#Aerospace Foams industry

Text

The aerospace foams market size is projected to grow from USD 4.4 billion in 2019 to USD 6.5 billion by 2024, at a CAGR of 8.2% from 2019 to 2024. The rising demand for lightweight and fuel-efficient aircraft have led to the extensive use of advanced materials such as PU foams and PE foams, among others, in the aerospace industry. The manufacture of advanced materials as well as new products launched by several prominent players for the aerospace industry is one of the key factors driving the growth of the aerospace foams industry across the globe.

Aerospace foams are advanced materials of various cell sizes, capacities, and properties. The cell sizes of the aerospace foams determine the flexibility or rigidity of the foams and thus, dictates the application areas where they can be used. Aerospace foams are manufactured using various materials, such as PU (polyurethane), PE (polyethylene), melamine, metal, and PMI/polyimide, among others, which meet the flame, smoke, and toxicity (FST) standards in the aerospace industry. These foams are used in various applications in aircrafts such as seating, seals, gaskets, carpet pads, headrests, rotor blades, doors, windshields, cockpit instrument panels, wingtip lens, and several others.

Based on material type, the aerospace foams market has been segmented into PU foams, PE foams, melamine foams, metal foams, PMI/polyimide foams, and others which includes PVDF foams, PPSU foams, silicone foams, ceramic foams, PEI foams, PET foams, PVC foams, and polycarbonate foams. The PU foams segment has the highest market share in terms of both value and volume, among all the material type segments in 2018. It is projected to follow the same trend from 2019 to 2024 in terms of both value and volume. PU foams are used in a variety of applications ranging from seating, airframes, interiors, and packaging in the aerospace industry. The availability in different forms ranging from low to high density with varying rigidity as well as ease-of-use makes them compatible to be used in a multitude of aerospace applications. Some useful properties of PU foams include durability, lightweight, and recyclability. These factors support the rising global demands for lightweight and fuel-efficient aircraft, which is one of the primary drivers of the aerospace foams market.

#Aerospace Foams Market#PU Foams#PE Foams#Melamine Foams#Metal Foams#PMI Foam#Polyimide Foams#erg metal foam#Global Aerospace Foams Market#COVID 19 impact on Aerospace Foams Market#Aviation foam suppliers#Aircraft structural foam#Aerospace Foams industry#Aerospace Foams Market Share#Aerospace Foams Market size#Demand of Aerospace Foams#Sales of Aerospace Foams#Aerospace Foams Market Manufacturers#Aerospace Foams Market Opportunity#growth of the aerospace foams industry#commercial aircraft Foams#aviation foams#PU aerospace foams

0 notes

Text

Navigating the Aerospace Foam Market Landscape: Key Players and Strategies

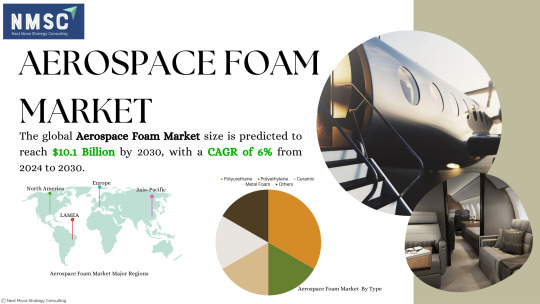

According to a comprehensive study conducted by Next Move Strategy Consulting, the global Aerospace Foam Market is poised to witness significant growth, with a predicted size of USD 10.1 billion and a compound annual growth rate (CAGR) of 5.8% by the year 2030.

This projection underscores the pivotal role that aerospace foam plays in shaping the trajectory of the aerospace industry, providing lightweight, durable, and innovative solutions to meet the evolving demands of modern aviation and space exploration.

Introduction:

The aerospace industry stands at the forefront of technological innovation, constantly pushing boundaries to enhance efficiency, safety, and performance. Central to this evolution is the integration of advanced materials, with aerospace foam emerging as a critical component in the pursuit of lightweight structures and enhanced functionalities.

Request for a sample, here: https://www.nextmsc.com/aerospace-foam-market/request-sample

Aerospace Foam Market Dynamics:

Understanding the dynamics of the aerospace foam market requires a closer look at the key players shaping its landscape. A multitude of factors, including technological advancements, market trends, and regulatory considerations, influence the strategies adopted by industry leaders.

Key Players in the Aerospace Foam Market:

Several prominent market players contribute to the growth and innovation within the aerospace foam market. Notable names such as BASF SE, Evonik Industries AG, Solvay, Greiner Aerospace, Boyd Corporation, Huntsman Corporation, Armacell, Pyrotek Inc., Zotefoams Plc, and General Plastics Manufacturing Company are among the industry giants actively engaged in developing and delivering cutting-edge solutions.

