#Injection-molded components

Explore tagged Tumblr posts

Text

What is an Injection Molding Machine? Get to know everything about it!

Injection molding is an important industrial technique. Although it is somewhat similar to die casting, but the raw material used in this case are different. Die casting uses metals that melt at extremely high temperatures, whereas injection molding mostly uses glasses, elastomers, and most frequently thermoplastic and thermosetting polymers. Nevertheless, this process is commonly used to create thermoplastic materials. In this method, raw materials are heated to a certain temperature and then injected under pressure into the mould cavity without changing their composition.

What are the main parts of injection molding machine?

The material hopper, barrel, an injection ram/rotating screw type plunger, heating element (heater), adjustable pattern, ejectors, and a mould inside mould cavity are the key components of an injection molding machine.

Injection molding machines typically operate horizontally. A barrel is part of an injection molding machine (cylindrical pipe). At one end of the barrel, there is a hopper. Inside the barrel is a revolving screw or hydraulic ram powered by an electric motor that provides force. The barrel has a heating element (warmer) attached to it that is used to melt the molding compound when it exits the hopper.

Mold cavity linked to the barrel's opposite side. During the entire production process, a movable pattern is used and the mould is situated inside the mould cavity. Typically, copper, aluminum, and tool steels are used to make mould. Distinct types of material moulds have different life cycles. This can be chosen based on your needs.

How does the injection moulding machine works?

Extrusion and injection molding both function similarly, as implied by their names. Using a feeding apparatus, molding material and raw materials are poured into the hopper. Following that, the molding material falls into the cylinder (barrel) as depicted in the diagram due to gravity. The material is melted using a circumferential heater that is mounted on the barrel. When molding compound in powder form enters the barrel from the hopper, it begins to melt, and a revolving screw or hydraulic ram applies pressure to advance the compound into the mould.

In this split mould, which is attached to the other side of the barrel, molten plastic material is pumped into a closed mould. The revolving screw constantly advances the molding material. The hydraulic system exerts pressure. Normal injection pressure ranges from 100 to 150 MPa. Following injection, pressure is exerted for a while or held in place with some force.

The pieces produced when the entire procedure is complete are appropriately cooled. The mould is then opened, and a few ejectors are utilized to remove the part properly and damage-free. The portion mould is reopened after removal. This process is very fast and automatically repeated. Here, it is simple to make pieces with complex shapes. The injection molding process may produce 12–16,000 components every cycle.

The Procedure

- The process parameter fluctuates based on the circumstances and demands. - The components made with this method typically weigh between 100 and 500 g. - A single part's cycle time ranges from 5 to 60 seconds, depending on how the item is made. - The heating range for molding material is 150 to 350 degrees Celsius. - The molding machine has an injection capacity of 12,000 to 2.2 106 mm3. - 100 to 150 MPa is the injection pressure. - From 0.1 to 8.0 MN is the locking force.

What are the advantages of Injection molding machine?

- The fundamental benefit of this method is that intricately shaped components with thin walls (5–15 mm) may be molded with ease and retrieved from the die without being harmed. - Injection-molded components offer good dimensional tolerance. - The main benefit of this method is that it produces far less scrap than certain other methods. - Investment cast iron and intricately machined pieces compete with parts produced through the Injection Moulding Method. - In comparison to other procedures, this process has a high production rate.

What are the various types of injection molding machines?

Following are the different types of injection molding machines. Have a look:

Hydraulic Injection Molding Machine

Hydraulic injection molding machine were the only types of machine at start. It is the oldest one in the industry. Following are the benefits of this machine-

1. Economical price These machines cost far less at the base level than comparable models.

2. Cheap parts If a machine component needs to be replaced because it has been damaged or has reached the end of its useful life, the replacement parts are less expensive and more readily available.

3. Robust components The machine's hydraulic components are longer-lasting and more resistant to deterioration.

4. Easy to use and maintain High-pressure clamping forces are typically simple to adjust on hydraulic injection devices.

5. Powerful The gripping force on hydraulic molding machines is outstanding.

Electric Injection Molding Machines

In the 1980s, electric injection molding machines were made available and soon gained popularity in the high precision plastic parts production sector. The positioning accuracy of today's full electric servo drive injection molding machines is exceptionally precise (of 0.0001 in), but at a very high cost.

