designers:

Lightweight Construction: PET foam board is significantly lighter than traditional materials such as wood, metal, or PVC foam board. Its lightweight nature makes it easier to handle, transport, and install, reducing labor costs and overall project expenses.

High Strength-to-Weight Ratio: Despite its lightweight composition, PET foam board exhibits remarkable strength and stiffness. Its closed-cell foam structure provides optimal load-bearing capacity, making it suitable for structural applications where strength and durability are essential.

Excellent Insulation Properties: PET foam board offers superior thermal and acoustic insulation compared to conventional materials. Its closed-cell foam structure minimizes heat transfer and sound transmission, creating a more comfortable and energy-efficient environment in buildings, vehicles, and industrial applications.

Chemical Resistance: PET foam board is highly resistant to chemicals, moisture, and corrosion, making it suitable for harsh environments such as marine and chemical processing facilities. Its durability and resistance to degradation ensure long-term performance and reliability in demanding applications.

Environmentally Friendly: PET foam board is made from recycled PET plastic, typically sourced from post-consumer waste such as plastic bottles and containers. By repurposing waste materials, PET foam board contributes to resource conservation and waste reduction, aligning with sustainability goals.

Design Flexibility: PET foam board can be easily cut, shaped, and molded to meet specific design requirements. It is compatible with various fabrication techniques such as CNC machining, thermoforming, and laminating, offering endless possibilities for creative design solutions.

Applications of PET Foam Board

The versatility and performance of PET foam board make it suitable for a wide range of applications across industries, including:

Construction: Used in insulation panels, structural components, and interior finishes for residential, commercial, and industrial buildings.

Transportation: Employed in automotive interiors, RV construction, marine vessels, and aircraft interiors for its lightweight and durable properties.

Packaging: Utilized as protective packaging, cushioning material, and void fillers for shipping and logistics applications.

Signage and Displays: Used in advertising signage, exhibition displays, and point-of-purchase displays for its lightweight and printable surface.

Arts and Crafts: Applied in DIY projects, art installations, and architectural models for its ease of use and versatility.

Conclusion

PET foam board offers a compelling combination of lightweight construction, high strength-to-weight ratio, excellent insulation properties, and environmental sustainability. Its versatility and performance make it a preferred choice for a wide range of applications across industries. As the demand for lightweight, eco-friendly materials continues to grow, PET foam board is poised to play a significant role in shaping the future of manufacturing and construction.

0 notes

Text

Top 5 Challenges In Fire Fighting Design Specialized Environments

Introduction

Firefighting design is the installation and management of fire safety measures in buildings and areas that are at risk of fire. It plays a crucial role in ensuring the safety of people from the effects of fire in residential, commercial, and industrial buildings. Fire protection has to be tailor-made to meet specific environments like high-rise structures, historical buildings, industrial buildings, and residential apartments. Customized evacuation plans and automated suppression systems reduce the impact of fire and protect life and property. Fire Fighting design is indispensable in the modern world but faces a few challenges in specialized environments. What are they?

What Are Firefighting Challenges?

Firefighters are exposed to occupational hazards like high intensity of heat, smoke inhalation, dehydration, and falls. They face challenges such as lifting people and heavy fallen debris in narrow hallways, elevators, and staircases. Multistoried buildings, cliffs, bridges, mountainsides, etc. pose challenges. Moreover, extreme weather conditions, poor visibility, natural disasters like storms, etc. are challenging. Accidents like chemical spills, radiation, and structural collapses are a big challenge for firefighters.

Challenges In Fire Fighting Design Specialized Environments

Marine Environments: Navigating Challenges at Sea

Marine emergencies often occur far from shore making it difficult for the team to go in time. So, the ship must be equipped with trained people and essential equipment. Moreover, the equipment must be designed to withstand the corrosive effects of the sea. The design and layout of the ship must be tailored to fit firefighting solutions.

Aircraft Hangars: Protecting Aviation Assets

Fire spreads rapidly in large open spaces of aircraft hangars. They are storage places for combustible fuels and other flammable substances. Moreover, they contain expensive and sensitive aviation equipment. Firefighting design should integrate advanced fire detection systems, foam-based suppression systems, specialized fire-resistant materials, etc.

Data Centers: Safeguarding Critical Infrastructure

Traditional water-based firefighting may damage electronic equipment. Specialized suppression systems such as gas-based systems have to be used. Moreover, data centers have a complex layout. The strategic placement of fire suppression systems is important. Firefighting design must address security concerns as data centers house secret data.

Oil and Gas Facilities: Managing Hazards In High-Risk Environments

The place has highly flammable substances. So, the firefighting system needs special equipment and suppression systems. Easy access and effective communication must be ensured as they are located in remote places. Firefighting design must also ensure minimal environmental impact.

