#Automated loading systems

Explore tagged Tumblr posts

Text

Everything Changes, Even Trucking

It’s no secret that our industry is changing at lightning speed, and adapting to these changes is key to staying on top. One of the biggest shifts we’re seeing is the rise of technology in trucking. From route optimization to automated loading systems, tech is becoming a huge part of our daily lives on the road. Embracing this technology can feel overwhelming, but it’s crucial for staying…

View On WordPress

#automated loading systems#business#cash flow management#Electric Trucks#freight industry#Freight Revenue Consultants#fuel optimization#fuel-efficient driving#future of trucking#Illinois trucking#independent truckers#leveraging technology in trucking#load management tools#logistics#Ohio trucking#online courses for truckers#production location shift#rising fuel costs#Route Optimization#small carriers#staying competitive in trucking#tech for truckers#technology in trucking#Texas trucking#Transportation#trucker training#truckers adapting to technology#Trucking#trucking business tips#trucking compliance tools

0 notes

Text

#lorry loads#freight transportation#trucking logistics#cargo hauling#haulage services#commercial vehicle operations#heavy load delivery#bulk goods shipment#oversize load transport#distribution trucking#logistics india#supply chain management india#freight forwarding india#transportation services india#warehousing india#distribution networks india#import export solutions india#third-party logistics india#cold chain logistics india#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems#house shifting services online india

0 notes

Text

#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems

0 notes

Text

Enhance Trailer Loading with Cargofloor Spare Parts and Advanced Automation

Maintaining operational efficiency in logistics requires robust systems and high-quality components. Spare Parts For Cargofloor Moving Floor System play a crucial role in ensuring seamless cargo movement within trailers. The Cargofloor system is widely known for its reliability and performance in transporting goods, but regular maintenance with genuine spare parts ensures its long-term durability and efficiency. These parts, ranging from hydraulic components to specialized floor slats, are designed to withstand the demands of heavy-duty applications, reducing downtime and increasing productivity.

In addition to reliable systems, advanced automatic loading systems for trailers and loading docks are transforming logistics operations. These systems are engineered to streamline loading and unloading processes, minimizing manual labor and maximizing speed. Whether handling bulk cargo or palletized goods, automatic systems offer a versatile and safe solution for high-volume operations. They reduce risks associated with manual handling, optimize space usage, and significantly cut down turnaround times at loading docks.

Combining the reliability of spare parts for Cargofloor moving floor systems with the efficiency of Automatic Loading Systems For Trailers And Loading Docks creates a seamless operational synergy. Businesses that invest in these solutions can expect improved workflow, reduced costs, and enhanced safety standards.

When choosing these systems and spare parts, always opt for trusted suppliers to ensure quality and performance. This investment not only supports operational excellence but also helps businesses stay ahead in today’s competitive logistics landscape.

Website- http://seconcomponents.com/en/

#automation of pallet/skid loading into trailers and loading docks.#Automatic Loading Systems For Trailers And Loading Docks#Spare Parts For Cargofloor Moving Floor System

0 notes

Text

Revolutionizing Logistics: Automated Truck Loading Systems Streamline your supply chain with cutting-edge automated truck loading systems. Simec Systems innovative solutions enhance efficiency, reduce labor costs, and ensure precise cargo handling, transforming the way goods are loaded and transported. For more details visit https://simecsystems.com/large-heavy-cargo-solutions/

0 notes

Text

#lorry loads#freight transportation#trucking logistics#cargo hauling#haulage services#commercial vehicle operations#heavy load delivery#bulk goods shipment#oversize load transport#distribution trucking#logistics india#supply chain management india#freight forwarding india#transportation services india#warehousing india#distribution networks india#import export solutions india#third-party logistics india#cold chain logistics india#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems#house shifting services online india

0 notes

Text

Electric Overhead Travel (EOT) Cranes

Introducing Avon Engineering advanced Electric Overhead Travel (EOT) Cranes – a pinnacle of innovation in material handling solutions. These cranes redefine the concept of heavy-duty lifting and movement, offering a seamless blend of efficiency, customization, safety, and durability for a wide range of industrial applications.