Strategies for Market Dominance:

Aerospace foam market players employ various strategies to maintain dominance and meet the ever-evolving needs of the industry. One common approach is the continuous launch of new and innovative products across different regions, enabling companies to stay ahead of the competition and cater to diverse market demands.

Strategic Partnerships: A notable example is the strategic partnership between Solvay and Zotefoams Plc. In June 2023, the two entities entered into a long-term supply agreement to enhance the availability of advanced cellular materials, including foams. This collaboration serves as a strategic move to address the growing demand for high-performance materials in critical applications, especially within the aerospace sector.

Innovative Product Launches: The aerospace industry demands materials that can withstand rigorous conditions while being lightweight and efficient. In May 2023, Huntsman Corporation announced the development of new materials specifically designed for aerospace applications. This innovation aims to meet the demanding requirements of the aerospace industry, focusing on enhancing performance and efficiency. The introduction of these materials underscores Huntsman's commitment to advancing technology in the aerospace foam market.

Strategic Investments: Evonik Industries AG, in March 2022, made a significant investment in a new production facility for Rohacell, a high-performance structural foam. This investment signals a commitment to advancing aerospace foam technology, catering to the increasing demand for lightweight and durable materials in the aerospace industry.

Market Trends and Future Outlook:

To navigate the aerospace foam market landscape effectively, it is crucial to stay abreast of emerging trends that influence industry dynamics. Key trends include:

Sustainability Initiatives: The aerospace industry is increasingly prioritizing sustainability, pushing market players to develop eco-friendly foam solutions that align with global environmental goals.

Digital Transformation: The integration of digital technologies is transforming manufacturing processes and supply chain management within the aerospace foam market, enhancing efficiency and reducing costs.

Urban Air Mobility (UAM): The rise of UAM presents new opportunities for aerospace foam market players, with the demand for lightweight materials in electric vertical takeoff and landing (eVTOL) vehicles.

Regional Insights and Market Segmentation:

The aerospace foam market is inherently diverse, with different regions exhibiting unique challenges and opportunities. Understanding regional dynamics and market segmentation is crucial for companies aiming to establish a global presence.

BASF SE: As one of the leading players in the aerospace foam market, BASF SE continually strives for innovation. An in-depth exploration of the company's strategies, product launches, and market influence provides valuable insights into its role within the industry.

Boyd Corporation: Examining Boyd Corporation's approach to market challenges, product development, and strategic partnerships sheds light on how this player maintains its competitive edge.

Challenges and Opportunities:

Navigating the aerospace foam market landscape is not without its challenges. From stringent industry regulations to evolving consumer preferences, companies must be agile in addressing obstacles while seizing opportunities for growth.

Supply Chain Disruptions: Global events such as pandemics, natural disasters, or geopolitical tensions can disrupt the aerospace foam supply chain, impacting production schedules and increasing costs. Companies need robust contingency plans to mitigate the effects of such disruptions and ensure continuity of operations.

Technological Complexity: Developing advanced aerospace foam solutions requires significant investment in research and development. Companies must navigate the complexities of material science, manufacturing processes, and regulatory compliance to bring innovative products to market successfully.

Competition from Alternative Materials: While aerospace foam offers unique advantages in terms of weight reduction and performance, it faces competition from alternative materials such as composite materials, lightweight metals, and 3D-printed components. Companies must differentiate their offerings and demonstrate the superior benefits of foam-based solutions to maintain a competitive edge.

Environmental Sustainability: The aerospace industry is under increasing pressure to reduce its environmental footprint and embrace sustainable practices. Companies in the aerospace foam market must innovate to develop eco-friendly foam materials that minimize environmental impact while meeting stringent performance requirements.

Future Outlook:

Despite these challenges, the aerospace foam market presents significant opportunities for growth and innovation. Advancements in material science, manufacturing technologies, and market demand for more efficient and sustainable solutions are driving the evolution of the industry.

Emerging Markets: Rapid urbanization, economic growth, and increased air travel demand in emerging markets present new opportunities for aerospace foam manufacturers. Companies that can adapt their strategies to cater to the specific needs of these markets stand to gain a competitive advantage.

Integration of Advanced Technologies: The integration of advanced technologies such as artificial intelligence, machine learning, and additive manufacturing is revolutionizing the aerospace foam industry. Companies that embrace these technologies can enhance product development processes, optimize production efficiency, and deliver tailored solutions to customers.

Collaboration and Partnerships: Collaboration between industry stakeholders, including manufacturers, suppliers, research institutions, and government agencies, is essential for driving innovation and addressing common challenges. Strategic partnerships can leverage complementary expertise and resources to accelerate product development and market penetration.

Focus on Customer-Centric Solutions: As aerospace OEMs and end-users increasingly prioritize performance, reliability, and cost-effectiveness, companies in the aerospace foam market must focus on delivering customer-centric solutions. Understanding and anticipating customer needs, preferences, and pain points are critical for maintaining competitiveness and driving long-term growth.

