#Injection Molding Machine Price

Text

What is an Injection Molding Machine? Get to know everything about it!

Injection molding is an important industrial technique. Although it is somewhat similar to die casting, but the raw material used in this case are different. Die casting uses metals that melt at extremely high temperatures, whereas injection molding mostly uses glasses, elastomers, and most frequently thermoplastic and thermosetting polymers. Nevertheless, this process is commonly used to create thermoplastic materials. In this method, raw materials are heated to a certain temperature and then injected under pressure into the mould cavity without changing their composition.

What are the main parts of injection molding machine?

The material hopper, barrel, an injection ram/rotating screw type plunger, heating element (heater), adjustable pattern, ejectors, and a mould inside mould cavity are the key components of an injection molding machine.

Injection molding machines typically operate horizontally. A barrel is part of an injection molding machine (cylindrical pipe). At one end of the barrel, there is a hopper. Inside the barrel is a revolving screw or hydraulic ram powered by an electric motor that provides force. The barrel has a heating element (warmer) attached to it that is used to melt the molding compound when it exits the hopper.

Mold cavity linked to the barrel's opposite side. During the entire production process, a movable pattern is used and the mould is situated inside the mould cavity. Typically, copper, aluminum, and tool steels are used to make mould. Distinct types of material moulds have different life cycles. This can be chosen based on your needs.

How does the injection moulding machine works?

Extrusion and injection molding both function similarly, as implied by their names. Using a feeding apparatus, molding material and raw materials are poured into the hopper. Following that, the molding material falls into the cylinder (barrel) as depicted in the diagram due to gravity. The material is melted using a circumferential heater that is mounted on the barrel. When molding compound in powder form enters the barrel from the hopper, it begins to melt, and a revolving screw or hydraulic ram applies pressure to advance the compound into the mould.

In this split mould, which is attached to the other side of the barrel, molten plastic material is pumped into a closed mould. The revolving screw constantly advances the molding material. The hydraulic system exerts pressure. Normal injection pressure ranges from 100 to 150 MPa. Following injection, pressure is exerted for a while or held in place with some force.

The pieces produced when the entire procedure is complete are appropriately cooled. The mould is then opened, and a few ejectors are utilized to remove the part properly and damage-free. The portion mould is reopened after removal. This process is very fast and automatically repeated. Here, it is simple to make pieces with complex shapes. The injection molding process may produce 12–16,000 components every cycle.

The Procedure

- The process parameter fluctuates based on the circumstances and demands.

- The components made with this method typically weigh between 100 and 500 g.

- A single part's cycle time ranges from 5 to 60 seconds, depending on how the item is made.

- The heating range for molding material is 150 to 350 degrees Celsius.

- The molding machine has an injection capacity of 12,000 to 2.2 106 mm3.

- 100 to 150 MPa is the injection pressure.

- From 0.1 to 8.0 MN is the locking force.

What are the advantages of Injection molding machine?

- The fundamental benefit of this method is that intricately shaped components with thin walls (5–15 mm) may be molded with ease and retrieved from the die without being harmed.

- Injection-molded components offer good dimensional tolerance.

- The main benefit of this method is that it produces far less scrap than certain other methods.

- Investment cast iron and intricately machined pieces compete with parts produced through the Injection Moulding Method.

- In comparison to other procedures, this process has a high production rate.

What are the various types of injection molding machines?

Following are the different types of injection molding machines. Have a look:

Hydraulic Injection Molding Machine

Hydraulic injection molding machine were the only types of machine at start. It is the oldest one in the industry. Following are the benefits of this machine-

1. Economical price

These machines cost far less at the base level than comparable models.

2. Cheap parts

If a machine component needs to be replaced because it has been damaged or has reached the end of its useful life, the replacement parts are less expensive and more readily available.

3. Robust components

The machine's hydraulic components are longer-lasting and more resistant to deterioration.

4. Easy to use and maintain

High-pressure clamping forces are typically simple to adjust on hydraulic injection devices.

5. Powerful

The gripping force on hydraulic molding machines is outstanding.

Electric Injection Molding Machines

In the 1980s, electric injection molding machines were made available and soon gained popularity in the high precision plastic parts production sector. The positioning accuracy of today's full electric servo drive injection molding machines is exceptionally precise (of 0.0001 in), but at a very high cost.

1. Less idle time

There is no possibility of oil leaking. Additionally, since no oil is used, there is no need to replace filters, which lowers consumable costs.

2. Efficiency while using energy

Electric Injection Molding Machines only consume energy when they are in use, thus their output is limited to what is necessary to support the load.

3. Fast procedure

Since these machines are digitally controlled, the procedure can be completely repeated without any oversight.

