#Ballscrewlinearmodule

Explore tagged Tumblr posts

Text

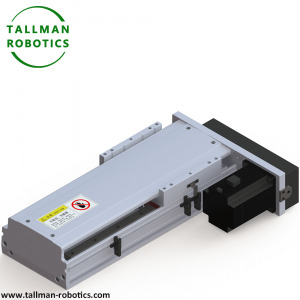

Screw Linear Motion Modules Will Be Delivered To USA

Screw Linear motion modules are mechanical systems designed to provide controlled linear movement in various applications. They are commonly used in industrial automation, robotics, and other fields where precise linear motion is required.

If you're experiencing issues or challenges with linear motion modules, it's important to identify the specific problems you're facing in order to determine the appropriate solutions. Here are a few common issues and some possible suggestions to overcome them: 1. Lack of precision: If your linear motion module is not providing the desired accuracy or precision, you may need to check if the mechanical components are properly aligned and lubricated. Additionally, consider the quality and condition of the module itself, as well as the control system used to drive it. 2. Mechanical failures: Linear motion modules consist of various mechanical components such as rails, bearings, screws, and belts. If you're experiencing frequent failures, it could be due to worn-out or damaged components. Regular maintenance and inspection can help identify and replace any faulty parts. 3. Insufficient load capacity: If you're trying to move loads that exceed the specified capacity of the linear motion module, it can lead to performance issues or even damage. Make sure you're using a module that is suitable for the intended load and consider upgrading to a higher capacity module if necessary. 4. Compatibility issues: Linear motion modules often need to be integrated into larger systems or work alongside other components. Compatibility issues can arise if the module is not properly matched with other parts of the system. Double-check the specifications and requirements of all components involved to ensure they are compatible. 5. Control and programming challenges: If you're struggling with controlling the linear motion module or programming it to perform specific tasks, it may be helpful to consult the documentation or seek support from the manufacturer. They can provide guidance on the programming interface, control signals, and troubleshooting techniques. Remember, linear motion modules are complex systems, and resolving issues might require a combination of mechanical, electrical, and software-related solutions. If you're still having difficulties, it may be beneficial to consult with experts or professionals in the field who have experience with linear motion modules. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#AcmeScrewsandLinearActuators#BallScrewandLinearMotionComponent#Ballscrewlinearmodule#LeadScrewDrivenLinearStagesModule#LeadScrews#LinearmodulesSmallModulesScrewDriven#LinearMotionGuideActuators#LinearMotionModule#PrecisionSlidingTableBallScrew#Screwdrivenmodules#ScrewLinearModules#StainlessSteelLinearModuleHighSpeedBallScrewRail

0 notes

Text

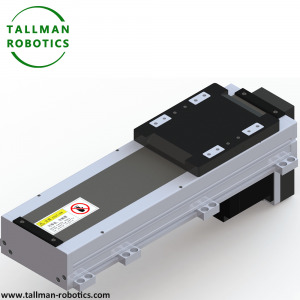

Linear Modules With Ball Screw Are Delivered to Russia

Linear Modules With Ball Screw Are Delivered to Russia.

Linear modules with ball screw are mechanical components used to convert rotational motion into linear motion with high precision, efficiency, and minimal friction. These modules are commonly used in various industrial applications, such as CNC machines, robotics, automation systems, and precision machinery. The main components of a linear actuator with a ball screw include: 1. Ball screw: A threaded shaft with a helical groove that contains ball bearings. The ball bearings are responsible for reducing friction between the screw and the nut, enabling smooth and precise linear motion. 2. Ball nut: A component that houses the ball bearings and mates with the ball screw. As the screw rotates, the nut moves linearly along the screw, driven by the motion of the ball bearings. 3. Linear guide: A set of rails and bearings that support and guide the movement of the ball nut along the linear path. Linear guides ensure that the motion is smooth and accurate, with minimal deflection or deviation from the intended path. 4. Drive system: Typically consists of a motor and a coupling that connects the motor to the ball screw. The motor provides the rotational force needed to drive the screw and create linear movement. 5. Support bearings and mounts: These components support the ball screw, motor, and other elements of the linear module, ensuring proper alignment and structural integrity. 6. End stops and limit switches: These safety features prevent the linear module from moving beyond its intended range of motion, protecting the system from damage or failure. Linear modules with ball screws offer several advantages, such as: 1. High precision and accuracy: Due to their low friction and high rigidity, ball screws provide precise positioning and repeatability. 2. High efficiency: The low friction in ball screws allows for efficient conversion of rotational motion into linear motion, reducing energy losses and heat generation. 3. Low maintenance: Ball screws require little maintenance due to their self-lubricating properties and long service life. 4. Load capacity: Ball screws can handle high loads and provide smooth motion even when subjected to significant forces. 5. Speed: Linear modules with ball screws can achieve high speeds while maintaining accurate positioning and repeatability. Some common applications of linear modules with ball screws include CNC machines, 3D printers, pick-and-place robots, and precision assembly equipment. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#BallScrewDriveLinearModuleSlidingTable#BallScrewLinearGuide#Ballscrewlinearmodule#BallScrewsforLinearActuators#Compactsimplelinearmodulewithballscrew

