#Injection Molding Machine

Explore tagged Tumblr posts

Text

Haitian 200T mars3 loading container

0 notes

Text

How Can a Rubber Injection Molding Machine Improve Your Production Efficiency?

In the ever-evolving world of manufacturing, efficiency and precision are two elements that can set a business apart. For companies working with rubber components, staying competitive means adopting advanced machinery that delivers reliable, repeatable results. One such innovation making waves across industries is the rubber injection molding machine, known for its speed, accuracy, and ability to produce high-quality rubber parts.

0 notes

Text

#Micro Injection Molding Machine Market#Micro Injection Molding Machine#Micro Injection Molding#Injection Molding Machine#Molding Machine#Injection Molding

0 notes

Text

CPVC Injection Molding Machine Manufacturer

At KSB Machinery, we are a leading CPVC Injection Molding Machine Manufacturer, dedicated to delivering high-quality and efficient machinery for your industrial needs. Our CPVC injection molding machines are designed with advanced technology to ensure superior performance, durability, and precision. Whether you are in the plumbing, electrical, or automotive industry, our machines provide exceptional reliability and efficiency, making us the trusted choice for CPVC Injection Molding Machine solutions.

1 note

·

View note

Text

قطعات دستگاه تزریق پلاستیک

دستگاه تزریق پلاستیک همانند بسیاری از ماشین های صنعتی دیگر از قطعات و بخش های مختلفی تشکیل شده است که هر کدام وظیفه ای خاص بر عهده دارند تا در نهایت، مواد اولیه پلاستیکی به یک محصول تبدیل شود. در لینک زیر مهمترین قطعات مربوط به این دستگاه معرفی شده است

injection molding machine components

0 notes

Text

Our injection molding machine controller provides precise control, consistency, automation, and monitoring for efficient and high-quality production

0 notes

Text

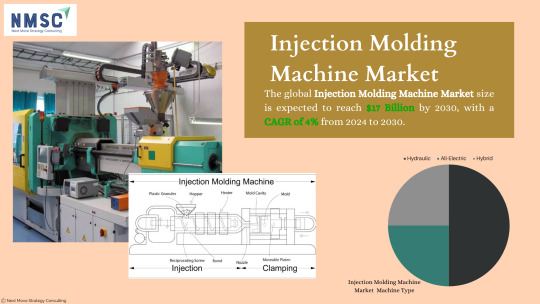

Asia-Pacific Leads, Rest of the World Grows: Insights into the Injection Molding Machine Market

Introduction

The injection molding machine market is a critical segment within the broader manufacturing industry, facilitating the production of a wide range of plastic products across various sectors. As per a study by Next Move Strategy Consulting, the global Injection Molding Machine Market is anticipated to reach a value of USD 17.22 billion by 2030, with a compound annual growth rate (CAGR) of 3.7%. This article aims to delve deeper into the dynamics of this market, with a particular focus on the contrasting trends observed in the Asia-Pacific region and the rest of the world (ROW).

Request for a sample PDF report: https://www.nextmsc.com/injection-molding-machine-market/request-sample

Asia-Pacific's Dominance in the Market

Asia-Pacific stands out as the undisputed leader in the injection molding machine market, boasting the largest market share globally. In 2022, the region commanded a market value of USD 7.12 billion, a testament to its robust manufacturing ecosystem and strategic initiatives undertaken by key players.

One of the primary factors driving Asia-Pacific's dominance is the expansion of manufacturing facilities by regional giants. For instance, Sumitomo (SHI) Demag China's announcement in February 2023 regarding the construction of a new 43,000 square-feet facility to double injection molding machine production in China underscores the commitment to meet escalating demand effectively.

Moreover, the automotive industry's expansion and diversification in the region further fuel the demand for injection molding solutions. Japan, with its reputation for automotive innovation and quality, serves as a prime example. As the world's third-largest automotive producer, Japan operates 78 factories across 22 prefectures, employing over 5.5 million individuals. This thriving automotive sector creates a sustained demand for high-quality injection molding machines, propelling market growth in the region.

