#Aerospace Foams Market

Text

Aerospace Foams Market Overview, Top Key Players, Growth Analysis by Forecast to 2031

The Insight Partners stands out as a reliable ally in the syndicated market research and consultation through its steadfast commitment to the market research industry. With extensive experience and proven dedication, we have been delivering outstanding outcomes. With a team of researchers catering to distinct business requirements, we can emerge as a trusted research partner in the past decade.

By prioritizing precision and trust ahead, we are proud to announce the addition of the latest offering titled “Aerospace Foams Market Growth Outlook to 2031”. This report ensures spotless coverage of recent updates and a range of business environment factors impacting the Aerospace Foams market growth. The meticulous approach opted by our researchers can assist companies in transforming business space into the Aerospace Foams market.

Aerospace Foams market report offers a comprehensive analysis of regional and global scenarios. The scope of the market report extends to the competitive landscape, cost analysis, key players, specific market regions, profit margin, and market situation. A glance at wide-ranging factors restricting Aerospace Foams market growth is deliberately included in this study.

Objectives of Aerospace Foams Market Report

To deliver a detailed market overview by integrating quantitative and qualitative analysis

To unveil growth strategies by evaluating the competitive landscape and examining key companies against their position and strategic advantage

To offer estimates on sales volume, market share, size, and CAGR for the projected period.

To offer segment wise insights

This detailed report on Aerospace Foams market size is heavily based on verified information and authoritative sources. The study intended to offer market players an overview of market opportunities in the coming period. This report helps clients as a first-hand source of knowledge on the market while providing a full-fledged analysis of each segment.

The study contains details on frontrunners in the market along with their recent collaborations, segments, revenues, product launches, and Aerospace Foams market trends. It projects the competition in the Aerospace Foams market for an estimated duration. This research further looks at industry channels and the performance of key market players to help businesses stay ahead in the market.

Our Report Sample May Brief On:

Scope of Aerospace Foams market report

Brief introduction of Aerospace Foams market and Industry Overview

Table of Contents

Top market players covered in this report

Report Structure

Research Methodologies by The Insight Partners

Regional Insights:

This section includes insights on different regions and key players present in the region. This section attempts to analyze the growth of a specific regional market based on economic, technological, and environmental factors. Readers may expect revenue-based data and sales insights gathered by our team after comprehensive research. This informative chapter remains an absolute perk for investors, as it will help them to understand potential investment value and expected returns in specific regions.

Report Attributes

Details

Segmental Coverage

Material

PU Foams

PE Foams

Melamine Foams

Others)

End Use

Commercial Aircraft

Military Aircraft

Others)

Application

Aircraft Seats

Aircraft Floor Carpets

Flight Deck Pads

Overhead Stowage Bins

Others)

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Armacell International S.A.

BASF SE

Boyd Corporation

Evonik Industries AG

ERG Materials and Aircraft Corp.

FoamPartner

Rogers Corporation

SABIC

UFP Technologies, Inc.

Zotefoams PLC.

Other key companies

Why The Insight Partners?

Proven Expertise: The Insight Partners comprises expert market research analysts who have extensive industry-specific knowledge. Through this report, our team is bringing years of experience to the table while safeguarding the accuracy of insights.

Actionable Insights: TIP relies on a combination of primary and secondary research methodologies that drive tangible results. We are committed to keeping our offerings clear, accessible, and concise to guide businesses in the decision-making process.

Integration of Technology: We embrace technology in all its forms as the core of our research tactics. We use various tools and platforms to analyze and interpret the data. This allows timely results.

Summary:

Current and Future Market Estimates- Aerospace Foams Market Share, and Size | 2031

Market Dynamics – Drivers, Challenges, Regional Trends, and Market Opportunities

Market Segmentation – Product, Application, End-use Industries, and Regional Growth Prospects.

Competition Matrix – Key Market Players and Strategies

Recent Developments and Innovation contributing Market Growth

Author’s Bio:

Shashikant Ligade

Senior Analyst The Insight Partners

0 notes

Text

Aerospace Foams Market Size, Share, Trends, Forecast 2030

0 notes

Text

The aerospace foams market size is projected to grow from USD 4.4 billion in 2019 to USD 6.5 billion by 2024, at a CAGR of 8.2% from 2019 to 2024. The rising demand for lightweight and fuel-efficient aircraft have led to the extensive use of advanced materials such as PU foams and PE foams, among others, in the aerospace industry. The manufacture of advanced materials as well as new products launched by several prominent players for the aerospace industry is one of the key factors driving the growth of the aerospace foams industry across the globe.