1. Less idle time There is no possibility of oil leaking. Additionally, since no oil is used, there is no need to replace filters, which lowers consumable costs.

2. Efficiency while using energy Electric Injection Molding Machines only consume energy when they are in use, thus their output is limited to what is necessary to support the load.

3. Fast procedure Since these machines are digitally controlled, the procedure can be completely repeated without any oversight.

4. Highly reproducible The injection device can be accurately controlled, the molding conditions can be stabilized, the injection control (such as pressure and speed) can be regulated in fine units, and there is a highly accurate control and monitoring system. It can handle challenging tasks like multi-stage hydraulic system extension and control the extension.

Injection Molding Machine Price

There are various types of machines. The Injection Molding Machine Price will also vary according to the complexity of the machine. Costs for large industrial injection molding equipment can range from $50,000 to $200,000 or more. Additionally, the facilities needed to operate, maintain, and monitor these equipment are more demanding and call for expert staff.

Who are the best injection molding machine manufacturers?

There are many Injection Molding Machine Manufacturers in India; however, some of them offer the exception quality products that last longer. Here is the list of some trusted manufacturer in India-

Milacron

Yizumi Injection Molding Machine

Primex Plastics Pvt. Ltd

Windsor Machines Limited

Haitian

Hikon

ENGEL Global

Indo-MIM

Micro Plastic

Kruger

Vikas Industries

Jagmohan PlaMech Pvt. Ltd

Neelgiri Machinery

These are some of the leading manufacturers offering the best quality Injection Molding Products. If you are looking for someone in your region, you can try to search on Google and write Injection Molding Machine near me. This way, you will find the list of top-rated manufacturers offering top-notch services in your area.

Types of products made with injection molding machine

There are various types of products that can be made with injection molding machines.

Some of them are listed below-

Toys

Plastic bottles

Machinery and automotive components

Household products like molded closures, containers, etc.

Healthcare industry

Agricultural products

Conclusion

Injection moulding may appear to be a complicated procedure, yet it is the most popular manufacturing technique because it can manufacture a wide range of everyday things quickly and effectively. One of the most economical methods for producing both working prototypes and finished goods is injection molding.

#Injection Molding Machine#molding material#raw materials#injection molding process#Injection-molded components#Injection Moulding Method.#hydraulic molding machines#Injection Molding Machine Price#Injection Molding Machine Manufacturers#Injection Molding Products

0 notes

Text

Injection molding plastic

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#plastic injection molded#injection molding#injection molding parts#injection molding components#plastic injection molding#plastic injection molding company#plastic injection molding parts#injection molded#injection molded parts#injection mould#injection moulding#injection moulding service#plastic mold#plastic molded#plastic molding

3 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Explore first-rate, precision-engineered plastic injection molds within the USA. We provide superior molding solutions to efficaciously meet your production wishes. Experience exceptional accuracy, consistency, and cost-efficient plastic molding production.

0 notes

Text

OPM Plastics is one of the top-rated plastic molded components manufacturers in Pune which is known for its high-quality injection-molded components customized as per the requirements of the customers.

#plastic injection molding products manufacturers India#plastic molded components manufacturers in Pune#automotive plastic injection molding companies#automotive plastic injection molding manufacturers in Pune

0 notes

Text

At Petron Thermoplast, we specialize in manufacturing top-quality injection molding parts designed to meet the needs of various industrial applications.

#Injection Molding#Custom Plastic Injection Molding#Injection Molding Parts#Injection Molding Components#Plastic Injection Molding Company

0 notes

Text

Unlock Infinite Possibilities with Custom Rubber Extrusion

Get your customized rubber extrusion solutions that offer unlimited possibilities. Get started today to enjoy accuracy, resilience and versatility in your projects! Read More: https://rubbermoldedproducts.wordpress.com/2024/12/19/infinite-possibilities-with-custom-rubber-extrusion/ Contact No: (647) 294-5240

#custom rubber extrusion#silicone manufacturers California#molded rubber components#rubber washer manufacturers#injection molding Winnipeg