Partnerships and collaborations also play a crucial role in driving the Asia-Pacific injection molding machine industry forward. SOLIZE India Technologies' partnership with Toray Engineering D Solutions in December 2022 to supply 3D injection molding machines for the Indian market exemplifies the collaborative efforts aimed at meeting regional demands efficiently.

ROW Market: Steady Growth Amidst Challenges

While Asia-Pacific leads the injection molding machine market, the rest of the world (ROW) presents a different landscape characterized by steady growth and unique challenges. Despite not matching the dominance of Asia-Pacific, ROW exhibits promising growth prospects driven by governmental initiatives and evolving manufacturing landscapes.

In September 2022, Argentina's government enacted tax and regulatory benefits for the automotive industry, offering incentives for investments in machinery and infrastructure. These initiatives aim to boost exports and attract investments, thereby driving demand for advanced machinery including injection molding machines.

Similarly, the United Arab Emirates (UAE) has emerged as a key player in various industries, including automotive, electronics, packaging, and consumer goods. The UAE's emphasis on industrial transformation towards smart manufacturing, as demonstrated by the Smart Manufacturing Incentive Program launched by the Abu Dhabi Department of Economic Development in June 2023, creates a conducive environment for the adoption of advanced injection molding solutions.

While ROW showcases steady growth, challenges such as regulatory complexities and geopolitical uncertainties persist. However, concerted efforts by governments and industry stakeholders are expected to mitigate these challenges and foster a conducive environment for market growth.

Inquire before buying: https://www.nextmsc.com/active-seat-belt-system-market/inquire-before-buying

Emerging Trends and Opportunities

In addition to regional dynamics, several emerging trends and opportunities are shaping the global injection molding machine market.

Customization and Personalization: Consumer preferences are increasingly favoring personalized products tailored to individual needs and tastes. Injection molding machines equipped with advanced software and automation capabilities enable manufacturers to efficiently produce customized components and products, catering to niche markets and enhancing customer satisfaction.

Medical and Healthcare Applications: The healthcare sector presents lucrative opportunities for the injection molding machine market, driven by the growing demand for medical devices, pharmaceutical packaging, and diagnostic equipment. With stringent quality standards and regulatory requirements, manufacturers are investing in state-of-the-art injection molding technologies to ensure precision, reliability, and compliance with medical industry standards.

Circular Economy Initiatives: Sustainability is a pressing concern for industries worldwide, prompting a shift towards circular economy models that prioritize resource efficiency, waste reduction, and recycling. Injection molding machines capable of processing recycled materials and biodegradable polymers are in high demand, aligning with corporate sustainability goals and regulatory mandates aimed at reducing environmental impact.

Industry 4.0 Integration: The integration of Industry 4.0 technologies, such as Internet of Things (IoT) sensors, data analytics, and predictive maintenance, is revolutionizing the injection molding process. Smart injection molding machines equipped with real-time monitoring and predictive analytics capabilities enable proactive maintenance, minimize downtime, and optimize production efficiency, thereby enhancing overall operational performance and competitiveness.

Reshoring and Nearshoring Trends: The ongoing geopolitical uncertainties and supply chain disruptions have prompted many manufacturers to reassess their sourcing strategies and consider reshoring or nearshoring production closer to their primary markets. This trend presents opportunities for injection molding machine suppliers to partner with local manufacturers and provide on-demand production solutions tailored to regional requirements, reducing lead times and transportation costs.

Advanced Materials Development: The injection molding machine market is witnessing a surge in demand for machines capable of processing advanced materials, including composites, bioplastics, and high-performance polymers. These materials offer superior mechanical properties, chemical resistance, and thermal stability, making them ideal for demanding applications in industries such as aerospace, automotive, and electronics. Injection molding machines equipped with specialized capabilities for handling these materials are poised to capitalize on this growing market segment.

Focus on Energy Efficiency: With increasing emphasis on sustainability and energy conservation, there is a growing demand for injection molding machines designed to minimize energy consumption and reduce carbon emissions. Manufacturers are investing in energy-efficient technologies such as servo-driven systems, variable frequency drives, and regenerative braking systems to optimize energy usage throughout the production process. Energy-efficient injection molding machines not only lower operational costs but also contribute to environmental preservation, aligning with corporate sustainability objectives and regulatory mandates.

