#Applications of Copper

Explore tagged Tumblr posts

Text

Applications for our RPG Maker zine are now opened! Artists and writers apply now! Applications close September 18th! Apply here!

#zine#rpg maker#zine applications#off mortis ghost#ynfg#yume nikki#yume nikki fangames#off game#mad father#811 game#ib#end roll#hylics#halope#super lesbian animal rpg#dweller's empty path#witch's heart#grimm's hollow#lisa the painful#lisa the joyful#lisa the first#copper odyssey

309 notes

·

View notes

Text

happy to report im still agonizing over the clay decision 💕

3 notes

·

View notes

Text

“What do you mean ‘inadequate offerings’? The Angels love mountain dew when you can manage to get past their answering machine. Yeah they have one of those. Yeah I just tried typing different numbers repeatedly over and over on my phone. 333, 44444444, 8888 stuff like that. Yeah they speak English. They sound like Californians but they speak English”

“The fuck is ‘Enochian’?”

“That’s a very interesting shade of purple”

And then the other direction:

��Okay I know you said there’s a science to this but literally nothing you just did made any kind of sense. How the fuck did you memorize all that, and more importantly HOW DID YOU AFFORD A FANCY PENTAGRAM INLAID ONTO THE FLOOR IN DIAMONDS!? I’M BARELY MAKING RENT!”

“…”

“whatdoyoumean ‘there are others’”

“…”

“whatdoyoumeanthisoneisjustforuseinthisspellandthisspellonly”

“…”

“I’m coming back with a fucking pickaxe”

i love pitting classically trained magic users against self-taught magic users in sci-fi/fantasy but it shouldn’t be snobbish disdain for them it should be terror

#there are precisely 42 different pentagrams#ritual circles#and sigils in the second wizards house.#each one delicately carved and inlaid into the floor in diamond within ring of copper silver or gold#they must be used at specific times of the year with specific offerings and you need to pronounce every syllable of the chant exactly right#And each one is made for a different individual spell#42 spells in total#to be fair#they are fairly versatile spells that have a lot of practical applications during the time of year within they must be used#one of them is essentially the entire ventilation system#heating and cooling#air control spell#works best during the hottest days of sumer and coldest days of winter#self-taught wizard is basically about to rob the other guy of his air conditioning unit#wizards

183K notes

·

View notes

Text

Exploring the Benefits of Jingda's Oxygen Free Copper Rod

Hello everyone! I wanted to share some insights about Jingda and their exceptional oxygen free copper rod. This product is renowned for its high conductivity and excellent corrosion resistance, making it a top choice for various industrial applications.

Jingda has established itself as a leader in the industrial materials sector, consistently delivering quality and reliability. The oxygen free copper rod they offer not only meets but exceeds industry standards, ensuring optimal performance in electrical and electronic applications.

If you're in the market for high-quality industrial materials, I highly recommend checking out Jingda's offerings. Their commitment to excellence is evident in every product they produce.

Thanks for reading!

#electronic applications#corrosion resistance#quality materials#oxygen free copper rod#high conductivity#Jingda

0 notes

Text

The Versatility of Round Copper Plates: Applications Across Industries

Copper has long been a preferred material in various industries due to its superior conductivity, durability, and corrosion resistance. Round copper plates play a crucial role in sectors like electrical, marine, and construction, offering unmatched efficiency and longevity. In this article, we explore the diverse applications of copper discs for industrial use and how businesses can benefit from their unique properties.

1. Electrical Industry: The Backbone of Conductivity

Power Distribution and Conductors

One of the most common uses of round copper plates is in electrical applications. Their high conductivity makes them ideal for:

Busbars and electrical terminals in power plants and substations.

Transformer components for efficient energy transfer.

Circuit breakers and switchgear to enhance electrical safety.

Case Study: A power distribution company replaced aluminum conductors with high-purity round copper plates, reducing energy loss by 20% and improving efficiency.

2. Marine Industry: Resisting Corrosion in Harsh Environments

Shipbuilding and Anti-Fouling Solutions

In marine environments, metals must withstand extreme moisture and salt exposure. Copper plates are widely used for:

Hull protection and anti-fouling coatings to prevent algae and barnacle buildup.

Seawater piping and heat exchangers for long-term durability.

Electrical grounding plates in ships and submarines to prevent galvanic corrosion.

Case Study: A shipbuilding firm adopted copper discs for industrial use in its grounding systems, enhancing vessel lifespan and reducing maintenance costs.

3. Construction Industry: Strength, Aesthetics, and Longevity

Architectural Elements and Roofing Solutions

The construction industry utilizes round copper sheet applications for both functional and aesthetic purposes:

Decorative wall panels and sculptures that develop a beautiful patina over time.

Roofing and flashing materials, offering unmatched durability and weather resistance.

Plumbing fittings and water filtration systems due to copper’s antimicrobial properties.

Case Study: A commercial building integrated copper roofing plates, cutting long-term repair costs by 30% while enhancing aesthetic appeal.

FAQs About Round Copper Plates

Q1: What sizes and thicknesses are available for round copper plates?

A: Accromet offers a wide range of copper plate dimensions, with customizable options to meet industrial specifications.

Q2: Are copper plates recyclable?

A: Yes! Copper is 100% recyclable, making it a sustainable choice for various industries.

Q3: How does copper compare to aluminum in conductivity?

A: Copper is nearly twice as conductive as aluminum, making it the superior choice for electrical applications.

Q4: Can copper plates be used in high-temperature applications?

A: Absolutely! Copper retains its strength and conductivity even at high temperatures, making it ideal for furnaces and heat exchangers.

Get High-Quality Round Copper Plates from Accromet

Looking for top-grade copper plates for your next project? Accromet offers premium round copper discs tailored for industrial and commercial applications. Whether you need custom sizes or bulk orders, we have the right solution for you!

👉 Contact us today to discuss your requirements and get a free quote!

0 notes

Text

Supreme Steel Brass sheet and rod suppliers| Dubai

Supreme Steel provides high-quality steel solutions for construction, manufacturing, and industrial applications. Strength, durability, and reliability in every product.

#Heavy-duty Inconel suppliers for extreme temperature applications#Top copper sheet suppliers for electrical and industrial use#Nickel alloy sheet and bar distributors#Industrial-grade stainless steel suppliers#Copper pipe and sheet suppliers

1 note

·

View note

Text

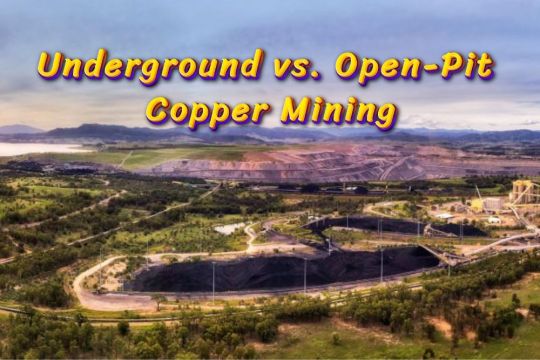

Underground vs. Open-Pit Copper Mining: Pros and Cons

Copper is one of the most essential metals in modern industry, used in everything from electrical wiring to renewable energy solutions. But before it reaches manufacturers and consumers, copper must be extracted from the earth through mining. There are two primary methods for mining copper: underground mining and open-pit mining. Each method has its advantages and disadvantages, affecting everything from environmental impact to economic feasibility. In this article, we’ll explore the key differences between these two techniques, helping you understand their benefits and challenges.

What is Open-Pit Copper Mining?

Open-pit mining is the most commonly used method for extracting copper when the ore is located relatively close to the surface. This technique involves removing layers of rock and soil to expose the mineral deposit. Large-scale excavation equipment, such as haul trucks and electric shovels, is used to extract and transport the ore for processing.

Pros of Open-Pit Copper Mining

✅ High Production Rates: Open-pit mining allows for large quantities of copper ore to be extracted efficiently, making it more cost-effective for companies.

✅ Lower Operational Costs: Since the ore is closer to the surface, excavation is less expensive compared to underground mining.

✅ Easier Access to Ore: Open-pit mining provides direct access to large ore deposits without the need for deep tunnelling.

✅ Safer Working Conditions: Because mining occurs at or near the surface, workers are less exposed to risks such as tunnel collapses or underground gas build-ups.

Cons of Open-Pit Copper Mining

❌ Significant Environmental Impact: Large-scale excavation can lead to deforestation, habitat destruction, and air pollution due to dust and emissions.

❌ Visual Pollution: Open-pit mines create massive scars on the landscape that can be seen from miles away, affecting local ecosystems and communities.

❌ Water Contamination Risks: Chemicals used in the extraction process can seep into groundwater, leading to potential water pollution.

❌ Limited Depth: Once the accessible surface ore is depleted, deeper deposits may require switching to underground mining.

What is Underground Copper Mining?

Underground mining is used when copper ore is located deep beneath the surface and cannot be efficiently reached through open-pit methods. This method involves digging tunnels and shafts to access the ore body, which is then extracted using specialized machinery.

Pros of Underground Copper Mining

✅ Less Surface Disruption: Since underground mining does not require large-scale excavation, it has a much smaller impact on the surrounding environment.

✅ Preserves Landscapes: Unlike open pits, underground mines do not drastically alter the natural scenery.

✅ Lower Water and Air Pollution: The contained nature of underground operations helps reduce exposure to pollutants.

✅ Access to Deeper Ore Deposits: Underground mining allows miners to extract copper from deeper levels, making it possible to tap into resources that open-pit methods cannot reach.

Cons of Underground Copper Mining

❌ Higher Costs: The construction of tunnels, ventilation systems, and safety measures makes underground mining significantly more expensive.

❌ Increased Safety Risks: Workers face cave-ins, underground explosions, and poor air quality hazards.

❌ Lower Production Rates: Compared to open-pit mining, underground extraction is slower and yields smaller quantities of ore.

❌ Complex Logistics: Transporting ore from deep underground to the surface requires additional equipment and time, increasing operational complexity.

Which Method is Better?

There is no single best method for copper mining; the choice between open-pit and underground mining depends on various factors, including:

Depth of the Ore Deposit: Shallow ore bodies are better suited for open-pit mining, while deeper deposits require underground extraction.

Environmental Regulations: Some regions have stricter laws on surface mining, making underground mining the only viable option.

Economic Considerations: Open-pit mining is often more profitable due to lower operational costs, but underground mining becomes necessary when deeper reserves hold significant value.

Local Community Impact: Open-pit mines can have a larger social and environmental footprint, while underground mining can reduce land disturbances.

Final Thoughts

Both open-pit and underground copper mining have their advantages and disadvantages. Open-pit mining is more cost-effective and productive but comes with greater environmental concerns. On the other hand, underground mining is less invasive but requires higher investment and poses more risks for workers. As the demand for copper continues to rise, mining companies must balance efficiency, safety, and sustainability to ensure responsible resource extraction. Whether through technological advancements or improved environmental practices, the future of copper mining will likely involve a mix of both methods, providing a steady supply of this essential metal for global industries.

#mining tenement#tenement#mining application#tenement consultant#tenement management#tenement management services#mining industry#hetherington#mining#underground mining vehicle#mining licence#copper mining

0 notes

Text

A Continuous Fiber Laser Welding Machine's Functions

Metal materials like copper and aluminum can be welded with a continuous fiber laser welding machine. For welding stability, the fuselage uses a high-strength gantry bed structure design. With its higher photoelectric conversion efficiency, lower power consumption, and higher beam quality, the current advanced continuous laser is chosen as the light source.

Benefits of the fiber laser apparatus include its small size, convenient use, and compact structure. Welding equipment can be efficiently integrated with other equipment in the system thanks to its versatile laser output mode. High speed and precision are ensured by the highly responsive servo motor output, which works with the high-precision and high-strength screw linear module as the operating transmission mechanism.

In the field of new energy lithium battery PACK modules, this makes the laser welding machine an essential piece of equipment. With its outstanding beam quality, quick welding speed, and gorgeous, sturdy welding pool, the continuous fiber laser welding machine offers the ideal, stable, and effective welding solution for the lithium battery welding process.

Unlocking the Advantages: Your Guide to the Equipment's Benefits

Perfect welding: Easy adjustment, fine focusing, imported optical lenses, high-precision laser welding head.

High-quality fiber laser: Internationally recognized, with years of industrial application, a long lifespan, and no maintenance required.

Energy efficiency: Low power consumption, high electro-optic conversion efficiency, and excellent beam quality.

Adjustable power: A continuous 2000-watt (adjustable) pure fiber laser that can penetrate materials with depths ranging from 0.1-3 mm.

Precision control: A precise servo system ensures welding accuracy.

User-friendly interface: Easy-to-learn PC industrial computer with a welding CNC programming system.

Wide range capabilities: large surface stroke welding, a gantry frame motion structure, high machine tool precision, and a stable, long-lasting service life.

Enhanced functionality: Data-saving call functions, strong drawing and editing graphics capabilities, and compatibility with a range of input formats.

Exploring Equipment Indicators and Parameters: Key Features

This welding equipment offers a range of features that make it versatile and reliable for various applications:

Material Compatibility: Welds materials with thicknesses ranging from 0.5 mm to 2.0 mm, suitable for diverse projects.

Workspace Flexibility: Effective travel range spans 870 mm in the X-axis and 600 mm in object workpiece height.

Adjustable Welding Speed: Operates at speeds of up to 10 mm/s, ensuring welds meet specific requirements.

Power Options: Offers adjustable laser power levels, including 2 KW, 3 KW, and 6 KW.

Durability: Features an optical fiber working medium with a service life exceeding five years.

Material Versatility: Suitable for welding nickel strips, copper sheets, and aluminum rows.

Welding Modes: Offers both continuous and pulse modes for versatile welding processes.

Spot Welding Capabilities: Achieves contact surface melting depths ranging from 0.5 mm to 1 mm, ensuring strong welds with tensile strength exceeding material destructive strength.

Characteristics of the Equipment

This welding equipment offers advantageous features for a seamless and efficient welding experience:

Maintenance-Free Operation: Reduces downtime and maintenance costs.

Adjustable Parameters: Allows for easy modification of welding parameters, including motion speed.

Fault Alerts: Real-time fault alarm prompts for immediate issue resolution.

Flexible Operation: Offers automatic and manual operation modes, supporting arc and straight-line interpolation.

Laser Processing: Enables the creation of various plane graphics such as points, straight lines, circles, and squares.

Durable Components: Equipped with imported lenses in the welding field mirror to withstand high laser-generated temperatures.

User-Friendly System: Easy-to-learn operating system simplifies manual operation.

Smoke and Slag Control: Built-in air-blown wind knife ensures welding quality.

Cooling System: A water-cooled cycle in the welding head ensures stable welding effects.

Precision Mechanism: High-precision screw transmission and high-speed servo motors ensure accuracy and responsiveness.

Environmental Conditions

To ensure optimal performance and safety, adhere to these specifications for the operating environment:

Ambient Temperature: Operates effectively between 5°C and 35°C.

Humidity: Maintain relative humidity levels between 20% and 90% to prevent condensation and corrosion.

Air Source Pressure: Requires a compressed air source with a pressure range of 0.5 to 0.6 Mpa.

Power Supply Voltage: A stable voltage of 380V at 50Hz or 60Hz is required.

Total Power: Consumes ≤10KW of power to prevent electrical overloading.

Load-Bearing Capacity: The installation area must support up to 500 kg/m².

Grounding Type: Direct grounding ensures safety and minimizes electrical hazards.

Installation Environment: Requires a flat, vibration-free, and shock-free area for precise and stable operations.

Adhering to these specifications ensures reliable operation, extending the equipment’s service life while preventing potential issues related to environmental conditions.

Final Thoughts

The continuous fiber laser welding machine represents a revolutionary step forward in welding technology. Its ability to deliver precise, efficient, and versatile welding solutions makes it an essential tool across industries, including automotive, aerospace, and renewable energy. By understanding its functions, benefits, and operational requirements, manufacturers can fully leverage this equipment to enhance productivity, reduce costs, and achieve superior product quality.

Investing in a continuous fiber laser welding machine is not just about adopting advanced technology—it's about future-proofing your manufacturing processes for the demands of tomorrow.

#Fiber Laser Welding Machine#Fiber Laser Welding Technology#High-Precision Welding Machines#Laser Welding for Copper and Aluminum#Industrial Laser Welding Equipment#Applications of Fiber Laser Welding#High-Strength Welding Equipment#Lithium Battery PACK Welding Solutions#Laser Welding for Automotive Manufacturing#Spot Welding vs. Continuous Laser Welding

0 notes

Text

Discover EC grade copper and aluminum bare wires and strips, ideal for busbars, earthing, terminal connections, and power control panels. High-quality solutions for electrical applications.

0 notes

Text

Lithium and Copper: The Metals That Will Shape the Future

🔋🌍 Lithium and copper are set to revolutionize the economy as the demand for electric vehicles and renewable energy soars! 🌱✨ With innovations in battery tech and sustainable materials, the future looks bright for clean energy.

In the coming years, certain metals are poised to fundamentally change the global economy—foremost among them are lithium and copper. These two raw materials are becoming increasingly indispensable for the energy and transportation industries as the world shifts towards renewable energy and electric vehicles. Lithium: The Fuel of the Energy Transition Lithium plays a central role in the…

#battery technology innovations#climate change solutions#copper demand forecast#eco-friendly materials#electric vehicle batteries#electrification of transportation#energy efficiency technologies#energy transition strategies#environmental impact of mining#future of electrification#innovations in renewable energy#Lithium market trends#Make money online#market analysis of lithium#metals for clean energy#nickel applications in batteries#Online business#Passive income#perovskite solar cells#renewable energy investment#renewable energy sources#sustainable metals#sustainable resource management

0 notes

Text

PCB Manufacturing Process: All You Need to Know

Creating a printed circuit board (PCB) is a systematic process that begins with meticulous design and material selection, crucial for ensuring functionality and durability. The initial steps involve the application of a thin layer of copper over a substrate material, typically a fiberglass substrate reinforced with epoxy resin and glass fiber, which provides the necessary rigidity and electrical insulation. This copper layer is then patterned to form conductive areas that will eventually carry electrical signals.

The layout design process utilizes advanced CAD software for precision, ensuring that the conductive paths and component placement areas are accurately defined. Once the design is finalized, it's transferred onto the PCB using photo reactive chemicals and UV exposure, a process known as outer layer imaging. This method allows for the precise alignment of layers and the creation of intricate circuit patterns.

After the design transfer, the excess copper is removed through a careful etching process, leaving behind the copper traces that form the circuitry. The PCB then undergoes a laminating process to apply a solder mask, a protective layer that covers the entire board while exposing the areas where components will be soldered. This solder mask application is crucial for preventing short circuits and ensuring the longevity of the PCB.

Following the application of the solder mask, a silkscreen printing process adds labels and markings to the PCB, aiding in component placement and board identification. The final step in the fabrication processes involves applying a surface finish, such as tin plating, to protect the exposed copper and ensure a reliable soldering surface. Other surface finishes like HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold) are also used depending on the application requirements.

Throughout the PCB manufacturing process, precision is maintained through the use of technologies like CNC machines for accurate drilling of holes that will accommodate electronic components. Each part of the PCB fabrication process, from the initial design to the final surface finish, is critical to enhancing the PCB's electrical performance and longevity.

The final stages of assembly involve the placement of components onto the PCB, often by a contract manufacturer specializing in PCB assembly. This is followed by soldering, which can be done through various methods, to securely attach the components to the board.

Rigorous electrical tests are conducted to validate the PCB's performance, ensuring that it meets stringent quality standards before integration into electronic devices. These tests verify the integrity of the conductive paths, the correct orientation of components, and the overall functionality of the PCB.

This holistic approach underscores the importance of meticulous craftsmanship and thorough quality assurance in producing reliable PCBs that power our modern gadgets effectively. Each step, from the initial plating process to the final surface finishing, contributes to enhancing the PCB's electrical performance and longevity, making it a vital component in the electronics industry.

To read more please visit:

Reachemical chemicals

16479857177

600 Matheson Blvd W Unit 5, Mississauga, Ontario ,ON L5R 4C1.

#thin layer of copper#plating process#excess copper#laminating process#tin plating#fabrication processes#substrate material#exposed copper#solder mask application#circuit board manufacturing process#conductive areas#surface finish#layer alignment#outer layer imaging#parts of the pcb fabrication process#epoxy resin and glass fiber#contract manufacturer#outer layers#electrical tests#photo reactive chemicals

0 notes

Text

What are the Applications of Oxygen-Free Copper?

As we continue to advance in the field of technology and connectivity, material composition is key as it contributes greatly towards set performance indices and overall durability. Remarkably, one of the heroes in this setting is oxygen-free copper (OFC), an extraordinarily pure and conductive material that leads by storm into different sectors.

Let us set sail and discover the inner workings of oxygen-free copper, its production process as well as the numerous fields that take advantage of its outstanding characteristics.

Explaining the Essence of OFC

Basically, oxygen-free copper is a refining process while virtually eliminating most of copper’s composed oxygen content. However, standard copper has inherent levels of trace oxygen associated with it; but the sustained sophisticated refining processes of OFC lowers this concentration to below that level.

This remarkable degree of refinement between OFC and standard copper sets it apart as being one that would provide better conductivity compared to the conventional used for purposes where such a level is necessary.

Purity as the Driving Factor

The striking purity of oxygen-free copper directly implies excellent electrical conductivity. Although copper can be associated with its high conductivity features, these impurities of oxygen are responsible for increasing resistance and poor performance.

OFC does not present these impurities allowing the electrons to advance through with very little resistance leaving signal loss and distortion minimal. This feature enables OFC to be labeled as a leader of materials, used in applications that require the highest levels of conductivity and signal integrity.

Uses in the Audiophile Field

One of the most outstanding venues where OFC's strengths stand out is in the audio cables and connectors area. Since OFC cables facilitate the precise and unadulterated transmission of audio signals, audiophiles, professionals, or musicians working in the entertainment sector use OFC cables.

While increasing the integrity of sound, low resistance in OFC adds a complex enhancement to it. On the other end of things, in high-end speaker cables and interconnects alike - OFC’S purity factor is now a key point essential to revealing the smallest distinctions within music.

Connectivity Past Sound

Although OFC is essential in the realm of audio, its utilization does not end there; indeed, quite a few other fields are dependent on it. High-speed data transfer cables including HDMI and Ethernet are the applications of OFC that use its excellent conductivity for reliable long-distance signal transmission without deterioration.

However, in sectors where data accuracy is critical like telecommunications and for the data centers OFC becomes insinuating material for network systems making reliable connections required for superior performance.

Different Electronic Usages

Oxygen-free copper goes even further in influencing many electronic components and applications. Related to this, its reliable and consistent electrical assets are also a distinct aspect of why it is used in the manufacturing of transformers, inductors, and other parts very important for electronic equipment.

In Ending This

With the surging demand for OFC from the electronics and the electrical sector, their demand will continue to rise in the years to come.

Source: P&S Intelligence

#Oxygen-Free Copper Market Share#Oxygen-Free Copper Market Size#Oxygen-Free Copper Market Growth#Oxygen-Free Copper Market Applications#Oxygen-Free Copper Market Trends

1 note

·

View note

Text

All You Need To Know About Copper Pipe Fittings

What are copper pipe fittings?

Copper pipe fittings are made up of copper tubes that run across your house and an assortment of fixtures attached to these pipes.

These fittings are essential in ensuring water flows smoothly and consistently to various parts of the house. They come in different shapes and sizes, including elbow, tee, reducer, coupling, and cap, among others.

Applications of copper pipe fittings

Copper pipe fittings are entirely versatile and can be used in many different applications. In plumbing, they are primarily used to join two copper pipes or control water flow.

These fittings are also used for air conditioner installation, gas supply, and heating system installation. In addition to these applications, copper pipe fittings are used in industrial processing, refrigeration, natural gas, and much more.

Benefits of using copper pipe fittings

One of the primary benefits of copper pipe fittings is that they are long-lasting and durable. Copper's natural properties prevent the pipework from corroding or decaying, ensuring the materials remain intact for a long time.

Copper pipe fittings are also easy to install, and joining two copper pipes is as simple as soldering them. Unlike plastic, copper fittings are resistant to extreme temperatures, and the material is hygienic, making them ideal for the potable water supply.

#Benefits of using copper pipe fittings#Applications of copper pipe fittings#All You Need To Know About Copper Pipe Fittings#What are copper pipe fittings

0 notes

Text

Why copper is an ideal choice for refrigeration fitting?

Bin Dasmal General Trading is the authorized copper pipe supplier in UAE and has a rich variety of items sourced from various international brands. Insulation in copper wire helps in obstructing the heat and making the premises cool for an exceptionally prolonged stretch of time. Copper is the metal chosen for cooling piping. To be sure, it is good with all refrigerants aside from smelling salts. It has a long life. It works similarly well to make the fundamental elbows or dungeons. One of the preferences is that it is a durable material that is invulnerable immune to wear and tear. Besides, the blower of the HVAC system doesn't need to stay at work longer than required to keep up the temperature of your rooms and halls.

Corrosion resistance: Copper is perfect in corrosion protection from both air and water erosion. Copper tube's internal erosion obstruction results in predominant stream limit. A copper fire sprinkler system can utilize littler measurements to give a similar sprinkler inclusion as a steel system—with noteworthy reserve funds in installed costs.

Easy to install: Copper's workability can cut installation time and decrease work cost.Copper is malleable and fit to the most design configuration. Copper is inflexible just as promptly formable, and it adds to add up to system honesty even when exposed to unfavorable conditions.

High thermal conductivity: Copper is the best conductor of warmth and conducts heat up to multiple times superior to different metals. Copper's prevalent thermal conductivity implies that thinner copper sheet can gather a similar warmth as a lot thicker-check sheet of aluminum or steel. It implies that copper gatherer tubes can be all the more generally divided.

Adaptability: Copper is easy to work and has amazing warm conductivity, erosion obstruction and toughness. It is accessible in two essential sorts of a tube—plumbing cylinder and refrigeration tube, and in both drawn (hard) and toughened (delicate) tempers.

Bin Dasmal General Trading offers a range of alternatives. The company is recognized as one of the most leading copper product suppliers in the UAE and also gives the best recommendations to the clients in the installation and setup of the equipment. The Company is dealing with many globally leading copper manufacturers to serve best products to their clients.

0 notes

Text

Explanation of Antique Copper Finish Sheets

What are antique copper finish sheets?

Antique copper finish sheets are metal sheets treated to achieve an aged, weathered look that resembles vintage copper.

Manufacturers achieve this finish by applying a patina solution to the surface of the copper, which creates a chemical reaction that forms highlights and lowlights that give the sheet a natural, textured look.

Antique copper finish sheets are available in various thicknesses, sizes, and patterns and can be used for a variety of applications, both indoors and outdoors.

Applications of antique copper finish sheets

Antique copper finish sheets can be used in various applications, from decorative accents to industrial purposes. Here are some of the popular applications for antique copper finish sheets:

Interior design: Antique copper finish sheets can accent walls, ceilings, and floors, adding warmth and character to any space. They can be incorporated into various design styles, including rustic, industrial, and contemporary.

Furniture design: Antique copper finish sheets can create unique, eye-catching furniture such as tables, chairs, and shelving. When used as an accent material, copper finish sheets can add a touch of elegance and sophistication to any furniture design.

Architectural elements: Antique copper finish sheets can cover exterior walls, cornices, or roofs to create an aged, weathered look that blends seamlessly with the surrounding buildings. They can also be used to create copper gutters, downspouts, and other architectural elements that require durability and resistance to weather.

Art and craft: Antique copper finish sheets can be used to create art and craft projects such as sculptures, wall hangings, and jewellery. It is a versatile material that can be cut, shaped, and formed however the artist desires.

Benefits of Using Antique Copper Finish Sheets

Aside from its unique characteristics and versatility, antique copper finish sheets offer several other benefits, including:

Durability: Copper is a durable material resistant to corrosion and degradation, making it an excellent option for outdoor applications.

Low Maintenance: Copper is a low-maintenance material that requires minimal upkeep. It is also easy to clean and can be polished to maintain its original shine.

Energy Efficient: Copper is an excellent conductor of heat and electricity, making it an ideal material for many applications where energy efficiency is important.

Sustainability: Copper is a natural material that is 100% recyclable. Using antique copper finish sheets in your project is an environmental choice that reduces the carbon footprint.

#What are antique copper finish sheets#Applications of antique copper finish sheets#Benefits of Using Antique Copper Finish Sheets

0 notes

Text

Australia's Copper Mines: A State-by-State Overview

Australia is one of the world's largest producers of copper, a critical metal used in electrical wiring, electronics, renewable energy technologies, and construction. The country’s vast mineral wealth makes copper mining a key contributor to its economy, with copper deposits spread across several states. Each region offers distinct contributions to Australia’s overall copper production, with varied mining methods, reserves, and operational practices. Below is an in-depth state-by-state overview of Australia’s copper mines and their significance.

South Australia

South Australia is home to some of the world’s largest and most significant copper deposits, with the Olympic Dam being a standout. Operated by BHP, Olympic Dam is one of the most important copper mines globally, not only for copper but also for its uranium and gold production. This polymetallic mine is the largest known deposit of uranium in the world, and its extensive copper reserves place it at the heart of South Australia’s mining industry. The mine's large scale and advanced processing facilities make it a key driver of both the state's economy and Australia's standing in the global copper market.

In addition to the Olympic Dam, South Australia also hosts the Prominent Hill mine, operated by OZ Minerals. This underground mine produces high-grade copper concentrates along with gold and silver as by-products. With an expanding underground operation, Prominent Hill is projected to remain a strong copper producer in the coming years.

Queensland

Queensland is known for its long history of copper mining, with the Mount Isa Mines standing as one of the most iconic copper operations in the world. Operated by Glencore, Mount Isa is a massive underground mining complex that has been in operation since the early 20th century. It is a significant source of copper, zinc, lead, and silver, playing a vital role in both Queensland's and Australia's mineral output. The mine's advanced technologies and deep, large-scale operations have kept it competitive, despite fluctuating commodity prices.

Another prominent Queensland copper mine is the Ernest Henry operation, also managed by Glencore. This is a copper-gold mine that utilizes underground sub-level caving techniques to extract ore efficiently. With significant gold by-products, Ernest Henry has been a key part of Glencore's copper portfolio.

Western Australia

While Western Australia is best known for its iron ore and gold industries, copper mining also plays a vital role in the state’s mining landscape. One of the most notable copper producers in this region is the DeGrussa mine, operated by Sandfire Resources. DeGrussa is an underground copper and gold mine located in the Gascoyne region, and it has become one of Australia’s highest-grade copper producers since it began operations in 2012. Sandfire Resources continues to explore and expand its copper projects, reinforcing Western Australia's role in copper production.

Additionally, the Nifty Copper Operation, operated by Cyprium Metals, is another significant copper mine in the Pilbara region. Nifty has a long history of copper production and is poised to continue contributing to the state’s copper output as Cyprium invests in refurbishing and expanding the mine’s infrastructure.

New South Wales

Although copper mining is not as prominent in New South Wales compared to states like South Australia or Queensland, it still makes an important contribution. The Cadia-Ridgeway mine, operated by Newcrest Mining, is primarily known as a gold mine, but it also produces significant amounts of copper as a by-product. Located in the Cadia Valley near Orange, this large-scale operation uses block-caving techniques to extract ore efficiently, making it one of the most cost-effective copper and gold producers in Australia.

Another key copper mine in New South Wales is Northparkes, a joint venture between China Molybdenum Co. Ltd and Sumitomo. Northparkes has been a leading copper and gold producer for decades, utilizing innovative underground mining methods like block caving, which allows for safe and efficient extraction at deeper levels.

Tasmania

Tasmania’s copper mining industry is relatively small compared to mainland states, but it has historical significance. The Mount Lyell copper mine, located in the state's west, has been in operation since the late 19th century. Despite challenges and operational closures in recent years, Mount Lyell has historically been a significant contributor to Tasmania’s mining sector and remains a potential player in the copper market if production resumes or expands in the future.

Northern Territory

The Northern Territory’s copper mining industry is less developed than other states, but it still holds promise for future growth. The Rocklands Copper Project, located near the border of Queensland and the Northern Territory, has shown potential to become a more prominent copper producer as the project develops. The region's vast untapped mineral resources suggest that the Northern Territory could become a more significant player in copper mining in the coming years.

Conclusion

Australia’s copper mines are spread across several states, each contributing uniquely to the nation's copper output. South Australia, with its world-class Olympic Dam, is a global copper powerhouse, while Queensland’s Mount Isa Mines continue to be a major source of copper, zinc, and other minerals. Western Australia is expanding its role in copper mining through high-grade operations like DeGrussa, and New South Wales contributes through large-scale operations at Cadia and Northparkes. While Tasmania and the Northern Territory may have smaller copper mining industries, they still offer significant future potential.

As global demand for copper grows, particularly in renewable energy technologies and electric vehicles, Australia is well-positioned to remain a leading supplier in the global market.

You may also read: How Is Technology Driving Efficiency in Copper Mining in 2024?

0 notes