#Aluminium Alloy Wheel

Text

Claveau Descartes, 1948. Another debutante at the 35th Paris Mondial de l'Automobile. An advanced 6 passenger luxury saloon by Émile Claveau with a SOHC alloy 2.3 litre V8 engine driving the front wheels through a 5 speed gearbox. The bodywork was fabricated from an alloy of aluminium and copper called Duralinox. Claveau had presented the car in model form a year before but 75 years ago this weekend he showed a fully working prototype that had been built with the cooperation of Aluminium Français. The Descartes had a drag coefficient of 0.29 and a top speed of 95 mph, both remarkable for 1948. However it went no further than a single prototype

#Claveau Descartes#Émile Claveau#prototype#V8#front wheel drive#aerodynamic#1948#75 years ago#aluminium#alloy#Paris Motor Show

152 notes

·

View notes

Text

Aluminium alloy wheel Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Aluminium alloy wheel Market and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Aluminium alloy wheel Market scenario, and feasibility study are the important aspects analyzed in this report.

The Aluminium alloy wheel Market is experiencing robust growth driven by the expanding globally. The Aluminium alloy wheel Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Aluminium alloy wheel Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. The global Aluminum Alloy Wheels Market size was USD 14.23 billion in 2020. The market is projected to grow from USD 16.43 billion in 2021 to USD 30.98 billion in 2028 at a CAGR of 9.5% during the 2021-2028 period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/105603

Key Strategies

Key strategies in the Aluminium alloy wheel Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Aluminium alloy wheel Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Aluminium alloy wheel Market.

Major Aluminium alloy wheel Market Manufacturers covered in the market report include:

LIST OF KEY COMPANIES PROFILED:

Status Wheels Inc. (Florida, U.S.)

Wheel Pros LLC. (Colorado, U.S.)

Fuel Off-Road Wheels (California, U.S.)

Citic Dicastal Co Ltd. (Hebei, China)

Enkei Wheels India Ltd (Pune, India)

Ronal AG (Härkingen, Switzerland)

BBS Kraftfahrzeugtechnik AG (Schiltach, Germany)

Alcoa wheels (Pennsylvania, U.S.)

MHT Luxury Wheels (California, U.S.)

Superior Industries (Minnesota, U.S.)

Alloy wheels have a widespread application due to their high resilience and lightweight. Furthermore, aluminum alloy wheels amplify the aesthetic appearance of the vehicle. Automakers are being forced to manufacture lighter, environment-friendly, and safer cars as the amount of carbon dioxide emitted is proportional to the amount of fuel consumption and the size of the vehicle; hence, reducing weight becomes a critical necessity.

Trends Analysis

The Aluminium alloy wheel Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Aluminium alloy wheel Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Aluminium alloy wheel Market Solutions.

Regions Included in this Aluminium alloy wheel Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Aluminium alloy wheel Market.

- Changing the Aluminium alloy wheel Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Aluminium alloy wheel Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Aluminium alloy wheel Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2024 to 2030?

► What are the key market dynamics influencing growth in the Global Aluminium alloy wheel Market?

► Who are the prominent players in the Global Aluminium alloy wheel Market?

► What is the consumer perspective in the Global Aluminium alloy wheel Market?

► What are the key demand-side and supply-side trends in the Global Aluminium alloy wheel Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Aluminium alloy wheel Market?

Table Of Contents:

1 Market Overview

1.1 Aluminium alloy wheel Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

308, Supreme Headquarters,

Survey No. 36, Baner,

Pune-Bangalore Highway,

Pune - 411045, Maharashtra, India.

Phone:

US:+1 424 253 0390

UK: +44 2071 939123

APAC: +91 744 740 1245

#Aluminium alloy wheel Market#Aluminium alloy wheel Market Share#Aluminium alloy wheel Market Size#Aluminium alloy wheel Market trends#Aluminium alloy wheel Market Growth#Aluminium alloy wheel Market Outlook

0 notes

Text

Welcome to the Shreeji Tyre Spot as a leading tyre retailer & Ahmedabad largest alloy wheel retail chain showroom. Feel free to contact us on below numbers or feel quick contact form. Our representative contact you soon.