Inquire before buying, here: https://www.nextmsc.com/aerospace-foam-market/inquire-before-buying

Conclusion:

In conclusion, the aerospace foam market is a dynamic and rapidly evolving sector within the broader aerospace industry. Key players are instrumental in shaping its trajectory through strategic partnerships, innovative product launches, and investments in advanced technologies. As the demand for lightweight, durable materials continues to rise, the aerospace foam market's future holds exciting possibilities, providing ample opportunities for companies to pioneer advancements and contribute to the next era of aerospace innovation.

0 notes

Text

Aerospace Foam Market will reach at a CAGR of 6.9% from 2023 to 2029

As per the new study published by Data Library Research, titled, “Aerospace Foam market by type, application, end user, and region: industry forecast and market potential analysis, 2023-2029,” the global Aerospace Foam market is rising at substantial rate and is projected to maintain its progress during the prediction period.

The study elaborates growth rate of the Aerospace Foam market…

View On WordPress

#Aerospace Foam#Aerospace Foam forecast#Aerospace Foam industry#Aerospace Foam market#Aerospace Foam price#Aerospace Foam share#Aerospace Foam trends

0 notes

Text

High Heat Foam Market

The report proves to be an effective tool that players can use to gain a competitive edge over their competitors and ensure lasting success in the global High Heat Foam market.

Download Free Research Report Sample PDF: https://cutt.ly/MMzVhFh

#highheatfoam#heatfoam#heatfoammarket#foam#foammarket#highheatfoammarket#heat#highheat#silicone#polyimide#melamine#polyethylene#automotive#industrial#aerospace#chemicals#chemicalsmarket#chemicalsindustry#chemicalsmanufacturer#statsmarketresearch

0 notes

Text

California State Senator Ben Allen represents the 24th Senate District, covering the Westside, Hollywood, South Bay, and Santa Monica Mountains communities of Los Angeles County. Ben was first elected in 2014 and is now serving his third and final term in the State Senate.

Ben chairs the Senate's Environmental Quality Committee and co-chairs the Legislature's Environmental Caucus, is a member of the Legislative Jewish Caucus, chairs the Legislature's Joint Committee on the Arts, and the Senate Select Committee on Aerospace and Defense. He previously served as Chair of the Education Committee (2017-2019) and Chair of the Elections and Constitutional Amendments Committee (2015-2016).

Ben has thrown himself into the important work of state government, focusing on wise decision-making and pushing for reforms that address systemic inadequacies in our state. He has authored nearly 60 new laws in various areas, from environmental protection to electoral reform.

During his first two terms in the Senate, fighting the climate crisis and protecting our state's precious natural resources have been among Ben's top priorities. CalMatters recently recognized him as one of the Legislature's foremost leaders in the field of environmental protection. He authored SB 54, groundbreaking legislation to address plastic pollution, which Governor Newsom signed into law to international acclaim. The New York Times called SB 54 "the most sweeping restrictions on plastics in the nation" and suggested the legislation is "another route for curbing carbon emissions and trying to sidestep the worst consequences of global warming" after the Supreme Court gutted the federal government's power to regulate carbon emissions. As Chair of the Senate Environmental Quality Committee, Ben worked with his colleagues to pass a powerful climate package requiring the state to become carbon-neutral by 2045 and produce 90% of its electricity from clean sources by 2035, among other measures. A member of the Ocean Protection Council and Coastal Conservancy, he has led a successful effort to phase out a dangerous carcinogen in firefighting foam, crafted a compromise to phase out destructive trawling gear, and brokered a major compromise that lessened the environmental impact of off-highway vehicle use at state facilities. "If only Congress could work out such compromises," wrote the Sacramento Bee editorial board about the bill.

Among his efforts to reform California campaign finance and elections laws, Ben authored the landmark Voter's Choice Act of 2016 to implement more flexibility in how and where to vote, creating the vote center model used in the 2020 elections, which resulted in significantly increased voter turnout. Ben also has been a leader for campaign transparency, and was a leader in passing the Disclose Act and Petition Disclose Act and other transparency measures that have dramatically improved the disclosure of donors to political causes for the public. The California Clean Money Campaign has routinely ranked him top in the Legislature for his commitment to clean money political reform.

An advocate for the Golden State's continued leadership in arts and entertainment, Ben is a member of the California Film Commission. He was part of a legislative effort to extend the Film & TV Tax Credit Program to further support and invest in California’s unrivaled film industry. Ben also authored the law that reinstated teaching credentials for theatre and dance educators, and he continues to fight for expanded access to the arts in schools and underserved communities. Ben has been a champion for science and was a joint author of the state's groundbreaking law that increased vaccination rates among school children.