Historical Buildings: Preserving Heritage Amidst Fire Risks

Non-invasive suppression systems are needed to protect aged materials and the building. Firefighting design must prioritize the preservation of cultural assets and valuable artifacts. Designing evacuation plans is essential because of the complex layouts and narrow passages.

Conclusion

Fire Fighting design plays an important role in protecting people, environment, and property against the hazards of fire. It is important to develop comprehensive solutions to address the challenges of specialized environments. We provide personalized firefighting designs to address specific challenges. Contact us today for efficient fire protection systems that ensure a safe and secure environment. https://www.arabianinfotech.qa/

0 notes

Text

Fire extinguisher

Get the top Fire System Contractor at Tgoatenterprise. we provide the best Fire system contractor that provides building Maintenance and fire extinguisher. Hire

WHO WE ARE

Welcome to our fire protection company, where we provide top-notch fire protection services and equipment. As a trusted distributor of renowned brands such as SRI and Unique Fire, we ensure that our clients receive only the best quality products for their safety needs. Our team of experts is committed to delivering excellent service, from fire risk assessments to installation and maintenance of fire protection systems. Contact us today to learn how we can help safeguard your property and assets.”

FIRE SAFETY SERVICES

Our fire safety services include provision of FM200 & Kitchen Hood fire suppression system and FSSD submission.

Our Customer Service Is Always Ready To Advice You

At TGOAT ENTERPRISE (M) SDN BHD, we understand that you may have several questions about the appropriate fire extinguishers that you should purchase, be it for your home usage, to place in your vehicle or for your shop and commercial space. Our customer service representative are happy to clear any questions you may have and help you make a more informed decision on the size and type of fire extinguishers to purchase.

I'd love to help craft that article for you, but I can't access external websites or specific content from them directly. However, I can provide a comprehensive piece on fire extinguishers and the role of fire system contractors based on general knowledge and information available. Would you like me to create an informative article covering these topics?

Fire extinguisher TGOAT ENTERPRISE (M) SDN BHD is a registered company with the Companies Commission of Malaysia (SSM) under the Malaysia Company ACT 1956, established on 10th October 2017. We also are Registered Company for CIDB Grade 4.Our team of technical experts has a combined experience of over ten years in the construction industry, bringing a wealth of knowledge and expertise to the company.

We are a distributor of fire equipment for famous brands such as SRI, Unique Fire, and more. We specialize in providing engineering, procurement, construction and commissioning (EPCC) solutions for a wide range of fire protection systems, including all water-based active fire protection systems, foam systems, water mist, gas suppression system, fire alarm and detection system for various industries such as commercial, industrial, refinery, government, and mercantile facilities, as well as power generation facilities, airports, aircraft hangers, and clean room facilities. Our services also encompass project management, supervision, testing and commissioning, training, and maintenance.

At TGOAT ENTERPRISE (M) SDN BHD, we are committed to delivering exceptional quality and reliability, adhering to international codes and regulations such as NFPA, BS Standard, FM Global Coding, MS Standard, and more. Our success is built on our strong network of connections with consultants, contractors, local authorities, and the market, ensuring that we provide customized solutions that meet the unique needs of our clients.

Fire extinguisher

Fire System Contractor

Building Maintenance

Visit for more information: https://tgoatenterprise.com/

0 notes

Text

Aircraft Seat Upholstery Market Size, Global Key Players, Types, Applications, Countries & Forecast 2023 to 2032

Emergen Research's latest market research report, titled Global Aircraft Seat Upholstery Market, provides estimated market size and shares, latest industry trends, global market growth rates, key drivers and opportunities, constraints, product segmentation, and major market players. Cost structure, market size, competitive landscape, product portfolio and specifications, and company profiles. This report is a fair prototype of the Aircraft Seat Upholstery-industry containing an in-depth study of the global Aircraft Seat Upholstery market. This report serves as a valuable source of data and information related to this industry. It covers various industry aspects with a particular focus on market scope and application areas. The report identifies the fundamental business strategies adopted by industry experts and offers an insightful study on the value chains and distribution channels of the global market. The report authors have also analyzed current industry trends, growth potential, current overview, and market limitations.

The aircraft seat upholstery market plays a crucial role in enhancing passenger comfort and aesthetics in commercial and private aircraft. Upholstery refers to the materials used to cover and cushion the seats, providing a comfortable seating experience for passengers. The global aircraft seat upholstery market size is expected to reach USD 2.70 Billion in 2032 and register a steady revenue CAGR of 3.60% during the forecast period, according to latest analysis by Emergen Research. The market is driven by several factors, including the increasing demand for air travel, advancements in seat design and materials, and the growing focus on passenger experience.