Shreeji Tyre Spot is a leading Alloy Wheel Shop/dealers in Ahmedabad, Gujarat. Get the most affordable price mag wheel services (installation) Ahmedabad area. Car Alloy Wheels Price in Ahmedabad, India - Shreeji Tyre Shop.

#alloy#alloys#apollo#alloy wheels#alloy rims restoration#the alloy of law#aluminium alloy#alloy wheel#alloy wheels shop in ahmedabad#alloy wheels in ahmedabad

0 notes

Text

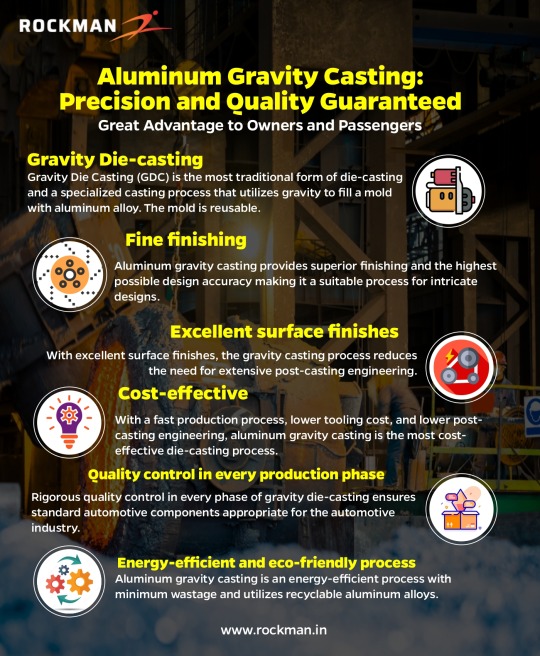

Aluminum Gravity Casting: Precision and Quality Guaranteed

Gravity Die-casting

Gravity Die Casting (GDC) is the most traditional form of die-casting and a specialized casting process that utilizes gravity to fill a mold with aluminum alloy. The mold is reusable.

Advantages of aluminum gravity casting

Fine finishing

Aluminum gravity casting provides superior finishing and the highest possible design accuracy making it a suitable process for intricate designs.

Excellent surface finishes

With excellent surface finishes, the gravity casting process reduces the need for extensive post-casting engineering.

Cost-effective

With a fast production process, lower tooling cost, and lower post-casting engineering, aluminum gravity casting is the most cost-effective die-casting process.

Quality control in every production phase

Rigorous quality control in every phase of gravity die-casting ensures standard automotive components appropriate for the automotive industry.

Energy-efficient and eco-friendly process

Aluminum gravity casting is an energy-efficient process with minimum wastage and utilizes recyclable aluminum alloys.

For more information on gravity casting and aluminum die-casting visit: https://www.rockman.in/

#Aluminum gravity casting#Alloy wheels for passenger cars#Aluminium die casting#die casting parts#High Pressure Die Casting suppliers in india#Aluminium casting#Aluminium Die cast#Aluminium die casting parts suppliers in india

0 notes

Text

Wheel

0 notes

Text

Welcome to Wheel Tech Rim Repair, a trusted and reputable wheel need company in Surrey, Canada. Please check our blog linked above. For booking or information details please contact us:

+1 604-593-5505 .

0 notes

Link

1 note

·

View note

Photo

Porsche “Berlin-Rome” Type 64 (1 of 2).

During 1938, Ferdinand Porsche and Major Adolf Hühnlein met, and the subject of establishing an endurance motor sport event was discussed. Hühnlein was inspired, and he set in motion a plan to organise a race from Berlin to Rome, a 1500km event that would take place in September 1939. No doubt Hühnlein’s motivation to his superiors included promoting Germany’s excellent system of Autobahns which this race would utilise, and the event would also tie in conveniently with the start of production of the KdF-Wagen.

In preparation for the race, it was decided to build three special long-distance race cars, and to Ferdinand Porsche’s delight, these were ordered and paid for by Volkswagen. For political reasons the cars were called KdF-Wagen and so in Volkswagen circles the car was known as the Type 60K10, although the Porsche engineers referred to it as the Type 64.

The 64 was to have an aluminium body, and the wheels were fully covered with removable alloy panels. Due to the event being a long-distance road race, Karl Fröhlich designed the car to carry two spare wheels in its nose, a move which meant the standard fuel tank would have to be relocated further back on the passenger side.