Key Features:

Experience the power of our EOT Cranes in efficiently lifting and transporting heavy loads with ease. Moreover, these cranes are designed to handle substantial weights, optimizing your material handling operations. Additionally, tailor your crane system to match your specific requirements. Avon Engineering Electric Overhead Travel EOT Cranes come in various configurations, including single girder, double girder, and underslung designs, ensuring a perfect fit for your workspace. Furthermore, achieve precise control over load movement with our advanced control systems. Safety is paramount, and our cranes are equipped with features like limit switches, overload protection, and emergency stop mechanisms to ensure secure and controlled operations. In addition, crafted for industrial environments, our EOT Cranes feature robust construction that can withstand the rigors of heavy usage. Lastly, built with quality materials and engineering expertise, they guarantee consistent performance and reliability over time. @avonengineering

Experience Cutting-Edge Material Handling: Our EOT Cranes introduce a new dimension of efficiency in material handling. Whether for manufacturing, construction, warehouses, or other sectors, these cranes deliver reliable, customizable, and safe load lifting and movement, optimizing your processes. They integrate technology, customization, safety, and durability, offering a forward-focused solution that aligns with your material handling goals. Elevate your material handling operations and invest in a product that ensures exceptional performance. Embrace a new era of material movement with our state-of-the-art EOT Cranes.

#Electric Overhead Travel Cranes#EOT Cranes#Industrial Lifting Equipment#Heavy-Duty Crane Systems#Overhead Crane Solutions#Electric Crane Technology#Material Handling Cranes#Customizable Crane Configurations#Precision Load Control#Safety Features for Overhead Cranes#Robust Construction for Industrial Use#High Capacity Lifting Solutions#Efficient Material Handling Equipment#Crane Automation Technology#EOT Crane Manufacturers

0 notes

Text

Load Port Module: The Essential Link Between Wafer Transport System and Process Tool

A Load Port Module serves as the interface between a wafer transport system and a semiconductor process tool such as an etcher or deposition system. It facilitates the safe and ultra-clean transfer of wafers from cassettes stored in the transport system into the vacuum environment of the process chamber for semiconductor fabrication steps. Let's take a closer look at the key components and functions of this critical module. Wafer Cassette Access The front end of a loadlock in Load Port Module includes a cassette-loading station where standard 25mm wafer cassettes containing up to 25 wafers can be automatically loaded and unloaded. A robotic handler on the transport system sets the cassette into place and latches it securely. An environmentally sealed door then closes to maintain isolation of the cleanroom air from the vacuum system. Sensor inputs confirming cassette presence and door closure status are relayed to the process tool's control system. Vacuum-Compatible Design Since wafers must be transferred between the atmospheric cassette environment and high-vacuum process chambers, a Load Port Module needs vacuum-compatible construction. Chambers, bellows sections, and sealing joints are machined from non-outgassing stainless steel or aluminum alloys certified for ultra-high vacuum contact. Viton O-rings, metal gaskets, and precision actuators enable dependable closure and integrity testing of all interfaces down to vacuum pressures below 1x10^-7 Torr. Wafer Transfer Mechanisms Various transfer mechanisms are incorporated into load port designs depending on the specific process tool interface. Common configurations include a linear motor-driven blade that reaches into the cassette to pick wafers one at a time or a robotic arm capable of lifting an entire shelf of wafers simultaneously. Cameras and light sources aid alignment while sensors confirm contact and monitor for particles during extraction and placement into the loadlock chamber. Loadlock Chamber Contained within the load port housing is a small, sealable loadlock chamber where wafers can be coated or undergo vacuum bake-out procedures before entering the process chamber. Magnetic or mechanical end effectors gently grip wafers during transfer to stationary wafer pedestals inside the chamber. A turbo pump then evacuates air from the chamber to prepare for opening the valve to the process tool. Closing this valve isolates the loadlock to allow venting back to atmospheric pressure for wafer removal. Chemical Delivery Ports Some advanced load port designs accommodate ports for purge gas, chemical, or vapor delivery into the loadlock chamber or direct wafer surfaces. This enables pre-etch surface treatment, post-process cleaning, or thin film deposition capabilities directly on the wafers without needing to move them to a dedicated tool. Integrated mass flow controllers ensure precise chemical dosing and vacuum-safe plumbing routes all lines to the chamber.

Get More Insights On This Topic: Load Port Module

#Load Port Module#Semiconductor Industry#Manufacturing#Automation#Material Handling#Robotics#Semiconductor Equipment#Integrated Systems#Industrial Technology#Port Logistics#Container Handling

0 notes

Text

Best Automated Truck Loading System

Revolutionize your logistics with their Automated Truck Loading System (ATLS). Enhance efficiency and reduce loading times with this cutting-edge technology. Streamline your supply chain operations for faster and more cost-effective loading processes, ensuring optimal productivity.