Aerospace foams are advanced materials of various cell sizes, capacities, and properties. The cell sizes of the aerospace foams determine the flexibility or rigidity of the foams and thus, dictates the application areas where they can be used. Aerospace foams are manufactured using various materials, such as PU (polyurethane), PE (polyethylene), melamine, metal, and PMI/polyimide, among others, which meet the flame, smoke, and toxicity (FST) standards in the aerospace industry. These foams are used in various applications in aircrafts such as seating, seals, gaskets, carpet pads, headrests, rotor blades, doors, windshields, cockpit instrument panels, wingtip lens, and several others.

Based on material type, the aerospace foams market has been segmented into PU foams, PE foams, melamine foams, metal foams, PMI/polyimide foams, and others which includes PVDF foams, PPSU foams, silicone foams, ceramic foams, PEI foams, PET foams, PVC foams, and polycarbonate foams. The PU foams segment has the highest market share in terms of both value and volume, among all the material type segments in 2018. It is projected to follow the same trend from 2019 to 2024 in terms of both value and volume. PU foams are used in a variety of applications ranging from seating, airframes, interiors, and packaging in the aerospace industry. The availability in different forms ranging from low to high density with varying rigidity as well as ease-of-use makes them compatible to be used in a multitude of aerospace applications. Some useful properties of PU foams include durability, lightweight, and recyclability. These factors support the rising global demands for lightweight and fuel-efficient aircraft, which is one of the primary drivers of the aerospace foams market.

#Aerospace Foams Market#PU Foams#PE Foams#Melamine Foams#Metal Foams#PMI Foam#Polyimide Foams#erg metal foam#Global Aerospace Foams Market#COVID 19 impact on Aerospace Foams Market#Aviation foam suppliers#Aircraft structural foam#Aerospace Foams industry#Aerospace Foams Market Share#Aerospace Foams Market size#Demand of Aerospace Foams#Sales of Aerospace Foams#Aerospace Foams Market Manufacturers#Aerospace Foams Market Opportunity#growth of the aerospace foams industry#commercial aircraft Foams#aviation foams#PU aerospace foams

0 notes

Text

Aerospace Foam Market: Dominance of North America in Driving Innovations and Market Growth

Introduction

The aerospace foam market is a critical component of the aerospace industry, providing essential materials that enhance the performance, safety, and efficiency of aircraft. These foams are used in various applications, including seating, insulation, packaging, and structural components.

As the aerospace industry continues to evolve, the demand for high-performance materials such as aerospace foams is on the rise. North America, in particular, stands out as the dominant region in this market, driven by technological advancements, a robust aerospace sector, and significant investments in research and development.

Download Free Sample: https://www.nextmsc.com/aerospace-foam-market/request-sample

Key Drivers of the Aerospace Foam Market in North America

Technological Advancements

North America is home to some of the world's leading aerospace companies and research institutions, which are at the forefront of technological advancements.

The region's focus on innovation has led to the development of advanced aerospace foams with enhanced properties such as improved thermal insulation, fire resistance, and lightweight characteristics. These advancements are crucial for meeting the stringent safety and performance standards of modern aircraft.

Robust Aerospace Sector

The aerospace sector in North America, particularly in the United States, is one of the largest and most advanced in the world. This sector encompasses a wide range of activities, including commercial aviation, defense, and space exploration.

The presence of major aircraft manufacturers, such as Boeing and Lockheed Martin, drives the demand for high-quality aerospace foams. Additionally, the defense sector's need for advanced materials for military aircraft and spacecraft further fuels market growth.

Investments in Research and Development

Significant investments in research and development (R&D) are a hallmark of the North American aerospace industry. Both government and private sectors allocate substantial funds to R&D projects aimed at developing new materials and improving existing ones.

This emphasis on R&D has resulted in continuous innovation in aerospace foams, making them more efficient, durable, and environmentally friendly. Government initiatives and collaborations between industry players and research institutions play a pivotal role in fostering these advancements.

Inquire Before Buying: https://www.nextmsc.com/aerospace-foam-market/inquire-before-buying

Key Applications of Aerospace Foams in North America

Seating and Interior Components

One of the primary applications of aerospace foams is in aircraft seating and interior components. Lightweight foams are used to manufacture comfortable and durable seats that contribute to the overall weight reduction of the aircraft. This weight reduction is essential for improving fuel efficiency and reducing emissions.

Additionally, aerospace foams are utilized in interior panels, overhead compartments, and other cabin components to enhance passenger safety and comfort.

Insulation and Noise Reduction

Aerospace foams are extensively used for insulation and noise reduction purposes. These foams provide excellent thermal insulation, helping to maintain a stable internal temperature in the aircraft.

Moreover, they play a crucial role in reducing noise levels within the cabin, ensuring a more pleasant flying experience for passengers. The ability of aerospace foams to dampen vibrations and minimize noise is especially important in the development of quieter and more efficient aircraft.

Structural Components and Packaging

In addition to seating and insulation, aerospace foams are used in various structural components and packaging applications. High-strength foams are employed in the construction of lightweight yet robust structures, such as wings, fuselage panels, and control surfaces.

These foams provide the necessary strength and rigidity while minimizing the overall weight of the aircraft. Furthermore, aerospace foams are utilized in packaging to protect delicate components and equipment during transportation and storage.

Market Trends and Opportunities

Growing Demand for Lightweight Materials

The aerospace industry is continuously striving to develop lighter and more fuel-efficient aircraft. This trend is driving the demand for lightweight materials, including advanced aerospace foams.

Manufacturers are focusing on developing foams with superior strength-to-weight ratios to meet the industry's evolving requirements.

The adoption of lightweight materials not only enhances fuel efficiency but also contributes to the reduction of greenhouse gas emissions, aligning with the industry's sustainability goals.

Increasing Use of Bio-Based Foams

Environmental sustainability is a significant concern in the aerospace industry. As a result, there is a growing interest in bio-based aerospace foams derived from renewable resources.

These foams offer similar or even superior performance characteristics compared to traditional petroleum-based foams while reducing the environmental footprint. The development and adoption of bio-based foams represent a promising opportunity for the aerospace foam market in North America.

Advancements in Manufacturing Techniques

Advancements in manufacturing techniques, such as additive manufacturing (3D printing), are revolutionizing the aerospace foam market. Additive manufacturing enables the production of complex foam structures with precise control over material properties.

This technology allows for the creation of customized aerospace foams tailored to specific applications, improving performance and efficiency. The integration of additive manufacturing into the aerospace foam production process is expected to drive market growth and open new avenues for innovation.

Focus on Fire-Resistant Materials

Safety is paramount in the aerospace industry, and the development of fire-resistant materials is a top priority. Aerospace foams with enhanced fire resistance properties are in high demand to ensure passenger safety and comply with stringent regulatory standards.

Ongoing research and development efforts are focused on improving the fire-resistant characteristics of aerospace foams without compromising their other performance attributes. This emphasis on safety is expected to drive the adoption of advanced fire-resistant foams in the market.

Conclusion

North America remains the dominant region in the aerospace foam market, driven by technological advancements, a robust aerospace sector, and significant investments in research and development. The region's focus on innovation and sustainability is propelling the market forward, with growing demand for lightweight, bio-based, and fire-resistant foams.

As the aerospace industry continues to evolve, the North American aerospace foam market is poised for sustained growth, contributing to the development of safer, more efficient, and environmentally friendly aircraft.

#aerospace foam#aerospace and defense industry#aviation#market research'#industry trends#industry analysis#business insights

0 notes

Text

Global Aerospace Foams Market Size, Share - Industry Forecast 2029

According to Precision Business Insights, The size analysis of the aerospace foams market is expected to reach a value of USD 9.6 billion from 2023-29

The global aerospace foams market size was valued at USD 6.2 Billion in 2022 and is poised to grow at a significant CAGR of 8.4% during the forecast period 2023-29. It also includes market size and projection estimations for each of the five major regions from 2023 to 2029. The research report includes historical data, trending features, and market growth estimates for the future. Furthermore, the study includes a global and regional estimation and further split by nations and categories within each region. The research also includes factors and barriers to the aerospace foams market growth, as well as their impact on the market's future growth. The report gives a comprehensive overview of both primary and secondary data.

View the detailed report description here - https://www.precisionbusinessinsights.com/market-reports/global-aerospace-foams-market

The global aerospace foams market segmentation:

1) By Foam Type : Polyurethane, Polyethylene, Ceramic, Metal foam, Others

2) By Application : General Aviation, Commercial Aircraft, Military Aircrafts

3) By Geography : North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa

The primary factors of the aerospace foams market drivers are increasing demand for lightweight and fuel-efficient aircraft. The aerospace foams market report helps to provide the best results for business enhancement and business growth. It further helps to obtain the reactions of consumers to a novel product or service. It becomes possible for business players to take action for changing perceptions. It uncovers and identifies potential issues of the customers. It becomes easy to obtain the reactions of the customers to a novel product or service. It also enlightens further advancement, so it suits its intended market.