The engine used in the Type 64/60K10 was the standard 985cc unit as used in the KdF-Wagen, by increasing the compression ratio, power output was raised to 32 bhp at 3500 rpm.

With the race date set for September 1939, production of the three cars, Sports Car 1, 2 and 3, commenced in the summer of that year. The three chassis numbers allocated to the race cars, also referred to as the KdF-Rekordwagen, was 38/41, 38/42 and 38/43.

Karosseriewerk Reutter were given the task of making the bodies for the three cars from 0.5mm alloy sheets, but it wasn’t until 19 August 1939 that the first body was completed, a fortnight before the official start date of the Second World War. The second car was only completed on 20 December that year in a dark colour, while the third car, finished in the same silver colour as the first car, was only completed on 15 June 1940.

The plans for Porsche’s own sports car were already on the drawing board in 1947 and the first of the new 356 models was officially registered in June 1948. Just as the Type 64 had looked so ultra-modern when compared to contemporary sports machinery of the day, so too did the Porsche 356 immediately date other sports cars of the period. It was at this time that, with the war now over and plans to develop the 356 into a really competitive sports car in the market, that the old Type 64 became redundant to Porsche. Fortunately, the Swiss racing driver Otto Mathé had shown an interest in acquiring the Type 64, otherwise this crucially important piece of Porsche history may well have gone the way of its two siblings, and been scrapped.

“Otto Mathé, was one of the first, if not the very first driver, to use Porsche products for racing,” said Oliver Schmidt of the Prototyp Museum in Hamburg. Today there are two Type 64s in existence, the first being the 38/41 car Mathé bought from Porsche in 1949. The second car has been built up from the spares that Mathé bought from Porsche.

145 notes

·

View notes

Text

UK customers can choose between:

V1 / VZ1 - from £43,340 or £55,935 this will offer 19” alloys, heated and foldable electric mirrors, LED headlights, dark tinted rear windows, navigation, 5.3” digital cockpit with a 15” central display, wireless phone charger, aluminium pedals, rain and light sensor, heated steering wheel, adaptive cruise control, rear view camera, keyless entry and start, forward collision warning and attention assist; and

V2 / VZ2 - from £53,835 or £60,835 this will offer 21” alloys, Matrix LED lights, electric tailgate, panoramic sunroof, Sennheiser premium audio, 3-zone climate control, bucket seats which are 12-way electrically adjustable, top view camera and dynamic chassis control.

But how will the new Tavascan electric perform? There will be two battery configurations to choose from including:

Endurance (286ps) - this RWD SUV will have a 77 kWh usable battery which will offer 0 – 62 times of 6.8 seconds, 112 mph top speeds and 210kW (or 282hp). Expect a combined winter range of 230 miles with warmer weather allowing for 320 miles – a 275 mile combined. On charging, the 11 kW AC max will allow 8 hour and 15 min 0 – 100% charging times with the 135 kW DC maximum allowing 28 minute 10 – 80% times. A cargo volume of 540L is available with this car. It has a vehicle fuel equivalent of 145 mpg. You can tow with this EV – 750kg (Unbraked) and 1000kg (Braked). It also has no V2L or V2G capabilities (so far). The Heat Pump is available but is an option; and

VZ (340ps) - this AWD SUV will have a 77 kWh usable battery which will offer 0 – 62 times of 5.5 seconds, 112 mph top speeds and 250kW (or 335hp). Expect a combined winter range of 220 miles with warmer weather allowing for 300 miles – a 265 mile combined. On charging, the 11 kW AC max will allow 8 hour and 15 min 0 – 100% charging times with the 135 kW DC maximum allowing 28 minute 10 – 80% times. A cargo volume of 540L is available with this car. It has a vehicle fuel equivalent of 139 mpg. You can tow with this EV – 750kg (Unbraked) and 1200kg (Braked). It also has no V2L or V2G capabilities (so far). The Heat Pump is available but is an option.

3 notes

·

View notes

Photo

Back in a former life, I had an addiction that I loved beyond sanity. Here’s the story of it.

2002 2003 2004 2005 2006 2007 2008 2009 pt1 2009 pt2 2009 Redux

This is the final spec list for my glorious, insane Brutal Truth.