Prior to his election to the Senate, Ben served as President of the Santa Monica-Malibu Unified School District Board of Education, lecturer at UCLA Law School, and worked as an attorney at the law firms of Bryan Cave LLP and Richardson & Patel and at the nonprofit Spark Program. While at law school, Ben served as the voting student member of the University of California Board of Regents and was a summer judicial clerk with the United Nations International Criminal Tribunal for Rwanda. Prior to law school, Ben worked in Washington DC for the Latin American team of the National Democratic Institute for International Affairs (NDI), and then as Communications Director for Congressman Jose Serrano (D-NY).

Ben grew up in the 24th Senate District and attended public schools, graduating from Santa Monica High School in 1996. His father, Michael, spent his career on the English Department faculty at UCLA and mother, Elena, was a public school teacher and artist who served as Chair of the Santa Monica Arts Commission. Ben has a Bachelor of Arts degree magna cum laude in History from Harvard University; a Master's degree in Latin American Studies from the University of Cambridge; and a Juris Doctor degree from UC Berkeley. Fluent in Spanish, Ben is a Senior Fellow with the international human rights organization Humanity in Action, an Aspen Institute-Rodel Fellow, a Truman National Security Project Fellow, and a graduate of the Jewish Federation's New Leaders Project. He and his wife Melanie, an attorney, have a little son, Ezra.

3 notes

·

View notes

Text

We offer a range of industrial cleaning services – Ultra high-pressure (UHP) water jetting, Dry ice blasting + glass beads, Fin fan foam cleaning, and chemical cleaning to meet our customers’ requirements in different industries such as aerospace, oil & gas, automotive, food & packaging, foundry, medical, printing, marine, building & infrastructure, and more!

For more details about this service, drop us an email at [email protected] | visit us at petracarbon.com.sg

#engineering#industrial#cleaning#maintenancecare#water jets#dry ice blasting#solutions#services#oil and gas#marine#automotive

3 notes

·

View notes

Text

The Aluminum Slug Market: Trends, Drivers, and Future Prospects

The aluminum slug market plays a pivotal role in the broader aluminum industry, supplying critical components for a diverse array of end-use applications. These small, cylindrical pieces of aluminum are essential in the manufacturing of various products, ranging from aerosol cans to automotive components. This article delves into the current trends, key drivers, challenges, and future prospects of the aluminum slug market.

Sample Report: https://www.econmarketresearch.com/request-sample/EMR0075/

Market Overview

Aluminum slugs are intermediate products in the aluminum processing chain, produced primarily through the extrusion process. They are further processed into end products by means of impact extrusion, a technique that involves forcing the slug into a mold at high pressure to create hollow shapes. This method is particularly valued for its ability to produce lightweight, durable, and corrosion-resistant items.

Key Applications

The aluminum slug market caters to several significant sectors:

Packaging Industry: One of the largest consumers of aluminum slugs is the packaging industry, especially for producing aerosol cans and beverage containers. The demand for convenient, lightweight, and recyclable packaging solutions has driven the growth in this sector.

Automotive Industry: Aluminum slugs are used to manufacture various automotive components such as shock absorber tubes, airbag inflators, and engine parts. The automotive industry's shift towards lightweight materials to enhance fuel efficiency and reduce emissions has bolstered the demand for aluminum slugs.

Pharmaceutical and Cosmetic Industries: The demand for aluminum tubes in the pharmaceutical and cosmetic industries has been robust, as these sectors require packaging that ensures product safety, hygiene, and extended shelf life.

Electrical and Electronics Industry: Aluminum’s excellent conductivity and lightweight properties make slugs valuable for producing electrical components and housings for electronic devices.

Gate Full Information: https://www.econmarketresearch.com/industry-report/aluminum-slug-market/

Other Reports:

SOC Containers Market Growth

HVAC Chillers Market Size

Aluminum Slug Market

Digital Brain Health Market Analysis

Cognitive Robotics Market Trends

Industrial IoT Display Market Share

Edible Offal Market Application

Potato and Yam Derivatives Market

Surgical Booms Market Overview

Marine Application Market Opportunities

Wind Power Parks Market Revenue

Fuel Cells In Aerospace And Defense Market

Floor Adhesive Market Sales

Pet Fitness Care Market Technology

Axial Flux Motor Market Drivers

Audio and Video Equipment Market Types

Self Stabilizing Spoon Market Challenges

Solar Backsheet Films Market Outlook

Marine Sensors Market Analysis

Dry Shipping Container Market Segmentation

Blood Stream Infection Testing Market Size

Ethyl Vanillin Market Growth

Prebiotic Fiber Market Future

Solar Watch Market Trends

Industrial and Commercial Floor Scrubbers Market Analysis

Electro-Mechanical Brake Market Share

Fiber-Reinforced Plastics Recycling Market Segmentation

Closed Cell Foam Market Drivers

Perfume Ingredient Chemicals Market Technology

Bucket Wheel Excavator Market Revenue

Female Fragrance Market Sales

Yard Crane Market Outlook

0 notes

Text

0 notes

Text

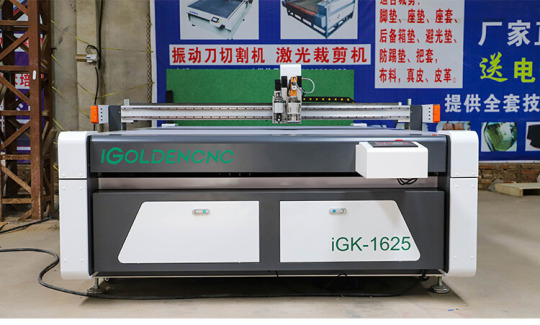

CNC Knife Cutter Machine for PE and EVA Foams

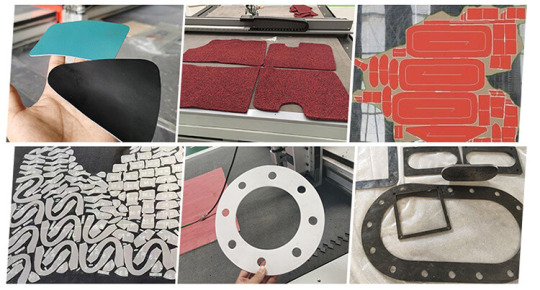

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

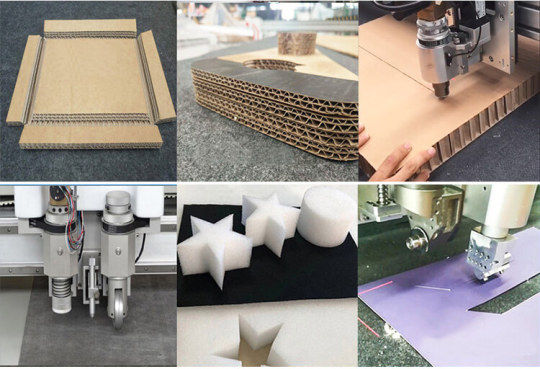

CNC Knife Cutter Machine Processing advantages

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

0 notes

Text

The Challenge of Vibration and Damping and the Future of the Latest Technology

INTRODUCTION

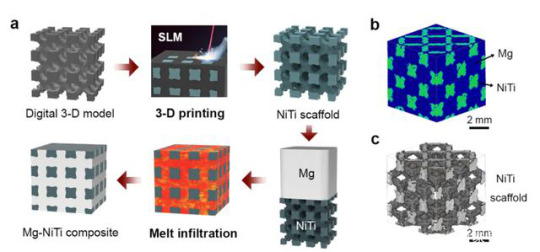

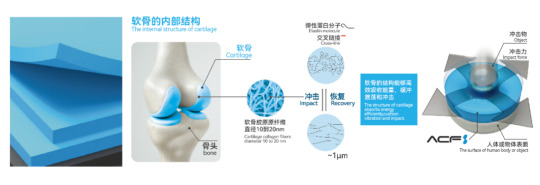

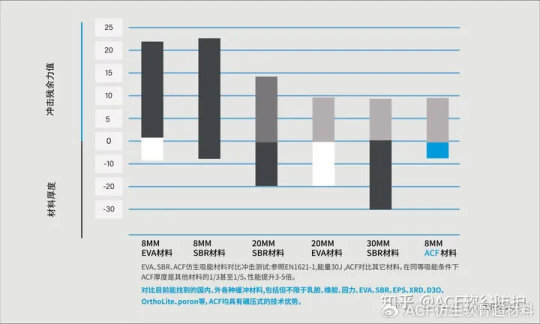

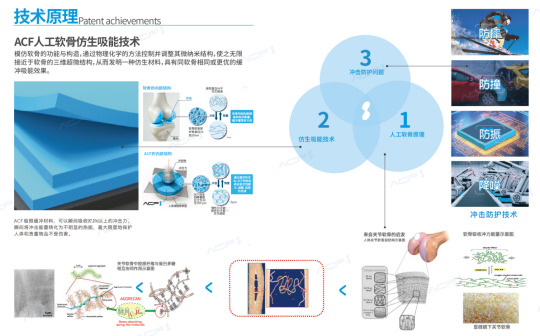

Seismic and vibration damping are two crucial concepts in the field of engineering and technology. They are concerned with reducing the effects of sudden shocks such as earthquakes and reducing the effects of continuous vibration on equipment and structures, respectively. However, both fields are facing their own challenges. In recent years, ACF (Artificial Cartilage Foam) technology from LinZhi Technology, as a new type of polymer impact resistant and energy absorbing composite material, has demonstrated significant advantages in the research in the field of shock absorption and vibration damping.