0 notes

Text

High-Quality Custom Injection Mold Components Service

When it comes to precision and reliability, custom injection mold components service stands out as an essential solution for manufacturers in various industries. This specialized service focuses on creating tailored mold components that meet the unique specifications of each project. By using advanced manufacturing techniques and cutting-edge technology, the service ensures that every component is perfectly designed to deliver consistent performance, durability, and accuracy. The process begins with an in-depth consultation to understand the client’s needs. Whether it's for automotive, medical, electronics, or consumer goods, custom injection mold components service is designed to cater to diverse requirements. Engineers collaborate closely with clients to develop 3D models and prototypes, ensuring the design aligns with functionality and efficiency. This meticulous approach minimizes errors and shortens production cycles, saving both time and costs. One of the key benefits of custom injection mold components service is its adaptability. With access to high-quality materials like steel, aluminum, and specialty polymers, manufacturers can customize the molds for optimal performance.

Understanding Custom Injection Mold Components Service

Custom injection mold components service is a specialized process that creates tailored mold components to suit specific production needs. From concept to completion, it ensures precision in every step, using advanced technologies like CAD modeling and CNC machining. This service helps manufacturers streamline production by designing molds with fine tolerances that lead to consistent product quality.

The Importance of Material Selection in Custom Injection Mold Components Service

Materials play a crucial role in the success of custom injection mold components service. Steel, aluminum, and specialized polymers are often chosen for their durability and performance. Selecting the right material ensures the mold withstands production pressures, leading to enhanced product quality and longer mold life.

How Precision Techniques Enhance Custom Injection Mold Components Service?

Precision is the backbone of custom injection mold components service. Advanced techniques such as EDM (Electrical Discharge Machining) and CNC machining enable intricate designs and high accuracy. These methods ensure that every mold component meets exact specifications, minimizing production errors and waste.

Benefits of Custom Injection Mold Components Service for Manufacturers

The benefits of custom injection mold components service are manifold. It ensures superior product quality, reduces production costs, and minimizes downtime. By using customized components, manufacturers can achieve faster production cycles and higher efficiency, giving them a competitive edge in their industry.

Custom Injection Mold Components Service for Automotive Industry

The automotive sector relies heavily on custom injection mold components service for parts like dashboards, bumpers, and interior elements. Tailored mold components ensure these parts meet stringent safety and performance standards while maintaining the desired aesthetic appeal.

Applications of Custom Injection Mold Components Service in Medical Equipment

Medical equipment production demands precision, making custom injection mold components service essential. From syringes to surgical instruments, the service enables manufacturers to produce complex medical components with tight tolerances and consistent quality.

Custom Injection Mold Components Service for Consumer Goods

In the consumer goods industry, custom injection mold components service helps create durable and visually appealing products. From household items to packaging solutions, this service ensures that components align with design specifications and market demands.

Conclusion

In the modern manufacturing landscape, custom injection mold components service has become an indispensable solution for industries seeking precision, efficiency, and cost-effectiveness. By offering tailored designs, advanced manufacturing techniques, and superior material selection, this service empowers businesses to streamline production and enhance product quality. From automotive and medical equipment to consumer goods, the versatility of custom molds meets the unique demands of diverse sectors.

0 notes

Text

Custom Injection Mold Components Service: Precision in Every Part

Custom injection mold components service is a vital offering for businesses that require high-precision, tailor-made parts across industries such as automotive, medical, electronics, and consumer goods. This service involves designing and manufacturing injection mold components to meet unique specifications, enabling companies to bring complex, high-quality parts to life. When using a custom injection mold components service, businesses benefit from streamlined production processes, ensuring accuracy and consistency across every batch, regardless of part complexity. What sets a custom injection mold components service apart is its ability to accommodate various materials, shapes, and sizes. From high-strength polymers to flexible, specialized plastics, the service allows for material selection that best suits the end-use environment of the part. Through advanced engineering and sophisticated machinery, providers of custom injection mold components service can meet exacting standards, guaranteeing minimal variance and reliable functionality in each product.

The Importance of a Custom Injection Mold Components Service for Precision Manufacturing

In manufacturing, precision is paramount, especially for industries like automotive and medical devices that rely on exact specifications. A custom injection mold components service provides businesses with tailored solutions for creating precise parts that meet unique requirements. This service ensures that each component is crafted to fit seamlessly into complex assemblies, maintaining consistency across production runs. By working closely with experienced mold designers, companies can enhance component accuracy and minimize defects, ultimately resulting in more reliable products.