Nissan Skyline BCNR33 GT-R (Type 2) manufactured in April 1996. JDM non V-Spec vehicle retailed through Osaka Nissan Prince in May/June 1996. Imported to the

UK in June 1997. Remained in original JDM spec without speedometer conversion until August 2002. Only the steering wheel & white dial sets were fitted in Japan.

Nismo RB26N1 bare engine: [N1 water pump (improved flow & less cavitation)/Reinforced cylinder block head bolt boss/Increased sump capacity (6L 20w60)/1.2mm oil restrictor]

N1 head with 0.5mm overbore (2598cc)

Cryogenically hardened N1 crankshaft

Wossner forged & cryogenically hardened pistons

Abbey Motorsport reinforced & cryogenically hardened con-rods

ACL Race Series conrod & crankshaft bearings

Tomei sump baffle kit

Tomei high flow (larger drive gears) oil pump

HKS 1.2mm metal head gasket

Tomei Procam Spec 2 cam kit (270 degree inlet & outlet with 10.25mm lift)

HKS V-Cam System Step 1 Type B (variable 248-278 degree inlet; replaces Procam inlet camshaft)

HKS vernier cam pulleys

HKS kevlar reinforced timing belt

Trust metal intake & throttle gaskets

HKS front pipe & decat gaskets

GReddy Iridium 08 Racing sparkplugs

Mocal 19-row oil cooler & Abbey Motorsport remote oil filter assembly

Abbey Motorsport catch tank & washer reservoir with SFS breather hoses

Abbey Motorsport Pro Alloy large radiator

Tomei fuel pump, fuel regulator & 600cc injectors

A’PEXi Power Intake induction kit

A’PEXi GT Spec intercooler (237x610x136mm) & hard pipe kit

HKS GT-SS turbos

HKS twin AFM delete kit

Tomei turbo elbows

HKS downpipes

HKS Silent Hi-Power exhaust

Abbey Motorsport 80mm decat pipe

Mine’s VX-ROM

HKS F-Con V Pro

HKS EVC 6 boost controller (1.6 bar)

AEM wideband lambda sensor

Splitfire DI Super Direct Ignition System

HKS Circle Earth kit

HKS GD Max twin-plate clutch (with lightened flywheel)

Abbey Motorsport rebuilt transfer box

Abbey Motorsport rebuilt gearbox with cryogenically hardened gear set, modified Nissan synchromesh upgrade and OS Giken strengthening plate

Abbey Motorsport rebuilt rear diff

Nismo gearbox mounts

Nismo Solid Shift gear stick (10% short shift)

Omex Shift Light Sequential

Sunsei SE-135 solar panel trickle charger mounted on a custom aluminium riser between the rear parcel shelf speaker enclosures.

Team Dynamics Equinox alloys 19x9.5, ET+15 in silver with polished stainless steel rim.

Falken FK452 265/30/19 Y-rated tyres

Cusco brake master cylinder brace

Cusco rear steering delete kit

Cusco front & rear upper suspension links

AST Sport Line 1 full suspension kit with UK spring setup

Nismo stainless steel braided brake hoses

StopTech 355mm rotor 4 pot caliper front brake kit

StopTech 355mm rotor 2 pot caliper rear brake kit with Abbey Motorsport modified pad retainers

Ferodo DS2500 brake pads front & rear

Bomex AD-390 front splitter

Nismo R34 smoked front indicators in custom aluminium mounting plates finished in crackle black

Nissan Xenon headlamp units

Border Racing Aero Fenders (vented front wings) with silver GT emblems from a R32 Skyline

Nismo smoked side repeaters

Top Mix one-off FRP twin blade rear spoiler on custom aluminium mounting plates

Entire exterior resprayed in BMW black (code 086) base and lacquer

Nissan Motorsport International carbon fibre B-pillar plates

PIAA carbon effect silicon wipers, front pair with spoilers, rear without

Nismo white face dial sets (dashboard & centre console) in carbon fibre panels

AEM AFR gauge mount replaces the lighter socket

HKS EVC display mounted on custom carbon fibre plate replacing the ashtray

Lighter socket relocated to the fog light switch panel

Nissan Momo steering wheel (with airbag)