Challenges to vibration damping and application of ACF technology

The unpredictability of vibrations and the complexity of structures are the main challenges to seismic mitigation. The intensity and frequency of vibrations are difficult to predict, while the complexity of structures makes seismic design difficult. To address these issues, ACF technology provides new solutions for vibration damping through its unique damping properties and shock resistance.

ACF material adopts micro and nano molecular structure to form a metamaterial, which is extremely lightweight and can effectively reduce the vibration response of the structure. Their excellent damping properties make them a powerful support for enhancing structural stability, especially in structural vibration shock objects such as complex vibrations. In addition, ACF materials can be adapted to the shape and size of various structures to provide customized solutions according to various spatial requirements. This means that ACF materials can provide more precise and effective support for vibration damping, whether in buildings, bridges or ground facilities.

Challenges of vibration damping and advantages of ACF technology

Compared with vibration damping, the challenges facing vibration damping are more diverse. The influence of multiple vibration sources and performance changes under different environmental conditions are the main problems facing vibration damping. To cope with these challenges, ACF technology shows great potential with its high-performance damping materials and intelligent control technology.

ACF material has high resistance to pressure and deformation, and can effectively transform, absorb and disperse vibration energy. Its highest energy absorption rate can reach 97.1%, which is 3-5 times higher than that of conventional materials for vibration damping and energy absorption. This material also has good processing performance, can be easily processed into various shapes and sizes to meet the vibration damping needs of different equipment. In terms of intelligent control technology, ACF materials can be combined with sensors, control systems and other modern technical means to achieve more accurate vibration control.

Fourth, the future outlook of ACF technology

With the continuous development of science and technology, the application prospect of ACF technology in the field of vibration damping and damping will be broader. On the one hand, the research of ACF materials will be deepened, and its damping performance, impact resistance and environmental adaptability will be further improved. On the other hand, ACF technology will be combined with other modern technical means to form a more efficient and intelligent vibration and damping system.

For example, in industrial production systems, ACF materials can be used as key components to provide more timely and effective protection for precision production and product manufacturing through their excellent vibration damping and energy absorption properties. ACF technology will also be widely used in aerospace, machinery manufacturing and transportation, and electronic chip protection to improve the stability and reliability of equipment and structures.

400-6543-699

www.acf.com

0 notes

Text

The aerospace foams market size is projected to grow from USD 4.4 billion in 2019 to USD 6.5 billion by 2024, at a CAGR of 8.2% from 2019 to 2024. The rising demand for lightweight and fuel-efficient aircraft have led to the extensive use of advanced materials such as PU foams and PE foams, among others, in the aerospace industry. The manufacture of advanced materials as well as new products launched by several prominent players for the aerospace industry is one of the key factors driving the growth of the aerospace foams industry across the globe.

Aerospace foams are advanced materials of various cell sizes, capacities, and properties. The cell sizes of the aerospace foams determine the flexibility or rigidity of the foams and thus, dictates the application areas where they can be used. Aerospace foams are manufactured using various materials, such as PU (polyurethane), PE (polyethylene), melamine, metal, and PMI/polyimide, among others, which meet the flame, smoke, and toxicity (FST) standards in the aerospace industry. These foams are used in various applications in aircrafts such as seating, seals, gaskets, carpet pads, headrests, rotor blades, doors, windshields, cockpit instrument panels, wingtip lens, and several others.

Based on material type, the aerospace foams market has been segmented into PU foams, PE foams, melamine foams, metal foams, PMI/polyimide foams, and others which includes PVDF foams, PPSU foams, silicone foams, ceramic foams, PEI foams, PET foams, PVC foams, and polycarbonate foams. The PU foams segment has the highest market share in terms of both value and volume, among all the material type segments in 2018. It is projected to follow the same trend from 2019 to 2024 in terms of both value and volume. PU foams are used in a variety of applications ranging from seating, airframes, interiors, and packaging in the aerospace industry. The availability in different forms ranging from low to high density with varying rigidity as well as ease-of-use makes them compatible to be used in a multitude of aerospace applications. Some useful properties of PU foams include durability, lightweight, and recyclability. These factors support the rising global demands for lightweight and fuel-efficient aircraft, which is one of the primary drivers of the aerospace foams market.