4. Highly reproducible

The injection device can be accurately controlled, the molding conditions can be stabilized, the injection control (such as pressure and speed) can be regulated in fine units, and there is a highly accurate control and monitoring system. It can handle challenging tasks like multi-stage hydraulic system extension and control the extension.

Injection Molding Machine Price

There are various types of machines. The Injection Molding Machine Price will also vary according to the complexity of the machine.

Costs for large industrial injection molding equipment can range from $50,000 to $200,000 or more. Additionally, the facilities needed to operate, maintain, and monitor these equipment are more demanding and call for expert staff.

Who are the best injection molding machine manufacturers?

There are many Injection Molding Machine Manufacturers in India; however, some of them offer the exception quality products that last longer. Here is the list of some trusted manufacturer in India-

Milacron

Yizumi Injection Molding Machine

Primex Plastics Pvt. Ltd

Windsor Machines Limited

Haitian

Hikon

ENGEL Global

Indo-MIM

Micro Plastic

Kruger

Vikas Industries

Jagmohan PlaMech Pvt. Ltd

Neelgiri Machinery

These are some of the leading manufacturers offering the best quality Injection Molding Products. If you are looking for someone in your region, you can try to search on Google and write Injection Molding Machine near me. This way, you will find the list of top-rated manufacturers offering top-notch services in your area.

Types of products made with injection molding machine

There are various types of products that can be made with injection molding machines.

Some of them are listed below-

Toys

Plastic bottles

Machinery and automotive components

Household products like molded closures, containers, etc.

Healthcare industry

Agricultural products

Conclusion

Injection moulding may appear to be a complicated procedure, yet it is the most popular manufacturing technique because it can manufacture a wide range of everyday things quickly and effectively. One of the most economical methods for producing both working prototypes and finished goods is injection molding.

#Injection Molding Machine#molding material#raw materials#injection molding process#Injection-molded components#Injection Moulding Method.#hydraulic molding machines#Injection Molding Machine Price#Injection Molding Machine Manufacturers#Injection Molding Products

0 notes

Text

#Vertical Injection Molding#Standard Table Injection Molding#Injection Molding Machines#Vertical Injection Molding Machine suppliers#Vertical Injection Molding Machine manufacturers#Vertical Injection Molding Machine price#dealers#traders#exporters

0 notes

Text

#Bumper Molding#plastic trim moulding#plastic injection moulding products#plastic injection moulding#injection moulding#injection moulding machine price#plastic injection molding machine

0 notes

Text

But I wanted her (knockoff playline dolls)

I don't use Temu! Temu bad! Temu steals your info! Temu -

Ooh. She's pretty. Yeah. I caved.

So technically, Defa Lucy is a Mexican Walmart knockoff of Barbie, but plastic playline knockoffs aren't viewed generally with the same level of distaste as recast BJDs. Others have their reasons, but mine goes a little something like this:

These toys are made with plastic injection molding machines. Here's a sales pitch video by Fit Precision Molding, a company that makes and sells these machines:

youtube

These machines are NOT cheap. This is the CNC (Computer Numerical Control) machine of toys. $20K (USD) for ONE machine is a starter price - and that's if you can get it cheap from China. So a company that has decided to create their own knockoff line also tends to have the funds to pick a legal fight with, say, Mattel (MGAE and Bratz). This is not a backyard art theft sort of operation. This is easily a $200K operation just for the machines.

Granted, YMY still got smacked good and hard by the company that makes Nendoroids, and they deserved to get smacked, cuz stealing is bad.

HOWEVER...

Playline companies steal from each other all the time (cough cough Barbie Extra trying to lift the LOL OMG line like that hot mess of clashing color outfits and ridiculous plastic jewelry can compare to the cohesiveness of MGAE looks cough). Generally, if one company is mad enough, they'll sue the "stealing" company pretty quickly, and the marketplace will figure it out.

The other reason it doesn't bother me is cuz I figure these companies kinda have it coming.

So when China opened up for business, companies all over the world ran there like their houses were on fire, cuz China so cheap! Such affordable labor force. Much lack of regulation - environmental or occupational safety. Companies initially balked at employees being required to join a union, but they were immediately comforted by the fact that Chinese labor unions do exactly squat for people. The unions exist solely to steal from the employees and transfer that money to members of government.

When you open a business in China, you're required to bring on a local company as a joint venture (same in Saudi Arabia, by the way), and the Chinese company will steal with delight and abandon - as actively encouraged by the Chinese government and CCP. Companies have whined extensively about this to their respective governments. "I want cheap labor force! I want to destroy water supply! I want to pollute their air! But they're stealing from me! Waaaaah!"