Dressycar Nismo harness pads

Redline Automotive leather gearstick & handbrake gaiters

Abbey Motorsport carbon fibre door sill trims

Carbon fibre boot sill trim

Inlet plenum and sundry induction pipework finished in powder grey

Trust clear cam pulley cover

HKS Kansai Service carbon fibre spark plug cover

Right hand cam cover finished in crackle black

Nismo radiator & washer reservoir caps

HKS Kansai Service front strut brace finished in high gloss black

GReddy aluminium slam panel finished in crackle black

Tein bonnet dampers with black sleeves

Custom made one-off Cobra Misano Lux front seats: [Alcantara (colour code 9189) outers/Alcantara (colour code 9182) centre panels/One-piece carbon fibre backs/Sidewinder bases on custom subframes adapted by Abbey Motorsport/Cobra logo in silver thread on the headpads/GT-R logo beneath the grommets on seat backs]

JVC KD-AVX2 multi-media DVD/CD receiver with built-in 3.5” widescreen monitor

2x JL Audio Evolution VR600-CXi 6” speakers (front)

2x JL Audio Evolution TR650-CXi 6.5” speakers (rear)

Multiple and interlaced Thatcham rated security systems.

500 bhp. 520 ft/lb.

Ludicrously, hilariously, unbelievably fast.

Hope you enjoyed this little trip down memory lane with me. Cheers! JM.

(Photo by N. Liassides.)

#r33#bcnr33#skyline#gt-r#nissan skyline#Abbey Motorsport#HKS#Bomex#Tomei#A'PEXi#GReddy#Nismo#RB26N1#Mocal#Team Dynamics

12 notes

·

View notes

Text

Royal Enfield Meteor 350 Gets Aurora Colour Variant At Rs 2.20 Lakh

Royal Enfield has widened the Meteor 350 range by launching the new Aurora variant of the cruiser.

It gets a couple of changes over other variants of the bike and comes with a price tag of Rs. 2,19,900 (ex-showroom, Chennai) which places it between the Stellar and Supernova trims of the Meteor 350.

RE Meteor 350 Thoroughly Overhauled

The new Aurora variant of the Meteor 350 comes equipped with spoke wheels and tube tyres, unlike other versions which get alloy wheels and tubeless rubbers.

Moreover, the engine case, exhaust system, and a few other components have been bestowed with chrome finishing. All of this is done to enhance the retro appeal of the bike.

You may like it : Best Bikes in India 2023

Royal Enfield Meteor 350 Aurora continues to receive the same J-series underpinnings, the 349 cc air-cooled, long-stroke engine, with 20.2 bhp and 2.75 kgm of torque, mated to a five-speed transmission.

What’s new with Aurora trim?

The trim introduces three new colourways and also debuts LED headlights to the range. Royal Enfield might make the latter feature standard with this range in the future.

You may like it : Royal Enfield Himalayan 452 Production Starts

As opposed to black treatment on all other trims, Aurora trim stands out in its classic appeal. RE is also giving Aurora LED headlights, a deluxe touring seat, aluminium switch cubes, a Tripper display for navigation and more.

Feature additions

Apart from adding Aurora trim, Royal Enfield has fettled with Meteor 350’s trim-wise features list too. Top-spec Supernova trim now gets LED headlights and aluminium switchgear, taking it a notch higher than before. Astral trim now gets Royal Enfield’s Tripper screen for navigation as standard fitment.

You may like it : RE Himalayan 452 Easily Clocks Over 140 km/h – VIDEO

With base Fireball trim, Royal Enfield has added a new Black stock colour which is both elegant and standard. Powering RE Meteor 350 is a 349cc J-series single-cylinder, air-cooled motor that kicks out 20.2 bhp at 6100rpm and a peak torque of 27 Nm at 4000rpm.

This unit is paired with a 5-speed gearbox. The same powertrain is found on newly launched Bullet 350 too.

Meteor 350 is underpinned by a dual-cradle J-series chassis which is suspended on 41mm RSU telescopic suspension at the front and twin shocks at the rear. Anchorage duties are handled by a 300mm front disc and a 270mm rear disc which are aided by a dual-channel ABS as standard.

In terms of features, it comes with a semi-digital instrument console, a USB charger, circular LED DRL and a side-stand engine inhibitor, among many.