How Custom Injection Mold Components Service Reduces Production Costs?

Investing in a custom injection mold components service can significantly reduce long-term production costs. By customizing molds to meet specific needs, companies can streamline production, decreasing waste and improving efficiency. The process enables businesses to optimize material use, shorten production times, and reduce rework costs. Custom molds also allow for multi-cavity setups, which means more parts produced in each cycle, boosting output without compromising quality. This service ultimately supports a cost-effective production line that aligns with a company's financial goals.

Enhancing Product Quality with a Custom Injection Mold Components Service

For companies that prioritize high-quality products, using a custom injection mold components service is essential. This service allows for the production of components that meet exacting standards, which is crucial for industries requiring parts with specific dimensions, durability, and functionality. By customizing the mold to suit each part’s needs, manufacturers can achieve superior consistency and quality across every production batch. As a result, customers receive products that meet or exceed expectations, supporting brand reputation and customer satisfaction.

The Role of Material Selection in a Custom Injection Mold Components Service

Material selection is critical in injection molding, as different applications require varying levels of strength, flexibility, and resistance. A custom injection mold components service offers the flexibility to choose from a wide range of materials, including high-strength polymers and specialized plastics, ensuring that each component is tailored to its intended use. By selecting the best materials, businesses can enhance the lifespan and performance of their products, while also reducing production issues related to poor material fit.

Prototyping Capabilities of a Custom Injection Mold Components Service

One of the key benefits of a custom injection mold components service is the ability to prototype components before full-scale production. Prototyping helps businesses test parts for fit, function, and durability, allowing them to identify any necessary design adjustments early on. This step significantly reduces the risk of costly production errors and ensures that the final product meets precise standards. With a reliable prototyping process, companies gain confidence in their components and avoid issues that could disrupt production.

Reducing Lead Times with Custom Injection Mold Components Service

Shortening lead times is crucial in today’s competitive market, where delays can impact overall product delivery. A custom injection mold components service provides streamlined mold production, helping businesses move from design to manufacturing faster. This service allows for efficient mold design and faster prototyping, enabling companies to meet market demands promptly. With shorter lead times, companies can keep up with production schedules, respond to changing market needs, and launch products faster without sacrificing quality.

Meeting Industry-Specific Standards with Custom Injection Mold Components Service

Industries like aerospace, medical, and automotive have stringent regulatory standards for product quality and consistency. A custom injection mold components service enables companies to meet these high standards by tailoring molds for specific applications. With custom mold designs, manufacturers can ensure that each part produced adheres to industry guidelines, reducing the risk of compliance issues. This tailored approach makes it easier for companies to maintain quality assurance and build trust with industry regulators and customers alike.

Conclusion

A custom injection mold components service offers significant advantages for businesses across diverse industries, from enhancing precision and quality to reducing costs and supporting sustainability. By providing tailored molds that meet specific design and material requirements, this service empowers companies to achieve high-performance, reliable components that align with rigorous industry standards. The flexibility of custom mold design not only enables intricate part production but also streamlines the manufacturing process, optimizing efficiency and reducing lead times.

0 notes

Text

Explore Excellence in Plastic Molding with Best Precision Tools

Are you searching for a reliable partner for your plastic molding needs? Look no further than Best Precision Tools, a leading manufacturer specializing in high-quality plastic injection molds, dies, and tools. Here's why you should consider them for your next project:

Expertise Across Industries

Best Precision Tools serves a diverse range of industries, including engineering, electronics, automotive, and healthcare. Their expertise in converting metal components to plastic not only reduces costs but also enhances efficiency and product performance.

Precision and Quality

At Best Precision Tools, precision is paramount. They utilize advanced technology and state-of-the-art machinery to ensure that every mold and component meets stringent quality standards. This commitment to precision ensures that your products are of the highest quality, giving you a competitive edge in the market.

Innovative Solutions

Innovation is at the heart of Best Precision Tools. They continuously invest in research and development to bring you the latest advancements in plastic molding technology. Whether you need complex geometries or specialized materials, their team of experts can provide innovative solutions tailored to your specific requirements.

