#Feed pellet making machine

Text

HMLH678 Feed Pellet Mill

Feed Pellet Mill Introduction

The HMLH678 feed pellet maker is one of the indispensable pieces of equipment in the feed mill plant. It can be used alone or in the feed pellet production line. The feed pellet maker machine can make various animal feeds: Poultry feed, such as chicken feed, duck feed, goose feed, and bird feed; livestock feed, such as horse feed, pig feed Feed, and rabbit feed;…

View On WordPress

0 notes

Text

youtube

Feed pellet making machine,chattle animal feeding machine,animal feed pellet making machine.

#Youtube#youtube shorts#youtube video#laxmi enterprises is the leading manufacturer#laxmienterprises#Feed pellet making machine#chattle animal feeding machine#animal feed pellet making machine.

0 notes

Text

#✅GROW YOUR BUSINESS WITH Sanjivani Agro Machinery#👉👉 Sanjivani Agro Machinery#WE ARE THE MANUFACTURE & EXPORTER OF ANIMAL FEED MAKING MACHINE !#Sanjivanii Agro Machinery & Vidarbha Sales#One of the leading manufacturers and exporters of the Cattle Feed Machine#Poultry Feed Machine#Biomass Pellet Machine#Floating Fish Food#Organic Fertilizer Machine etc.#- Customer Care Support#- Safe & Trusted Transport#- 100% Original Product -#All India Delivery Available#More Details: www.sanjivanii.com#Youtube Link: https://bit.ly/2AKrcz0#Call: +91 72190 30002#smallbusinessidea2022#manufacturingbusinessidea#animalfeedmachine#animalfeed#animalfeedpelletmachine#animalfeedmachinepriceindia#agromachine#fishfeedmachine#cattlefeedpelletemakingmachine#pelletmachine#agromachinenagpur#agromachinemanufactures#cyclonegrinder#poultryfeed

2 notes

·

View notes

Text

Fish Feed Pellet Making Machine Market Outlook, Current and Future Landscape Analysis 2023 to 2033

The global fish feed pellet making machines market is expected to reach US$ 2,167.9 million in 2033, growing at a 5.6% CAGR between 2023 and 2033. The market is expected to reach $1,257.2 million by 2023.

According to FMI, increased exports of fish and other seafood products from various countries around the world are expected to drive market sales. International companies are expected to enter emerging economies in order to capture the overall industry.

Furthermore, rising awareness of the importance of sustainability as well as animal welfare is expected to boost sales of organic farming. As a result, fish farmers use organic farming methods to provide chemical-free and genetically modified products.

The growing consumer preference for organic foods is expected to compel key manufacturers to increase their organic feed production capacity. Other factors that would accelerate market sales include changing eating habits and lifestyles of consumers in both developed and developing countries.

Request a Sample to Obtain Authentic Analysis @

https://www.futuremarketinsights.com/reports/sample/rep-gb-16533

Key Takeaways from the Fish Feed Pellet Making Machine Market Study:

Top 3 countries in the global fish feed pellet making machine market are projected to generate a share of 8% in the next ten years.

The global fish feed pellet making machine market is estimated to be valued at US$ 1,190.5 million by the end of 2022 from a valuation of US$ 1,006.0 million in 2018.

The USA fish feed pellet making machine market is anticipated to generate the lion’s share of nearly 8% by 2033.

Germany fish feed pellet making machine market is predicted to account for a considerable share of about 3% in Europe during the estimated time frame.

In Asia Pacific, India is likely to witness moderate growth and exhibit a CAGR of 3% from 2023 to 2033.

“Key companies in the fish feed pellet making machine market are anticipated to invest huge sums in the manufacturing of dry pelleted fish feed. This type of feed is projected to be extensively used for improving digestibility and balance of nutrients for matching specific needs of various fish species,” says a lead analyst at Future Market Insights.

Competition Landscape: Fish Feed Pellet Making Machine Market

Leading players in the fish feed pellet making machine market are CPM Asia, Andritz Group, Buhler AG, Salmco Ltd., and Zhengchang Group among others. These companies are aiming to strengthen their positions in the global market by launching state-of-the-art equipment. A few other players are striving to generate more shares by joining hands with local companies across the globe.