0 notes

Photo

(via https://substack-post-media.s3.amazonaws.com/public/images/d18e5226-8335-4455-909d-5a6ef98747a6_1280x1664.gif (1280×1664))

1 note

·

View note

Text

The Impact of AI and Automation on the Trucking Industry

Photo by Ricky Esquivel on Pexels.com So, we’ve all heard about the buzz around AI and automation in the trucking industry, right? It’s pretty fascinating stuff. I know it sounds all high-tech and futuristic, but it’s really changing the game for truckers in ways that are super practical and beneficial. First off, there’s predictive maintenance. Imagine you’re on the road, hauling a load, and…

View On WordPress

#AI and truck safety#AI driving systems#AI for truck maintenance#AI for truckers#AI in logistics#AI in transportation#AI in trucking#AI route planning#AI transportation management#AI truck efficiency#AI truck technology#AI trucking solutions#automated load matching#automated trucking#automation in trucking#autonomous driving trucks#autonomous trucks#business#cash flow management#digital freight platforms#driver assistance systems for trucks#Freight#freight industry#Freight Revenue Consultants#logistics#predictive maintenance for trucks#route optimization for truckers#small carriers#Transportation#truck automation benefits

0 notes

Text

#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems

0 notes

Text

#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems

0 notes

Text

Distribution Feeder Automation Market Business Research, Types and Applications, Demand by 2032

Market Overview: The Distribution Feeder Automation Market refers to the market for advanced technologies and systems that automate the monitoring, control, and management of distribution feeders within an electrical distribution network. Distribution feeder automation improves the efficiency, reliability, and resiliency of power distribution by utilizing sensors, communication networks, and automation software to monitor and control power flows, fault detection, and restoration. These solutions enhance the performance of distribution feeders and enable utilities to deliver electricity more effectively.

Feeder Automation Market is projected to be worth USD 7.85 Billion by 2030, registering a CAGR of 8.2% during the forecast period (2022 - 2030)

Demand: The demand for distribution feeder automation is driven by several factors, including:

Distribution feeder automation solutions help utilities improve the reliability and resiliency of their distribution networks. By automating fault detection, isolation, and restoration, these systems minimize outage durations and enhance the overall performance of the grid, ensuring a more reliable power supply for customers.

Distribution feeder automation systems streamline operations by reducing manual interventions, optimizing power flow, and enhancing network monitoring capabilities. These solutions enable utilities to manage distribution feeders more efficiently, reduce costs, and improve the overall operational performance of their networks.

The increasing integration of renewable energy sources, such as solar and wind power, into the distribution grid presents operational challenges. Distribution feeder automation helps utilities manage the intermittent nature of renewables, optimize power flow, and ensure grid stability, facilitating the integration of clean energy sources.

Latest technological developments, key factors, and challenges in the Distribution Feeder Automation Market:

Latest Technological Developments:

Intelligent Sensors and IoT Integration: Distribution feeder automation is leveraging intelligent sensors and Internet of Things (IoT) integration to monitor real-time data from various points along the distribution feeders. These sensors provide insights into voltage levels, current flow, fault detection, and other parameters, enabling quicker fault localization and resolution.

Advanced Communication Protocols: Modern distribution feeder automation systems are adopting advanced communication protocols like for seamless data exchange between field devices and control centers. This facilitates real-time monitoring, remote control, and efficient data transmission.

Decentralized Control and Edge Computing: Distribution feeder automation systems are moving toward decentralized control and edge computing. This allows decision-making and control to occur closer to field devices, reducing latency and enhancing responsiveness.

Distributed Energy Resource (DER) Management: With the integration of distributed energy resources like solar panels, wind turbines, and energy storage systems, feeder automation systems are being developed to manage these resources effectively, ensuring grid stability and optimal energy distribution.

Advanced Analytics and AI: Distribution feeder automation is incorporating advanced analytics and artificial intelligence to analyze data from various sources. AI algorithms can predict and prevent potential faults, optimize energy flows, and enhance overall feeder performance.

Key Factors:

Reliability Enhancement: Distribution feeder automation improves the reliability of electricity distribution by enabling quicker fault detection, isolation, and restoration. This minimizes outage durations and enhances overall grid reliability.

Efficient Grid Management: Feeder automation allows utilities to manage the distribution grid more efficiently. Load balancing, voltage regulation, and fault management can be automated, leading to optimized energy delivery.