Well - you get what you pay for, now don't you. You want access to exploited labor forces (forced labor for Uyghurs in the Xinjiang province, imported North Korean slaves). You want rights to dump your toxic crap into the Chinese water supply and the Chinese air without repercussions - which travels over to California and gets trapped in LA, by the way (air moves, idiots).

You'll have to forgive me if my sympathies are not particularly high for you.

This sucks for anyone trying to be an ethical consumer. Walk into your local store and flip over any box. They all say "Made in China." All of them.

This is why even though dolls like Momoko and Obitsu are more expensive, I am willing to pay to import them. Japanese wages suck, but at least they're making some money. The dolls are made in Japan. That's why they cost as much as they do. If you want to be an ethical doll collector, your options are basically BJDs and Japanese dolls (maybe Korean). Anything on US shelves is made in China and therefore unethical AF.

#defa lucy#temu#playline doll companies#yeah I'm banned from visiting China#probably why I can't sign up for Taobao lol#Youtube

19 notes

·

View notes

Text

Tangents

okay, so heres that tangent I warned about

so for the last like 10 years I have had this fantasy of winning the lottery and starting a business.....that first part is mostly the fantasy, because without that theres no way I could afford to do the latter

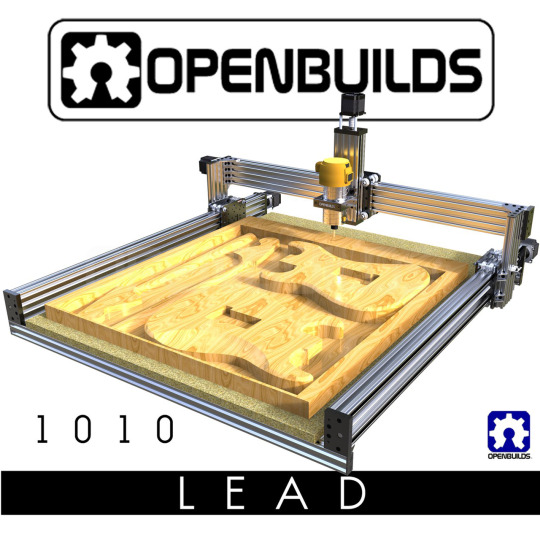

basically it comes down to new technology that allows automation for small guys like me, stuff like these

basically with 3D printing and affordable cnc and laser cutting machines, a guy like me could have the man power of like 10 people, and if I hired maybe 10 people total to assist, I could easily do something on par with much bigger companies.

my initial fantasy just involved making guitars, granted more advanced guitars then I think the market insists upon, because they are locked in the habit of what has proven sellable to MOST people. fender scale length, bolt on neck, 2 humbuckers, faux les paul look and feel. every company does it, no shame. just not my thing.

I've had this idea, which I've experimented with and talked about in the past, the guitar of the future. Ive done mockups etc like this

but as I've grown older, honestly what I think it should really be is a cheap reliable guitar with a few tricks up its sleeve. so I have reimagined it as basically this

telecasters are simple, and on a cnc machine if you made it as layers that were later glued together, you could make it very easily. the 4x2 headstock is better for straight string pull, and helps eliminate tuning instability. replacing the old school pickups with active style pickups like emg would make it more versatile, and then adding the b bender, along with string drops a g bender, and maybe even a strap actuated bender, the guitar could cover a lot more roles then a standard electric guitar. plus I honestly think benders are cool and more people need to play them, so making them as cheap and accessable as possible is a good idea

just a simple guitar, maybe of paulownia or plywood, cut as 2 or 3 sections and glued together, and then maybe even using a circuit board instead of wire to speed up production, its a great idea.

but I started looking into what else I could do with this hypothetical company that basically 3D prints things, and cncs plywood

I guess bikes

I am a big fan of ebikes, mainly because I believe genuinely in the next 10 years they will begin to be a lot more common in most major cities, their prices will come down as there are more batteries in circulation for evs, and being able to make quick simple bikes like this to sell locally, it seems like a way to directy serve the market I want to live in.

I also looked into stereo equipment, as I am a big hifi guy, and I am a huge raspberry pi fan, so seeing stuff for hifi pi, again it would be a market i understand, and think shouldnt be so fuckin expensive

I also genuinely would love to make a cheap hammond organ clone

like sub $500, because when I was wanting to pickup the instrument it was very hard to get the $ together to do so, and I know if you could injection mold the keys, cnc the body print the circuit boards, and use an arduino or raspberry pi to run a soft synth hammond clone, you could easily hit that price point

more people need to play the organ

lastly is furniture

I love basic designs and furniture has always been something that I enjoy looking at, modern furniture designs, stuff from the last 50s early 60s, its so timeless and the open source furniture movement just scratches that itch. it's simple, but stylish, its utilitarian but it doesnt look bland

the idea of being able to make these things, locally, and just being able to put out into the world things I want and I know other people would too.....I think i'd like that

just wish I didnt have to win the lottery to do it

8 notes

·

View notes

Text

The She230 ppr Pipe Fitting Making Injection Molding Machine from China Sanshun is designed for efficient PPR pipe fitting production. It features precise injection device control, high-tensile steel tie-bars, and triple security protection. The double cylinder balanced injection unit provides optimal performance.