#Aerospace Foams Market#PU Foams#PE Foams#Melamine Foams#Metal Foams#PMI Foam#Polyimide Foams#erg metal foam#Global Aerospace Foams Market#COVID 19 impact on Aerospace Foams Market#Aviation foam suppliers#Aircraft structural foam#Aerospace Foams industry#Aerospace Foams Market Share#Aerospace Foams Market size#Demand of Aerospace Foams#Sales of Aerospace Foams#Aerospace Foams Market Manufacturers#Aerospace Foams Market Opportunity#growth of the aerospace foams industry#commercial aircraft Foams#aviation foams#PU aerospace foams

0 notes

Text

0 notes

Text

Coating Additives Market Industry Analysis| 2031

The Insight Partners introduces its new market research as “Coating Additives Market Industry Analysis| 2031”. The company specializes in syndicated market research and consultation services. Through this research company is offering both qualitative and quantitative data assisting Coating Additives market investors.

Key Chapters Under This Research

Current Market Scenario and Estimates to 2031

Market Drivers, Opportunities, and Trends

Market Competition Analysis

This chapter offers insights on established and new entrant Coating Additives market players. Understanding competition helps companies understand their position in the market. Through this chapter, the report offers insights on threats and opportunities ahead of Coating Additives market players. Comparing pricing strategies and organic growth strategies used by key market participants provides opportunities for growth in the Coating Additives market.

Report Attributes

Details

Segmental Coverage

Type

Acrylic

Metallic

Fluoropolymer

Urethane

Others

Formulation

Water-Borne

Solvent-Borne

Powder-Based

Function

Anti-Foaming

Wetting and Dispersion

Biocides

Rheology Modification

Others

Application

Automotive

Architectural

Industrial

Wood and Furniture

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

AkzoNobelN.V.

ArkemaGroup

AshlandInc.

BASFSE

BYK-ChemieGmbH

EastmanChemicalCompany

Elementisplc

EvonikIndustriesAG

MomentivePerformanceMaterialsInc.

TheDowChemicalCompany

Other key companies

Research Methodology

This Coating Additives market report includes findings based on scrutiny of different factors impacting on business environment. Both primary and secondary methods of research are used to generate insights. Details on Coating Additives market share, key players, micro-financial pointers, and other demographic factors.

Key market players are analyzed for their market share and overall growth in the industry. Based on forecast duration, these key market players are evaluated for their incomes. This market research brings local, regional, and national level information on the market

Go-To-Market Framework:

Development trends, competitive landscape analysis, supply-side analysis, demand-side analysis, year-on-year growth, competitive benchmarking, vendor identification, CMI quadrant, and other significant analysis, as well as development status.

Customized regional/country reports as per request and country-level analysis.

Potential & niche segments and regions exhibiting promising Coating Additives market growth are covered.

Analysis of Coating Additives Market Size (historical and forecast), Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM), Market Growth, Technological Trends, Market Share, Market Dynamics, Competitive Landscape, and Major Players (Innovators, Start-ups, Laggard, and Pioneer).

Key Benefits for Buyers

Strategic Insights to increase per-customer revenue and overall consumer experience.

Assistance and strategic roadmap to device marketing tactics

Details-oriented approach, authorized information, and new optimal business solutions

Preferred target demographic, regions, and market channels

Customized Insights and Consultation services.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

PUF Panels and Sandwich Panels: Applications Across Industries

Efficiency, durability, and versatility are essential in the realms of construction and industrial design. One innovation that has revolutionized these aspects is the introduction of Polyurethane Foam (PUF) panels and sandwich panels. These composite materials, consisting of a core sandwiched between two outer layers, offer numerous advantages and are widely used across various industries. In this text, we will explore the different areas where PUF panels and sandwich panels are commonly applied.

Cold Storage and Refrigeration: PUF panels excel in thermal insulation properties, making them ideal for cold storage facilities and refrigeration units. These panels create an efficient barrier against temperature fluctuations, helping to maintain the desired temperature inside the storage area. From food processing plants to pharmaceutical storage facilities, PUF panels ensure the integrity and freshness of perishable goods.

Commercial and Industrial Buildings: The versatility of PUF panels and sandwich panels extends to the realm of commercial and prefab construction. These panels are widely used for roofing, wall cladding, and partitioning in warehouse manufacturers, factories, workshops, and offices. Their lightweight nature facilitates quick installation, reducing construction time and costs. Moreover, their excellent insulation properties contribute to energy efficiency, leading to reduced heating and cooling expenses.

Modular Construction: The modular construction industry heavily relies on PUF panels and sandwich panels for their prefabricated structures. Whether it's modular homes, portable cabins, or temporary shelters, these panels offer a convenient solution for rapid assembly and disassembly. The modular nature of PUF panels allows for easy customization, enabling architects and designers to create versatile spaces tailored to specific needs.

Transportation Sector: PUF panels play a vital role in the transportation sector, particularly in the construction of refrigerated trucks, vans, and containers. These panels help to create insulated compartments that safeguard perishable goods during transit. Additionally, sandwich panels find applications in the aerospace industry for aircraft interiors, providing lightweight yet robust solutions for cabin walls and partitions.