The aerospace foams marketresearchreport gives a comprehensive outlook across the region with special emphasis on key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America was the largest region in the aerospace foams market report, accounting for the highest share in 2022. It was followed by Asia Pacific, and then the other regions.

Request sample report at - https://www.precisionbusinessinsights.com/request-sample/?product_id=35263

The important profiles and strategies adopted by aerospace foams market key players are BASF SE, Huntsman Corporation, ARMACELL, Boyd Corporation, Evonik Industries, Rogers Corporation, SABIC Innovative Plastics, General Plastics Manufacturing Company, Zetofoams Plc, ERG Materials, covered here to help them in strengthening their place in the market.

About Precision Business Insights:

We are a market research company that strives to provide the highest quality market research insights. Our diverse market research experts are enthusiastic about market research and therefore produce high-quality research reports. We have over 500 clients with whom we have a good business partnership and capacity to provide in-depth research analysis for more than 30 countries. In addition to deliver more than 150 custom solutions, we already have accounts with the top five medical device manufacturers.

Precision Business Insights offers a variety of cost-effective and customized research services to meet research requirements. We are a leading research service provider because of our extensive database built by our experts and the services we provide.

Contact:

Mr. Satya

Precision Business Insights | Toll Free: +1 866 598 1553

Email: [email protected]

Kemp House, 152 – 160 City Road, London EC1V 2NX

Web: https://precisionbusinessinsights.com/ | D U N S® Number: 852781747

#aerospace foams market size#aerospace foams market share analysis#aerospace foams market growth drivers#aerospace foams market trends#aerospace foams market dynamics

0 notes

Text

Aerospace Foam Market Surge to Witness Huge Demand at a CAGR of 6.20% during the forecast period 2028

Industry Analysis

Data Bridge Market Research analyses that the aerospace foam market will witness a CAGR of 6.20% for the forecast period of 2021-2028 and is likely to reach at USD 10.41 billion by 2028.

Aerospace foam is a high-performance insulating substance that provides cushioning, support, and structural support to the regions where it is employed. These materials give protection against undesirable vibrations, improve insulation, and increase comfort by increasing cushioning levels.

Additionally, the credible Aerospace Foam Market report helps the manufacturer in finding out the effectiveness of the existing channels of distribution, advertising programs, or media, selling methods and the best way of distributing the goods to the eventual consumers. Taking up such market research report is all the time beneficial for any company whether it is a small scale or large scale, for marketing of products or services. It makes effortless for Chemical and Materials industry to visualize what is already available in the market, what market anticipates, the competitive environment, and what should be done to surpass the competitor.

Get a Free Sample of The Report: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-aerospace-foam-market

Market Insights and Scope

The rise in the demand for lightweight and fuel-efficient aircraft is the major driver that will influence the growth of aerospace foam market. Furthermore, the rise in the volume of air traffic and airways travelling population coupled with the increasing disposable income will accelerate the aerospace foam market growth rate. In addition to this, upsurge in the demand for flame retardant and customizable foams for different application areas and rapid urbanization will positively impact the market growth rate.

The Aerospace Foam Market report encompasses various segments linked to Chemical and Materials industry and market with comprehensive research and analysis. These comprise industry outlook with respect to critical success factors (CSFs), industry dynamics that mainly covers drivers and restraints, market segmentation & value chain analysis, key opportunities, application and technology outlook, regional or geographical insight, country-level analysis, key company profiles, competitive landscape, and company market share analysis. All the data, figures and information are backed up by well recognized analysis tools which include SWOT analysis and Porter’s Five Forces analysis. So, take business to the peak level of growth with the all-inclusive Data Bridge Market research report.

Get full access to the report: https://www.databridgemarketresearch.com/reports/global-aerospace-foam-market

Industry Segmentation and Size

Aerospace foam market is segmented on the basis of type, application and end use. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target market.

On the basis of type, the aerospace foam market is segmented into PU foam, PE foam, ceramic foam, melamine foam, metal foam, PI foam, PET foam, PVC foam, specialty high performance foam and others.

On the basis of application, the aerospace foam market is segmented into aircraft seats, aircraft floor carpets, flight deck pads and overhead stow bins.