Contact us today to learn more and get the latest pricing!

#led bulb cover making injection blow machine#injection blow molding machine#plastic auxiliary machine#injection moulding machine#high speed machine

0 notes

Text

Paver Base

A paver base is a type of aggregate used to build patios and walkways using pavers as the top layer. The layer of native material beneath the planned surface is referred to as the subgrade in constructing such a surface. The paver base for paving stones is made of a combination of gravel. The floor offers a strong foundation. When you squeeze, the substance becomes obstructed. Sizes vary from dust to three-quarters of an inch. The most common stone used in this application is crushed limestone. There may be regional differences in the material and color of the product. Any paving job needs to have a sufficiently constructed foundation. Never skimp on quality; never compact the bedding layer; and never place plastic underneath any pavement treatment. Please always use the appropriate bedding; you should measure the substrate exactly to achieve this. The typical paver or stone patio base is a 6-inch-deep layer of compacted gravel. Base panels for paver patios are made of lightweight high-density polypropylene.

Our pavers are a fantastic, reasonably-priced driveway choice. The construction and locking mechanism makes installation simple. These plastic pavers with exceptional impact permeability are also long-lasting. They will continue to look natural and earthy while supporting large machines and cars. Compared to ordinary grass ground, these pavers make a surface that is more resilient for cars to park on or drive through in residential driveways. They will also aid in halting erosion and the formation of mud holes.

Using an injection molding technique, recycled plastic is used to create our permeable plastic pavers. The pavers may be installed more quickly than 1000 square feet in an hour because of their design. For roads, parking lots, or paths, these permeable pavers work well as gravel or grass pavers.

0 notes

Text

0 notes

Text

Exploring the Cost of Injection Molding Machines

Introduction

Injection molding is a widely used manufacturing process for producing parts by injecting molten material into a Mold. One of the critical considerations in injection molding is the cost of the machines used in the process. Let's delve into the various factors that contribute to the cost of injection molding machines.

Factors Influencing the Cost

1. Machine Size and Capacity

Larger machines capable of handling higher volumes of production typically come with a higher price tag.

The capacity of the machine, measured in terms of clamping force, determines its suitability for different types of molds and production requirements.

2. Complexity and Features

Machines with advanced features such as multi-material capabilities, automation, and precision controls tend to be more expensive.

Complexity in design and engineering also contributes to the overall cost.

Factors Influencing the Cost (Contd.)

3. Brand and Reputation

Well-established brands with a reputation for reliability and quality often command higher prices for their machines.

While opting for a reputable brand may incur a higher initial cost, it can lead to long-term cost savings through enhanced performance and durability.

4. Maintenance and Support

Consideration should be given to the availability of maintenance services and technical support, as these can impact the overall cost of ownership.

Machines with comprehensive support packages may have a higher upfront cost but can result in lower maintenance expenses over time.

Evaluating Total Cost of Ownership (TCO)

1. Initial Investment

The upfront cost of purchasing the machine, including any additional accessories or customization required.

2. Operational Costs

Expenses related to material usage, energy consumption, labor, and maintenance over the machine's lifespan.

3. Downtime and Efficiency

Downtime due to machine breakdowns or maintenance can significantly impact productivity and profitability.

Investing in reliable machines with minimal downtime can lead to cost savings in the long run.

Conclusion

Understanding the factors influencing the cost of injection molding machines is crucial for making informed decisions during the procurement process. By evaluating not only the initial investment but also the total cost of ownership, manufacturers can optimize their operations for efficiency and profitability.

0 notes

Text

#Vertical Injection Molding#Rotary Slide Injection Molding#Injection Molding Machines#Vertical Injection Molding Machine suppliers#Vertical Injection Molding Machine manufacturers#Vertical Injection Molding Machine price#dealers#traders#exporters

0 notes

Video

youtube

China Hair Dryer Factory Site High Speed Hair Dryer Manufacturing in Pro...

Find a Good high speed hair dryer and has a Best hair Dryer Wholesale Prices 1.Design hair dryer appearance and packaging, PCBA circuit boards 2.Mold factory mold injection hair dryer shell, check the appearance 3.Produce high speed brushless motor with 110,000 rpm and purchase other hair dryer spare parts. 4.Assemble hair dryer spare parts: mold + PCBA + motor and heating wire, line and other spare parts. 5. Hair dryer power test, wind speed test, aging test, safety test, etc. 6. Packaging inspection: check the appearance of the hair dryer, start packaging, over the plastic film machine packaging and shipping Web site:https://www.teejoiniot.com/ GlobalSources:http://www.globalsources.com/teejion.co Follow us:-------------------------------------------------------- LinkedIn:https://www.linkedin.com/company/teejoin-smartappliances/ Instagram:https://www.instagram.com/teejoin.smartappliance/ Facebook:https://www.facebook.com/TeejoinSmartAppliances #hairdryer #blowdryer #highspeedhairdryer #hairstyling #BeautyTools #PerfectAtAllTimes #NewHairTrend #EasyHairStyling #hairstyle #Factory #hairtools #hairgrowth #SupersonicHairDryer #bldcmotor #newhairdryer #chinaproducts #chinabeauty #chinafactory #hairtools #exhibitions #unboxing #newstyle #professionallife #newproduct #HairDryerFactory #HairDryermanufacturer #hairbeauty #fashionstyle #makeupshorts #dryer

0 notes

Text

Explore Yuken Pv2r Series Vane Pumps With Shriank

When it comes to hydraulic systems, efficiency and reliability are paramount. The Yuken hydraulic pump PV2R Series is a stellar example of high-performance hydraulic pumps that deliver consistent and robust performance. We at ShriAnk offer a comprehensive range of Yuken PV2R Series Vane Pumps that not only match but exceed expectations in various industrial applications.

What Makes Yuken PV2R Series Vane Pumps Stand Out?

The Yuken PV2R Series Vane Pumps are renowned for their durability, high efficiency, and ability to handle high pressures up to 210 BAR (3000 PSI). These pumps are integral to numerous industrial machines, including plastic injection molding machines, hydraulic presses, and tractor backhoe loaders, among others. The versatility and reliability of these pumps make them a preferred choice for industries that demand precise and powerful hydraulic solutions.

A Perfect Replacement Solution

At ShriAnk, under our HYDRANK brand, we specialize in providing one-to-one replacements for Yuken Single Vane Pumps and Double Vane Pumps. Our 12 vane designs are compatible with Yuken’s PVR, PVM, and PV2R Series Pumps, ensuring seamless integration and minimal downtime. Whether you need a replacement for a PV2R 1 pump or a PV2R 34 pump, we have you covered with our HYDRANK equivalents that are always in stock.

Why Choose HYDRANK Pumps?

Direct Compatibility: HYDRANK pumps are designed to directly replace Yuken PV2R Series Vane Pumps. This ensures that there is no need for modifications or adjustments during installation.

High Efficiency: Our pumps maintain the high-efficiency standards set by Yuken, ensuring optimal performance in your hydraulic systems.

Cost-Effective: HYDRANK pumps are competitively priced, providing a cost-effective alternative without compromising on quality or performance.

Minimal Downtime: With a comprehensive stock of pumps and spare parts, we ensure that your operations face the least downtime during replacements.

Types Of Yuken PV2R Series Vane Pumps And Their HYDRANK Equivalents

Yuken Pump PV2R 1

The Yuken Pump PV2R 1 is a versatile and efficient option for various hydraulic applications. Our H-PV2R 1 pump matches its specifications with a maximum pressure of 210 BAR and a speed of 1800 RPM. This pump is particularly suitable for use in plastic injection molding machines and hydraulic presses. The high-pressure tolerance and reliable performance make it a perfect replacement for the Yuken hydraulic pump PV2R 1, ensuring that your machinery operates smoothly without any disruptions.

Yuken Pump PV2R 2

For those using the Yuken Pump PV2R 2 , our H-PV2R 2 pump offers a seamless replacement. It is designed to deliver the same performance standards with easy availability to ensure your machinery remains operational. This pump is ideal for hydraulic bailing presses and fly ash brick-making machines, where consistent pressure and flow are crucial. With our Yuken hydraulic pump PV2R 2, you can expect minimal downtime and sustained efficiency, making it a reliable choice for high-demand applications.

Yuken Pump PV2R 3

The H-PV2R 3 pump is our direct replacement for the Yuken Pump PV2R 3 . It maintains the high efficiency and reliability needed for demanding industrial applications such as hydraulic bending machines and tractor-backhoe loaders. The robust design and precise engineering of the Yuken hydraulic pump PV2R 3 ensures that it can handle intense workloads with ease, providing a cost-effective and efficient solution for your hydraulic systems.

Yuken Pump PV2R 12

Our H-PV2R 12 pump stands in for the Yuken Pump PV2R 12 , ensuring your hydraulic systems operate at their peak with minimal downtime and maximum efficiency. This pump is particularly effective in applications where high performance and reliability are paramount, such as in complex hydraulic press operations. The Yuken hydraulic pump PV2R 12 offers the same high standards of performance, making it an excellent replacement that guarantees seamless integration and continued productivity.

