#Animal Feed Pellet Machine

Text

HMLH320 Feed Pellet Mill

Feed Pellet Mill Introduction

The HMLH320 feed pellet maker is one of the indispensable pieces of equipment in the feed mill plant. It can be used alone or in the feed pellet production line. The feed pellet maker machine can make various animal feeds: livestock feed, such as horse feed, pig feed, and rabbit feed; poultry feed, such as chicken feed, duck feed, goose feed, and bird feed; ruminant…

View On WordPress

0 notes

Text

Agriculture Equipments Manufacturers in India | Farm Equipments | Garden Equipments - Vinglob Greentech

Agriculture Equipments Manufacturers in India | Farm Equipments | Garden Equipments - Vinglob Greentech

Elevate Your Farming and Gardening Efforts with Vinglob Greentech: Leading Agriculture Equipments Manufacturers in India

Agriculture is the backbone of India, and the role of modern equipment in enhancing productivity and sustainability cannot be overstated. Vinglob Greentech stands at the forefront as one of the premier Agriculture EquipmentsManufacturers in India, dedicated to revolutionizing farming and gardening practices across the nation.

The Significance of Agriculture Equipment in India

India's agriculture sector is diverse and complex, encompassing a wide range of crops and practices. Whether you are a smallholder farmer or part of a large agribusiness, the right agriculture equipment can make a world of difference. Here's why agriculture equipment is crucial in India:

Enhanced Productivity: Modern agriculture equipment significantly boosts productivity, allowing farmers to produce more with less manual labor.

Time Efficiency: Farming equipment saves time, enabling farmers to focus on multiple tasks and achieve higher crop yields.

Cost Efficiency: By reducing labor costs and increasing output, agriculture equipment contributes to cost-efficiency, benefiting both farmers and consumers.

Sustainability: Many modern farming equipment and techniques are designed to be environmentally friendly, reducing the environmental impact of agriculture.

Precision Agriculture: Equipment like precision seeders and harvesters enables precise planting and harvesting, optimizing resource utilization.

Vinglob Greentech: Pioneering Agriculture Equipment Manufacturers in India

Vinglob Greentech is a name synonymous with innovation, quality, and reliability in the field of agriculture equipment manufacturing. Here's why they are the preferred choice for farmers and gardeners across India:

Wide Range of Equipment: Vinglob Greentech offers an extensive range of agriculture equipment, catering to diverse farming and gardening needs. Whether you're cultivating crops, tending to a garden, or managing a sprawling farm, they have the right tools for you.

Innovative Solutions: The company is committed to staying at the forefront of agricultural technology. They continuously innovate and adapt their equipment to meet the evolving needs of Indian farmers.

Quality Assurance: Vinglob Greentechplaces a premium on quality. Their equipment undergoes rigorous testing and quality checks to ensure durability and performance in the field.

Affordability: The company believes that modern agriculture equipment should be accessible to all. They offer competitive pricing without compromising on quality.

Dedicated Customer Support: Vinglob Greentech is not just about selling equipment; they are committed to providing comprehensive support to their customers. From product selection to after-sales service, they are there every step of the way.

Agriculture Equipment Offerings

Vinglob Greentech's product portfolio spans a wide spectrum of agriculture and gardening equipment. Here are some of their key offerings:

Tractors and Tillers: Vinglob Greentech manufactures a range of tractors and tillers, from compact models suitable for small farms to powerful tractors for large-scale agriculture.

Seeders and Planters: Their precision seeders and planters ensure accurate and efficient planting, reducing seed wastage and optimizing crop yield.

Harvesters: The company offers a variety of harvesters for different crops, making the harvesting process faster and more efficient.

Irrigation Equipment:Vinglob Greentech provides a range of irrigation solutions, including drip irrigation systems, sprinklers, and pumps, to ensure optimal water management.

Garden Tools: For gardening enthusiasts, they offer a selection of garden tools and equipment, including lawnmowers, hedge trimmers, and more.

Cultivators and Ploughs: Their cultivators and ploughs are designed to prepare the soil for planting, ensuring a healthy and productive crop.

Embrace Modern Agriculture with Vinglob Greentech

As India's agriculture sector continues to evolve, embracing modern farming and gardening practices becomes increasingly important. Vinglob Greentech empowers farmers and gardeners with high-quality, innovative agriculture equipment that enhances productivity, sustainability, and profitability.

Whether you're a traditional farmer looking to modernize your operations or a gardening enthusiast seeking efficient tools, Vinglob Greentech has you covered. Contact them today to explore their wide range of agriculture and gardening equipment and embark on a journey towards more productive and sustainable farming and gardening practices. Elevate your agricultural endeavors with Vinglob Greentech, your trusted partner in agriculture equipment manufacturing in India.

For More Information

https://www.vgtindia.in/products.php

A/2, Bharat Small Industrial Estate, Pin Code :- 382445

B/H. Gujarat Offset, Vatva, Ahmedabad,

7984030141 | 9909793721

#Agriculture Equipments Manufacturers India#Agriculture Equipments Manufacturers#Agriculture Equipments in India#Agriculture Equipments#power weeder#power weeder manufacturers#business#health & fitness#animal feed pellet machine manufacturers in india#animal feed pellet machine

0 notes

Text

Deekay Overseas is a leading manufacturer and exporter of animal feed pellet machine. We offer a wide range of pellet machines in various sizes and models to suit the needs of different types of animals. Our machines are designed to produce high-quality feed pellets with minimum labor and cost. The machines are also equipped with advanced safety features to ensure the safety of operators. Deekay Overseas also offers after-sales service and maintenance of their machines.

1 note

·

View note

Text

#✅GROW YOUR BUSINESS WITH Sanjivani Agro Machinery#👉👉 Sanjivani Agro Machinery#WE ARE THE MANUFACTURE & EXPORTER OF ANIMAL FEED MAKING MACHINE !#Sanjivanii Agro Machinery & Vidarbha Sales#One of the leading manufacturers and exporters of the Cattle Feed Machine#Poultry Feed Machine#Biomass Pellet Machine#Floating Fish Food#Organic Fertilizer Machine etc.#- Customer Care Support#- Safe & Trusted Transport#- 100% Original Product -#All India Delivery Available#More Details: www.sanjivanii.com#Youtube Link: https://bit.ly/2AKrcz0#Call: +91 72190 30002#smallbusinessidea2022#manufacturingbusinessidea#animalfeedmachine#animalfeed#animalfeedpelletmachine#animalfeedmachinepriceindia#agromachine#fishfeedmachine#cattlefeedpelletemakingmachine#pelletmachine#agromachinenagpur#agromachinemanufactures#cyclonegrinder#poultryfeed

2 notes

·

View notes

Text

youtube

Feed pellet making machine,chattle animal feeding machine,animal feed pellet making machine.

#Youtube#youtube shorts#youtube video#laxmi enterprises is the leading manufacturer#laxmienterprises#Feed pellet making machine#chattle animal feeding machine#animal feed pellet making machine.

0 notes

Text

Add green roughage to grass chickens

With the continuous rise of feed prices, it is necessary and feasible to add a certain amount of green roughage to the diet of grass chickens, but the following issues need to be paid attention to during the addition process:

Different feeding methods are adopted according to different growth stages of grass chickens. Chickens are fed with concentrate, and about 20% of chopped green vegetables can be added to the concentrate from the age of 4 days. Due to the small capacity of the esophagus, it should be fed less frequently, so that the chicks can form a good conditioned reflex for food, and lay the foundation for them to forage grassy food in the pasture after dewarming.

When the grass chickens are 36 to 80 days old, grazing can be adopted if conditions permit. During the grazing period, pay attention to supplementing the grass chickens with full-price ingredients in the morning and evening. If there is no condition for stocking flocks, green roughage can be added to the diet at a ratio of 1:1. The feeding method is to feed a single full-price feed to the chickens first, and then put the same amount of green roughage in the feeding bucket after 1 hour, so that the chickens can eat freely. The feeding amount of green roughage can be appropriately reduced 15 days before the grass chickens are released to help shorten the fattening period and increase the daily weight gain. And you can use the animal feed machine.

The use of green roughage should be combined in a variety of ways to ensure quality. None of the green forages have comprehensive nutritional value. If they are matched in various ways, they can complement each other, improve the utilization rate of various amino acids in the feed, and reduce the cost of the feed. For example, legume feed is matched with grass feed, aquatic feed is matched with sweet potato vine powder or flour, but straw powder should not be matched with husk, rice husk, and bran.

Pay attention to the processing and modulation of green roughage. The green roughage is best to be chopped, beaten and mixed with the concentrated feed. If it is stored for too long or is simmered, it may cause nitrite poisoning or even death of grass chickens. Forages such as sweet potato vine, bitter vine, peanut vine, alfalfa and champagne grass should be dried immediately after harvesting, and their integrity should be kept as far as possible.

Ensure the uniform supply of green roughage throughout the year. Affected by the seasons, the supply of green forage in many areas in our province is not balanced throughout the seasons, but as long as the planning of forage planting is strengthened, this problem can be solved. For example, plant chicory, Rumex, and alfalfa in spring; plant champagne grass and amaranth in early summer; plant vetch, winter cabbage, and cabbage in winter.

Any questions, you can come to lima contact.

#lima contact#lima feed machine#animal feed machine#lima machinery#chicken feed pellet machine#chicken farm

1 note

·

View note

Note

Reminds me at animal sanctuaries and zoos there's quarter machines to get pellets or seeds for animals you can hand feed and just imagining a little quarter machine for pumpkin seeds that pours in a cup we hand to your persona

116 notes

·

View notes

Text

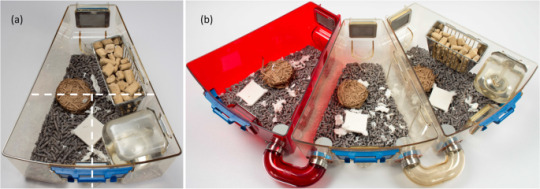

Upgrading Lab-mouse cages

This topic goes close to me bc I work in a lab and have hours every day to think about what I can do for these tiny creatures

Lab mice are kept in these cages by standard:

The minimum legal enrichment (at least in germany) is a nest, something to climb, something to chew, and a way to socialize. This cage has a hut for a nest, the top bars for climbing and the hardened pellets for chewing

In my opinion that's both unfitting and not enough. There's some very simple changes and a lot of bigger/harder changes:

Simple changes:

Using wooden or paper huts. It's commonly believed that mice can't see red, but in reality they will always choose darker colours and more natural materials as hides

lowering the light in one part of the cage, eg simple cage sleeves, lowering the general room light, shading the rack

raising the temperature. Mouse are generally kept at 21 - 24°C, but really prefer 26 - 30°C

scanning the room for ultra sounds

scattering some grains for foraging (this is also perfect for training the mice to make health checks easier)

Other still very simple changes:

adding nesting materials. Mouse prefer paper scraps, paper towels, etc, but there's also cotton squares and wood wool commercially available

adding wood for chewing. Again there's many options ranging from wooden bricks over wooden huts to whole branches

adding a running plate or wheel (I know running plates are said to cause spinal deformity, but in my experience that is a very low chance as opposed to the negative effects no movement has)

adding more bedding so digging is easier

adding tubes, boxes, swings and climbing structures

Changes that get closer to pet keeping:

add diggable bedding for builing nests and tunnels

add more huts. More! Mooore! (seriously mouse love a cluttered space and feel most comfortable walking along walls)

add a second layer (most easy part is just wedging a wooden board in there) and raising the top bars (there's raised cage tops for more height)

adding a maze/labyrinth to allow the mice to compartimentalise their cage/hide from light, sounds, movement, etc

stopping to feed ad libitum. In comercial setting, this can be done with feeding machines, privately this can be done by feeding like any other pet (adding a bowl of fresh food twice a day and removing after an hour or two)

scatter feeding instead of having the food in a rack

adding a digging box

Changes for pet keeping:

Going at least one, better two sizes up with the cages

adding toys

adding more mice to the group (in research most mice are kept in groups of 2 to 5. Mice prefer bigger groups though (plus "two" is a pair, not a group))

adding a big, big layer of bedding (see previous category)

adding toys, including food toys, smell toys, etc

giving food treats like yogurt, comercial treats, varied food, dead or life insects (mice are good hunters!)

feeding grains and similar (if you're unsure about a balanced diet, feeding grains additionally to pellets is totally fine)

adding a bigger wheel or running plate (a wheel is better, if you can provide a good one with appropriate size)

offer a free run time. This could for example be in a bath tub. Lay it out with linen or carpets, fill the tub with toys, treats and cardboard boxes, and offer the mice to go there (eg by builing a stairwell, or by training them "taxi" with a travel box)

spend regular time with them to aclimate them to humans

Changes for a near perfect enclosure:

Upgrate to an aquarium with a grid top

add more climbing options. Like way more!

Put heavier huts on stilts

Add even more tunnels

provide fresh food

change up their enrichment (eg digging box, swimming pool, fresh plants, offer tea additionally to water)

All these images have good and bad items, and imo all enclosures can be adapted to the housed animals needs. I'll try to add credit, but please message me if you have questions about specific images

I was about to add sources but found some great in a single site: here

I also always recommend bin cages as they are cheap and very very customisable. The best example I found is this one

#long post#mouse care#mice#rodents#pet enclosure#my post#lab mice#enrichment#idk I have no based opinions about beddings#this post is not quite yet what I want it to but we're getting there#feel free to message me about any of this#I love talking about mice#I'll try to add some sources#lowkey proud of my first post#pls support me by reblogging and commenting

18 notes

·

View notes

Text

Cost of Cattle Feed Plant

Establishing a cattle feed plant is a profitable business venture, especially in countries like India, where agriculture and animal husbandry form a large part of the economy. With the growing demand for milk and meat, the need for high-quality cattle feed is on the rise. However, understanding the financial aspects, especially the cost of setting up a cattle feed plant, is crucial for anyone looking to venture into this business.

In this blog, we will discuss the factors that influence the cost of a cattle feed plant, the role of why choosing the right cattle feed machine manufacturer in India is critical for success.

1. Key Factors Influencing the Cost of a Cattle Feed Plant

The overall cost of setting up a cattle feed plant can vary significantly depending on several factors, including:

a. Plant Size and Capacity

One of the primary factors influencing the cattle feed plant cost in India is the size and production capacity of the plant. A smaller plant with a production capacity of 1 to 2 tons per hour will cost significantly less than a large-scale plant that can produce 10 tons or more per hour.

b. Location and Infrastructure

The geographical location of the plant also plays a critical role in determining its cost. Urban locations tend to have higher land and labor costs compared to rural areas. Infrastructure, including access to water, electricity, and transportation, also adds to the cost.

c. Machinery and Equipment

The type and quality of machinery used in the cattle feed plant significantly influence the cost. A reliable cattle feed plant manufacturing company can offer various machinery types, including mixers, grinders, pellet machines, and more, each with varying price points. Opting for automated machinery can reduce labor costs but will require a higher initial investment.

d. Raw Materials

The availability and cost of raw materials such as maize, barley, wheat bran, and soybean meal can also affect the overall expenditure. In India, raw material prices may fluctuate depending on seasonality, transportation costs, and regional availability, directly impacting the cost of production.

e. Labor Costs

Labor costs vary widely based on the location of the cattle feed plant. Urban areas generally have higher labor rates compared to rural areas. Additionally, the complexity of the machinery used in the plant may require skilled labor, further increasing costs.

2. The Role of a Cattle Feed Plant Manufacturing Company

Choosing a reliable cattle feed plant manufacturing company is one of the most critical decisions you’ll make when setting up your cattle feed business. The right manufacturer will provide durable, high-quality machinery that ensures efficient production and minimizes downtime.

A trusted cattle feed plant manufacturing company typically offers comprehensive services, including:

Customized plant designs based on specific production needs.

Installation and maintenance of machinery.

Providing operator training to ensure smooth operations.

Offering warranty and after-sales services.

Investing in a reputable cattle feed machine manufacturer in India can ultimately save you money in the long run by reducing equipment failure rates and ensuring maximum productivity.

3. Cattle Feed Plant Cost in India: A General Overview

The cattle feed plant cost in India can vary depending on several factors mentioned earlier. However, to give you a general idea, the cost of setting up a small to medium-sized plant (with a capacity of 1 to 5 tons per hour) ranges between ₹20 lakhs to ₹1 crore. For larger plants with higher production capacities, the cost can go up to ₹2 crores or more.

Here’s a rough breakdown of the major cost components:

Land and Infrastructure: Depending on the location, this can range from ₹5 lakhs to ₹50 lakhs.

Machinery and Equipment: A complete set of machinery, including mixers, grinders, and pellet machines, typically costs between ₹10 lakhs to ₹70 lakhs, depending on the capacity and automation level.

Installation and Commissioning: Setting up the machinery and getting it operational can cost an additional ₹3 lakhs to ₹15 lakhs.

Labor and Operational Costs: These can vary but are an ongoing expense you should account for when planning your budget.

It's essential to work closely with a reliable cattle feed machine manufacturer in India to get an accurate estimate based on your plant size, production capacity, and specific needs.

4. Finding the Right Cattle Feed Machine Manufacturer in India

India is home to several cattle feed machine manufacturers, but selecting the right one requires careful research. Consider the following factors:

Reputation: Check reviews, ask for references, and do thorough research to ensure the manufacturer is reputable and experienced in producing high-quality machinery.

Customization: The manufacturer should be willing to customize the machinery according to your specific needs and production capacity.

After-Sales Service: After-sales service is critical, as it ensures your machinery continues to function optimally. Ensure the manufacturer offers prompt support and warranty services.

Cost and Quality: Strike a balance between cost and quality. Don’t opt for the cheapest machinery available, as it might not be durable or efficient in the long run.

Conclusion

Setting up a cattle feed plant is a significant investment, and understanding the cost dynamics is crucial for success. The cattle feed plant cost in India depends on various factors like plant size, machinery, location, and labor. Partnering with a reliable cattle feed plant manufacturing company can make a considerable difference in the overall profitability of your venture. By carefully planning and making informed decisions, you can establish a successful cattle feed plant that meets the growing demand for high-quality feed in the livestock industry.

0 notes

Text

In modern agricultural production, the choice of fertilizer has a crucial impact on the growth and quality of vegetables. Organic and inorganic fertilizers are two common types of fertilizers with significant differences in composition, mechanism of action, and impact on the environment. This article will discuss the characteristics of these two fertilizers, and introduce the related fertilizer granulator equipment.

Characteristics of organic fertilizer

Organic fertilizers are mainly derived from plant and animal residues, such as compost, green manure and animal manure. These fertilizers are rich in organic matter and microorganisms, which can improve the soil structure and increase the water and fertilizer retention capacity of the soil. The decomposition and nutrient release of organic fertilizer is a slow process, so it is able to provide long-term and stable nutrition for vegetables.

Characteristics of inorganic fertilizer

Inorganic fertilizers, also known as chemical fertilizers, are fertilizers produced by chemical synthesis methods, such as nitrogen, phosphate and potassium. This kind of fertilizer contains a high concentration of essential plant nutrients, which can be quickly absorbed by plants and rapidly promote plant growth. However, long-term use of inorganic fertilizers may lead to deterioration of soil structure and environmental pollution.

Application of fertilizer granulator equipment

In the production process of fertilizer, granulator equipment is indispensable. The following are several types of granulator equipment related to the production of organic and inorganic fertilizers:

1. Flat-Die Pellet Machine: This kind of equipment is suitable for pressing organic fertilizers such as compost and animal manure into pellets, which is easy to apply and improve the uniformity of fertilizers. The Flat-Die Pellet Machine compresses the raw material into particles through physical pressure, which helps to improve the stability and application effect of the fertilizer.

2. Rotary Drum Granulator: Rotary Drum Granulator is suitable for granulating inorganic fertilizers, especially for fertilizers that need to dissolve and release nutrients quickly. This device uses a rotating drum to mix the fertilizer raw material with water to form particles, which are then made into a finished product through a drying and cooling process.

3. Disc Granulator: Disc Granulator is an efficient granulation equipment suitable for the production of organic and inorganic fertilizers. It disperses the raw material into fine particles by rotating disks, which are then made into fertilizer particles through a drying and curing process.

4. Fertilizer Granules Compaction Machine: This machine is suitable for the production of high density fertilizer granules, whether organic or inorganic. The Fertilizer Granules Compaction Machine extrudes the feed stock into pellets by two rolls that rotate in opposite directions, improving the density and efficiency of the fertilizer.

Conclusion

When growing vegetables, the choice of organic or inorganic fertilizer depends on the specific production goals and environmental conditions. Organic fertilizers pay more attention to the long-term health and sustainability of the soil, while inorganic fertilizers quickly provide the nutrients that plants need. Through the use of suitable fertilizer granulator equipment, the application efficiency of fertilizer and the growth quality of crops can be improved, so as to achieve efficient and environmentally friendly agricultural production.

#Flat-Die Pellet Machine#Rotary Drum Granulator#Disc Granulator#Fertilizer Granules Compaction Machine

0 notes

Video

youtube

Complete animal feed pellet machine line: from crushing, mixing, pelletizing, cooling to packaging

0 notes

Text

3-4T/H Feed Pellet Line

What is The 3-4T/H Feed Pellet Line ?

Our 3-4 t/h feed pellet line is suitable for processing various animal feeds, such as chicken feed, poultry feed, goose feed, livestock feed, sheep feed, pig feed, cattle feed, camel feed, horse feed, goat feed, fish feed, shrimp feed, crab feed, aquatic feed, etc.

The main equipment of a complete 3-4 ton per hour feed pellet mill includes a hammer mill…

View On WordPress

0 notes

Text

#Animal Feed Pellet Machine Manufacturers in India#Animal Feed Pellet Machine Manufacturers#Animal Feed Pellet Machine

0 notes

Text

The Future of Livestock: Feed Production Line Innovations

In the fast-evolving world of agriculture, the role of an efficient feed production line cannot be overstated. As the demand for high-quality livestock feed grows, the need for advanced and efficient production processes becomes crucial. A feed production line is the backbone of modern livestock farming, ensuring that animals receive the optimal nutrition they need for growth, health, and productivity.

What is a Feed Production Line?

A feed production line is a series of interconnected machines designed to produce animal feed efficiently. This line includes several stages, from raw material grinding, mixing, and pelletizing to cooling, packaging, and storage. Each stage is meticulously engineered to ensure the feed meets specific nutritional standards, catering to the diverse needs of different livestock.

The Importance of Automation

Automation is at the heart of modern feed production lines. By automating various processes, feed manufacturers can achieve higher efficiency, consistency, and quality. Automation reduces human error, ensures precise mixing of ingredients, and enables the production of feed on a large scale, meeting the ever-increasing demand.

Sustainability in Feed Production

Sustainability is a growing concern in all sectors, and feed production is no exception. Modern feed production lines are now being designed with energy efficiency and waste reduction in mind. By optimizing energy consumption and recycling by-products, feed manufacturers can reduce their environmental impact while maintaining high production levels.

The Role of Technology

Advanced technology is transforming feed production lines. Innovations such as IoT (Internet of Things) sensors and data analytics are enabling real-time monitoring and control of production processes. This ensures that every batch of feed is produced with the highest quality, meeting the specific nutritional needs of livestock.

Challenges and Opportunities

While the benefits of modern feed production lines are clear, there are challenges to overcome. The initial investment in advanced machinery and technology can be high, and operators need to be trained to manage these complex systems. However, the long-term benefits, including increased efficiency, reduced waste, and higher product quality, far outweigh the initial costs.

Conclusion

The feed production line is an essential component of modern agriculture, driving innovation and sustainability in livestock farming. As technology continues to advance, we can expect even more efficient and environmentally friendly production lines in the future, ensuring that our livestock receives the best possible nutrition.

0 notes

Text

Animal Feed Pellet Machines: Revolutionizing Livestock Nutrition and Farm Efficiency

Introduction:

In the dynamic world of agriculture and animal husbandry, efficient feeding solutions are not just beneficial – they’re essential. As farmers and ranchers face increasing pressure to optimize costs, improve animal health, and boost productivity, the animal feed pellet machine emerges as a pivotal technology. This comprehensive guide explores the transformative impact of animal feed…

0 notes

Text

Animal Feed Pellet Machine Manufacturer — Finix Agro Tech

The nutritional value, consistency, and safety of the feed directly impact the health, productivity, and overall well-being of your animals. Enter the Animal Feed Pellet Machine Manufacturer — Finix Agro Tech — a game-changer in the agricultural sector designed to enhance feed efficiency and livestock productivity.

Equipped with robust motors, these pellet machines are engineered for high performance. They efficiently process various raw materials, including grains, oil cakes, and roughages, transforming them into nutrient-rich pellets.

Click here to know more about Animal Feed Pellet Machine.

Finix Agro Tech

Contact: 93613 66651

Webiste: https://finixagrotech.com/

0 notes