Comprehensive Services

From design and prototyping to production and delivery, Best Precision Tools offers a comprehensive range of services to support your project at every stage. Their collaborative approach ensures that your vision is realized with precision and efficiency.

Customer Satisfaction

Customer satisfaction is their top priority. Best Precision Tools prides itself on building long-term relationships with clients by delivering exceptional service and support. Their team is dedicated to understanding your needs and exceeding your expectations.

Global Standards

Best Precision Tools adheres to global standards of manufacturing excellence. Their commitment to quality management and continuous improvement ensures that you receive products that not only meet but surpass international benchmarks.

Environmental Responsibility

In addition to their technical prowess, Best Precision Tools is committed to sustainable practices. They strive to minimize environmental impact through efficient processes and eco-friendly materials, ensuring a greener future for all.

Why Choose Best Precision Tools?

Experience and Expertise: Decades of experience in the industry with a focus on precision and quality.

Advanced Technology: Cutting-edge machinery and technology to deliver superior products.

Customized Solutions: Tailored solutions to meet the unique needs of various industries.

Comprehensive Support: End-to-end services from design to delivery.

Commitment to Sustainability: Eco-friendly practices that contribute to environmental preservation.

When you choose Best Precision Tools, you're partnering with a company that values excellence, innovation, and customer satisfaction. Elevate your production capabilities and achieve new heights of success with their top-tier plastic molding solutions.

Visit Best Precision Tools to learn more about their offerings and how they can help you achieve your manufacturing goals.

#plastic moulding company#Plastic moulding parts manufacturer#Plastic components manufacturer#Injection molds manufacturer

0 notes

Text

Optimizing Design for Injection Molded Plastic Components

In the realm of manufacturing, injection molded plastic components have become indispensable due to their versatility, cost-effectiveness, and rapid production capabilities. Optimizing the design of these components is crucial for achieving superior performance and ensuring efficient manufacturing processes. In this blog post, we will delve into key considerations for optimizing the design of injection molded plastic components.

Material Selection: The foundation of any successful injection molding project lies in selecting the right materials. Factors such as the intended application, environmental conditions, and mechanical requirements must be meticulously considered. At we offer a comprehensive range of high-quality materials, each tailored to specific needs, ensuring optimal performance and longevity of the molded components.

Design for Manufacturability: A well-thought-out design not only enhances functionality but also streamlines the manufacturing process. Our team at Adroit emphasizes the importance of designing components with manufacturability in mind. This involves minimizing complex features, incorporating uniform wall thickness, and strategically placing ribs and gussets to improve structural integrity.

Tooling and Mold Design: The efficiency of injection molding largely depends on the precision of the tooling and mold design. Adroit utilizes state-of-the-art technology to create molds that ensure consistency and repeatability in production. This approach minimizes defects and contributes to the production of high-quality, dimensionally accurate plastic components.

Quality Control and Testing: Rigorous quality control measures are essential to guarantee the reliability of injection molded components. At Adroit, we implement stringent testing protocols to identify and address any potential defects. This commitment to quality ensures that the final products meet or exceed industry standards.

In conclusion, optimizing the design for injection molded plastic components is a multifaceted process that demands expertise and attention to detail. At Adroit, our dedication to providing high-quality solutions is evident in our commitment to material excellence, design precision, and stringent quality control. Visit to explore how our expertise can elevate your injection molding projects, delivering components that excel in both performance and durability.

0 notes

Text

8 Benefits of Professional Injection Mold Manufacturers

It is necessary to partner with the right injection mold manufacturer, who can utilize the resources in the best possible manner to give you stunning results in terms of efficiency and productivity.

1 note

·

View note

Text

Automotive Plastic Injection Molding Companies in India

The automotive industry in India has been evolving continuously, and plastic injection molding has become an integral part of vehicle manufacturing because of several benefits like fuel efficiency, lightweight components, and cost-effectiveness. As the automotive industry has been witnessing advancements in technological tools, more skilled workers, and an increase in demand for customized plastic products, we can observe substantial growth in the industry. As India is growing to be the hub for automotive production, there are many injection molding companies in India that are delivering plastic products for vehicles to serve both global and local markets.