Integration of Renewable Energy: As the penetration of renewable energy sources increases, distribution feeder automation becomes crucial for managing the intermittent nature of these resources and maintaining grid stability.

Grid Resilience and Outage Management: Feeder automation systems enhance grid resilience by providing real-time data on grid conditions and faults. This facilitates faster response and restoration during outages, minimizing customer impact.

Challenges:

Interoperability: Integrating various devices and protocols into a cohesive feeder automation system can be challenging due to the need for interoperability between different vendors and technologies.

Cybersecurity: With increased connectivity and data exchange, distribution feeder automation systems face cybersecurity threats. Ensuring the security of these systems is paramount to prevent unauthorized access and data breaches.

Cost and Infrastructure: Implementing distribution feeder automation can involve significant upfront costs, including hardware, software, and training. Retrofitting existing infrastructure for automation may also pose challenges.

Complexity of Data Management: Feeder automation generates vast amounts of data that need to be effectively managed, analyzed, and acted upon. Handling this complexity can be demanding.

Change Management: Transitioning from manual to automated processes requires change management efforts to train personnel, address resistance, and ensure smooth integration.

Maintenance and Upgrades: Ensuring the proper functioning of feeder automation systems over time requires regular maintenance and potential upgrades to keep up with technology advancements.

Distribution feeder automation is at the forefront of modernizing electricity distribution networks. While it offers significant benefits in terms of reliability, efficiency, and resilience, addressing technical challenges and ensuring a smooth transition is crucial for successful implementation.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.���

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/distribution-automation-solutions-market/10965/

Market Segmentations:

Global Distribution Feeder Automation Market: By Company

• ABB

• Eaton

• Grid Solutions

• Schneider Electric

• Siemens

• Advanced Control Systems

• Atlantic City Electric

• CG

• G&W Electric

• Kalkitech

• Kyland Technology

• Moxa

• S&C Electric Company

• Schweitzer Engineering Laboratories (SEL)

Global Distribution Feeder Automation Market: By Type

• Fault Location

• Isolation

• Service Restoration

• Automatic Transfer Scheme

Global Distribution Feeder Automation Market: By Application

• Industrial

• Commercial

• Residential

Global Distribution Feeder Automation Market: Regional Analysis

The regional analysis of the global Distribution Feeder Automation market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Distribution Feeder Automation market report are as follows:

North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Distribution Feeder Automation in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product.

Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Distribution Feeder Automation in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors.

Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Distribution Feeder Automation in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction.

Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors.

South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Distribution Feeder Automation in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Click Here, To Buy Report: https://stringentdatalytics.com/purchase/distribution-feeder-automation-market/10966/?license=single

Reasons to Purchase Distribution Feeder Automation Market Report:

Comprehensive Market Insights: Global research market reports provide a thorough and in-depth analysis of a specific market or industry. They offer valuable insights into market size, growth potential, trends, challenges, and opportunities, helping businesses make informed decisions and formulate effective strategies.

Market Analysis and Forecasts: These reports provide detailed analysis and forecasts of market trends, growth rates, and future market scenarios. They help businesses understand the current market landscape and anticipate future market developments, enabling them to plan and allocate resources accordingly.

Competitive Intelligence: Global research market reports provide a competitive landscape analysis, including information about key market players, their market share, strategies, and product portfolios. This information helps businesses understand their competitors' strengths and weaknesses, identify market gaps, and develop strategies to gain a competitive advantage.

Industry Trends and Insights: These reports offer insights into industry-specific trends, emerging technologies, and regulatory frameworks. Understanding industry dynamics and staying updated on the latest trends can help businesses identify growth opportunities and stay ahead in a competitive market.

Investment and Expansion Opportunities: Global research market reports provide information about investment opportunities, potential markets for expansion, and emerging growth areas. These reports help businesses identify untapped markets, assess the feasibility of investments, and make informed decisions regarding expansion strategies.

Risk Mitigation: Market reports provide risk assessment and mitigation strategies. By analyzing market dynamics, potential challenges, and regulatory frameworks, businesses can proactively identify risks and develop strategies to mitigate them, ensuring better risk management and decision-making.

Cost and Time Efficiency: Conducting comprehensive market research independently can be time-consuming and expensive. Purchasing a global research market report provides a cost-effective and time-efficient solution, saving businesses valuable resources while still gaining access to reliable and detailed market information.