On the basis of end use, the aerospace foam market is segmented into general aviation, commercial aviation and military aircraft.

Market Country Level Analysis

The countries covered in the aerospace foam market report are

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

A reliable Aerospace Foam Market marketing report proves to be the finest and excellent market research report as it is formulated with the following critical factors. These consist of primary research, benchmarking studies, secondary research, company profiles, competitive intelligence & reporting, syndicated research, data collection, data processing and analysis, survey design, and survey programming. The report performs market study and analysis to provide market data by considering new product development from beginning to launch. The Chemical and Materials business report also provides evaluations based on the market type, organization size, availability on-premises, end-users’ organization type, and the availability in areas such as North America, South America, Europe, Asia-Pacific and Middle East & Africa.

Industry Share Analysis

The major players covered in the aerospace foam market report are

BASF SE, Armacell, Boyd Corporation, Evonik Industries AG, ERG Aerospace Corp., SABIC, Zotefoams plc, Solvay, Fritz Nauer AG, UFP Technologies, Inc., NCFI Polyurethanes, DuPont, Recticel, Rogers Corporation, Huntsman International LLC, Aerofoam Industries, LLC, Technifab, Inc., Forest City Technologies, Inc., Pyrotek, Greiner Foam International GmbH, SINFO, spol. s r.o., Airex AG, among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately.

Browse Related Reports@

Global Whiskey Market

South Africa Battery Market

Global Plant-Based Egg Market

Global Nutritional Beverages market

MENA Tahini market

Global Dental Membrane and Bone Graft Substitute Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Aerospace Foam Market Popularity#Aerospace Foam Market Global Brands#Aerospace Foam Market drivers#Aerospace Foam Market CAGR rate#Aerospace Foam Market Demands#Aerospace Foam Market Competitors#Aerospace Foam Market Competition#Aerospace Foam Market Types#Aerospace Foam Market Chemicals and Materials

0 notes

Text

Firefighting Foam Market is Estimated To Witness High Growth Owing To Stringent Safety Regulations

The global Firefighting Foam Market is estimated to be valued at US$ 7.31 billion in 2023 and is expected to exhibit a CAGR of 5.9% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights. Market Overview: Firefighting foam is a specialized product used for extinguishing flammable liquid fires. It is highly effective in suppressing fires by forming a thick blanket over the fire, thus preventing oxygen from reaching the fuel and cooling the flames. Firefighting foam offers several advantages such as quick extinguishing capabilities, improved fire retardation, and reduced re-ignition. The increasing need for effective and efficient fire control methods, along with the stringent safety regulations imposed by various government agencies, are driving the demand for firefighting foam in the market. Market Key Trends: One key trend in the firefighting foam market is the growing adoption of environmentally friendly foam solutions. With increasing concerns regarding the environmental impact of firefighting foam, manufacturers are focusing on developing environmentally sustainable foam solutions.

These environmentally friendly foams are biodegradable and possess low toxicity, reducing the potential harm caused to the environment during firefighting activities. This trend is driven by the rising awareness among end-users and government regulations promoting the use of eco-friendly firefighting products. Overall, the global firefighting foam market is expected to witness significant growth due to the increased emphasis on fire safety and the growing demand for environmentally friendly foam solutions. PEST Analysis: Political: The political factors impacting the firefighting foam market include regulations and policies related to fire safety and environmental protection. Governments around the world are increasingly implementing stringent regulations to restrict the use of firefighting foams containing harmful chemicals like PFAS. This has led to the development and adoption of eco-friendly and more sustainable alternatives. Economic: The economic factors affecting the market include the overall economic growth and investments in infrastructure development.

As economies grow, there is an increased demand for fire safety measures and firefighting equipment, including foams. Investments in industries such as oil and gas, aerospace, and construction also contribute to the demand for firefighting foams. Social: The social factors influencing the market include the awareness and concern for fire safety among individuals and organizations. With the increasing number of fire incidents and the potential risks associated with them, there is a greater emphasis on implementing effective firefighting measures. The demand for firefighting foams is driven by the need to protect lives and minimize property damage. Technological: The technological factors impacting the market include advancements in foam formulation and delivery systems. Manufacturers are constantly developing innovative products that are more efficient in suppressing fires. These advancements include the development of fluorine-free foams, improved foam stability, and better compatibility with various fire hazards.