Adoption of Hybrid and Electric Machines: The shift towards greener manufacturing practices and stricter emissions regulations is driving the adoption of hybrid and electric injection molding machines. These machines offer significant advantages over traditional hydraulic models, including higher energy efficiency, reduced noise levels, and lower maintenance requirements. As environmental awareness continues to grow, manufacturers are increasingly turning to hybrid and electric machines to enhance their sustainability credentials and gain a competitive edge in the market.

Digital Twin Technology: Digital twin technology is revolutionizing the injection molding process by enabling virtual simulations and predictive modeling of machine behavior. By creating digital replicas of physical injection molding machines, manufacturers can optimize process parameters, identify potential issues, and test new configurations in a risk-free virtual environment. Digital twin technology enhances operational efficiency, reduces time-to-market, and enables data-driven decision-making, ultimately improving overall productivity and profitability.

Focus on Worker Safety and Ergonomics: As occupational health and safety regulations become more stringent, there is a growing emphasis on designing injection molding machines with enhanced safety features and ergonomic design principles. Manufacturers are integrating advanced safety systems such as light curtains, safety interlocks, and automated guarding to protect operators from hazards and minimize the risk of workplace injuries. Additionally, ergonomic enhancements such as adjustable controls, intuitive interfaces, and ergonomic workstations improve operator comfort and productivity, leading to a safer and more efficient working environment.

These emerging trends and developments underscore the dynamic nature of the injection molding machine market and highlight the opportunities for innovation and growth. By staying abreast of these trends and investing in cutting-edge technologies, manufacturers can position themselves for success in an increasingly competitive landscape

Conclusion

In conclusion, the injection molding machine market is undergoing significant transformation, driven by regional dynamics, emerging trends, and technological advancements. While Asia-Pacific maintains its dominance, the rest of the world presents promising growth opportunities amidst challenges.

Sustainable practices, technological innovations, and digitalization are shaping the future of the industry, offering manufacturers new avenues for growth and differentiation. As stakeholders navigate this evolving landscape, collaboration, innovation, and adaptability will be key to unlocking the full potential of the injection molding machine market.

Also Browse:

0 notes

Text

What is an Injection Molding Machine? Get to know everything about it!

Injection molding is an important industrial technique. Although it is somewhat similar to die casting, but the raw material used in this case are different. Die casting uses metals that melt at extremely high temperatures, whereas injection molding mostly uses glasses, elastomers, and most frequently thermoplastic and thermosetting polymers. Nevertheless, this process is commonly used to create thermoplastic materials. In this method, raw materials are heated to a certain temperature and then injected under pressure into the mould cavity without changing their composition.

What are the main parts of injection molding machine?

The material hopper, barrel, an injection ram/rotating screw type plunger, heating element (heater), adjustable pattern, ejectors, and a mould inside mould cavity are the key components of an injection molding machine.

Injection molding machines typically operate horizontally. A barrel is part of an injection molding machine (cylindrical pipe). At one end of the barrel, there is a hopper. Inside the barrel is a revolving screw or hydraulic ram powered by an electric motor that provides force. The barrel has a heating element (warmer) attached to it that is used to melt the molding compound when it exits the hopper.

Mold cavity linked to the barrel's opposite side. During the entire production process, a movable pattern is used and the mould is situated inside the mould cavity. Typically, copper, aluminum, and tool steels are used to make mould. Distinct types of material moulds have different life cycles. This can be chosen based on your needs.

How does the injection moulding machine works?

Extrusion and injection molding both function similarly, as implied by their names. Using a feeding apparatus, molding material and raw materials are poured into the hopper. Following that, the molding material falls into the cylinder (barrel) as depicted in the diagram due to gravity. The material is melted using a circumferential heater that is mounted on the barrel. When molding compound in powder form enters the barrel from the hopper, it begins to melt, and a revolving screw or hydraulic ram applies pressure to advance the compound into the mould.

In this split mould, which is attached to the other side of the barrel, molten plastic material is pumped into a closed mould. The revolving screw constantly advances the molding material. The hydraulic system exerts pressure. Normal injection pressure ranges from 100 to 150 MPa. Following injection, pressure is exerted for a while or held in place with some force.