Decision-Making Support: Global research market reports serve as decision-making tools by providing data-driven insights and analysis. Businesses can rely on these reports to support their decision-making process, validate assumptions, and evaluate the potential outcomes of different strategies.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Distribution Feeder Automation#Smart Grid Technology#Intelligent Sensors#IoT Integration#Edge Computing#Advanced Analytics#AI in Grid Management#Microgrid Integration#Fault Detection#Voltage Regulation#Load Balancing#Power Distribution Optimization#Grid Resilience#Outage Management#Renewable Energy Integration#Distribution System Efficiency#Energy Management Solutions.

0 notes

Text

🎄💾🗓️ Day 4: Retrocomputing Advent Calendar - The DEC PDP-11! 🎄💾🗓️

Released by Digital Equipment Corporation in 1970, the PDP-11 was a 16-bit minicomputer known for its orthogonal instruction set, allowing flexible and efficient programming. It introduced a Unibus architecture, which streamlined data communication and helped revolutionize computer design, making hardware design more modular and scalable. The PDP-11 was important in developing operating systems, including the early versions of UNIX. The PDP-11 was the hardware foundation for developing the C programming language and early UNIX systems. It supported multiple operating systems like RT-11, RSX-11, and UNIX, which directly shaped modern OS design principles. With over 600,000 units sold, the PDP-11 is celebrated as one of its era's most versatile and influential "minicomputers".

Check out the wikipedia page for some great history, photos (pictured here), and more -

And here's a story from Adafruit team member, Bill!

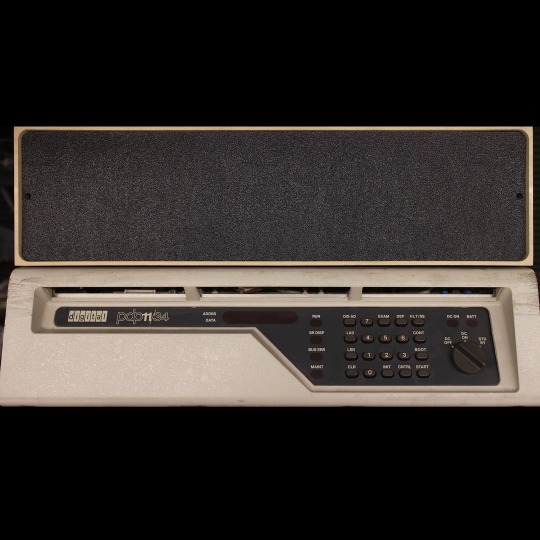

The DEC PDP-11 was the one of the first computers I ever programmed. That program was 'written' with a soldering iron.

I was an art student at the time, but spending most of my time in the engineering labs. There was a PDP-11-34 in the automation lab connected to an X-ray spectroscopy machine. Starting up the machine required toggling in a bootstrap loader via the front panel. This was a tedious process. So we ordered a diode-array boot ROM which had enough space to program 32 sixteen bit instructions.

Each instruction in the boot sequence needed to be broken down into binary (very straightforward with the PDP-11 instruction set). For each binary '1', a diode needed to be soldered into the array. The space was left empty for each '0'. 32 sixteen bit instructions was more than sufficient to load a secondary bootstrap from the floppy disk to launch the RT-11 operating system. So now it was possible to boot the system with just the push of a button.

I worked with a number DEC PDP-11/LSI-11 systems over the years. I still keep an LSI-11-23 system around for sentimental reasons.

Have first computer memories? Post’em up in the comments, or post yours on socialz’ and tag them #firstcomputer #retrocomputing – See you back here tomorrow!

#dec#pdp11#retrocomputing#adventcalendar#minicomputer#unixhistory#cprogramming#computinghistory#vintagecomputers#modulardesign#scalablehardware#digitalcorporation#engineeringlabs#programmingroots#oldschooltech#diodearray#bootstraploader#firstcomputer#retrotech#nerdlife

290 notes

·

View notes

Text

#lorry loads#freight transportation#trucking logistics#cargo hauling#haulage services#commercial vehicle operations#heavy load delivery#bulk goods shipment#oversize load transport#distribution trucking#logistics india#supply chain management india#freight forwarding india#transportation services india#warehousing india#distribution networks india#import export solutions india#third-party logistics india#cold chain logistics india#online lorry loads services#freight marketplace#truck load boards#digital logistics platform#transport automation#load matching#carrier connectivity#real-time tracking#capacity utilization#transportation management systems#house shifting services online india

0 notes