Yuken Pump PV2R 13

With the H-PV2R 13 pump, you get a direct replacement for the Yuken Pump PV2R 13 . It provides the same robustness and performance for your hydraulic needs, making it suitable for a wide range of applications, including heavy machinery and industrial automation systems. Yuken hydraulic pump PV2R 13 is designed to ensure longevity and reliability, helping you maintain consistent operations and reduce maintenance costs.

Yuken Pump PV2R 23

The H-PV2R 23 pump from HYDRANK is designed to replace the Yuken Pump PV2R 23 . It offers high performance and reliability in various industrial applications, including hydraulic presses and injection molding machines. The Yuken hydraulic pump PV2R 23 pump’s ability to handle high pressure and speed ensures that your machinery operates efficiently, providing a dependable solution for your hydraulic systems.

Yuken Pump PV2R 33

For those using the Yuken Pump PV2R 33 , our H-PV2R 33 pump is the ideal replacement. It ensures consistent and efficient operation of your hydraulic systems, making it suitable for use in heavy-duty industrial equipment. The Yuken hydraulic pump PV2R 33 pump’s durability and high performance make it a cost-effective choice, helping you maintain high productivity levels without the need for frequent replacements or repairs.

Yuken Pump PV2R 24

Our H-PV2R 24 pump provides a direct and efficient replacement for the Yuken Pump PV2R 24 . It maintains high standards of performance and durability, making it suitable for demanding applications such as hydraulic bailing presses and fly ash brick-making machines. Yuken hydraulic pump PV2R 24 pump’s robust design ensures that it can withstand high pressures and deliver consistent performance, helping you achieve optimal results in your operations.

Yuken Pump PV2R 34

The H-PV2R 34 pump is our replacement for the Yuken Pump PV2R 34 . It is designed to meet the rigorous demands of your hydraulic systems with ease. This pump is ideal for applications requiring high reliability and efficiency, such as hydraulic presses and bending machines. Yuken hydraulic pump PV2R 34 pump’s advanced design and engineering ensure that it delivers consistent performance, reducing downtime and maintenance costs.

Applications of Yuken PV2R Series Vane Pumps

The Yuken Pumps PV2R Series are highly utilized across a range of industrial machines due to their superior performance and reliability. Here are some of the common applications:

– Plastic Injection Molding Machines: These pumps provide the necessary pressure and flow for precise molding operations.

– Hydraulic Presses: Essential for delivering consistent force in various pressing applications.

– Hydraulic Bailing Presses: Used in recycling and waste management, these pumps ensure efficient baling processes.

– Hydraulic Bending Machines: They enable accurate and powerful bending operations in metalworking.

– Fly Ash Brick-Making Machines: These pumps are critical in ensuring the consistent quality and production rate of bricks.

– Tractor Backhoe Loaders: Providing the hydraulic power needed for efficient digging and loading operations.

Why Partner with ShriAnk for Your Hydraulic Needs?

Partnering with ShriAnk means choosing reliability, efficiency, and a commitment to quality. Our HYDRANK brand pumps are engineered to offer a perfect replacement solution for Yuken PV2R Series Vane Pumps. We ensure that our pumps not only match the specifications of Yuken pumps but also provide additional benefits such as cost savings and reduced downtime.

In conclusion, if you are looking for a reliable, efficient, and cost-effective solution for replacing your Yuken PV2R Series Vane Pumps, look no further than ShriAnk’s HYDRANK brand. Our extensive range of pumps ensures that you can find the perfect match for your hydraulic system needs, maintaining the performance and reliability you expect. Explore our offerings today and experience the difference that HYDRANK can make in your industrial applications.

0 notes

Text

Quality Carpet Cleaning Solutions in Penrith

Carpets are a staple in many homes, providing warmth and comfort underfoot. But they can also be magnets for dirt, allergens, and stains. In Penrith, a region known for its dynamic weather, keeping carpets clean is essential. This article explores quality carpet cleaning solutions in Penrith, emphasizing why professional cleaning is crucial and offering tips for maintaining pristine carpets.

The Importance of Quality Carpet Cleaning

Health Benefits

Reducing Allergens

Carpets can trap allergens like dust, pollen, and pet dander. Regular cleaning reduces these irritants, helping those with allergies or asthma breathe easier. A clean carpet means a healthier home environment.

Preventing Mold Growth

Penrith’s climate can be humid, creating a breeding ground for mold in dirty carpets. Quality cleaning removes moisture and dirt, preventing mold and mildew from taking hold and spreading.