The pieces produced when the entire procedure is complete are appropriately cooled. The mould is then opened, and a few ejectors are utilized to remove the part properly and damage-free. The portion mould is reopened after removal. This process is very fast and automatically repeated. Here, it is simple to make pieces with complex shapes. The injection molding process may produce 12–16,000 components every cycle.

The Procedure

- The process parameter fluctuates based on the circumstances and demands. - The components made with this method typically weigh between 100 and 500 g. - A single part's cycle time ranges from 5 to 60 seconds, depending on how the item is made. - The heating range for molding material is 150 to 350 degrees Celsius. - The molding machine has an injection capacity of 12,000 to 2.2 106 mm3. - 100 to 150 MPa is the injection pressure. - From 0.1 to 8.0 MN is the locking force.

What are the advantages of Injection molding machine?

- The fundamental benefit of this method is that intricately shaped components with thin walls (5–15 mm) may be molded with ease and retrieved from the die without being harmed. - Injection-molded components offer good dimensional tolerance. - The main benefit of this method is that it produces far less scrap than certain other methods. - Investment cast iron and intricately machined pieces compete with parts produced through the Injection Moulding Method. - In comparison to other procedures, this process has a high production rate.

What are the various types of injection molding machines?

Following are the different types of injection molding machines. Have a look:

Hydraulic Injection Molding Machine

Hydraulic injection molding machine were the only types of machine at start. It is the oldest one in the industry. Following are the benefits of this machine-

1. Economical price These machines cost far less at the base level than comparable models.

2. Cheap parts If a machine component needs to be replaced because it has been damaged or has reached the end of its useful life, the replacement parts are less expensive and more readily available.

3. Robust components The machine's hydraulic components are longer-lasting and more resistant to deterioration.

4. Easy to use and maintain High-pressure clamping forces are typically simple to adjust on hydraulic injection devices.

5. Powerful The gripping force on hydraulic molding machines is outstanding.

Electric Injection Molding Machines

In the 1980s, electric injection molding machines were made available and soon gained popularity in the high precision plastic parts production sector. The positioning accuracy of today's full electric servo drive injection molding machines is exceptionally precise (of 0.0001 in), but at a very high cost.

1. Less idle time There is no possibility of oil leaking. Additionally, since no oil is used, there is no need to replace filters, which lowers consumable costs.

2. Efficiency while using energy Electric Injection Molding Machines only consume energy when they are in use, thus their output is limited to what is necessary to support the load.

3. Fast procedure Since these machines are digitally controlled, the procedure can be completely repeated without any oversight.

4. Highly reproducible The injection device can be accurately controlled, the molding conditions can be stabilized, the injection control (such as pressure and speed) can be regulated in fine units, and there is a highly accurate control and monitoring system. It can handle challenging tasks like multi-stage hydraulic system extension and control the extension.

Injection Molding Machine Price

There are various types of machines. The Injection Molding Machine Price will also vary according to the complexity of the machine. Costs for large industrial injection molding equipment can range from $50,000 to $200,000 or more. Additionally, the facilities needed to operate, maintain, and monitor these equipment are more demanding and call for expert staff.

Who are the best injection molding machine manufacturers?

There are many Injection Molding Machine Manufacturers in India; however, some of them offer the exception quality products that last longer. Here is the list of some trusted manufacturer in India-

Milacron

Yizumi Injection Molding Machine

Primex Plastics Pvt. Ltd

Windsor Machines Limited

Haitian

Hikon

ENGEL Global

Indo-MIM

Micro Plastic

Kruger

Vikas Industries

Jagmohan PlaMech Pvt. Ltd

Neelgiri Machinery

These are some of the leading manufacturers offering the best quality Injection Molding Products. If you are looking for someone in your region, you can try to search on Google and write Injection Molding Machine near me. This way, you will find the list of top-rated manufacturers offering top-notch services in your area.

Types of products made with injection molding machine

There are various types of products that can be made with injection molding machines.

Some of them are listed below-

Toys

Plastic bottles

Machinery and automotive components

Household products like molded closures, containers, etc.

Healthcare industry

Agricultural products

Conclusion

Injection moulding may appear to be a complicated procedure, yet it is the most popular manufacturing technique because it can manufacture a wide range of everyday things quickly and effectively. One of the most economical methods for producing both working prototypes and finished goods is injection molding.

#Injection Molding Machine#molding material#raw materials#injection molding process#Injection-molded components#Injection Moulding Method.#hydraulic molding machines#Injection Molding Machine Price#Injection Molding Machine Manufacturers#Injection Molding Products

0 notes

Text

Plastic Products Manufacturing Business Plan

Hey you! 👋 Ever wondered how to kickstart your own Plastic Products Manufacturing Business? 🛠️Look no further! This post has all the tips and tricks you need. 💡 Ready to turn your dreams into reality? CLICK LINK to get started today! #PlasticBusiness

Plastic products have become an integral part of our daily lives, And, plastic products serve as a versatile and cost-effective solution for various industries including FMCG, healthcare, automotive, and construction. Due to the diversity of plastics, products made of plastic are being manufactured today not only for industrial use but also for manufacturing primary products of daily use.…

View On WordPress

#best business ideas#business ideas#business ideas in india#how to start a business#how to start a plastic products manufacturing business#injection molding machine#low investment business ideas#manufacturing business ideas#new business ideas#new business oppurtunity#plastic manufacturing business ideas#plastic product manufacturing#plastic product manufacturing business#plastic products manufacturing business ideas#small business ideas

0 notes

Link

#adroit market research#injection molding machine#injection molding machine 2021#injection molding machine size

0 notes

Text

Injection molding machine original condition 99%new, if you are interested let me know

0 notes

Text

1 note

·

View note

Text

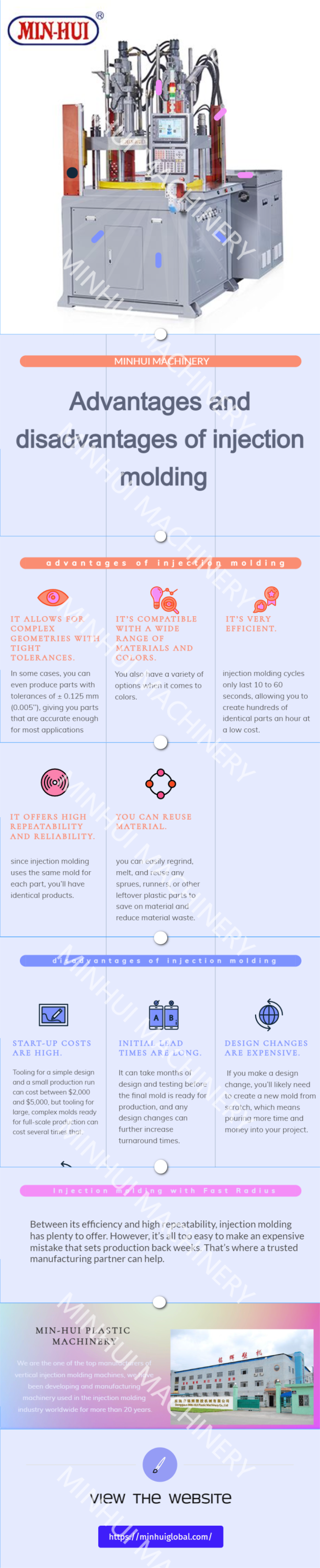

Advantages and disadvantages of injection molding

#minhui machinery#vertical injection molding machine#injection molding machine#min-hui#Advantages and disadvantages of injection molding

0 notes

Video

youtube

OYU Precision Technology - 2024 Alibaba Verified Supplier

20+Years Experience Professional CNC Precision Machining & Injection Moulding Service Solution Provider

Sky Zhu Mob/WeChat/WhatsApp/Skype: +86 136 8254 0281 Email: [email protected]

2 notes

·

View notes

Text

Our injection molding machine controller provides precise control, consistency, automation, and monitoring for efficient and high-quality production

0 notes

Text

Plastic injection moulding

#prototyping#prototype#rapid prototyping#prototype machining#plastic injection molding parts#injection molding#plastic injection molding company#injection molding parts#plastic injection molding#injection molding services#plastic injection molded#plastic injection molded parts#plastic injection moulding#plastic injection#injection moulding#injection moulding service

2 notes

·

View notes