We have curated a list of automotive plastic injection molding companies that are known for their expertise, experience, and premium work.

1. Supreme Moulders

Established in 1987, Supreme Moulders is one of the best automotive plastic injection molding companies that has been delivering high-quality products for many years. Located in Delhi, this company is utilizing gas injection technology along with fully electric presses to manufacture precise and lightweight auto components and healthcare devices.

2. OPM Plastics

Headquartered in Pune, OPM Plastics is recognized as one of the most trusted automotive plastic injection molding manufacturers in Pune which has a strong presence in the market. Being in the industry for more than 60 years, this company is known for its precision, detail-oriented work in injection molding. It has a big manufacturing plant of 80000 SqFt with different rooms for different purposes like molding, assembly area, storage, mold storage room, tool room, utility area, and dispatch zones. With the utilization of its highly equipped big manufacturing units, this company can complete bulk orders in minimal possible time.

3.Primex Plastics Pvt Ltd.:

Primex Plastics Pvt Ltd. was founded in 1991 in Bangalore. The main industries served by this company are automotive, household goods, and electronics. With a 25000 SqMtr operational facility, this company can take big orders and complete them with precision. Renowned for its high-quality and customized solutions, this company is making a good place in the industry of automotive plastic injection molding.

4. Lumax Auto Technologies Ltd.:

Another trusted name in the automotive plastic injection molding industry is Lumax Auto Technologies, which has been providing amazing products for many years. The plastic division of this company is known for a variety of plastic injection-molded products like engine covers, HVAC components, and other important parts. The key strengths of this company are the use of advanced simulation tools for mold flow analysis and a strong hold over plastic components utilized in both 2-wheeler and 4-wheeler segments.

5. Plastic Moulders Ltd.

Located in Chennai, Plastic Moulders Ltd. has strategically chosen its location on the auto manufacturing belt of South India. It supplies high-grade molded plastic components for interior and under-the-hood applications. It is in close proximity to major auto manufacturers, including Ford and Hyundai. Its key strengths are high production lines with robotic arms, consistent quality, and fast delivery time.

How OPM Helps:

Modern vehicle production means lightweight automotive parts with reduced costs and enhanced durability. All of them can be achieved through just one process, plastic injection molding. OPM Plastics is one of the top-rated plastic molded components manufacturers in Pune which is known for its high-quality injection-molded components customized as per the requirements of the customers.

Recognized for its automotive plastic injection molding in India, OPM Plastics Ltd uses high-strength, lightweight polymers so the durability of vehicle parts can be enhanced without any compromise in its structure. With its expertise in engineering-grade plastics, this company ensures that every product must meet the standards of safety and performance. This company utilizes automated production processes to minimize defects and enhance repeatability for mass production of plastic components.

Being one of the best plastic injection molding products manufacturers India, this company utilizes advanced molding technology to achieve accuracy in every component manufactured. This company has a team of experienced professionals who follow sustainable practices to provide energy-efficient manufacturing with customized solutions. Whether it is about enhanced impact resistance, aesthetic finishing, or temperature tolerance, its experts know how to integrate specialized plastic components perfectly.

Conclusion:

The Indian automotive industry is changing and growing every year. Because of this evolution, we can see an increase in the need for high-quality, eco-friendly, and creative plastic components. Numerous plastic injection molding companies in India are delivering premium services in the automotive sector, and OPM Plastics is one of the most recommended plastic injection molding companies in Pune, which is known for its reliable solutions.

Get in touch with OPM Plastics today if you are looking to create magic in the automotive sector!

#plastic injection molding products manufacturers India#plastic molded components manufacturers in Pune#automotive plastic injection molding companies#automotive plastic injection molding manufacturers in Pune

0 notes

Text

Choosing the right injection molding parts manufacturer is crucial for achieving precision, quality, and cost-effectiveness. Petron Thermoplast provides industry-leading injection molding solutions with expertise in custom and high-volume production.