You may like it : Best Electric Bikes in India

Words from the manufacturer

Speaking about the new range and enhancements on the Meteor 350, B Govindarajan, CEO – Royal Enfield said, “As we reflect on the remarkable success of the Meteor 350 in India and international markets it is evident that the Meteor has struck a chord with many long distance riders and motorcycling enthusiasts. Its dynamic cruising ability and dependable performance have resonated deeply with our riders.

The Aurora range is a result of our constant interactions with our community of riders, where we witnessed a strong inclination towards retro-inspired cruisers. The new colourways and features are sure to elevate the pleasure of pure retro-cruising among our customers.”

#Meteor #Overhauled

2 notes

·

View notes

Text

TECH TUESDAY: Williams become the latest team to adopt a tech trend thats set to sweep the grid

Following the lead of Aston Martin and Red Bull (as discussed here previously) Williams are the latest team to follow the trend of super-drilled brake callipers. These were introduced on the FW45 in Melbourne and were raced by both Alex Albon and Logan Sargeant.

When compared to the traditional style undrilled callipers on the current Ferrari, it can be seen how much more extensively they are drilled around the area where the calliper is clamping the pads to the brake disc.

This will increase the cooling capacity for the brake disc, requiring smaller brake ducts for a given level of cooling, and therefore an aerodynamic benefit – as the front brake ducts are quite aerodynamically disruptive.

TECH TUESDAY: The cunning design area that Red Bull and Aston Martin are leading the way in exploiting

However, the fact that there is less material in that part of the calliper (because of the drilled holes) means that the calliper itself would tend to get hotter as there is less material to dissipate the heat. To combat this, there is an array of exposed pins within some of the holes, made from material with good heat conductivity, taking heat away from the body of the calliper.

Aston Martin's 2023 brake set-up on the left, with Red Bull's on the right

These callipers save around 200 grammes per corner over the conventional undrilled component, giving a total saving of 0.8kg. Not only is that valuable in getting the car on or below the minimum weight limit, but the saving is all in un-sprung weight, which is extra valuable. Sprung weight is supported by the suspension but un-sprung masses such as the wheels and brakes have a much bigger impact upon the car’s ride and mechanical grip.

TECH TUESDAY: Dissecting the design secrets of the RB19 – and why Red Bull’s rivals are likely to be worried

Brake callipers represent one of the few remaining areas of the car where there is still a big degree of design freedom. The manufacture of these new-style callipers is a long and expensive process.

Williams’ new drilled brake calliper, with the array of cooling pins (highlighted in yellow) which are there to conduct heat away from the calliper body which is being transferred from the brake disc

Typically each of them takes around 20 hours to create, compared to around 12 hours for the traditional type. Special equipment has to be made to drill within the aluminium alloy of the calliper. It cannot be drilled too quickly as the heat this would create would warp the calliper and render it scrap.

Williams are only the third team to switch to incorporate this drilled/pinned calliper technology but it can be expected the others will follow.

Ferrari are still running a traditional undrilled calliper. This would typically weigh around 200 grammes more and require a greater brake duct size for a given level of cooling. It should however be stiffer, giving a better brake pedal feel

via Formula 1 News https://www.formula1.com

#F1#TECH TUESDAY: Williams become the latest team to adopt a tech trend that’s set to sweep the grid#Formula 1

2 notes

·

View notes

Text

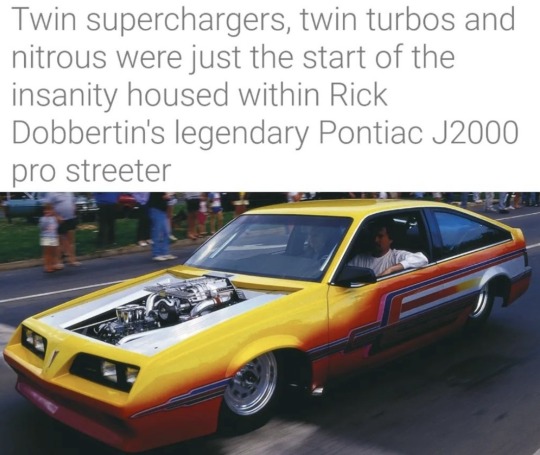

Rick Dobbertin's outrageous Pontiac J2000. Magazines of the day described the J2000 as being from another planet. It featured a pneumatically lifted flip-up body and a flip-front, all covered in insane graphics incorporating dozens of colours. Its tube-frame chassis was made from polished 304 stainless steel. An alloy 350 Chevy up front ran dual Magnuson superchargers, dual Rotomaster turbos and a 20-port nitrous system. Like the engine block, the aluminium four-speed Lenco was fully polished, while the solidly mounted Dana 60 rear end measured just 25 inches axle flange-to- axle flange which left only 8.25 inches between the tyre's sidewall bulges! It had to be that narrow to tuck those custom-made 20-inch-wide wheels and tyres high up into the narrow J2000 body.