Get Valuable Insights into Fish Feed Pellet Making Machine Market

FMI, in its new offering, provides an unbiased analysis of the fish feed pellet making machine market presenting historical demand data (2018 to 2022) and forecast statistics for the period from (2023 to 2033). The study divulges compelling insights on the demand for fish feed pellet making machine market based on type (ring die pellet mill, flat die pellet mill), by application (small-scale aquaculture, large-scale aquaculture, others), by sales channel (online, offline), and by region (North America, Europe, Asia Pacific, Latin America, the Middle East and Africa).

For More Information on this Report @

https://www.futuremarketinsights.com/reports/fish-feed-pellet-making-machine-market

Fish Feed Pellet Making Machine Market Outlook by Category

By Type:

Ring Die Pellet Mill

Flat Die Pellet Mill

By Application:

Small-Scale Aquaculture

Large-Scale Aquaculture

Others

By Sales Channel:

Online

Offline

By Region:

North America

Europe

Asia Pacific

Latin America

MEA

RoW

0 notes

Text

I love Warframe, so much.

The super fluid, only touch the ground to start another parkour sequence, the floor is lava, bouncing off walls and flying across rooms and down hallways style of movement.

The >utterly overwhelming< number of weapons available. Primaries range from bows (Paris, Dread) to rocket launchers (ogris) grenade launchers (penta, tonkor), a handheld laser cannon (opticor), spicy bows (Lenz and Bramma are both rocket launchers cosplaying as bows), an 18th century naval cannon (zarr), machine guns with a 200 round magazine (soma prime) and machine guns that get more accurate the longer you fire (Tenora my beloved), innately suppressed smg (baza). You want a chaining lightning gun that will kill the guy you’re aiming at, and the next two rooms of people via daisy chains? Amprex. if you need a tactical weapon for grouping enemies the Mutalist cernos shoots an arrow full of grabby tentacles that brings enemies together for group hugs. Do you need a rifle to hunt cthulu T-Rexes (eidolons)? Rubico (Prime) or, my favorite, Kuva Chakkhurr - a black powder musket that shoots moderately slow projectiles, high skill high reward, you land a shot, it’s gonna feel it. Here’s a goody - Tigris (Prime) - it’s a double barreled shotgun, with a duplex trigger - you squeeze the trigger, it fires one round, you release the trigger, it fires the second! really interesting to play with, though with the changes to shotgun status a few years ago it’s no longer the powerhouse it was, though quite potent. Phenmor is also one of my favorites, a precision semi auto rifle, land a couple headshots to charge it, and it evolves into an archgun (gun for mecha or exosuits, bigger, and badder) that’s basically a minigun. Corinth (prime) is cool, primary fire is crit based shotgun, alt fire shoots an air burst grenade you can manually detonate over enemies heads (prime version, regular corinth is locked at 20m detonation). Kohm is an auto shotgun that spoils up like a minigun, the higher the spool the more pellets it shoots, very ammo hungry, but man if it isn’t satisfying to point down a hallway and watch it fill with red mist. Astilla is a shotgun that shoots glass slugs that explode on impact. Arcs Plasmor shoots solid walls of energy. like straight up, point down hallway, and you shoot a bright blue (ur energy color) brick wall of plasma. you can’t miss. Simulor is a gun that shoots miniature black holes. Trumna charges it’s alt fire with the literal souls of the enemies you kill. Shedu and Bubonico are the weapon arm cannons of sentient (enemy robot faction) that we ripped off and stole.

secondaries are have a bit less variety, but we’ve still got oodles of goodies

Pandero, a pocket sniper rifle, this lil handcannon is hella accurate for reaching out to touch someone, and alt fire dumps the entire magazine in an automatic burst. Laetum is the cooler pandero, land a few headshots and it evolves into an automatic assault rifle. Lex (Prime) was my starchart clearing gun, back in the day. space deagle. Nukor (and it’s cooler older sister Kuva Nukor (Kukor)) are similar to the amprex in that they chain to enemies, however they also have the quirk of having the highest critical damage in the game, with the lowest critical chance. (there’s shenanigans you can do to force them to crit, making them devestating). Pyrana (Prime) is an auto shotgun, it’s got high spread and high rate of fire, but get in their face and drop mag and see the magic. Zakti (Prime) shoots small needles that explode in clouds of aoe gas after a moment, really good for priming status effects and swapping to melee or primary to take advantage of. Euphona Prime - look, i love it, it’s not great, you gotta build it exclusively for the slug firemode or for the shotgun fire mode. it’s really cool, you should try it if you can, but it’s solidly just okay. Sepulcrum feeds on the souls of its victims to power its alt fire, and it’s just a massive beefy fuckin pistol straight out of 40K. Tenet Spirex force procs impact, and with the hemorrhage mod you can guarantee you turn some of those impact procs into bleed procs for DOT damage. Athodai is straight up like retro sci-fi laser pistol, it shoots beams, and alt fire has a big burst of energy aoe in front of you. Twin Kohmak are like the kohm, but smaller, and akimbo, for pocket dakka. Twin Grakata MOAR DAKKA. A beloved meme gun in the warframe community. just two fuckin bullet hoses that will eat your ammo faster than you can find it. truly one of the guns of all time, and a joy to fire.

and don’t think for a moment i’m going to forget about melees lmao.

we got Nikanas (space katana - nikana (prime) , skiajati ), we got greatswords(Gram (prime), Galatine (prime)), we got throwing glaives(Glaive(prime) Xoris), we got gun blades (like think those bizarre renaissance era swords with guns built into the hilts? got it? yeah, those, but space-y. redeemer (prime), sarpa), we have claws (venka) , we have sword & board (silva & aegis) scythes (reaper prime), hammers (heliocor, jat kittag), dual blades up the wazoo, single daggers, dual daggers, fist weapons, fist and feet weapons, war fans (quassus, arum spinosa), staves (Bo, pupacyst), tonfa (kronen), a gigantic saw (ghoulsaw), rapiers (endura, ), blade & whips (atterax, lacera)

#warframe#long post#totally normal about this game#also i own almost every weapon#i’m missing the most recent 5

28 notes

·

View notes

Text

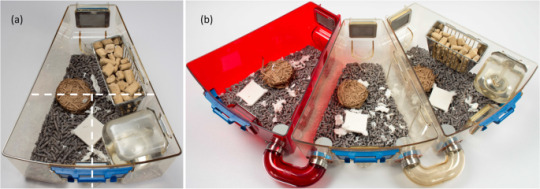

Upgrading Lab-mouse cages

This topic goes close to me bc I work in a lab and have hours every day to think about what I can do for these tiny creatures

Lab mice are kept in these cages by standard:

The minimum legal enrichment (at least in germany) is a nest, something to climb, something to chew, and a way to socialize. This cage has a hut for a nest, the top bars for climbing and the hardened pellets for chewing

In my opinion that's both unfitting and not enough. There's some very simple changes and a lot of bigger/harder changes:

Simple changes:

Using wooden or paper huts. It's commonly believed that mice can't see red, but in reality they will always choose darker colours and more natural materials as hides

lowering the light in one part of the cage, eg simple cage sleeves, lowering the general room light, shading the rack

raising the temperature. Mouse are generally kept at 21 - 24°C, but really prefer 26 - 30°C

scanning the room for ultra sounds

scattering some grains for foraging (this is also perfect for training the mice to make health checks easier)

Other still very simple changes:

adding nesting materials. Mouse prefer paper scraps, paper towels, etc, but there's also cotton squares and wood wool commercially available

adding wood for chewing. Again there's many options ranging from wooden bricks over wooden huts to whole branches

adding a running plate or wheel (I know running plates are said to cause spinal deformity, but in my experience that is a very low chance as opposed to the negative effects no movement has)

adding more bedding so digging is easier

adding tubes, boxes, swings and climbing structures

Changes that get closer to pet keeping:

add diggable bedding for builing nests and tunnels

add more huts. More! Mooore! (seriously mouse love a cluttered space and feel most comfortable walking along walls)

add a second layer (most easy part is just wedging a wooden board in there) and raising the top bars (there's raised cage tops for more height)

adding a maze/labyrinth to allow the mice to compartimentalise their cage/hide from light, sounds, movement, etc

stopping to feed ad libitum. In comercial setting, this can be done with feeding machines, privately this can be done by feeding like any other pet (adding a bowl of fresh food twice a day and removing after an hour or two)

scatter feeding instead of having the food in a rack

adding a digging box

Changes for pet keeping:

Going at least one, better two sizes up with the cages

adding toys

adding more mice to the group (in research most mice are kept in groups of 2 to 5. Mice prefer bigger groups though (plus "two" is a pair, not a group))

adding a big, big layer of bedding (see previous category)

adding toys, including food toys, smell toys, etc

giving food treats like yogurt, comercial treats, varied food, dead or life insects (mice are good hunters!)

feeding grains and similar (if you're unsure about a balanced diet, feeding grains additionally to pellets is totally fine)

adding a bigger wheel or running plate (a wheel is better, if you can provide a good one with appropriate size)

offer a free run time. This could for example be in a bath tub. Lay it out with linen or carpets, fill the tub with toys, treats and cardboard boxes, and offer the mice to go there (eg by builing a stairwell, or by training them "taxi" with a travel box)

spend regular time with them to aclimate them to humans

Changes for a near perfect enclosure:

Upgrate to an aquarium with a grid top

add more climbing options. Like way more!

Put heavier huts on stilts

Add even more tunnels

provide fresh food

change up their enrichment (eg digging box, swimming pool, fresh plants, offer tea additionally to water)

All these images have good and bad items, and imo all enclosures can be adapted to the housed animals needs. I'll try to add credit, but please message me if you have questions about specific images

I was about to add sources but found some great in a single site: here

I also always recommend bin cages as they are cheap and very very customisable. The best example I found is this one

#long post#mouse care#mice#rodents#pet enclosure#my post#lab mice#enrichment#idk I have no based opinions about beddings#this post is not quite yet what I want it to but we're getting there#feel free to message me about any of this#I love talking about mice#I'll try to add some sources#lowkey proud of my first post#pls support me by reblogging and commenting

18 notes

·

View notes

Text

Cost of Cattle Feed Plant

Establishing a cattle feed plant is a profitable business venture, especially in countries like India, where agriculture and animal husbandry form a large part of the economy. With the growing demand for milk and meat, the need for high-quality cattle feed is on the rise. However, understanding the financial aspects, especially the cost of setting up a cattle feed plant, is crucial for anyone looking to venture into this business.

In this blog, we will discuss the factors that influence the cost of a cattle feed plant, the role of why choosing the right cattle feed machine manufacturer in India is critical for success.

1. Key Factors Influencing the Cost of a Cattle Feed Plant

The overall cost of setting up a cattle feed plant can vary significantly depending on several factors, including:

a. Plant Size and Capacity

One of the primary factors influencing the cattle feed plant cost in India is the size and production capacity of the plant. A smaller plant with a production capacity of 1 to 2 tons per hour will cost significantly less than a large-scale plant that can produce 10 tons or more per hour.

b. Location and Infrastructure

The geographical location of the plant also plays a critical role in determining its cost. Urban locations tend to have higher land and labor costs compared to rural areas. Infrastructure, including access to water, electricity, and transportation, also adds to the cost.

c. Machinery and Equipment

The type and quality of machinery used in the cattle feed plant significantly influence the cost. A reliable cattle feed plant manufacturing company can offer various machinery types, including mixers, grinders, pellet machines, and more, each with varying price points. Opting for automated machinery can reduce labor costs but will require a higher initial investment.

d. Raw Materials

The availability and cost of raw materials such as maize, barley, wheat bran, and soybean meal can also affect the overall expenditure. In India, raw material prices may fluctuate depending on seasonality, transportation costs, and regional availability, directly impacting the cost of production.

e. Labor Costs

Labor costs vary widely based on the location of the cattle feed plant. Urban areas generally have higher labor rates compared to rural areas. Additionally, the complexity of the machinery used in the plant may require skilled labor, further increasing costs.

2. The Role of a Cattle Feed Plant Manufacturing Company

Choosing a reliable cattle feed plant manufacturing company is one of the most critical decisions you’ll make when setting up your cattle feed business. The right manufacturer will provide durable, high-quality machinery that ensures efficient production and minimizes downtime.

A trusted cattle feed plant manufacturing company typically offers comprehensive services, including:

Customized plant designs based on specific production needs.

Installation and maintenance of machinery.

Providing operator training to ensure smooth operations.

Offering warranty and after-sales services.

Investing in a reputable cattle feed machine manufacturer in India can ultimately save you money in the long run by reducing equipment failure rates and ensuring maximum productivity.

3. Cattle Feed Plant Cost in India: A General Overview

The cattle feed plant cost in India can vary depending on several factors mentioned earlier. However, to give you a general idea, the cost of setting up a small to medium-sized plant (with a capacity of 1 to 5 tons per hour) ranges between ₹20 lakhs to ₹1 crore. For larger plants with higher production capacities, the cost can go up to ₹2 crores or more.

Here’s a rough breakdown of the major cost components:

Land and Infrastructure: Depending on the location, this can range from ₹5 lakhs to ₹50 lakhs.

Machinery and Equipment: A complete set of machinery, including mixers, grinders, and pellet machines, typically costs between ₹10 lakhs to ₹70 lakhs, depending on the capacity and automation level.

Installation and Commissioning: Setting up the machinery and getting it operational can cost an additional ₹3 lakhs to ₹15 lakhs.

Labor and Operational Costs: These can vary but are an ongoing expense you should account for when planning your budget.

It's essential to work closely with a reliable cattle feed machine manufacturer in India to get an accurate estimate based on your plant size, production capacity, and specific needs.

4. Finding the Right Cattle Feed Machine Manufacturer in India

India is home to several cattle feed machine manufacturers, but selecting the right one requires careful research. Consider the following factors:

Reputation: Check reviews, ask for references, and do thorough research to ensure the manufacturer is reputable and experienced in producing high-quality machinery.

Customization: The manufacturer should be willing to customize the machinery according to your specific needs and production capacity.

After-Sales Service: After-sales service is critical, as it ensures your machinery continues to function optimally. Ensure the manufacturer offers prompt support and warranty services.

Cost and Quality: Strike a balance between cost and quality. Don’t opt for the cheapest machinery available, as it might not be durable or efficient in the long run.

Conclusion

Setting up a cattle feed plant is a significant investment, and understanding the cost dynamics is crucial for success. The cattle feed plant cost in India depends on various factors like plant size, machinery, location, and labor. Partnering with a reliable cattle feed plant manufacturing company can make a considerable difference in the overall profitability of your venture. By carefully planning and making informed decisions, you can establish a successful cattle feed plant that meets the growing demand for high-quality feed in the livestock industry.

0 notes

Text

Exporter of Multilayer Blown Film Extrusion Machine in Uganda

Adroit Extrusion is an Exporter of Multilayer Blown Film Extrusion Machine in Uganda.

Our Registered office and manufacturer unit is in Ahmedabad, Gujarat, India.

Adroit Extrusion is a manufacturer, supplier, and exporter of monolayer blown film machines, aba and ab blown film machines, and multilayer blown film machines.

Available various types of multilayer blown film machines like 7/5 layer barrier, 5 layer pod

And 3-layer layer-blown film plant.

A Multilayer Blown Film Extrusion Machine produces high-quality plastic films by melting and extruding multiple layers of polymer materials.

This technology enhances film properties, making it suitable for various applications, including packaging and industrial uses.

Produces films with varied properties by combining different polymers tailored for specific applications effectively.

Engineered for high efficiency, enabling faster production rates while maintaining superior quality standards consistently.

Advanced control systems regulate temperature, pressure, and thickness to guarantee uniform film quality throughout production.

The user-friendly design facilitates quick setup and maintenance, significantly reducing downtime for optimal productivity.

Work Process:

Material Feeding: Raw plastic pellets are fed into the extruder.

Melting: The extruder heats and melts the materials, turning them into a viscous melt.

Extrusion: The machine forces the melted polymer through a die, forming a continuous tubular film.

Blowing: The machine introduces air into the tubular film, expanding it to the desired thickness and dimensions.

Cooling: Air rings cool the film to maintain its structure and properties.

Winding: The operator winds the finished film onto rolls for easy handling and further processing.

Applications:

Packaging

Agriculture

Construction

Consumer Products

Medical

Adroit Extrusion is an Exporter of Multilayer Blown Film Extrusion Machine in Uganda including Locations like Kampala, Nansana, Kira, Ssabagabo, Mbarara, Mukono, Njeru, Gulu, Lugazi, Masaka, Kasese, Hoima, Lira, Mityana, Mubende, Masindi, Mbale, Jinja, Entebbe, Kitgum.

Feel free to contact us for more information and inquiries.

View Product: Click Here

Read the full article

0 notes

Video

youtube

How to Make Fish Feed Pellets with Our Advanced Pellet Machine #fishfeed...

0 notes

Text

This is one of those new techs that few people even know about but which is set to transform the world:

Adsorbant-based Atmospheric Water Collection

Basically, they design adsorbants that can specifically bind to certain shaped/sized molecules. In this case, water molecules. The water in the air will cling to this stuff, and once the temperature is raised (either by the sun, or through electric heating/cooling cycles), the water flows out as a liquid, and the material can start the process again.

Unlike the old methods of compressing air to generate water (e.g. like your air conditioner does), this uses much less energy. If you rely on the sun to heat it directly, then it requires literally no artificial energy inputs.

Some people are making these to generate drinking water by electrically running many hot/cold cycles in a day. The water is generally clean, but minerals have to be added for it to be drinking safe. That said, I don't think that issue applies to plants.

Other people are taking a different approach, like the one in this article: The material isn't used in a machine, but rather, it is mixed into the soil. This way it does two things: 1: It retains water a LOT better. 2: It can even generate some of its own water using the day/night cycle.

This article shows massive benefits for crops that used this. In addition, they also engineered the materials to contain fertilizers which, like water, are retained in the water for longer, and which are released into the soil for plant uptake in a much more efficient way.

Considering that agriculture uses *most* of society's water, this can revolutionize farming, potentially drastically reducing farm water needs. Even more, this material can be especially useful in depleted soils and/or in areas with minimal irrigation options.

You can literally produce water in the desert with this stuff.

Just as solar panels created energy independence; this stuff will create water independence.

Just imagine an agri-voltaic farm, producing energy, which produces water, which can be used for both plants and (with some modification) drinking as well.

Just imagine projects like both Africa's and China's "Great green wall" projects, which seek to stop desertification through planting in depleted and sandy soils. They, like many tree planting campaigns, have struggled, in part, because these trees lack the water they need to survive. This could change that.

FYI: DARPA is really interested in this stuff. Just imagine a soldier's canteen that can refill itself. (Maybe a tiny pellet of minerals is added before use.)

So many applications. Really revolutionary stuff.

1 note

·

View note

Text

How to Choose Best Continuous Fryers Machine in India

Gulab Singh and Company is a prominent manufacturer of Continuous Fryers in India, offering innovative and efficient frying solutions for large-scale food production. Specializing in industrial fryers, they cater to the growing demand in snack and food processing industries, ensuring superior performance, durability, and energy efficiency. Features of Continuous Fryers by Gulab Singh and Company •High Efficiency: Designed for continuous operations, these fryers ensure high throughput with minimal downtime. •Temperature Control: Equipped with advanced temperature control systems, they maintain consistent frying conditions, resulting in uniform cooking and crispy textures. •Oil Filtration System: An integrated oil filtration mechanism helps in extending oil life, reducing waste, and maintaining the quality of the fried product. •Durable Construction: Built from high-grade stainless steel, the fryers are corrosion-resistant and built for long-term industrial use. •Energy Efficient: Their innovative design ensures optimal energy use, reducing operational costs. •Safety Features: Safety valves, emergency shutdown systems, and easy access for cleaning and maintenance make these fryers user-friendly and safe to operate. Uses of Continuous Fryers Gulab Singh and Company’s continuous fryers are widely used in the production of: •Potato chips and snack pellets •Namkeen (Indian savory snacks) •Nuts like peanuts and cashews •Puffed snacks and extruded products •Frozen foods such as french fries and nuggets How Continuous Fryers Work The fryers operate by continuously feeding food items through a conveyor system into hot oil. The temperature is precisely controlled to ensure consistent frying. As the food passes through the fryer, it is evenly cooked and drained of excess oil before exiting. The continuous process allows for efficient production and maintains the high quality of fried products. In conclusion, Gulab Singh and Company’s continuous fryers are an essential solution for high-capacity food processing, delivering consistent, high-quality fried products across various industries. For more information Visit our Website :- https://www.gulabsinghandco.com Contact us :- +91–9953108079, +91–9313119875

0 notes

Text

What is a 5-7 T/H Feed Pellet Making Machine?

Product OverviewThe production line is a very popular animal feed machinery that adopts manual weighing and batching, and the designed total capacity of finished products is 5-7TPH for feed pellets finished products. The raw materials need to be pre-weighed and then fed from two different feeding ports into the production line.

The raw materials to be crushed are fed from the granular feeding…

View On WordPress

0 notes

Text

Cattle Feed Pellet Machine Manufacturer - Finix Agro Tech

The Biomass Cattle Feed Pellet Machine Manufacturer — Finix Agro Tech stands out as a groundbreaking solution, offering numerous advantages for farmers and livestock alike. With a powerful motor, this machine can produce a substantial quantity of pellets per hour, meeting the needs of even large farms without requiring multiple machines.

The pellet machine excels in processing a wide range of biomass materials, from crop residues to grasses and other organic matter. This versatility allows it to convert waste materials into valuable feed. Despite its high output, the Biomass Cattle Feed Pellet Machine is designed to be energy efficient, reducing operational costs and making it an eco-friendly choice for sustainable farming.

Click here to know more about Cattle Feed Pellet Machine.

Finix agro Tech

Contact; 93613 66651

Website: https://finixagrotech.com/

0 notes

Text

Chicken manure processing into organic fertilizer required equipment details

In chicken farms, chicken manure is a kind of high-quality organic fertilizer raw material, and its treatment and processing are of great significance to improve agricultural production efficiency, promote resource recycling and protect the ecological environment. The main equipment required for processing chicken manure into organic fertilizer and its functions will be described in detail.

1. Raw material pretreatment equipment

Uniform Feeder

Function: Evenly and continuously feed the collected chicken manure into the subsequent treatment equipment.

Features: reasonable design, simple operation, can effectively control the feeding speed and quantity, for the rear

Continuous crushing and mixing provide a steady supply of raw materials.

Cage Crusher

Function: The chicken manure is broken and processed to make its particle size uniform, which is convenient for subsequent mixing and fermentation.

Features: High crushing efficiency, adjustable particle size, can effectively reduce the agglomeration phenomenon between materials, improve the fermentation effect.

Function: Mix the broken chicken manure with other additives (such as microbial agents, humus, etc.) to ensure the even distribution of nutrients during fermentation.

Features: high mixing uniformity, high mixing efficiency, can effectively improve the quality of organic fertilizer.

2. fermentation equipment

Compost machine

Function: Provide a closed or semi-closed environment for chicken manure, carry out aerobic fermentation through the action of microorganisms, decompose organic matter, and convert it into nutrients that can be easily absorbed by plants.

Features: Using advanced fermentation technology, can effectively control fermentation temperature, humidity and oxygen content, improve fermentation efficiency and quality.

Function: In the compost fermentation process, regularly turn the chicken manure pile to promote oxygen entry, even the fermentation temperature, prevent local overheating or anaerobic fermentation.

Features: high degree of automation, easy operation, can effectively improve the fermentation efficiency and product quality.

3. Granulation equipment

Function: The fermented chicken manure is processed into pellets for easy storage, transportation and use.

Features: HIGH granulation efficiency, uniform particles, beautiful appearance, can improve the application effect of fertilizer and market competitiveness.

4. Drying equipment

Rotary Dryer Machine

Function: Remove the excess water in granular organic fertilizer, prevent its mildew and decay, and extend the shelf life.

Features: Using advanced drying technology, low energy consumption, good drying effect, can effectively ensure the quality of organic fertilizer.

5. Screening and packaging equipment

Rotary Screening Machine/Vibration Screening Machine

Function: Sieve the dried granular organic fertilizer to remove unqualified particles and impurities and ensure product quality.

Features: High screening efficiency, high screening precision, can effectively improve product purity and market value.

Automatic packing machine/sealing machine

Function: Automatic packing and sealing of qualified granular organic fertilizer for convenient transportation and sales.

Features: high degree of automation, fast packaging speed, tight sealing, can effectively improve production efficiency and product quality.

6. Summary

The processing of chicken manure from chicken farms into organic fertilizer is a complex and systematic process that requires a series of advanced equipment and technical support. From pretreatment of raw materials to fermentation, granulation, drying, screening and packaging, each step is crucial. By adopting these equipment and technologies, not only the production efficiency and product quality of organic fertilizer can be effectively improved, but also the win-win situation of resource recycling and ecological environmental protection can be realized. With the development of agricultural modernization, chicken manure organic fertilizer production line will play an increasingly important role in the future agricultural development.

1 note

·

View note

Text

Working principle of Fertilizer Granules Compaction Machine:

Fertilizer Granules Compaction Machine is the use of pressure to directly squeeze the material into the finished product granulation process, especially suitable for the granulation of thermal sensitive materials. There are usually two types of extrusion machinery: one is the push type granulator; The other is Fertilizer Granules Compaction Machine. The two types have various forms due to their different structures. The water content of the feed of the push and press type extrusion granulator is usually 5% ~ 8%, and the cylindrical product is obtained after extrusion, and the compound fertilizer product with water content less than 5% is obtained by cooling. The water content of the feed of the pelleting Fertilizer Granules Compaction Machine can be lower, foreign reports can be between 0.5% and 1.5%, the belt material obtained by extrusion is broken by the Chain Crusher, and the double screen is screened to get the bulk or compound fertilizer products with edges and angles. The fine powder after crushing is returned to the extrusion machine for pelleting. Coarse blocks are then returned to the Chain Crusher for crushing. Because the product contains low moisture, it does not need to be dried. The granulation rate is usually about 85%.