Visit Website - https://petronthermoplast.com/injection-molding/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#injectionmolding #plasticinjectionmolding #plastic #injectionmold #engineering #plastics #manufacturing #molding #plasticsindustry #plasticinjection #plasticmolding #plasticmold

#Injection Molding#Custom Plastic Injection Molding#Injection Molding Parts#Injection Molding Components#Plastic Injection Molding Company

0 notes

Text

#custom rubber extrusion#rubber washer manufacturers#injection molding Winnipeg#silicone manufacturers California#molded rubber components

0 notes

Text

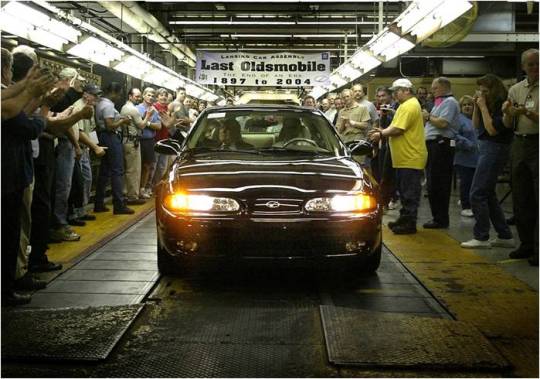

Oldsmobile

April 29'th 2004. The last Oldsmobile rolls off the line. You may be surprised to learn, that for a long time Oldsmobile meant innovation. Here are just a few of the Automotive technologies Olds pioneered in it's 100+ years in business:

1898: Olds Motor Vehicle Company exports the first American car, a steam-powered automobile, to Mumbai, India.

1901: The first speedometer offered on a production car was on an Oldsmobile Curved Dash.

1901: Oldsmobile was the first to procure parts from third-party suppliers.

1901: Olds produces 635 cars, becoming the first high-volume gasoline automobile producer.

1901: Oldsmobile becomes the first manufacturer to publicly promote their vehicles.

1902: The Oldsmobile Curved Dash is the first mass-produced vehicle in America.

1903: Oldsmobile builds the first purpose-built mail truck.

1908: Oldsmobile rebadges the Buick Model B as the Oldsmobile Model 20, possibly creating the first badge-engineered car.

1915: First standard windshield introduced by Oldsmobile.

1926: Oldsmobile is the first to use chrome plating on trim.

1929: Oldsmobile creates the first Monobloc V8 engine in its Viking Sister brand.

1932: Oldsmobile introduces the first automatic choke.

1935: Oldsmobile offers the first all-steel roof on an automobile.

1940: Oldsmobile introduces the Hydra-Matic, the first fully automatic transmission.

1948: Oldsmobile offers one-piece curved windshields, along with Buick and Cadillac.

1949: Oldsmobile introduces the Rocket, the first high-compression OHV V8 engine.

1952: Oldsmobile introduces the "Autronic Eye," the first automatic headlight dimming system.

1953: Oldsmobile switches its lineup to the 12v charging system.

1962: Oldsmobile creates the first production turbocharged car, the F-85 Jetfire.

1962: Oldsmobile also creates the first production car with water injection, the F-85 Jetfire.

1966: The Oldsmobile Toronado is the first mass-produced front-wheel-drive American car.

1969: First use of chromed ABS plastic exterior trim on the 1969 Oldsmobile Toronado.

1969: First electric grid window defogger on an American car, the 1969 Oldsmobile Toronado.

1971: The Oldsmobile Toronado is one of the first cars to feature a high-mounted brake light.

1974: The Toronado is the first American car to offer a driver-side airbag.

1977: The Toronado is the first American car with a microprocessor to run engine controls.

1982: First use of high-impact molded plastic body components on the 1982 Oldsmobile Omega.

1986: Oldsmobile introduces the Delco VIC touchscreen interface on the Toronado, shared with Buick Riviera.

1988: The first production heads-up display system is introduced on the 1988 Oldsmobile Cutlass Supreme Indy Pace Car.

1988: Oldsmobile breaks a world speed record with the Oldsmobile Aerotech at 267 mph, driven by A.J. Foyt.

1990: Oldsmobile updates the color touchscreen interface with a built-in cellular phone on the 1990 Toronado Trofeo.

1995: Oldsmobile introduces Guidestar, the first onboard navigation system on a U.S. production car.

1997: Oldsmobile becomes the first American car company to turn 100 years old.

2001: The redesigned 2002 Oldsmobile Bravada becomes the first truck to pace the Indianapolis 500.

95 notes

·

View notes