Key Takeaways: The global Firefighting Foam Market Share is expected to witness high growth, exhibiting a CAGR of 5.9% over the forecast period (2023-2030). This growth is driven by several factors, including increasing regulations and policies focused on fire safety and the environment. The shift towards eco-friendly foams is expected to boost market demand. In terms of regional analysis, North America is expected to be the fastest-growing and dominating region in the firefighting foam market. This can be attributed to the stringent regulations in the region, the presence of major key players, and increased awareness and investment in fire safety measures. Key players operating.

1 note

·

View note

Text

0 notes

Text

0 notes

Text

https://jomosocial.com/blogs/32686/Aerospace-Foam-Market-to-Witness-Heightened-Revenue-Growth-During-the

0 notes

Video

youtube

USA Market 3.25-8 3.50-8 Wheelbarrow flat free wheel, Hand Truck Trolley...

Provide polyurethane PU foaming equipment, processes, formulas and raw material services Web: www.modicasterwheels.com Email: [email protected] #Lawnmower #Tooltrolley #aerospacemanufacturing #equipment #Lawnmowertire #rollen #flatfreelawnmowertires #factories #productionengineering #flatfreetire #punctureprooftire #industrialsolutions #nhsengland #hospitalmanagement #castors #government #amazing #movingforward #aerospace #automation #gbmfg #innovationculture #innovation #quality #safety #automotiveindustry #engineering #supplychainsolutions #Trolley #manufacturingexcellence #automotive #manufacturinguk #industry #nhslongtermplan #ukmfg #wheels #engineeringuk #manufacturers #retweeet #protectthenhs #blickle #supportthenhs #nhs #supplychain #sourcing #industrial #b2b #industrialsupplies #casters #manufacturing #manufacturingindustry #materialhandling #Wheelbarrow #Dolly #Tools #garden #barrow #carts #caster #castor #cart #pu #Plastic #Solidtire #gardentools #tire #Tyre #weeder #Kart #gokart #shoppingcart #tractor #Handtruck #Handcart #toolcart #Toolbox #wheelchair #stroller #Constructiontools #manufacturer #manufacture #Factory #machine #production #plasticbox #wheelsandtires #casterwheels #wheelchairaccessories #solidtires #wheelchairwheels #wheelchairparts #mobilityscooteraccessories #solidtyres #solidtires #mobilityscooterparts

0 notes

Text

0 notes

Text

The aerospace foams market size is projected to grow from USD 4.4 billion in 2019 to USD 6.5 billion by 2024, at a CAGR of 8.2% from 2019 to 2024. The rising demand for lightweight and fuel-efficient aircraft have led to the extensive use of advanced materials such as PU foams and PE foams, among others, in the aerospace industry. The manufacture of advanced materials as well as new products launched by several prominent players for the aerospace industry is one of the key factors driving the growth of the aerospace foams industry across the globe.

Aerospace foams are advanced materials of various cell sizes, capacities, and properties. The cell sizes of the aerospace foams determine the flexibility or rigidity of the foams and thus, dictates the application areas where they can be used. Aerospace foams are manufactured using various materials, such as PU (polyurethane), PE (polyethylene), melamine, metal, and PMI/polyimide, among others, which meet the flame, smoke, and toxicity (FST) standards in the aerospace industry. These foams are used in various applications in aircrafts such as seating, seals, gaskets, carpet pads, headrests, rotor blades, doors, windshields, cockpit instrument panels, wingtip lens, and several others.

Based on material type, the aerospace foams market has been segmented into PU foams, PE foams, melamine foams, metal foams, PMI/polyimide foams, and others which includes PVDF foams, PPSU foams, silicone foams, ceramic foams, PEI foams, PET foams, PVC foams, and polycarbonate foams. The PU foams segment has the highest market share in terms of both value and volume, among all the material type segments in 2018. It is projected to follow the same trend from 2019 to 2024 in terms of both value and volume. PU foams are used in a variety of applications ranging from seating, airframes, interiors, and packaging in the aerospace industry. The availability in different forms ranging from low to high density with varying rigidity as well as ease-of-use makes them compatible to be used in a multitude of aerospace applications. Some useful properties of PU foams include durability, lightweight, and recyclability. These factors support the rising global demands for lightweight and fuel-efficient aircraft, which is one of the primary drivers of the aerospace foams market.