The extrusion granulation process of compound Fertilizer with an annual output of 10,000 to 20,000 tons is shown in the figure below (NPK Fertilizer Production Line) :

Due to the precipitation of water during the reaction process, the material becomes thin, wet and sticky. At the same time, the decomposition rate of urea increases, making granulation impossible. Therefore, in the formulation must be equipped with human calcium magnesium phosphate fertilizer or other fertilizers, such as potassium sulfate and potassium chloride.

In the extrusion granulation process, two basic fertilizers, calcium superphosphate and urea, cannot be used alone for production, because calcium superphosphate contains free acid, which chemically reacts with urea during extrusion as follows: H3PO4+CO (NH2) 2→CO (NH2) 2·H3PO4

Process analysis of Fertilizer Granules Compaction Machine production line

Selection of appropriate raw materials and preparation of mixtures are important factors in the production of qualified extruded fertilizers. Some raw materials can be mixed and extruded according to their respective characteristics. Such as potassium chloride, ammonium sulfate and urea are raw materials with good extrusion properties. Super phosphate, lime nitrogen [calcium cyanamide (CaCN2)], hard boron calcium stone and phosphate rock can be extruded, but they do not have as good extruding performance as the above raw materials. However, some fertilizers, such as super phosphate, can be pre-dried or extended its ripening period to improve its extruding performance. In terms of raw materials, other factors that affect the extrusion performance of products include: particle size distribution, moisture content, temperature, plasticity and hardness. Extrusion operation conditions include pressure, roller diameter and speed, roller surface and spacing between two rollers, etc. The PRACTICE SHOWS THAT USING ammonium sulfate, diam monium phosphate, super PHOSPHATE, potassium CHLORIDE and UREA (MOISTURE ≤1.5%) as raw materials, THE PRODUCTION of 13-13-21 and 15-15-15 compound fertilizers has obtained satisfactory results.

The materials that have been used for extrusion granulation are as follows:

Ammonium chloride urea monoammonium phosphate ammonium sulfate + dicyandiamide (cyanoguanidine)

Ammonium sulfate urinary aldehyde diammonium sulfate lime nitrogen [cyanamide calcium (CaCN2)]

Calcium sulfate phosphate ore vanadium sulfate gypsum (CaSO4·2H2O) peat mixture

Limestone heavy ore potassium chloride potassium chloride + trace element fertilizer

Organic fertilizer potassium sulfate NPK magnesium mixed fertilizer

Slow-acting fertilizer Port Gate phosphate fertilizer (acid slag)

Fertilizer Granules Compaction Machine has a wide range of applications and can graninate a variety of raw materials. So it is also known as ammonium sulfate compound fertilizer dry extrusion granulator, Fertilizer Granules Compaction Machine, potassium magnesium fertilizer Fertilizer Granules Compaction Machine, calcium chloride Fertilizer Granules Compaction Machine, dry ammonium sulfate roller granulator, compound fertilizer roller granulator, ammonium sulfate granulator, compound fertilizer extrusion granulator.

0 notes

Text

youtube

Capsule Making Machine

Automatic capsule filling machine, also known as the completely automatic capsule filling machine, fills capsules in an automatic mode. The machine uses a multi-position tamping method with intermittent motion to finish tasks such capsule orientation, separation, filling, closing, and ejection. The machine is appropriate for size #00, #0, #1, #2, #3, #4, and #5 capsules with the aid of various size parts. A variable frequency drive, or VFD, can be used to regulate the speed of production. The machine is built in compliance with cGMP guidelines. Stainless steel 316 is used for all product contact parts, while stainless steel 304 is used to cover the machine. The machine’s innovative design, well-thought-out structure, accurate dosage, safety and dependability, high filling rate, etc. are its advantages.

As a manufacturer of capsule filling machines, we create our designs using the technology at our disposal and our nearly two decades of experience in the field of safe capsule filling and closing. The entire spectrum of cGMP pharmaceutical sanitation is integrated into the machine’s design and construction. It’s interesting to note that on demand, an extra tablet feeding or pellet filling station for capsules is available. In addition, we provide machines for metal detection, sorting, polishing, and inspection of capsules, completing automatic capsule filling lines.

#Automatic capsule filling machine#automatic capsule filling lines#Capsule Making Machines#capsule filling machines#Youtube

0 notes