1 note

·

View note

Text

Sky Scrap Metal: Your Go-To for Scrap Metal Solutions

Welcome to the Sky Scrap Metal blog! Whether you're a car enthusiast looking to recycle those old aluminium MAG wheels, a business owner managing scrap metal, or just curious about scrap metal prices, we’ve got you covered. At Sky Scrap Metal, we’re dedicated to offering the best solutions and information on scrap metal purchasing. Let’s dive into some key aspects of our services and what you need to know about the scrap metal market.

Aluminium MAG Wheel Scrap: What You Need to Know

Aluminium MAG wheels are not just stylish additions to your vehicle but also valuable commodities in the scrap metal market. These wheels, made from high-grade aluminium alloys, are prized for their lightweight and durability. When you're ready to part ways with your old MAG wheels, Sky Scrap Metal offers competitive prices and convenient services to help you get the best value for your scrap.

Why Recycle Aluminium MAG Wheels?

Environmental Benefits: Recycling aluminium conserves natural resources and reduces energy consumption. The process of recycling aluminium uses up to 95% less energy compared to producing new aluminium from ore.

Economic Value: Aluminium MAG wheels scrap are worth more than many other types of scrap metal due to the quality of the material. By recycling them, you can earn a decent amount while contributing to a greener planet.

At Sky Scrap Metal, we ensure a seamless process from collection to payment. Our team evaluates the condition and weight of your MAG wheels to offer a fair market price.

Car Batteries Scrap Price: Maximizing Your Returns

Car batteries are another significant category of scrap metal that we handle at Sky Scrap Metal. The scrap price for car batteries varies depending on several factors, including the type of battery and the current market conditions.

Factors Influencing Car Battery Scrap Prices

Lead Content: Most car batteries contain lead, a valuable metal in the recycling market. The more lead a battery contains, the higher its scrap value.

Battery Type: Different types of car batteries (e.g., lead-acid, AGM) have different recycling values. Lead-acid batteries, which are common, typically fetch a higher price due to the large amounts of lead they contain.

Market Trends: Scrap metal prices fluctuate based on market demand and supply. Staying updated with market trends can help you sell your scrap batteries at the optimal time.

Sky Scrap Metal offers competitive prices for car battery scrap and ensures that all batteries are disposed of responsibly, in line with environmental regulations. We provide hassle-free collection and immediate payment, making the process convenient for you.

Why Choose Sky Scrap Metal?

Competitive Pricing: We constantly monitor market trends to offer you the best prices for your scrap metal.

Eco-Friendly Practices: We adhere to strict environmental standards, ensuring that all scrap metal is recycled properly and responsibly.

Professional Service: Our team is dedicated to providing top-notch customer service, from quick responses to prompt payments.

How to Get Started with Sky Scrap Metal

Ready to recycle your scrap metal? Contact us at Sky Scrap Metal today for a quote or to schedule a pickup. Whether you have aluminium MAG wheels, car batteries, or other scrap metal, we make the process easy and profitable.

Thank you for visiting our blog! Stay tuned for more updates, tips, and news from the world of scrap metal recycling. At Sky Scrap Metal, we’re here to help you turn your scrap into cash while making a positive impact on the environment.

0 notes

Text

The Advantage of Alloy Wheels for Motor Cycle

Alloy wheels are mostly manufactured with a combination of aluminum and magnesium alloys through die casting. These products are lighter than the traditional spoke wheels. Lightweight brings several benefits especially in control and maneuverability. It also reduces the unsprung weight.

For more information log on to www.rockman.in/

#passenger car alloy wheels#Casting wheel#Alloy Aluminium#alloy wheel manufacturers in india#two wheeler alloy wheels#alloy wheel

0 notes