#Aerospace Foams Market#PU Foams#PE Foams#Melamine Foams#Metal Foams#PMI Foam#Polyimide Foams#erg metal foam#Global Aerospace Foams Market#COVID 19 impact on Aerospace Foams Market#Aviation foam suppliers#Aircraft structural foam#Aerospace Foams industry#Aerospace Foams Market Share#Aerospace Foams Market size#Demand of Aerospace Foams#Sales of Aerospace Foams#Aerospace Foams Market Manufacturers#Aerospace Foams Market Opportunity#growth of the aerospace foams industry#commercial aircraft Foams#aviation foams#PU aerospace foams

0 notes

Text

Navigating the Aerospace Foam Market Landscape: Key Players and Strategies

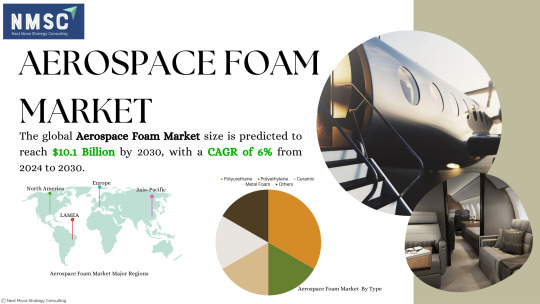

According to a comprehensive study conducted by Next Move Strategy Consulting, the global Aerospace Foam Market is poised to witness significant growth, with a predicted size of USD 10.1 billion and a compound annual growth rate (CAGR) of 5.8% by the year 2030.

This projection underscores the pivotal role that aerospace foam plays in shaping the trajectory of the aerospace industry, providing lightweight, durable, and innovative solutions to meet the evolving demands of modern aviation and space exploration.

Introduction:

The aerospace industry stands at the forefront of technological innovation, constantly pushing boundaries to enhance efficiency, safety, and performance. Central to this evolution is the integration of advanced materials, with aerospace foam emerging as a critical component in the pursuit of lightweight structures and enhanced functionalities.

Request for a sample, here: https://www.nextmsc.com/aerospace-foam-market/request-sample

Aerospace Foam Market Dynamics:

Understanding the dynamics of the aerospace foam market requires a closer look at the key players shaping its landscape. A multitude of factors, including technological advancements, market trends, and regulatory considerations, influence the strategies adopted by industry leaders.

Key Players in the Aerospace Foam Market:

Several prominent market players contribute to the growth and innovation within the aerospace foam market. Notable names such as BASF SE, Evonik Industries AG, Solvay, Greiner Aerospace, Boyd Corporation, Huntsman Corporation, Armacell, Pyrotek Inc., Zotefoams Plc, and General Plastics Manufacturing Company are among the industry giants actively engaged in developing and delivering cutting-edge solutions.

Strategies for Market Dominance:

Aerospace foam market players employ various strategies to maintain dominance and meet the ever-evolving needs of the industry. One common approach is the continuous launch of new and innovative products across different regions, enabling companies to stay ahead of the competition and cater to diverse market demands.

Strategic Partnerships: A notable example is the strategic partnership between Solvay and Zotefoams Plc. In June 2023, the two entities entered into a long-term supply agreement to enhance the availability of advanced cellular materials, including foams. This collaboration serves as a strategic move to address the growing demand for high-performance materials in critical applications, especially within the aerospace sector.

Innovative Product Launches: The aerospace industry demands materials that can withstand rigorous conditions while being lightweight and efficient. In May 2023, Huntsman Corporation announced the development of new materials specifically designed for aerospace applications. This innovation aims to meet the demanding requirements of the aerospace industry, focusing on enhancing performance and efficiency. The introduction of these materials underscores Huntsman's commitment to advancing technology in the aerospace foam market.

Strategic Investments: Evonik Industries AG, in March 2022, made a significant investment in a new production facility for Rohacell, a high-performance structural foam. This investment signals a commitment to advancing aerospace foam technology, catering to the increasing demand for lightweight and durable materials in the aerospace industry.

Market Trends and Future Outlook:

To navigate the aerospace foam market landscape effectively, it is crucial to stay abreast of emerging trends that influence industry dynamics. Key trends include:

Sustainability Initiatives: The aerospace industry is increasingly prioritizing sustainability, pushing market players to develop eco-friendly foam solutions that align with global environmental goals.

Digital Transformation: The integration of digital technologies is transforming manufacturing processes and supply chain management within the aerospace foam market, enhancing efficiency and reducing costs.

Urban Air Mobility (UAM): The rise of UAM presents new opportunities for aerospace foam market players, with the demand for lightweight materials in electric vertical takeoff and landing (eVTOL) vehicles.

Regional Insights and Market Segmentation:

The aerospace foam market is inherently diverse, with different regions exhibiting unique challenges and opportunities. Understanding regional dynamics and market segmentation is crucial for companies aiming to establish a global presence.