The rising demand for air travel is a major driver for the aircraft seat upholstery market. According to the International Air Transport Association (IATA), global air passenger traffic is expected to double by 2037. This increasing number of passengers creates a demand for comfortable and visually appealing seating options, driving the need for high-quality seat upholstery.

Advancements in seat design and materials have also contributed to the market growth. Manufacturers are constantly innovating to develop lightweight and durable materials that offer enhanced comfort and support. These advancements include the use of memory foam, ergonomic designs, and adjustable features to cater to the diverse needs of passengers.

However, there are certain restraints that may hinder the growth of the aircraft seat upholstery market. One of the major challenges is the stringent regulations and certifications required for aircraft interiors. Upholstery materials need to meet strict safety and fire resistance standards to ensure passenger safety. Compliance with these regulations can increase the cost and complexity of manufacturing seat upholstery.

The global Aircraft Seat Upholstery market report employs an extremely extensive and perceptive process that analyzes statistical data relating to services and products offered in the market. The research study is a pivotal document in understanding the needs and wants of the clients. The report is comprised of significant data about the leading companies and their marketing strategies. The Aircraft Seat Upholstery industry is witnessing an expansion and change of dynamics owing to the entry of several new players.

The study outlines the rapidly evolving and growing market segments along with valuable insights into each element of the industry. The industry has witnessed the entry of several new players, and the report aims to deliver insightful information about their transition and growth in the market. Mergers, acquisitions, partnerships, agreements, product launches, and joint ventures are all outlined in the report.

Get a sample of the report @ https://www.emergenresearch.com/request-sample/1979

The Global Aircraft Seat Upholstery Market report provides full coverage of the companies’ data, including details about their production and manufacturing capacity, product portfolio, business overview, revenue, gross profit margins, sales network and distribution channel, financial standing, and market position. The report also studies business strategies and strategic alliances undertaken by companies to gain a robust footing in the market. The report sheds light on the mergers and acquisitions, collaborations, joint ventures, brand promotions and product launches, agreements and partnerships, and corporate and government deals. The comprehensive analysis of the competitive landscape offers the readers a deeper understanding about the competitors.

Competitive Terrain:

The global Aircraft Seat Upholstery industries are highly consolidated owing to the presence of renowned companies operating across several international and local segments of the market. These players dominate the industry in terms of their strong geographical reach and a large number of production facilities. The companies are intensely competitive against one another and excel in their individual technological capabilities, as well as product development, innovation, and product pricing strategies.

Leading Market Players Profiled in the Report:

Spectra Interior Products, Douglass Interior Products, Inc., Omnavia, Franklin Products, Lantal, Tritex Corporation, Tapis Corporation, Perrone, Spectra Interior Products, INTECH AEROSPACE

To seek a discount on this report, click on the link: @ https://www.emergenresearch.com/request-discount/1979

Product Type Segmentation & Application Segmentation:

Material Outlook (Revenue, USD Billion; 2019–2032)

Fabric

Leather

Vinyl

Seat Cover Outlook (Revenue, USD Billion; 2019–2032)

Bottom Covers

Back Rest

Armrests

Headrests

Seat Rear Pockets

Seat Type Outlook (Revenue, USD Billion; 2019–2032)

First Class

Business Class

Premium Economy Class

Economy Class

Regional Analysis of the Aircraft Seat Upholstery Market:

North America (U.S., Canada)

Europe (U.K., Italy, Germany, France, Rest of EU)

Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

Latin America (Chile, Brazil, Argentina, Rest of Latin America)

Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

To access the full coverage of the global Aircraft Seat Upholstery market report, visit @ https://www.emergenresearch.com/industry-report/aircraft-seat-upholstery-market

Key market aspects studied in the report:

Market Scope: The report explains the scope of various commercial possibilities in the global Aircraft Seat Upholstery market over the upcoming years. The estimated revenue build-up over the forecast years has been included in the report. The report analyzes the key market segments and sub-segments and provides deep insights into the market to assist readers with the formulation of lucrative strategies for business expansion.

Competitive Outlook: The leading companies operating in the Aircraft Seat Upholstery market have been enumerated in this report. This section of the report lays emphasis on the geographical reach and production facilities of these companies. To get ahead of their rivals, the leading players are focusing more on offering products at competitive prices, according to our analysts.

Report Objective: The primary objective of this report is to provide the manufacturers, distributors, suppliers, and buyers engaged in this sector with access to a deeper and improved understanding of the global Aircraft Seat Upholstery market.

Request customization of the report @ https://www.emergenresearch.com/request-for-customization/1979

How will this Report Benefit you?