Aesthetic Benefits

Prolonging Carpet Life

Regular cleaning removes dirt and debris that can wear down carpet fibers, extending the life of your carpets. Think of it like routine maintenance for your car – essential for longevity.

Enhancing Home Appearance

Clean carpets make your home look and feel fresh. Stains and grime are unsightly, and a professional clean can revive your carpet’s original beauty, making your home more inviting.

Environmental Benefits

Eco-friendly Cleaning Products

Many professional carpet cleaners in Penrith use eco-friendly products that are safe for the environment and your family. These products are effective yet gentle, avoiding harsh chemicals that can harm the planet.

Sustainable Cleaning Practices

Quality carpet cleaning services often employ sustainable practices, such as using energy-efficient machines and water-saving techniques, reducing the overall environmental impact.

Common Carpet Cleaning Methods

Hot Water Extraction

How It Works

Hot water extraction, or steam cleaning, uses hot water mixed with cleaning agents. This solution is injected into the carpet and then extracted along with dirt and debris.

Pros and Cons

Pros: Deep cleans, removes tough stains, and kills bacteria. Cons: Longer drying time and higher cost.

Dry Cleaning

How It Works

Dry cleaning involves using cleaning solvents and minimal moisture. The solvents break down dirt, which is then vacuumed away.

Pros and Cons

Pros: Quick drying time and effective for surface cleaning. Cons: May not remove deep-seated dirt.

Steam Cleaning

How It Works

Steam cleaning uses steam to loosen dirt from carpet fibers. It’s often confused with hot water extraction but uses less water.

Pros and Cons

Pros: Effective at killing germs and allergens. Cons: May not be suitable for all carpet types and can be more expensive.

Bonnet Cleaning

How It Works

Bonnet cleaning involves a rotating brush immersed in cleaning solution that scrubs the carpet surface, ideal for maintenance cleaning.

Pros and Cons

Pros: Quick and less expensive. Cons: Doesn’t clean deeply and can push dirt deeper into the fibers.

Choosing the Right Carpet Cleaning Service in Penrith

Reputation and Reviews

Look for companies with strong reputations and positive customer reviews. Word of mouth and online testimonials can provide insights into the quality of service.

Services Offered

Ensure the company offers the specific services you need, whether it’s stain removal, pet odor elimination, or eco-friendly cleaning options.

Pricing and Packages

Compare pricing and packages. Look for transparency in pricing and what each package includes. Sometimes, the cheapest option isn’t the best value.

Customer Service

Good customer service is crucial. Choose a company that is responsive, professional, and willing to answer your questions and address concerns.

Benefits of Professional Carpet Cleaning

Deep Cleaning

Professionals have the tools and expertise to deep clean carpets, removing dirt, allergens, and stains that regular vacuuming can’t handle.

Time-saving

Hiring professionals saves you time and effort. Carpet cleaning can be labor-intensive, and professionals can do it more efficiently.

Expertise and Experience

Experienced cleaners know how to handle different types of carpets and stains, ensuring effective cleaning without damaging your carpet.

DIY Carpet Cleaning Tips

Regular Vacuuming

Vacuuming regularly prevents dirt from embedding into the carpet fibers, making professional cleanings more effective and less frequent.

Spot Cleaning

Address spills and stains immediately with spot cleaning to prevent them from setting. Use appropriate cleaners for different types of stains.

Using the Right Cleaning Products

Choose cleaning products that are safe for your carpet type and the environment. Avoid harsh chemicals that can damage fibers and affect indoor air quality.

Eco-friendly Carpet Cleaning Solutions

Green Cleaning Products

Opt for green cleaning products that are biodegradable and non-toxic. These products clean effectively without harming the environment.

Energy-efficient Machines

Professional services often use energy-efficient machines that consume less power, contributing to environmental conservation.

Waste Reduction Practices

Look for services that prioritize waste reduction, such as recycling water and minimizing the use of disposable cleaning materials.

Understanding Carpet Cleaning Costs

Factors Affecting Cost

Several factors affect carpet cleaning costs, including the size of the area, the type of carpet, the cleaning method used, and the level of dirtiness.

Average Price Range in Penrith

In Penrith, professional carpet cleaning typically ranges from $25 to $75 per room, depending on the factors mentioned above.

Value for Money

While cost is important, consider the value of the service. A higher upfront cost might save money in the long run by extending the life of your carpets.

Carpet Maintenance Tips for Longevity

Regular Cleaning Schedule

Stick to a regular cleaning schedule to keep carpets looking their best. Professional cleaning once a year is a good rule of thumb for most households.

Protecting High-Traffic Areas

Use rugs or runners in high-traffic areas to protect carpets from wear and tear. These can be easily cleaned or replaced.

Dealing with Stains Immediately

Tackle stains as soon as they happen to prevent them from setting. Blot, don’t rub, to avoid spreading the stain.