BASF SE: As one of the leading players in the aerospace foam market, BASF SE continually strives for innovation. An in-depth exploration of the company's strategies, product launches, and market influence provides valuable insights into its role within the industry.

Boyd Corporation: Examining Boyd Corporation's approach to market challenges, product development, and strategic partnerships sheds light on how this player maintains its competitive edge.

Challenges and Opportunities:

Navigating the aerospace foam market landscape is not without its challenges. From stringent industry regulations to evolving consumer preferences, companies must be agile in addressing obstacles while seizing opportunities for growth.

Supply Chain Disruptions: Global events such as pandemics, natural disasters, or geopolitical tensions can disrupt the aerospace foam supply chain, impacting production schedules and increasing costs. Companies need robust contingency plans to mitigate the effects of such disruptions and ensure continuity of operations.

Technological Complexity: Developing advanced aerospace foam solutions requires significant investment in research and development. Companies must navigate the complexities of material science, manufacturing processes, and regulatory compliance to bring innovative products to market successfully.

Competition from Alternative Materials: While aerospace foam offers unique advantages in terms of weight reduction and performance, it faces competition from alternative materials such as composite materials, lightweight metals, and 3D-printed components. Companies must differentiate their offerings and demonstrate the superior benefits of foam-based solutions to maintain a competitive edge.

Environmental Sustainability: The aerospace industry is under increasing pressure to reduce its environmental footprint and embrace sustainable practices. Companies in the aerospace foam market must innovate to develop eco-friendly foam materials that minimize environmental impact while meeting stringent performance requirements.

Future Outlook:

Despite these challenges, the aerospace foam market presents significant opportunities for growth and innovation. Advancements in material science, manufacturing technologies, and market demand for more efficient and sustainable solutions are driving the evolution of the industry.

Emerging Markets: Rapid urbanization, economic growth, and increased air travel demand in emerging markets present new opportunities for aerospace foam manufacturers. Companies that can adapt their strategies to cater to the specific needs of these markets stand to gain a competitive advantage.

Integration of Advanced Technologies: The integration of advanced technologies such as artificial intelligence, machine learning, and additive manufacturing is revolutionizing the aerospace foam industry. Companies that embrace these technologies can enhance product development processes, optimize production efficiency, and deliver tailored solutions to customers.

Collaboration and Partnerships: Collaboration between industry stakeholders, including manufacturers, suppliers, research institutions, and government agencies, is essential for driving innovation and addressing common challenges. Strategic partnerships can leverage complementary expertise and resources to accelerate product development and market penetration.

Focus on Customer-Centric Solutions: As aerospace OEMs and end-users increasingly prioritize performance, reliability, and cost-effectiveness, companies in the aerospace foam market must focus on delivering customer-centric solutions. Understanding and anticipating customer needs, preferences, and pain points are critical for maintaining competitiveness and driving long-term growth.

Inquire before buying, here: https://www.nextmsc.com/aerospace-foam-market/inquire-before-buying

Conclusion:

In conclusion, the aerospace foam market is a dynamic and rapidly evolving sector within the broader aerospace industry. Key players are instrumental in shaping its trajectory through strategic partnerships, innovative product launches, and investments in advanced technologies. As the demand for lightweight, durable materials continues to rise, the aerospace foam market's future holds exciting possibilities, providing ample opportunities for companies to pioneer advancements and contribute to the next era of aerospace innovation.

0 notes

Text

The global aerospace foams market estimated to be valued US$ 4.8 billion in 2020 and poised to grow at significant CAGR of over 8.4% during 2021 to 2027 to reach USD 8.3 billion by 2027. Growing need for economical carrier airlines has augmented the demand for aerospace foam in viable aircrafts, on the account of its insulating properties and excellent lightweight. Moreover, industrial development has boosted the demand for aerospace foam in the aircraft manufacturing. Government initiatives undertaken by government to provide financial assistance in military aircrafts is projected to lift the aerospace market. Furthermore, the rising use age of polyurethane foam products in interior cabins and aircraft flight decks has improved, due to their cushioning formulations and outstanding absorption. However, high cost associated with the use of these products dampens the growth of market. Request Sample : https://www.precisionbusinessinsights.com/request-sample/?product_id=35263

#aerospace foams market size#aerospace foams market share analysis#aerospace foams market growth drivers#aerospace foams market trends#aerospace foams market dynamics

0 notes