An Emergen Research report of 250 pages features 194 tables, 189 charts, and graphics. Our new study is ideal for anyone who wants to learn about the global Aircraft Seat Upholstery market commercially and deeply, as well as to analyze the market segments in depth. With the help of our recent study, you can analyze the entire regional and global market for Aircraft Seat Upholstery. To increase market share, you must obtain financial analysis of the entire market and its segments. Our research suggests there are significant opportunities in this rapidly expanding market for energy storage technology. Look at how you might take advantage of these revenue-generating opportunities. Additionally, the research will help you develop growth strategies, strengthen competitor analysis, and improve business productivity by enabling you to make better strategic decisions.

Related Reports:

Laser Tracker Markethttps://www.emergenresearch.com/industry-report/laser-tracker-market

Aircraft Seating Markethttps://www.emergenresearch.com/industry-report/aircraft-seating-market

Customs Brokerage Markethttps://www.emergenresearch.com/industry-report/customs-brokerage-market

Vascular Graft Markethttps://www.emergenresearch.com/industry-report/vascular-graft-market

Singapore Intelligence Data Processing Markethttps://www.emergenresearch.com/industry-report/singapore-intelligence-data-processing-market

Thank you for reading the report. The report can be customized as per the requirements of the clients. For further information or query about customization, please reach out to us, and we will offer you the report best suited for your needs.

About Emergen Research

Emergen Research is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target, and analyze consumer behavior shifts across demographics, across industries, and help clients make smarter business decisions. We offer market intelligence studies ensuring relevant and fact-based research across multiple industries, including Healthcare, Touch Points, Chemicals, Types, and Energy

Contact Us:

Eric Lee

Corporate Sales Specialist

Emergen Research | Web: https://www.emergenresearch.com/

Direct Line: +1 (604) 757-9756

E-mail: [email protected]

Explore Our Blogs and Insights Section: https://www.emergenresearch.com/insights

0 notes

Text

Sustaining Altitude: Projecting Aerospace Foams Market Share for Long-Term Success

According to the latest research report released by Kings Research, the global Aerospace foams market generated USD 3.42 Billion in revenue in 2022. The study suggests that the sector is poised to accrue USD 6.19 Billion in revenue by 2030, demonstrating a strong CAGR of 7.85% from 2023 to 2030. The Aerospace foams market has been getting a lot of attention in recent years. The rapid growth of the sector and its impact on various industries has been highlighted in this report. The market extensively assesses the types of products, services, and technologies transforming the way industries work.

By considering a number of factors, including market dynamics, research methodologies, segmentation analysis, growth factors, restraining factors, challenges faced by market participants, growth opportunities, regional analysis, and the competitive landscape, this in-depth market research report aims to provide detailed insights into the Aerospace foams market.

👉Get a Sample PDF of the Report: https://www.kingsresearch.com/request-sample/aerospace-foams-market-105

The aerospace industry has witnessed significant advancements in materials technology, with foams playing a pivotal role in enhancing aircraft performance and safety. Aerospace foams, characterized by their lightweight, durable, and insulating properties, find applications in various components such as seating, insulation, composites, and structural elements. This market analysis aims to provide a comprehensive overview of the aerospace foams market, focusing on current trends, key players, emerging technologies, and growth prospects.

Competitive Landscape

The competitive landscape of the Aerospace foams market is marked by intense rivalry, the emergence of innovative startups, and the dominance of key players. Leading businesses are promoting innovation, establishing standards for the sector, and adopting lucrative tactics to increase their market share. The competitive scenario is being shaped by strategic decisions, alliances, acquisitions, and product launches, which foster a dynamic environment for market participants.

Some of the prominent players reviewed in the research report include:

· Boyd Corporation

· DuPont

· ERG Aerospace Corporation

· Evonik Industries AG

· Huntsman Corporation

· Solvay

· Technifab, Inc.

· UFP Technologies, Inc.

· BASF SE

· NEFAB GROUP

· SABIC

The report begins by outlining the historical development of aerospace foams and their evolution in tandem with technological advancements in the aerospace sector. It discusses the primary types of foams utilized in aerospace applications, including polyurethane, polyethylene, and melamine, highlighting their unique properties and advantages.

Segmentation Analysis

An analysis of the Aerospace foams market's segments has been carried out during the study in order to present an extensive overview of the industry. The market is divided into segments based on product type, end-users, and geography. This strategy made it possible to thoroughly examine the distinctive traits, growth potential, and difficulties of each segment. The segmentation analysis identifies important insights or patterns prevalent in the global business.

The global Aerospace Foams Market is segmented as:

By Type

· PU Foams

· PE Foams

· Melamine Foams

· PMI/Polyimide Foams

· Metal Foams

· Others

By Application

· Aircraft Seats

· Aircraft Floor Carpets

· Flight Deck Pads

· Cabin Walls and Ceilings

· Overhead Stow Bins