Conclusion

Quality carpet cleaning is essential for maintaining a healthy, attractive, and sustainable home in Penrith. By understanding the benefits of professional cleaning, the different methods available, and how to choose the right service, you can keep your carpets in top condition. Regular maintenance and eco-friendly practices further enhance the longevity and appearance of your carpets, ensuring a comfortable living space for years to come.

0 notes

Text

Looking for precision mechanical components in China? Look no further than Hsmolds.net. With a reputation for quality and reliability, Hsmolds offers a wide range of precision mechanical components to suit your needs. From CNC machining to injection molding, they have the expertise to deliver top-notch products at competitive prices. Explore their catalog today for your manufacturing needs.

0 notes

Text

China Sanshun’s She360hd Nylon Cable Injection Molding Machine is designed for nylon cable tie manufacturing. It features a progressive auto grease lubrication system for optimal performance. The precise screw system and PID temperature control gives accuracy and efficiency. The hopper sliding arrangement simplifies material removal.

Contact us today for more information and latest pricing.

#high speed machine#led bulb cover making injection blow machine#injection blow molding machine#plastic auxiliary machine#injection molding machine

0 notes

Text

Plastic Injection Molding Machine Market; Size, Share, Latest Trends, and Growth Research Report 2024-2036

A comprehensive analysis of the “Plastic Injection Molding Machine Market; Size, Share, Latest Trends, and Growth Research Report 2024-2036” provides an accurate overview and thorough analysis of the market industries in the present and the future. This report provides a comprehensive overview of the market, including current market trends, future projections, and an in-depth analysis of the major players in the industry. It provides a comprehensive overview of the market, including current market trends, future projections, and an in-depth analysis of the major players in the industry.

Request Free Sample Copy of this Report @

https://www.researchnester.com/sample-request-6007

Report findings provide valuable insights into how businesses can capitalize on the opportunities provided by these dynamic market factors. It also provides a comprehensive overview of the major players in the industry, including their product offerings, contact and income information, and value chain optimization strategies. Furthermore, it offers an in-depth analysis of the leading businesses in the industry based solely on the strength of their business plans, product descriptions, and business strategies.

Key Findings

Plastic Injection Molding Machine Market has experienced significant growth in recent years, driven by factors such as increasing consumer demand and technological advancements.

The market segmentation analysis revealed several key segments, including Machine Type, Application each with unique characteristics and growth potential.

Regional analysis highlighted the strong performance of Plastic Injection Molding Machine Market in regions such as North America, Europe, and Asia-Pacific, with emerging markets showing promising growth opportunities.

Analyzing the Plastic Injection Molding Machine Market

A thorough understanding of the Plastic Injection Molding Machine Market will provide businesses with opportunities for growth such as customer acquisition, enhancements to their services, and strategic expansions.

By incorporating market intelligence into their operations, businesses can anticipate changes in the economy, assess the effect these factors may have on their operations, and create plans to counteract any negative effects.

Market intelligence helps organizations stay ahead of the curve through insights into consumer behavior, technological advancements, and competitive dynamics.

Using Plastic Injection Molding Machine Market data can provide organizations with an edge in the competitive market and establish prices and customer satisfaction levels.

Request for customization @

https://www.researchnester.com/customized-reports-6007

In a dynamic market environment, business validation helps companies develop business plans and assures their long-term survival and success.

What are the most popular areas for Plastic Injection Molding Machine Market?

The North American continent includes Canada, Mexico, and the United States.

The European Union is made up of the United Kingdom, France, Italy, Germany, the Republic of Turkey, and Russia.

The Asia-Pacific region is comprised of China, Japan, Korea, India, Australia, Vietnam, Thailand, Indonesia, and Malaysia.

The region of Latin America, which includes Brazil, Argentina, and Columbia

In addition to Africa, the Middle East includes South Africa, Egypt, Nigeria, Saudi Arabia and the United Arab Emirates.

Report highlights include:

There is a 360-degree synopsis of the industry in question in this study, which encompasses all aspects of the industry.

The report presents numerous pricing trends for the keyword.

Additionally, the report includes some financial data about the companies included in the competitive landscape.

The study enumerates the key regulatory norms governing the keyword market in developed and developing economies.

Additionally, the keyword report provides definitions of the market terms referred to in the document for the sake of convenience.

Future Potential

In the keyword research report, various primary and secondary sources are used to describe the methodology of conceptualizing the study. It has been discussed in the study what the scope of the report is and what elements it contains in terms of the growth spectrum of the keyword. The document also includes financial data of the companies profiled, along with the current price trends of the keyword.

Access our detailed report at@

https://www.researchnester.com/reports/plastic-injection-molding-machine-market/6007

0 notes