0 notes

Text

Ball Screw Driven Linear Modules

Ball Screw Driven Linear Modules You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. The transmission method of Ball Screw Driven Linear Modules is characterized by high repeatability, up to ±0.005mm, high accuracy and high load. Usually used in the production process with a certain precision in industrial production. In the selection process of the ball screw drive, attention should be paid to the selection of the screw, which is usually determined according to factors such as load, speed, and torque. Pay attention to the maintenance of the screw when using the linear module of the ball screw. After cleaning a long distance, clean dirt and grease should be replaced in time, usually every half a month. Ball screw is an ideal product that converts rotary motion into linear motion, or converts linear motion into rotary motion. The ball screw is composed of a screw, a nut and a ball. Its function is to convert rotary motion into linear motion, which is a further extension and development of ball screws. The important significance of this development is to change the bearing from rolling motion to sliding motion. Due to its small frictional resistance, ball screws are widely used in various industrial equipment and precision instruments.

What are the Basic Specification of Ball Screw Driven Linear Modules from Tallman Robotics Limited Model No Max Payload(kgs) Max Stroke (mm) Repeatability (mm) Drive Solution Motor Power (W) TMS30 4 400 ±0.01/±0.005 screw 30 TMS45 10 800 ±0.01/±0.005 screw 50/100 TMB45 4 800 ±0.04 belt 50/100 TMS62 20 1050 ±0.01/±0.005 screw 100/200/400 TMB62 16 2000 ±0.04 belt 100/200/400 TMS65 30 800 ±0.01/±0.005 screw 50/100 TMB65 4 800 ±0.04 belt 50/100 TMS85 50 1050 ±0.01/±0.005 screw 100/200/400 TMB85 16 2000 ±0.04 belt 100/200/400 TMS100 65 1050 ±0.01/±0.005 screw 100/200/400 TMB100 40 3500 ±0.04 belt 100/200/400 TMS135 110 1250 ±0.01/±0.005 screw 200/400/750 TMB135 42 3500 ±0.04 belt 200/400 TMS150 120 1500 ±0.01/±0.005 screw 400/750 TMB150 75 3500 ±0.04 belt 400/750 TMS170 130 1500 ±0.01/±0.005 screw 400/750 TMB170 75 3500 ±0.04 belt 400/750 TMS220 150 1500 ±0.01/±0.005 screw 750 TMB220 75 3500 ±0.04 belt 750 Ball Screw Driven Linear Modules are composed of multiple single-axis robots to realize multi-axis combination through different combination styles, to achieve applications such as Cartesian actuators, XYZ multi-axis actuators (XY table), and so on. It is widely used in the positioning, transfer, handling, inspection, dispensing, welding, cutting, etc. of LCD panels, semiconductors, home appliances, daily chemicals, automobiles, batteries and other fields. Related Knowledge: The main features of the application of the ball screw in the module. The ball screw is the most commonly used transmission element in machine tools and precision machinery. Its main function is to convert rotary motion into linear motion, or convert torque into axial repetitive force, and it has both high precision, reversibility and high Features of efficiency. Ball screw is also called ball screw and ball screw. 1) High positioning accuracy The ball screw pair realizes rolling friction between the nut and the screw by ball rolling. The motion of the rolling linear guide is realized by rolling of the steel ball. The friction resistance of the guide pair is small, the difference between dynamic and static friction resistance is small, and no crawling occurs at low speeds. . High repeat positioning accuracy, suitable for moving parts that frequently start or change directions. 2) Less wear Due to the low frictional energy consumption of rolling contact, the friction loss of the rolling surface is also reduced correspondingly, so the rolling linear guide system can be in a high-precision state for a long time. At the same time, the use of lubricating oil is also very small, which makes it very easy to design and use and maintain the lubrication system of the machine tool. 3) Long life For the nut of the ball screw pair, the screw hardness reaches HRC58-62, and the ball hardness reaches HRC62-66, and there is rolling friction between them, so higher fatigue life and accuracy life can be achieved. 4) Adapt to high-speed movement Due to the low friction resistance of the rolling linear guide module, the required power source and power transmission mechanism can be miniaturized, and the driving torque can be greatly reduced. It can realize high-speed linear motion and improve the working efficiency of the machine tool. 5) Strong carrying capacity Rolling linear guides have good load-bearing performance and can withstand forces and moment loads in different directions, such as up, down, left, and right directions, as well as bump moments, rocking moments and swing moments. Therefore, it has good load adaptability. 6) Easy to assemble and interchangeable The ball screw and rolling guide are interchangeable. As long as the slider or the guide rail or the entire rolling guide pair is replaced, the module can regain high precision. 7) Micro and high-speed feed can be realized The ball screw pair will not produce such as sliding phenomenon, can realize the micro-feed; as long as the feed pulse is small enough, the ball screw pair can realize the micron-level feed. Because of the low heat generation of the ball screw pair and the ability to manufacture a large lead screw, high-speed feed can be achieved. Read the full article

#BallScrewDrivenLinearModules#BallScrewLinearModule-BallScrewLinearStage#LinearModuleswithballscrewdrive#LinearMotionStages#Miniaturesizedlinearmotion#PrecisionLinearStages#ScrewDrivenActuators#ScrewDrivenModularLinearActuators#X-YStages

0 notes