Clean Rooms and Laboratories: Precision-controlled environments such as clean rooms and laboratories require stringent temperature and contamination control. PUF panels offer an ideal solution due to their ability to create airtight enclosures with superior insulation properties. These panels help maintain stable environmental conditions necessary for sensitive manufacturing processes, research, and testing activities.

Agricultural Sector: In agriculture, PUF panels are utilized for constructing storage facilities, cold rooms, and greenhouses. These panels help farmers and growers extend the shelf life of their produce by providing an insulated environment conducive to preservation. Additionally, sandwich panels are employed in livestock housing, offering comfortable and hygienic shelters for animals.

Conclusion: PUF panels and sandwich panels have emerged as indispensable materials across a myriad of industries, thanks to their exceptional thermal insulation, structural strength, and versatility. From cold storage facilities to commercial buildings, from transportation to clean room environments, the applications of these panels are diverse and far-reaching. As technology continues to advance, we can expect further innovations in the design and utilization of PUF panels, driving efficiency, sustainability, and performance across various sectors.

1 note

·

View note

Text

Acrylic Foam Tape Manufacturers Bring Perfect Adhesive Solutions in Cheap!

Acrylic foam tape revolutionizes bonding application across the industries with a versatile adhesive solution. This adhesive on both sides is composed of a viscoelastic acrylic foam core; with durability and strength this tape offers unexpected bonding. It has unique composition that allows it to conform to irregular surfaces while creating a strong bond and permanent bond that can resist the temperature fluctuations, UV exposure and moisture. One of the best features of this foam tape is that its ability to distribute stress evenly and the risk of substrate damage or failure are reduced. This makes an ideal choice for people to use it.

Brings innovative adhesive solutions

In supplying industries with innovative adhesive solutions Acrylic foam tape manufacturers plays a vital role while meeting diverse bonding needs. In research and development to engineer tapes that exhibit superior performance, versatility and durability this manufactures invest heavily. To produce acrylic foam tapes with consistent quality and adherence to stringent standards the leading manufacturers employ advanced manufacturing processes. Throughout the process they utilize state of the art facilities and stick to a strict quality control measures to ensure that each roll of tape meets or exceeds expectations of the customer. And where precision and reliability are supreme, acrylic foam tape finds application in electronics and aerospace industries.

Comes with excellent adhesion and tack

Ensuring a strong bond upon the application the acrylic double sided tape provides an excellent initial tack and adhesion. Even in challenging conditions this tape maintains it's bonding strength over time and making it ideal for long term bonding solutions. In industries like automotive, electronics and construction this doubled sided tape is widely used. While offering a cleaner and more efficient alternative to traditional mechanical, the automotive manufacturers use this tape for attaching trim, molding and emblems. Providing a secure and aesthetically pleasing solution, in construction it is used for mounting mirrors, glass, and other elements that are architectural.

0 notes

Text

Eco-friendly Innovations Propel Industrial Foam Market Toward Sustainable Growth on Global Scale by 2033

Overview and Scope

Industrial foam is an expanded plastic and rubber created by forcing gas bubbles into a polymer material. Industrial foam is highly-efficient for insulation against water, air, chemical substances, and adhesives. Industrial foam is used as padding for several consumer and business products, such as mattresses, furniture, car interiors, carpet underlay, and packaging.

Sizing and Forecast

The industrial foam market size has grown strongly in recent years. It will grow from $63.14 billion in 2023 to $68.05 billion in 2024 at a compound annual growth rate (CAGR) of 7.8%.

The industrial foam market size is expected to see strong growth in the next few years. It will grow to $91.5 billion in 2028 at a compound annual growth rate (CAGR) of 7.7%.

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/industrial-foam-global-market-report

Segmentation & Regional Insights

The industrial foam market covered in this report is segmented –

1) By Foam Type: Flexible, Rigid

2) By Resin Type: Polyurethane, Polystyrene, Polyolefin, Phenolic, PET, Other Resin Types

3) By End-Use: Building And Construction, HVAC, Industrial Pipe Insulation, Marine, Aerospace, Industrial Cold Storage, Others End-Uses

Asia-Pacific was the largest region in the industrial foam market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the industrial foam market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8209&type=smp

Major Driver Impacting Market Growth

Growing demand for energy-efficient and lightweight materials is expected to propel the industrial foam market. Lightweight materials are manufactured using lightweight raw materials that directly reduce the weight of the material while maintaining its performance. Industrial foam is a type of lightweight material made up of tiny cells filled with gas or air and used in applications such as insulation, packaging, and construction.

Key Industry Players

Major companies operating in the industrial foam market report are Covestro AG, BASF SE, Dow Inc., Huntsman Corporation, Sekisui Chemical Co. Ltd., Saint-Gobain S.A., Chemtura Corporation, Recticel N.V, Rogers Corporation

The industrial foam market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes